Patents

Literature

75results about How to "Realize automatic tensioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

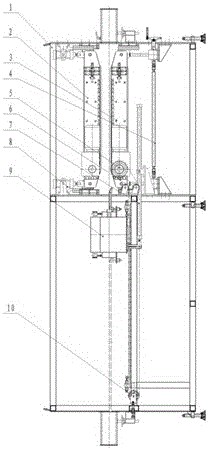

Automatic tightening device of belt conveyor

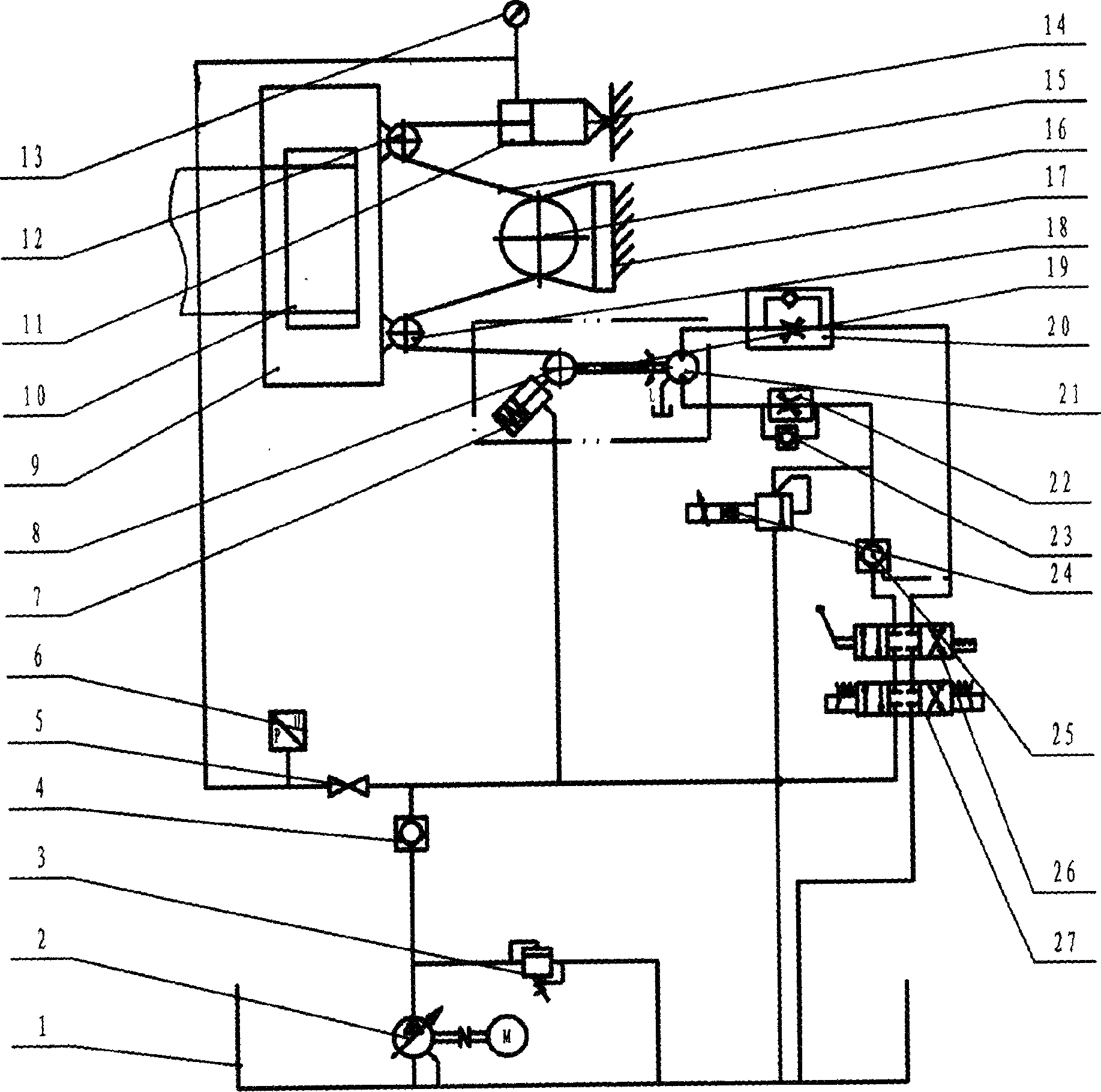

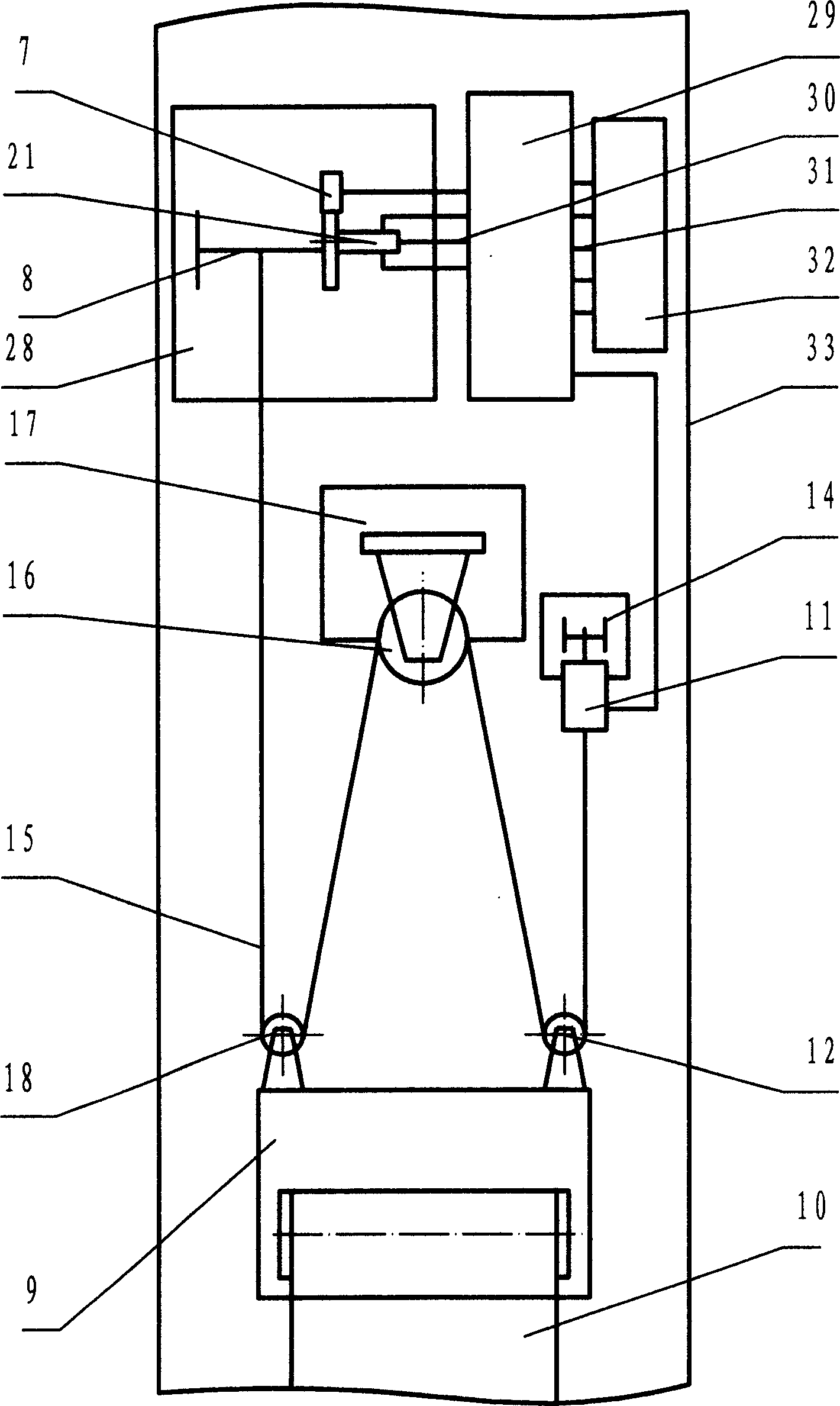

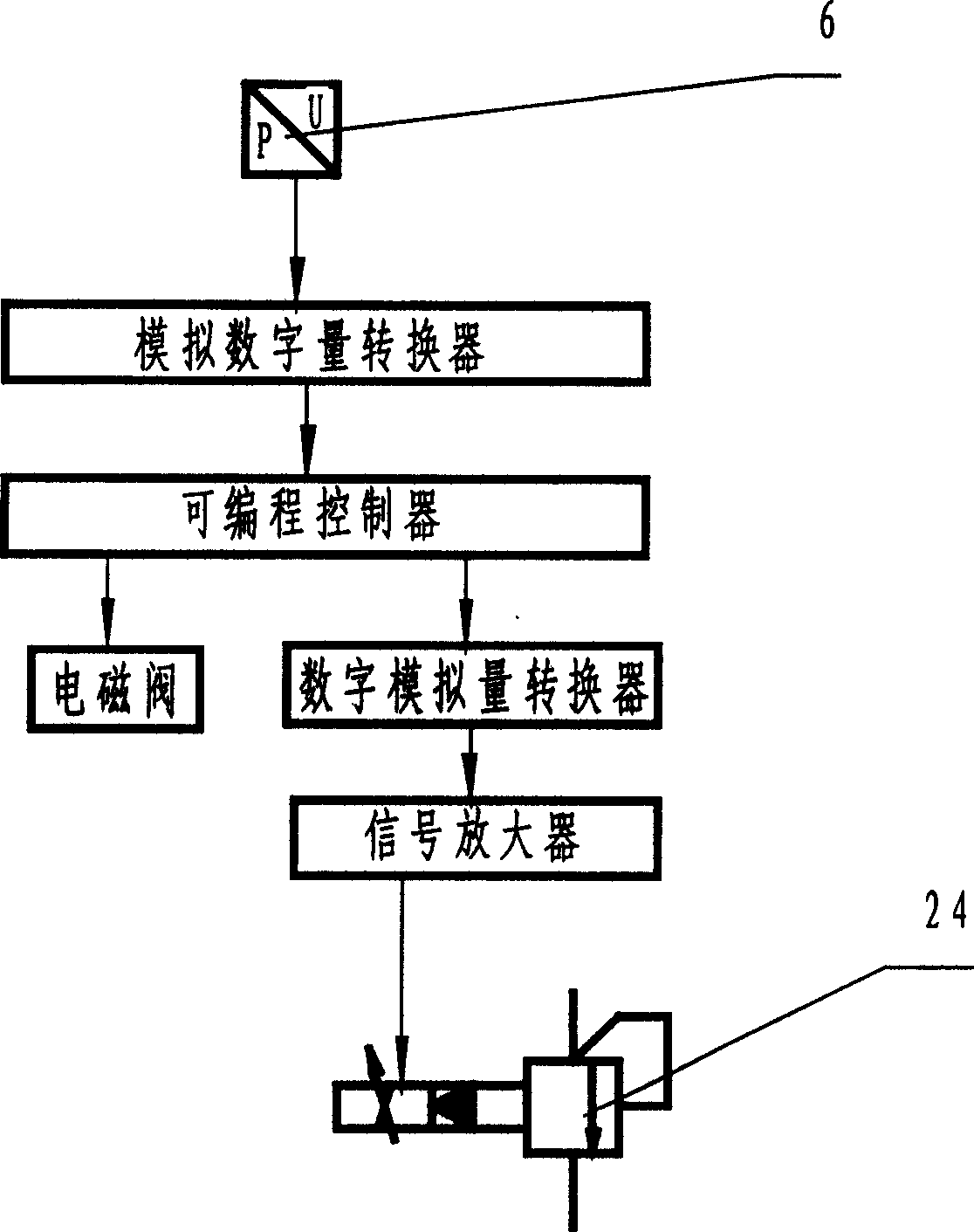

An automatic tensioning device for belt conveyor is suitable for long-range covneyor or a rubber belt conveyer, of which belt has a large extension rate. It achieves a large regulative range, an accurate control of tension force, and stable adjustment. The system consists of a tension monitor, a hydraulic device and a hydraulic hoist. The tension monitor comprises a detecting cylinder, a pressure sensor, a shutoff valve and a pressure meter. The hydraulic device comprises a pump, a reversing solenoid valve, a overflow valve, a manual valve, a hydraulic one-way valve, a proportional reversing valve, a one-way throttle valve, a one-way valve, a throttle valve, a tank, and oil-way. The outlet of the pump is respectively connected with the tension monitor, the cylinder and the driving circuit of the hydraulic hoist via the one-way valve.

Owner:TAIYUAN UNIV OF TECH

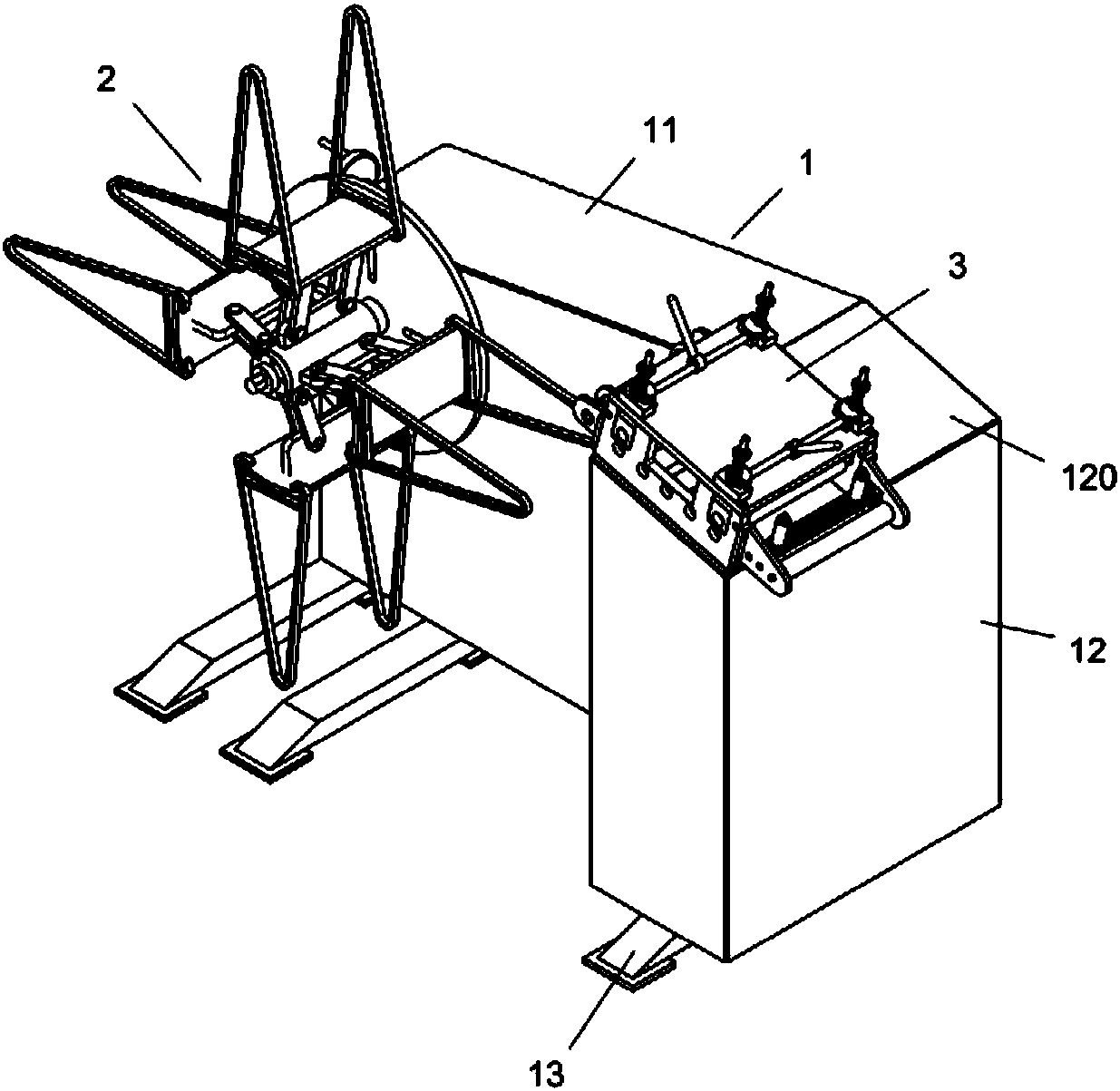

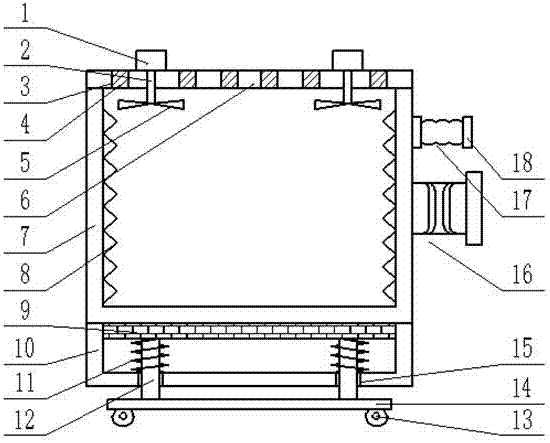

Cloth winding device of textile dyeing and cloth-collecting equipment

InactiveCN108423472AAvoid offsetAdjust the clearanceTextile treatment carriersWebs handlingEngineeringCentrifugal force

The invention discloses a cloth winding device of textile dyeing and cloth-collecting equipment, the device comprises a machine box, wherein a cloth guiding device and a cloth winding device are arranged at the upper part of the machine box sequentially, a cloth guiding driving mechanism and a cloth winding driving mechanism are arranged in the machine box, the cloth guiding driving mechanism drives the cloth guiding device to operate, and the cloth winding driving mechanism drives the cloth winding device to operate. According to the cloth winding device of the textile dyeing and cloth-collecting equipment, the cloth guiding device and the cloth winding device are arranged, the cloth guiding device can be used for guiding incoming cloth, the cloth winding device is in an automatic tension-type winding structure, a center shaft can be driven to rotate by a driving mechanism, further a swing rod at the upper part of the center shaft is driven to swing, the swing rod will drive an arc-shaped cloth winding plate to expand outwards under the action of centrifugal force, further a paper tube with which the upper part of the cloth winding plate is sleeved is tensioned, automatic cloth winding is realized, when the center shaft stops rotating, the swing rod drives the arc-shaped cloth winding plate to retract, and accordingly, the paper tube is released.

