Patents

Literature

643results about How to "Realize automatic replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

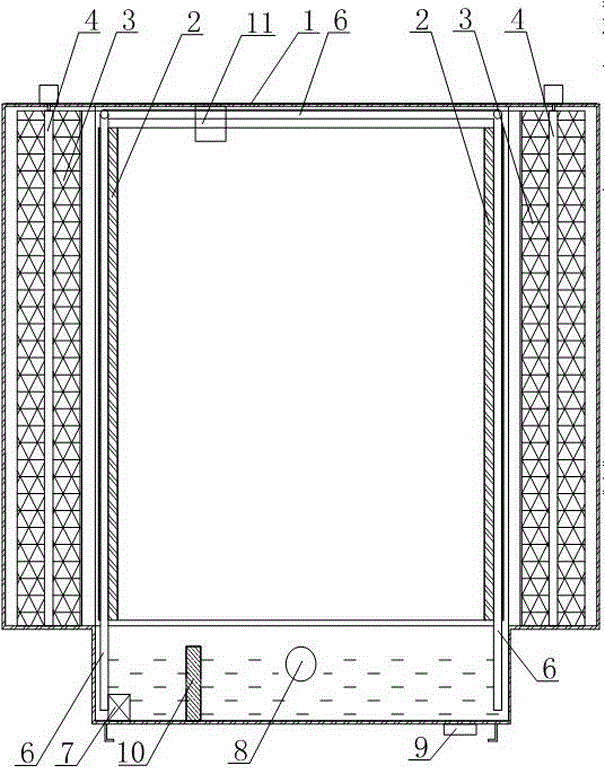

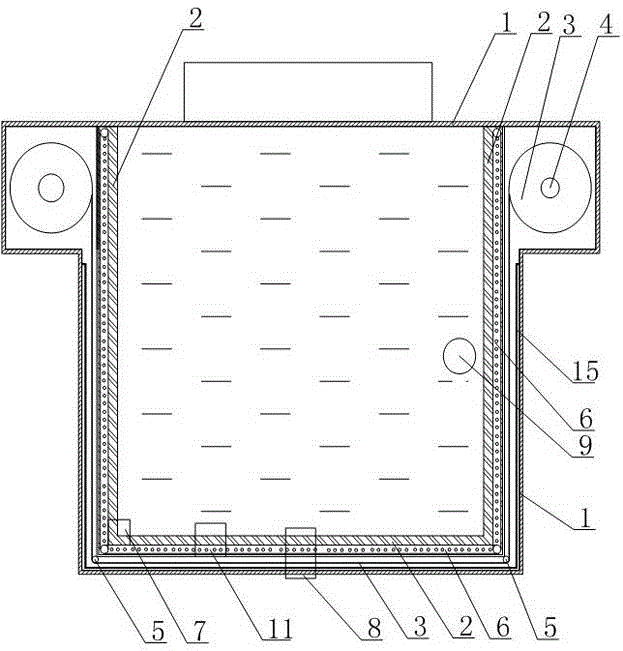

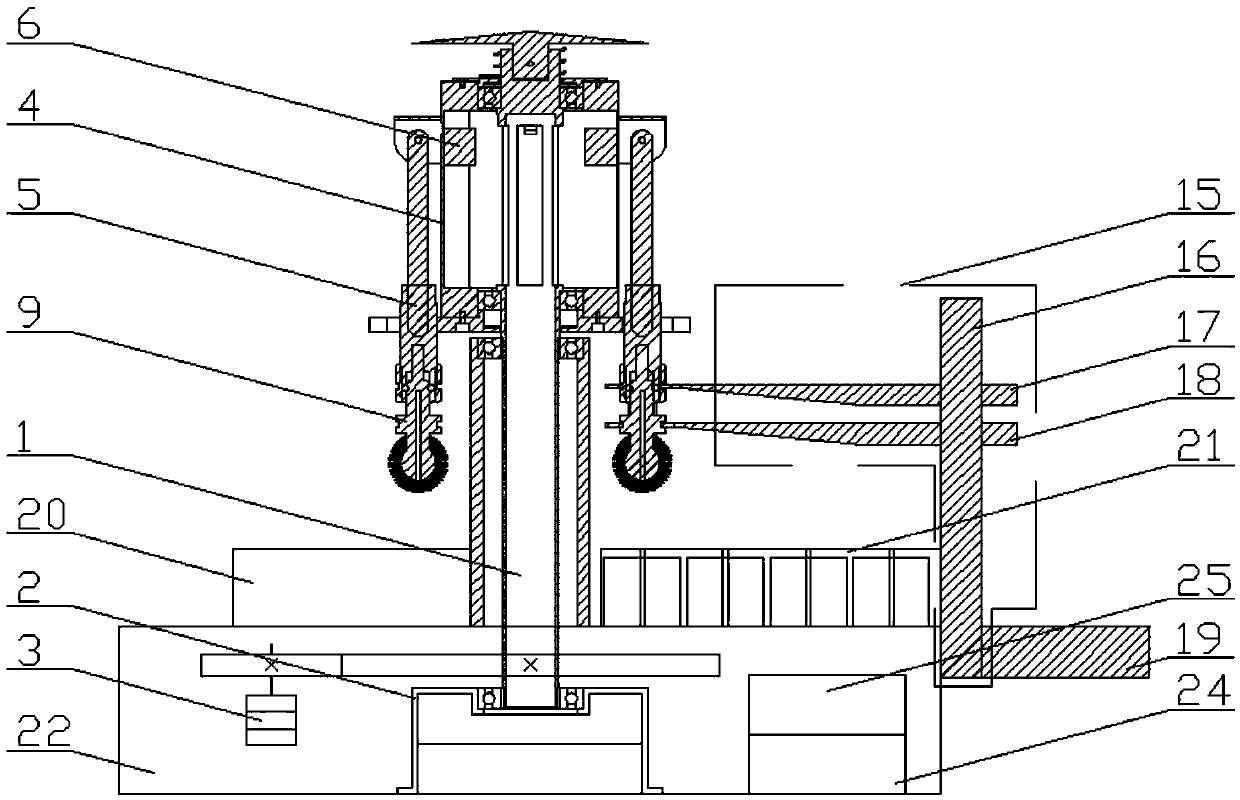

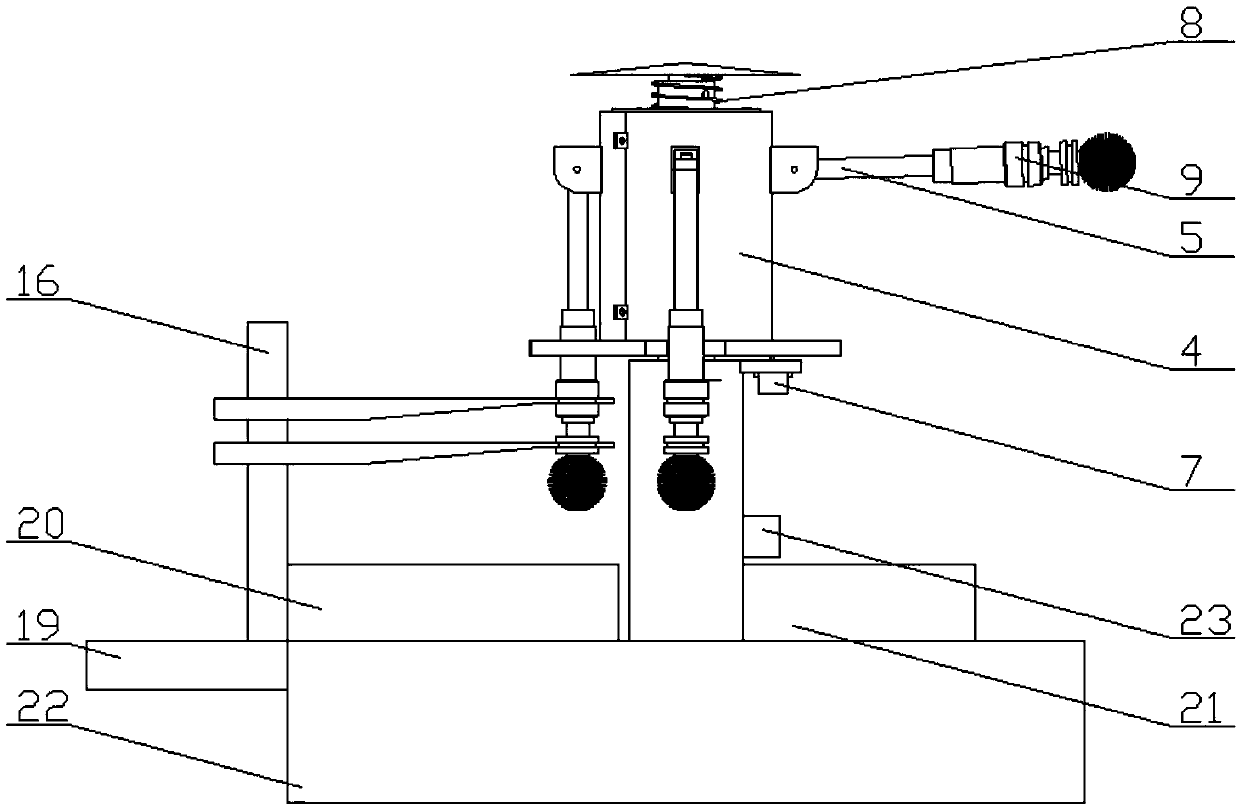

Three-dimensional printer with replaceable nozzle

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

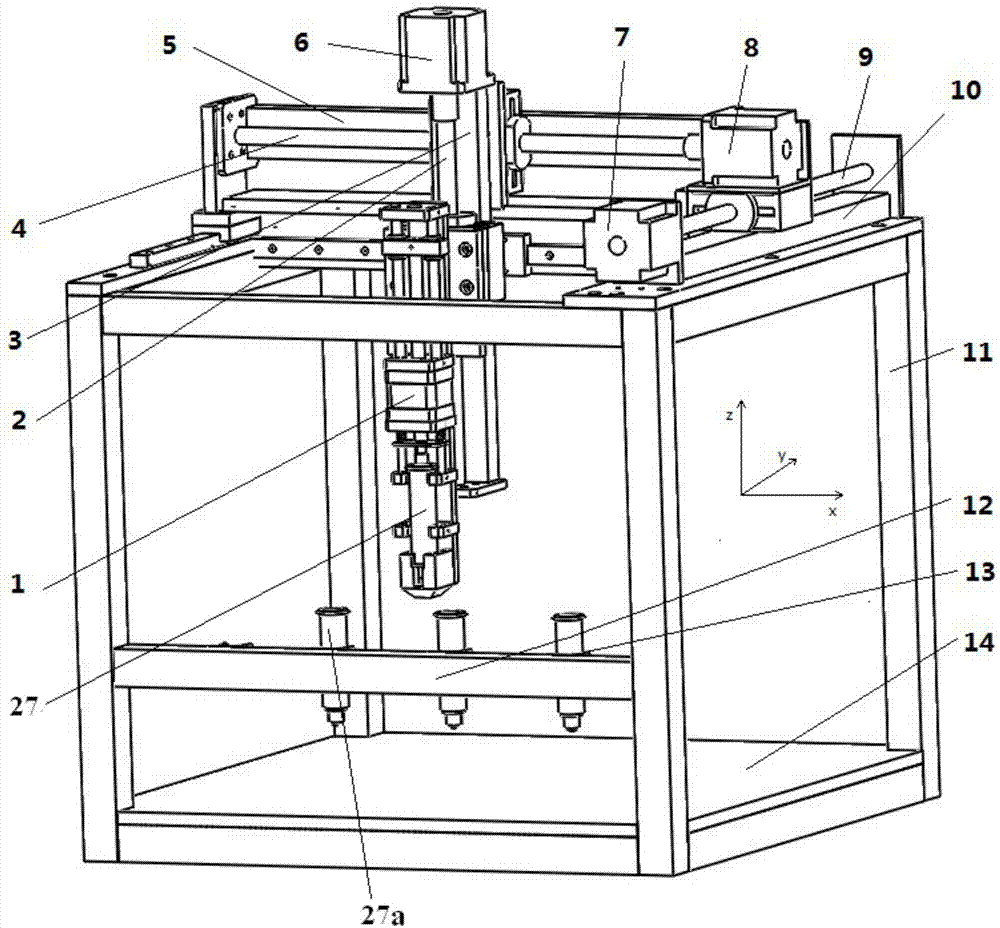

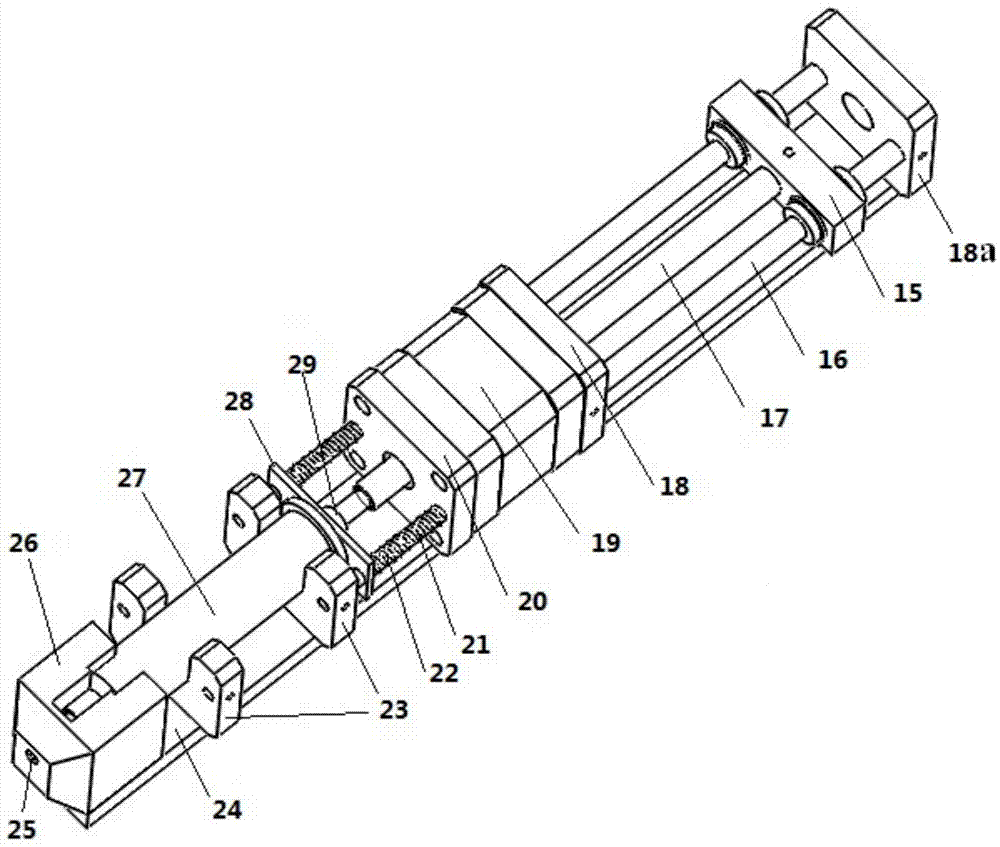

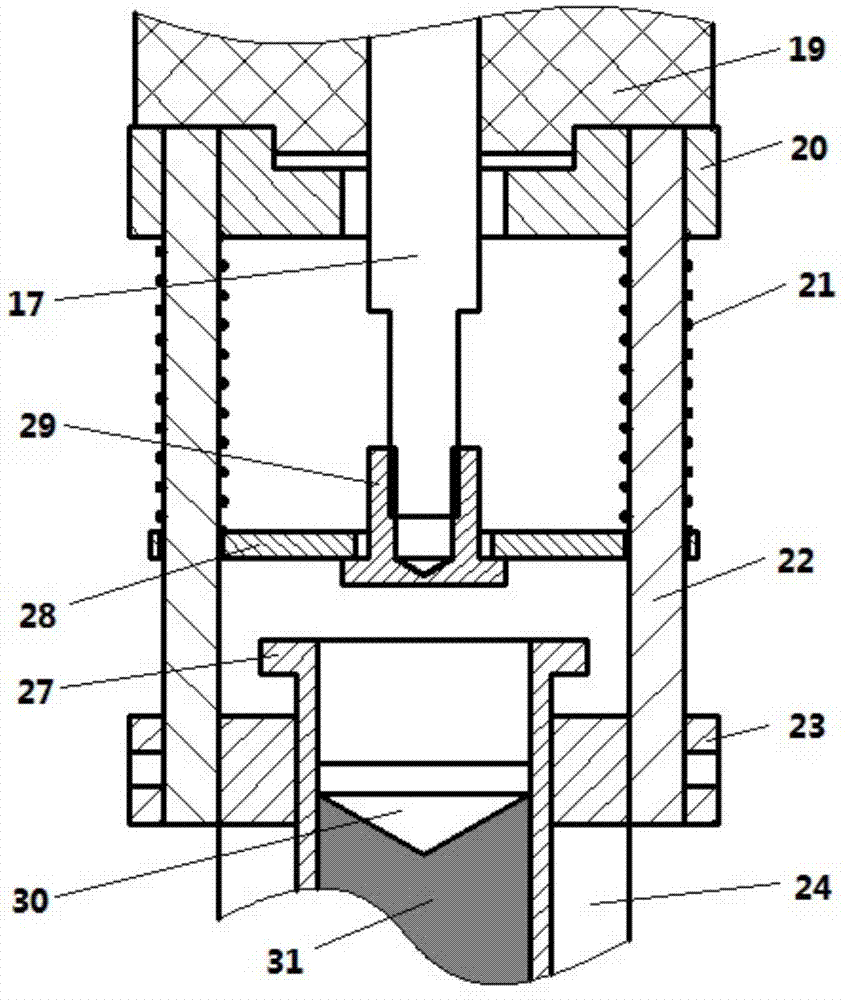

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

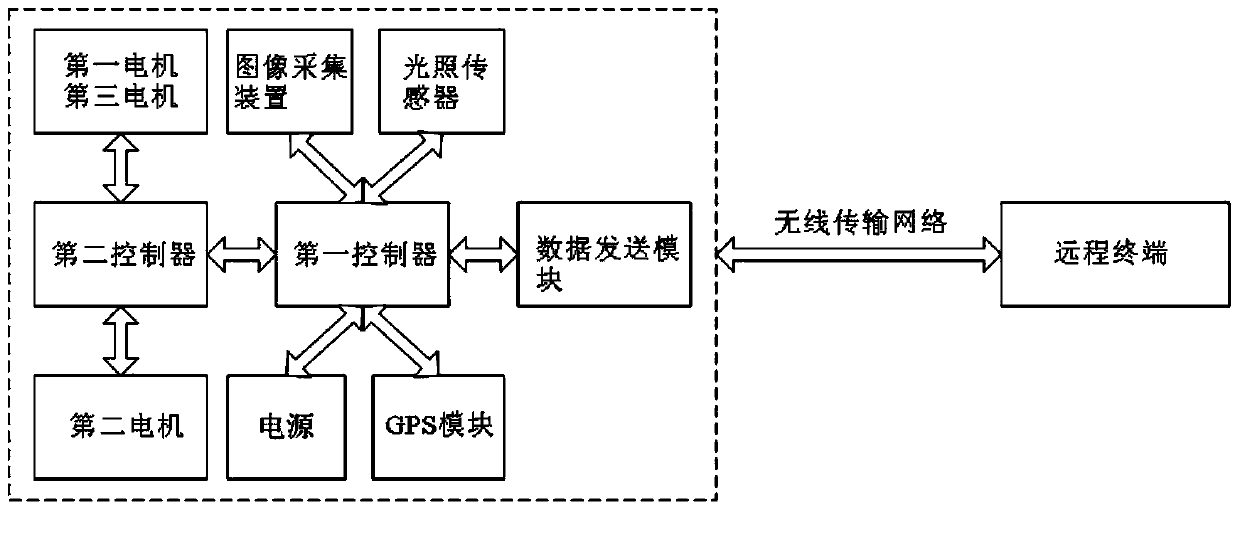

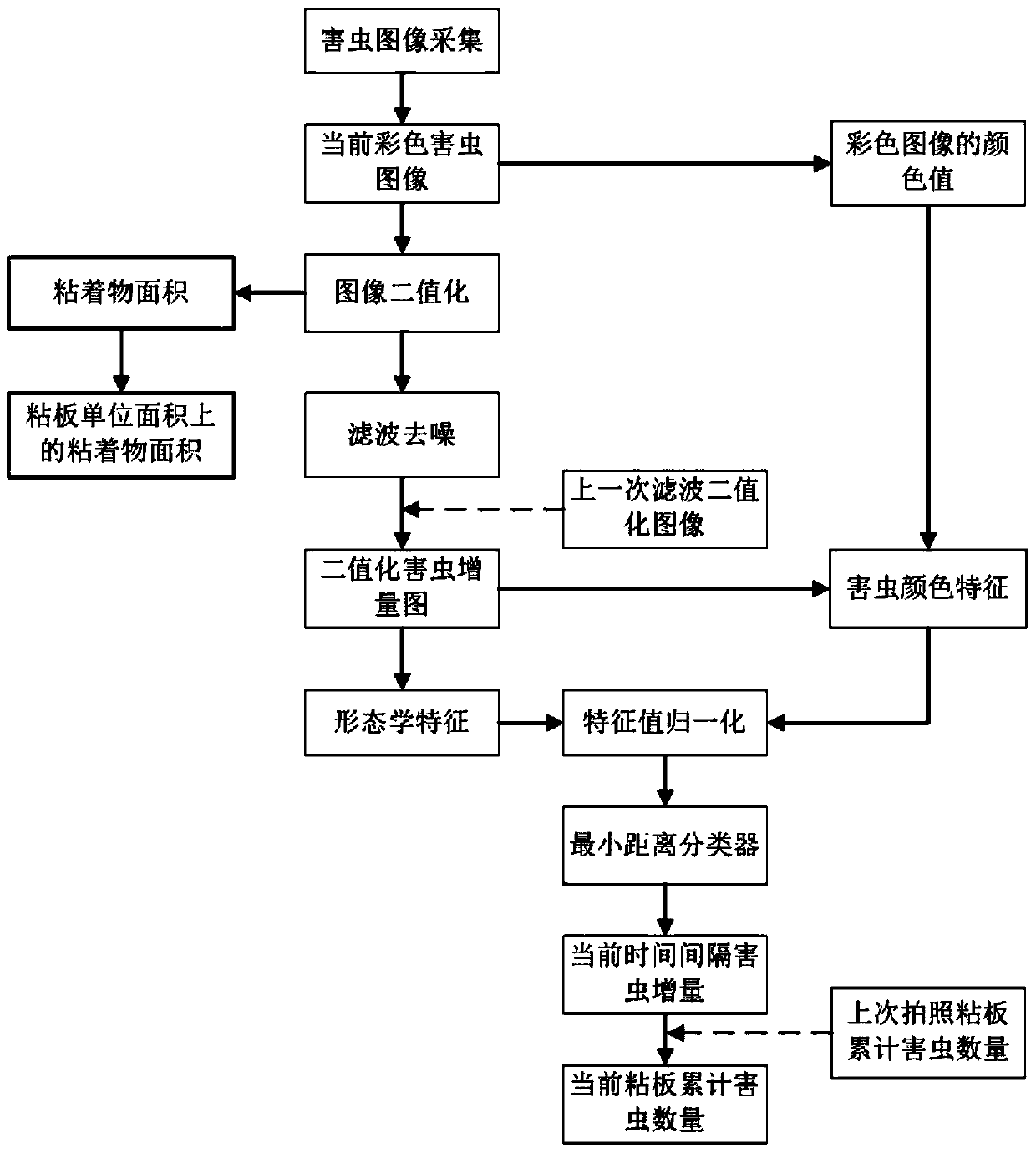

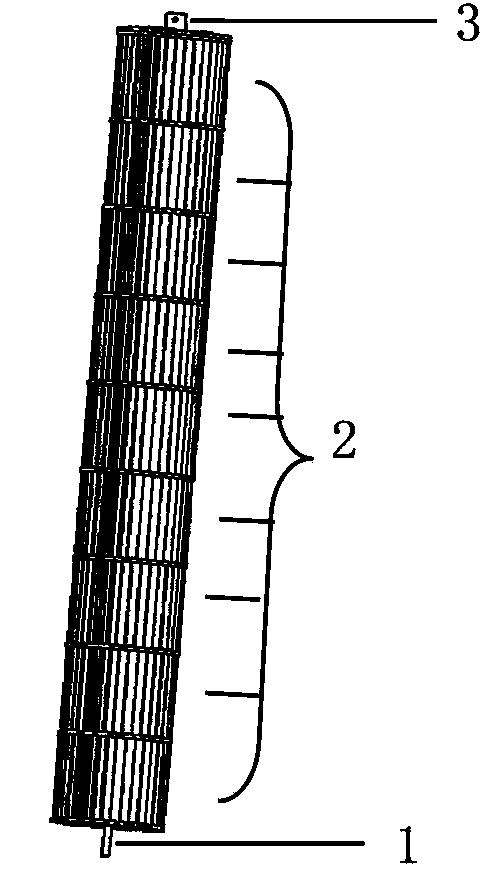

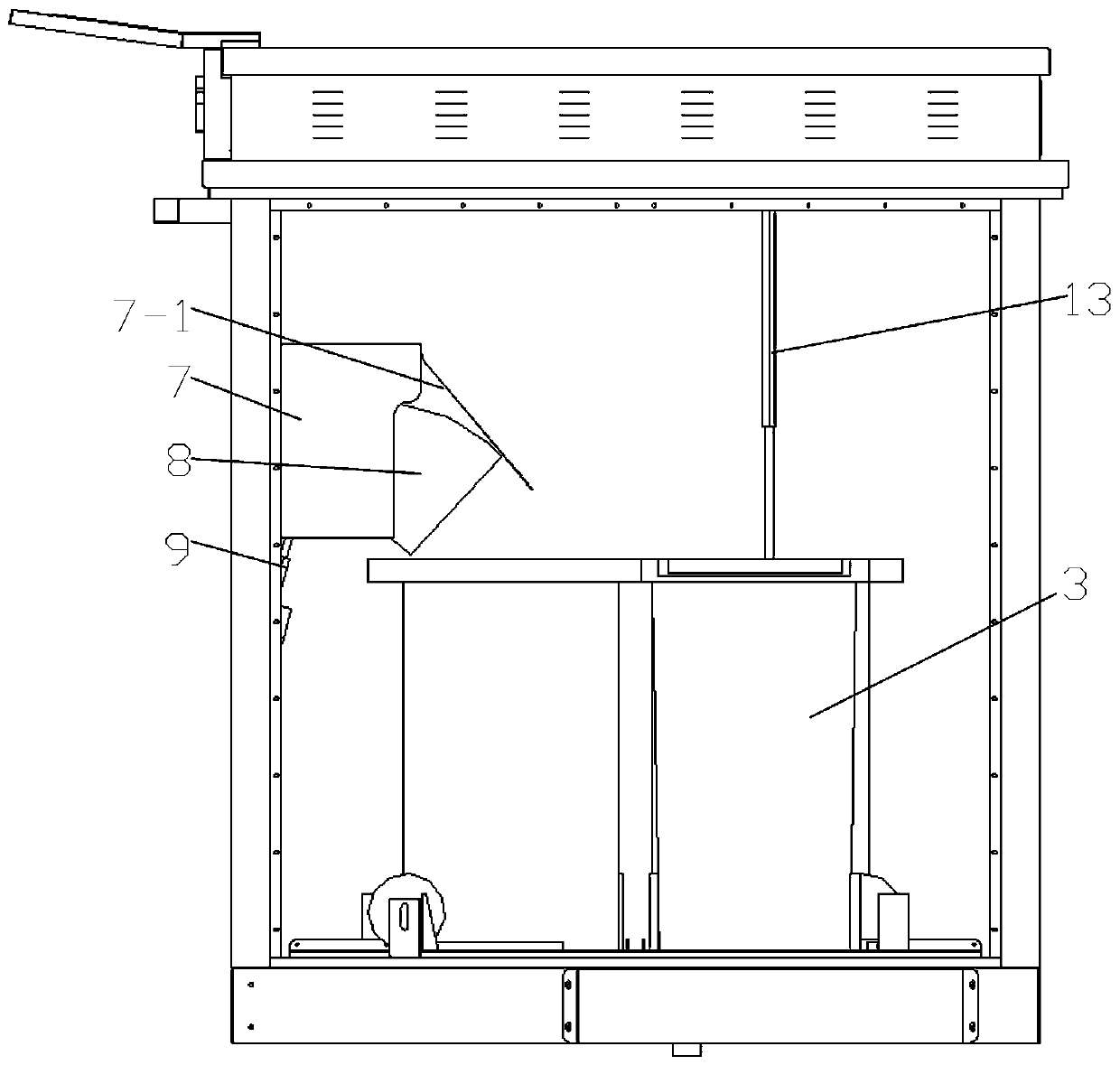

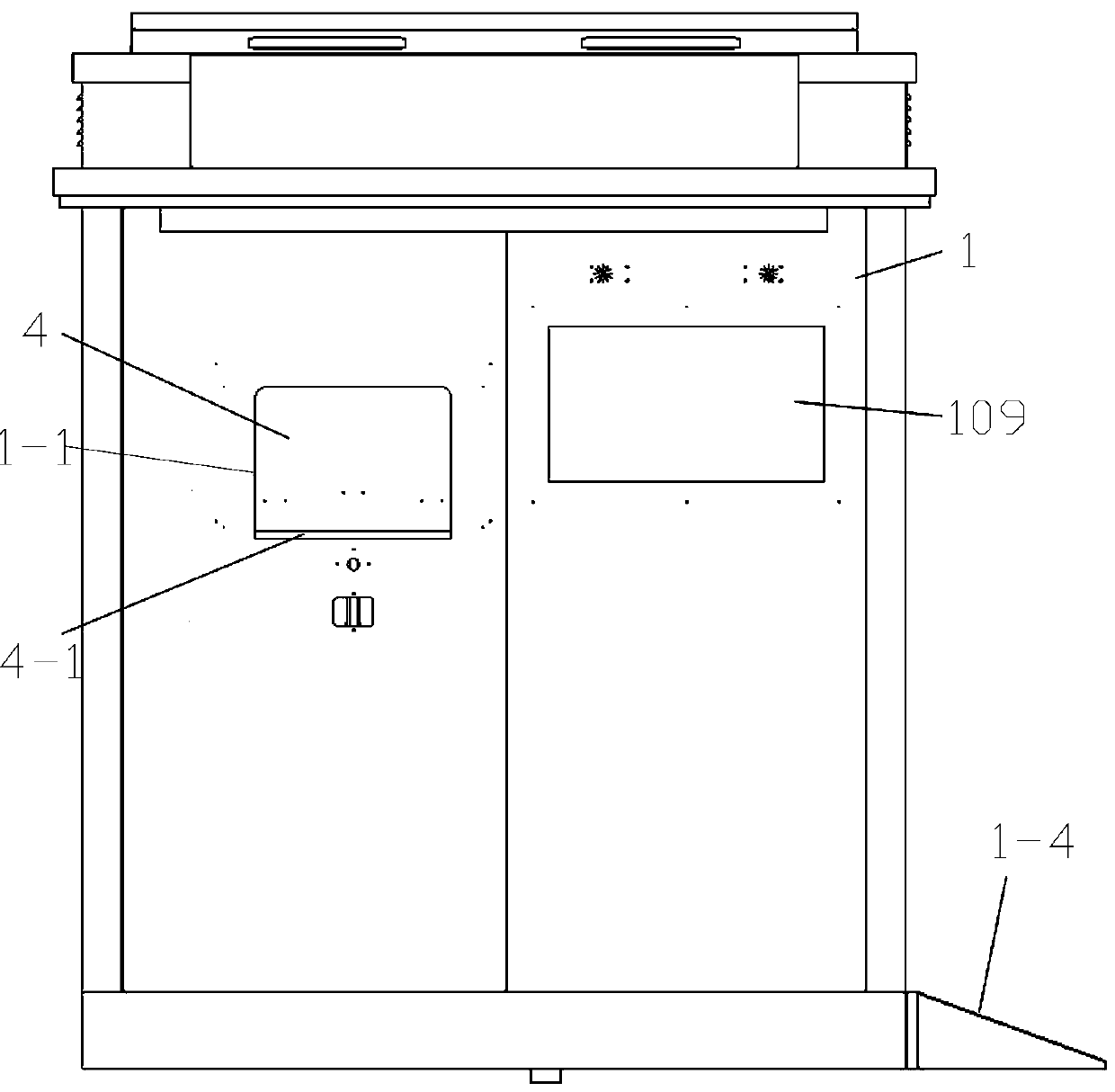

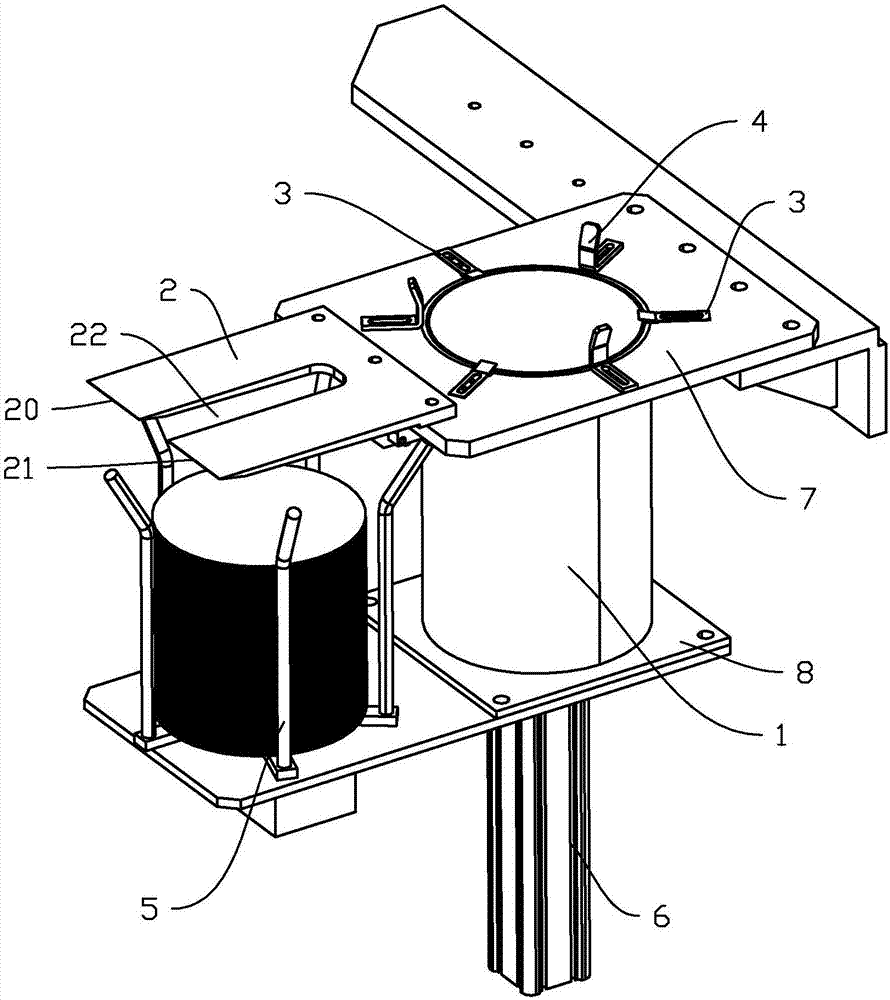

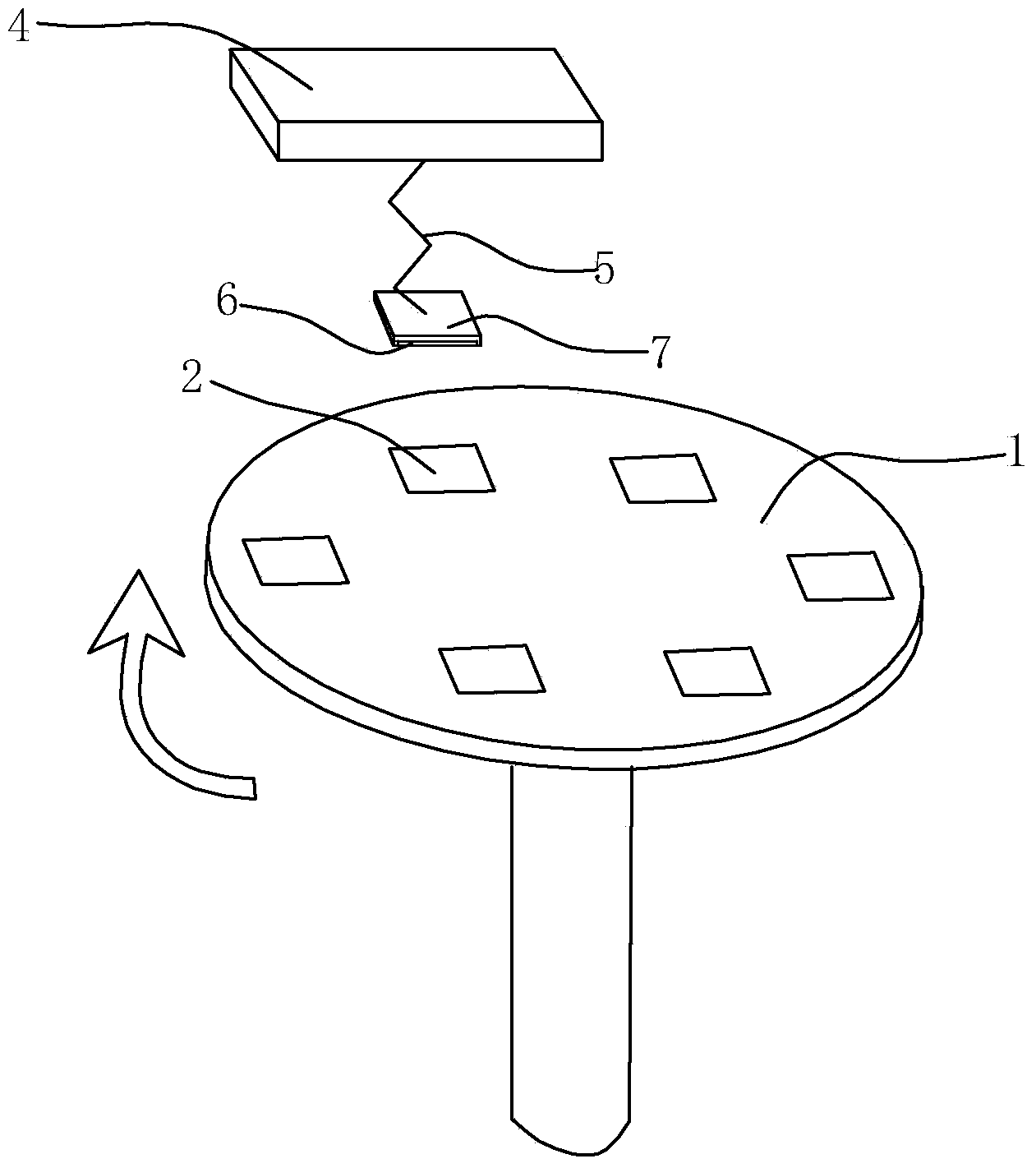

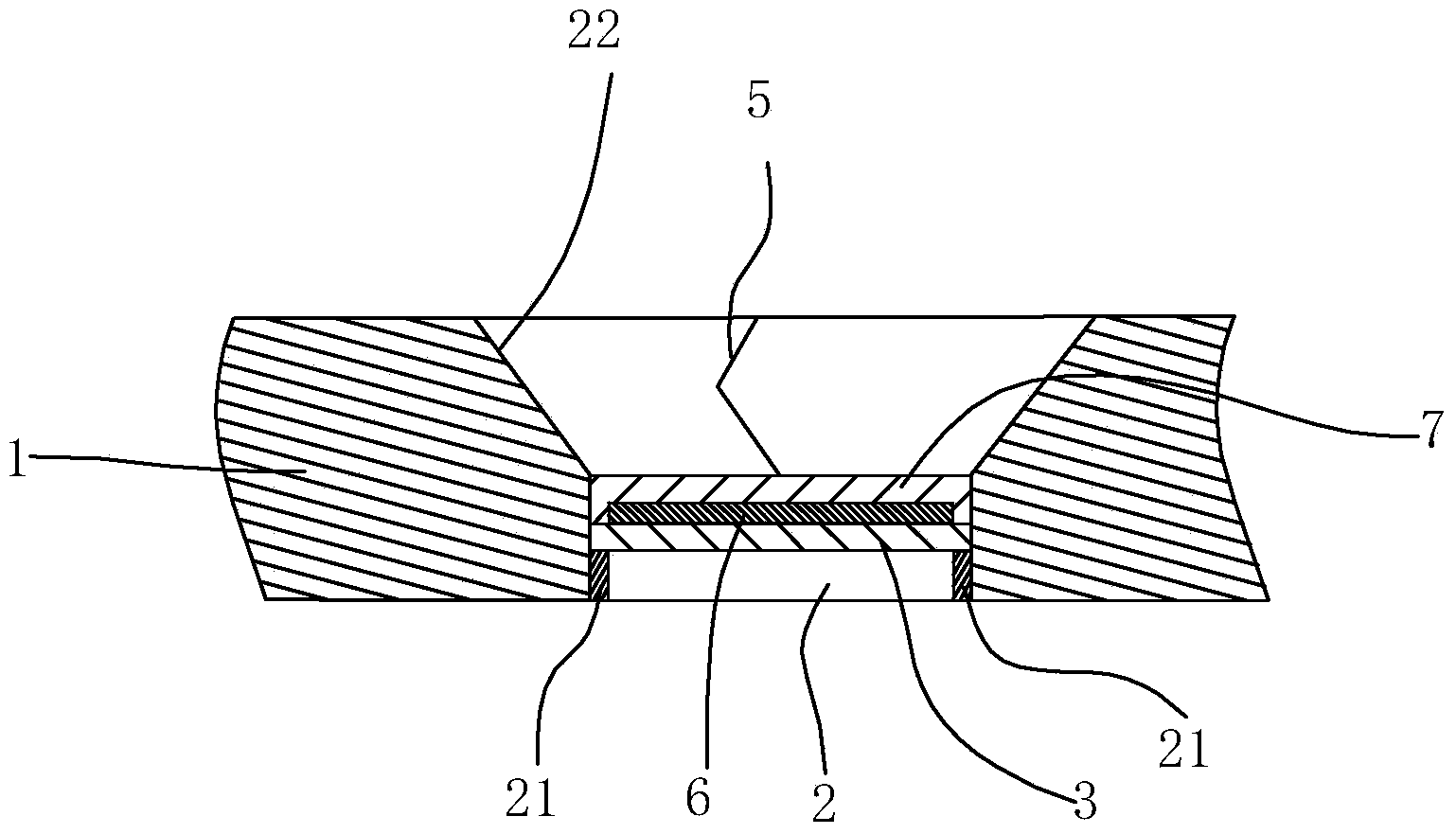

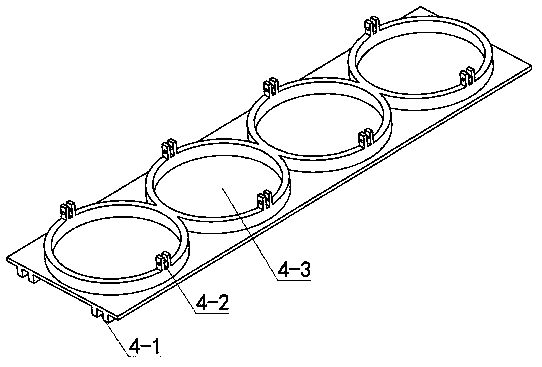

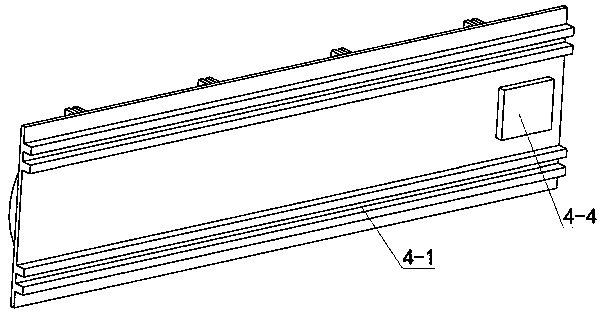

Pest monitoring system capable of automatically replacing pest sticky board and monitoring method

ActiveCN104186449ARealize automatic replacementImprove replacement efficiencyInsect catchers and killersMonitoring systemComputer science

The invention discloses a pest monitoring system capable of automatically replacing a pest sticky board and a monitoring method. The system comprises a trapping device, an image collecting device and a processing control device, wherein the trapping device is located in the center of the pest monitoring system; the image collecting device is located in the center of the trapping device and used for collecting an image of the pest sticky board of the