Reflective photomask and reflective photomask blank

A photomask and reflective technology, applied in optics, originals for photomechanical processing, instruments, etc., can solve the problem of half-tone photomasks depending on the transmittance or reflectivity, and achieve the goal of reducing the projection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

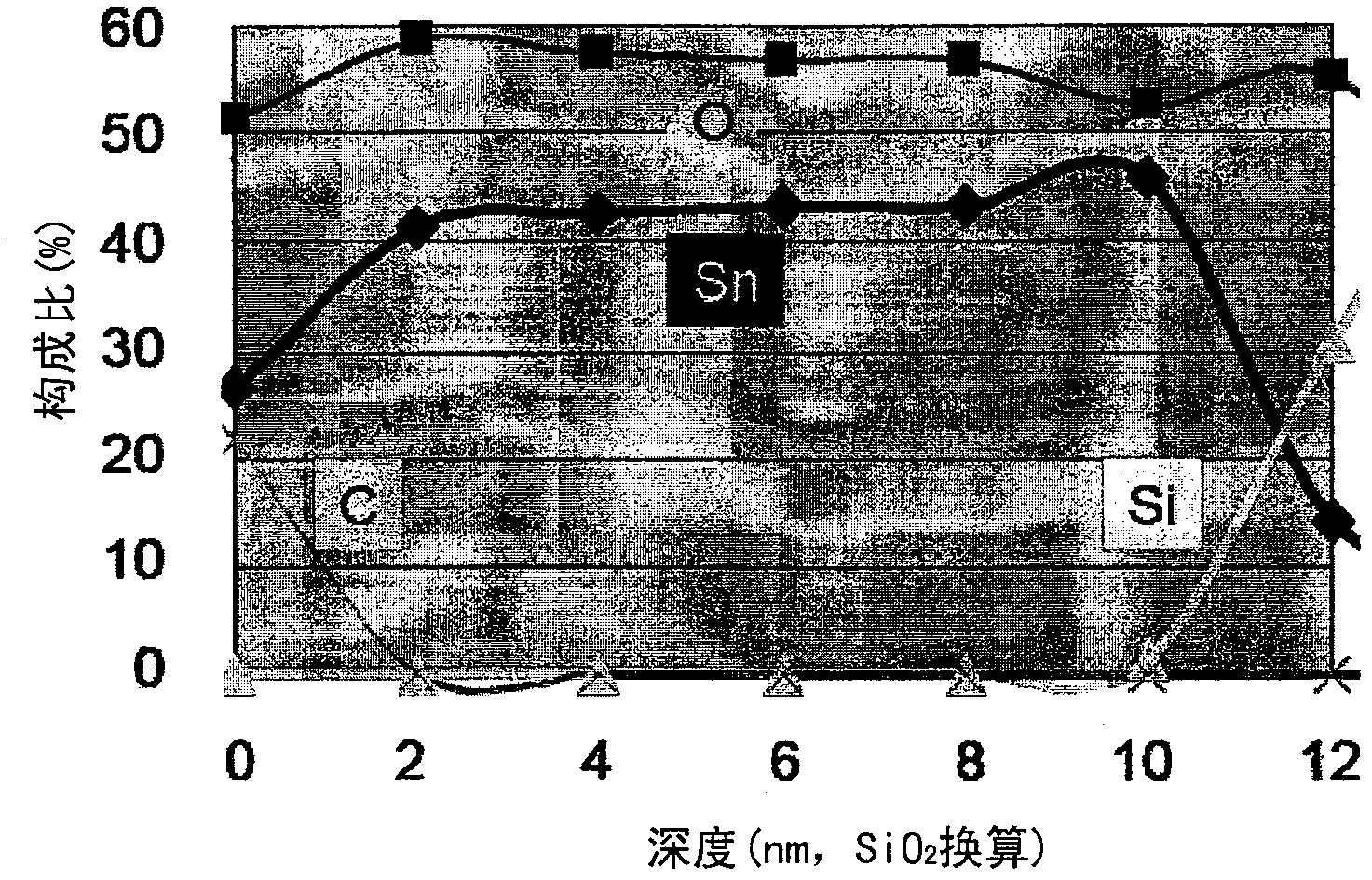

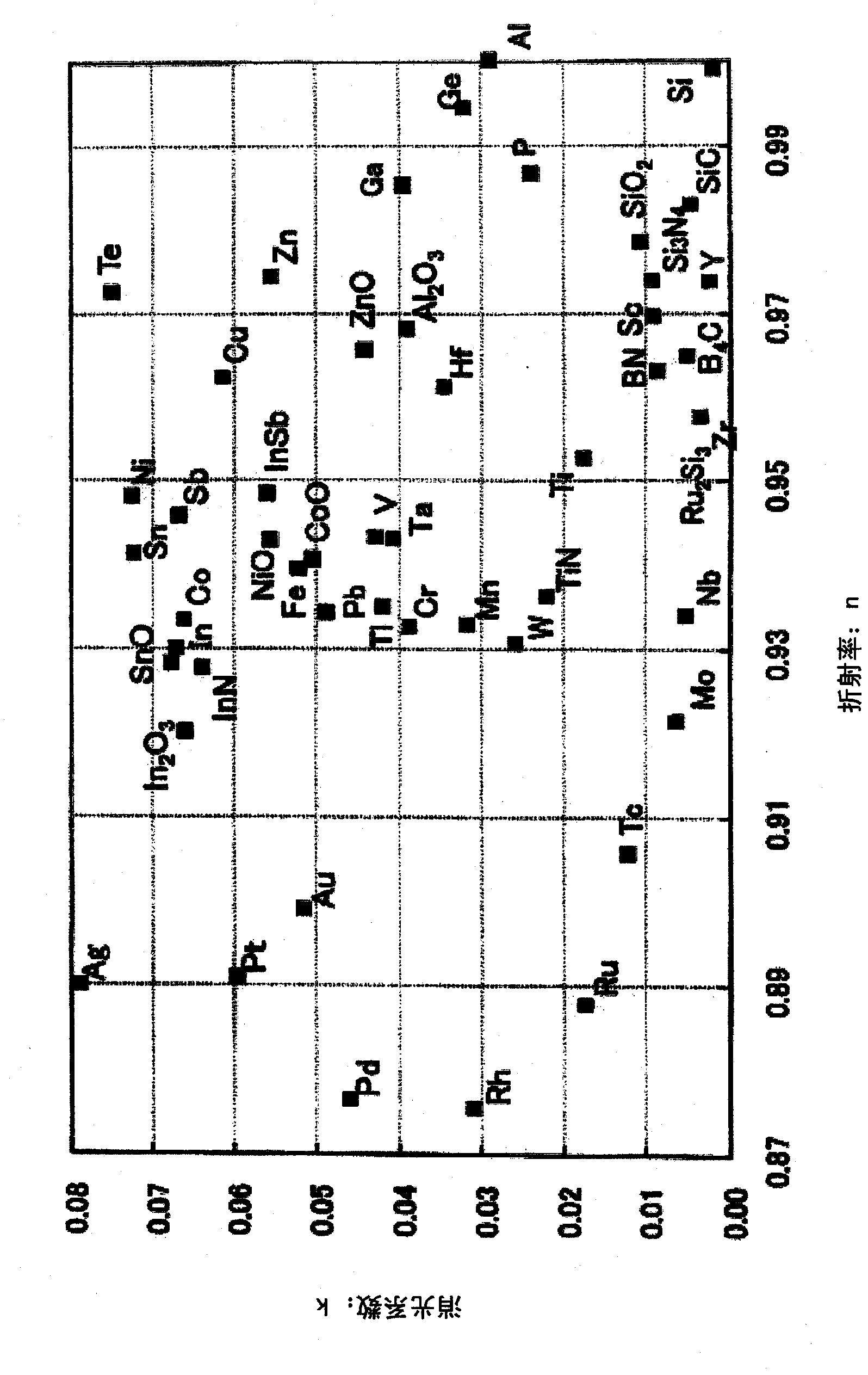

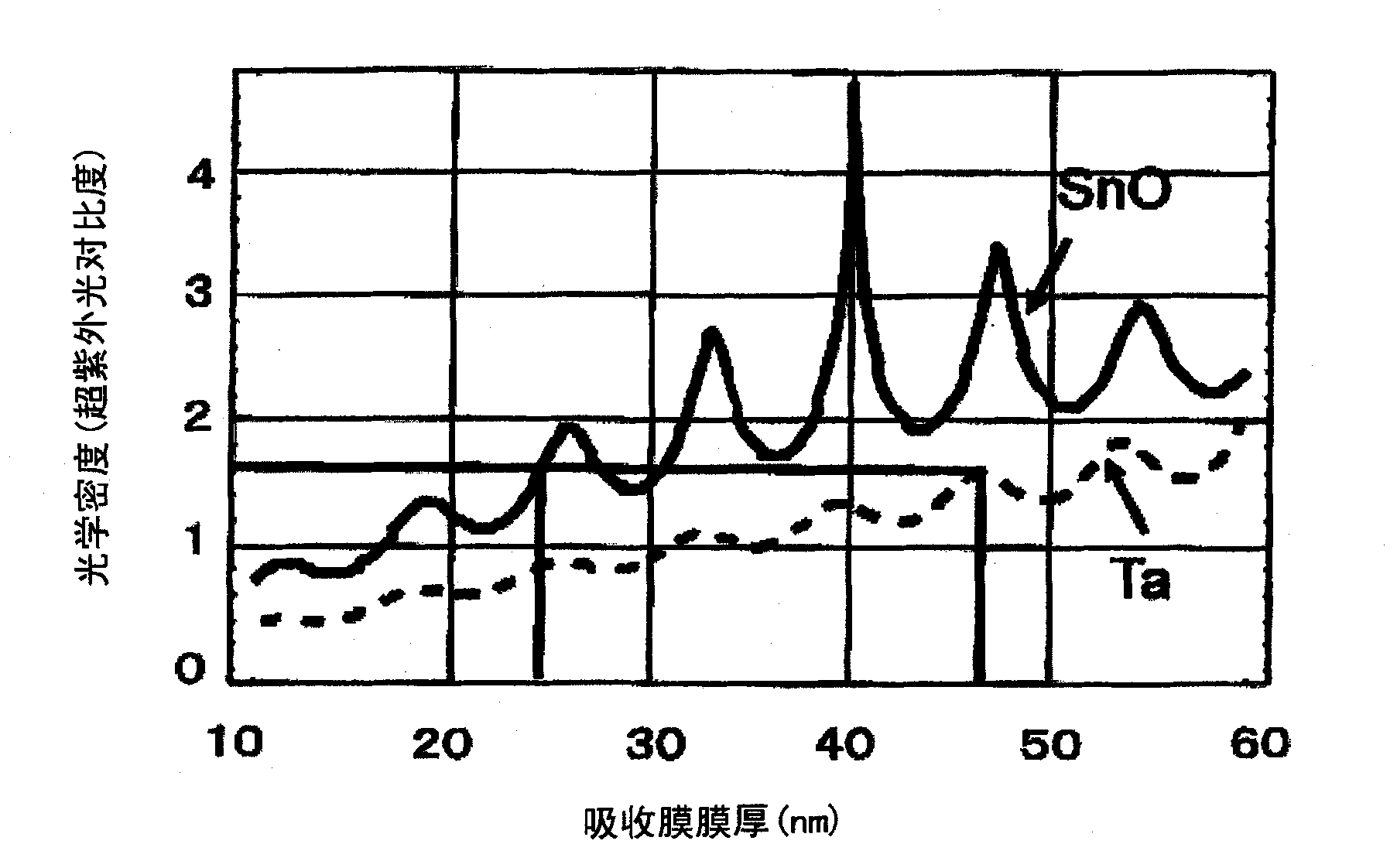

[0106] Such as Figure 11 As shown, the reflective photomask substrate 10 according to the first embodiment of the present invention has: a substrate 1; a multilayer reflective film 2 formed on the substrate 1 and having high reflectivity; a protective film 3 formed on the multilayer reflective The film 2 is used to protect the multilayer reflective film 2; the buffer film 4 is formed on the protective film 3; the absorbing films 5a, 5b are formed on the buffer film 4, have low reflectivity, and have a multilayer structure. Here, the upper absorber film 5b is composed of a film containing Sn and oxygen as main elements. In addition, as described above, the lower absorber film 5 a can function as the buffer film 4 in the mask manufacturing process.