Owner:苏州默声熙达设备科技有限公司

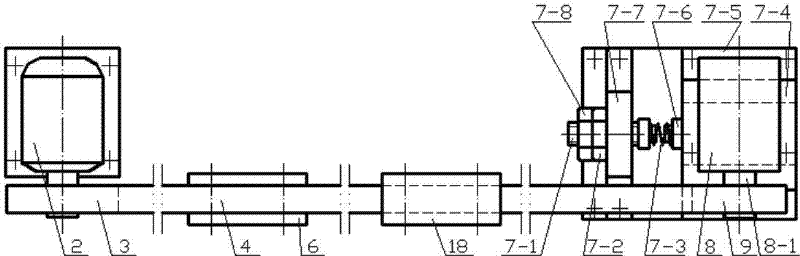

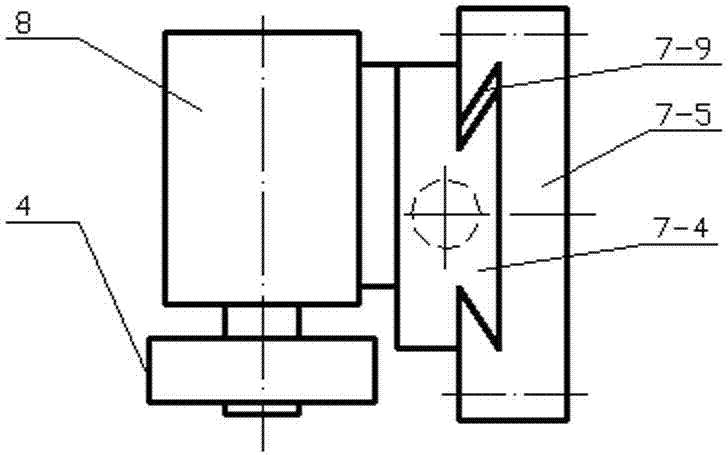

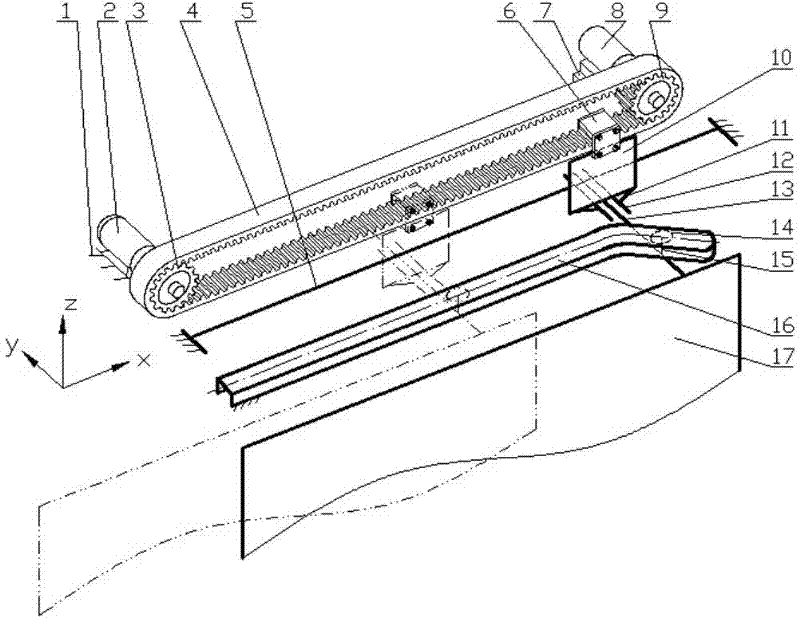

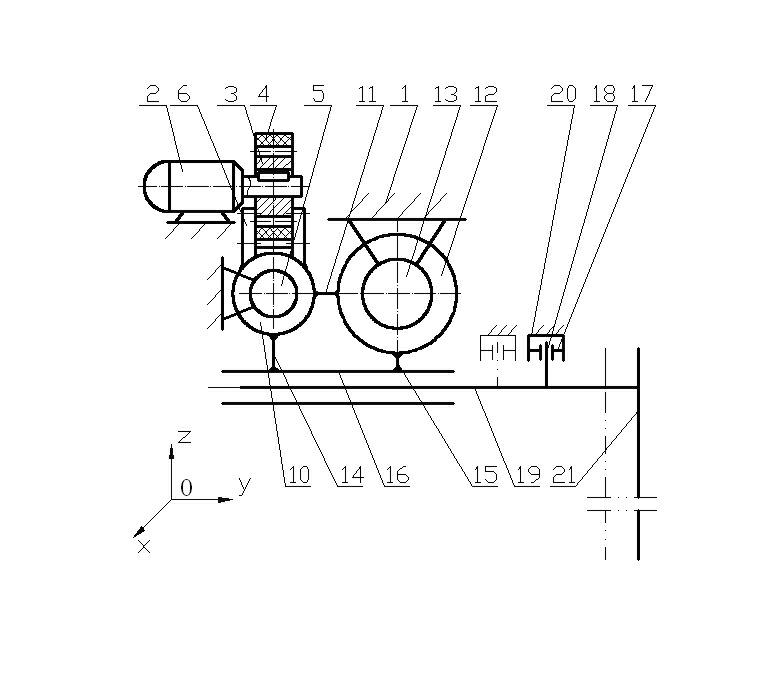

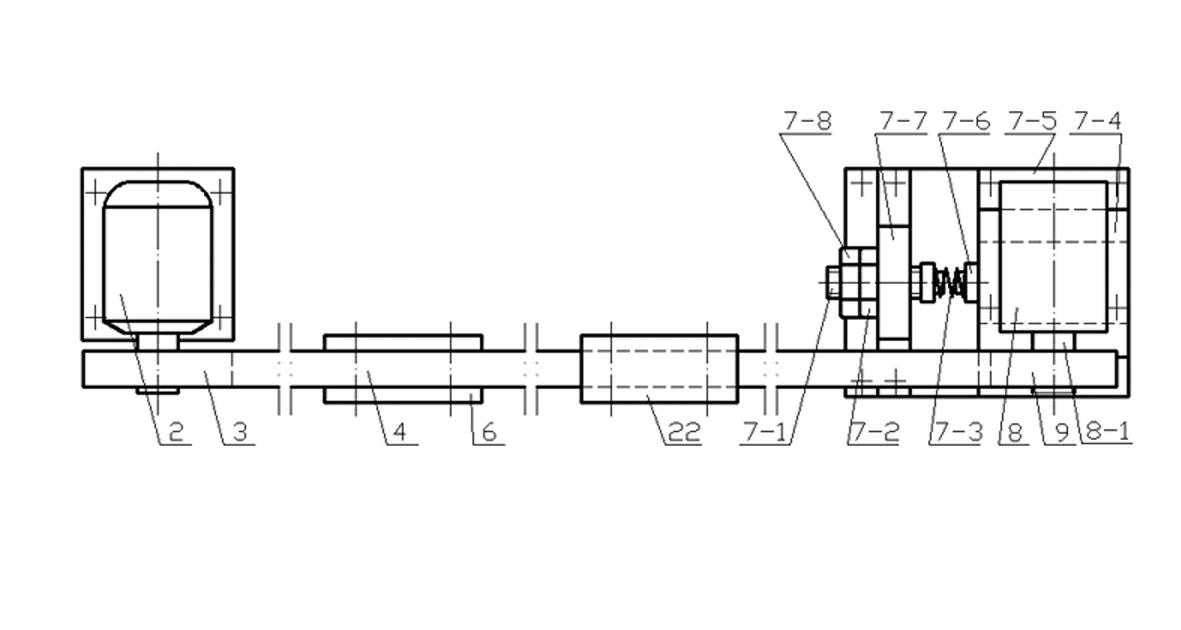

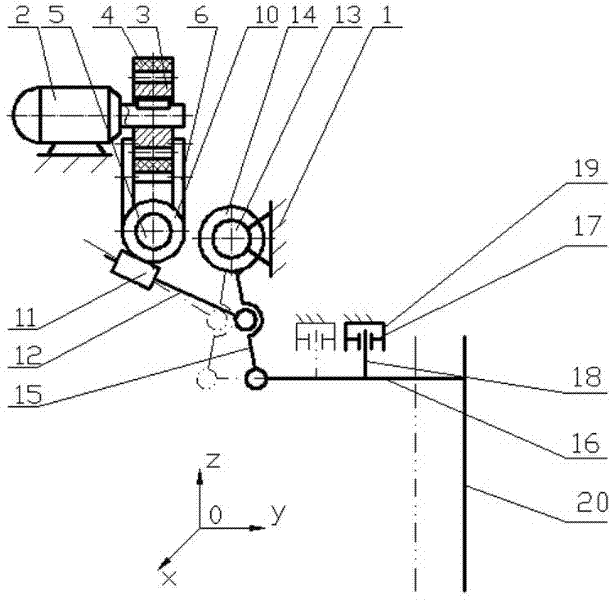

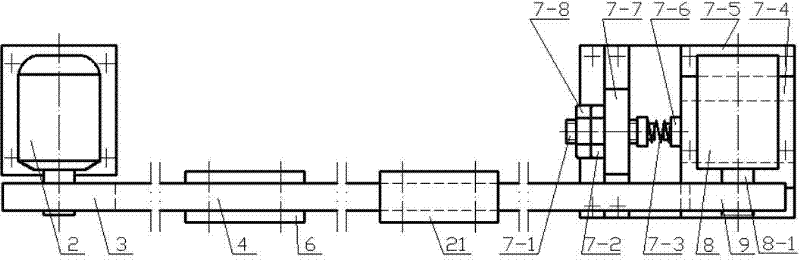

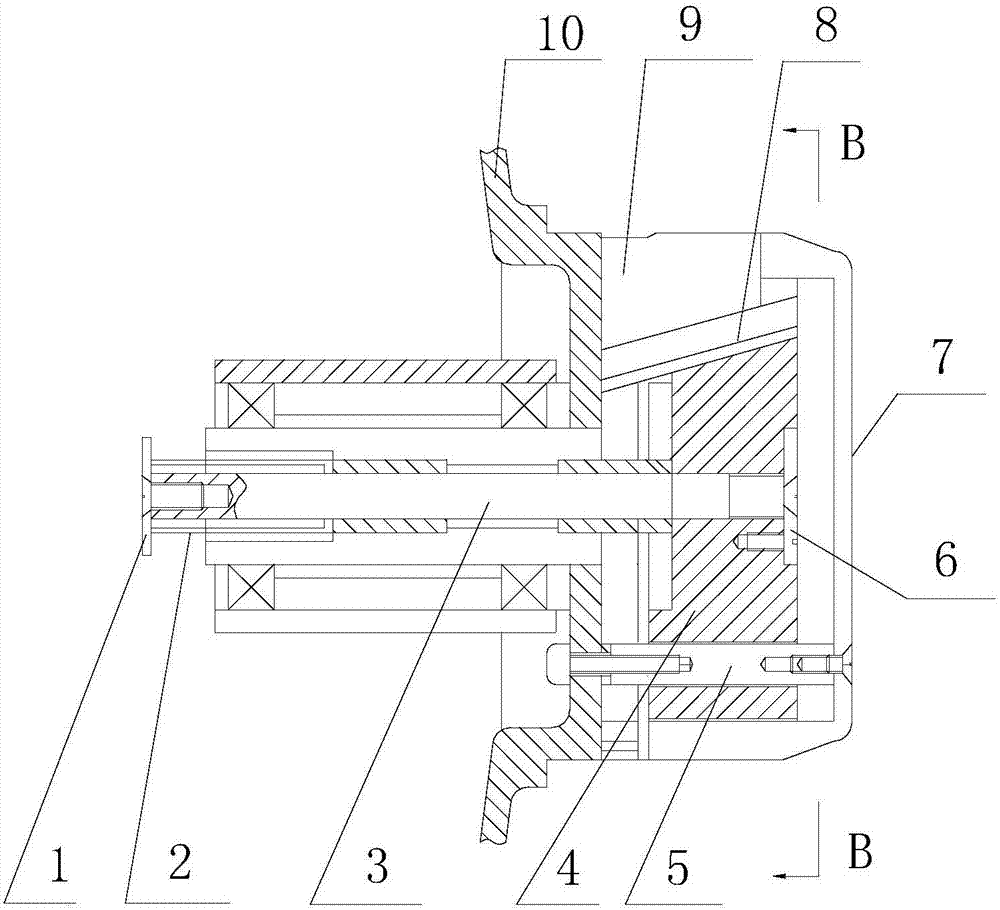

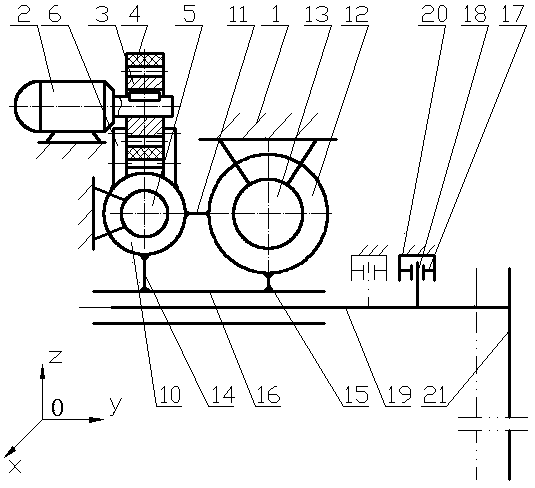

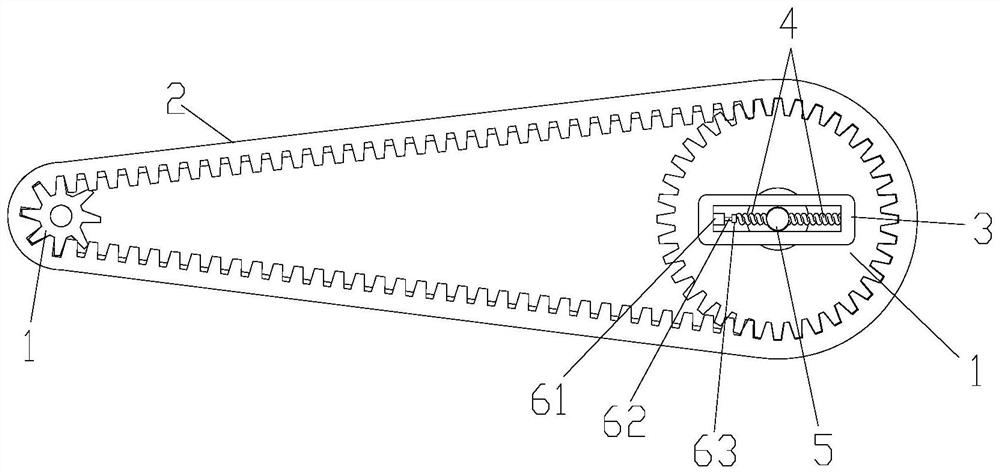

A combination space mechanism of plug tooth with uniaxial guide rod groove type cam

InactiveCN102296904AQuick opening and closingSierra seal is reliablePower-operated mechanismDoor arrangementEngineeringCam

The invention relates to a tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism of a sliding plug door, which relates to an open and close mechanism of sliding plug hermetization of the sliding plug door of a vehicle, in particular to the tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism of the sliding plug door of a high-speed railway vehicle and other railway vehicles. The tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism comprises a door frame, a motor, a driving tooth gear, a tooth strap, a load-bearing shaft, a strap clamp, a tensioning device, a bearing seat, a driven tooth gear, a load-bearing shaft sleeve, a connecting rod, a guide rod sleeve, a door carrying guide rod, a roller, a roller shaft, a groove-shaped cam and a door leaf; a tooth strap mechanism comprises the driving tooth gear, the tooth strap, the strap clamp, the tensioning device, the bearing seat and the driven tooth gear, and the strap clamp is fixedly connected with the load-bearing shaft sleeve, the connecting rod and the guide rod sleeve into a whole so as to form a single shaft and guide rod mechanism with the load-bearing shaft, the door carrying guide rod, the door frame and the like; and a groove-shaped cam mechanism comprises the load-bearing shaft, the load-bearing shaft sleeve, the guide rod sleeve, the roller, the roller shaft, the door carrying guide rod, the groove-shaped cam and the door leaf, and the three mechanisms are connected with one another to form the tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism.

Owner:NANJING INST OF TECH

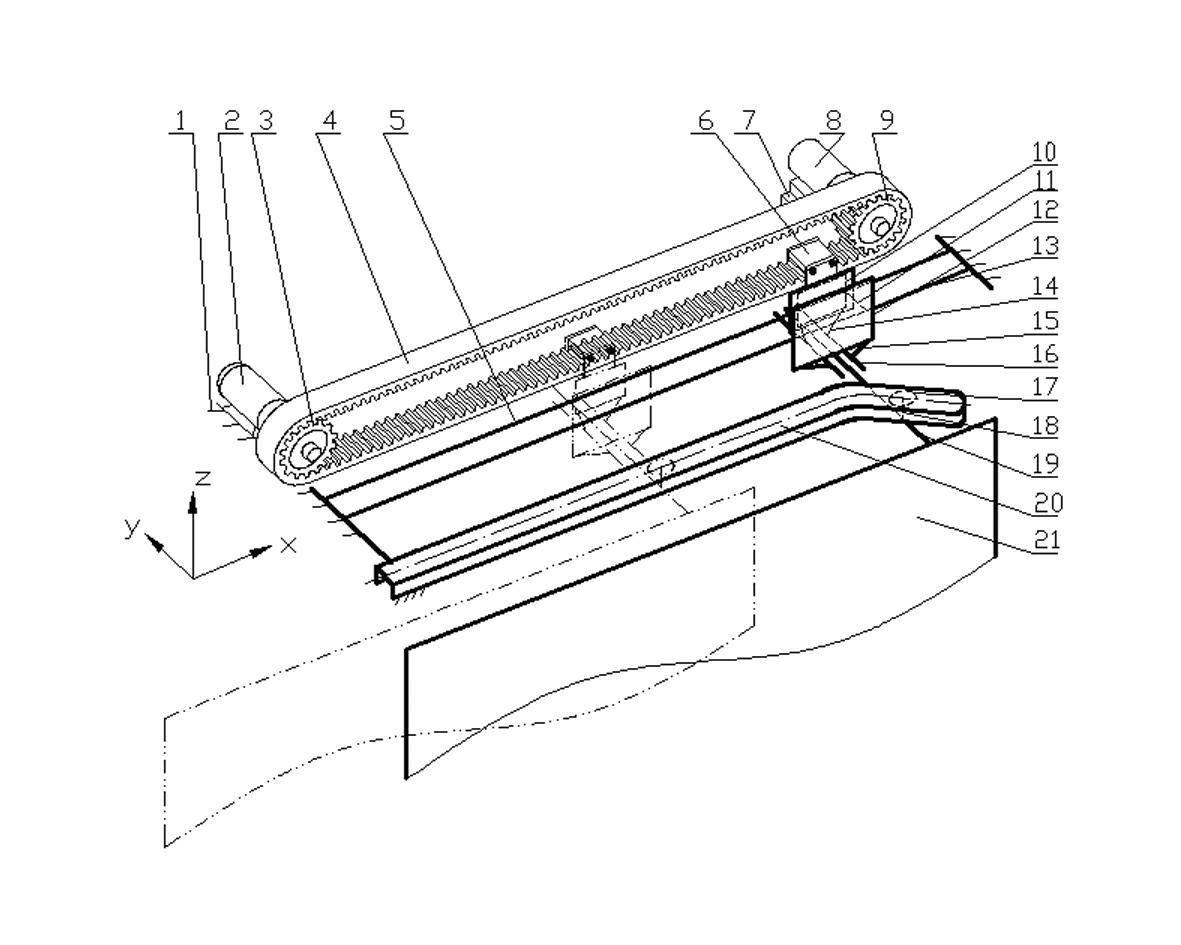

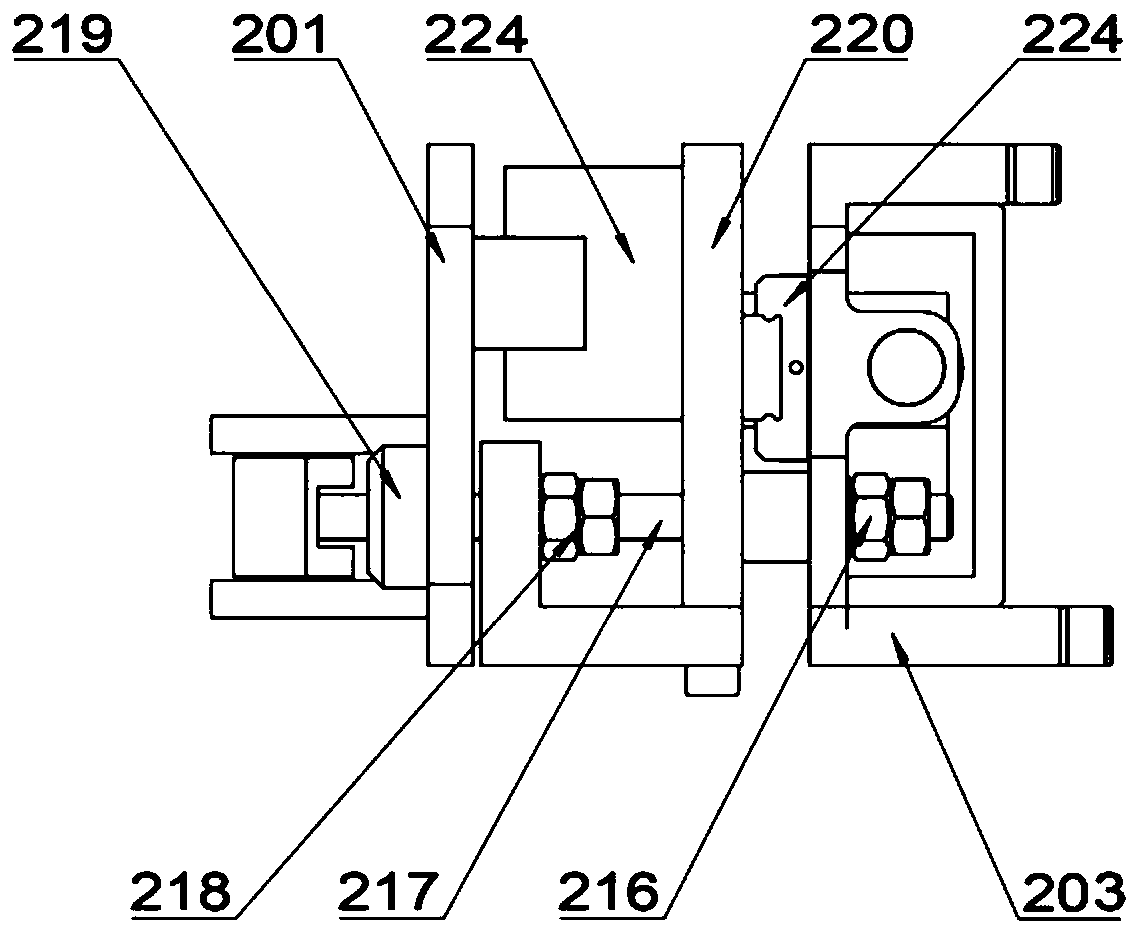

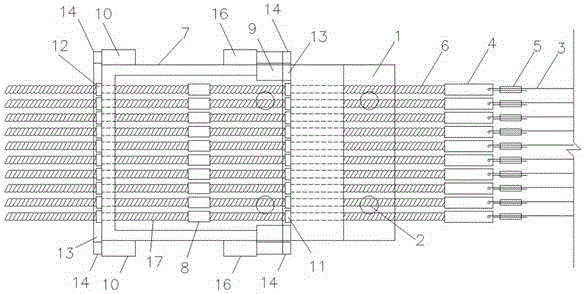

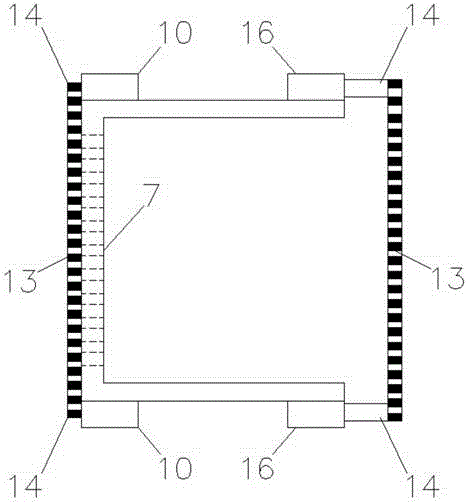

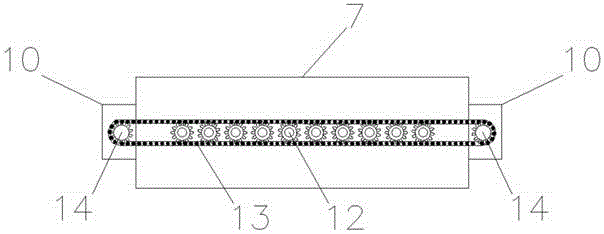

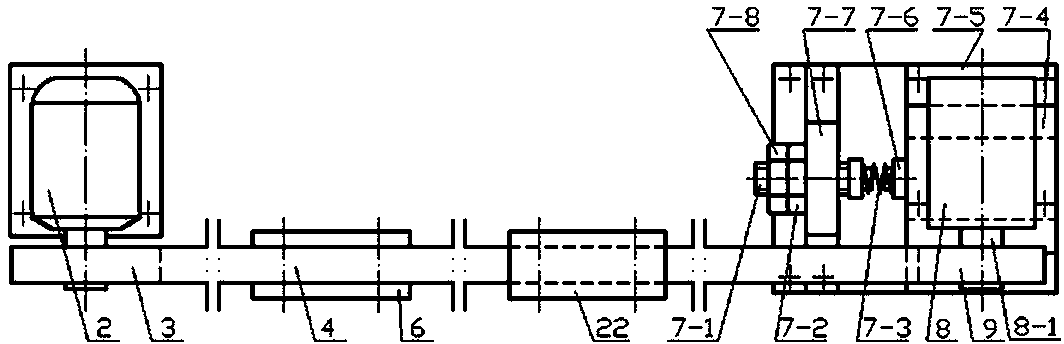

Tooth belt double-shaft guide rod groove cam combination space mechanism for sliding-plug door

InactiveCN102305009AQuick sealQuick opening and closingPower-operated mechanismDoor arrangementDrive wheelCoupling

The invention discloses a tooth belt double-shaft guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the tooth belt double-shaft guide rod groove cam combination space mechanism for high-speed rail or other railway vehicles. The mechanism comprises a door frame, a motor, a driving wheel, a tooth belt, an auxiliary bearing shaft, a belt clamp, a tension device, a bearing pedestal, a driven wheel, an auxiliary shaft sleeve, a coupling rod A, a main shaft sleeve, a main bearing shaft, a coupling shaft B, a coupling shaft C, a guide rod sleeve, a roller, a roller shaft, a door carrying guide rod, a groove cam and a door leaf; a tooth belt transmission mechanism consists of the driving wheel, the tooth belt, a lower belt clamp, the tension device, the bearing pedestal, and the driven wheel; a double-shaft guide rod mechanism consists of the coupling rod A, the main shaft sleeve, the coupling rod B, the coupling rod C and the guide rod sleeve which are connected fixedly and integrally, the main bearing shaft, the auxiliary shaft, and the door frame; and a groove cam mechanism consists of the main shaft sleeve, the main shaft, the coupling rod C, the roller, the roller shaft, the door carrying guide rod, the groove cam, the door leaf, the main shaft sleeve and the door frame.

Owner:NANJING INST OF TECH

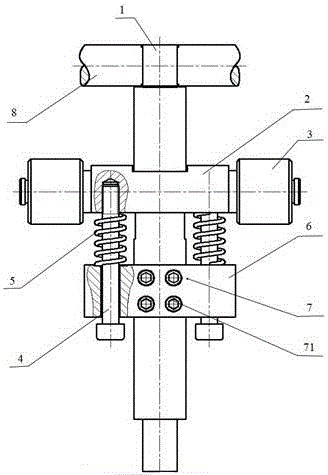

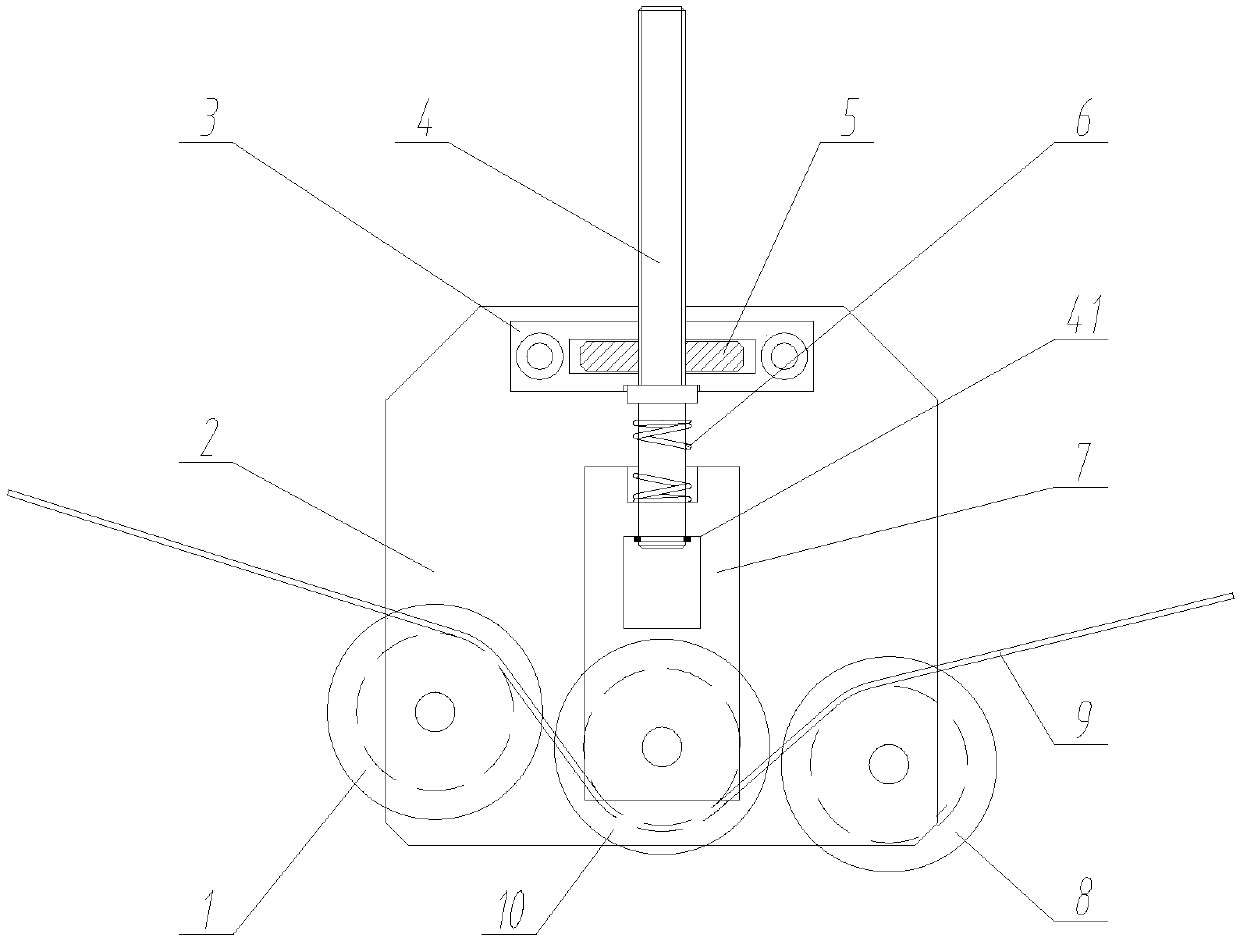

Tensioning device of conveyer belt of sealing machine

The invention relates to a tensioning device of a conveyer belt of a sealing machine. The tensioning device comprises a tensioning wheel. The tensioning wheel is arranged on the inner side of the conveyer belt. The tensioning device additionally comprises a movable frame. The tensioning wheel is hinged to the movable frame through a pin roll. The movable frame is arranged on a support through a guide rail. The movable frame can slide along the guide rail. A raised part is formed on one side of the support towards the movable frame. An adjusting bolt penetrates through a hole in the movable frame and is connected with the raised part. The adjusting bolt is used for adjusting the position of the tensioning wheel, so that the tensioning extent of the conveyer belt can be adjusted and the demands for conveying different articles can be met; since a spring is arranged between the movable frame and the adjusting bolt, automatic tensioning can be realized and the relaxation of the conveyer belt due to deformation is compensated; since the conveyer belt has certain elasticity, the requirements for conveying different articles can be self-adapted within a certain range.

Owner:ZHENJIANG YUANCHUN MEAT PRODS

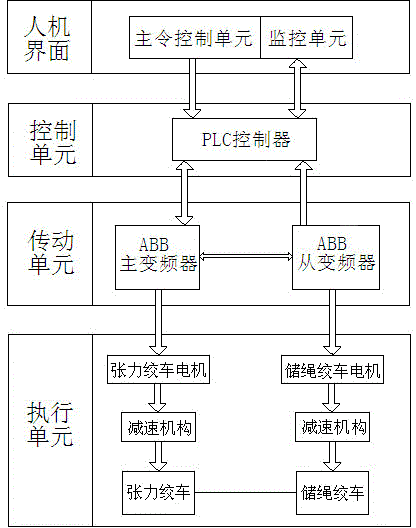

Master-slave control system for automatically tensioning winch mooring rope of anchor moored positioning system

InactiveCN104443275ATempo syncSimple control systemAnchoring arrangementsFrequency changerHuman–machine interface

The invention provides a master-slave control system for automatically tensioning a winch mooring rope of an anchor moored positioning system. The master-slave control system comprises a man-machine interface, a control unit, a transmission unit and an execution unit. The transmission unit comprises an ABB master frequency converter and an ABB slave frequency converter. The execution unit comprises a tension winch motor, a rope storage winch motor, a tension winch and a rope storage winch. The control unit is in communication connection with the ABB master frequency converter and the ABB slave frequency converter. The ABB master frequency converter is connected with the tension winch motor, the ABB slave frequency converter is connected with the rope storage winch motor, and the ABB master frequency converter is in communication connection with the ABB slave frequency converter. Software mathematic models of alternating current asynchronous motors are arranged in the ABB master frequency converter and the ABB slave frequency converter and capable of controlling the rotating speeds of the tension winch motor and the rope storage winch motor respectively, speed synchronization between the tension winch and the rope storage winch is kept, and the automatic tensioning function of the tension winch and the rope storage winch is achieved.