trapping device; the processing control device is respectively connected with the trapping device and the image collecting device, and is used for automatically replacing the pest sticky board by controlling the trapping device when the area of attached objects on the pest sticky board in a unit area exceeds a preset threshold value or preset time is up. According to the system, the image of the pest sticky board is obtained and the number of pests and the area of the attached objects are obtained after the image of the pest sticky board is processed and analyzed; the pest sticky board is automatically replaced through control of a motor or the motor is controlled to work through timing so that the pest sticky board can be automatically replaced; the system is simple in structure and easy to operate and replacement efficiency of the pest sticky board is improved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

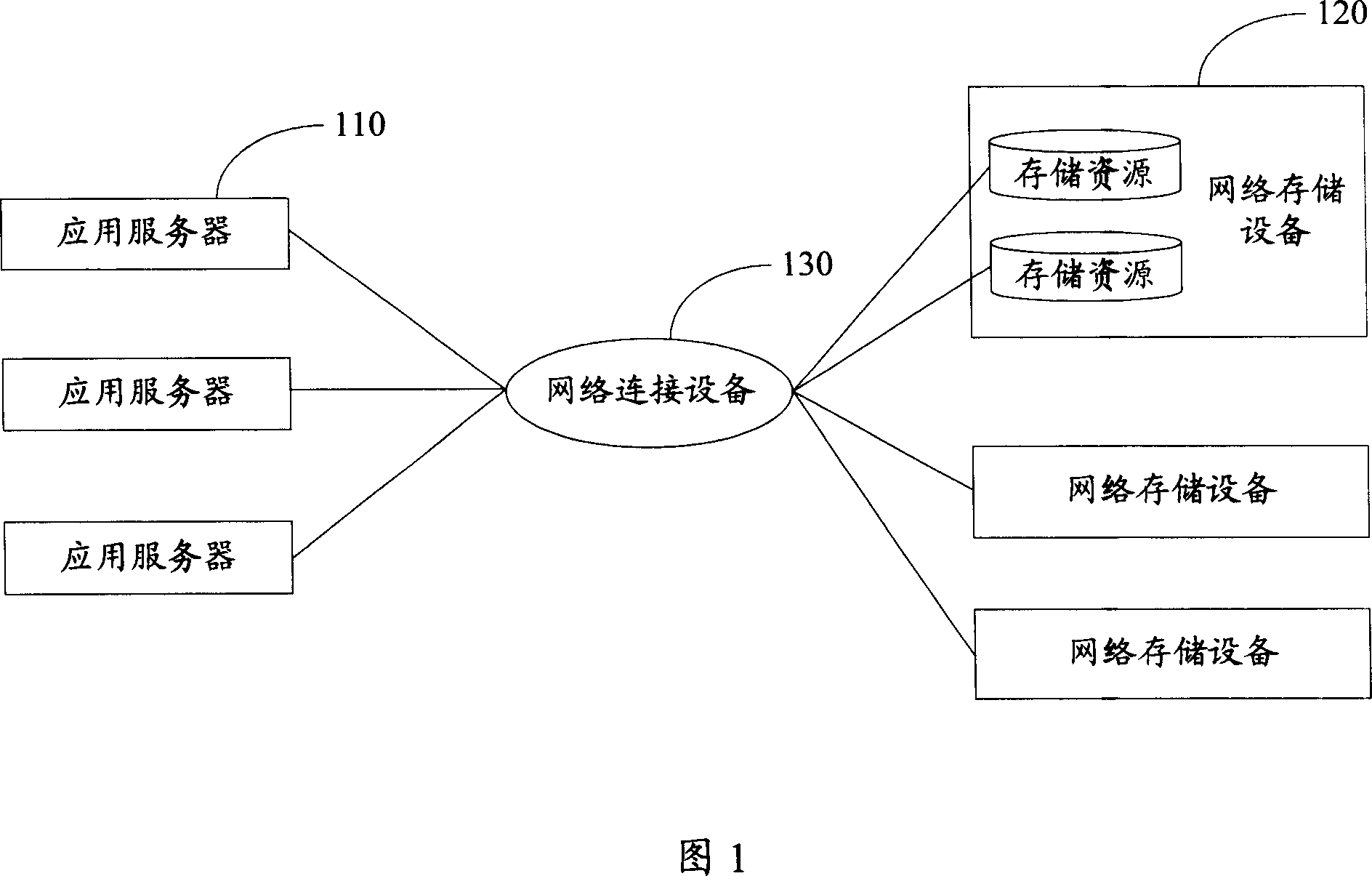

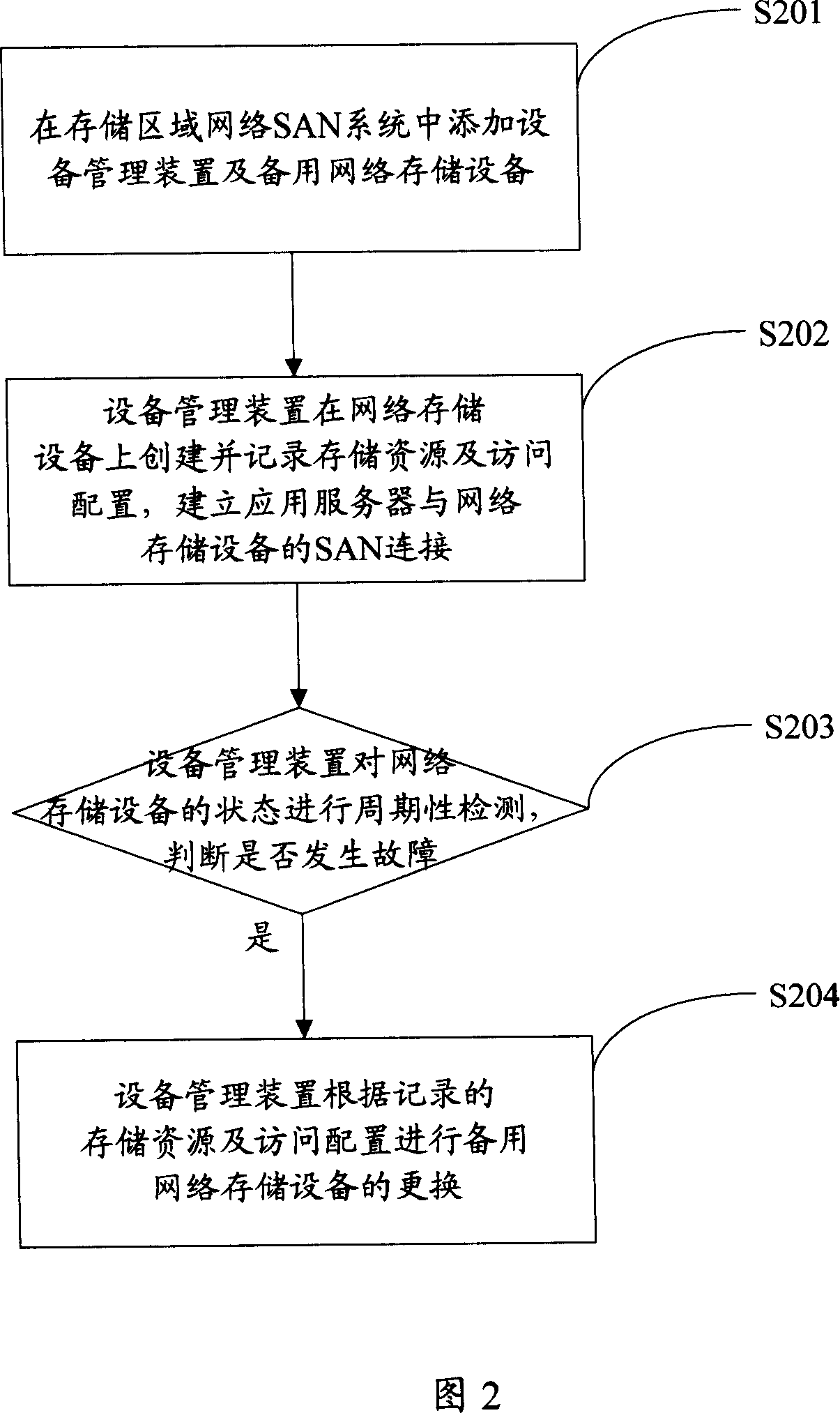

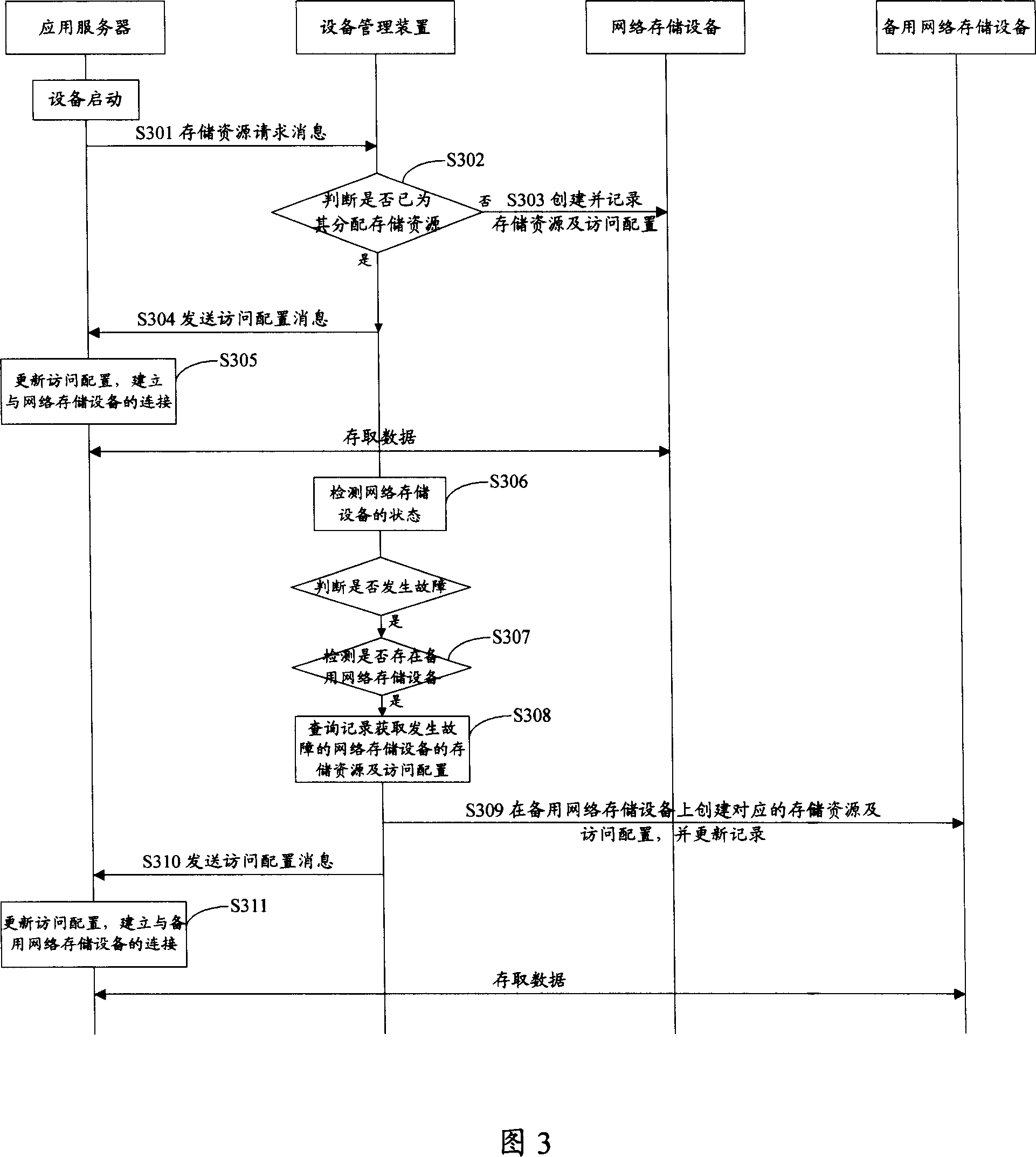

Network storage equipment fault protecting method and device

ActiveCN101022363AReduce workloadReduce lossError detection/correctionData switching networksApplication serverManagement unit

A fault protecting method of network storage device includes adding device management unit in storage region network SAN system, using said device management unit to set up data storage channel of application server and network storage device and carrying out automatic replacement of fault network storage device when it is detected out that network storage device is fault. The device management unit used for realizing said method is also disclosed.

