Intelligent garbage chamber with automatic dustbin replacing function

An automatic replacement and trash can technology, applied in the field of garbage room, can solve the problems of lack of intelligent turntable garbage room garbage delivery mechanism, unreasonable design of garbage delivery port, limited number of trash cans, etc., so as to reduce labor maintenance costs and improve space. The effect of utilization rate and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

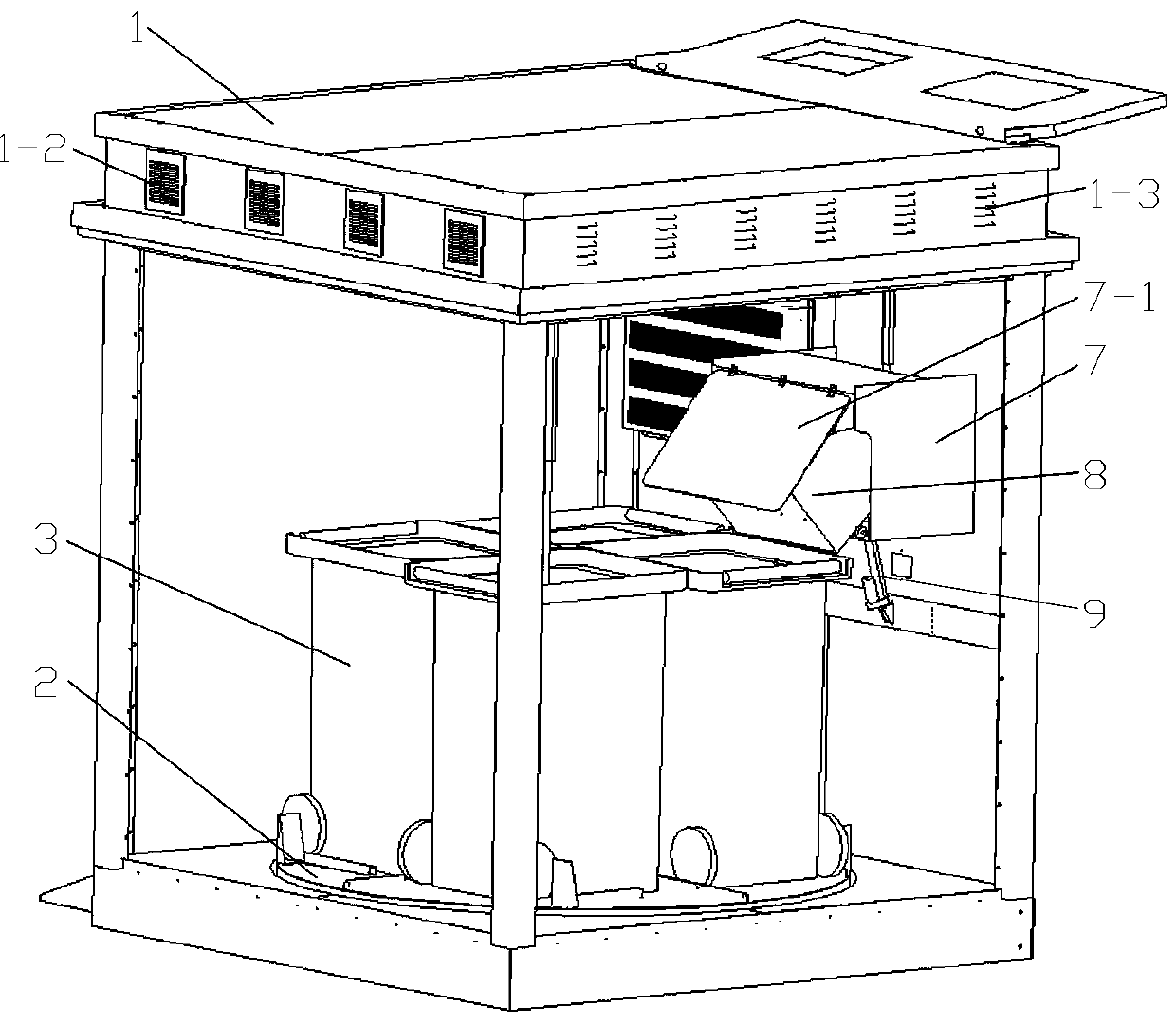

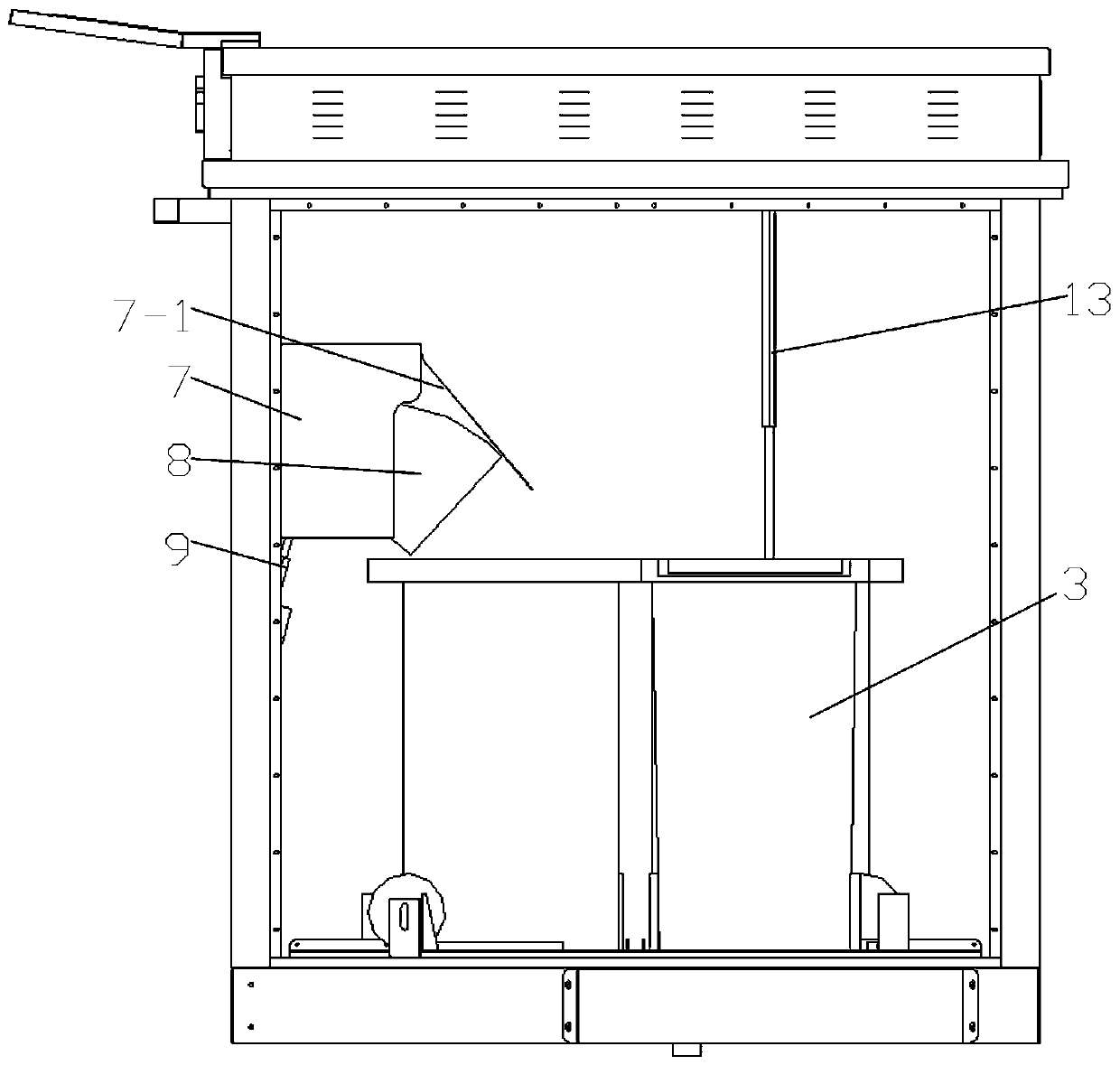

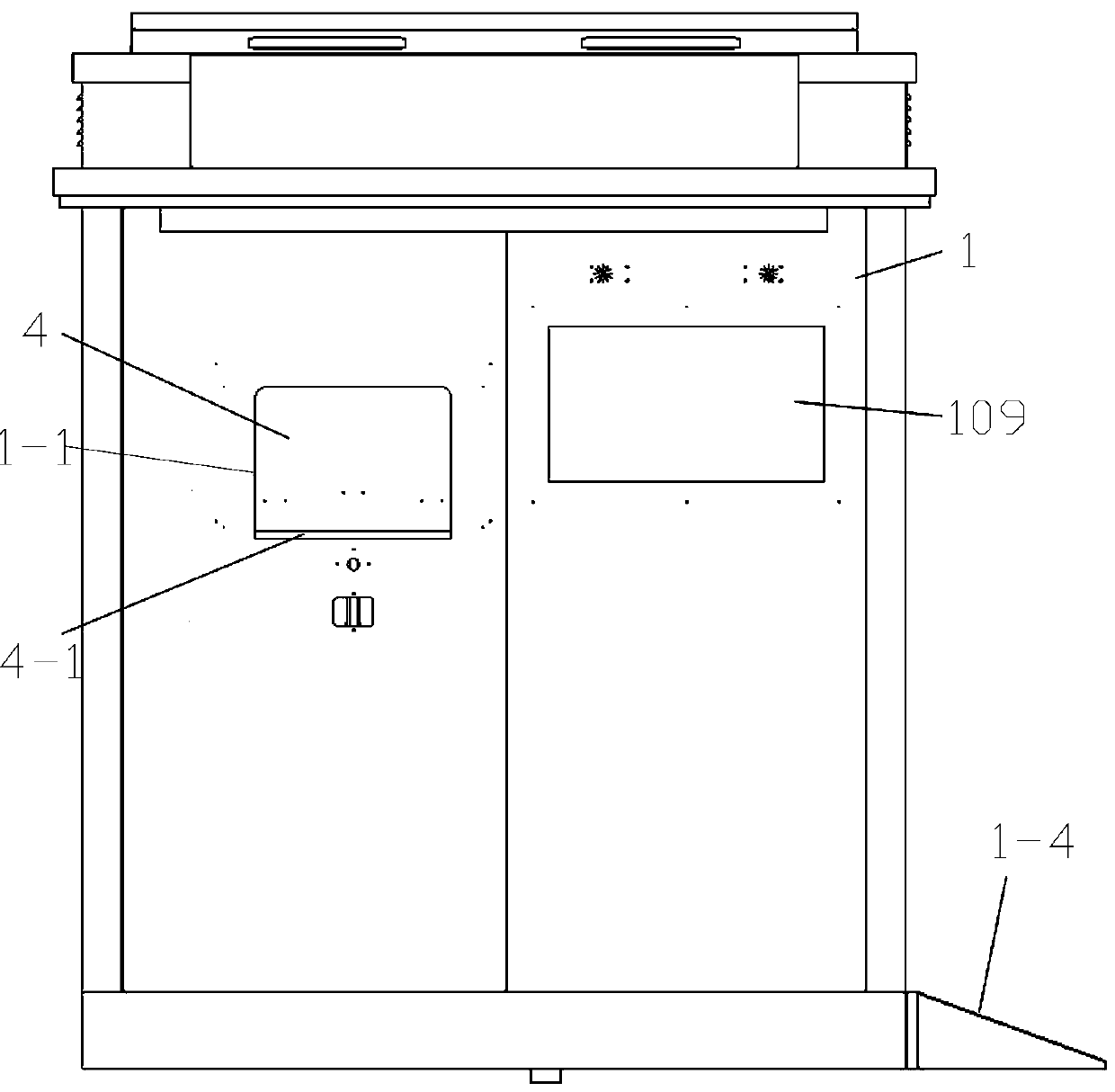

[0032]As shown in the figure: this embodiment provides an intelligent garbage room for automatic replacement of garbage cans, including a housing 1, a feeding port 1-1 is installed on the front of the housing 1, and a Discharge system, comprises intake fan 1-2 and exhaust window 1-3, is provided with the slope 1-4 that is used to facilitate garbage bin 3 to enter and exit on one side of housing 1, is installed on the bottom plate of housing 1 interior for Place the turntable 2 of the trash can 3, the turntable 2 can rotate relative to the bottom plate, the turntable 2 is a circular structure, and a plurality of isolation platforms 2-1 are arranged on the turntable 2, and the isolation platforms 2-1 are set outward from the center of the turntable 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com