Owner:WUHAN MARINE MACHINERY PLANT

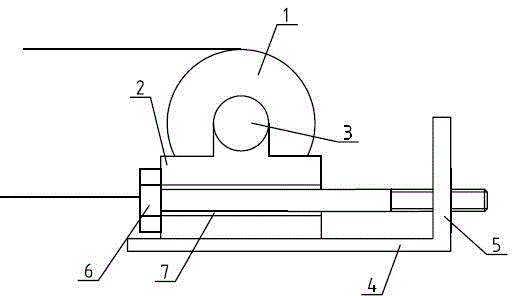

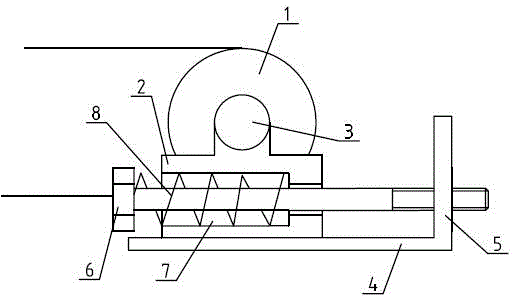

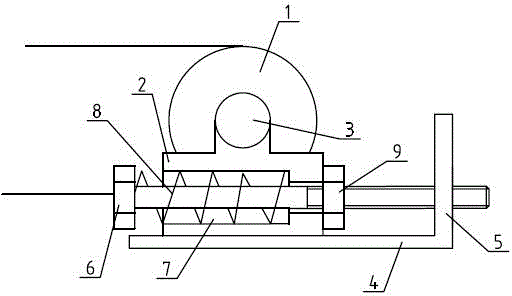

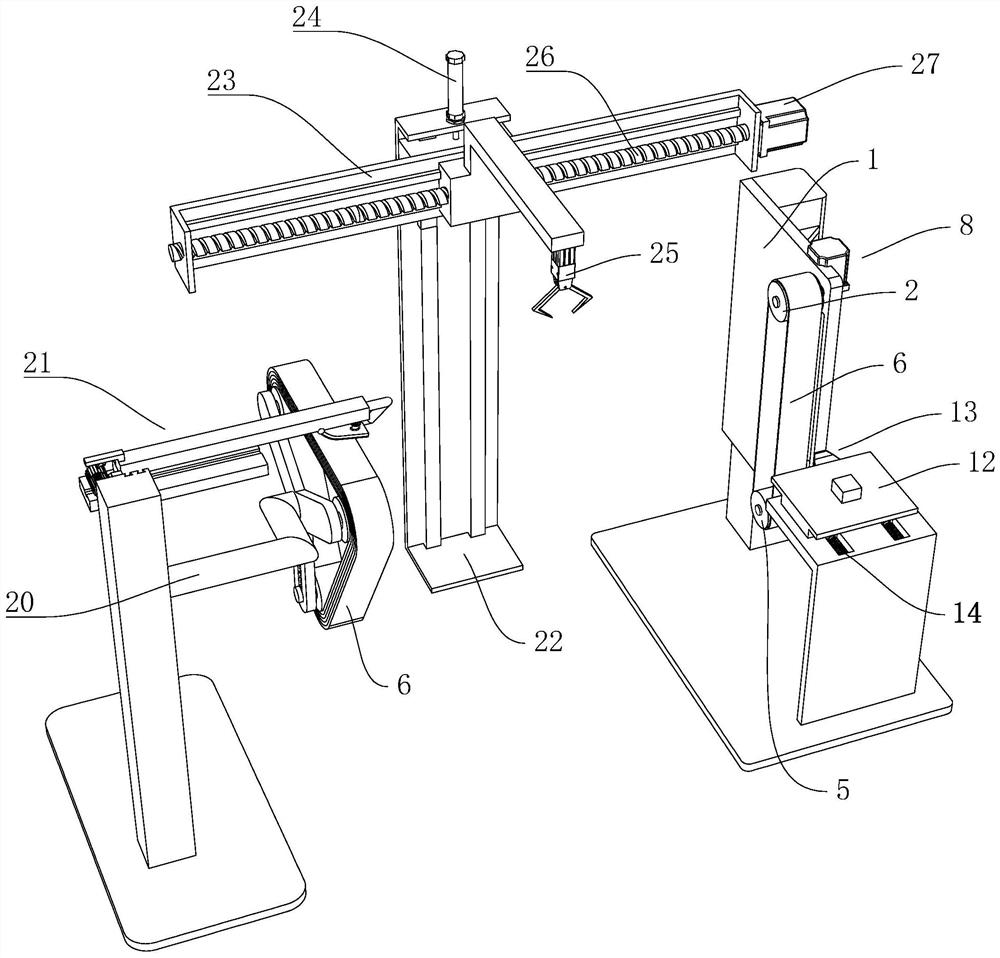

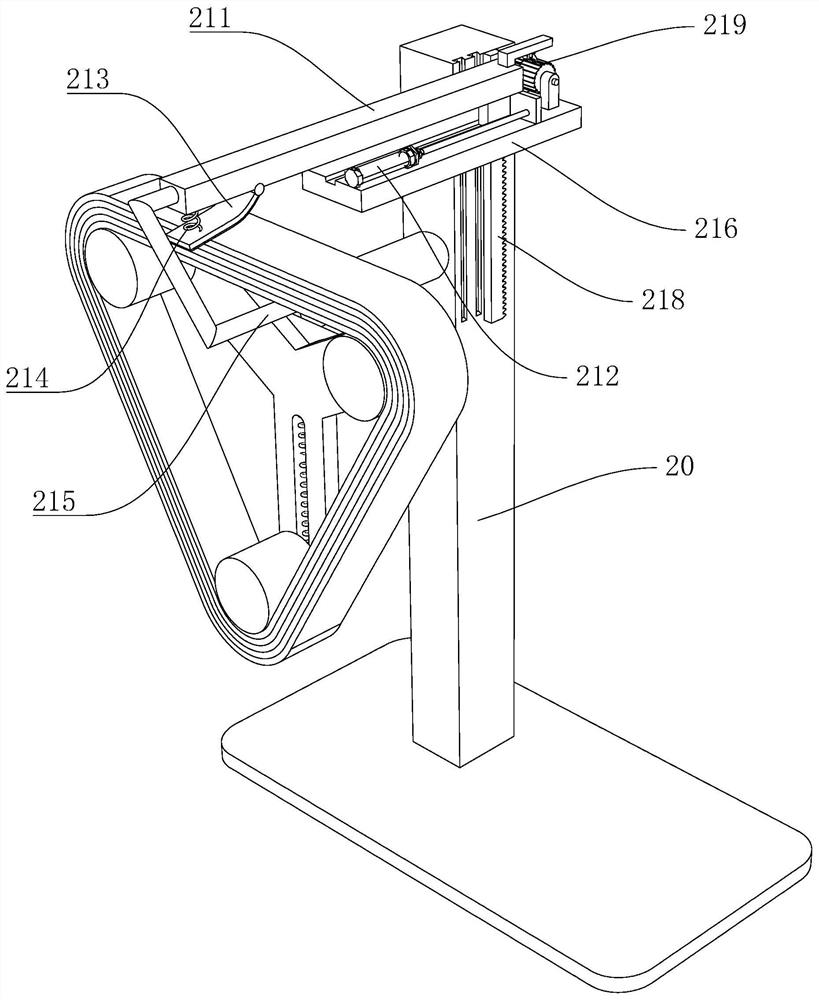

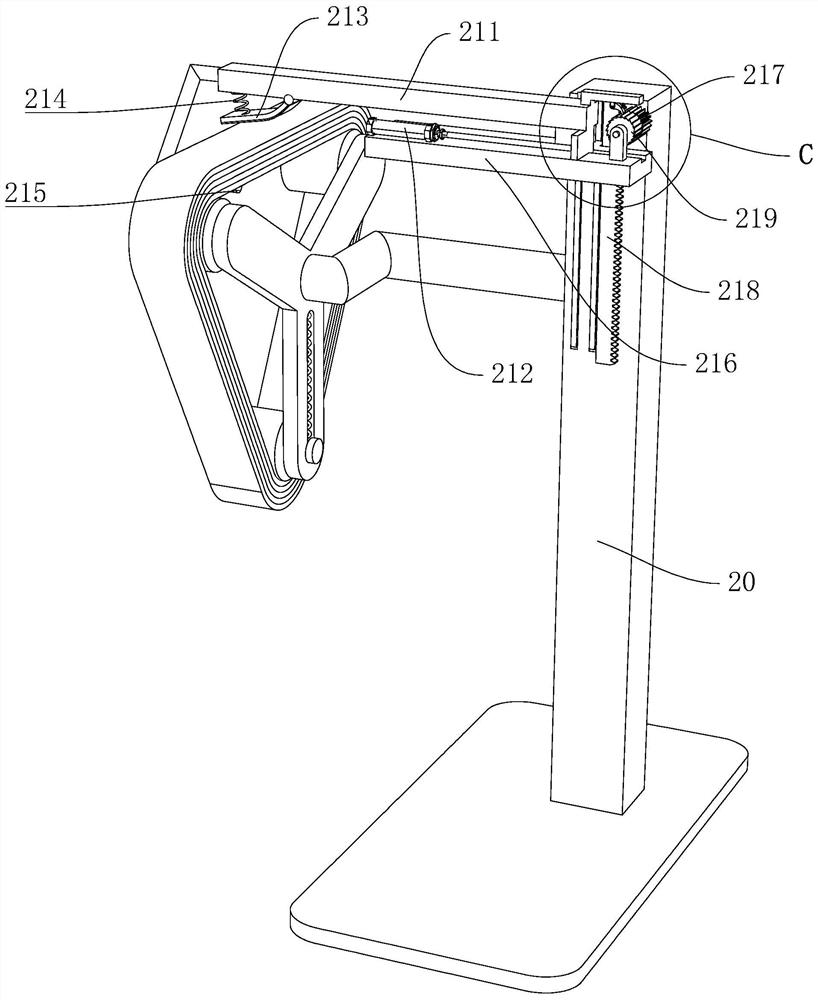

Full-automatic abrasive belt grinding machine

ActiveCN112139931ARealize automatic adjustmentRealize automatic replacementBelt grinding machinesBelt grindingStructural engineering

The invention discloses a full-automatic abrasive belt grinding machine. The abrasive belt grinding machine comprises a rack and a driven belt wheel, a sliding groove is formed in the rack, a slidingseat is arranged in the sliding groove, a first driving piece and a driving belt wheel are arranged on the sliding seat, an abrasive belt is arranged between the driving belt wheel and the driven beltwheel in a sleeving mode, a linkage block is arranged in the sliding groove in a sliding mode, a driving component for driving the linkage block to reciprocate is arranged on the rack, the sliding seat is detachably and fixedly connected with the linkage block, a tensioning frame is arranged on one side of the rack, a taking-out device is arranged on the tensioning frame, a fixed seat is arrangedbetween the taking-out device and the rack, a movable seat is arranged on the fixed seat, a third driving piece for driving the movable seat to move is arranged on the fixed seat, a clamping jaw is arranged on the moving seat, and a second screw rod which is in threaded connection with the clamping jaw and a fourth driving piece which is used for driving the second screw rod to rotate are rotationally arranged on the moving seat. The full-automatic abrasive belt grinding machine has the following advantages and effects that automatic adjustment of abrasive belt tensioning can be achieved, theabrasive belt can be automatically replaced, and therefore the production cost is reduced, and the workload of workers is reduced.

Owner:ZHEJIANG CANAAN TECH

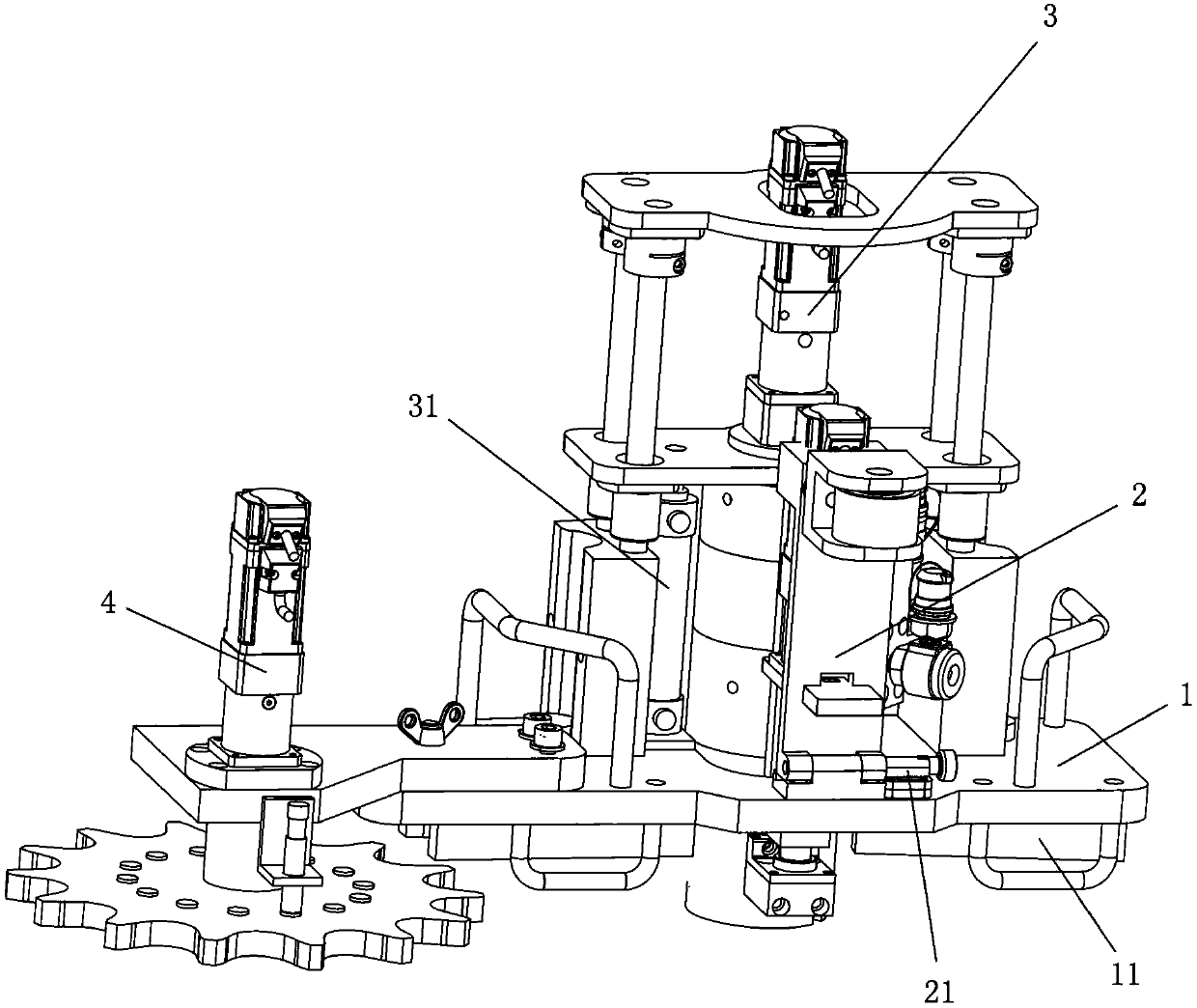

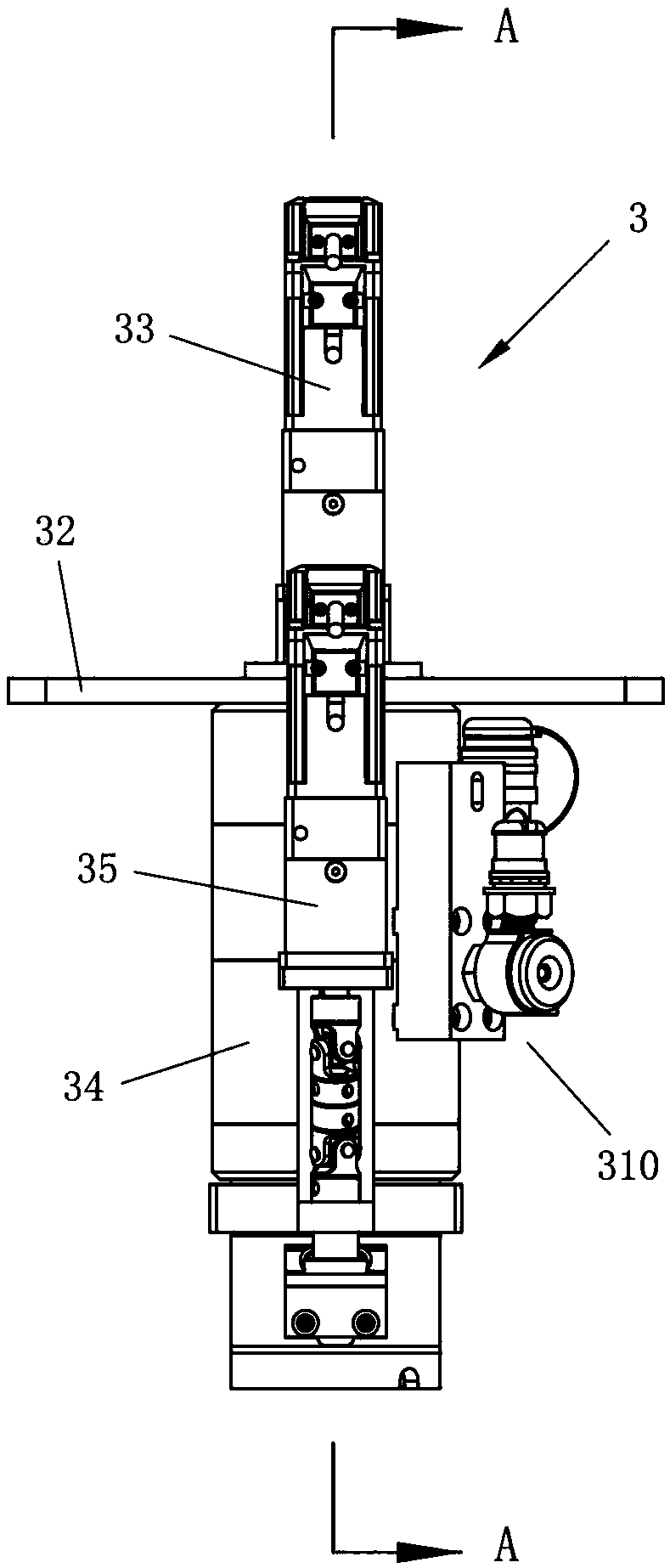

Control system for bolt fastening device

ActiveCN107717817AReduce labor intensityImprove fastening efficiencySpannersWrenchesExecution controlControl system

The invention discloses a control system for a bolt fastening device. The bolt fastening device comprises a support, an execution unit and a travelling unit, wherein the execution unit is installed onthe support and is used for tensioning a bolt in the extending direction of the corresponding bolt and screwing a nut on the corresponding bolt, and the traveling unit is arranged on the support andis used for driving the bolt fastening device to travel along paths of a plurality of bolts. The control system comprises an execution control module, an advancing control module and a controller, wherein the execution unit is used for controlling the operation of the execution unit, the advancing control module is used for controlling the operation of the advancing unit, and the controller is communicated with the execution control module and the advancing control module so as to command the execution unit to tension the bolt and fasten the nut, and command the travelling unit to advance forwards, so that the bolt fastening device moves to a next bolt after the fastening operation of one bolt is completed. The control system automatically achieves the fastening of the bolts, reduces the manual operation investment, and improves the installation quality.

Owner:XINJIANG GOLDWIND SCI & TECH

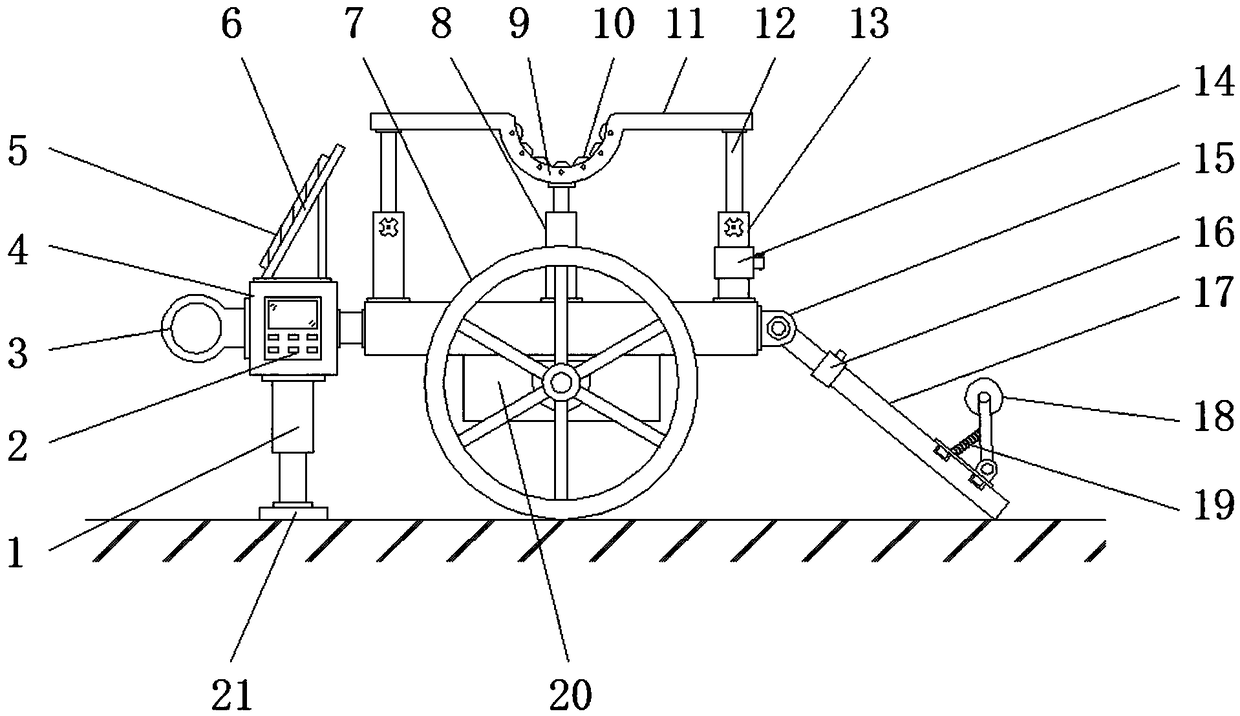

Rolling tensioning structure for chain conveyer

The invention provides a rolling tensioning structure for a chain conveyer. The rolling tensioning structure for the chain conveyer changes sliding friction in the tensioning process into rolling friction, reduces the acting force in the adjustment process, avoids fault tensioning of the chain conveyer under poor working conditions, meets the use requirements of equipment, reduces fault rate, and lowers maintenance cost. The rolling tensioning structure for the chain conveyer comprises a conveying chain, wherein the tail end of the conveying chain is installed on a rotary shaft in a sleeved mode, and the two ends of the rotary shaft are supported on a bearing seat respectively. The rolling tensioning structure for the chain conveyer is characterized in that two sides of the bottom of the bearing seat are respectively provided with an installation plate in a fastening mode, idler wheels are arranged in the middle positions of the two ends of each installation plate respectively, the idler wheels are supported on a limiting guide rail at the bottom, the upper portion of the bearing seat is connected with one end of an adjustment screw rod in a fastening mode, the other end of the adjustment screw rod penetrates through a support vertical plate and then is provided with a nut in a sleeved mode, an automatic spring is arranged between the nut and the outer lateral surface of the support vertical plate and installed on the adjustment screw rod in a sleeved mode, and a limiting protruding block is arranged at the bottom of the bearing seat in a downward protruding mode.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