Owner:XINHUASAN INFORMATION TECH CO LTD

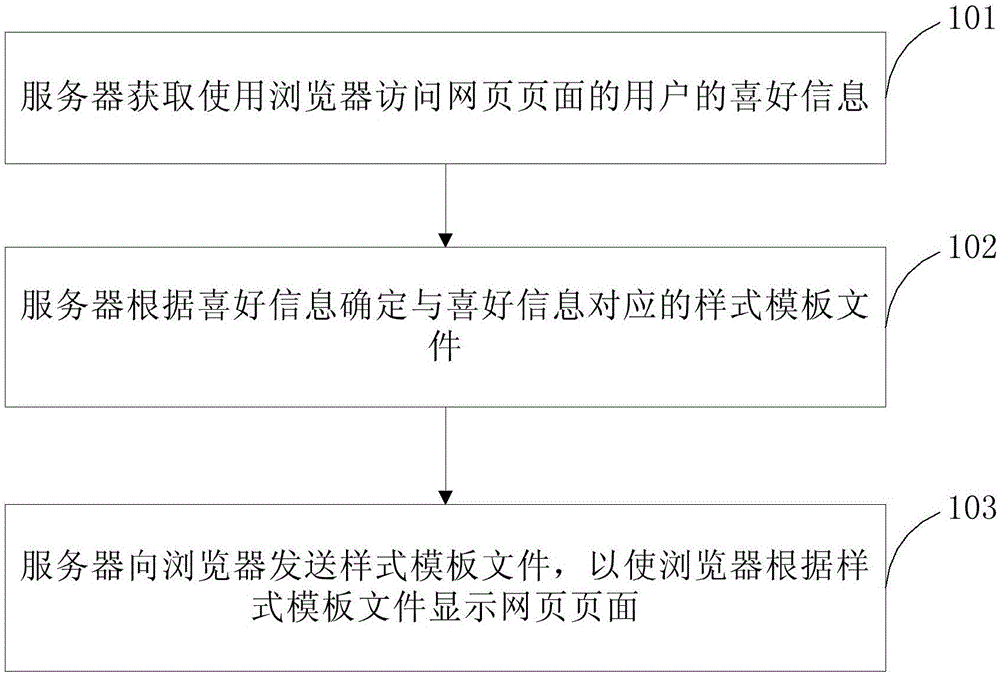

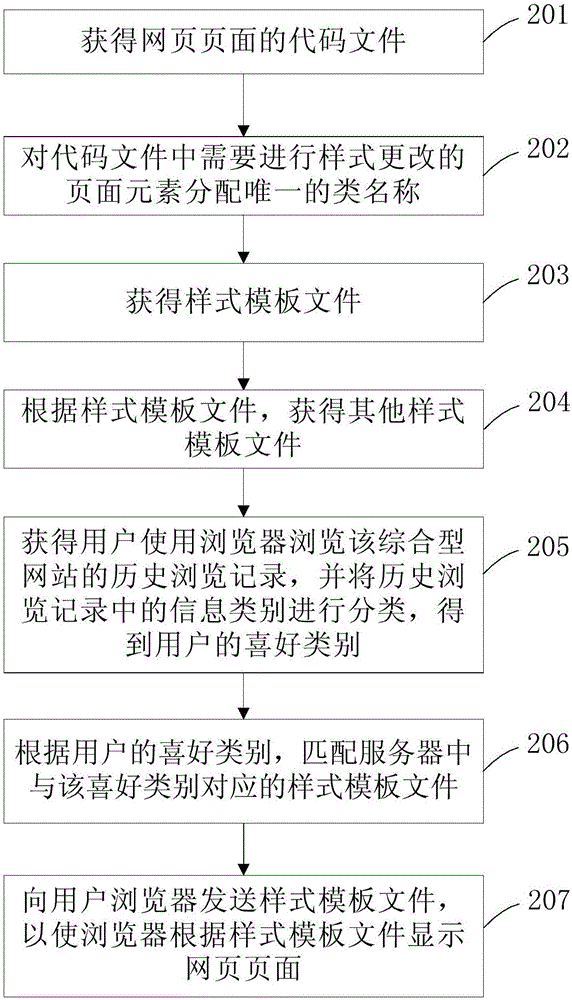

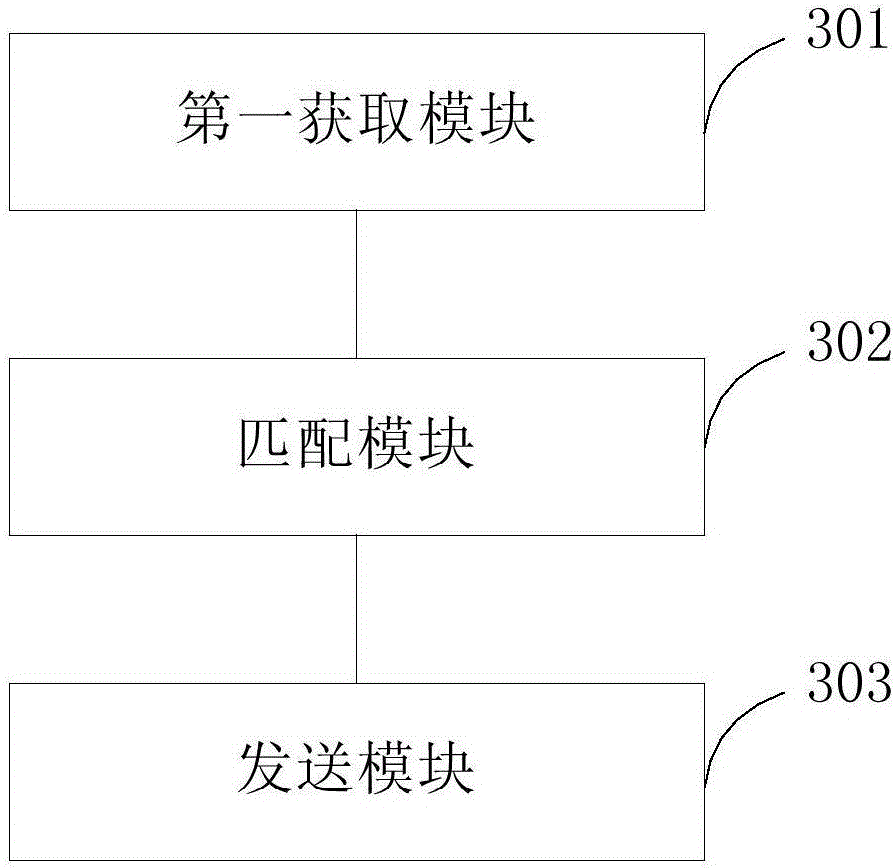

Method and device for displaying webpage style

InactiveCN106503200AImprove experienceRealize automatic replacementSpecial data processing applicationsWeb pageDatabase

Owner:福建中金在线信息科技有限公司

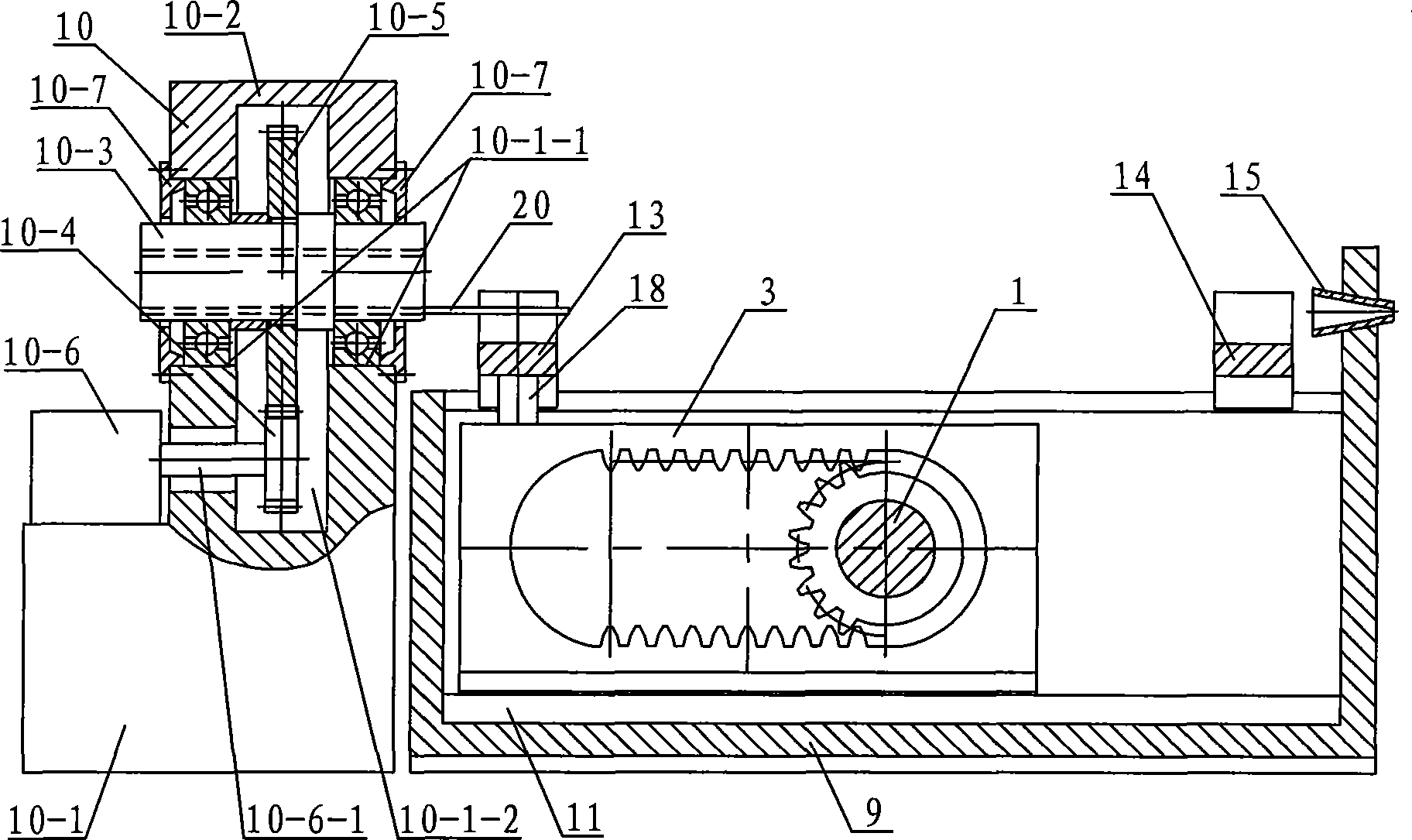

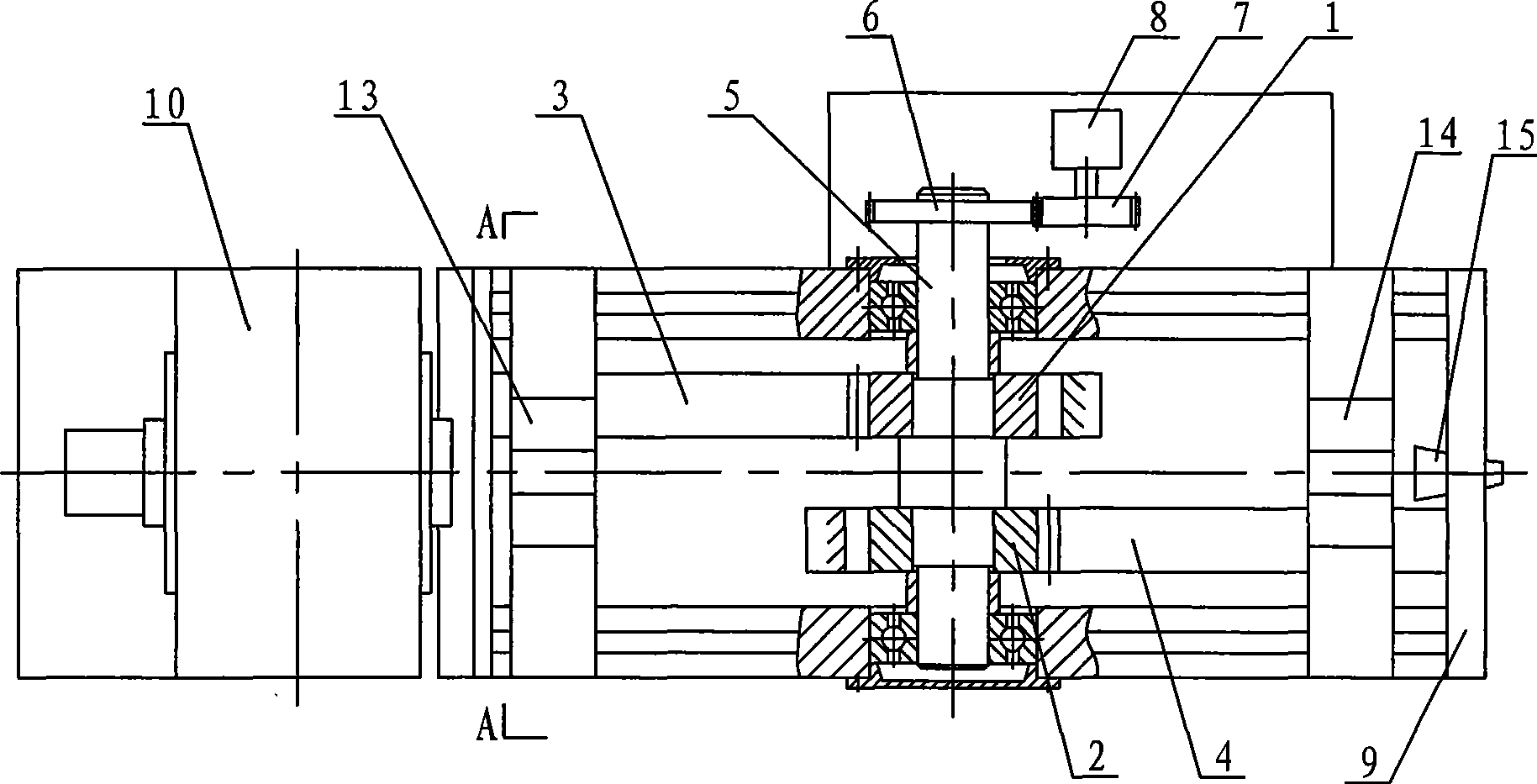

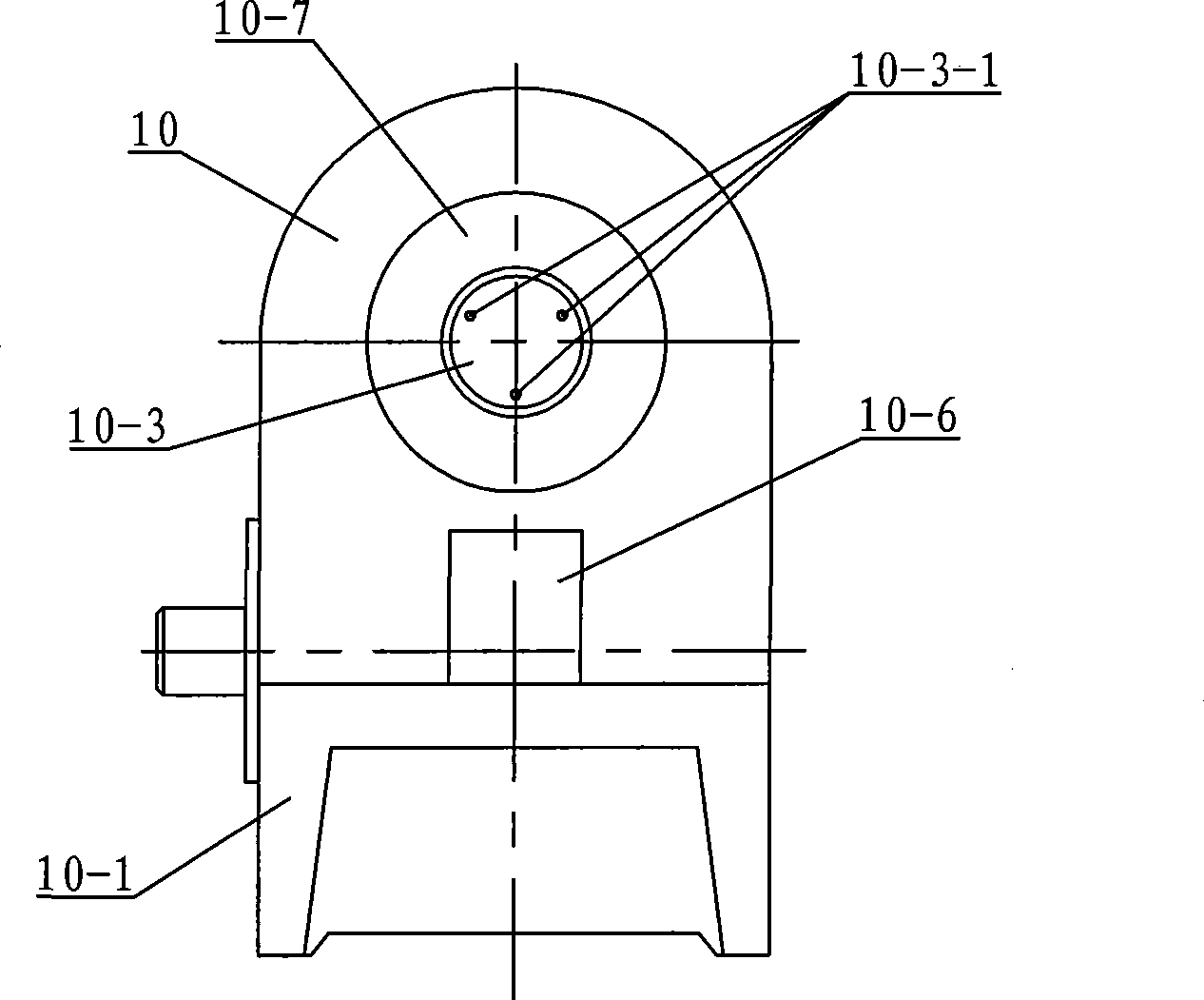

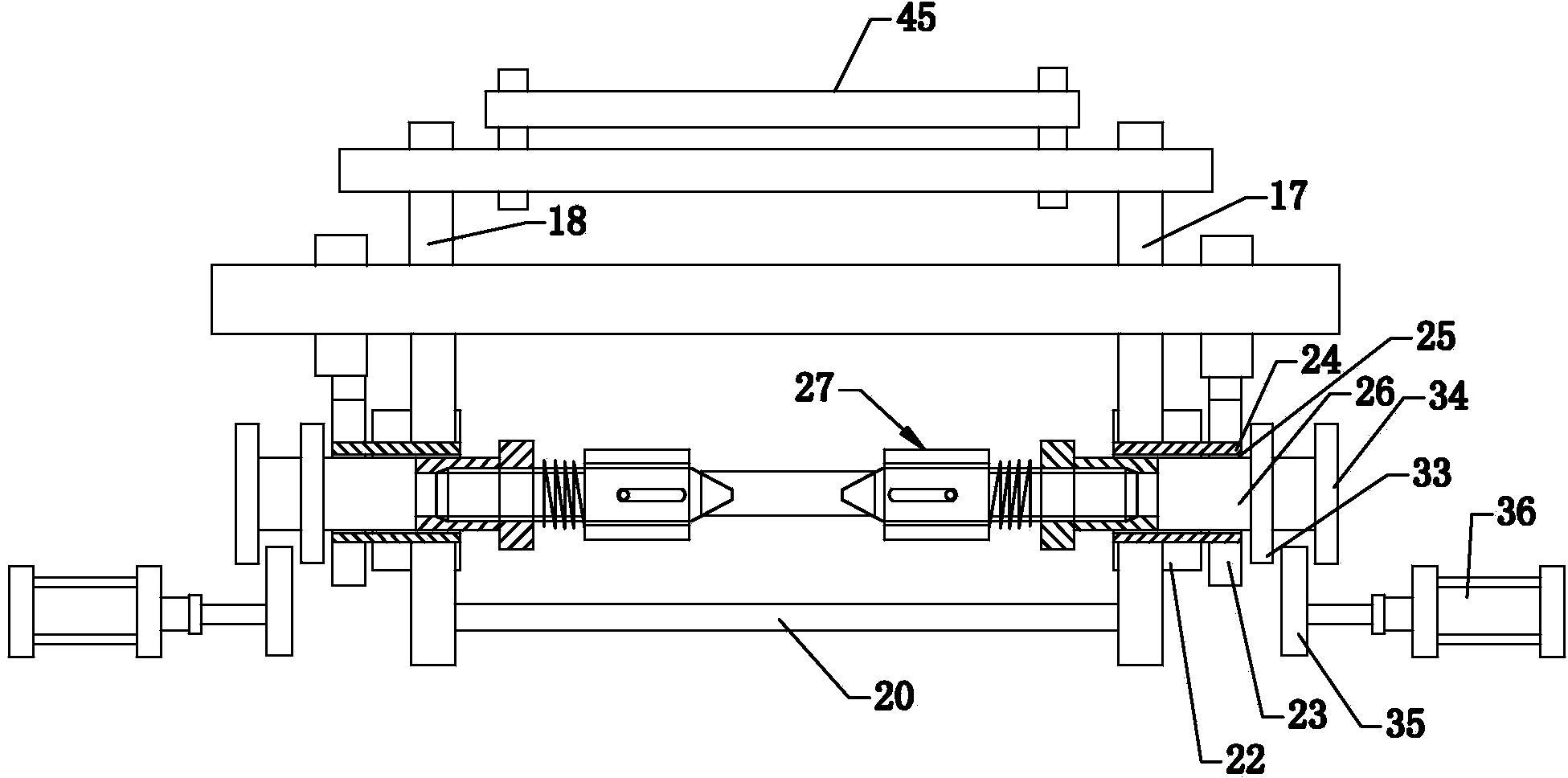

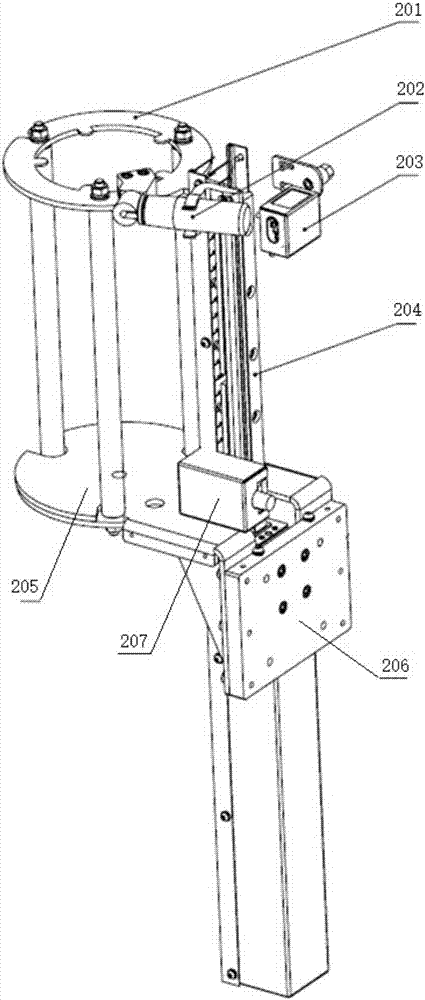

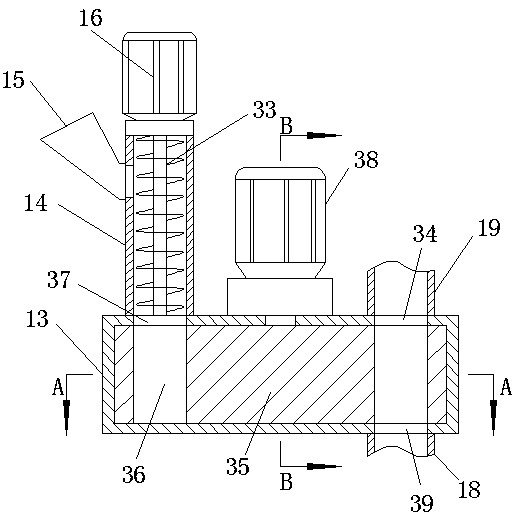

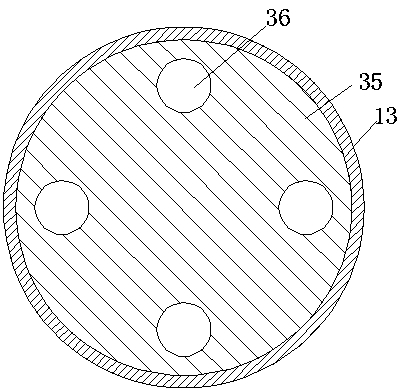

Automatic intervention device of catheter

A conduit automatic intervention device relates to a conduit delivery mechanism. The conduit automatic intervention device solves the problems that the existing continuous mode delivery mechanism has difficult force feedback and has slippage; the motor of a batch-type delivery mechanism needs frequently positive inverted alternation. Two holding jaw fixed rails are symmetrically arranged on the outside of a first fixed rail and a second fixed rail. A dovetail at the lower end of a first double rack is matched with a dovetail groove of the first fixed rail. The dovetail at the lower end of a second double rack is matched with the dovetail groove of the second fixed tail. A first half gear and a second half gear are respectively arranged on a shaft, the two ends of which are articulated with the two holding jaw fixed rails. A first holding jaw mechanism is fixedly arranged on a first connection plate and a second holding jaw mechanism is fixedly arranged on a second connection plate. The centre line of a catheter sheath is superposed with the axle center of the first holding jaw mechanism and the second holding jaw mechanism. The axle center of a tunnel body of a tube replacing mechanism is superposed with the axle center of the first holding jaw mechanism and the second holding jaw mechanism. The conduit automatic intervention device realizes the continuous delivery of the conduit and avoids the frequency starting of the motor.

Owner:HARBIN INST OF TECH

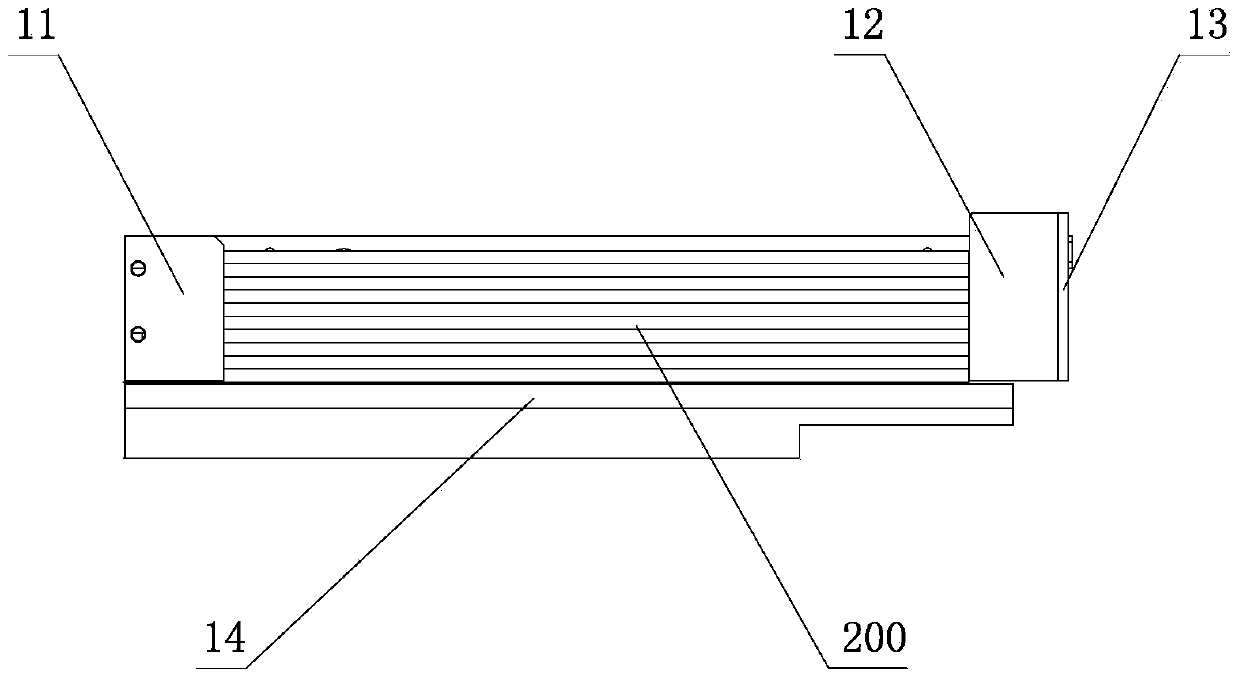

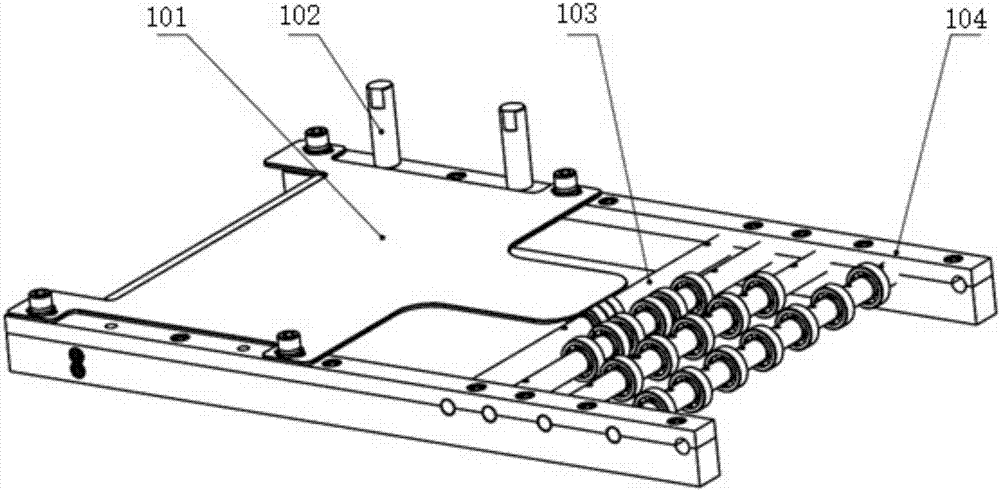

Automatic material receiving and tray assembling device of winding machine

ActiveCN103972590ARealize fully automatic loadingRealize automatic replacementAssembling battery machinesFinal product manufactureWinding machineEngineering