[0107] For the substrate 1 according to the first embodiment of the present invention, a silicon substrate, quartz, titanium-added low thermal expansion glass, etc. can be used, but it is preferable to use a material with a small ...

no. 2 approach

[0117] Such as Figure 13 As shown, the reflective photomask substrate 30 of the second embodiment of the present invention has: a substrate 1; a multilayer reflective film 2 formed on the substrate 1 and having high reflectivity; a protective film 3 formed on the multilayer reflective On the film 2, it is used to protect the multilayer reflective film 2; the buffer film 4 is formed on the protective film 3; the absorption film 5a, 5b, 5c is formed on the buffer film 4, has low reflectivity, and has a multilayer structure. Here, the absorption film 5b is composed of a film containing Sn and oxygen as main elements. In addition, in this case also in the mask manufacturing process, the lower layer absorbing film 5 a can function as the buffer film 4 .

[0118] For the substrate 1 of the second embodiment of the present invention, a silicon substrate, quartz, titanium-added low thermal expansion glass, etc. can be used, but it is preferable to use a material with a small therma...

no. 3 approach

[0125] exist Figure 15 A reflective photomask blank 50 according to the third embodiment of the present invention is shown in FIG. figure 1 The point of difference between the reflective photomask blanks 10 according to the first embodiment of the present invention shown in FIG. In addition, since the description content other than the dual-purpose film 34 overlaps with 1st Embodiment, the description is abbreviate|omitted.

[0126] The dual-purpose film 34 is provided between the lower absorbing film 5a and the multilayer reflective film 2, and this dual-purpose film 34 can function as both the protective film 3 and the buffer film 4 for protecting the multilayer reflective film 2 shown in the first embodiment. role. As a material of such dual-purpose film 34 , for example, a Si film or a silicon nitride film can be used, but the present invention is not limited thereto.

[0127] Next, at Figure 16 In the reflective photomask 60 of the third embodiment of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com