Production line and process of fried straight noodles

A production line and fryer technology, which is applied in the fields of dough processing, oil/fat baking, dough forming and cutting equipment, etc., can solve the problems of not being able to replace the oil residue of the oil pan in time, single production method, unsanitary fried noodles, etc. To achieve the effect of convenient cleaning and maintenance, simple structure and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

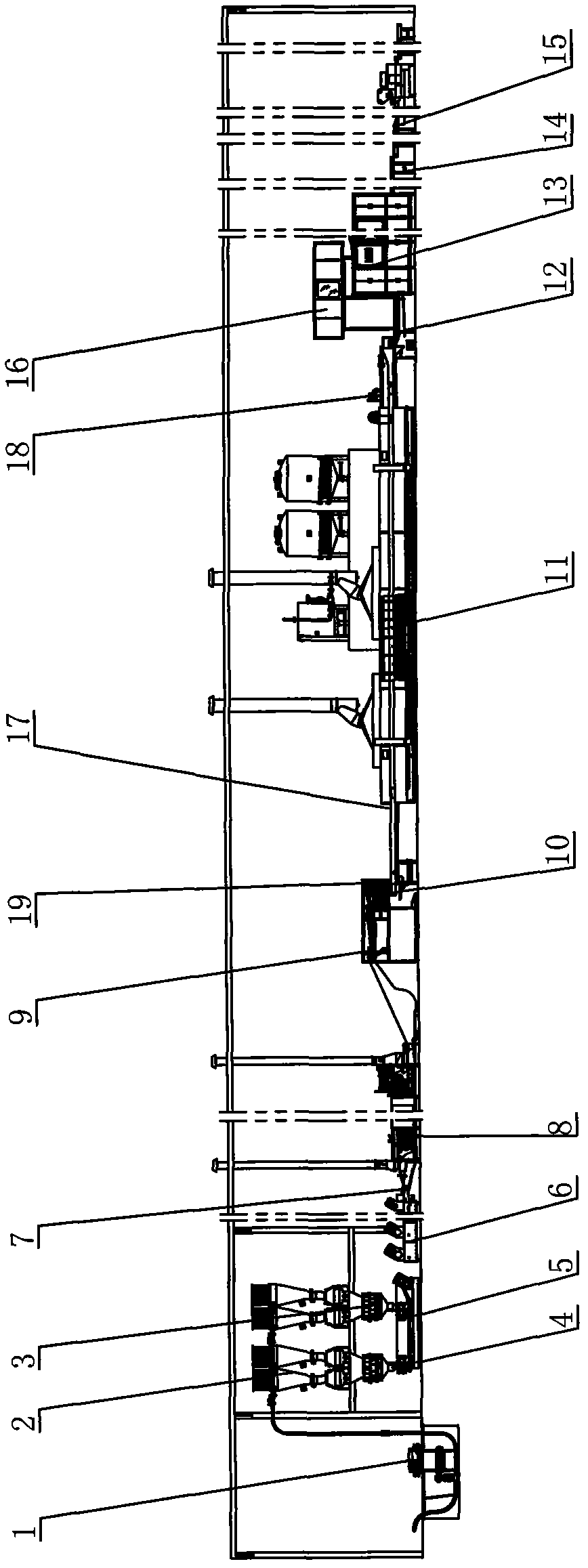

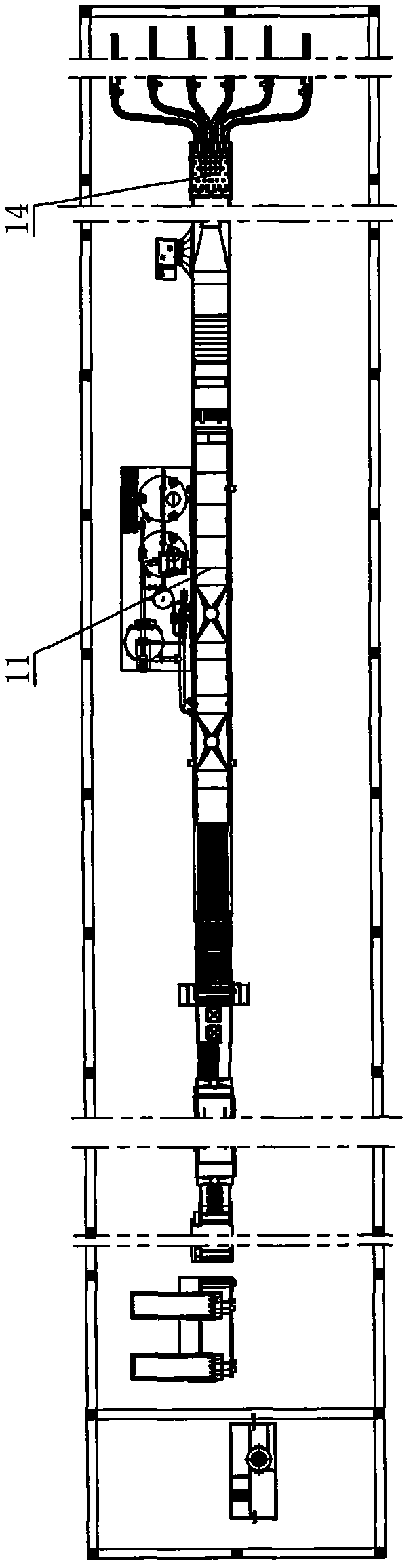

[0048] like Figure 1 to Figure 2 The fried straight noodle production line shown includes flour sieving machine 1, flour air conveyor 2, powder-liquid mixer 3, dough ripening