The invention discloses an automatic material receiving and tray assembling device of a winding machine. The automatic material receiving and tray assembling device comprises a horizontal conveying mechanism, a material-receiving mechanical arm and a material tray mechanism, wherein the material tray mechanism is arranged at one side of the horizontal conveying mechanism, the material tray mechanism is provided with two material tray placing grooves, the top of the material tray mechanism is provided with the material-receiving mechanical arm capable of moving in the three directions, the material-receiving mechanical arm comprises a first horizontal moving component, a second horizontal moving component and a vertical moving component which are sequentially connected, a material-receiving clamp is arranged at one end of the vertical moving component, close to the ground, a sucking disc mechanism capable of moving up and down is arranged at one side of the first horizontal moving component, away from a winding machine body, and a sucking nozzle for sucking a battery cell material tray is arranged on the sucking disc mechanism. According to the automatic material receiving and tray assembling device of the winding machine, the full-automatic tray charging of battery cells is realized by the material-receiving mechanical arm; the sucking disc mechanism is arranged to automatically replace the battery cell material tray; a short-circuit detection mechanism is arranged to realize the quality detection and the distinctive recovery of the battery cells.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

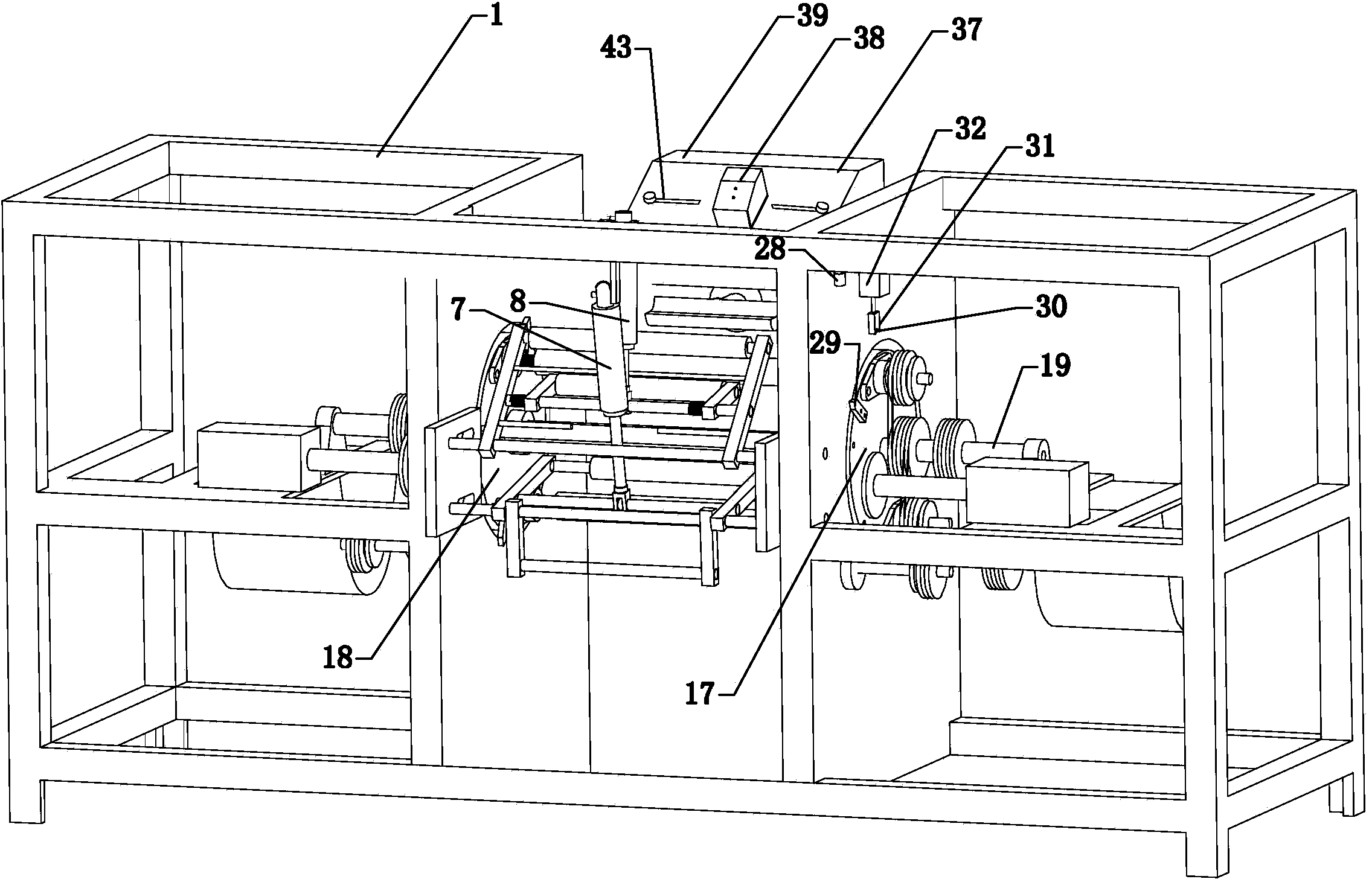

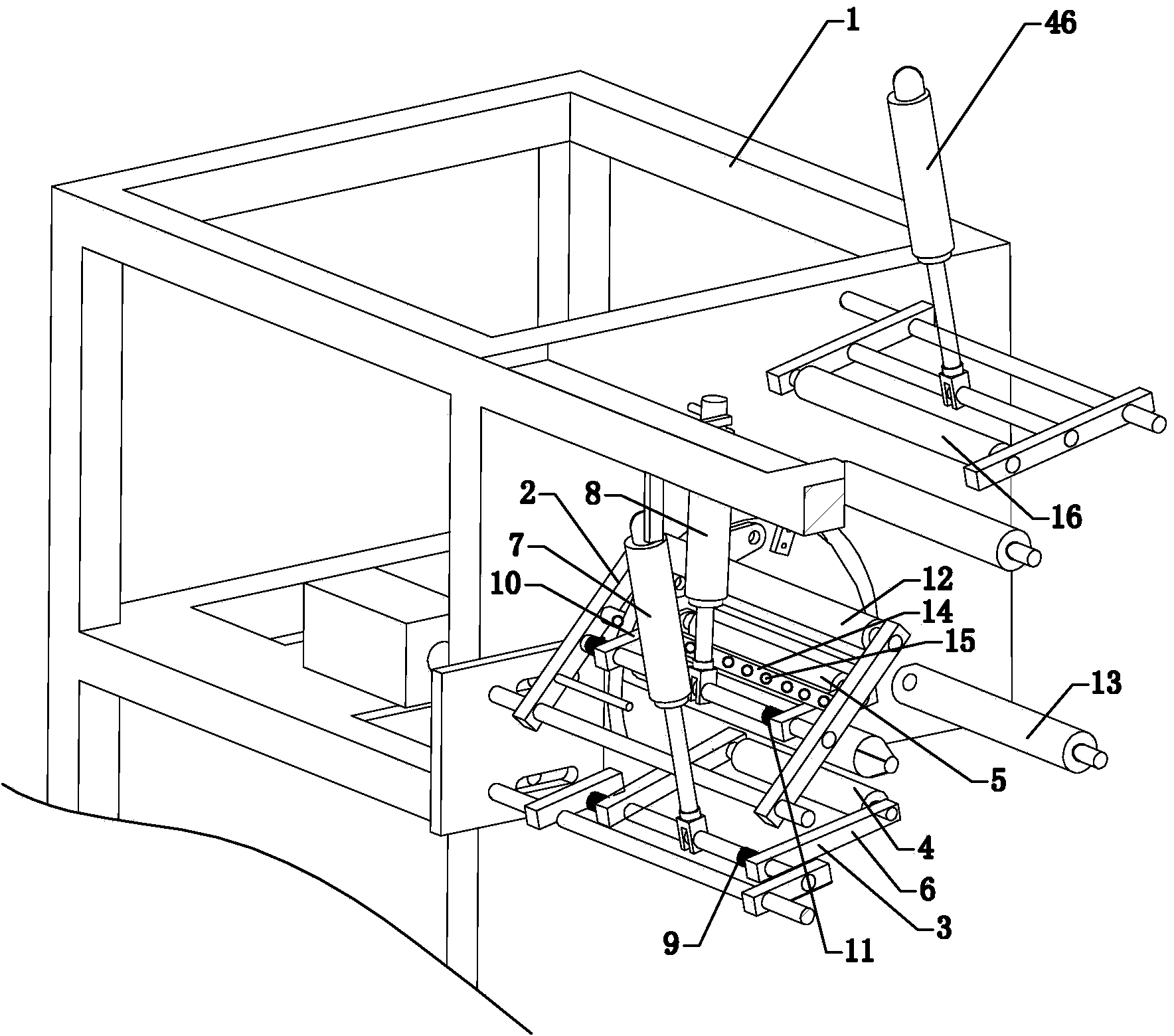

Automatic take-up and reel alternation machine for plastic bags

The invention discloses an automatic take-up and reel alternation machine for plastic bags. The automatic take-up and reel alternation machine comprises a machine frame and further comprises a reel-alternating mechanical arm, an overturning mechanism and a clamping mechanism in the conveying direction of plastic bag films. The reel-alternating mechanical arm is used for reel alternation of the plastic bag films and is installed on the machine frame. The overturning mechanism is used for making reels of the plastic bags reach a working position alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The clamping mechanism is used for clamping and dismantling the reels alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The automatic take-up and reel alternation machine for the plastic bags is used in cooperation with a bag making machine, realizes automatic take-up and reel alternation of the plastic bag films, is reliable in operation and high in automation degree, lowers the labor intensity of workers, improves the production efficiency of the plastic bag films, and greatly lowers production cost.

Owner:潍坊兴信工程项目管理有限公司

Automatic welding rod replacing device for rotor spot welding machine

ActiveCN104191119ARealize automatic replacementEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlSpot welding

The invention provides an automatic welding rod replacing device for a rotor spot welding machine. The automatic welding rod replacing device comprises a new welding rod storage clamp, a welding rod push rod mechanism, a used welding rod receiving device, a welding rod positioning device, a welding rod clamping seat and a tightening device. The new welding rod storage clamp is used for storing standby welding rods; the welding rod push rod mechanism is used for pushing welding rods to a welding required position; the used welding rod receiving device is used for collecting incompletely used welding rods; the welding rod positioning device is used for positioning welding rods; the welding rod clamping seat is used for clamping the welding rods during welding to prevent the welding rods from slipping; the tightening device is used for tightening or loosening a fixing device on the welding rod clamping seat. By the automatic welding rod replacing device, the problems of demounting of the used welding rods, storage and discharging of new welding rods, positioning and clamping of the new welding rods, spot welding count setting and automatic control of the whole process are solved, automatic replacing and clamping of the welding rods can be realized without manual intervention, automation degree is greatly improved, labor intensity is relieved, uniformity in clamping of the welding rods can be guaranteed, and production efficiency is improved.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

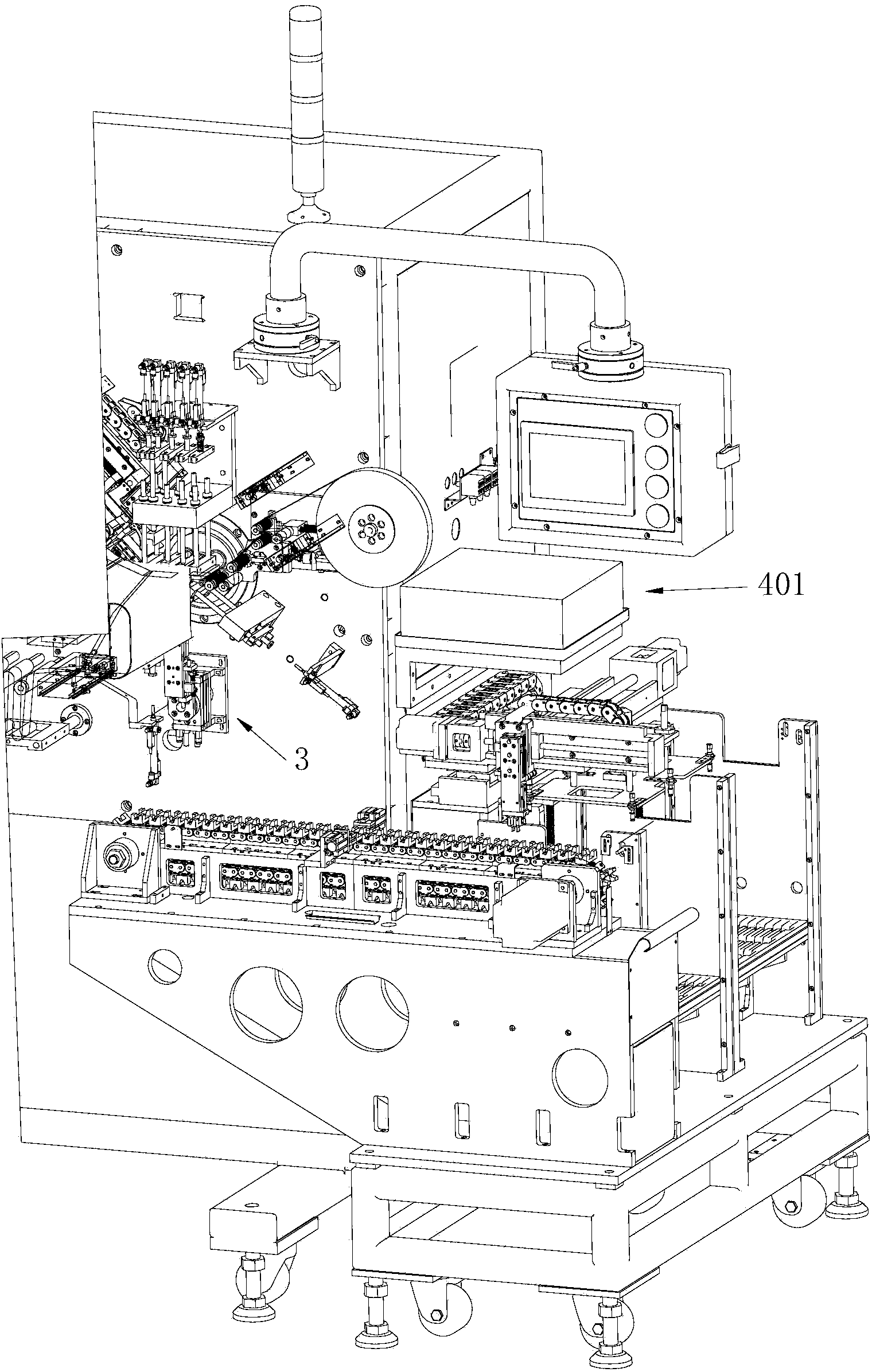

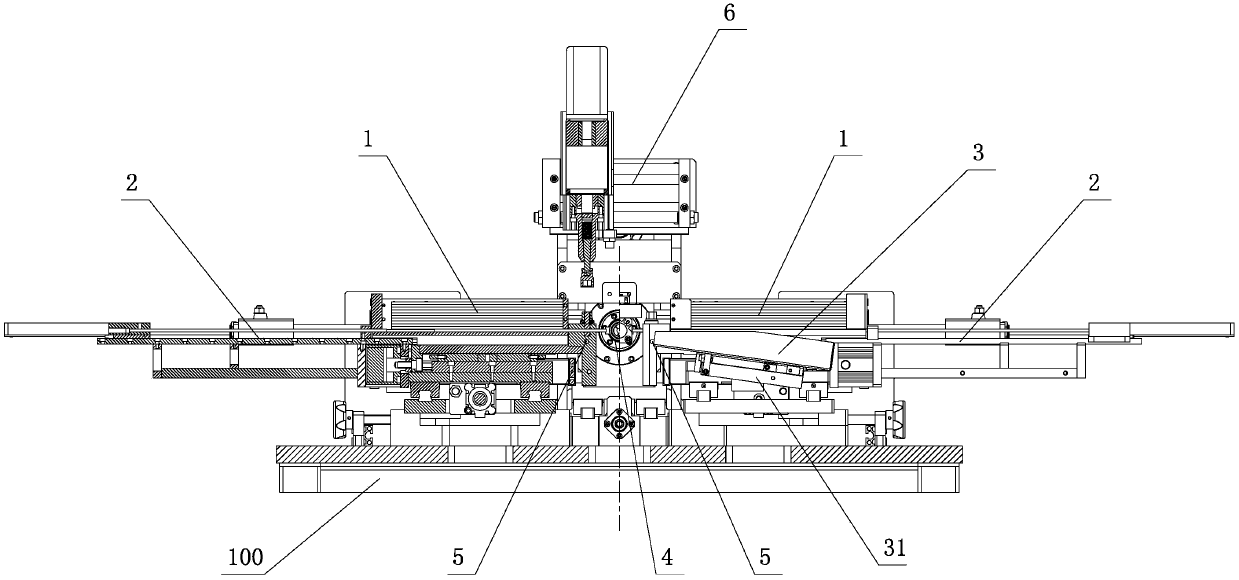

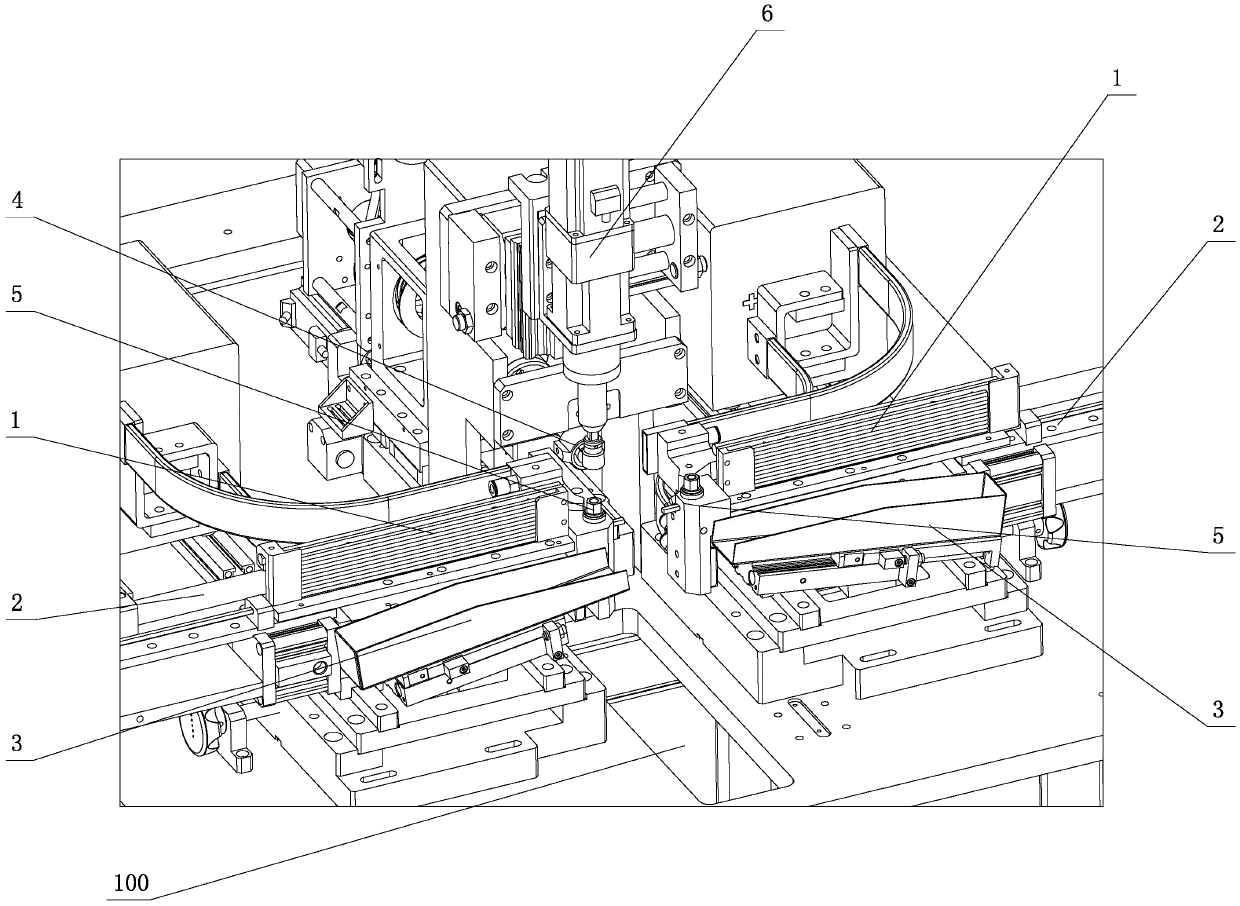

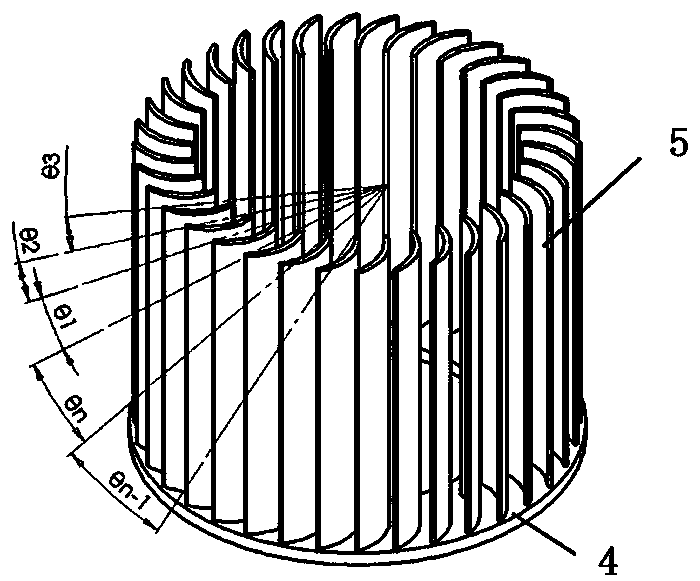

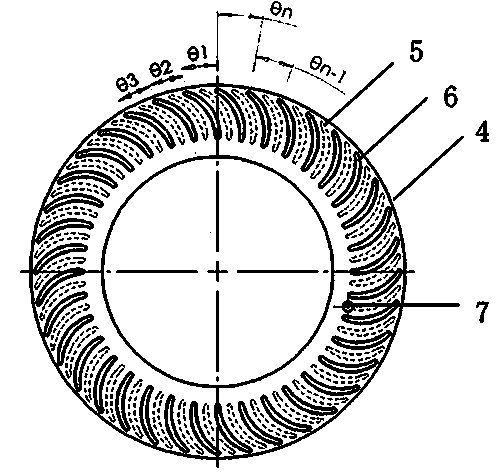

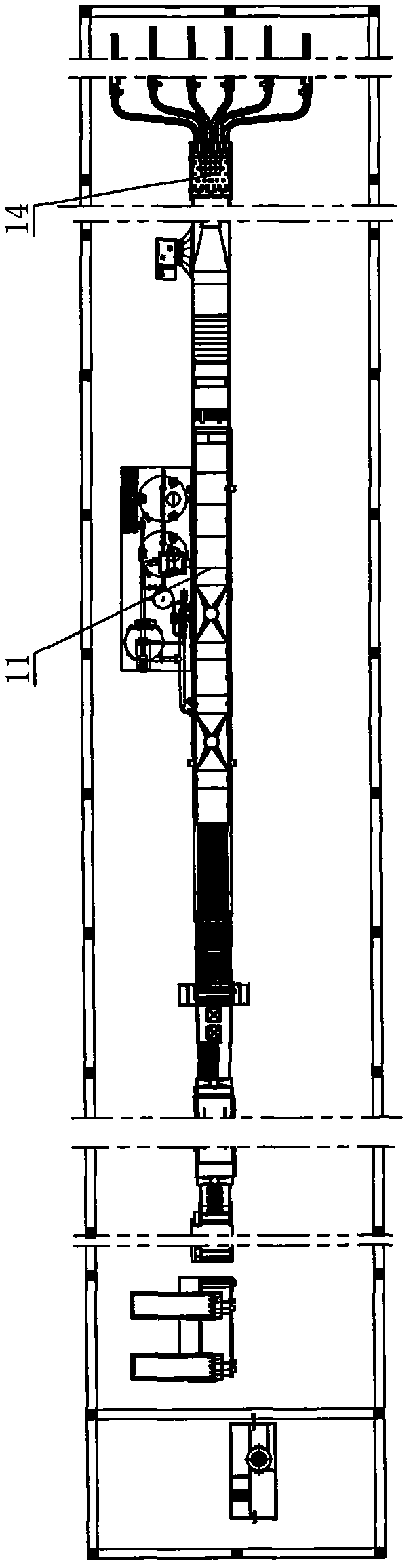

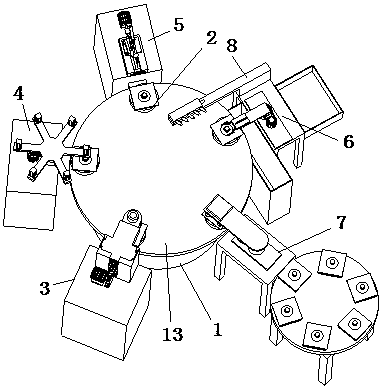

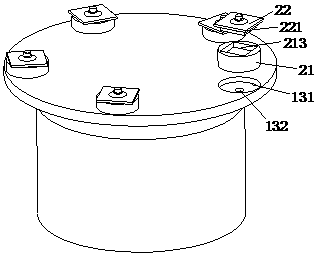

Cross-flow fan blade welding robot

The invention discloses a cross-flow fan blade welding robot. The cross-flow fan blade welding robot comprises a material distribution and conveying module, a material grabbing mechanical arm, a pre-positioning module, a feeding module, an ultrasonic welding machine and a material receiving module; the welding robot is used for conveying a workpiece to the material grabbing mechanical arm through the material distribution and conveying module and is primarily shaped and self-centered through being clamped by three clamping claws; then the workpiece is conveyed into the pre-positioning module to realize eight-clamping-claw clamped self-centering and rotary alignment of positioning marks; four-clamping-claw clamped self-centering, compensation of translation errors and rotary angle errors, and blade embedment of soft landing and rotary search are realized by the feeding module, and furthermore, the welding is finished in an ultrasonic welding machine through the clamping self-centering and the clamping force control of four guide rods, two-grade type welding head movement and a digital power supply driven ultrasonic transducer; then the material receiving module is used for taking out a welded finished product and conveying the welded finished product to a material storage belt line. The cross-flow fan blade welding robot has the advantages of rapid welding period, low noises, high yield, short line exchanging time, online real-time quality monitoring, stability and reliability in operation and the like.

Owner:SHENZHEN SIJIECHUANG TECH CO LTD

Intelligent abrasive paper replacing device for robot grinding and polishing

PendingCN107199508ARealize automatic replacementReduce labor costsGrinding wheel securing apparatusEmery paperMoving parts

The invention provides an intelligent abrasive paper replacing device for robot grinding and polishing. The intelligent abrasive paper replacing device comprises an abrasive paper removing device and an abrasive paper pasting device; the abrasive paper removing device comprises a cut-in plate, a parallel bearing mechanism and a frame structure, wherein the cut-in plate and the parallel bearing mechanism are connected to the frame structure, and the cut-in plate is provided with a cut-in opening used for being inserted between a polishing machine and abrasive paper; the abrasive paper pasting device comprises an imitated model storing mechanism, a detection mechanism and a sliding block guide rail mechanism, wherein the imitated model storing mechanism comprises an abrasive paper check ring, a lower supporting plate, a supporting rod, a tray and an installing plate, the supporting rod is connected between the abrasive paper check ring and the lower supporting plate to form a moving part to be connected to the sliding block guide rail mechanism, the tray is located between the abrasive paper check ring and the lower supporting plate and connected to the installing plate, and then a static part is formed, and the moving part downwards moves according to a resultant force of self gravity and friction force of a sliding block and a guide rail in the guide rail sliding block mechanism. According to the intelligent abrasive paper replacing device for robot grinding and polishing, automatic replacement of abrasive paper can be achieved, dependence of abrasive paper replacement on people is reduced, and the enterprise labor cost is reduced.

