An in-situ mask changing device and an application method thereof

A conversion device and mask technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of easily causing shadow effect, affecting sample quality, time-consuming sample contamination of mask replacement, etc. The effect of saving replacement time, improving preparation efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

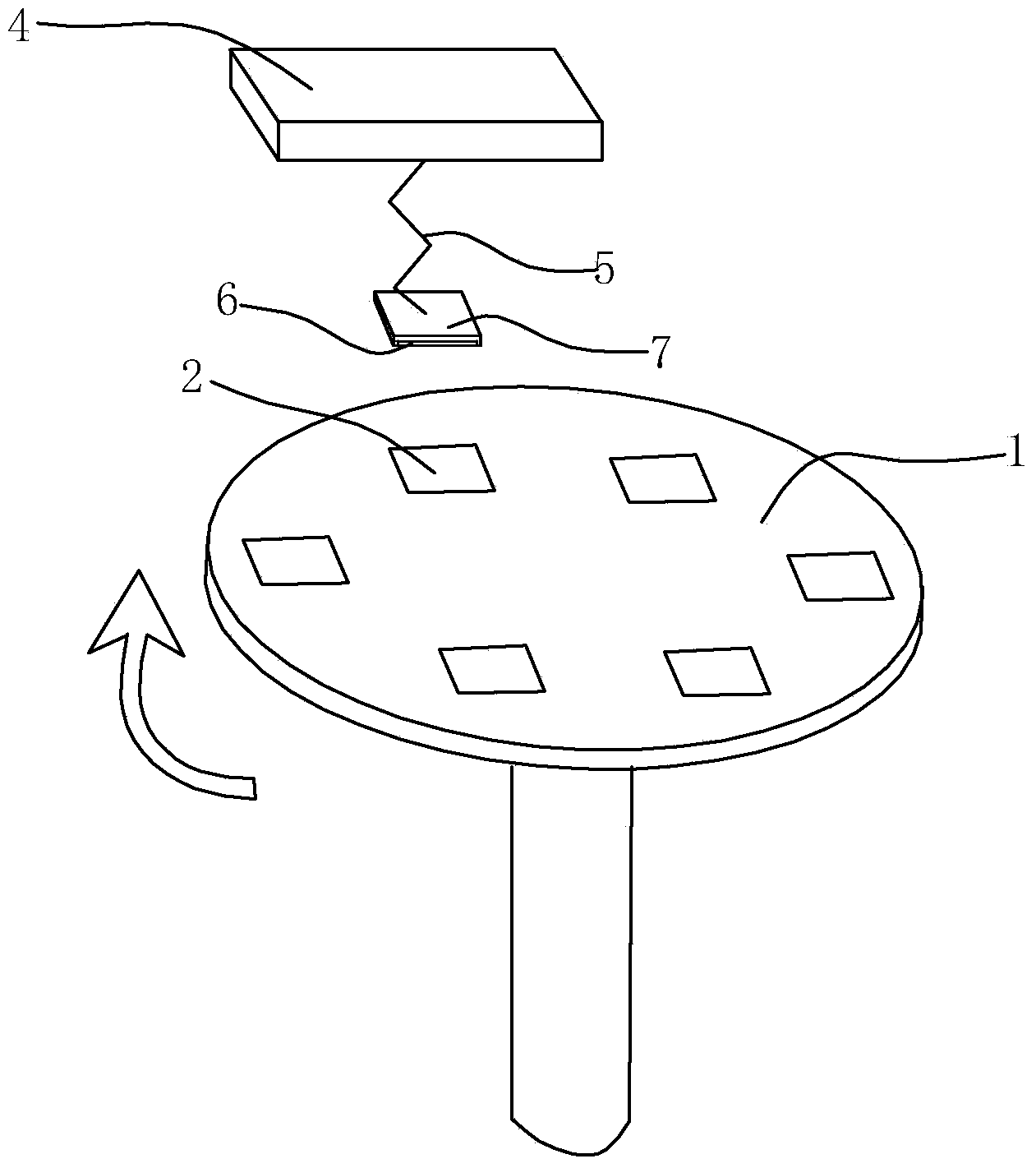

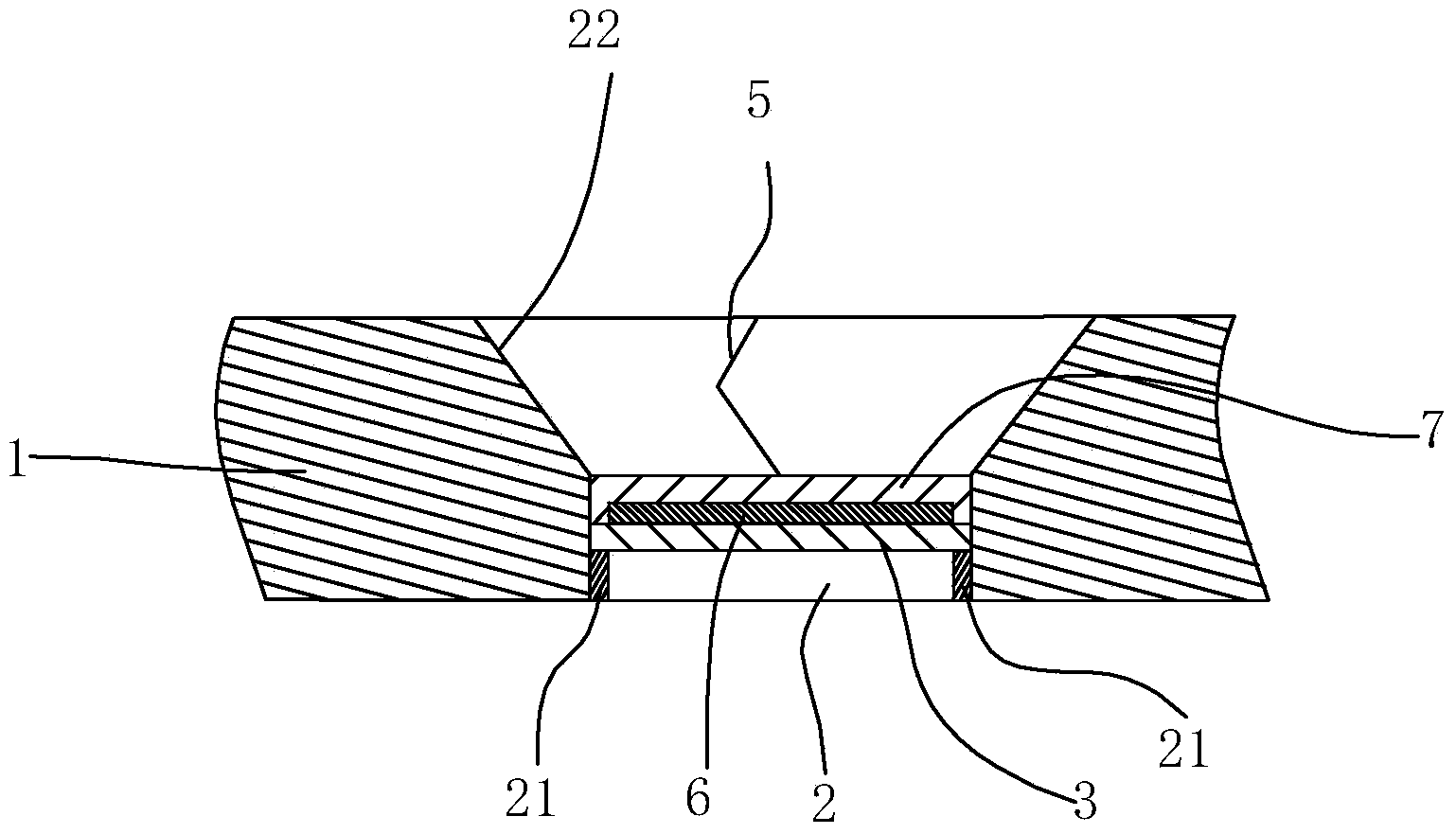