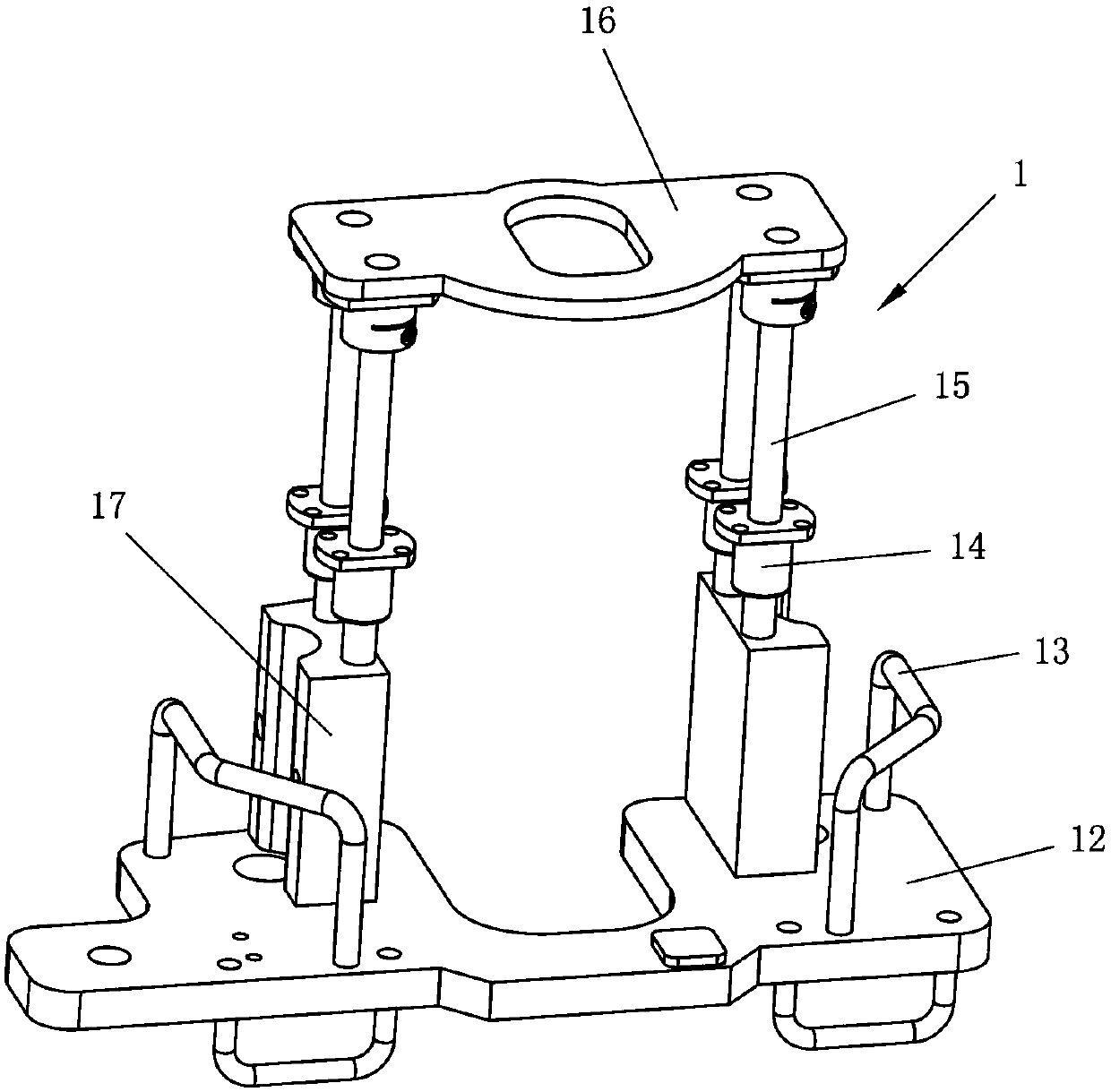

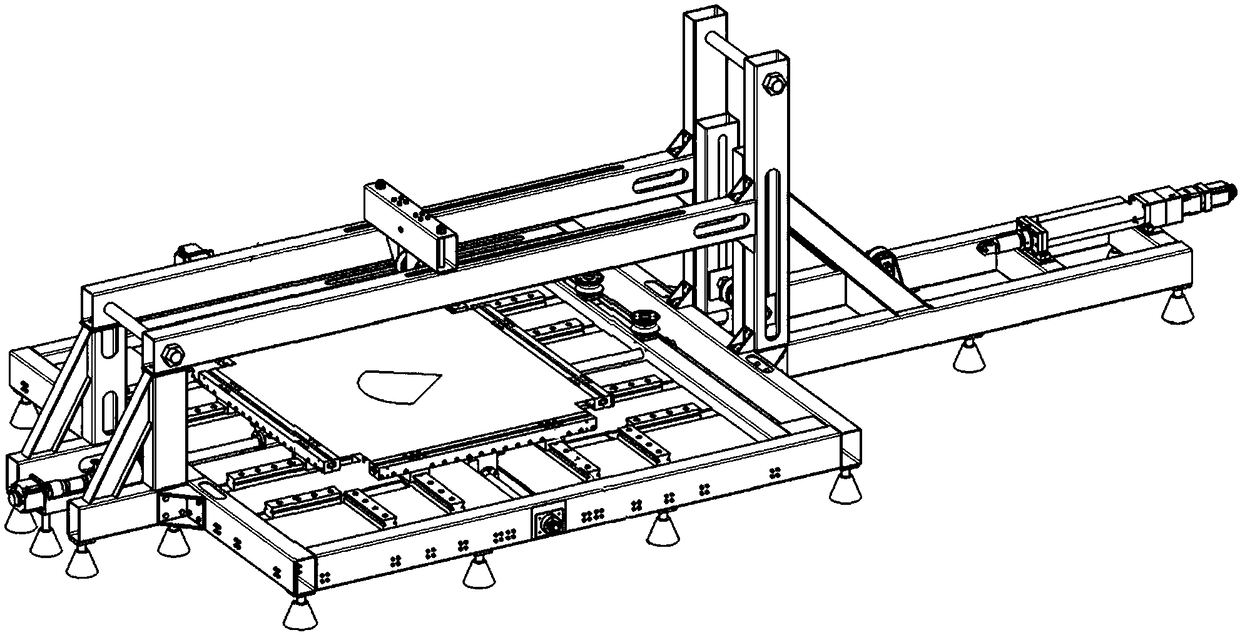

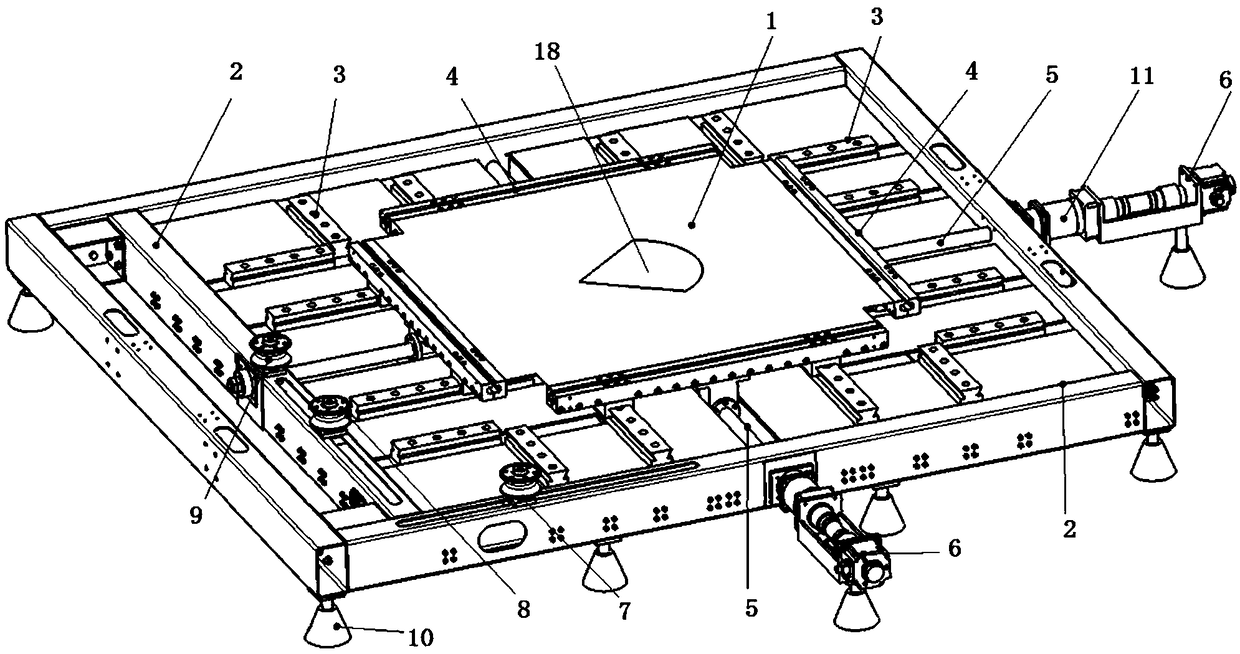

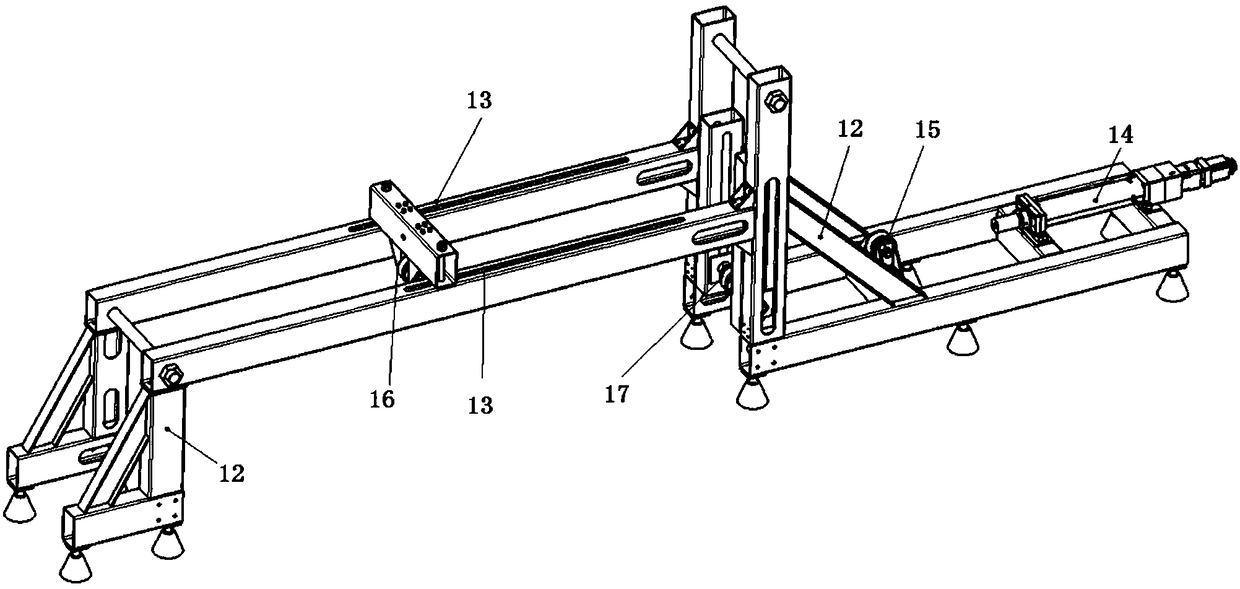

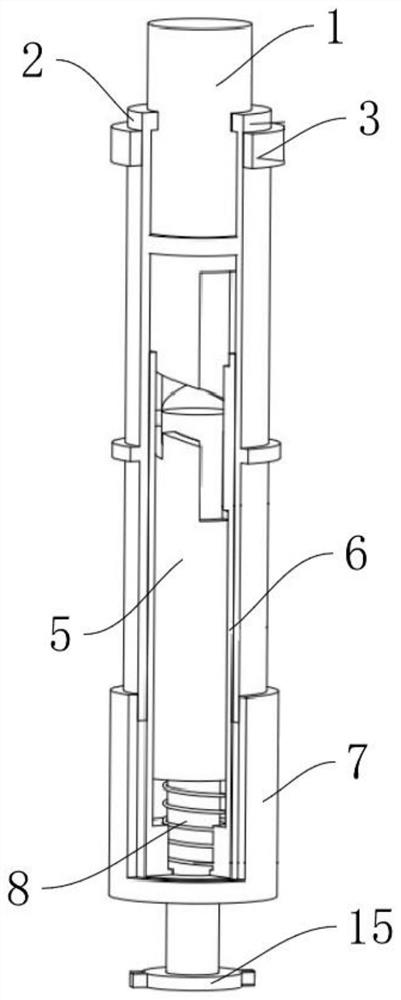

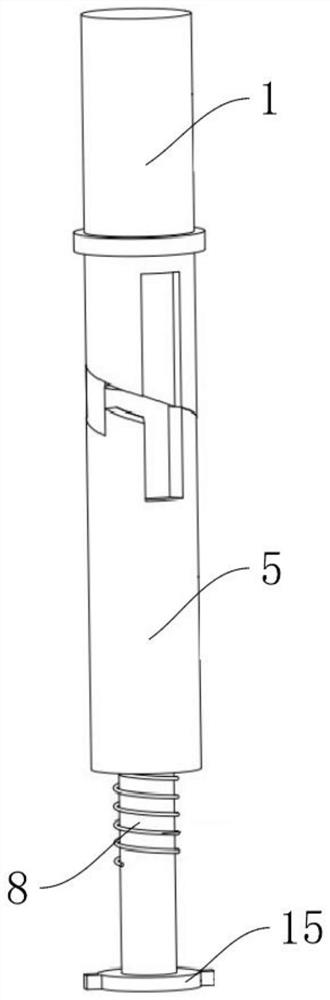

Strength testing device for connector of aerostat

ActiveCN109029967AQuick installationEasy to operateMachine part testingMaterial strength using tensile/compressive forcesAutomatic controlAerostat

The invention belongs to the field of aerostat testing, and in particular relates to a strength testing device for a connector of an aerostat. There is currently no special test device specifically designed for the strength test of a typical connector for aerostats. The object of the invention is to change the disadvantages such as large field occupying, low installation efficiency, long test period, and poor repeatability in the existing test methods. A fixing module tightens and fixes the edge of a base fabric on a fixing gantry; horizontal loading pulleys are further disposed at different positions of the edge of the fixing gantry; a loading module fixes pulley rails above the fixing gantry through a loading gantry, and movable vertical loading pulleys are mounted on the pulley rails; the loading module further has an operating cylinder, one end of the cable is connected to the operating cylinder, and the other end is connected to the connecting cloth via the loading pulleys, thereby realizing the automation of test installation and loading, and greatly improving the test efficiency. The test device is automatically controlled by programs from installation to loading, which greatly improves the test efficiency.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Anti-wire jumbling computer case

InactiveCN107256071AEasy to moveAvoid enteringDigital processing power distributionDamping functionElastic plastic

The invention discloses a computer case for preventing messy wires, which comprises a case body, a plurality of reflector plates are fixedly connected to the inner side wall of the case body, a case cover is arranged on the upper end of the case body, and two sides of the upper end of the case cover are fixedly installed The drive motor, the output shaft of the drive motor is connected with the rotating shaft, and the fan blade is fixedly connected to the rotating shaft. The outer wall of the box body is provided with a winding frame and a clamping frame in sequence from top to bottom, and a ring-shaped frame is provided on the winding frame. The wire winding groove, the wire clamping frame includes the wire clamping body and the flange. The cross section of the clamping body is rectangular. There is a vertically penetrating wire clamping groove on the front and rear surfaces of the clamping body. The wire clamping groove is fixed with an elastic The plastic pad, the elastic plastic includes a plastic body and a plastic wrapping. The invention has a simple structure and a reasonable design, can accelerate heat dissipation, and can also prevent dust. At the same time, the device has a shock-absorbing function, and can also be wound, and has strong practicability.

Owner:丽水市莲都区君正模具厂

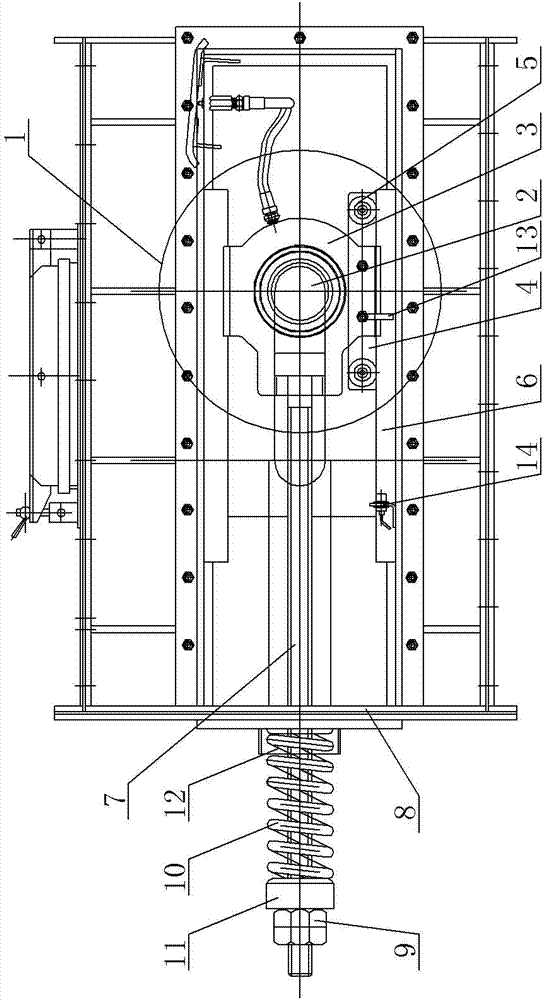

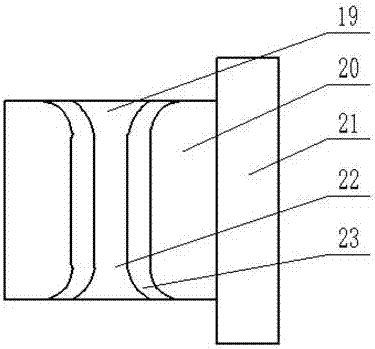

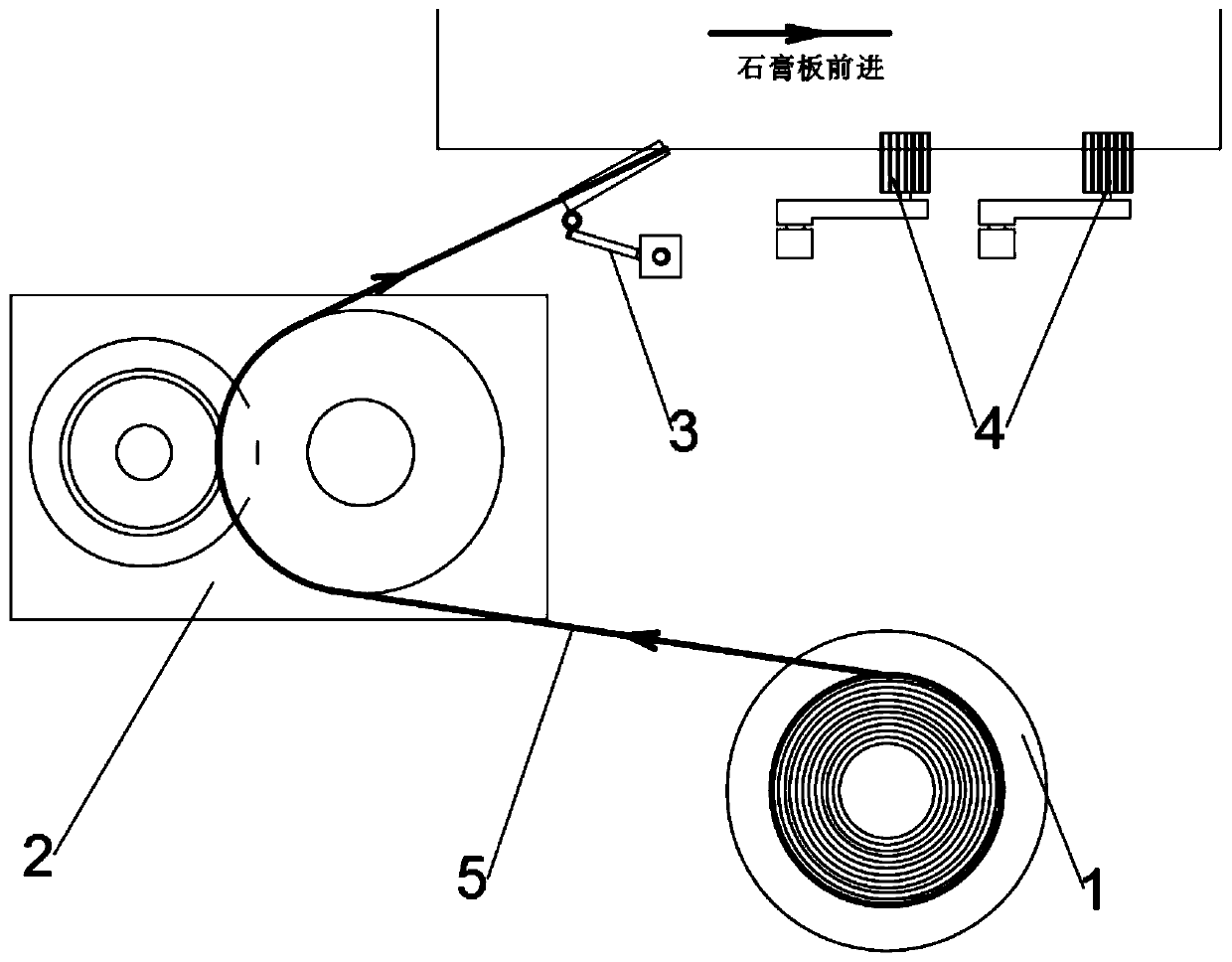

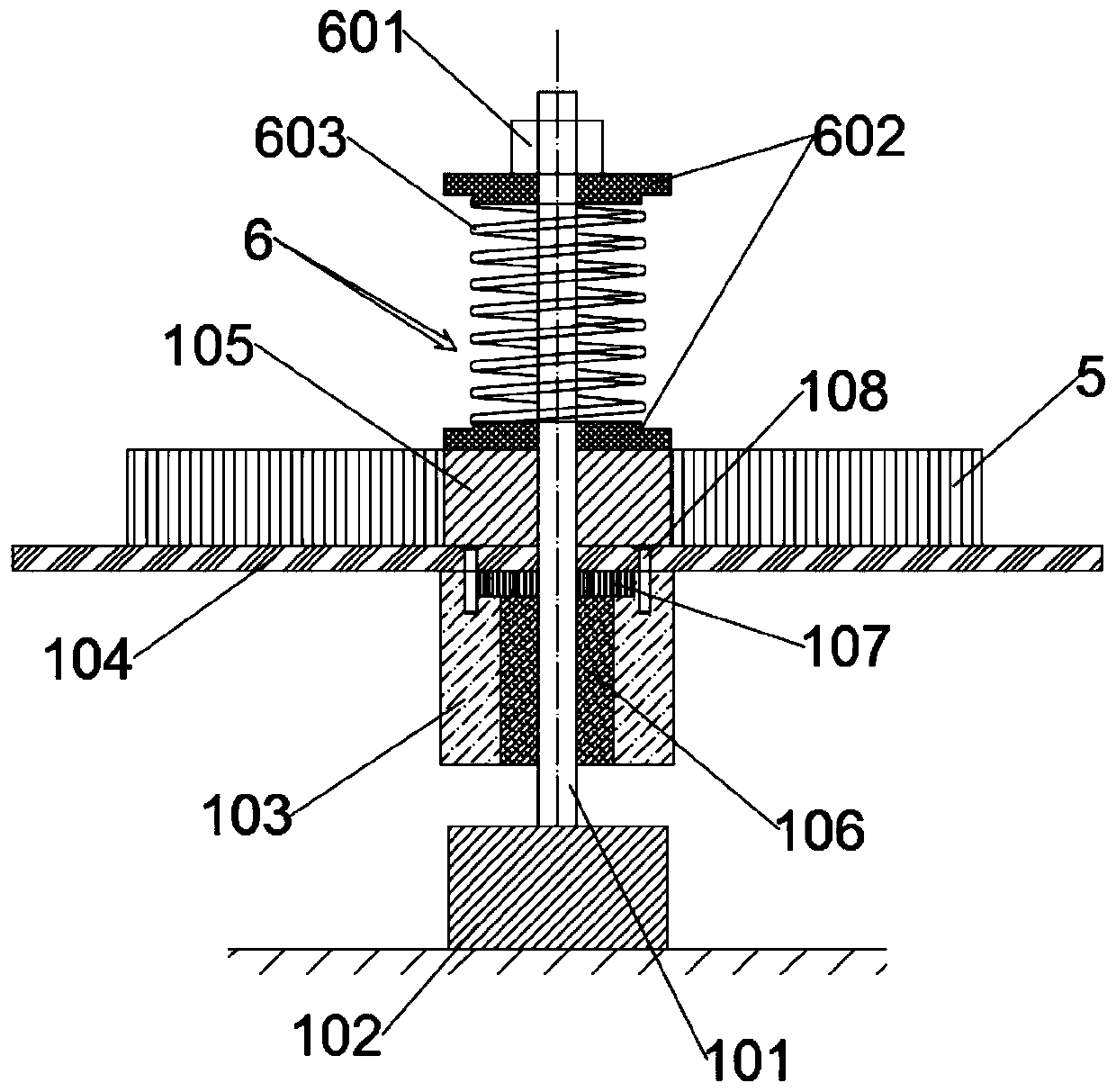

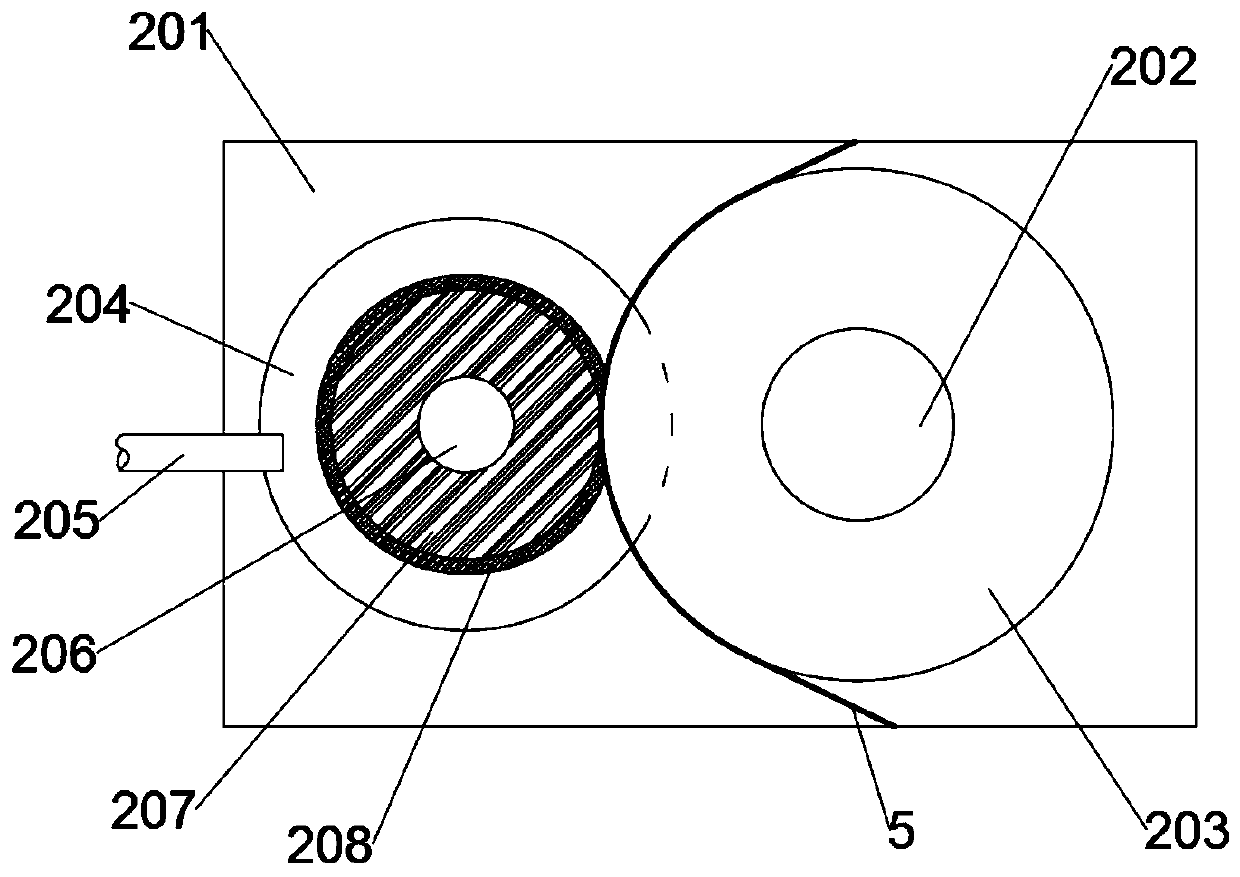

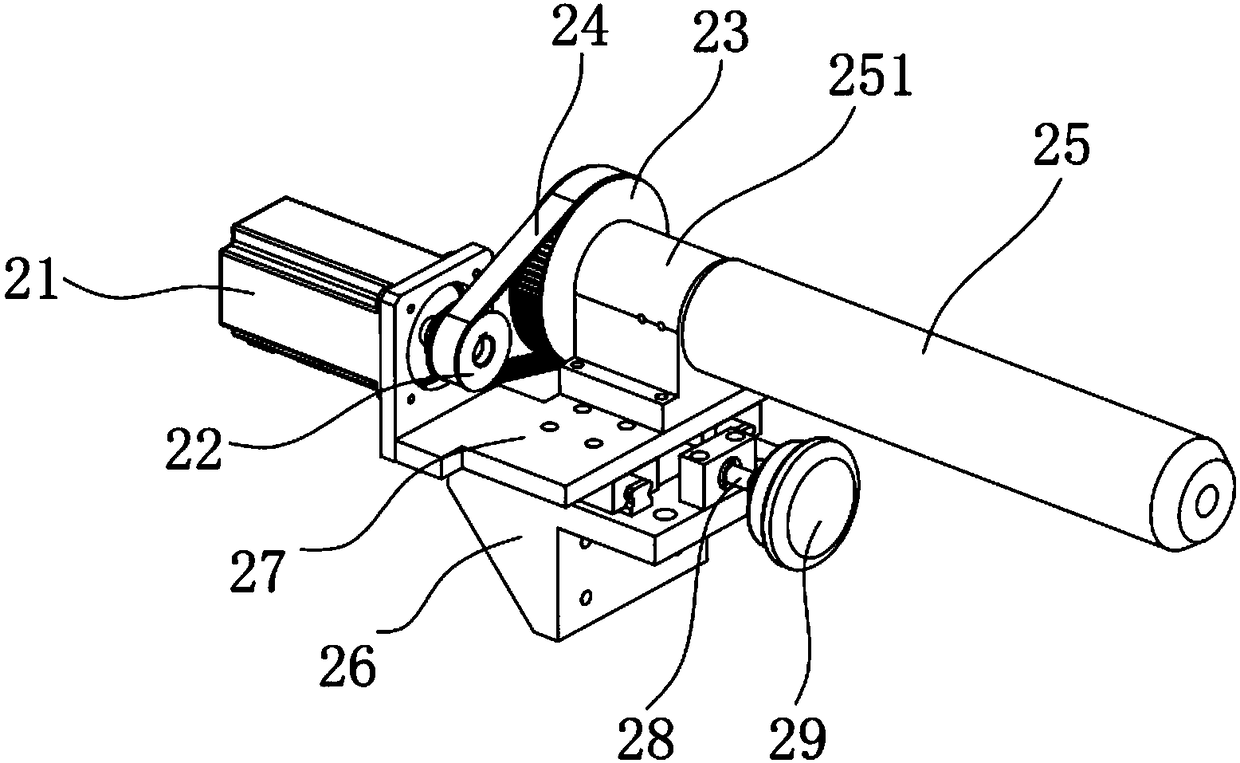

Automatic tensioning device for edge sealing belt

ActiveCN110524722ARealize automatic tensioningPrevent deviationStone-like material working toolsCoil springGypsum

The embodiment of the invention discloses an automatic tensioning device for an edge sealing belt. The automatic tensioning device comprises a self-tensioning tray, a redirection water supply assembly, a paper folder and an edge sealing pressing roller. An edge sealing belt is wound on the self-tensioning tray; the edge sealing belt sequentially passes through the redirection water supply assembly, the paper folder and the edge sealing pressing roller and is pressed on the gypsum board by the edge sealing pressing roller; the self-tensioning tray comprises a main shaft and a base; the lower end of the main shaft is fixed on the base; a rotating wheel, a tray and a positioning cylinder are rotatably arranged on the main shaft in sequence from bottom to top in a penetrating manner; the rotating wheel is rotatably fixed on the main shaft through a bearing, a coil spring is arranged between the rotating wheel and the main shaft, the tray is connected with the rotating wheel through a bolt,and the edge sealing belt is wound on the positioning cylinder, so that the automatic tensioning of the edge sealing belt is realized, the deviation of the edge sealing belt is avoided, and the edgesealing effect is ensured.