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

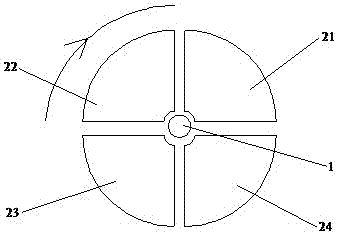

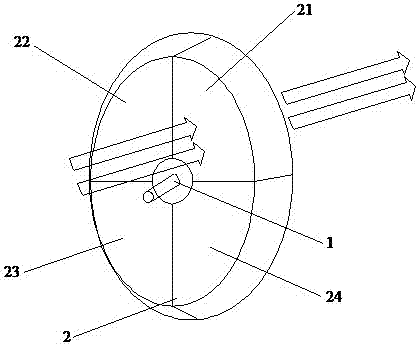

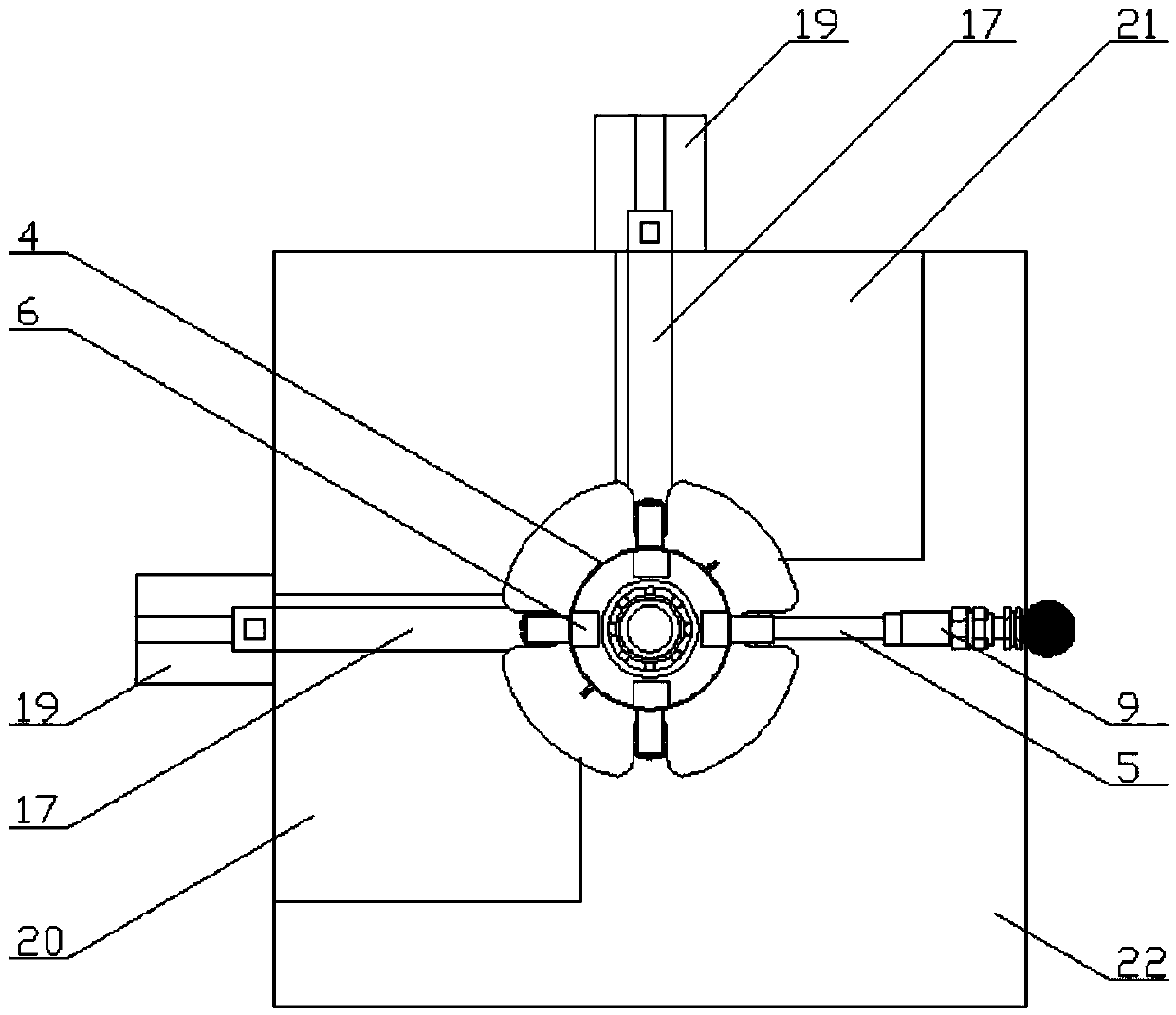

Rotary filter net replacement device

InactiveCN107166623AReasonable designRealize automatic replacementLighting and heating apparatusSpace heating and ventilation detailsFresh airControl theory

The invention relates to the technical field of fresh air systems, in particular to a rotary filter net replacement device. The rotary filter net replacement device is arranged in a ceiling suspended fresh air ventilator and composed of servo motors and four sector-shaped efficient filter nets driven by the servo motors. The four sector-shaped efficient filter nets are arranged into a circle. Panels on the front side and the rear side of one of the sector-shaped efficient filter nets are provided with an air inlet and an air outlet separately. A fresh air duct is formed between the air inlet and the air outlet. The rotary filter net replacement device is reasonable in design, and the efficient filter nets can be replaced automatically under driving of the servo motors when in need instead of being manually replaced by operation workers, so that labor is greatly reduced, and the work efficiency is improved.

Owner:山东泰朗禾通风设备有限公司

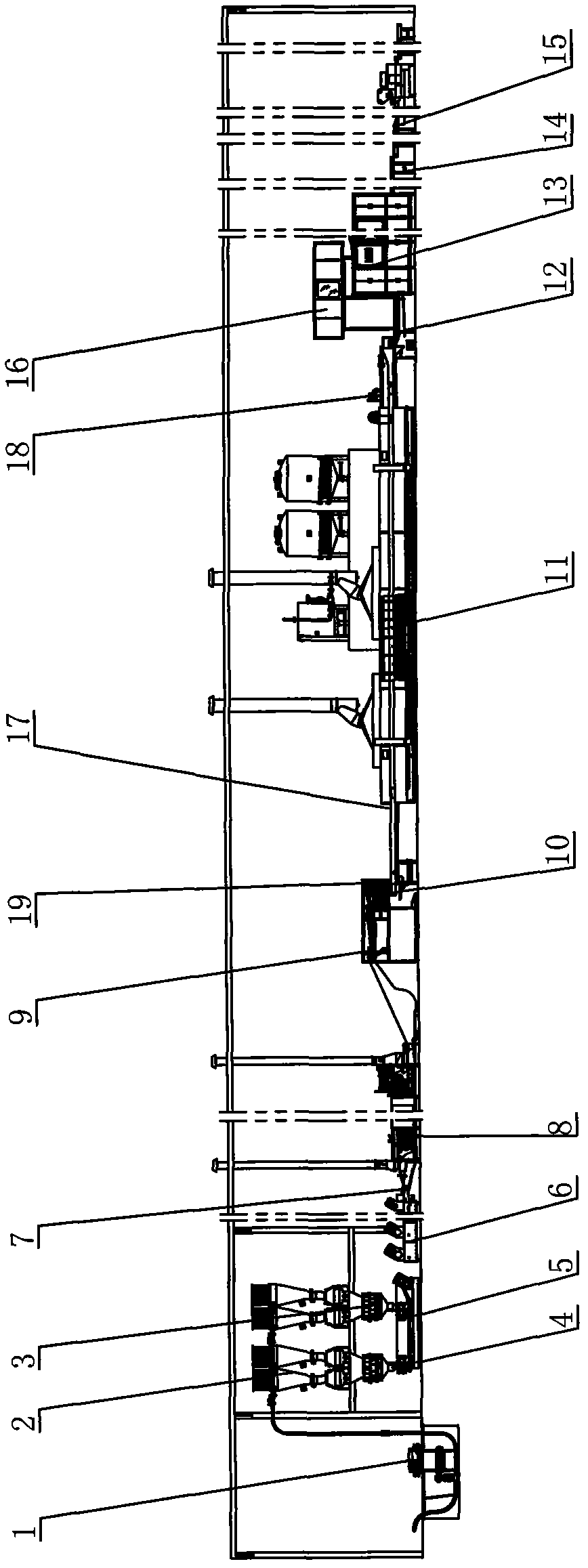

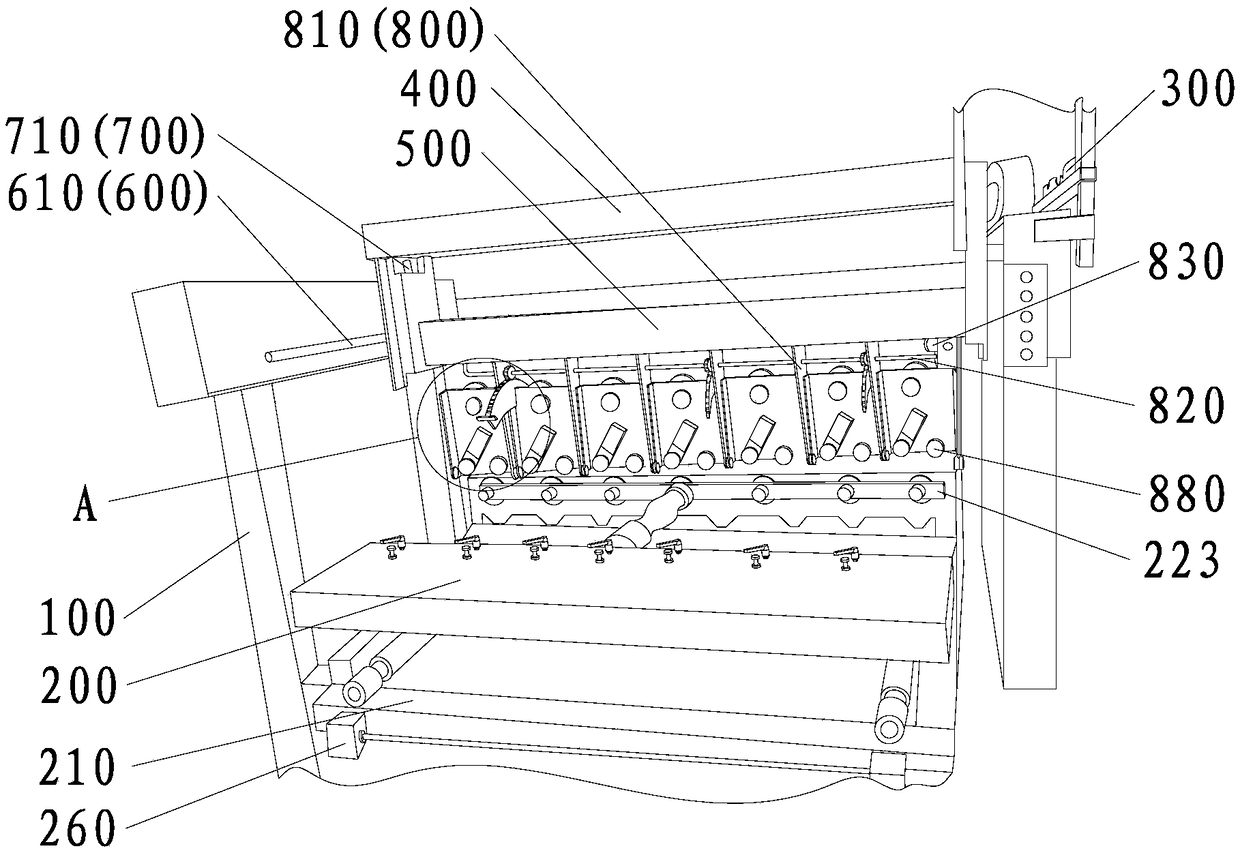

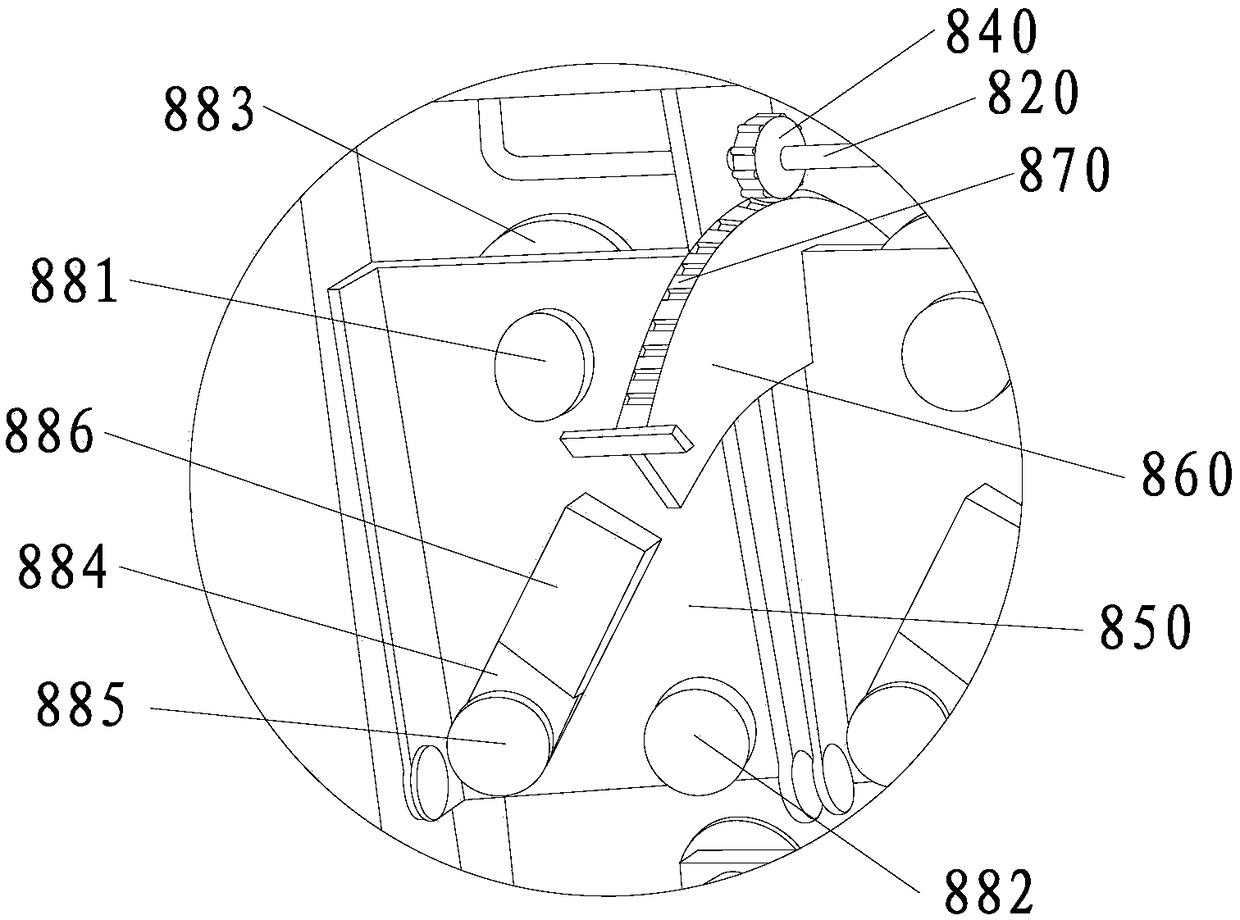

Steel wire rust removal production line and rust removal process

InactiveCN110936274AReduce pollutionImprove rust removal efficiencyGrinding carriagesMetallic material coating processesManufacturing lineManufacturing engineering

The invention relates to a steel wire rust removal production line and a rust removal process. The production line comprises an uncoiling machine, a rust removal device and a coiling machine which aresequentially arranged in the running direction of the production line, wherein a steel wire penetrates through the uncoiling machine, the rust removal device and the coiling machine in sequence, andthe uncoiling machine is used for pulling the steel wire to be straight and pull the steel wire into the rust removal device and performing preliminary rust removal treatment on the surface of the steel wire; the rust removal device is used for further processing the surface of the steel wire; and the coiling machine is used for coiling the steel wire subjected to rust removal treatment. The rustremoval production line and the rust removal process are small in pollution and high in rust removal efficiency.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

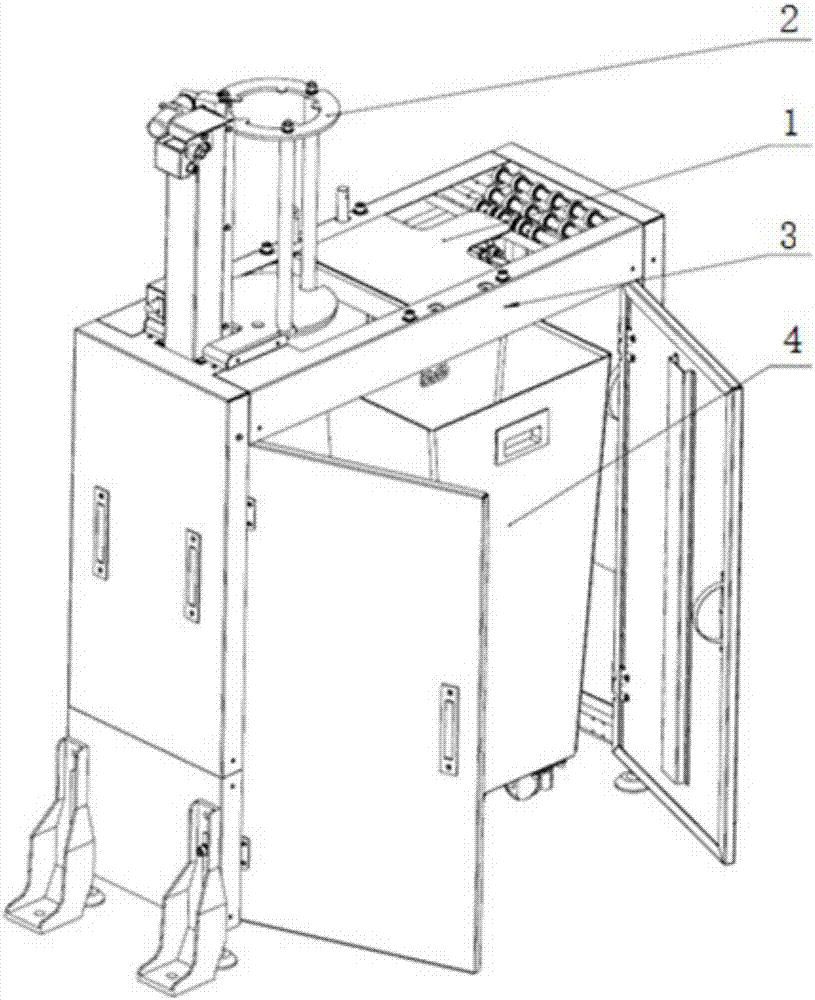

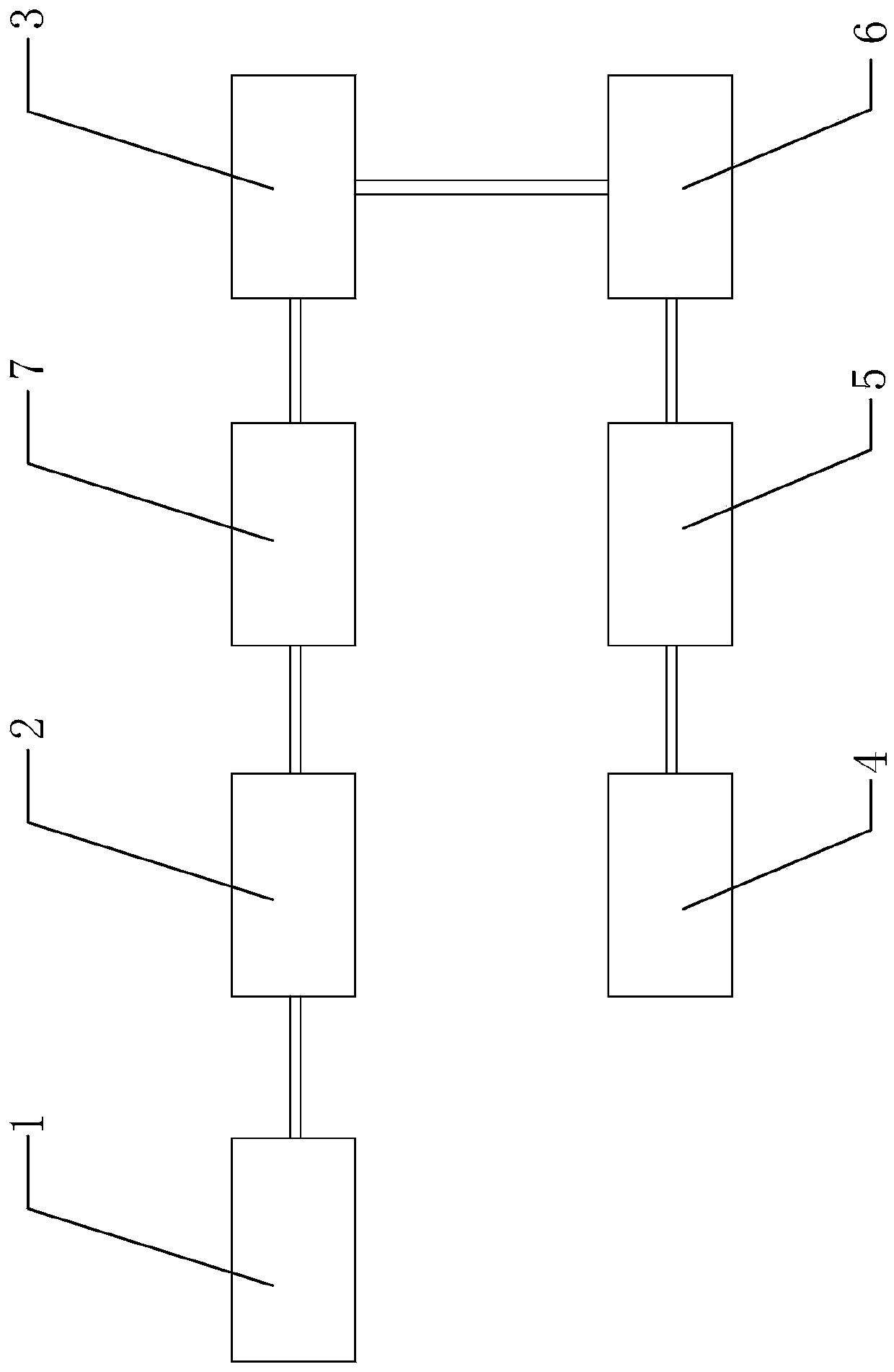

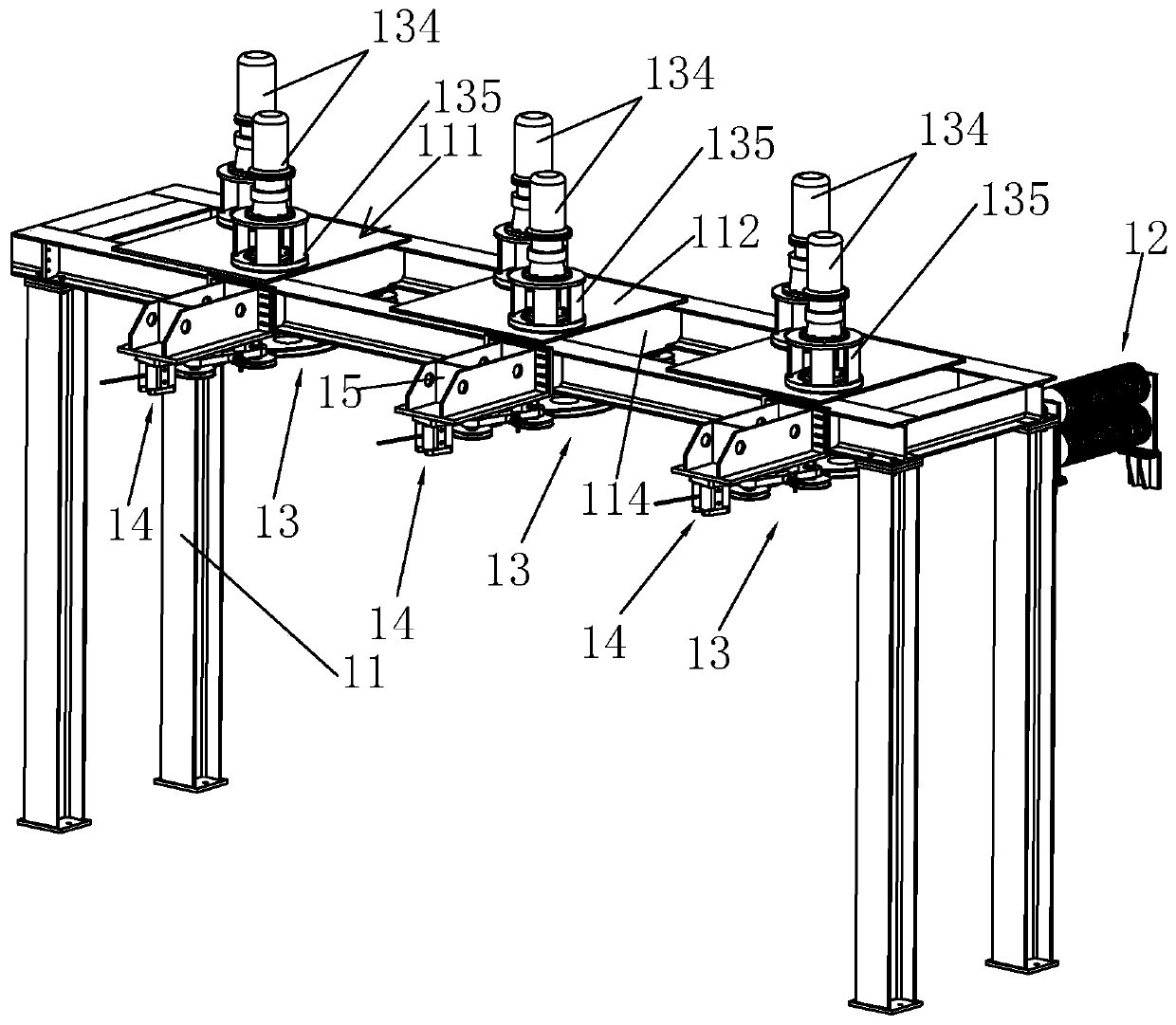

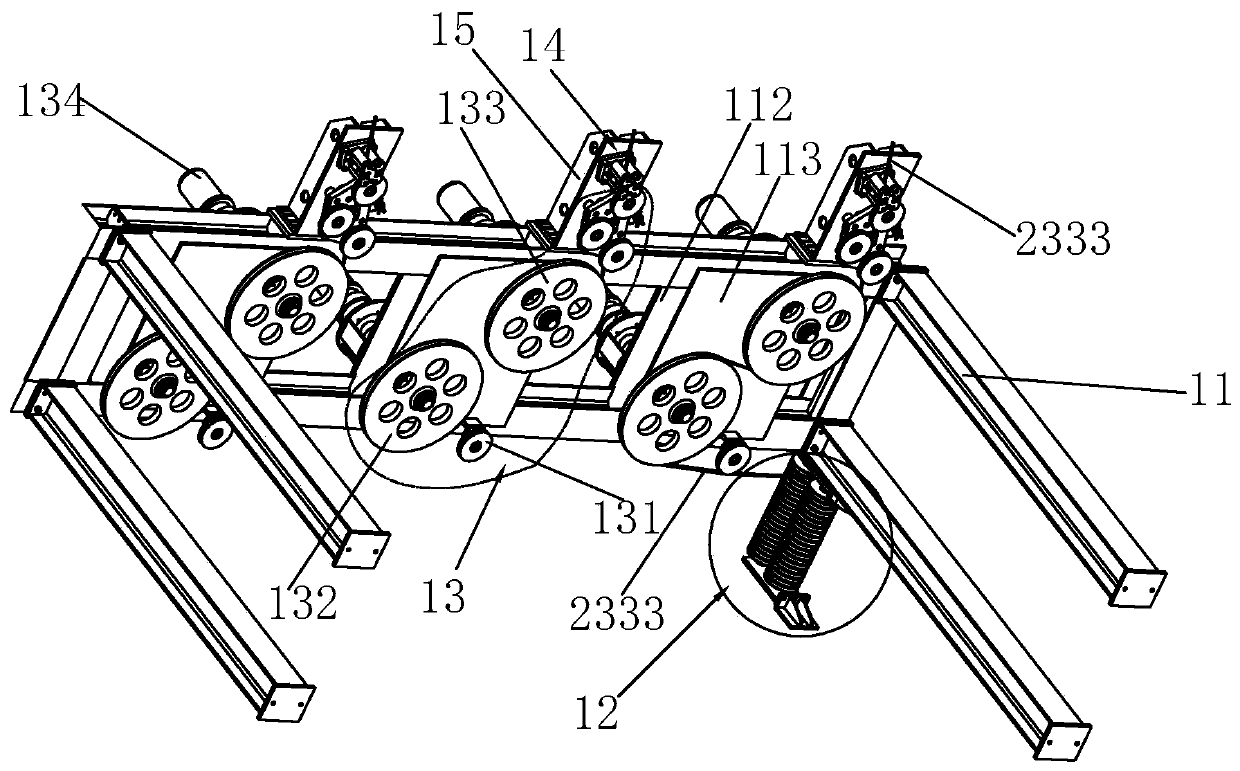

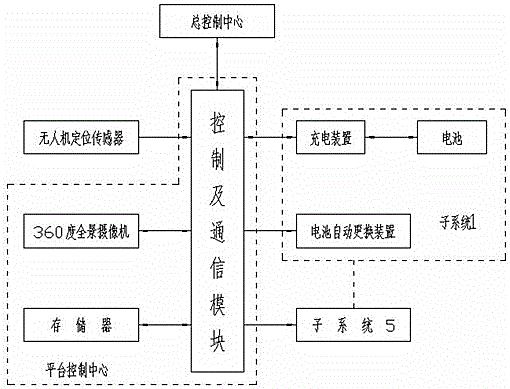

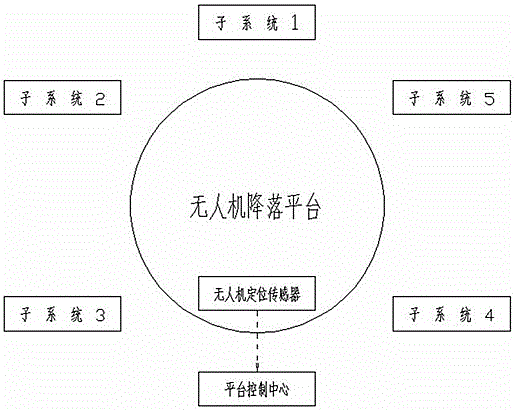

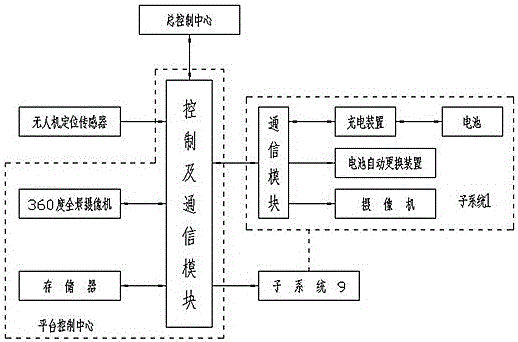

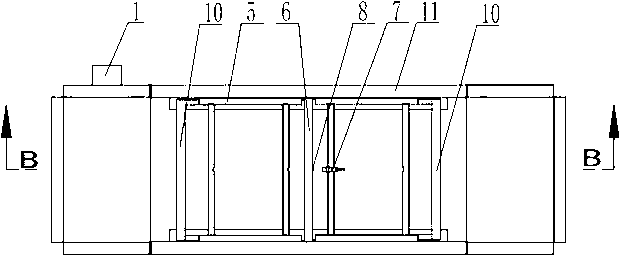

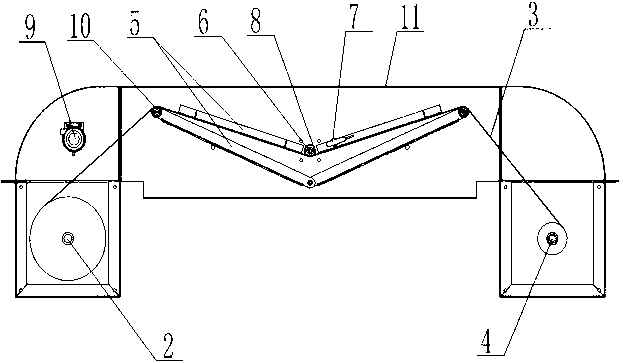

Unmanned aerial vehicle battery automatic exchange, data transmission and fault detection platform

InactiveCN106218912ARealize automatic replacementFully automatedGround installationsComputer moduleUncrewed vehicle

The invention discloses an unmanned aerial vehicle battery automatic exchange, data transmission and fault detection platform which is savable in time and effort and capable of effectively prolonging the endurance time and improving the working efficiency. The unmanned aerial vehicle battery automatic exchange, data transmission and fault detection platform is provided with a platform control center communicating with a master control center, and a plurality of subsystems are connected to the platform control center. The platform control center is provided with a control and communication module, and a memory and a 360-degree panoramic camera are connected to the control and communication module. Each subsystem is provided with a charging device and a battery automatic exchange device which are connected with the control and communication module. The output end of each charging device is connected with a battery. An unmanned aerial vehicle landing platform is provided with an unmanned aerial vehicle positioning sensor. The output end of the unmanned aerial vehicle positioning sensor is connected with the control and communication module.

