Ring illuminator and fusion recognition method utilizing ring illuminator illumination based on shape, grain and weight of tool

A ring light source and tool technology, applied in the field of fusion recognition, can solve problems such as inability to accurately obtain tool texture information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

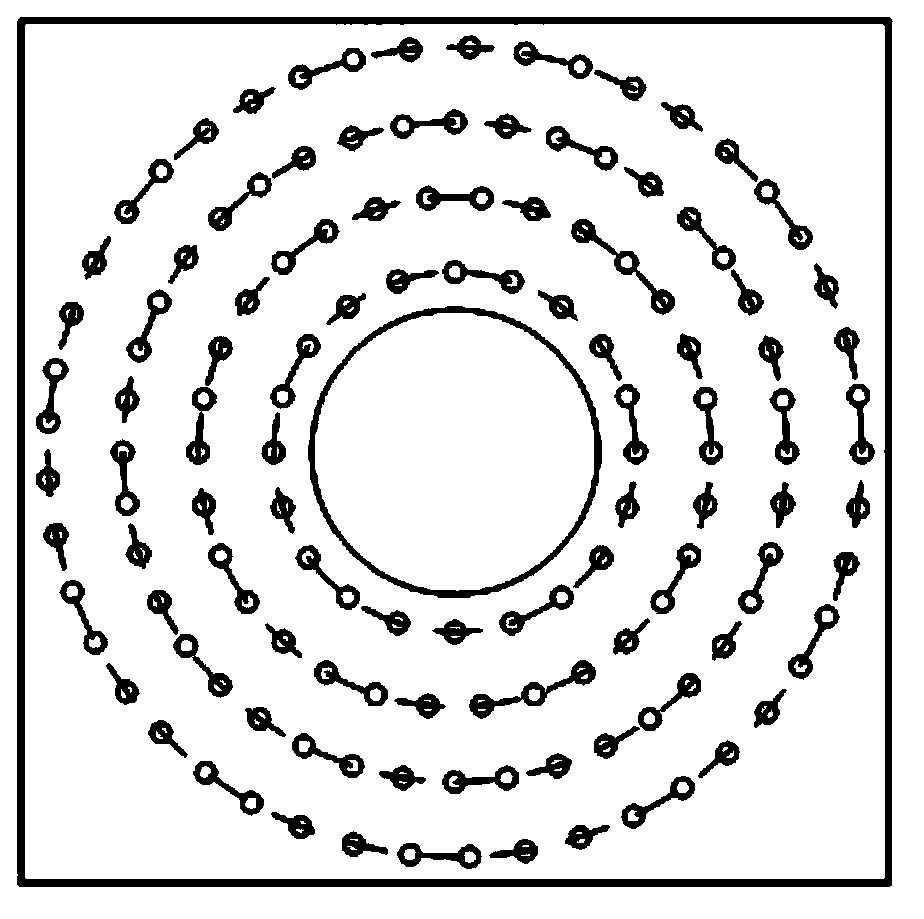

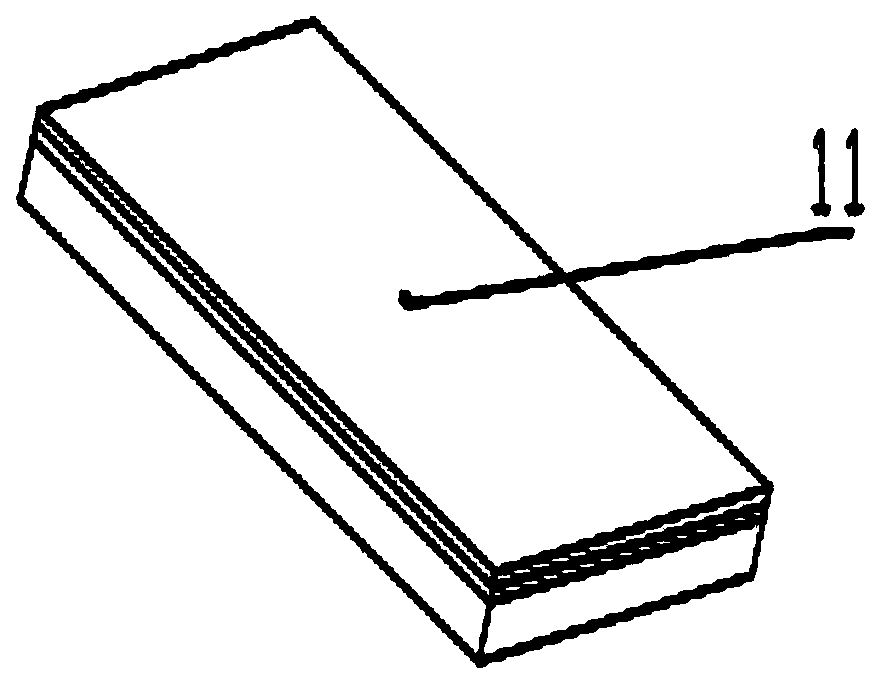

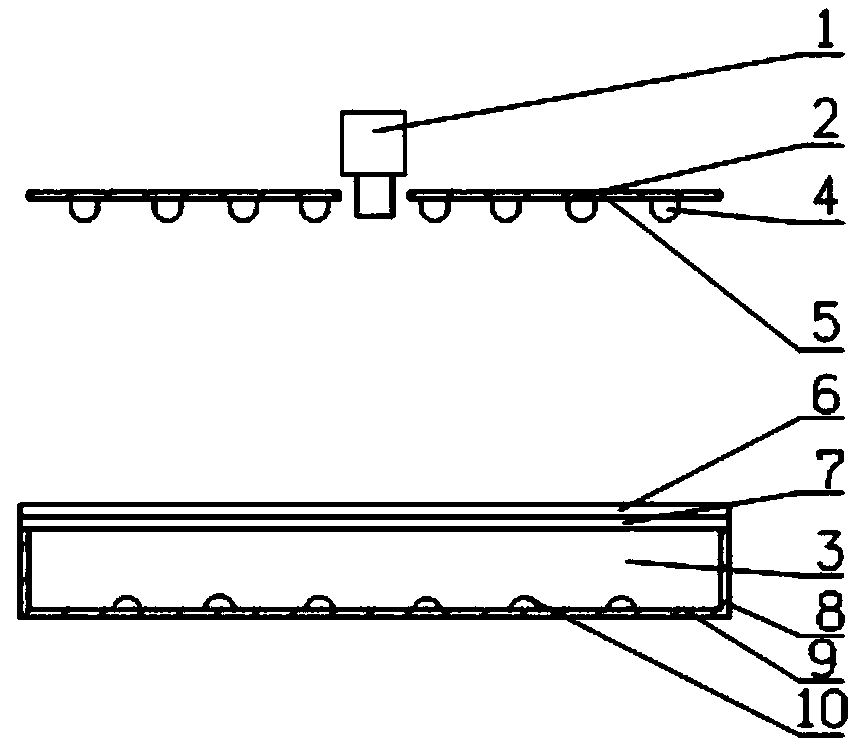

[0081] Example 1. Reference figure 1 -4. The ring light source is composed of a main light source 2 and a back light source 3. The main light source 2 is composed of a concentric circular luminous band formed by four LED point light sources 4 fixed on the bottom plate 5, which maintains the rotation invariance of the captured tool texture. The backlight source 3 is composed of a support plate 6, a diffuse reflection plate 7, a box body 8, a light source 9 and a reflective layer 10; the box body 8 is made of a PVC board and has a rectangular parallelepiped with an opening on the top. The reflective layer is a reflective film that is uniform. Ground attached to the inner surface of the box body, the LED point light sources 4 are evenly arranged on the lower bottom plate of the box body 8 to form the light source 9, and the diffuse reflection plate 7 is located under the support plate 6 and fixed on the box body 8. The main light source 1 adopts 142 LED point light sources 4 arr...

Embodiment 2

[0082] Example 2. The specific steps of the fusion recognition method based on the tool shape texture weight using the ring light source are as follows.

[0083] In this embodiment, the shape and texture information acquisition camera 1 is an industrial camera of the MV1300 model of Weishi Digital Image Technology Co., Ltd., and the distance between the camera and the target to be measured is 30 cm.

[0084] In this embodiment, a cylindrical tool with a tool number of 0008 and a tool diameter of φ10 is selected from the tool database, and its shape and texture are photographed, and its weight information is obtained through a gravity sensor. With the support of the main light source 2 and the backlight source 3, the shutter speed is selected as 20ms, the gain adjustment is 0, the screen mode is 640*512, and the acquisition speed is high. The image collected by the MV1300 industrial camera is used as an implementation example under the reading tooling, and the image size is 640*512...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com