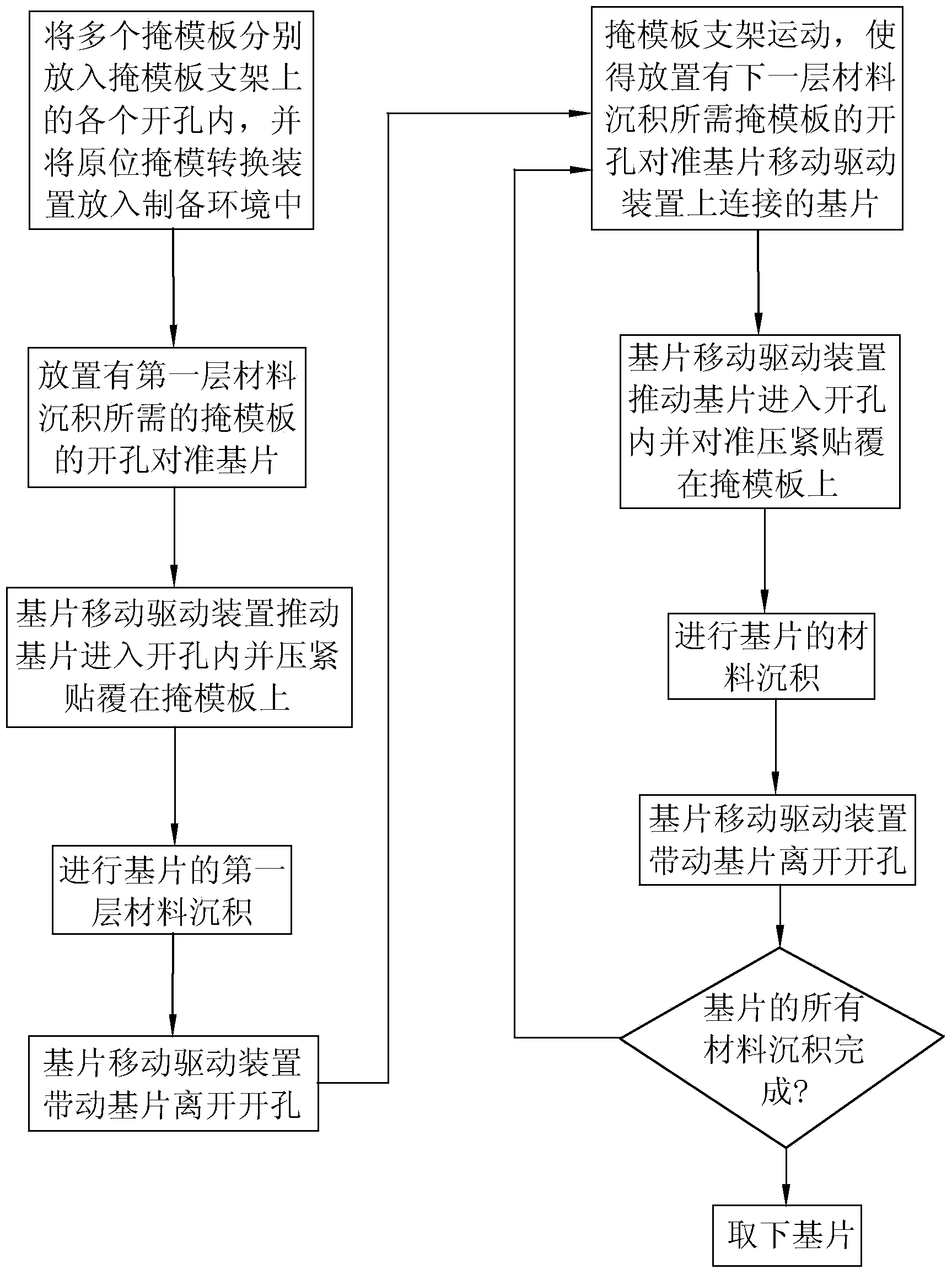

[0031] like figure 1 , figure 2As shown, the in-situ mask conversion device in this embodiment includes a movable mask holder. According to different design requirements, the mask holder is a rotatable disc body 1, a translatable belt-shaped support body or a movable A combination of a rotating disc body 1 and a translatable belt-shaped support. In this embodiment, a rotatable disk body 1 is selected as the mask plate support, and the disk body 1 can be connected to a power source by a driving rod to drive the disk body 1 to rotate clockwise or counterclockwise. In order to facilitate control and use, the disc body 1 is disc-shaped, and there are at least two openings 2 on the disc body 1, and a mask plate 3 is placed in the opening 2, and the mask plate 3 is fixedly placed in the opening in this embodiment. 2, the shape of the opening 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com