Owner:CHINA HUALU PANASONIC AVC NETWORKS

Scroll filter and automatic control method thereof

ActiveCN103301691ARealize automatic replacementAvoid completenessDispersed particle filtrationLighting and heating apparatusAutomatic controlControl signal

The invention discloses a scroll filter and an automatic control method thereof. The scroll filter comprises a driving scroll for installing a scroll motor and a driven scroll for installing filtering cotton, and the scroll filter also comprises a support, wherein the filtering cotton is drawn out from the driven scroll and then is wound onto the driving scroll after passing through the support, the support is provided with a rolling rod, magnetic steel of a hall sensor is installed on the rolling rod, a probe of the hall sensor which is installed on the rolling rod is fixed on the support, and the scroll filter also comprises a controller, an output signal of the hall sensor is transmitted to the controller to be used as a control signal of the controller for controlling the scroll motor. The pressure difference on two side surfaces of the filtering cotton is used as a condition for starting the scroll motor, a sensing count of the hall sensor is used as a condition for stopping the scroll motor, so that whether the filtering cotton is clogged and can be normally used or not can be reversed, the sensing count of the hall sensor is used as a condition for judging a replacement length, so that the filtering cotton can be prevented from being half replaced or incompletely replaced.

Owner:CHENGDU HOP ENVIRONMENTAL PROTECTION TECH

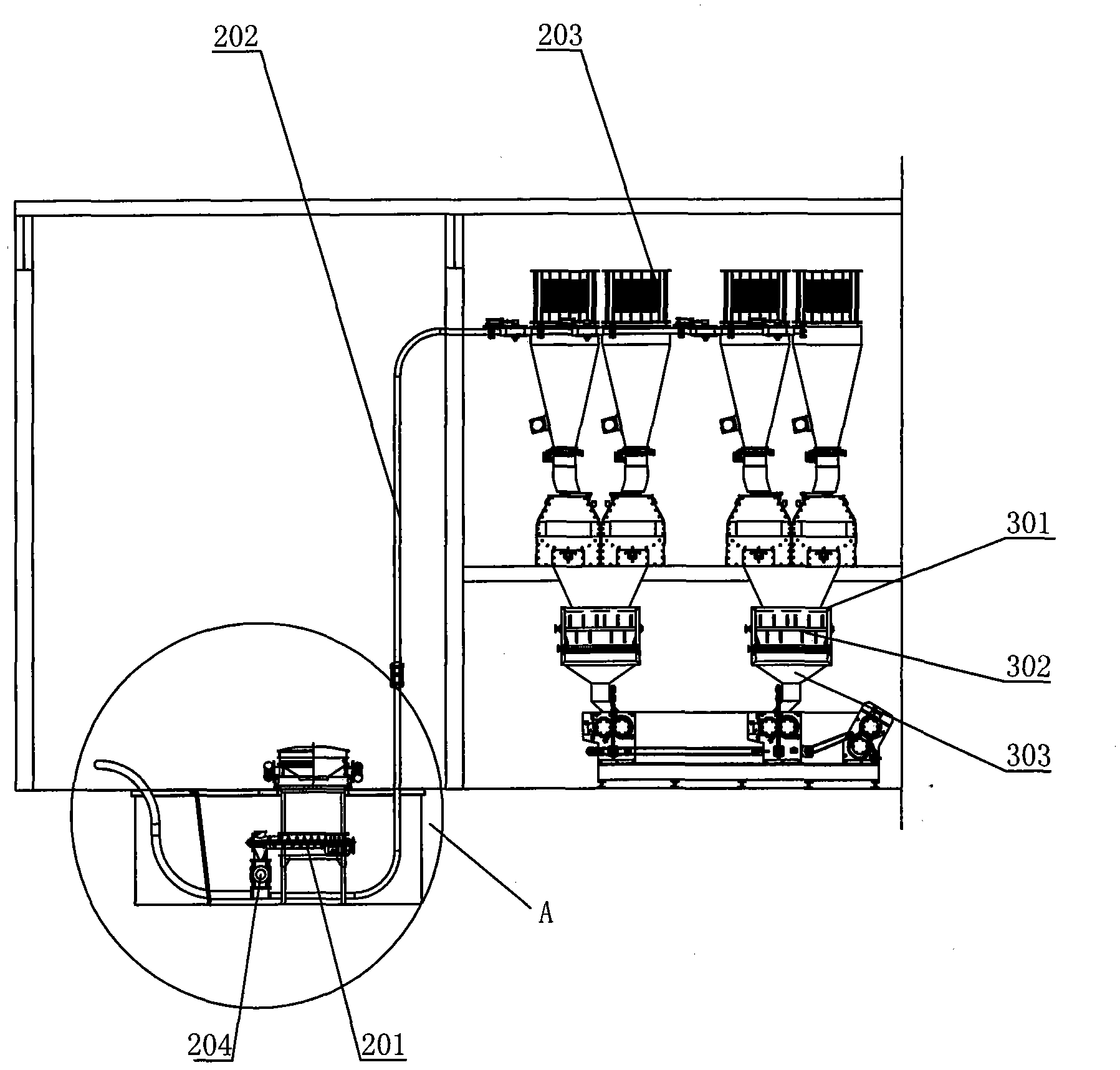

Production line and process of fried straight noodles

InactiveCN102144749AEasy to replaceImprove cleanlinessOil/fat bakingDough shaping and cutting apparatusProduction lineEngineering

The invention relates to a production line and a production process of fried straight noodles. The production line comprises a flour sieving and filtering machine, a flour air blower, a powder liquid mixing machine, a dough curing and conveying machine, a composite noodle press, a continuous noodle press, a shredding forming machine, a noodle steaming machine, a dry method differential fluffer, avibrating fluffer, a quantitative cut-off falling machine, a noodle oil-pouring machine, a frying machine, a dough deoiling machine, an arraying machine, an air cooled machine, a distributing conveyor and a packaging conveyer which are arranged sequentially. The production process comprises the following steps of: sieving and filtering flour; pneumatically conveying the flour; mixing powder and liquid; curing and conveying dough; performing composite noodle press; performing continuous noodle press; shredding and forming; steaming noodles; loosening the noodles by a dry method; loosening the noodles in a vibrating mode; quantitatively cutting off the noodles, so that the noodles fall into a box; pouring oil on the noodles; frying the noodles; deoiling the paste; arraying the noodles; performing air cooling; performing distributed conveying; and performing packaging conveying. By the production line and the production process of the fried straight noodles, the production efficiency is high; various types of noodles cam be produced on one production line; and the produced noodles are healthful and delicious.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

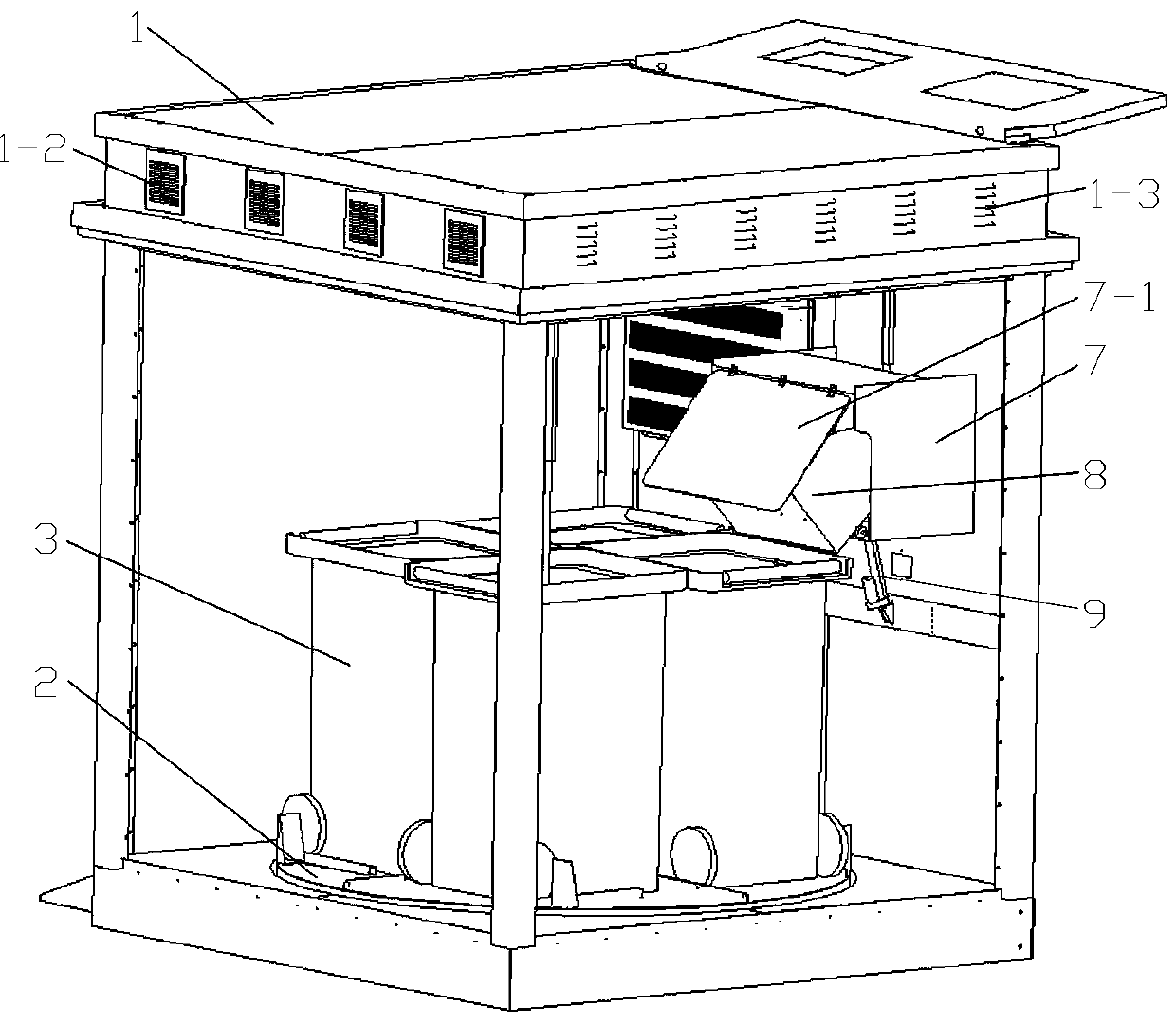

Intelligent garbage chamber with automatic dustbin replacing function

PendingCN111301902AIncrease capacity to accommodate recycling wasteEasy to placeRefuse receptaclesComputer hardwareAutomatic control

The invention discloses an intelligent garbage chamber with an automatic dustbin replacing function. The intelligent garbage chamber comprises a shell, and a dumping opening is mounted in the front face of the shell. A rotary disc for containing a dustbin is mounted on a bottom plate in the shell, and the rotary disc can rotate relative to the bottom plate. The rotary disc is of a round structure,and multiple separation tables are arranged on the rotary disc. The separation tables are arranged outwards from the center of the rotary disc, and divide the upper end face of the rotary disc into multiple independent areas. An outer blocking part is arranged in each independent area, the outer blocking parts are parallel to the separation tables, and a containing area for positioning and containing the dustbin is formed. A movable door mechanism is arranged on the dumping opening, and comprises a movable baffle arranged on the dumping opening and a baffle push rod motor for controlling themovable baffle to be opened and closed. The device is simple and reasonable, the rotary disc is high in stability, operation by a user is safe, easy and convenient, and automatic control over dustbinreplacement of the garbage chamber can be achieved.

Owner:HENAN TONGDA MULTIMEDIA MAKING

Multistation gradient film coating equipment

InactiveCN101985736ACommon axis of symmetryEliminate radial disturbanceVacuum evaporation coatingSputtering coatingBiochemical engineeringFilm-coated tablet

The invention belongs to the field of vacuum coating equipment, in particular relating to a multistation gradient film coating equipment, which comprises a driving module, a base plate (8), a workpiece disc (7), a mask mechanism (10) and a balancing mechanism (11), wherein the workpiece disc (7) is arranged on the base plate (8), can rotate around the axis thereof, and has a constant gap with the base plate (8); the workpiece (7) is fixedly provided with a coating station; a coating hole is arranged on the position of the base plate (8) corresponding to the coating station; the mask mechanism (10) is fixedly arranged between the coating station and the coating hole; the balancing mechanism (11) is fixedly arranged on the base plate (8) at the lower part of the coating hole; and the working end of the driving module is fixedly connected with the workpiece disc (7). The coating equipment of the invention can realize steady and accurate rotation transformation for stations (chips to be coated), and improve the product quantity coated by single vacuumization, thus improving the production efficiency of the whole system.

Owner:SHENYANG ACAD OF INSTR SCI

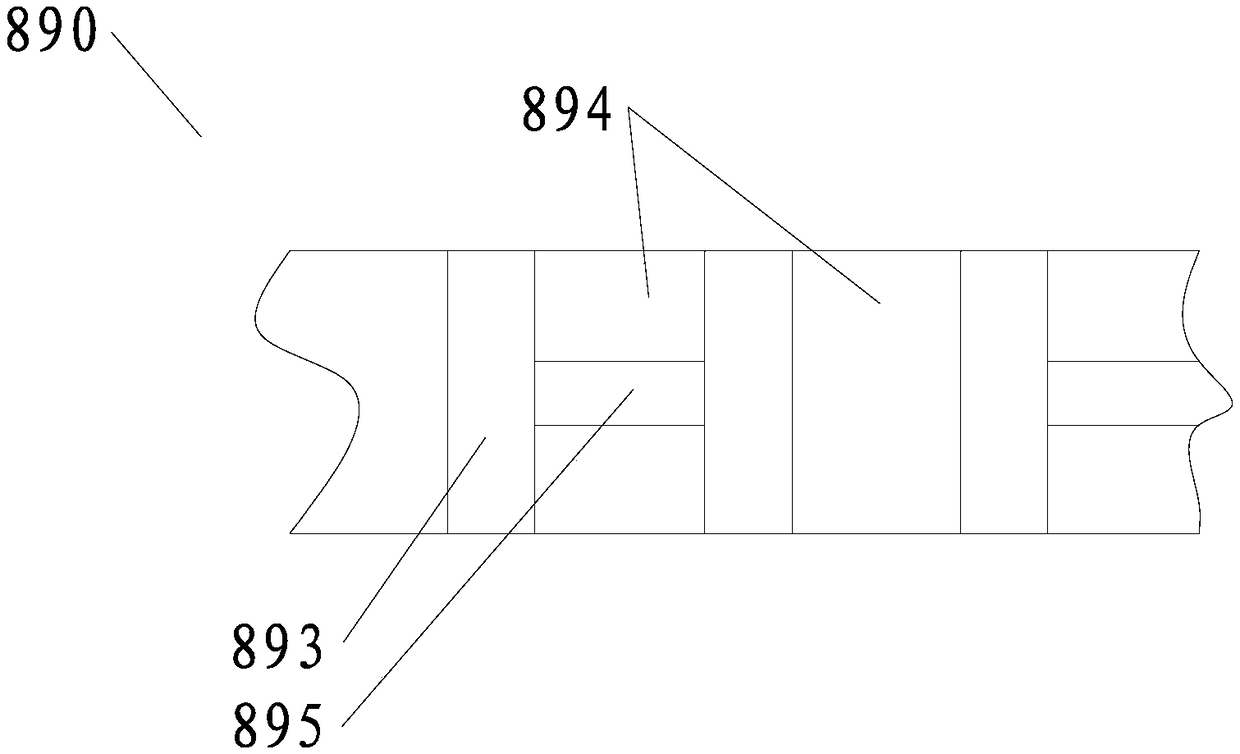

Automatic sandpaper switching mechanism for pneumatic grinding and polishing machine

PendingCN107283288ARealize automatic replacementNo manual operationGrinding machine componentsPolishing machinesMechanical engineeringSandpaper

The invention discloses an automatic sandpaper switching mechanism for a pneumatic grinding and polishing machine. The automatic sandpaper switching mechanism comprises a new sandpaper storage cylinder and an old sandpaper detaching cutter located beside the new sandpaper storage cylinder. A sandpaper conveying air cylinder for pushing sandpaper in the new sandpaper storage cylinder upwardly is arranged below the new sandpaper storage cylinder. The upper end of a new sandpaper discharging cylinder is open. According to the automatic sandpaper switching mechanism for the pneumatic grinding and polishing machine, by arranging the new sandpaper storage cylinder, the old sandpaper detaching cutter and the sandpaper conveying air cylinder for pushing the sandpaper in the new sandpaper storage cylinder upwardly, a robot moves a grinding and polishing head to the front of the old sandpaper detaching cutter, the robot moves slowly, the robot moves to the portion over new sandpaper after old sandpaper is torn down by the old sandpaper detaching cutter, the sandpaper is pressed on the grinding and polishing machine by the sandpaper conveying air cylinder, the robot moves away, and pasting of the new sandpaper is completed; and the robot continuously conducts grinding and polishing, and after the grinding and polishing are conducted multiple times, the actions mentioned above are repeated. By the adoption of the automatic sandpaper switching mechanism for the pneumatic grinding and polishing machine, automatic replacement of the sandpaper is achieved, no manual operation is needed, and the potential safety hazards existing in the prior art are solved.

Owner:GUANGZHOU LASEN INTELLIGENCE TECH CO LTD

Environment-friendly rubber O-shaped ring material processing device

InactiveCN110815676APrevent fallingRealize automatic trimming operationDomestic articlesMetal working apparatusCouplingElectric machinery

The invention relates to the field of rubber O-shaped ring machining equipment, in particular to an environment-friendly rubber O-shaped ring material processing device. The environment-friendly rubber O-shaped ring material processing device comprises a processing table, wherein a first coupling seat is arranged at the top of the processing table, the top of the first coupling seat is provided with a vertically arranged first rotating shaft, a first rotating disc coaxial with the first rotating shaft is arranged at the top of the first rotating shaft, and five fixing fixtures evenly distributed in the circumferential direction of the first rotating disc are arranged on the first rotating disc; a stepping motor is arranged in the processing table, and the output end of the stepping motor is connected with the first coupling base; and a feeding mechanism, a material pressing mechanism, an edge trimming mechanism, a discharging mechanism and a jig replacing mechanism are sequentially arranged in the rotating direction of the first rotating disc, and a waste cleaning mechanism is arranged on the discharging mechanism. According to the environment-friendly rubber O-shaped ring materialprocessing device, automatic edge trimming work is carried out on rubber O-shaped rings, a jig can be automatically replaced without shutdown, and the edge trimming efficiency of the rubber O-shapedrings is improved.

Owner:王伟

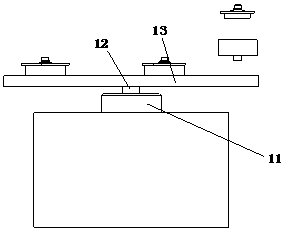

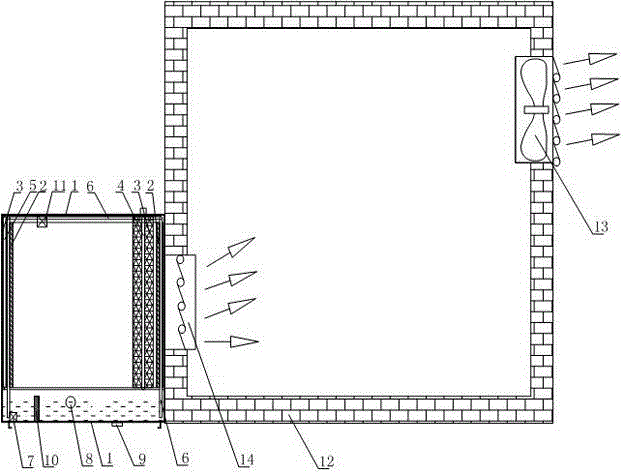

Machine room evaporation, refrigeration and heat-extraction system and implementation method

ActiveCN103335372AReduce power consumptionReduce the temperatureSpace heating and ventilation safety systemsLighting and heating apparatusCold airFiltration

The invention discloses a machine room evaporation, refrigeration and heat-extraction system and an implementation method. The machine room evaporation, refrigeration and heat-extraction system comprises an evaporation and cooling device and a heat-extraction device, where in the evaporation and cooling device and the heat-extraction device are arranged in a machine room. The machine room evaporation, refrigeration and heat-extraction system further comprises a control system controlling the evaporation and cooling device and heat-extraction device. A power-driven air valve is arranged on an output port of the evaporation and cooling device. The method includes a heat-extraction step, a water circulation control step and a filtration cotton replacement control step. According to the machine room evaporation, refrigeration and heat-extraction system and the implementation method, outdoor air temperatures are further lowered through filtration and evaporation cooling treatment, then outdoor cold air after being evaporated and cooled is absorbed naturally, and therefore the purposes of cooling the machine room and reducing power consumption for machine room cooling are achieved; types of power consumption of a machine room air conditioner mainly comprises compressor power consumption, evaporator fan power consumption, condenser fan power consumption and controller power consumption in the prior art, and the air conditioner compressor power consumption occupies 80-90% of the air conditioner total power consumption. The machine room evaporation, refrigeration and heat-extraction system can be used for machine room air conditioner cooling all year around.

Owner:CHENGDU HOP ENVIRONMENTAL PROTECTION TECH

Automatic wild animal hair collecting device for narrow path

InactiveCN105532500AUnlimited sizeGuaranteed purityOther apparatusGrooming devicesAutomatic controlHair streams

The invention provides an automatic wild animal hair collecting device for a narrow path, and belongs to wild animal studying equipment. According to the device, a base, a collecting hand storage box with hair, a standby collecting hand storage box, a horizontal sliding rail, an electromotor, a sensor, a power supply and an automatic control assembly are installed on a bottom seat, an assembling and disassembling assembly composed of an upper assembling and disassembling hand, a lower assembling and disassembling hand and a stand column is assembled on the horizontal sliding rail, a main shaft is assembled on the base, a rotating barrel assembled with stepping motors and mechanical arms is installed on the main shaft, and a hair collecting part composed of a collecting hand and a rubber thorn ball is installed on each mechanical arm. The collecting device is high in automation degree, good in sampling effect, free of harm to wild animals, high in applicability and capable of saving manpower resources.

Owner:NORTHEAST FORESTRY UNIVERSITY

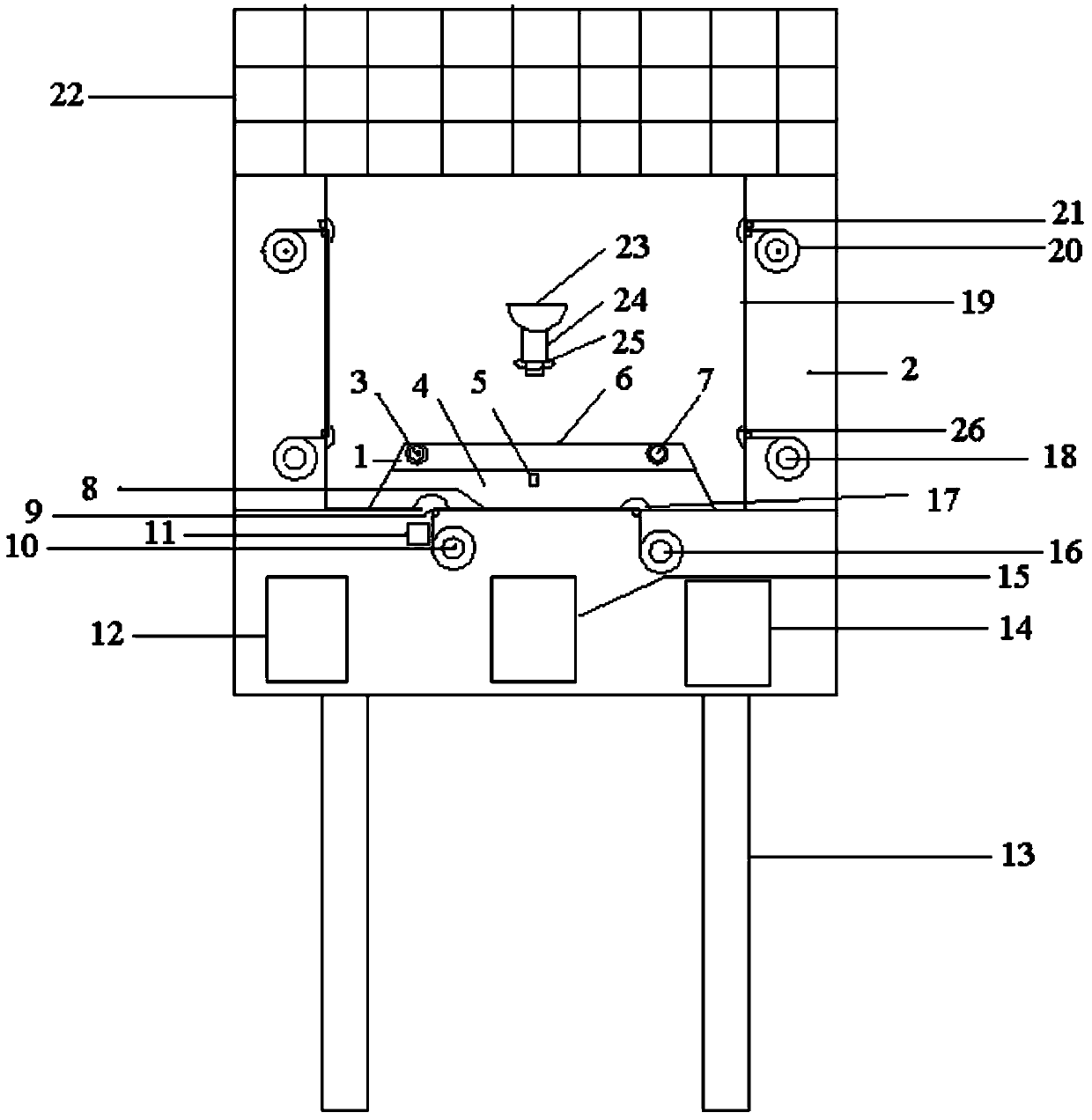

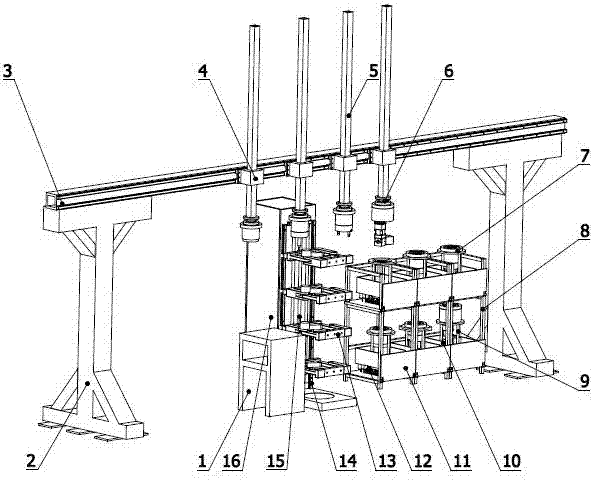

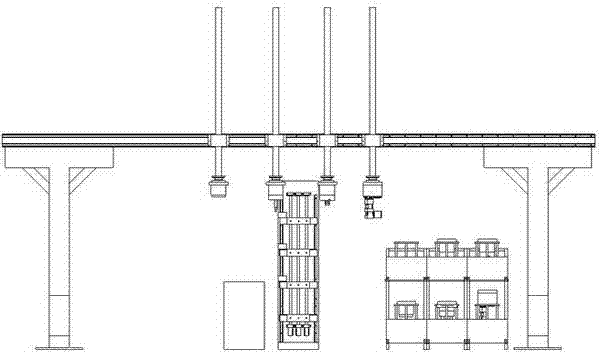

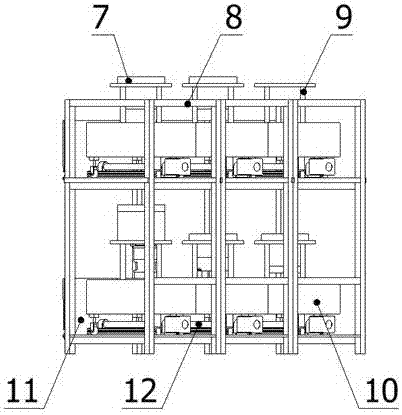

Flexible assembly system based on intelligent end effector

PendingCN106863326ACompact structureAccurate detectionProgramme-controlled manipulatorAssembly machinesAssembly lineAssembly systems

The invention belongs to the application field of assembly automation, and particularly relates to a flexible assembly system based on an intelligent end effector. The flexible assembly system comprises a part placing table, a truss robot, a work head library and a fixed work table, wherein the part placing table, the fixed work table and the work head library are arranged side by side, and the truss robot is located above the part placing table, the fixed work table and the work head library. According to the flexible assembly system, a large mechanical product is assembled through the truss robot, the work head library and the like, and the flexible assembly system is compact in structure compared with a traditional assembly line type assembly line.

