Full-automatic abrasive belt grinding machine

A fully automatic and grinding machine technology, which is applied in the direction of abrasive belt grinders, grinding machines, grinding/polishing equipment, etc., can solve problems that affect workers' life safety, cumbersome operations, and affect workers' processing efficiency, so as to reduce production costs and work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

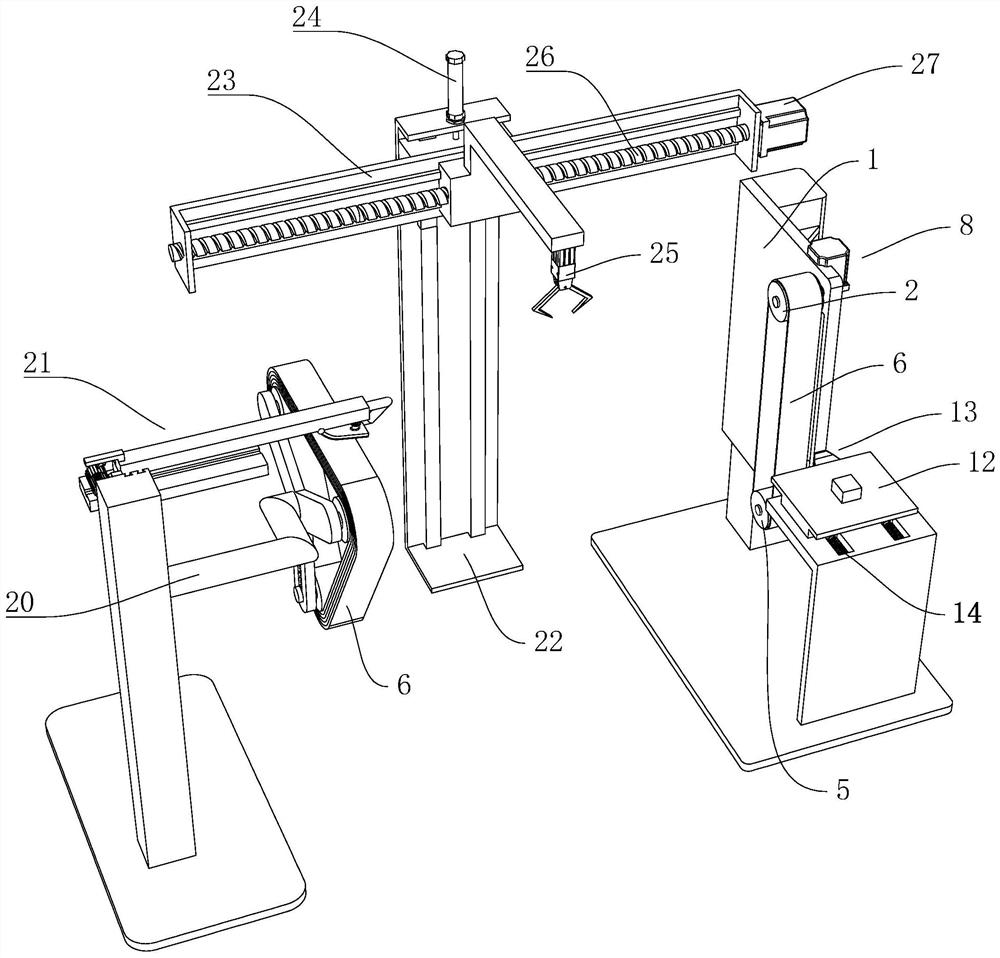

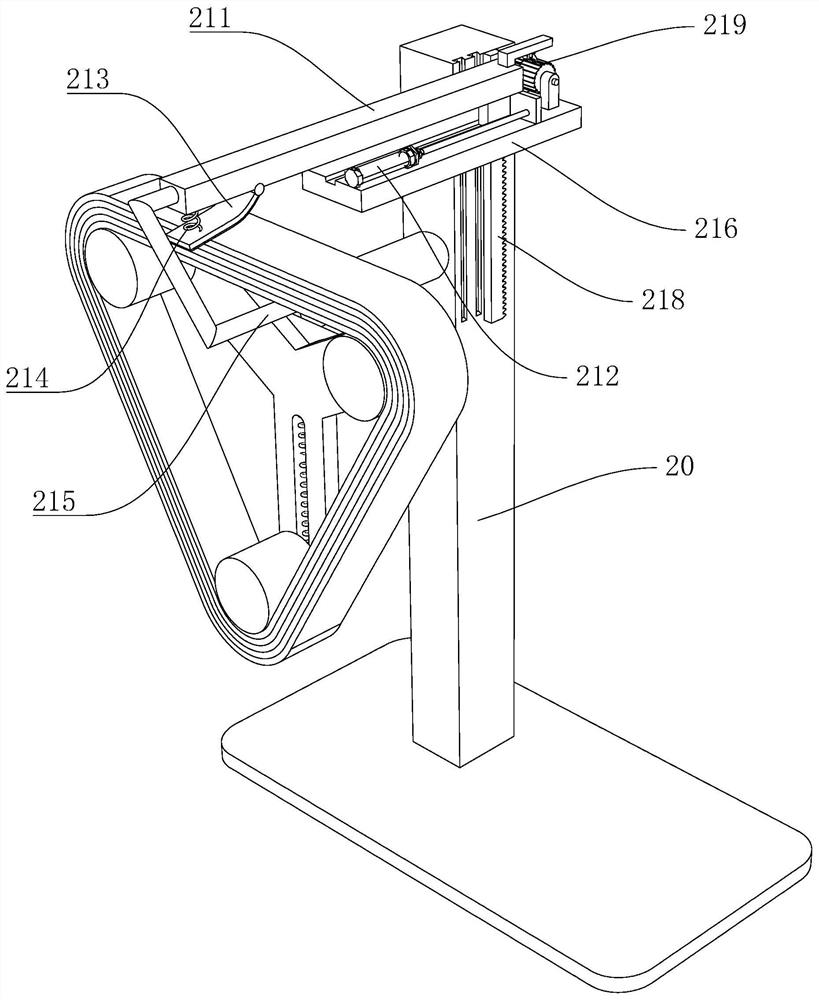

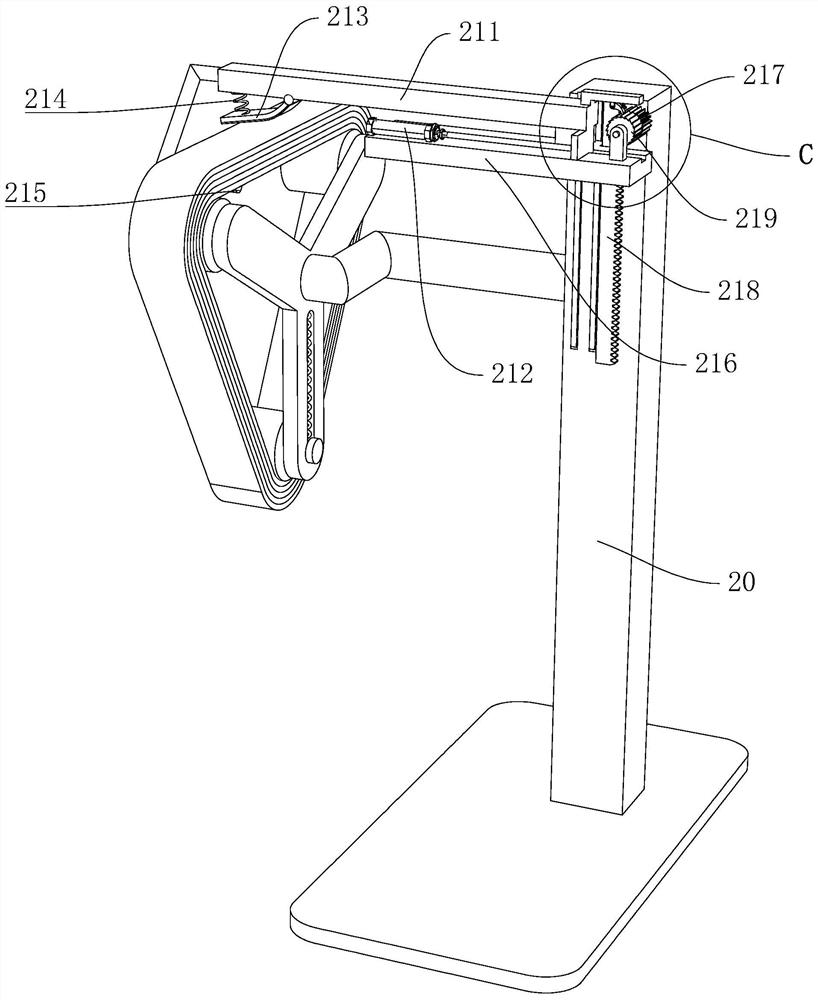

[0038] refer to Figure 1 to Figure 13 , a full-automatic abrasive belt grinding machine, comprising a frame 1 and a driven pulley 2 which is rotatably arranged on the frame 1, and a vertically arranged chute 19 is provided on the frame 1, and slidingly arranged in the chute 19 The sliding seat 3 located directly below the driven pulley 2 and reciprocatingly slides toward the driven pulley 2, the sliding seat 3 is fixedly provided with the first driving member 4 and the driving pulley 5 driven by the first driving member 4, the driving belt An abrasive belt 6 is sleeved between the wheel 5 and the driven pulley 2 . The first driving member 4 is a motor, and the driving pulley 5 is fixedly arranged on the output shaft of the motor.

[0039] One side of the frame 1 is provided with a tensioning frame 20 for fixing the abrasive belt 6, and the abrasive belt 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com