Owner:GUCHENG NEW BUILDING MATERIALS LTD +1

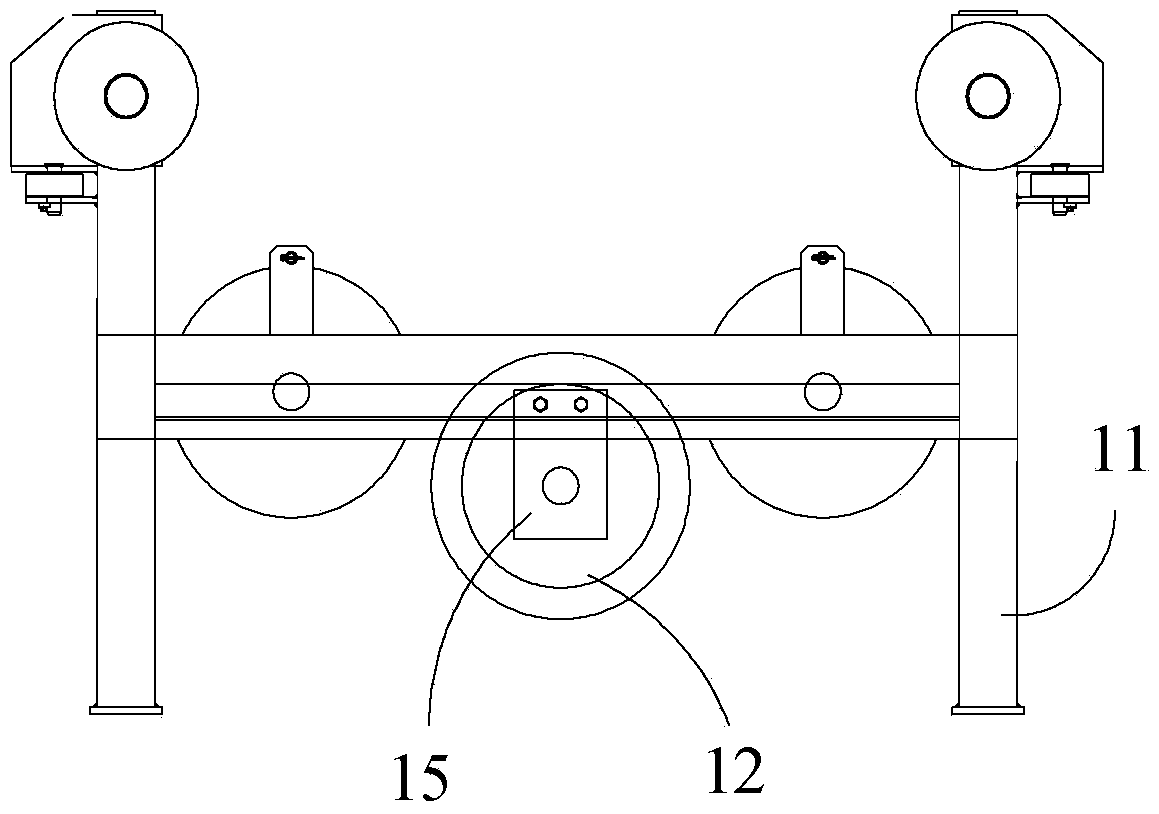

Crab trolley, crab trolley luffing system of crane with crab trolley and crane

ActiveCN103588091ARealize automatic tensioningEasy to control automaticallyCranesTrolleysEngineeringMechanical engineering

The invention provides a crab trolley, a crab trolley luffing system of a crane with the crab trolley, and a crane. The crab trolley comprises a frame (11), and further comprises a first winding drum (12) pivoted on the frame (11), and a second winding drum (13) arranged in linkage with the first winding drum (12), wherein the central axis of the second winding drum (13) is parallel to or collinear with that of the first winding drum (12). The technical scheme of the invention is convenient to automatically control tension of a luffing rope so as to improve the tension effect.

Owner:ZOOMLION HEAVY IND CO LTD

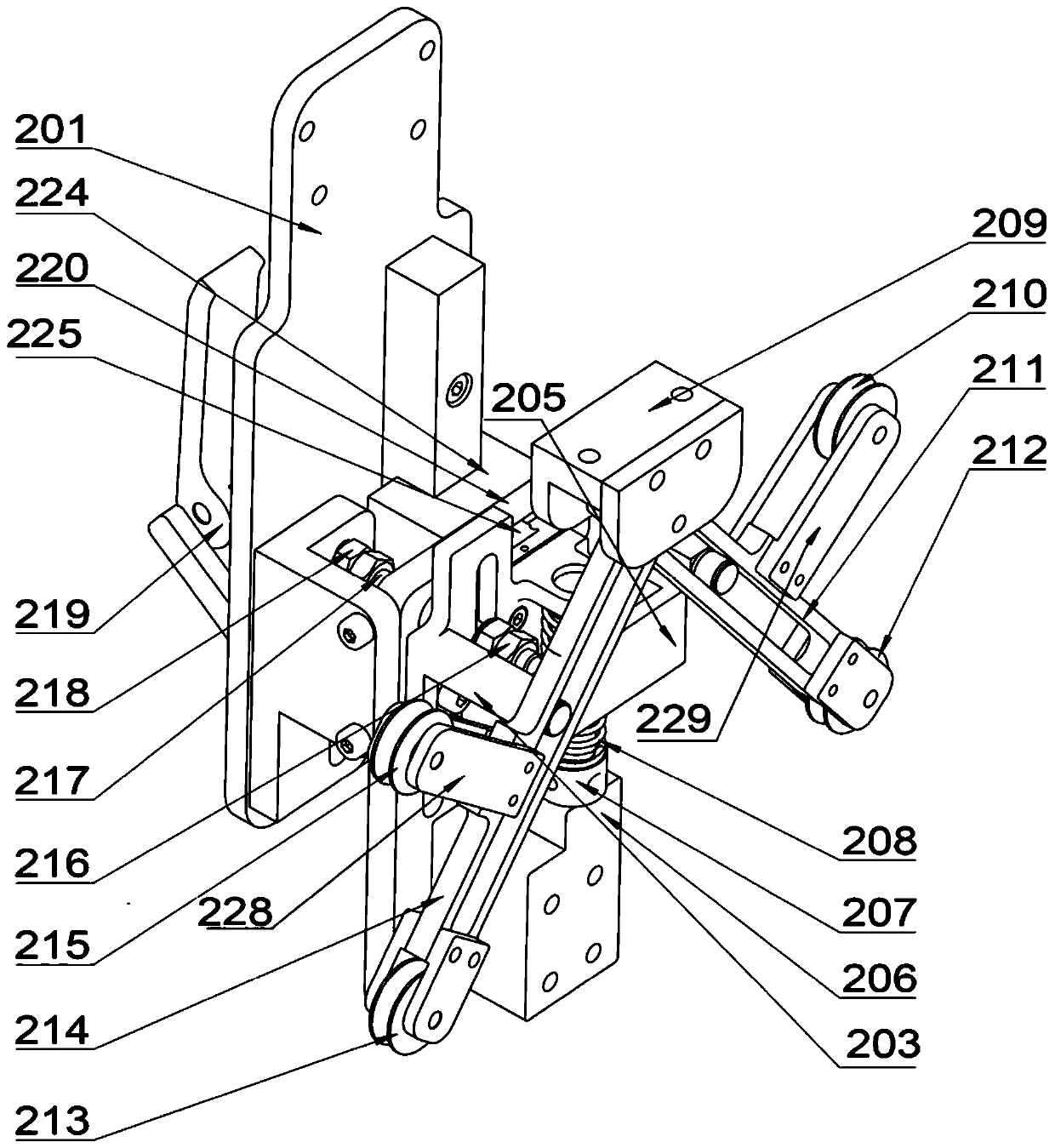

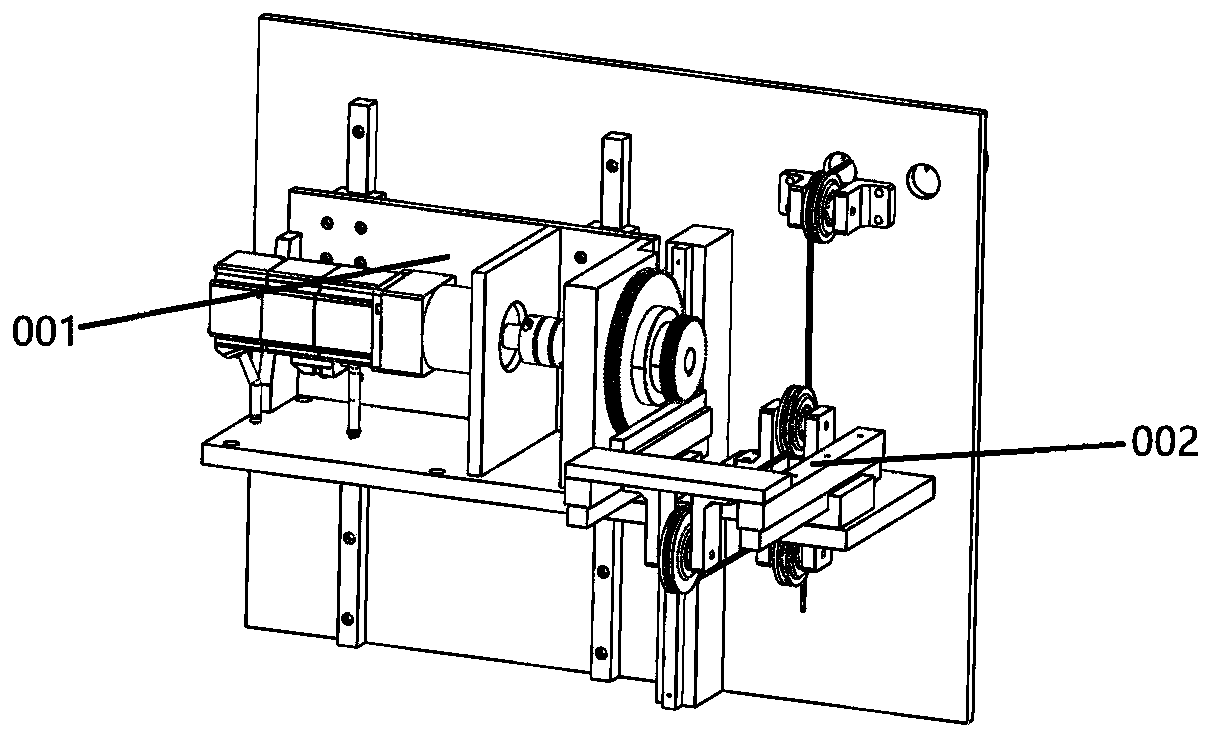

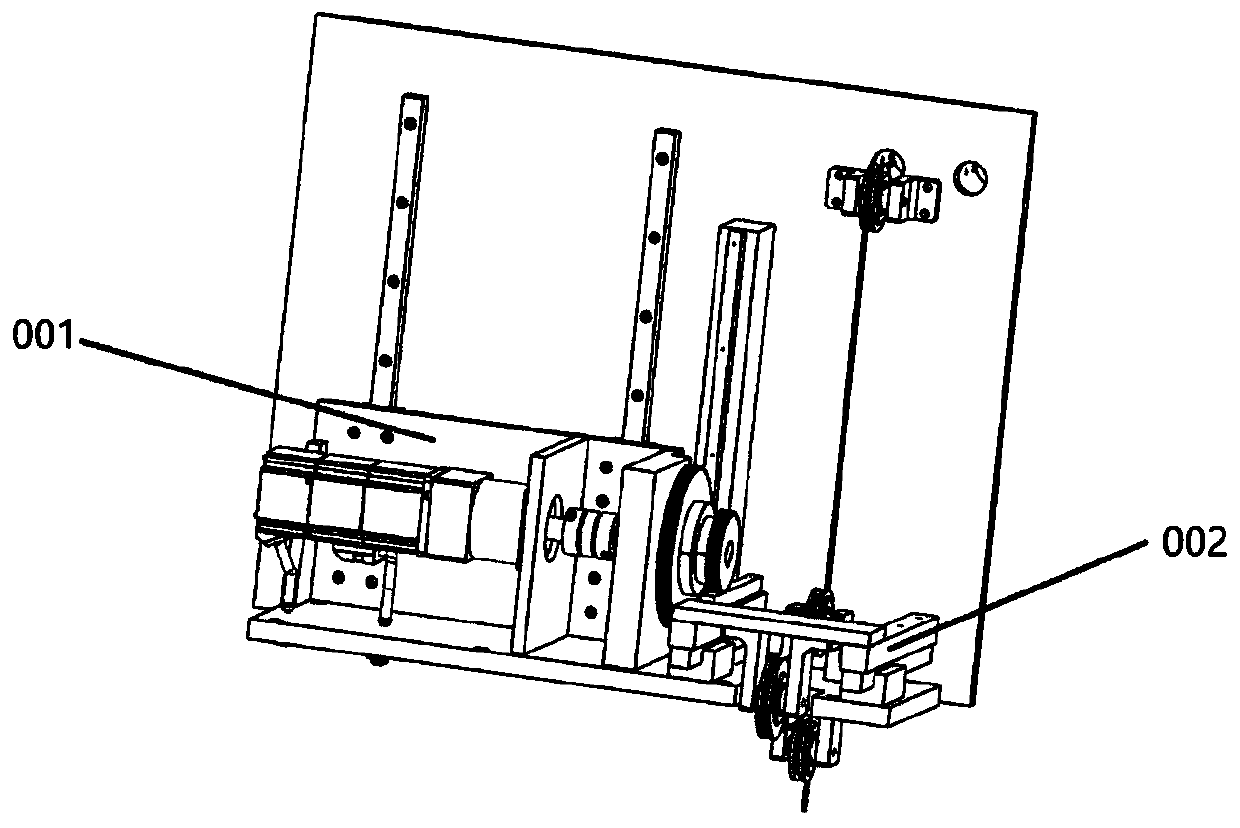

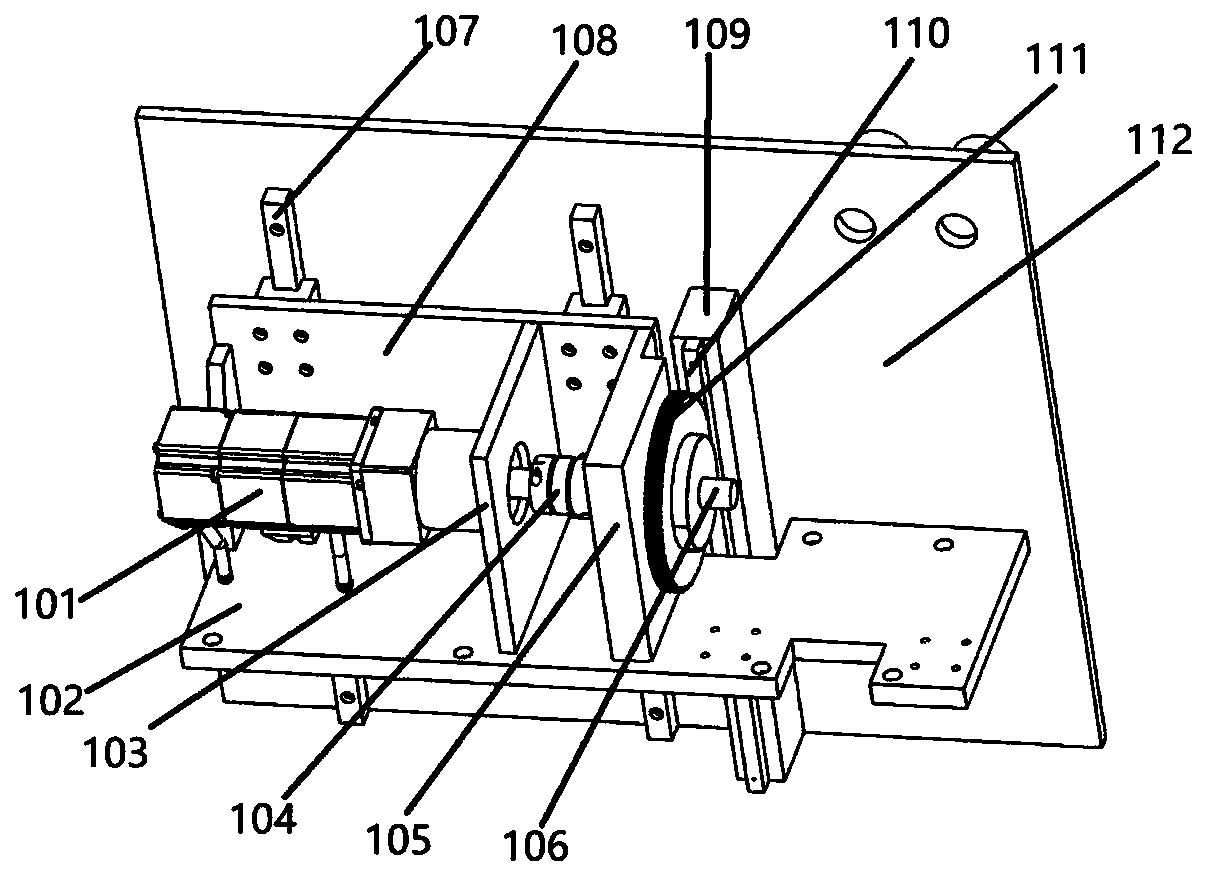

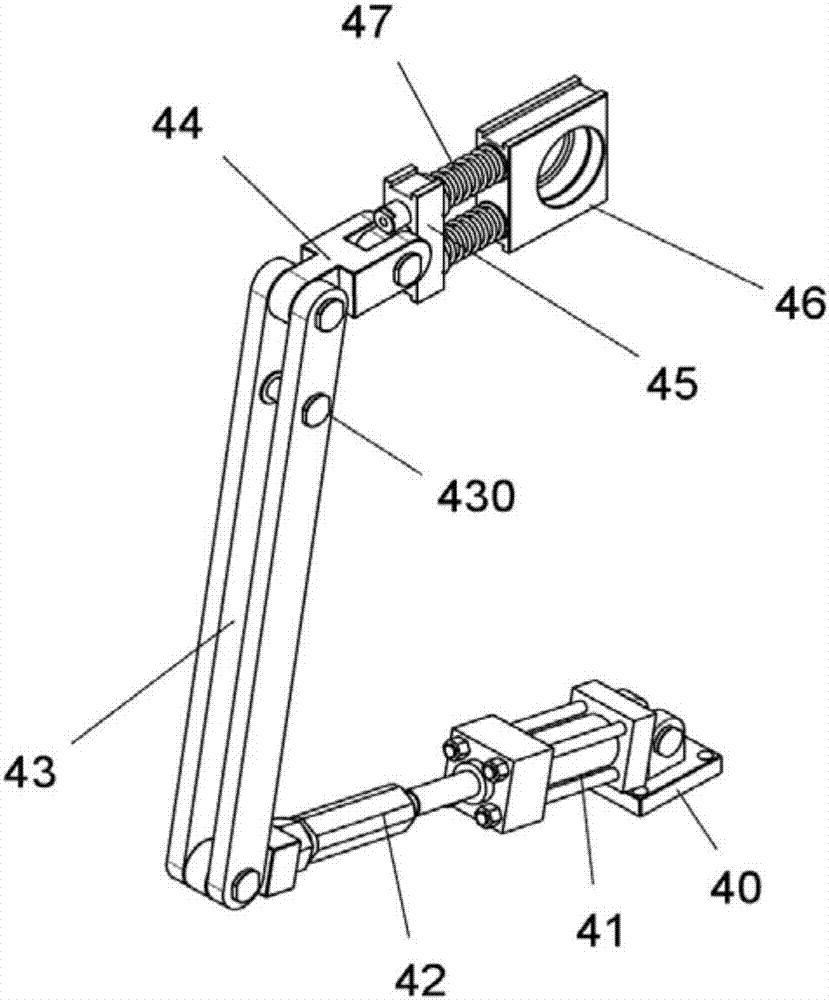

Arm length adjusting device and tensioning mechanism of upper limb exoskeleton rehabilitation robot

ActiveCN110327181ACompact structureReduce volumeProgramme-controlled manipulatorChiropractic devicesLinear motionUpper limb

The invention discloses an arm length adjusting device and tensioning mechanism of an upper limb exoskeleton rehabilitation robot. The mechanism comprises an automatic tensioning part for automatically tensioning a power rope; the automatic tensioning part comprises a sliding plate assembly, a second sliding unit, an elastic assembly of which the original state is a compressed state, and a tensioning assembly; the sliding plate assembly is fixed to the second sliding unit, is connected to the elastic assembly in a compressed state at the same time, and can move in the length direction of the robot arm along with the second sliding unit under external acting force and acting force of the elastic assembly; meanwhile, a first supporting rod in the tensioning assembly and a second strip groovein a second supporting rod match with connecting columns; the linear motion of the sliding plate assembly in the vertical direction is converted into the change of the rotating angle between the first supporting rod and the second supporting rod; and when the rotating angle between the first supporting rod and the second supporting rod is changed, the length of the power rope wound on a leading sheave is correspondingly changed, so that automatic tensioning adjustment of the power rope is achieved.

Owner:湖北英特搏智能机器有限公司

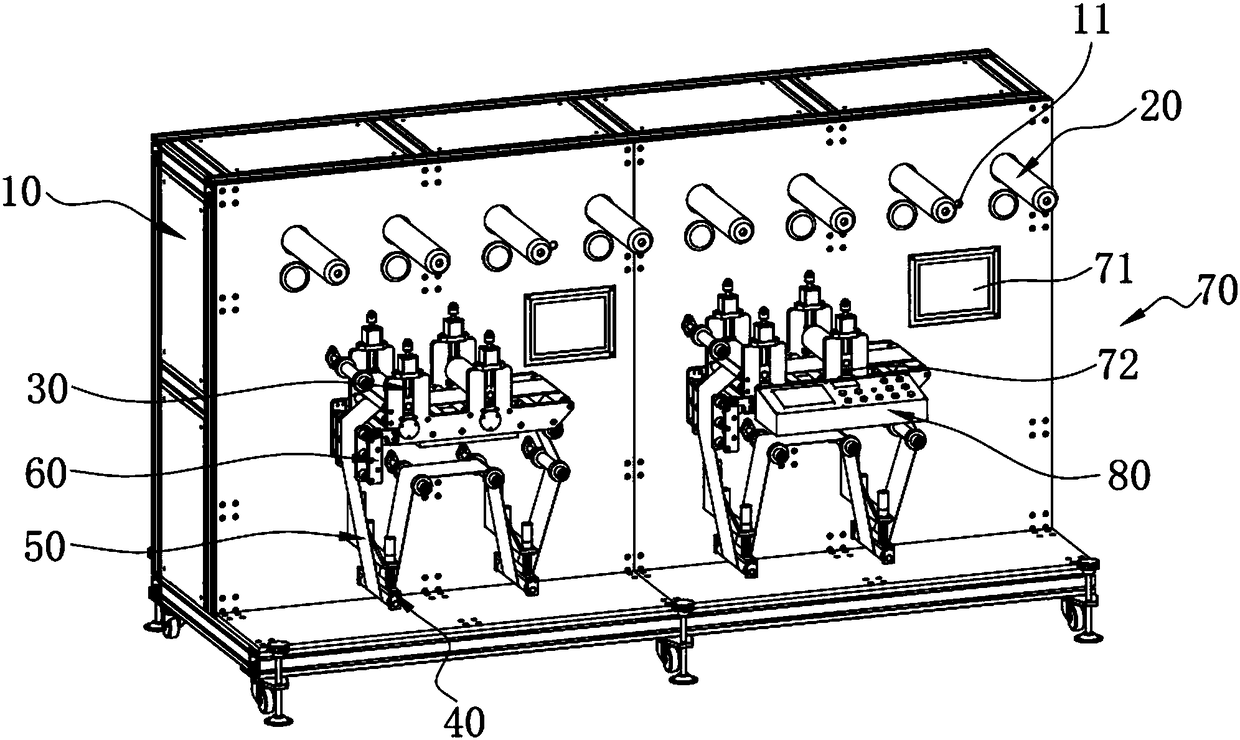

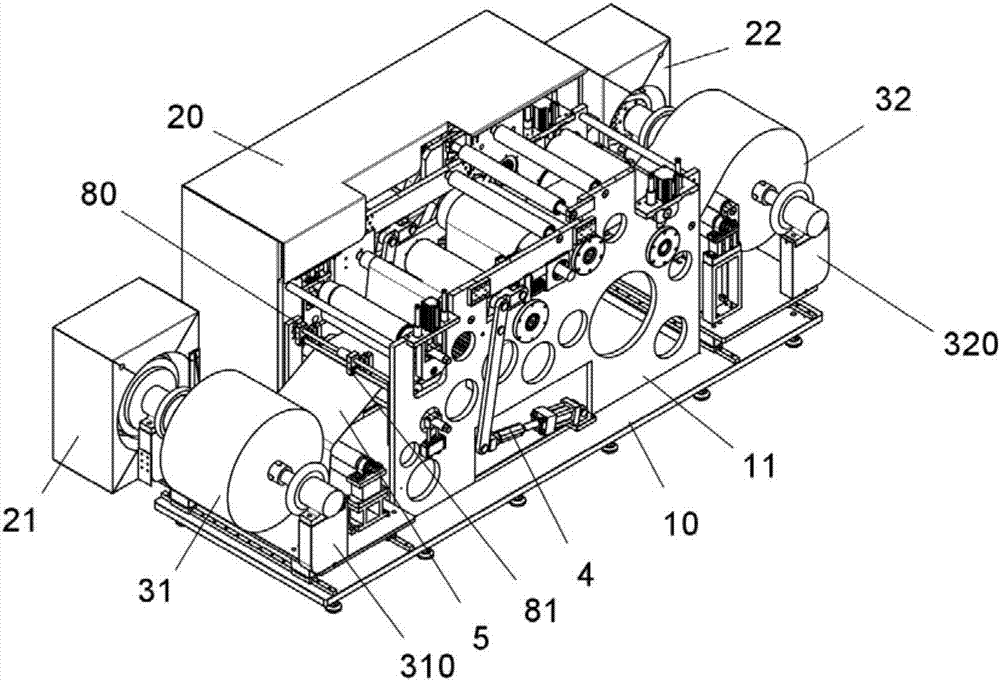

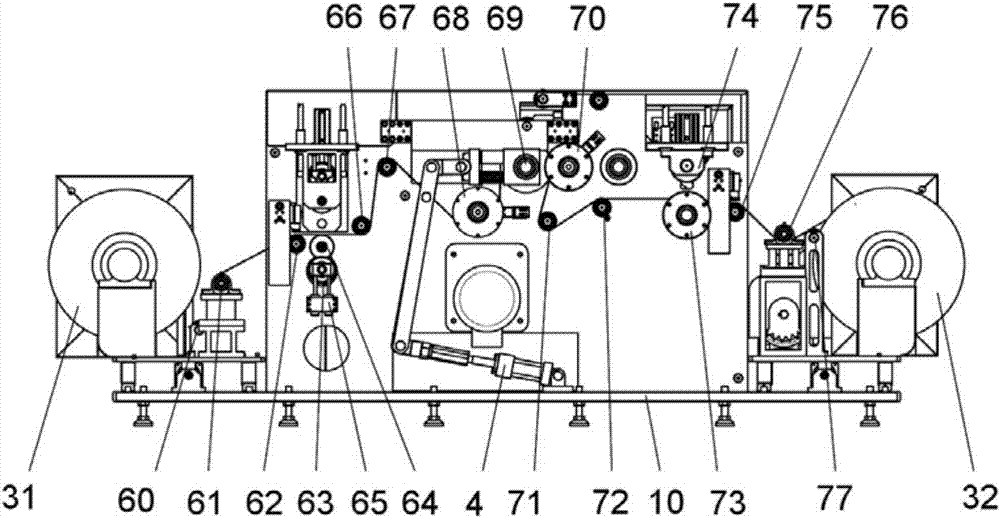

Multifunctional rolling machine

PendingCN108481779AQuality assuranceGuaranteed effectConveyorsLamination ancillary operationsDisplay deviceEngineering

The invention discloses a multifunctional rolling machine. The multifunctional rolling machine comprises a rack, a plurality of roller extending and retracting units arranged on the rack, at least onerolling unit, conveying belts and pressure sensor units. The rolling units are arranged on the rack and located below the roller extending and retracting units and each comprise a support fastened onthe rack, a transmission roller unit arranged on the support, and a pressing roller unit arranged on the support and located over the transmission roller unit; the conveying belts are tensioned on the transmission roller units; and each pressure sensor unit comprises a pressure sensor, pressing blocks and a display. The multifunctional rolling machine is capable of improving the rolling quality of a strip effectively and has the advantages of being convenient to operate, safe and reliable.

