Transfer printing equipment of bandages

A bandage and equipment technology, applied in the field of bandage transfer printing equipment, can solve the problems of low processing efficiency and inability to form continuous processing equipment, so as to improve processing efficiency and realize the effect of mechanical automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

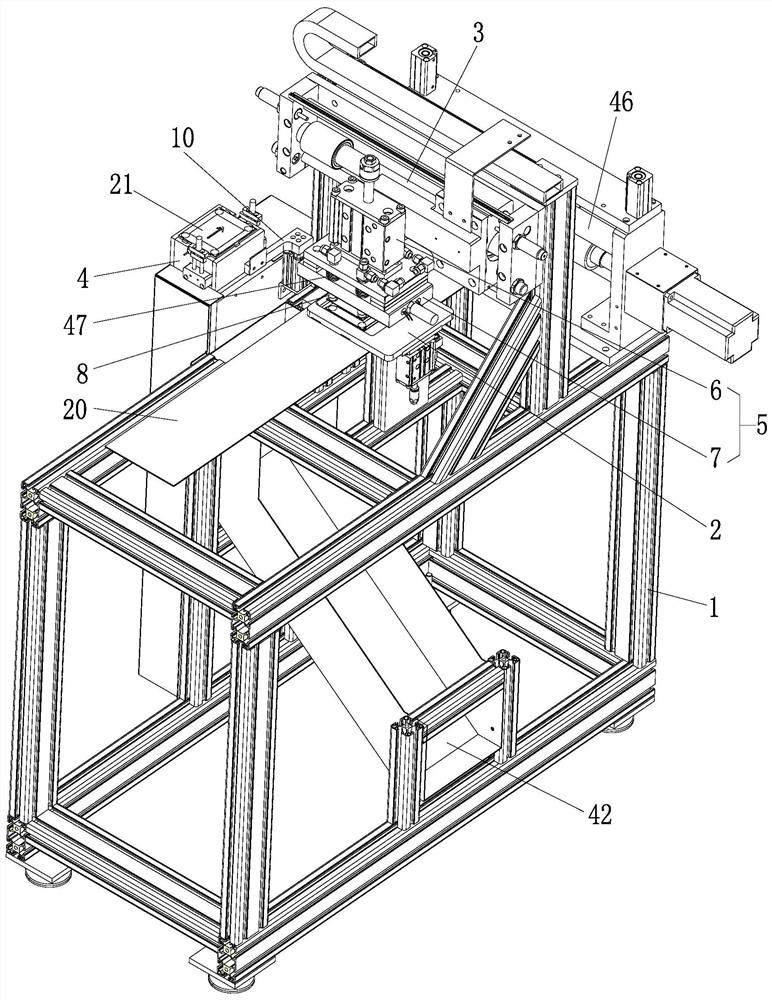

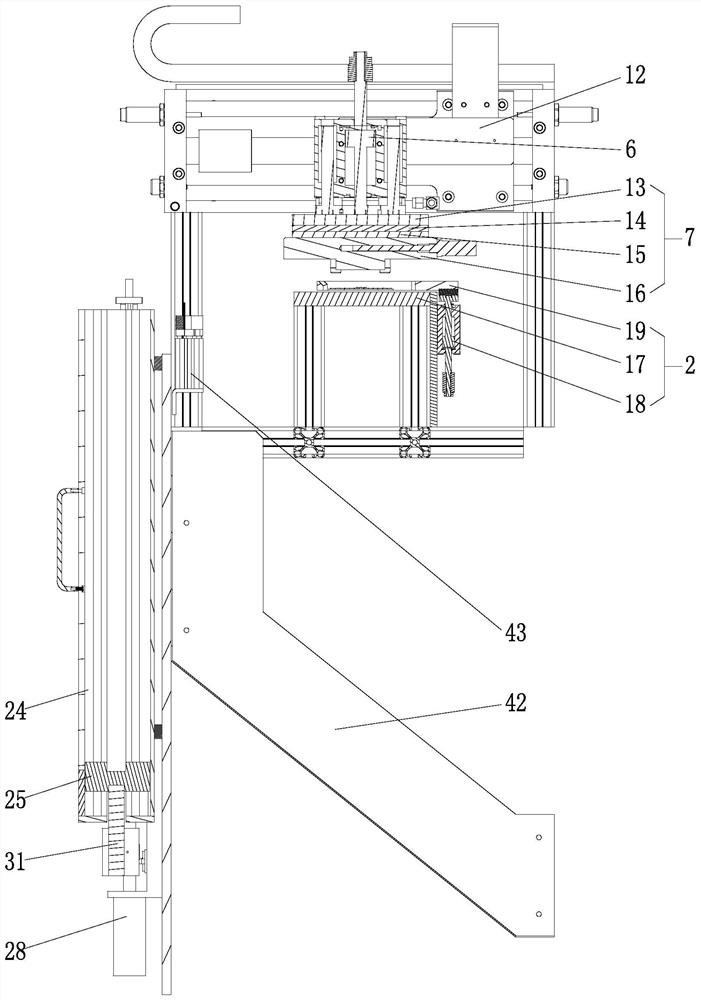

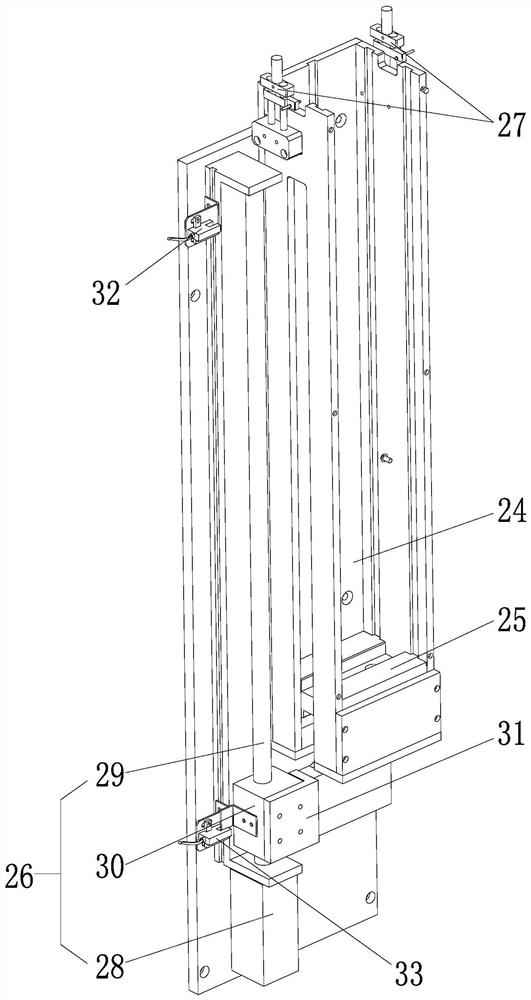

[0026] see Figure 1 to Figure 9 , the present invention provides a bandage transfer device, including a frame 1, a feeding mechanism 46 arranged on the frame 1, a paper tearing mechanism 2, a translation mechanism 3, and a paper tearing mechanism 2 connected to the translation mechanism 3. The transfer device 5 that reciprocates between the transfer paper feeding device 4, the transfer device 5 includes a transfer cylinder 6, a transfer head 7 connected to the stroke rod of the transfer cylinder 6, and the translation mechanism 3 There are also several suction rods 8 connected to it, and the suction rods 8 are inserted in the stepped holes 9 of the transfer head 7, and the center line of the stepped holes 9 is collinear with the moving direction of the transfer head 7, so that the transfer The head 7 moves up and down along the center lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com