Flexible assembly system based on intelligent end effector

An end effector and flexible assembly technology, applied in the direction of assembly machines, program-controlled manipulators, metal processing equipment, etc., can solve the problem of not being able to adapt to the assembly of various parts, glue coating, high-precision assembly, and large-scale products. Assembly and other issues, to achieve the effect of accurate detection, compact structure, efficient and fast assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

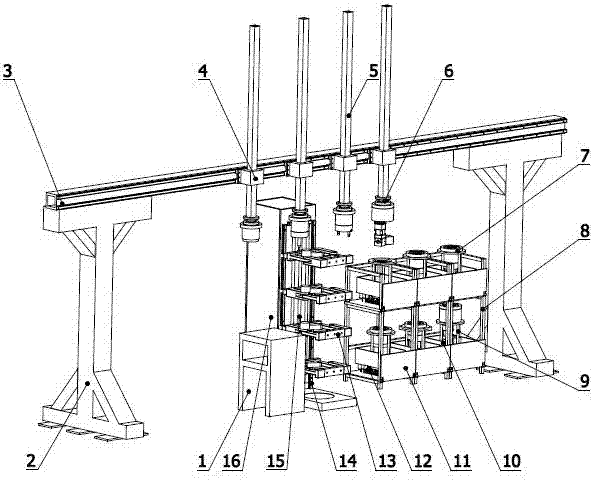

[0030] A flexible assembly system based on an intelligent end effector includes a part placement table 1, a truss robot, a warehouse of working heads 7, and a fixed workbench. The robot is positioned above the part placement table 1, the fixed workbench and the working head 7 warehouses. The basic parts of the product are clamped on the fixed workbench, and the end effector of the truss robot clamps / absorbs the parts from the part placement table 1, and then assembles them on the basic parts of the product; during the assembly process, the warehouse of the working head 7 cooperates with the robot to complete the automatic Replacement to realize the flexible assembly process of large mechanical products. The truss robot is connected with the working head 7 through a quick joint; the male joint is installed at the end of the robot, and the female joint is installed on the working head 7; the automatic replacement of the end effector can be realized by using the quick joint.

Embodiment 2

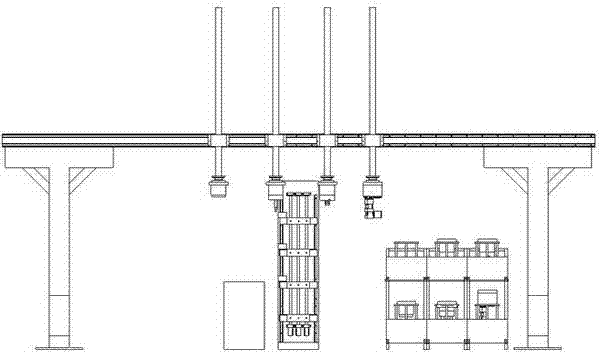

[0032] A flexible assembly system based on an intelligent end effector includes a part placement table 1, a truss robot, a warehouse of working heads 7, and a fixed workbench. The robot is positioned above the part placement table 1, the fixed workbench and the working head 7 warehouses.

[0033] The truss robot includes a crossbeam 3, the two ends of the crossbeam 3 are connected with columns 2, the crossbeam 3 is provided with a plurality of supporting plates 4, each supporting plate 4 is connected with a hanging arm 5, and the lower end of the hanging arm 5 is It is connected with the male head 6 of the working head.

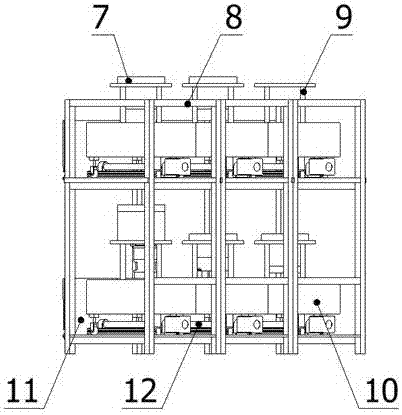

[0034] Working head 7 storehouse comprises working head storehouse support 8, and described working head storehouse support 8 is provided with at least one leading screw guide rail moving pair 12, and described leading screw guide rail moving pair 12 links to each other with moving pallet 10, and described working head storehouse The support 8 is connected w...

Embodiment 3

[0044] On the basis of Embodiment 1 and Embodiment 2, the present invention will be further described in detail with reference to the accompanying drawings.

[0045] Such as figure 1 , figure 2 As shown, a flexible assembly system based on an intelligent end effector, the system includes a parts placement table 1, a truss robot, a working head warehouse and a fixed workbench; wherein, the truss robot includes: a column 2, a beam 3, a pallet 4, a hanger Arm 5, working head male head 6; working head warehouse includes: working head 7, working head storehouse support 8, working head supporting frame 9, moving supporting plate 10, side supporting plate mechanism 11, lead screw guide rail moving pair 12; fixed working The table includes: a clamping device 13, a moving guide rail 14, a lead screw 15, and a body bracket 16. The specific implementation and working process of each part in this embodiment will be described in detail below.

[0046] The parts placing table 1 has a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com