Owner:川臻精密机械(苏州)有限公司

Stretchable motion device with rope automatic tensioning function

ActiveCN111571574ARealize automatic tensioningRealize power transmissionProgramme-controlled manipulatorChiropractic devicesGear wheelReduction drive

The invention relates to a stretchable motion device with a rope automatic tensioning function. The device comprises a stretchable motion mechanism and a steel wire rope length compensation mechanism,wherein the stretchable motion mechanism comprises a bottom plate and a motor-reducer arranged on the bottom plate, the output end of the motor-reducer is provided with a gear rack mechanism I, and the output end of the gear rack mechanism I is fixed on a lifting plate; the steel wire rope length compensation mechanism comprises a gear rack mechanism II mounted at the output end of the motor-reducer, the gear rack mechanism II is slidably connected with the bottom plate through a wire rail sliding block assembly II, and the second wire rail sliding block assembly II is connected with the lifting plate through a pulley block; and one end of a steel wire rope is connected with a counterweight module, and the other end of the steel wire rope is connected with an arm of a patient through thepulley block. According to the stretchable motion device with the rope automatic tensioning function, the gear rack mechanisms and the pulley block structure are adopted to realize automatic tensioning of the steel wire rope.

Owner:湖北英特搏智能机器有限公司

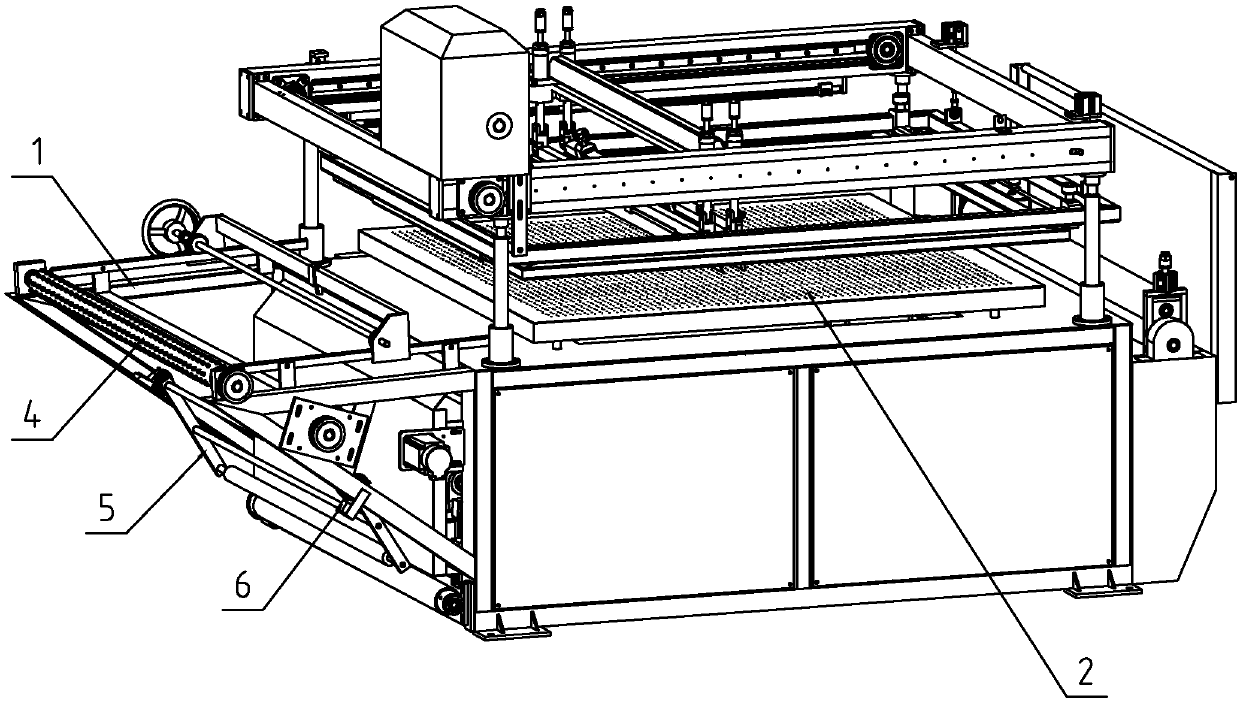

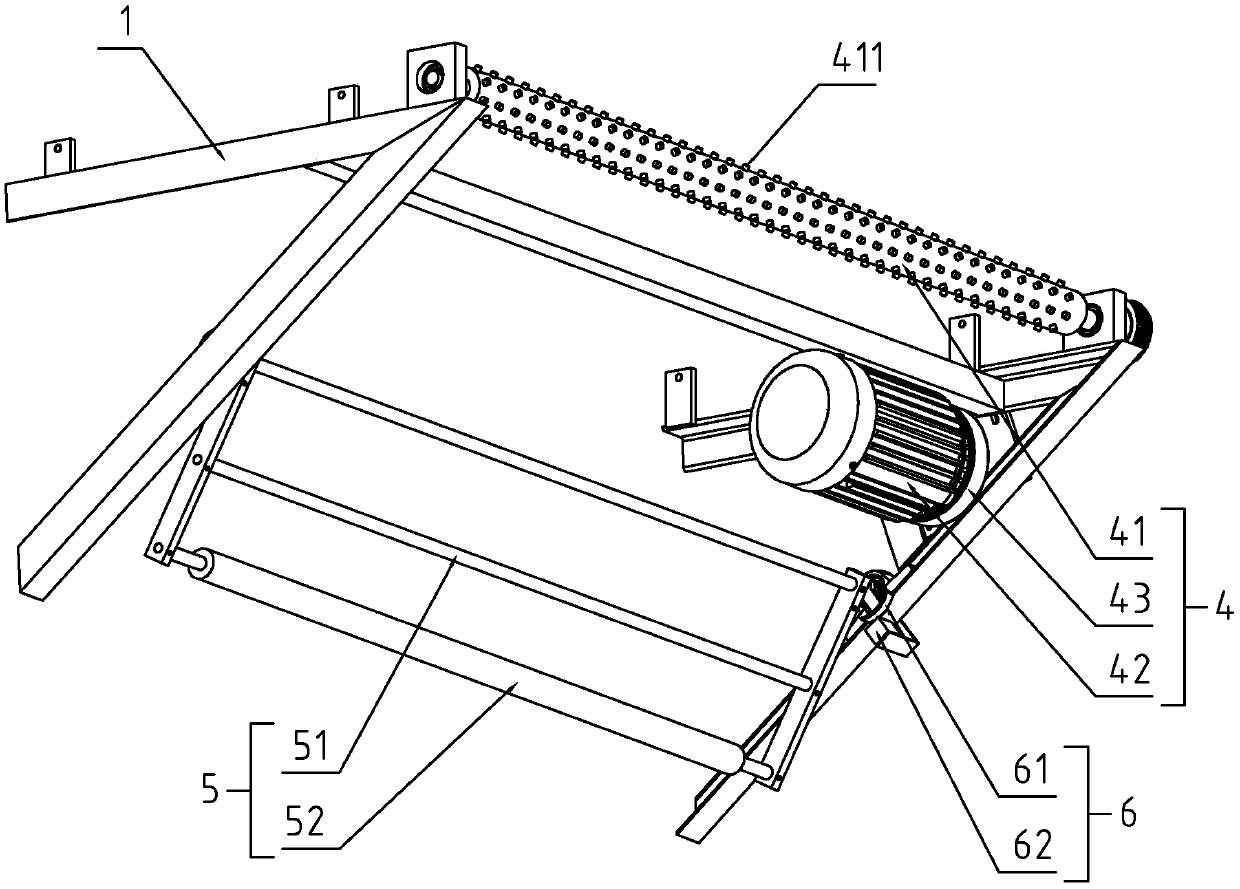

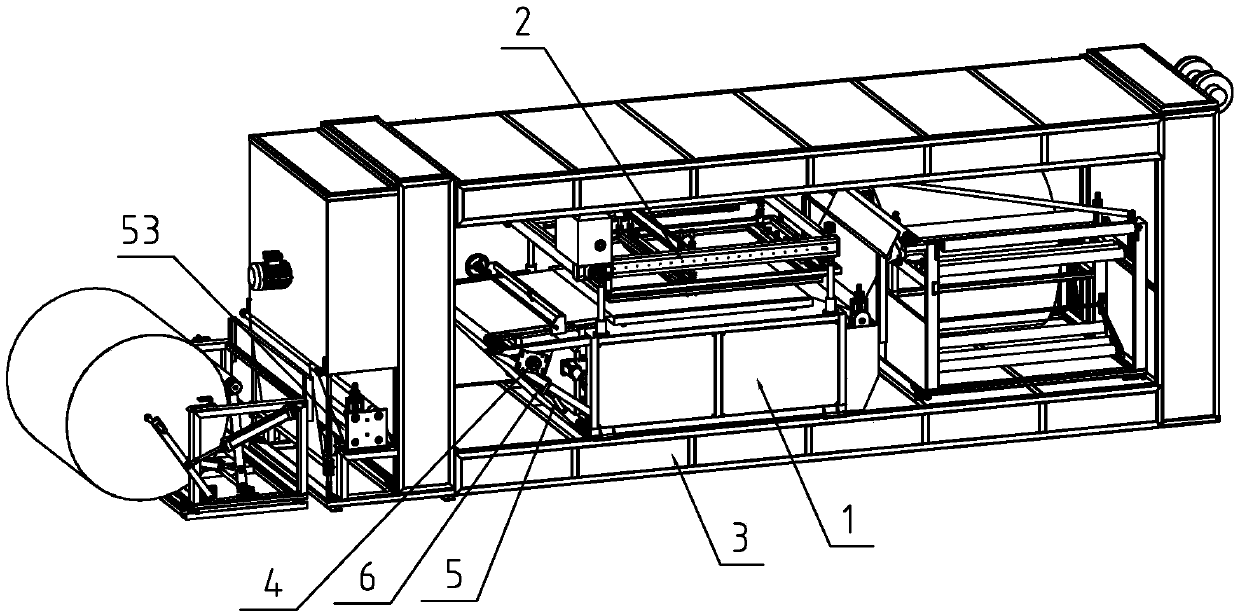

Tensioning device for screen printing machine

PendingCN109605916AReduce pulling forceImprove printing and drying effectScreen printersMagnetic powderMagnetic particle clutch

The invention discloses a tensioning device for a screen printing machine. The technical scheme of the device is characterized by comprising a machine frame, a printing device and a drying device; themachine frame is further provided with a printing tensioning mechanism and a drying tensioning mechanism; the printing tensioning mechanism comprises a tensioning roller and a tensioning motor, wherein the tensioning roller is used for allowing a strip-shaped material to be wound therearound, and an output end of the tensioning motor is provided with a magnetic powder clutch used for driving thetensioning roller to maintain the constant tension of the strip-shaped material; and the drying tensioning mechanism comprises a gravity tensioning frame capable of tensioning the strip-shaped material wound around the tensioning roller under the action of gravity, wherein the gravity tensioning frame is located at a feeding end of the drying device, one end of the gravity tensioning frame is rotationally connected to the machine frame, the other end of the gravity tensioning frame is provided with a gravity roller, and the gravity tensioning frame can maintain the strip-shaped material woundaround the tensioning roller in a tensioned state through the gravity roller under the action of gravity in the process of axially rotating around the machine frame. The tensioning device can keep thestrip-shaped material automatically tensioned, so that the printing effect and the drying effect of the strip-shaped material are improved.

Owner:温州欧宏机械有限公司

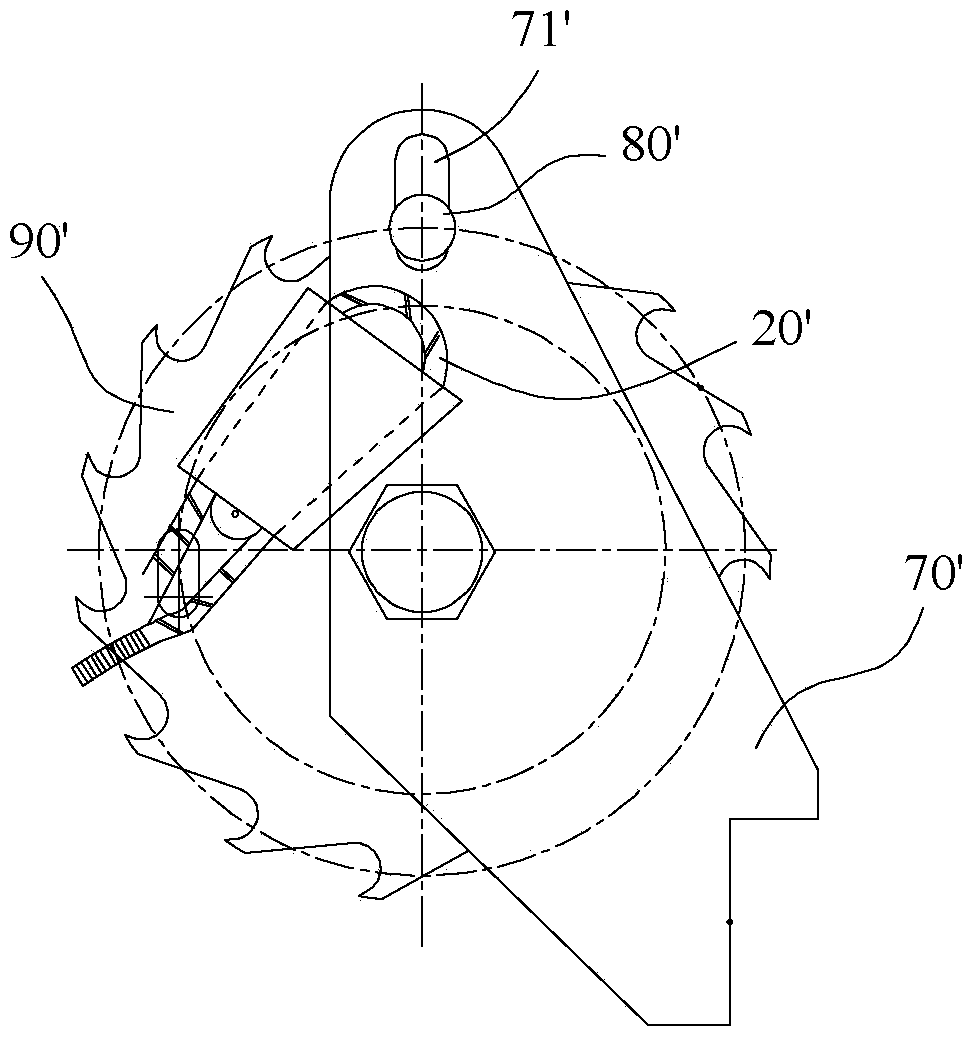

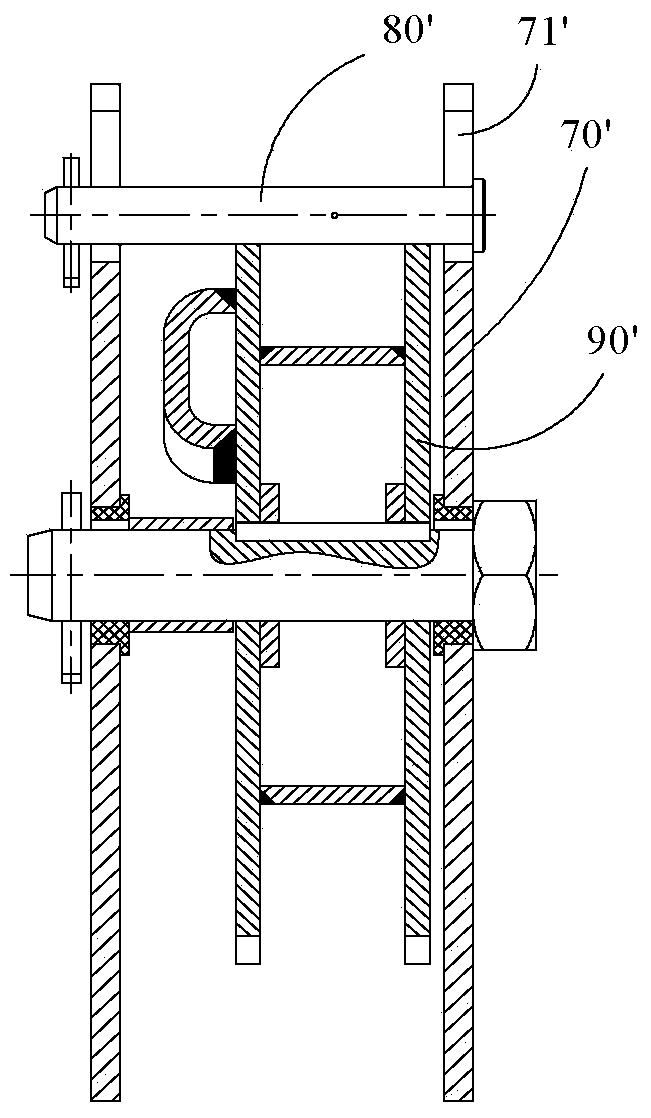

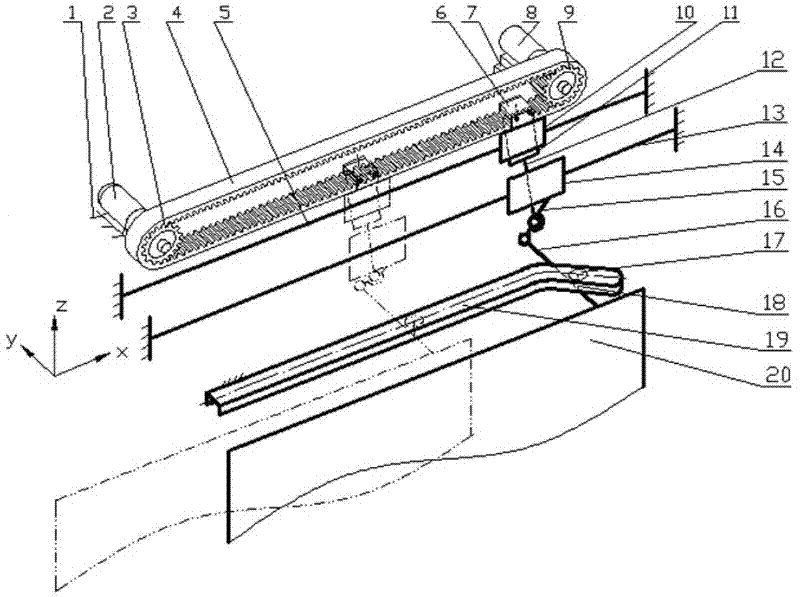

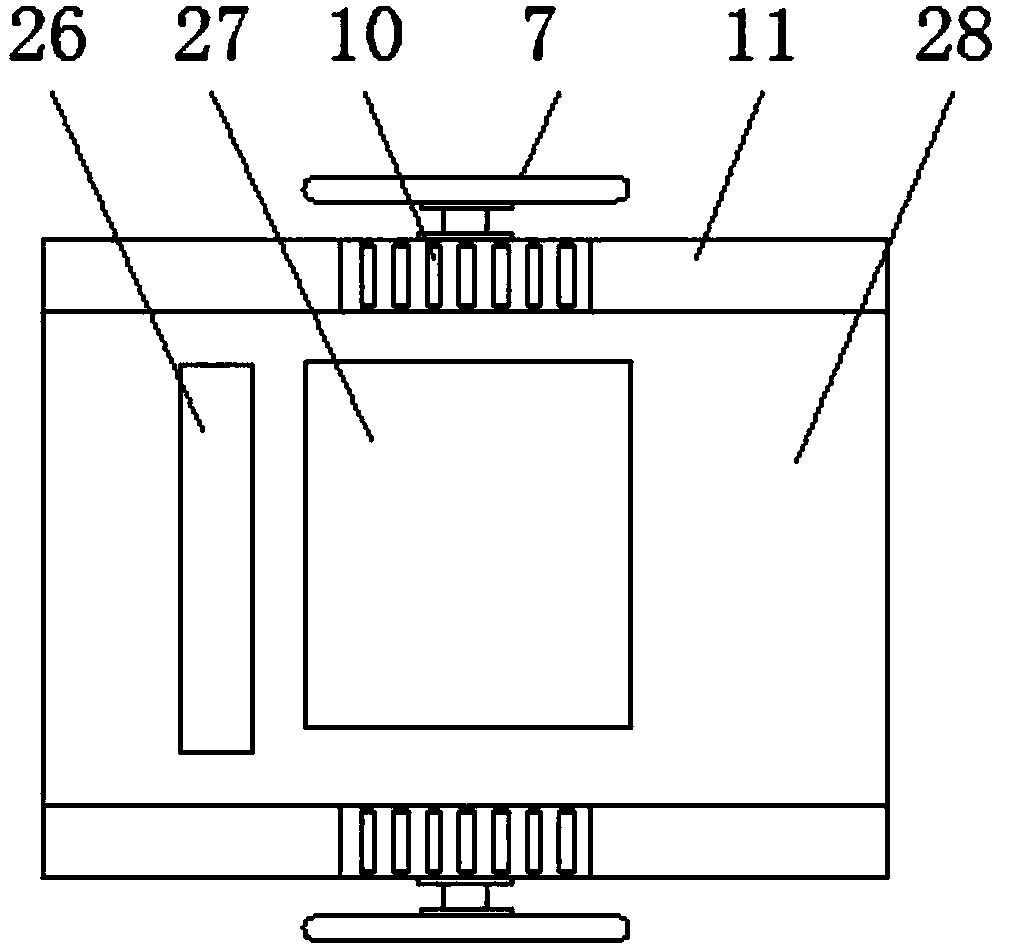

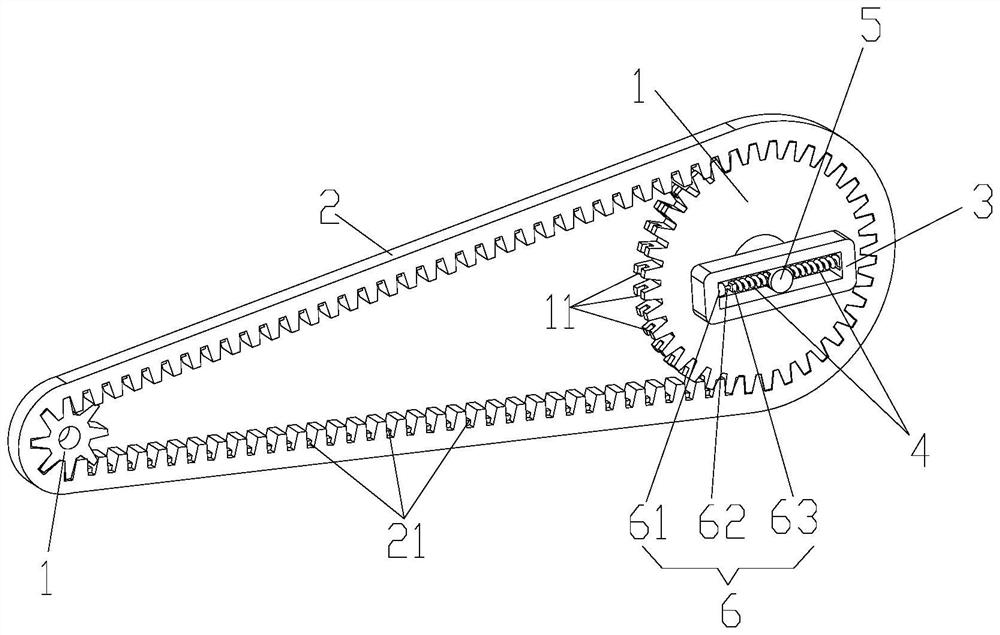

A slotted cam combination space mechanism with plug teeth and rocker guide rod

InactiveCN102296903AEasy to useRealize automatic tensioningPower-operated mechanismDoor arrangementCamEngineering

The invention relates to a tooth strap, rocking block and guide rod, and groove-shaped cam combined spatial mechanism of a sliding plug door, which relates to an open and close mechanism of sliding plug hermetization of a railway vehicle automatic door, in particular to the tooth strap, rocking block and guide rod, and groove-shaped cam combined spatial mechanism of the sliding plug door of a high-speed railway vehicle and other railway vehicles. The tooth strap, rocking block and guide rod, and groove-shaped cam combined spatial mechanism comprises a door frame, a motor, a driving wheel, a tooth strap, an auxiliary shaft, a lower strap clamp, a tensioning device, a bearing seat, a driven wheel, an auxiliary shaft sleeve, a rocking block, a guide rod, a load-bearing shaft, a load-bearing shaft sleeve, a rocking rod, a doorknob, a roller, a roller shaft, a groove-shaped cam and a door leaf, wherein a tooth strap transmission mechanism comprises the driving wheel, the tooth strap, the lower strap clamp, the tensioning device, the bearing seat and the driven wheel, and a rocking block and guide rod mechanism comprises the auxiliary shaft, the auxiliary shaft sleeve, the rocking block, the guide rod, the load-bearing shaft, the load-bearing shaft sleeve and the rocking rod; and a groove-shaped cam mechanism comprises the load-bearing shaft, the load-bearing shaft sleeve, the rocking rod, the doorknob, the roller, the roller shaft, the groove-shaped cam, the door leaf and the door frame, and the tooth strap transmission mechanism, the rocking block and guide rod mechanism and the groove-shaped cam mechanism are combined into the tooth strap, rocking block and guide rod, and groove-shaped cam combined spatial mechanism.