Owner:中国东方电气集团有限公司

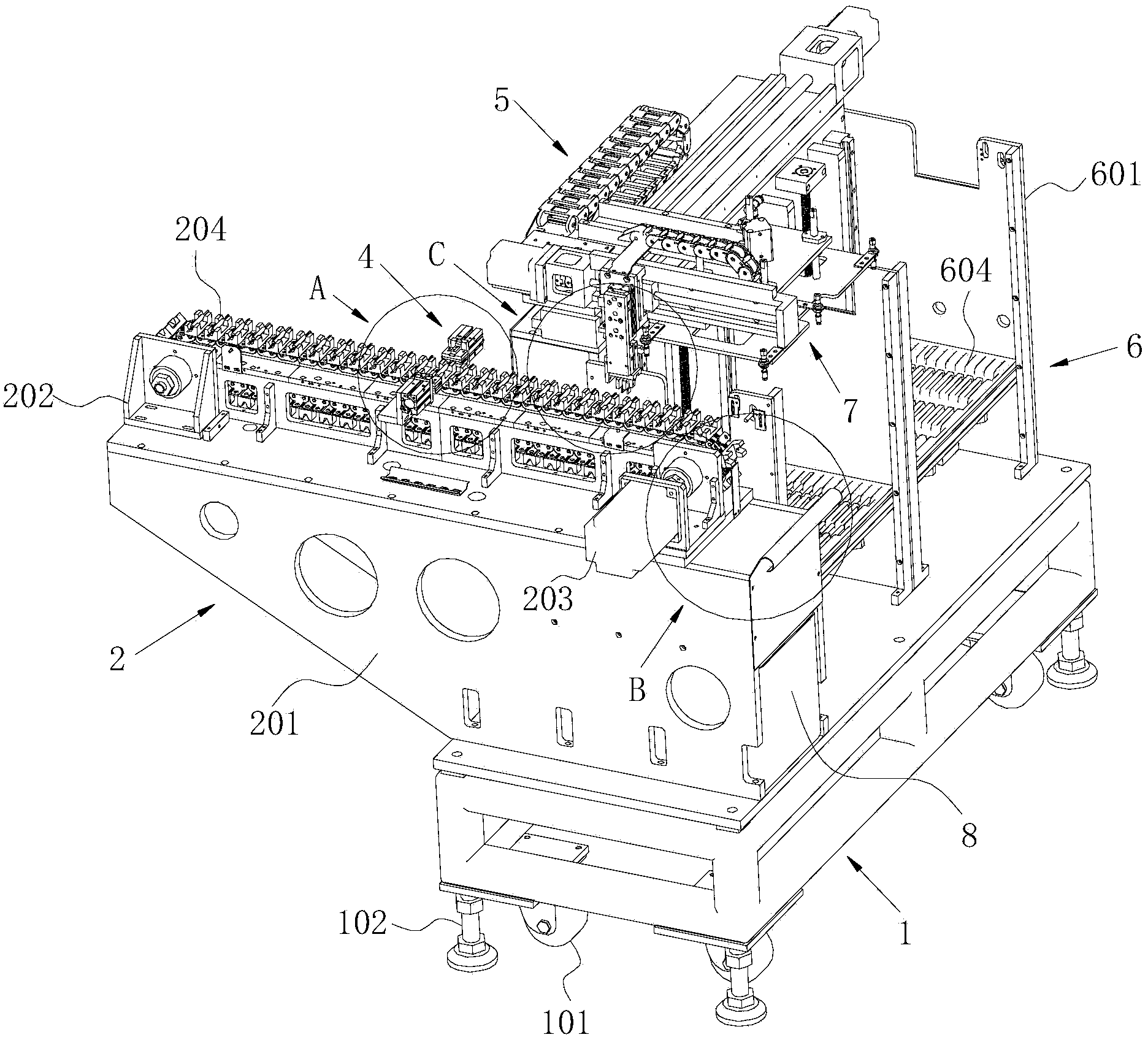

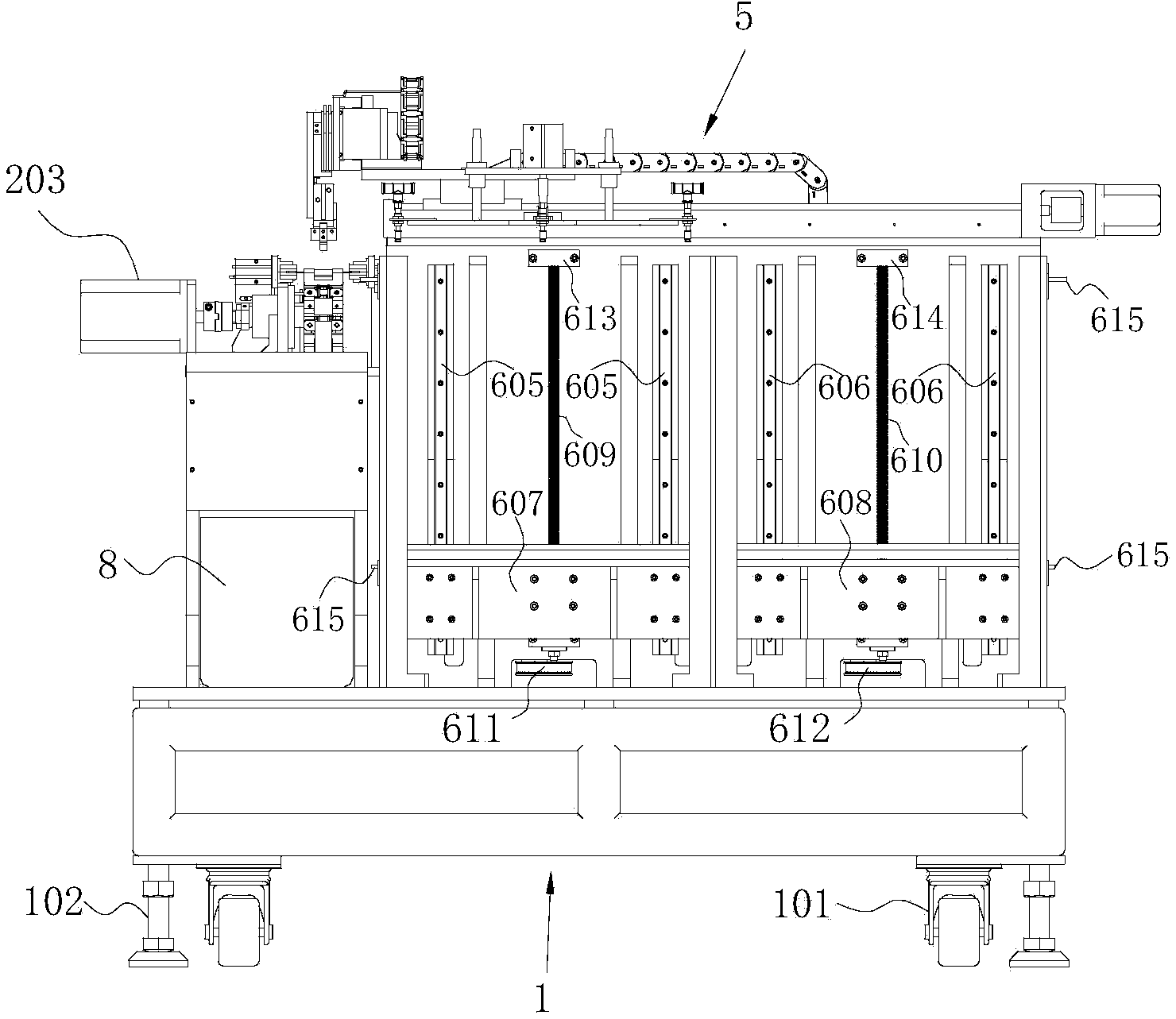

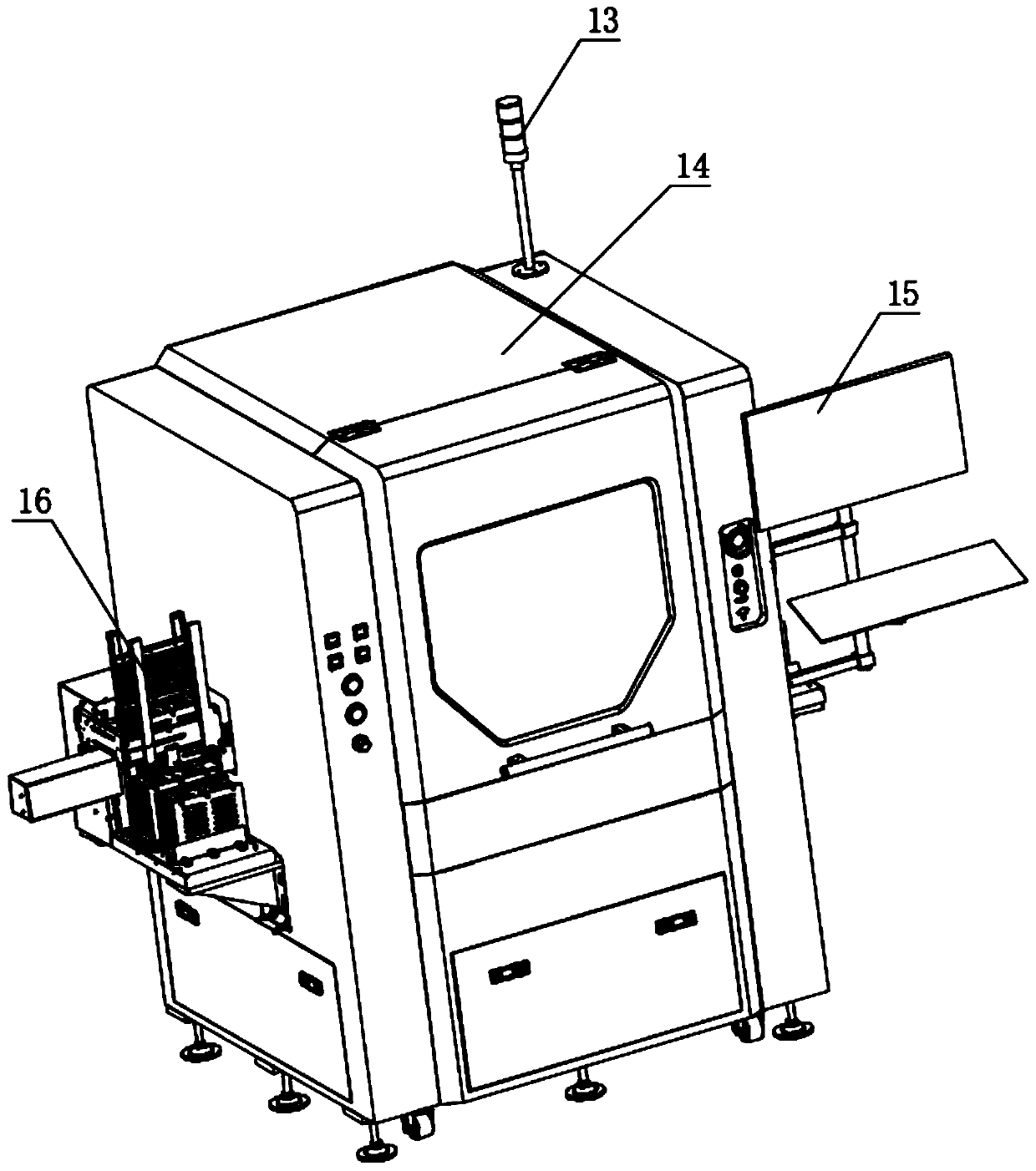

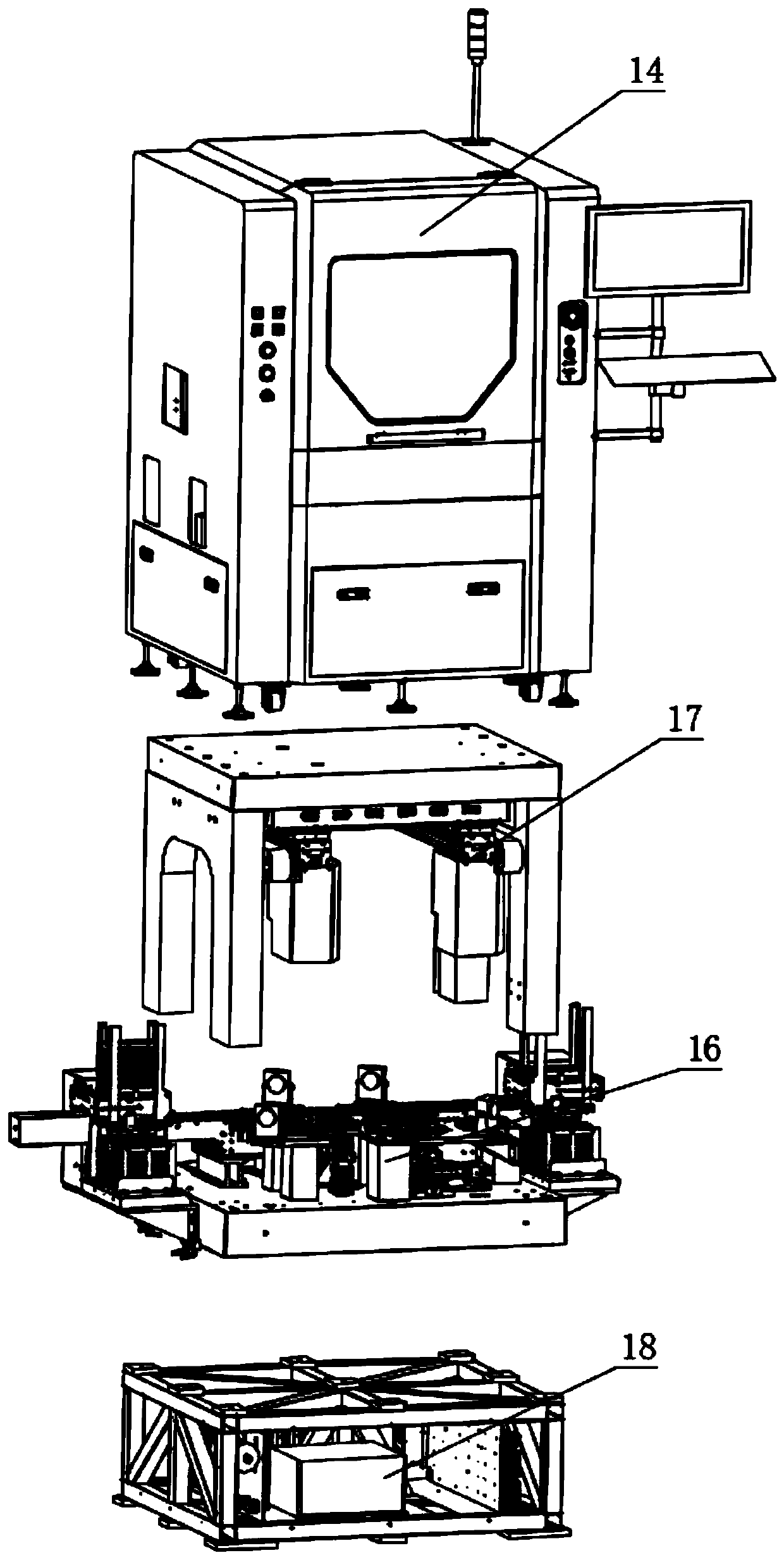

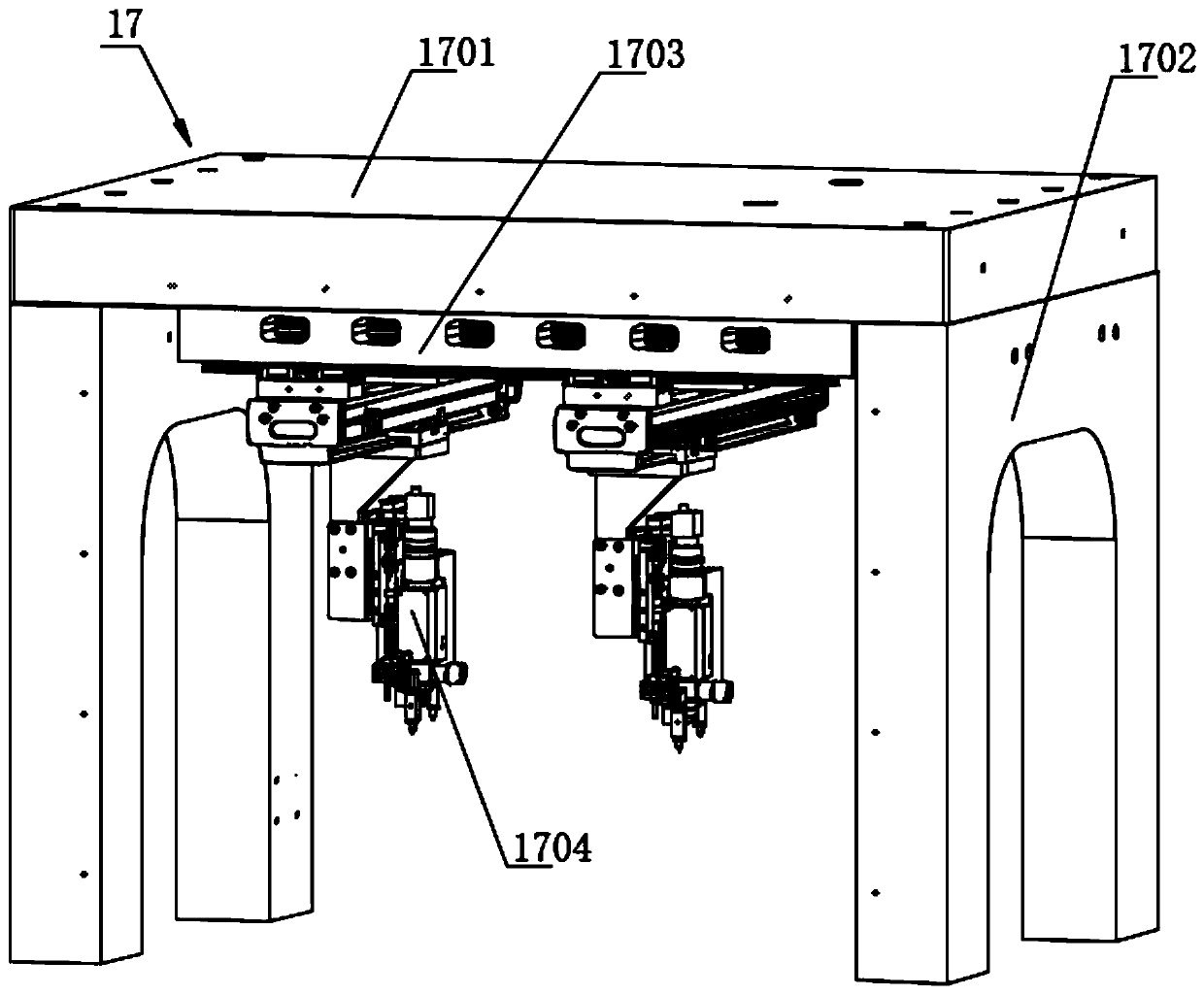

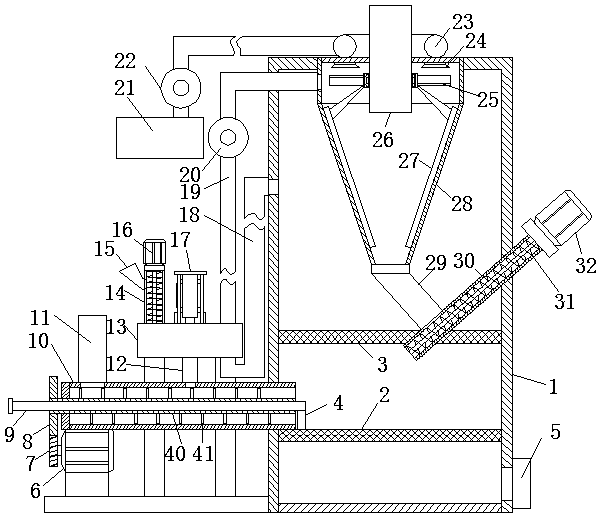

High-precision multifunctional chip mounter and using method thereof

PendingCN110491809AEasy loading workCompact structureSemiconductor/solid-state device manufacturingConveyor partsSmall footprintEngineering

The invention discloses a high-precision multifunctional chip mounter and a using method thereof. The multifunctional chip mounter comprises a shell, a control device is installed at the bottom in the shell, a multifunctional chip picking and placing device is installed above the control device, a multifunctional double-station welding head mechanism is installed above the multifunctional chip picking and placing device in a matched mode, and the multifunctional double-station welding head mechanism is installed at the top in the shell. The mounter is compact and reasonable in structure, andconvenient in operation, through the mutual cooperation of the functional chip picking and placing device, the multifunctional double-station welding head mechanism, the control device and other mechanisms, the chip mounting work of the chip can be conveniently and automatically completed, the chip mounting precision reaches + / -7 microns, at most eight types of chips can be mounted, the UPH can reach about 1.5 times that of the prior art, the functions are compressed and integrated as much as possible on the basis, the equipment size is small, and the occupied area is small.

Owner:恩纳基智能科技无锡有限公司

Composite biomass staged gasification furnace

The invention relates to the technical field of gasification furnaces, and in particular to a composite biomass staged gasification furnace. The furnace comprises a furnace body; a fire grate is fixedon the side wall of the lower part in the furnace body; a space below the fire grate is a slag cavity; an ash discharge port is formed in the side wall of the furnace body corresponding to the slag cavity; a filter screen is also fixed on the inner wall of the furnace body; the filter screen is positioned above the fire grate; a fine filter is fixed to the top wall of the interior of the furnacebody, a feeding mechanism is fixed to the outer side of the furnace body, a primary filtering mechanism is fixed to the feeding mechanism and connected with the feeding mechanism through a feeding pipe, and the primary filtering mechanism is connected with the upper portion of the side wall of the furnace body and a fine filtering mechanism through a first air pipe and a second air pipe. Accordingto the composite biomass staged gasification furnace, the content of tar and smoke dust in fuel gas is greatly reduced, the fuel gas quality is improved, equipment is protected, the filtered tar is returned to the furnace again to be subjected to high-temperature cracking to generate small molecular fuel gas, then the fuel gas generation efficiency is improved again, and the tar generation amountis reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING

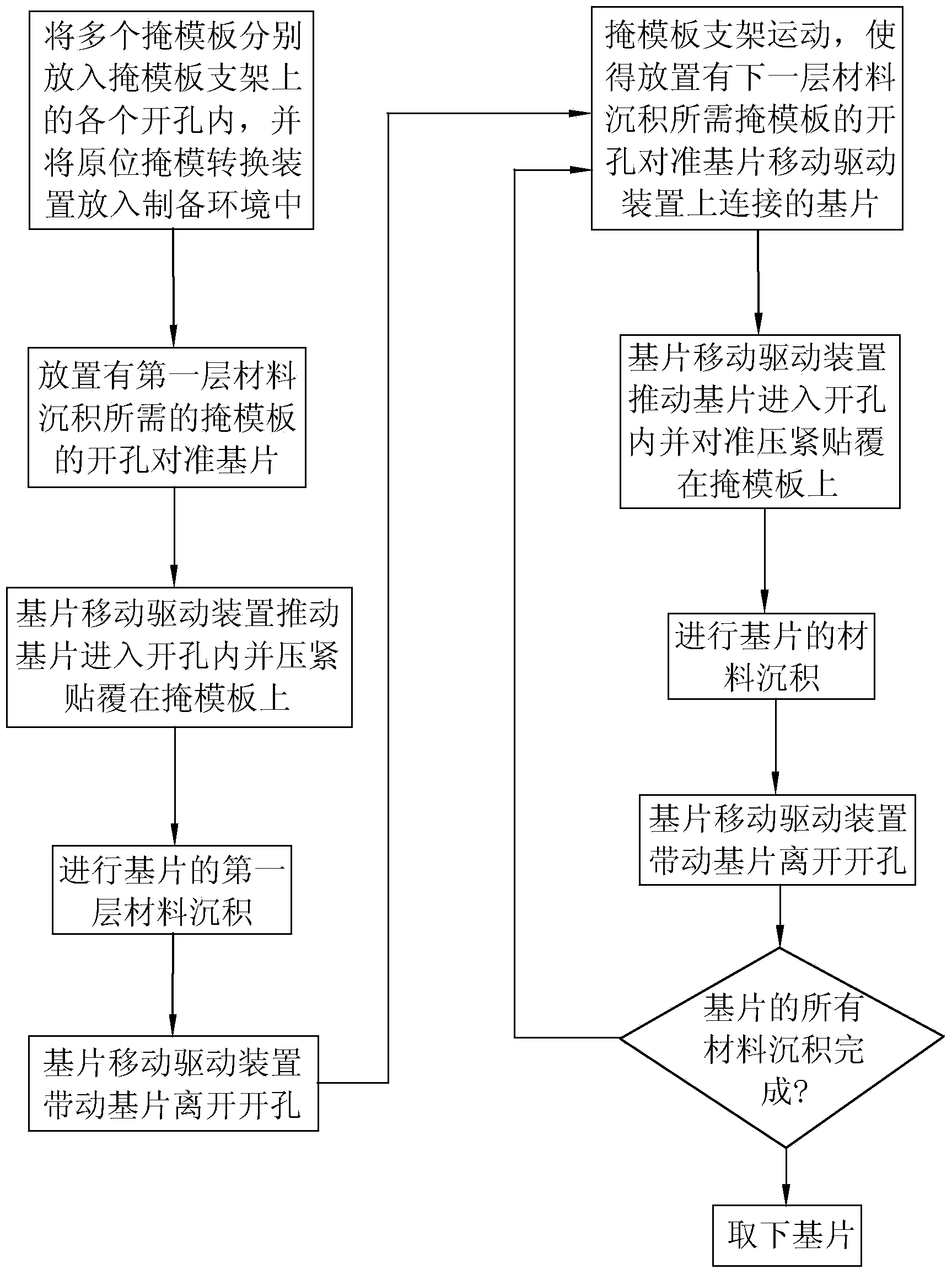

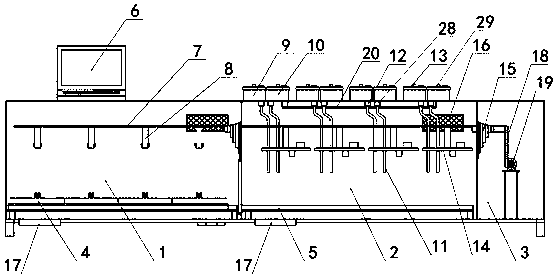

An in-situ mask changing device and an application method thereof

ActiveCN104213074AReduce shadowing effectRealize automatic replacementVacuum evaporation coatingSputtering coatingEngineeringShadow effect

The invention relates to an in-situ mask changing device. The device comprises a movable mask plate support. At least two openings are formed on the mask plate support. A mask plate is placed in each opening. A movable substrate movement drive device is arranged beside the mask plate support. The substrate movement drive device is detachably connected with a substrate matching with each mask plate. The substrate movement drive device can push the substrate into the openings and in contact with the mask plates. The substrate movement drive device can further drive the substrate away from the openings. The in-situ mask transforming device can be applied to a vacuum chamber, realize the change of the mask plates in a vacuum environment, and efficiently avoid pollution to the sample. In addition, the device further suppresses the shadow effect caused by the mask plates in the preparation process and guarantees the film quality. The invention further relates to an application method of the in-situ mask changing device. The method can realize automatic change of the mask plates in a preparation environment, save the change time of the mask plates and improve the preparation efficiency. Moreover, the operation is more convenient.