conveyor 4, compound noodle press machine 5, continuous noodle press machine 6, Shred forming machine 7, three-layer steamed noodle machine 8, dry differential speed loosening machine 9, vibration loosening machine 19, quantitative cutting and box dropping machine 10, noodle oil shower machine 17, frying machine 11, noodle block removal Oil machine 18, alignment machine 12, air cooler 13, distribution conveyor 14 and packaging conveyor 15.

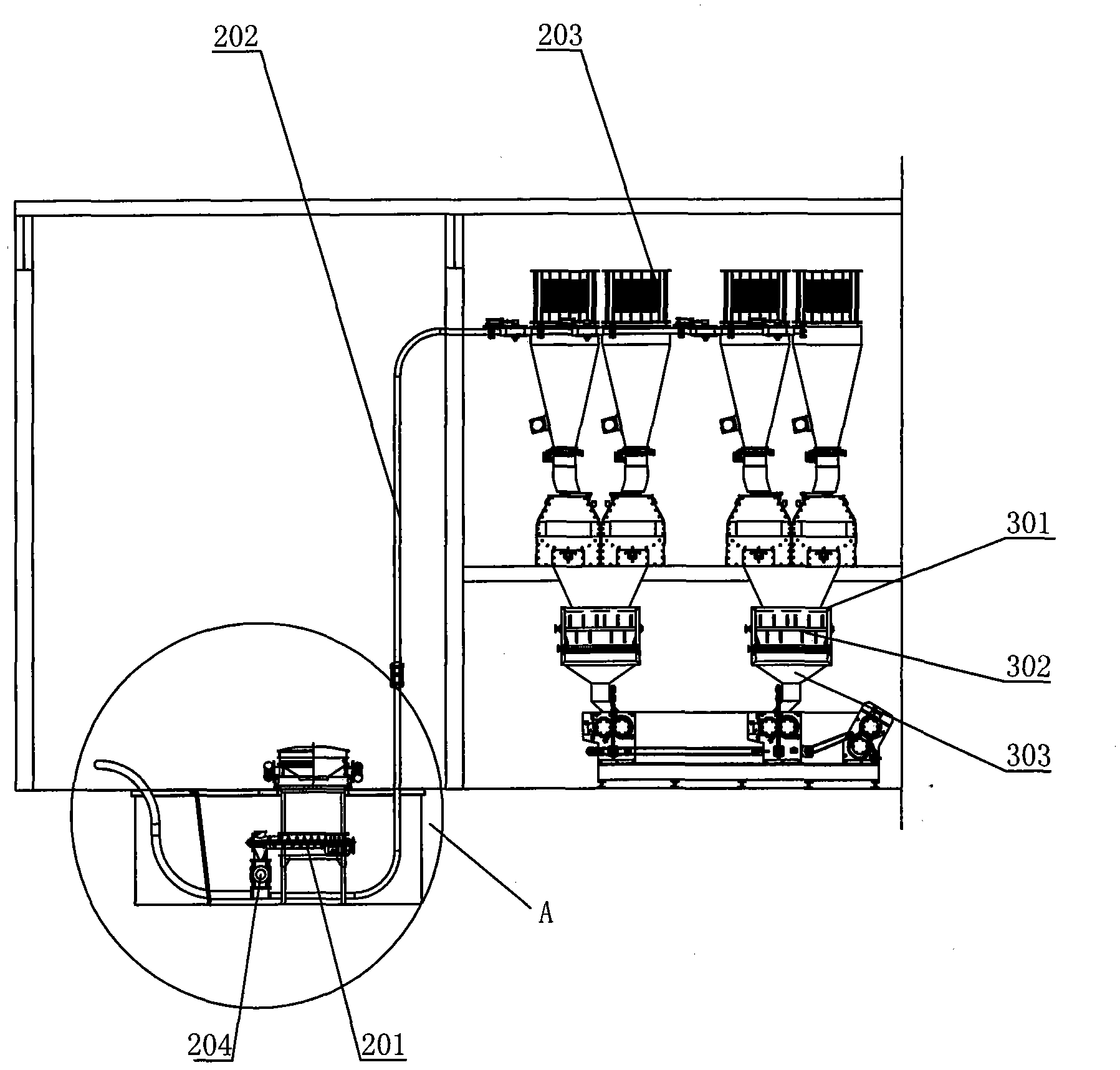

[0049] like image 3 and Figure 4 As shown, the flour air delivery machine 2 includes a feeder 201, an air delivery duct 202, a Roots blower (not shown), and an air delivery funnel 203. Feeding machine 201 comprises mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com