Owner:NANJING INST OF TECH

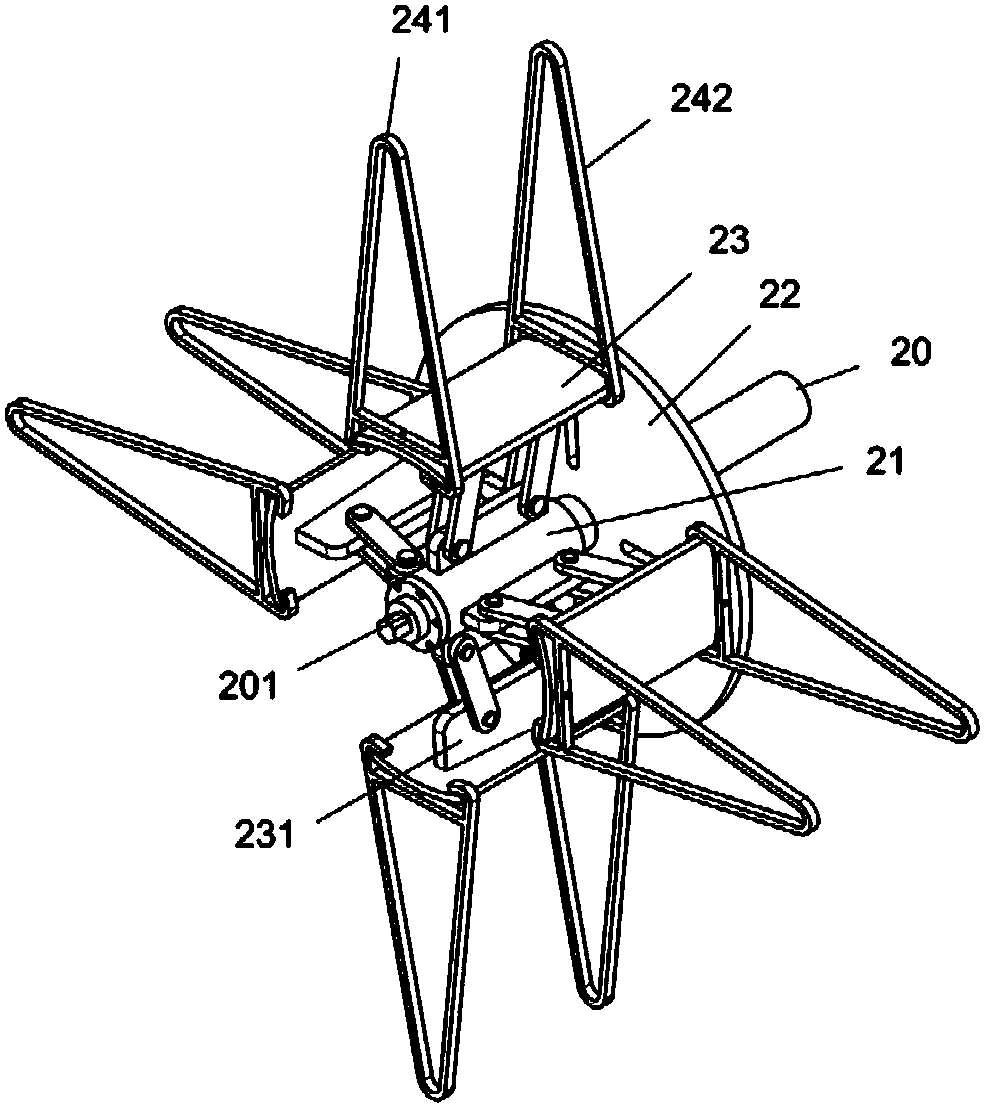

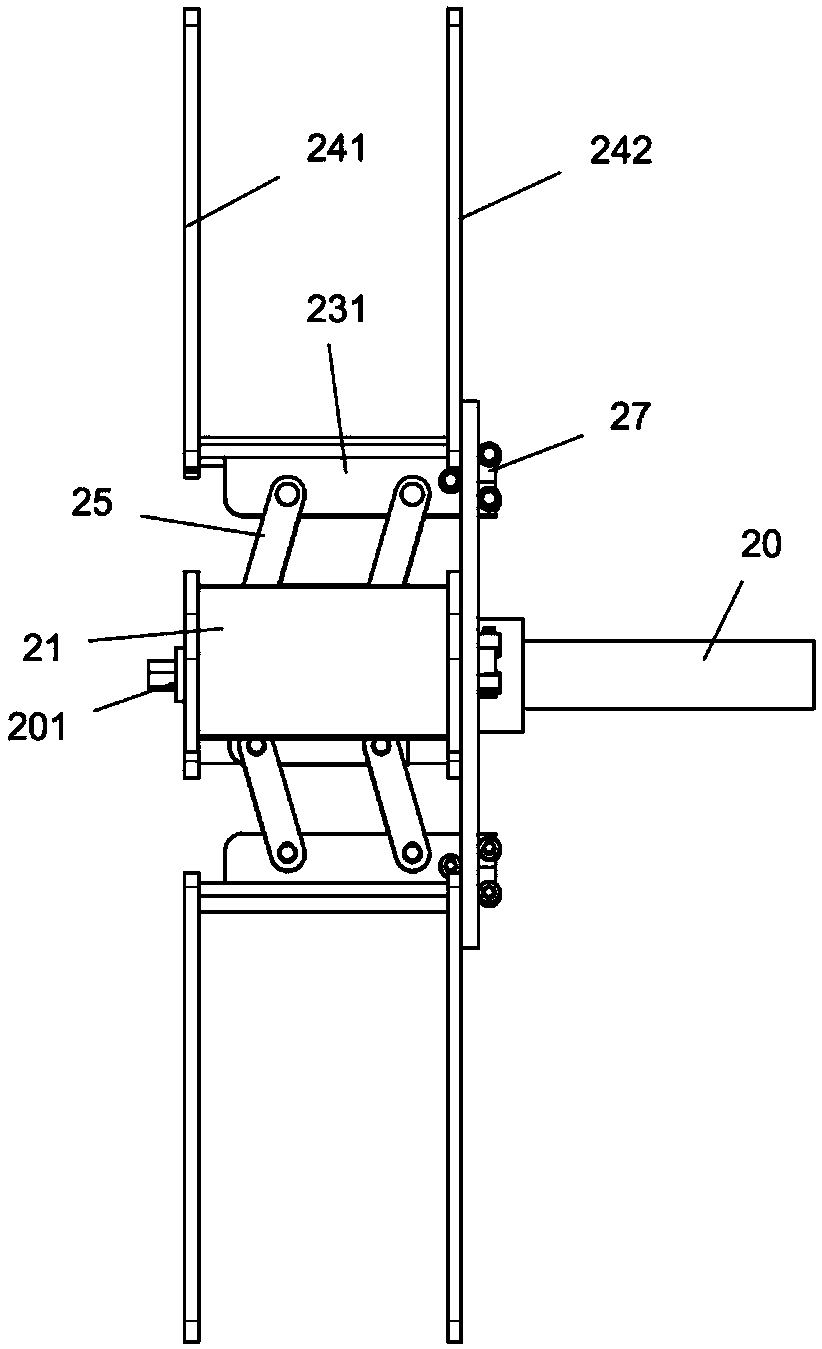

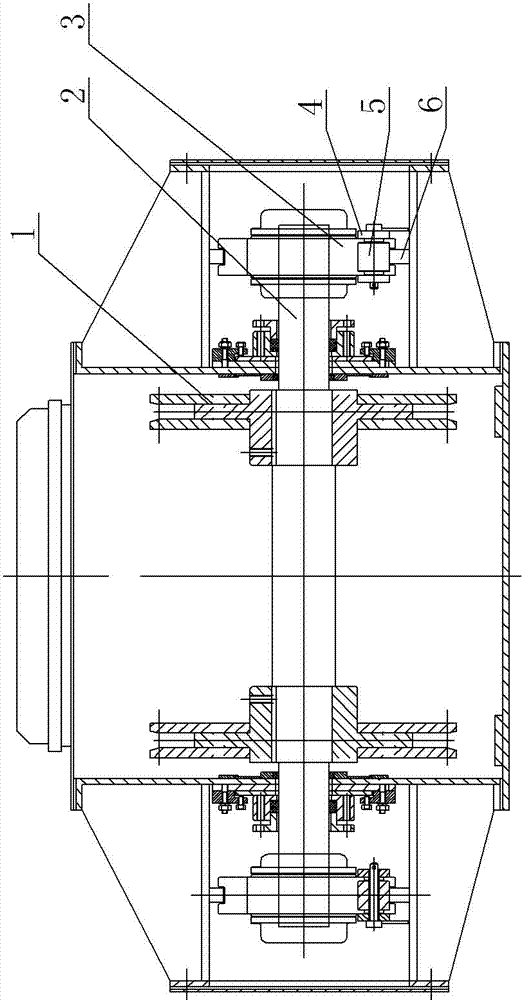

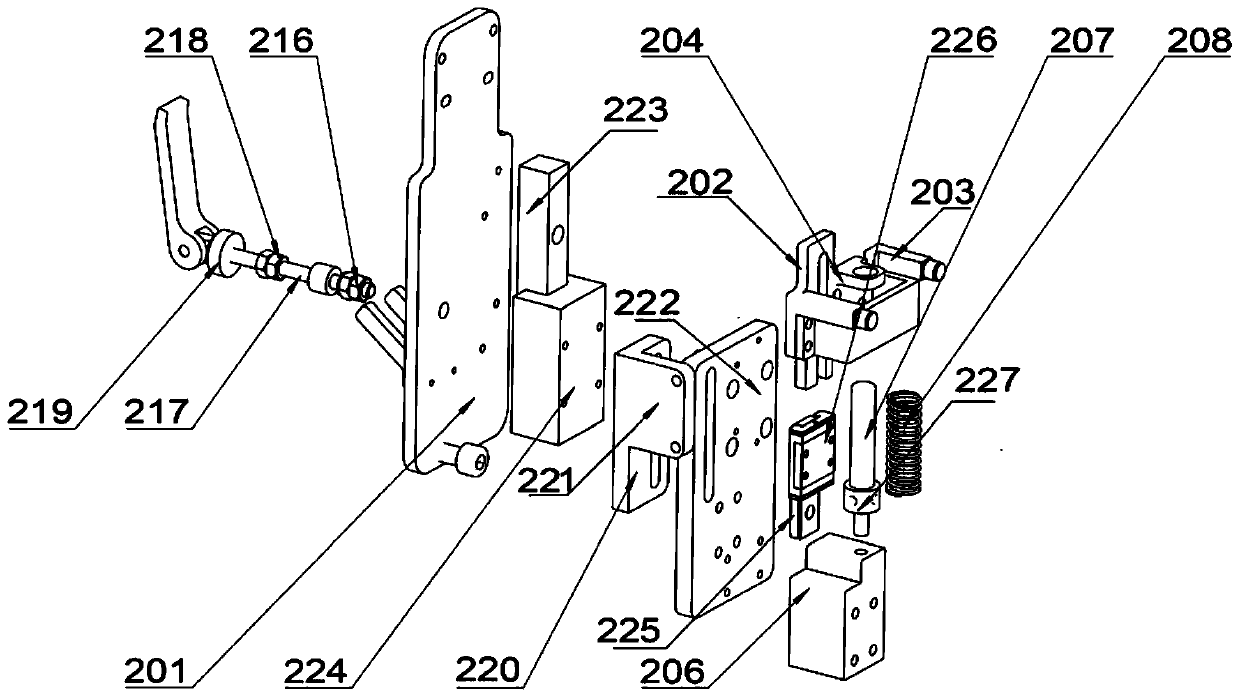

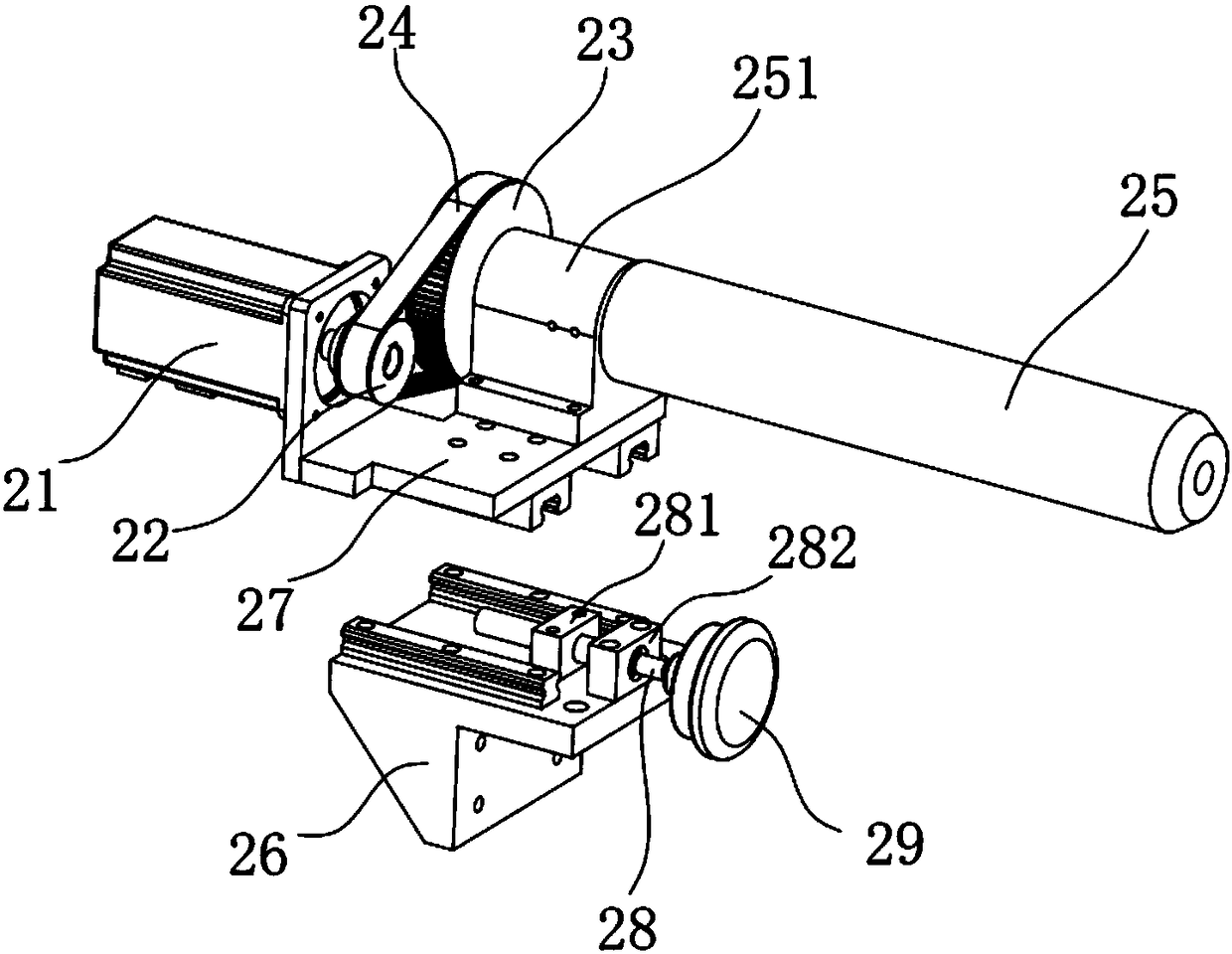

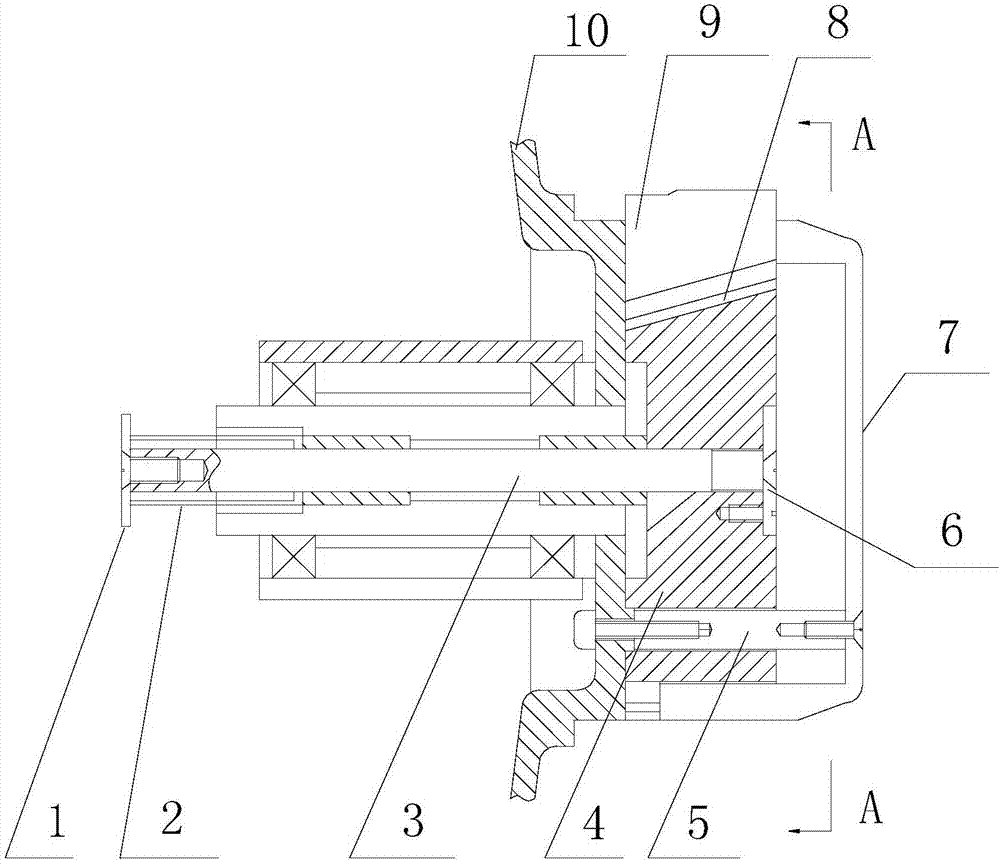

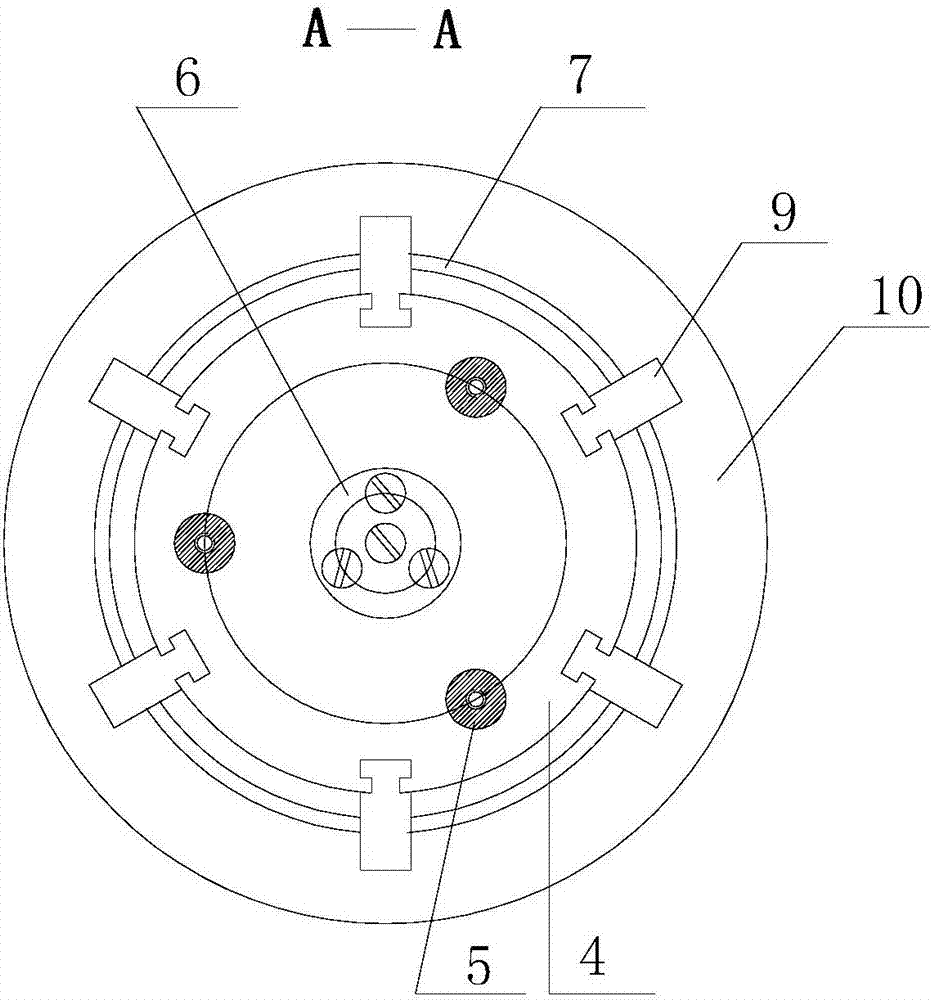

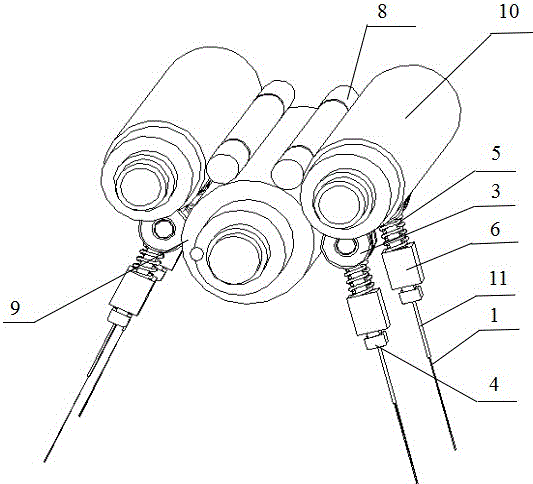

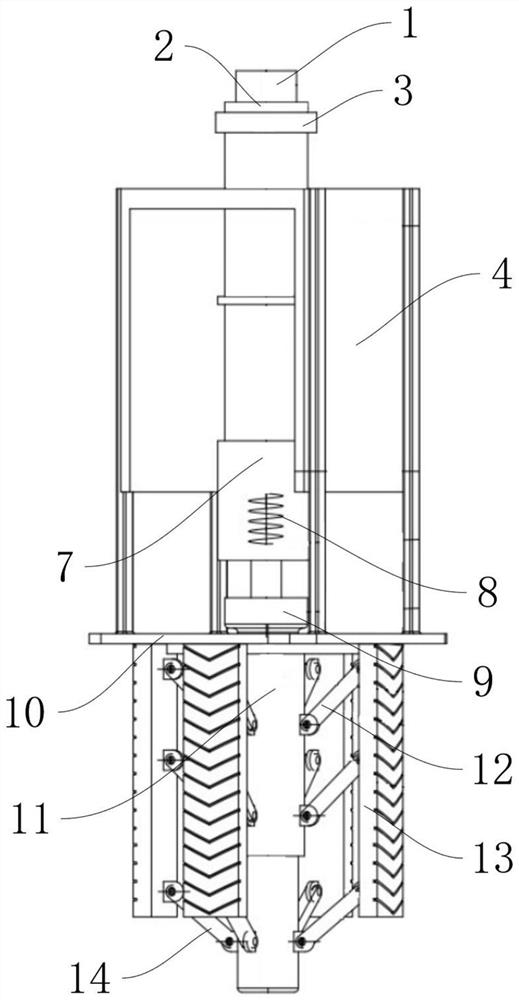

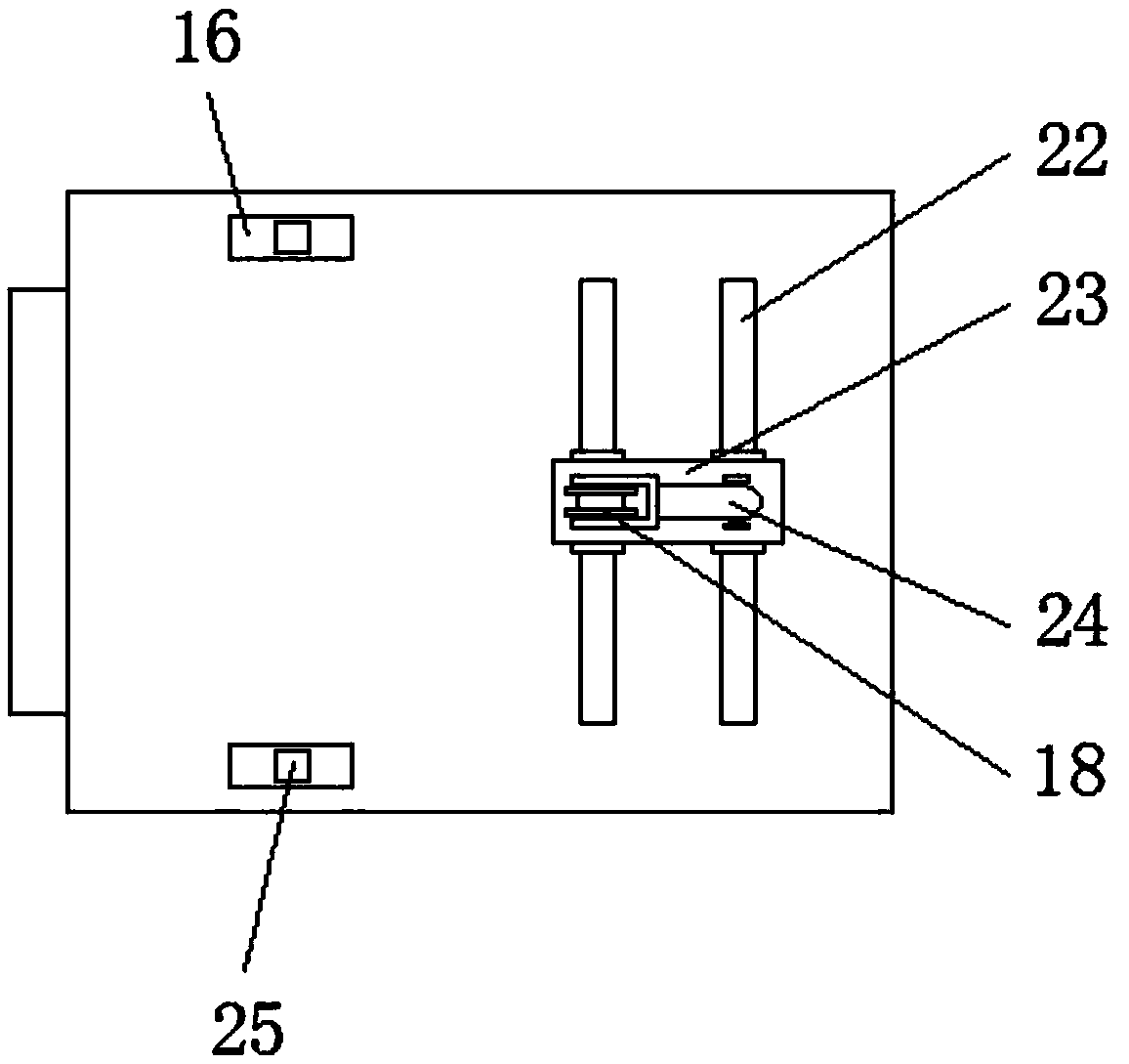

Bobbin paper mandrel tensioning device for cigarette making and tipping machine combination

InactiveCN107098183AGuaranteed uptimeReduce maintenance workloadCigarette manufactureWebs handlingBobbinEngineering

The invention discloses a bobbin paper mandrel tensioning device for a cigarette making and tipping machine combination. The bobbin paper mandrel tensioning device comprises a base. A mandrel is arranged in the center of the base in a sliding manner. A sliding disc is fixedly connected with the right end of the mandrel. The sliding disc and the mandrel are coaxial. Multiple inclined sliding grooves are formed in the periphery edge of the sliding disc. One sliding tensioning block is connected into each inclined sliding groove in a sliding manner. The inner end face of each sliding tensioning block is an inclination face in sliding fit with the bottom wall face of the corresponding inclined sliding groove. The outer end face of each sliding tensioning block is an arc face. The outer end faces of the multiple sliding tensioning blocks form an outer circle in an enclosure manner. A drive mechanism drives the mandrel to slide along the base left and right, thus the sliding disc is driven to move left and right, then the multiple sliding tensioning blocks embedded into the multiple inclined sliding grooves are driven to move in the direction close to or away from the circle center of the sliding disc, the size of the diameter of the whole outer circle is adjusted, and therefore bobbin paper rings sleeved outside the multiple sliding tensioning blocks are tensioned. The bobbin paper mandrel tensioning device has the beneficial effect of being capable of achieving automatic tensioning of the bobbin paper rings safely and reliably.

