Equipment for processing the pointed ends of chopsticks

A technology of chopsticks and equipment, which is applied in the field of equipment for automatic processing of chopstick ends, can solve problems such as low efficiency and increased labor costs, and achieve the effect of avoiding the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

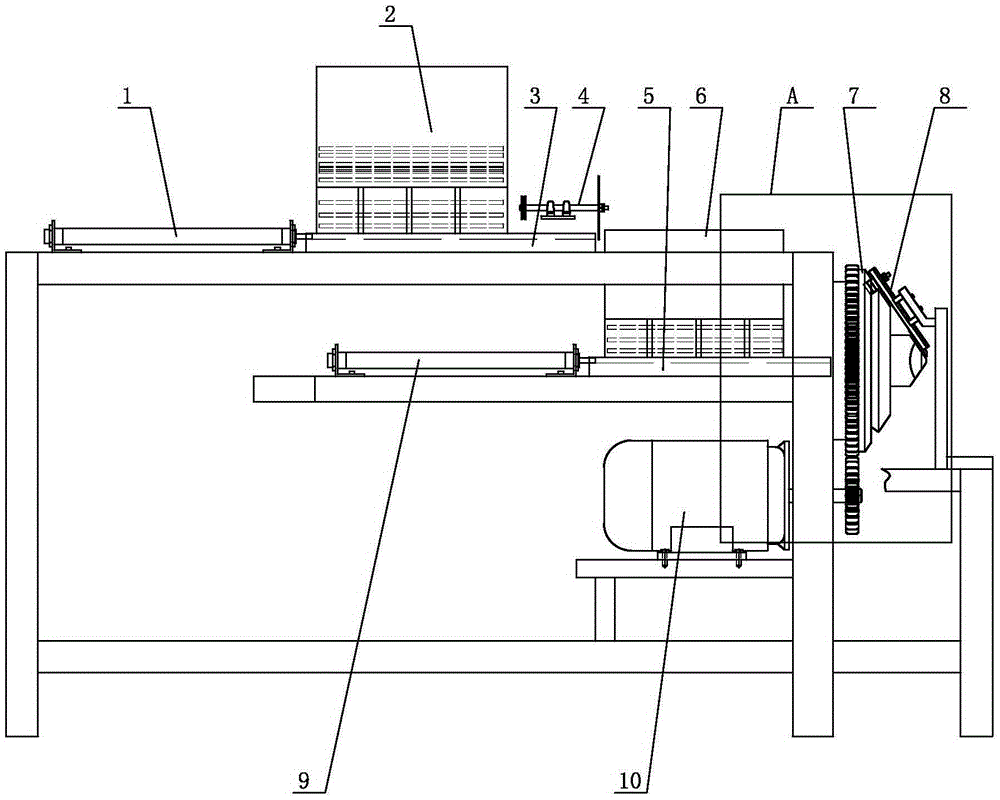

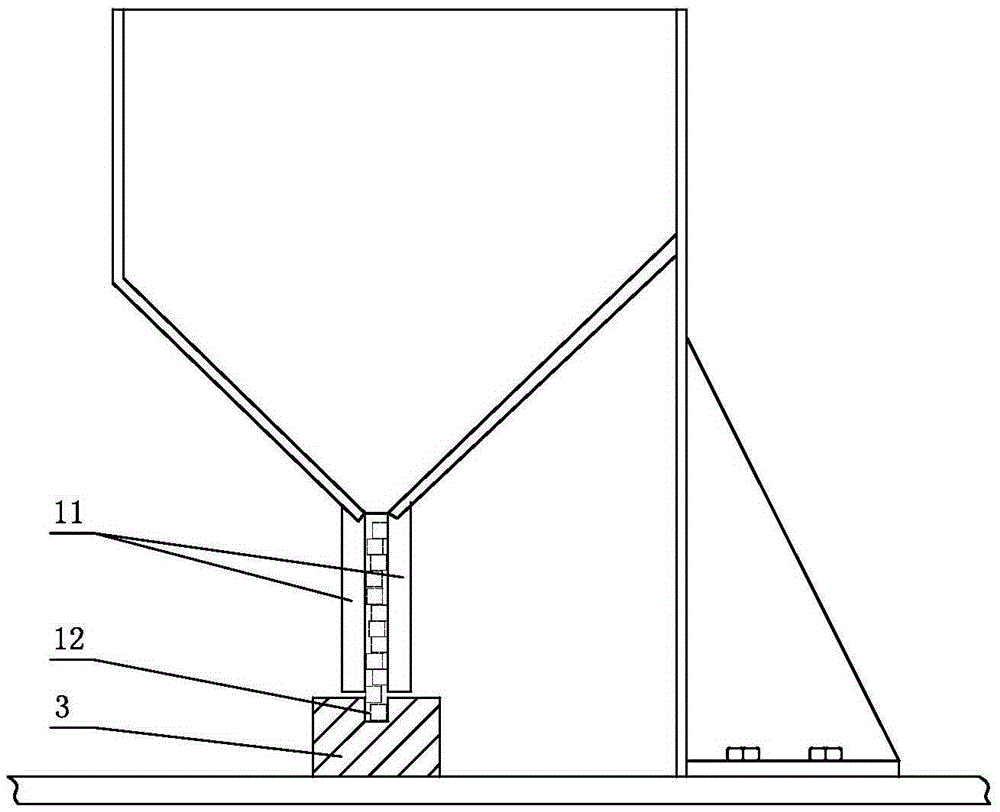

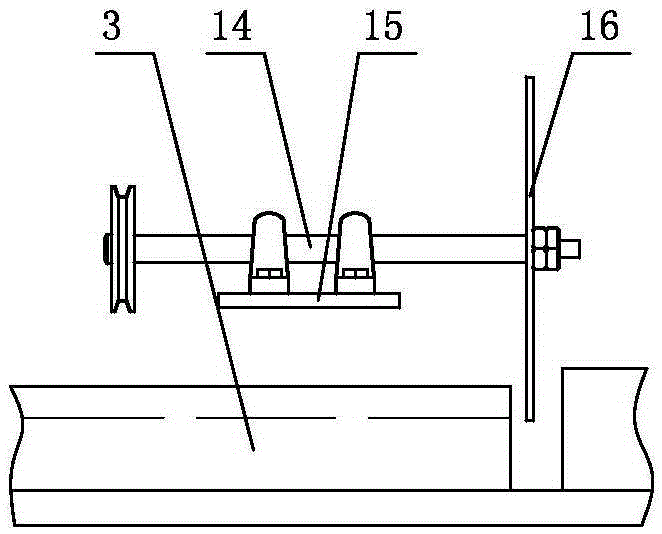

[0025] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings, taking a preferred specific structure as an example.

[0026] refer to Figure 1-4 , the equipment of this example includes a frame, and the first hopper 2, the first push cylinder 1, the pre-cutting assembly 4, the second hopper 6, the second push cylinder 9, a cutting mechanism, and a receiving box arranged on the frame (not shown).

[0027] Wherein the first hopper 2 is used to hold chopsticks to be processed in batches, and the second hopper is used to accommodate pre-cut chopsticks, both of which include a left side plate, a right side plate, and a front and rear baffle plate. The front and rear edges are respectively fixed with the front and rear baffles, and the bottom of the left side plate and the bottom of the right side plate are bent towards each other, and a chopstick leakage opening is formed at the minimum distance between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com