Owner:INFINITE MATERIALS TECH

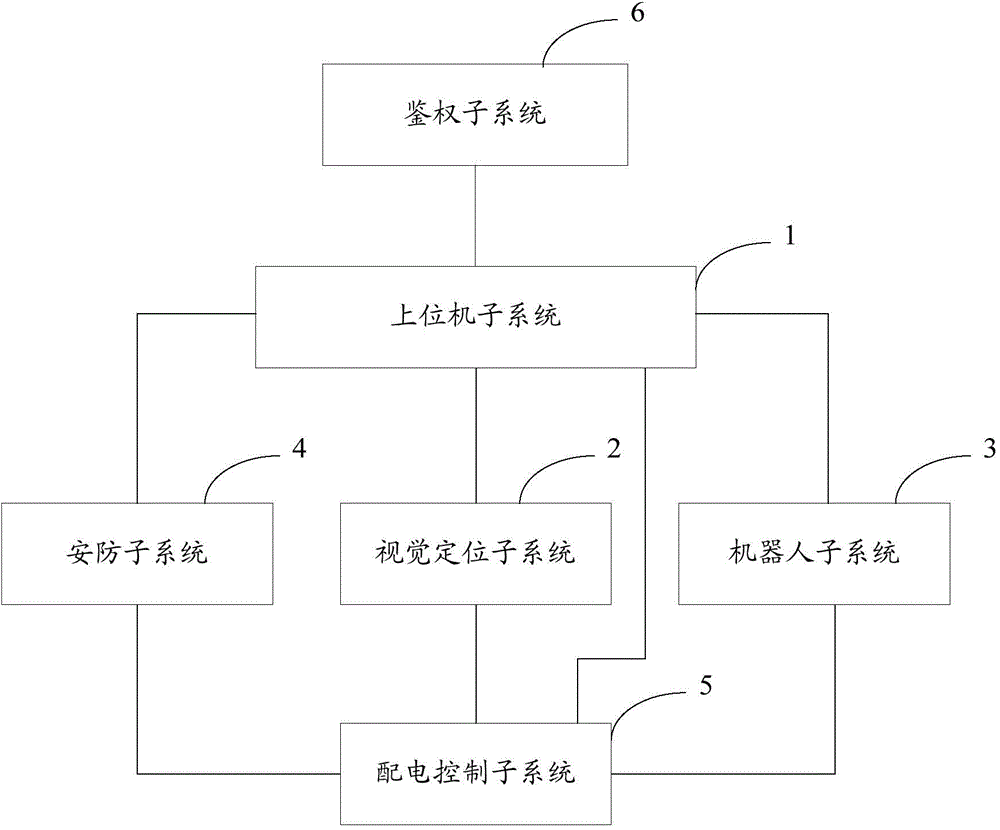

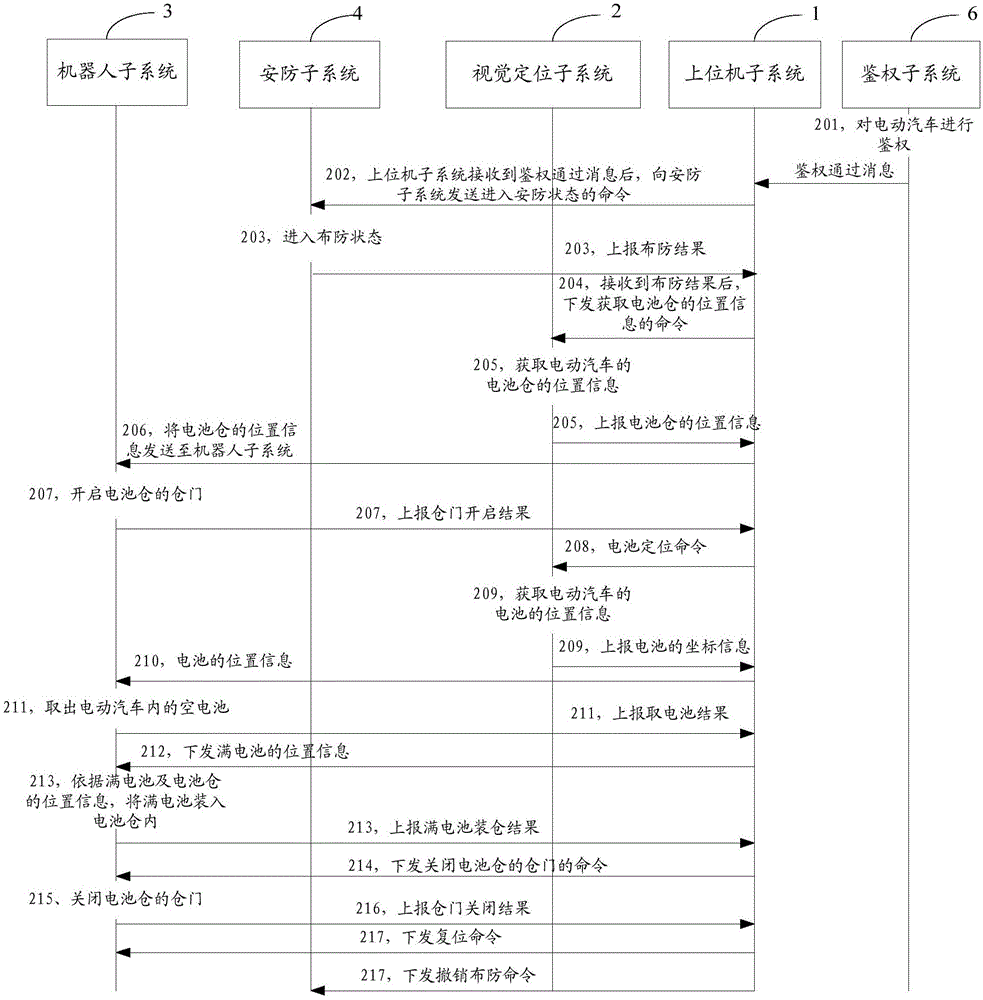

Battery replacing system of electric car

ActiveCN104417503ARealize automatic replacementElectric propulsion mountingVehicle servicing/repairingElectricityAutomotive battery

The invention discloses a battery replacing system of an electric car. The system comprises a host computer subsystem, a visual positioning subsystem and a robot subsystem. According to the battery replacing system of the electric car, the host computer subsystem controls the visual positioning subsystem and the robot subsystem, the visual positioning subsystem acquires the position information of a battery in the electric car and the position information of the battery full of electricity, then the robot subsystem removes an empty battery from the electric car and stores the battery full of electricity into a battery bin in the electric car according to the position information of the battery in the electric car and the position information of the battery full of the electricity, so as to realize the automatic replacement of the battery of the electric car.

Owner:STATE GRID CORP OF CHINA +2

Cell culture equipment

PendingCN108913602AAchieve isolationGuaranteed sterilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid ChangeAir filtration

The invention discloses cell culture equipment, and belongs to the technical field of biomedical cell culture. The cell culture equipment mainly comprises a sample injection chamber, a culture chamberand a motor chamber, and specifically comprises a culture dish conveying device, a culture dish-cover separation and closing device, a liquid changing device, an air filtering system, a disinfectingheating device, an automatic control system and a culture dish. According to the present invention, with the cell culture equipment, the isolation between the culture chamber and the outside world isachieved, the culture condition of the cells in the culture dish can be real-timely observed or shot and recorded, the automatic replacement of the culture liquid is achieved, and the gas in the culture dish and the gas in the culture chamber can be freely and smoothly exchanged while the water in the culture dish cannot be removed from the culture dish by evaporation. In the prior art, the pollution in the incubator is easily caused during the taking and placing of the culture dish, the manual adding or replacing of the culture liquid is cumbersome in the operation and easily causes the liquid changing error or the culture liquid pollution, and the growth condition of the cells in the culture dish is inconveniently observed. With the cell culture equipment of the present invention, the problems in the prior art can be solved.

Owner:山西正一康生物科技有限公司

Profiling polishing equipment

PendingCN108705420AIncrease productivityQuality improvementBelt grinding machinesAutomotive engineering

The invention provides profiling polishing equipment. The profiling polishing equipment comprises a frame, a control module, a clamping workbench, a profiling device, a transverse moving frame, a lifting frame, a transverse moving drive device, a lifting drive device and a polishing main machine. The profiling device, the transverse moving drive device, the lifting drive device and the polishing main machine are in communication connection with the control module. The profiling device comprises a profiling seat arranged on the frame, a profiling support arranged on the lifting frame, an adjusting motor fixedly connected to the profiling support, an adjusting screw rod positioned above the profiling seat and vertically arranged, an adjusting screw rod nut arranged on the adjusting screw rodin a sleeving manner and a profiling contact arranged at the lower end of the adjusting screw rod. The adjusting screw rod nut is in transmission connection with the adjusting motor. By arranging theprofiling device, stones can be polished without obtaining the profile track of the stones to be polished in advance, the production efficiency is relatively high and the use is relatively convenient.

Owner:泉州市贤兴机械制造有限公司

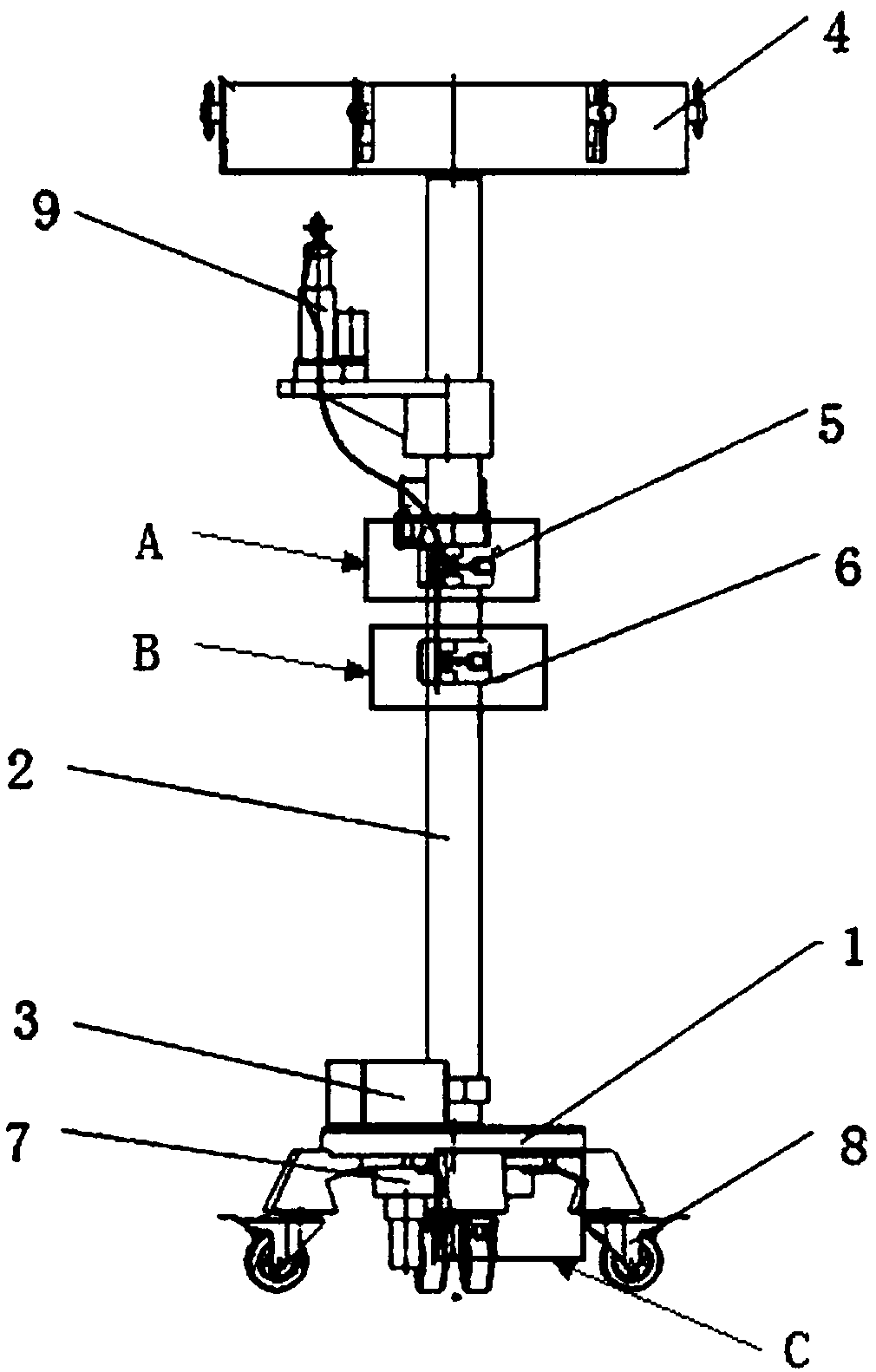

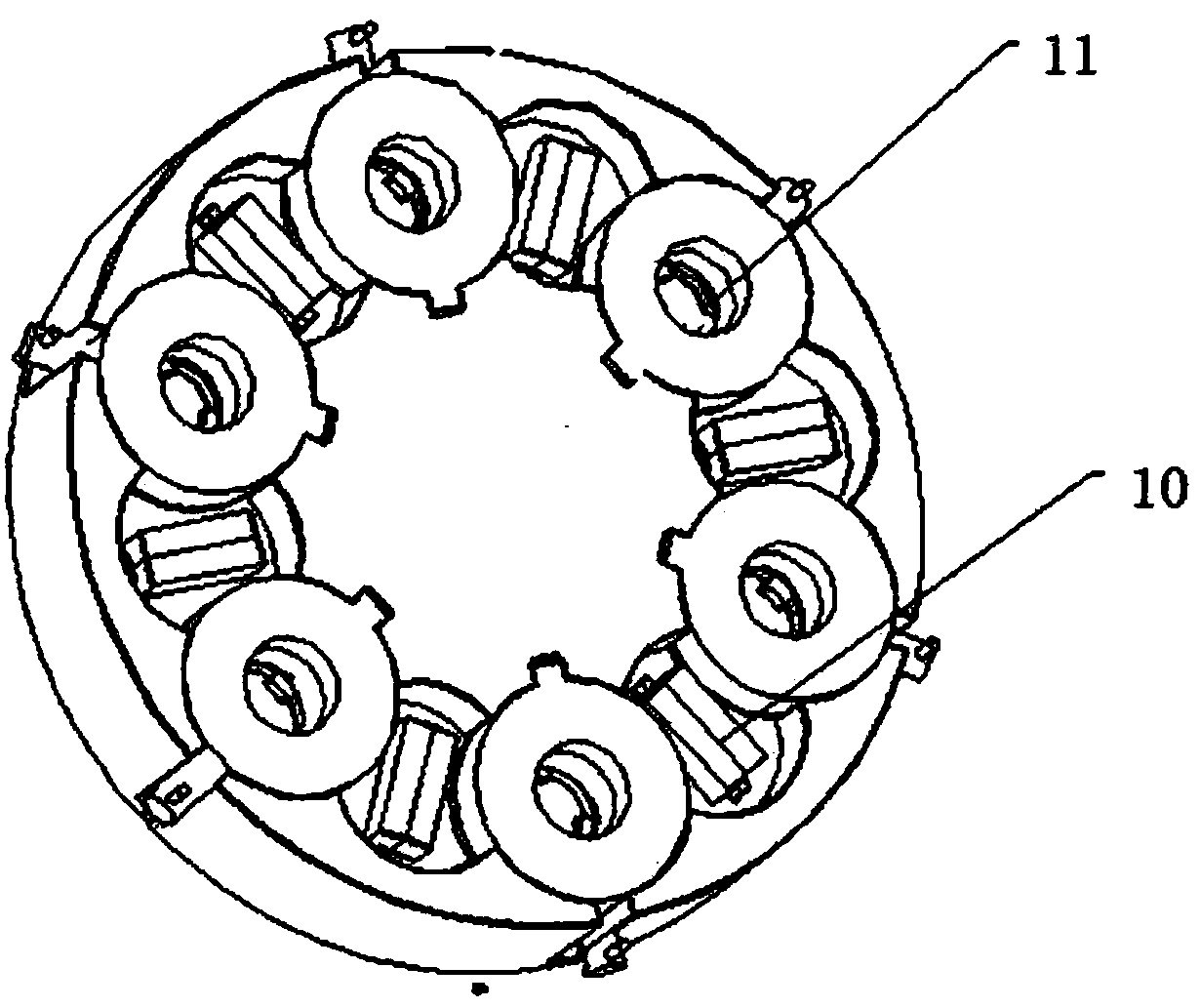

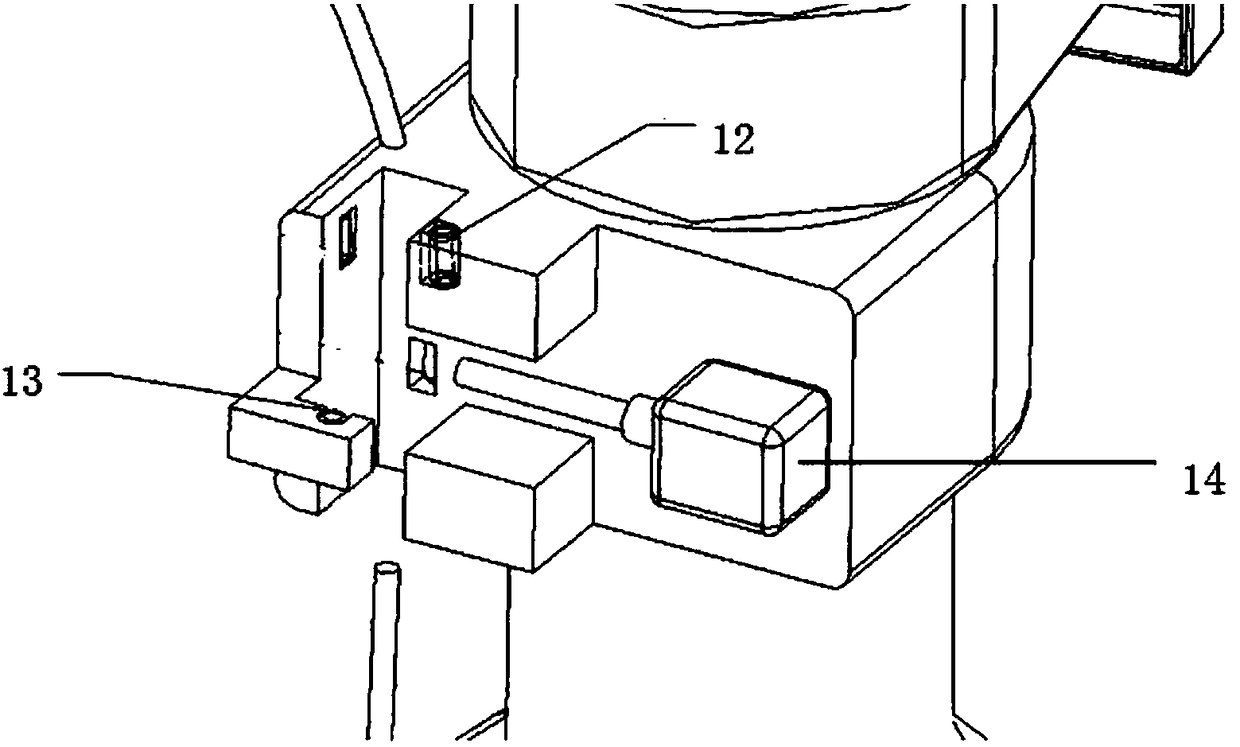

Infusion device

InactiveCN108295332ARealize automatic replacementInfusion SafetyMedical devicesFlow monitorsEngineering

The invention discloses an infusion device, and relates to the field of medical apparatuses. The infusion device comprises a base, a supporting pillar and a chuck, a motor which is arranged at the bottom of the base, a controller which is arranged at the top of the base and a rotating shaft which is arranged in the supporting pillar and is movable, wherein the rotating shaft is driven via a gear by the motor; the chuck is arranged at the top of the rotating shaft and can rotate along with the rotating shaft; via the chuck, an infusion part, which is arranged in the chuck, can be clamped; via aneedle inserting and withdrawing device in coordination with the chuck and a liquid level measuring part, the infusion part can be replaced; the liquid level measuring part is used for detecting a liquid level of liquid in a Murphy dropper; the liquid level measuring part is used for transmitting an electrical signal to the controller when the liquid level of the liquid in the Murphy dropper is lower than a preset threshold; the controller, in accordance with the received electrical signal, is used for controlling the motor to drive the rotating shaft to rotate; and subsequently, the chuck isdriven to rotate via the rotating shaft, and the infusion part is replaced via the needle inserting and withdrawing device under control; therefore, infusion efficiency and safety are improved.

Owner:NINGBO INTELLIGENT MFG IND RES INST

Automatic infusion device and method

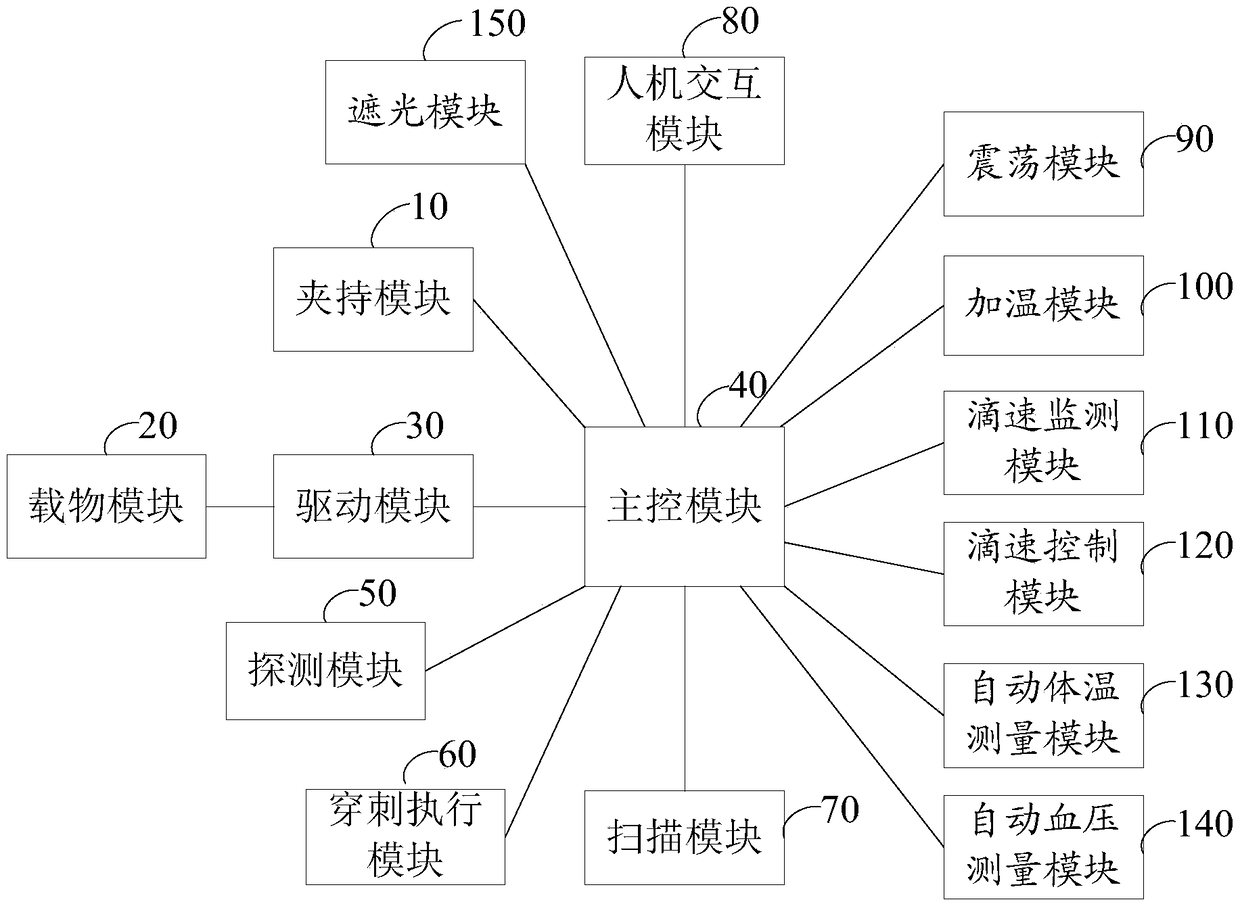

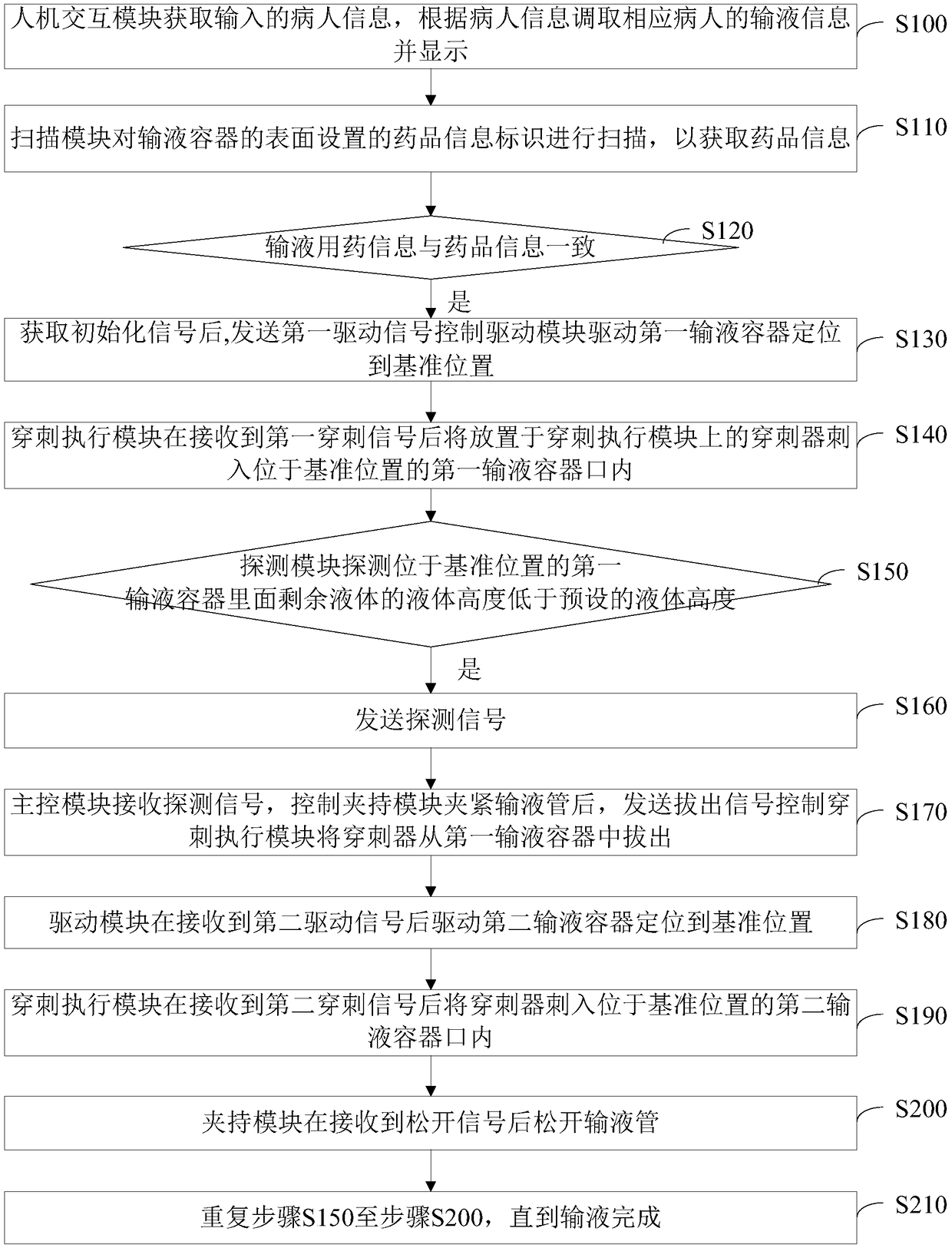

InactiveCN108653857AAvoid pollutionImprove work efficiencyMedical devicesFlow monitorsLiquid heightComputer module

The invention relates to an automatic infusion device and method. The automatic infusion device is characterized in that an object carrying module is connected with a driving module, and the driving module is connected with a main control module; a man-machine interaction module is connected with the main control module and used for obtaining input patient information, calling infusion informationof a corresponding patient from a background according to the patient information and displaying the infusion information; a scanning module is connected with the main control module and used for scanning drug information identifiers arranged on the surfaces of infusion containers so as to obtain drug information; a clamping module is connected with the main control module; and a detecting moduleis used for sending a detection signal to the main control module when detecting the situation that the liquid height of remaining liquid in the first infusion container is smaller than the preset liquid height, the main control module controls the clamping module to clamp an infusion tube according to the detection signal and then controls a puncture outfit of a puncture executing module to be pulled out of the first infusion container, and then an opening of the second infusion container is punctured. According to the automatic infusion device and method, a plurality of infusion bottles (orbags) can be replaced automatically during continuous infusion and do not need to be manually replaced by a nurse, and thus the working efficiency of the nurse is improved.

Owner:深圳市刚竹医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com