Owner:CHINA TOBACCO ANHUI IND CO LTD

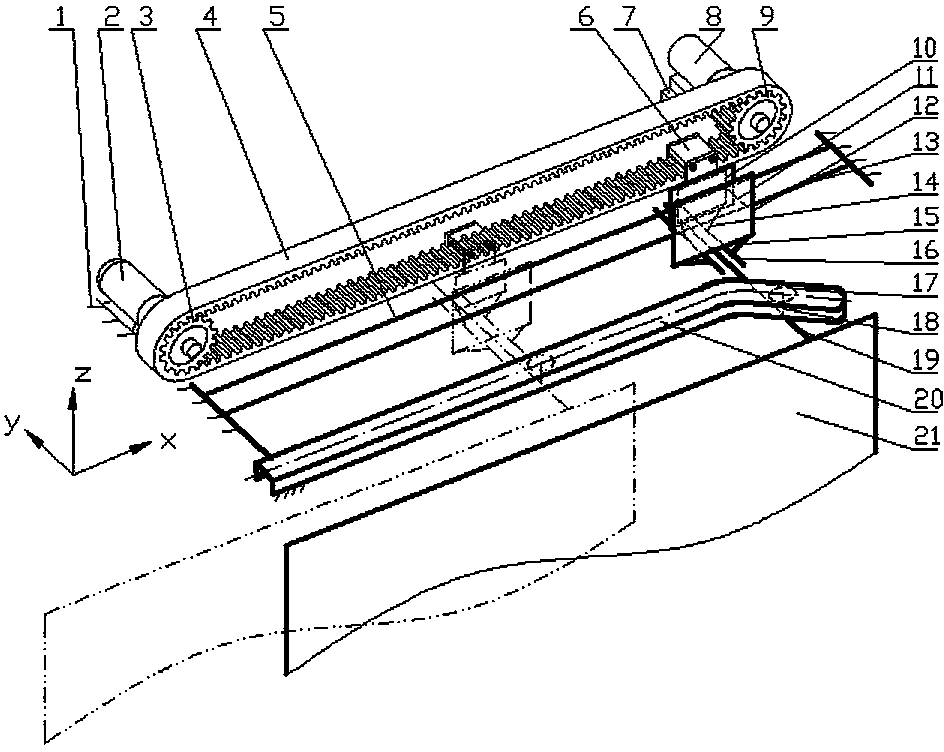

Chain link type automatic synchronous tensioning system and method for prestressed wire ropes

ActiveCN106436587AImprove reinforcement efficiencyImprove reinforcement effectBuilding repairsBridge erection/assemblyEngineeringChain link

The invention discloses a chain link type automatic synchronous tensioning system and method for prestressed wire ropes. The chain link type automatic synchronous tensioning system comprises an anchor plate, wherein the anchor plate is fixed on a structure to be reinforced through planted bars; a plurality of main threaded rods are arranged in the anchor plate in a parallel and penetrating manner; one end of each of the main threaded rods is connected with a corresponding screw sleeve, and the other end of each of the screw sleeves is connected with a corresponding steel wire rope; after the other end of each of the main threaded rods penetrates through a corresponding opening of the anchor plate, the other end of each of the main threaded rods is fixed by a corresponding anchoring toothed nut; a tensioning bracket is arranged on one side of the anchor plate; after the main threaded rods penetrate in the tensioning bracket, each of the main threaded rods is connected with a corresponding secondary threaded rod through a corresponding connecting sleeve; after the other ends of the secondary threaded rods penetrate out of the tensioning bracket, the other ends of the secondary threaded rods are separately fixed on the tensioning bracket by corresponding tensioning toothed nuts; and the anchoring toothed nuts and the tensioning toothed nuts are separately connected with a driving mechanism. According to the chain link type automatic synchronous tensioning system disclosed by the invention, anchoring a plurality of steel wire ropes can be realized through one anchor plate, so that the reinforcing efficiency and the reinforcing effect of a conventional structure are improved; and synchronous tensioning and synchronous locking are performed on all the steel wire ropes on the anchor plate, so that the situation that the bearing capacity is reduced due to uneven distribution of the prestressing force of the steel wire ropes is avoided, and the automatic synchronous tensioning system is convenient to use, and simple and high-efficiency to mount.

Owner:JIANGXI GANYUE EXPRESSWAY +2

Inserting roller tensioning device of adjustable roller group prawn husking machine

ActiveCN105746671ARealize automatic tensioningRealize mechanical automation processingShrimp/lobster processingLocking mechanismEngineering

The invention discloses an inserting roller tensioning device of an adjustable roller group prawn husking machine. The middle part of a pull strip is arranged on an inserting roller in a sleeving manner; two ends of the pull strip penetrate through a support wheel shaft and a guide sleeve block; a pair of support wheels is respectively and rotationally arranged at two ends of the support wheel shaft; the pair of the support wheels is connected with a first husking roller and a second husking roller in a propping manner; one end of each one of a pair of guide rods is arranged on each side of the support wheel shaft; the other ends of the pair of the guide rods respectively penetrate through the guide sleeve block; a pair of springs is respectively arranged on the pair of the guide rods in the sleeving manner; a locking mechanism is arranged on the guide sleeve block and is used for locking the pull strip. According to the embodiment of the invention, the pair of the support wheels are taken as fulcrums, the inserting role is tensioned in the direction of the husking roller group through the elastic force of the springs, so that automatic tensioning of the inserting roller and the husking roller group can be achieved, and the propping state between the inserting roller and the husking roller group can be maintained. In addition, the tensioning force of the inserting roller and the husking roller group can be adjusted by the locking mechanism.

Owner:HEBEI AGRICULTURAL UNIV.

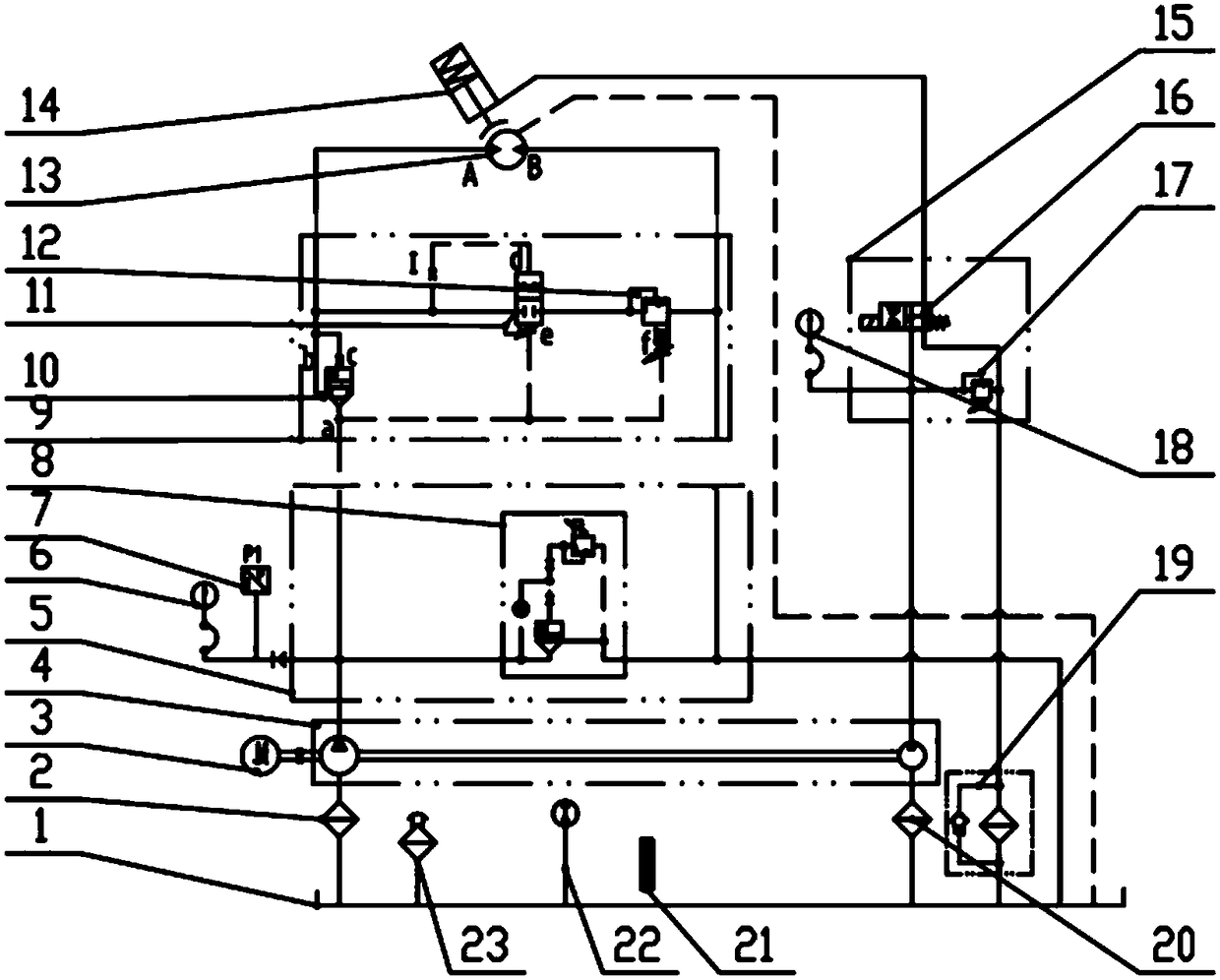

A hydraulic control system of automatic tensioning and free-releasing rope winch

ActiveCN106167233BImprove startup response speedImprove delivery efficiencyServomotorsWinding mechanismsFailure rateWinch

The invention discloses a winch hydraulic control system achieving automatic tensioning and free reeling off. The winch hydraulic control system comprises an oil tank, an electric motor, a double pump and a motor, wherein the motor is connected with a winch drum; the winch hydraulic control system further comprises a pressure control system, an automatic reeling off control assembly, a braking system assembly and a controller; the pressure control system comprises a first pressure gauge, a pressure transmitter and a proportional overflow valve; the automatic reeling off control assembly comprises a one-way valve, a two-position hydraulic control reversing valve and a pilot overflow valve; the braking system assembly comprises a brake used for conducing braking on the motor and a brake valve group, and the brake valve group is composed of a magnetic exchange valve, an overflow valve and a second pressure gauge. The winch hydraulic control system is high in automation degree and capable of accurately achieving stepless control of a tensioning force of a belt conveyor in real time, impact of start and stop of a winch can be effectively reduced, and therefore the failure rate can be reduced; meanwhile, the winch hydraulic control system can achieve a rapid response of start of the winch, therefore, the conveying efficiency of the belt conveyor can be improved, and energy consumption can be effectively saved.

Owner:XUZHOU WUYANG TECH

All-in-one machine for chipless cutting of plastic pipes

InactiveCN105058470ASolve the problem of high acceleration and fast speedSolving Traction ProblemsMetal working apparatusWhole bodyEngineering

The invention discloses a dual-traction chipless cutting machine applied to production of plastic pipes. An upper track, a lower track and a cutter are respectively fixed onto a rack, the upper track is used for pressing and releasing the pipes through a pressing assembly, the height of the lower track can be regulated by a lifting assembly so as to adapt to production of pipes of different specifications and guarantee that a traction center and a cutter center are on one straight line, a synchronous chain wheel is internally provided with a regulation clutch, is arranged on the lower track and is connected with the cutter to form a whole body through a synchronously chain so as to realize synchronization of a tractor and the cutter, a spring self-tension device is arranged at a tension chain wheel and can be used for guaranteeing automatic tension of the chain during production of different pipes, and a return cylinder is fixed onto the rack and is used for resetting the cutter after cutting action is finished, thereby realizing synchronism of the tractor and the cutter and guaranteeing stability of traction and cutting.

Owner:南通联恒新材料有限公司

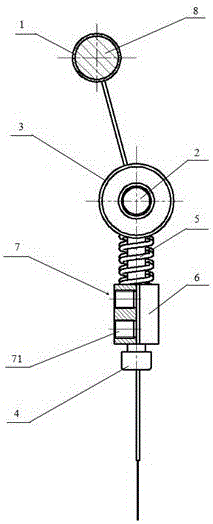

Wire tensioning device

InactiveCN108054002AAchieve tensionMaintain constant tensionInductances/transformers/magnets manufactureAgricultural engineeringEngineering

The invention discloses a wire tensioning device. The device comprises a fixing plate, a left idler wheel, a middle idler wheel, a right idler wheel and a center shaft; the left idler wheel is rotatably arranged at the front end of the left side of the fixing plate, the right idler wheel is rotatably arranged at the front end of the right side of the fixing plate, and the middle idler wheel is arranged on a connection block and located at the front end of the middle of the fixing plate; the lower portion of the center shaft is up and down slidingly arranged on the connection block, a limit ring is arranged at the lower end of the center shaft, the lower portion of the center shaft is sleeved with an elastic device, one end of the elastic device is in contact with the middle of the center shaft, and the other end of the elastic device is in contact with the upper end of the connection block; the upper portion of the center shaft is of a threaded structure and penetrates through a top plate, an adjustment block is matched with the upper portion of the center shaft through a screw thread and located in a through hole in the middle of the top plate, and the top plate is fixedly arranged at the upper end of the fixing plate; the upper ends of the left idler wheel and the right idler wheel are in contact with the lower surface of a wire, and the lower end of the middle idler wheel isin contact with the upper surface of the wire. The wire tensioning device is simple in structure, automatic wire tensioning can be achieved, and the constant tension of the wire is kept.

Owner:马西刚

Spray printing device for textile printing and dyeing cloth

ActiveCN106995152AEasy to navigateRealize automatic tensioningPower drive mechanismsOther printing apparatusTextile printerEngineering

The invention discloses a spray printing device for textile printing and dyeing cloth. The device comprises a base. A cloth inlet roller and a cloth outlet roller are arranged on the upper portion of the base. A spray printing mechanism and a cloth guiding mechanism are arranged between the cloth inlet roller and the cloth outlet roller. A transmission box is arranged at the end of the cloth guiding mechanism and electrically connected with a control mechanism. Vertical plates are arranged on the two sides of the upper portion of the base, and the cloth guiding mechanism is arranged between the two vertical plates. The cloth guiding mechanism comprises a first guide roller, a second guide roller, a third guide roller, a fourth guide roller, a fifth guide roller, a sixth guide roller, a seventh guide roller, an eighth guide roller, a ninth guide roller, a tenth guide roller, an eleventh guide roller and a twelfth guide roller, all of which are sequentially arranged from left to right, and a clamping roller set is arranged between the third guide roller and the fourth guide roller. The multiple guide rollers and a movable sprayer capable of moving at multiple freedom degrees are arranged, the cloth is guided through the guide rollers, and it is achieved that the cloth is transferred from the cloth inlet roller to the cloth outlet roller; and a compressing roller is arranged on an adjusting mechanism, automatic tensioning is achieved, and guiding of the cloth is promoted.

Owner:嘉兴市前荣织造有限公司

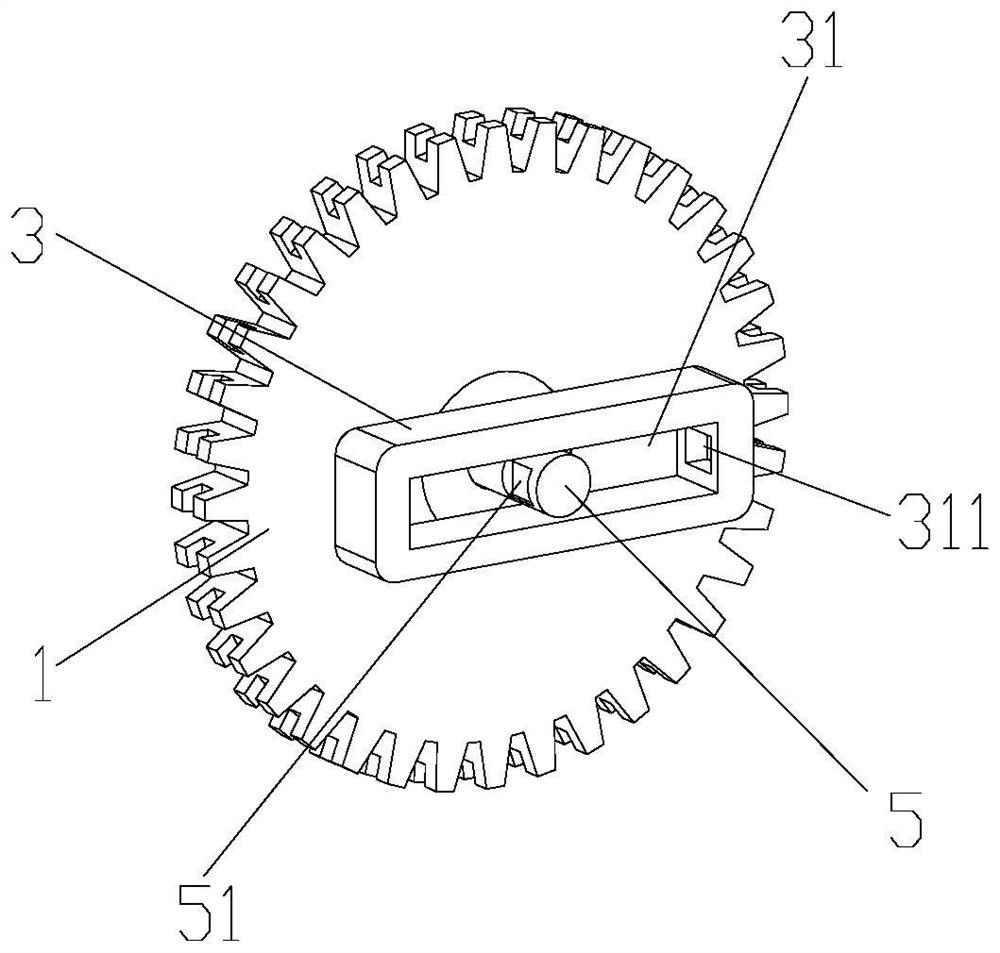

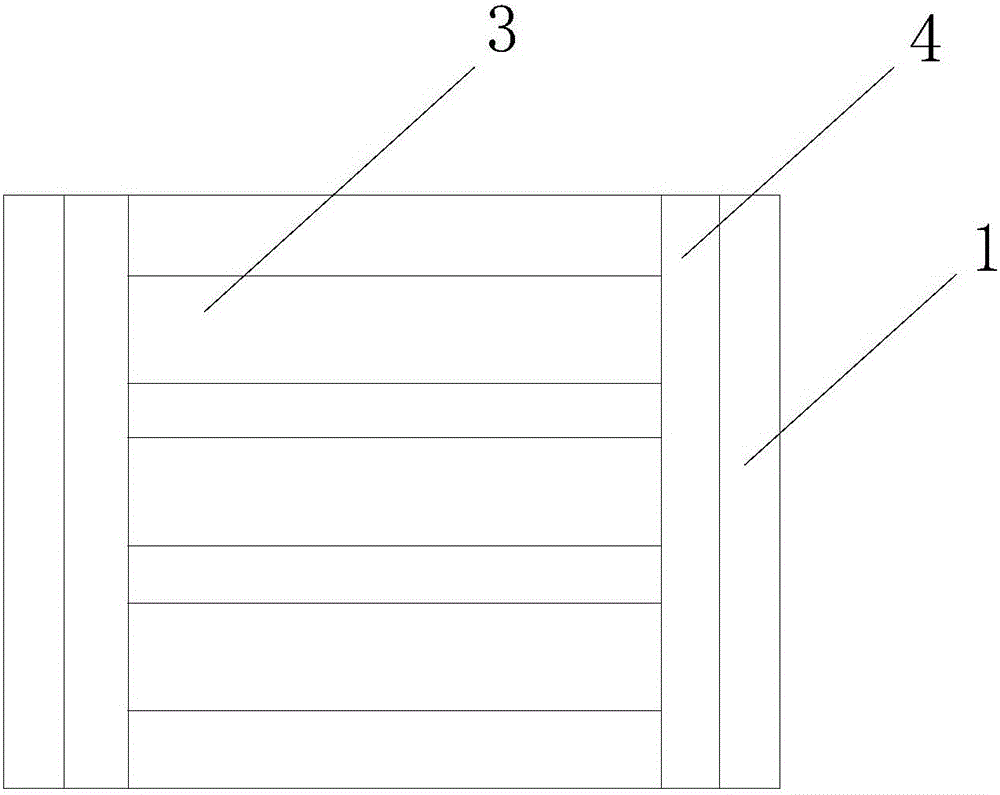

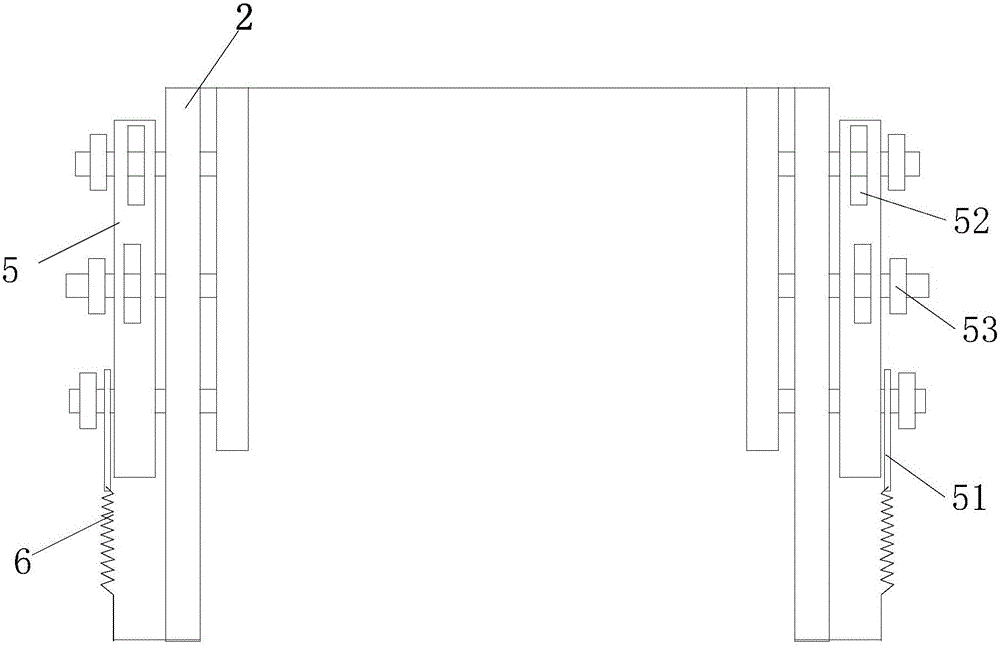

Clamp suitable for clamping object with circular through hole characteristic

ActiveCN112894663AIncreased clamping area and reliabilityLight in massWork holdersRatchetControl theory

The invention discloses a clamp suitable for clamping an object with a circular through hole characteristic, and belongs to the technical field of special clamps. The clamp suitable for clamping the object with the circular through hole characteristic comprises a fixed plate; a rotary adjusting device is inserted to the fixed plate; a supporting frame is fixedly connected to the bottom end of the fixed plate; a claw-shaped internal expansion clamping device is connected to the supporting frame; the rotary adjusting device comprises a lifting rod; the outer side of the lifting rod is movably sleeved with a fixed sleeve; the top end of the fixed sleeve is fixedly connected with a check ring; the bottom of the fixed sleeve is sleeved with a sleeve cover; an inner sleeve is fixedly connected to the inner bottom face of the sleeve cover; a ratchet wheel clamping shaft is further sleeved into the inner sleeve; the bottom end of the ratchet wheel clamping shaft is fixedly connected with a fixed connecting rod; the bottom end of the fixed connecting rod is fixedly connected with a clamping ring; and the clamping ring is matched with the claw-shaped internal expansion clamping device. The problem that common design on the market is inconvenient to clamp objects with circular through hole characteristics is effectively solved.

Owner:HEFEI UNIV OF TECH

Paying off device for cable production

InactiveCN108428515ARealize automatic tensioningGuarantee the quality of follow-up processingApparatus for feeding conductors/cablesArchitectural engineeringEngineering

Owner:安徽协创科技产业园有限公司

Tooth belt double-shaft guide rod groove cam combination space mechanism for sliding-plug door

InactiveCN102305009BQuick sealQuick opening and closingPower-operated mechanismDoor arrangementDrive wheelCoupling

The invention discloses a tooth belt double-shaft guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the tooth belt double-shaft guide rod groove cam combination space mechanism for high-speed rail or other railway vehicles. The mechanism comprises a door frame, a motor, a driving wheel, a tooth belt, an auxiliary bearing shaft, a belt clamp, a tension device, a bearing pedestal, a driven wheel, an auxiliary shaft sleeve, a coupling rod A, a main shaft sleeve, a main bearing shaft, a coupling shaft B, a coupling shaft C, a guide rod sleeve, a roller, a roller shaft, a door carrying guide rod, a groove cam and a door leaf; a tooth belt transmission mechanism consists of the driving wheel, the tooth belt, a lower belt clamp, the tension device, the bearing pedestal, and the driven wheel; a double-shaft guide rod mechanism consists of the coupling rod A, the main shaft sleeve, the coupling rod B, the coupling rod C and the guide rod sleeve which are connected fixedly and integrally, the main bearing shaft, the auxiliary shaft, and the door frame; and a groove cam mechanism consists of the main shaft sleeve, the main shaft, the coupling rod C, the roller, the roller shaft, the door carrying guide rod, the groove cam, the door leaf, the main shaft sleeve and the door frame.

Owner:NANJING INST OF TECH

Electric control type belt tensioning device for vehicle

The electric control type belt tensioning device for the vehicle is provided with a sliding frame fixed to a vehicle frame, a transverse sliding hole is formed in the sliding frame, a linear driving module and an elastic module are installed in the transverse sliding hole, and a pressure sensor is clamped at the contact position of the elastic module and an installation shaft. The pressure sensor is electrically connected with the controller, and the controller controls the telescopic end of the linear driving module to stretch or retract according to a received pressure sensor signal, so that the elastic module is compressed or stretched by a corresponding length. When the pressure detected by the pressure sensor is reduced, the flexible belt is soft, at the moment, the telescopic end of the linear driving module extends to enable the elastic module to be compressed by the set length, so that the pressure on the mounting shaft and the gears is increased, the gears are pushed, the distance between the two gears is increased, and the flexible belt is lengthened and tensioned. Therefore, automatic tensioning of the flexible belt is achieved, and quantitative control over the tensioning degree is achieved.

Owner:SHENZHEN HOMETECH TECH CO LTD

Synchronous belt tensioning mechanism for conveying mold strips

InactiveCN105858084ARealize automatic tensioningSimple structureConveyorsEngineeringMechanical engineering

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com