Machine room evaporation, refrigeration and heat-extraction system and implementation method

An evaporative cooling and heat removal system technology, which is applied in heating and ventilation control systems, heating methods, air conditioning systems, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

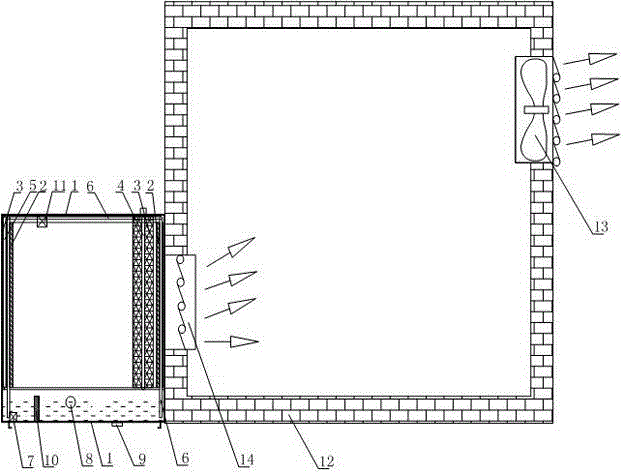

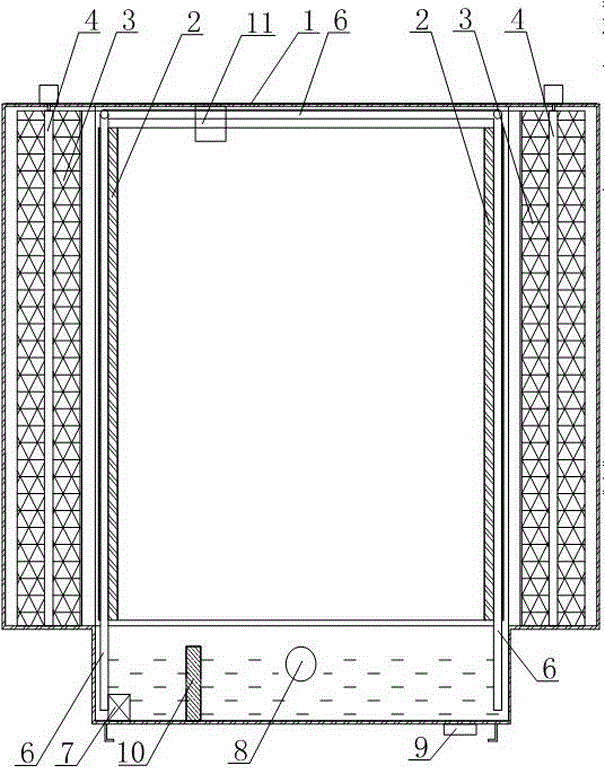

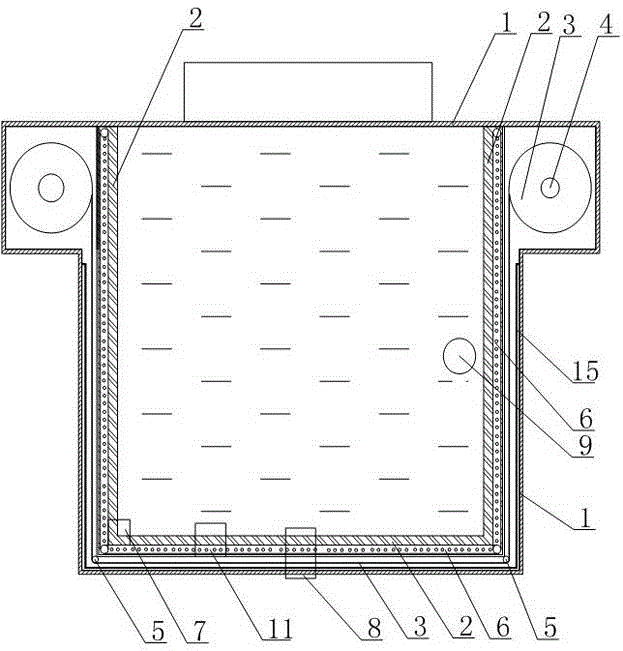

[0031] Such as figure 1 As shown, the machine room 12 of the present invention has an air inlet and an exhaust port. The air inlet and the exhaust port are located near the body diagonal of the machine room 12. An evaporative cooling device is installed at the air inlet. The evaporative cooling device includes a housing 1, The housing 1 is a cuboid, and the bottom of the housing 1 is airtight to form a water tank. A water inlet valve 8 and a drain valve 9 are installed at the position of the water tank. A liquid level sensor 10 is installed in the water tank, and the liquid level sensor 10 controls the state of the water inlet valve 8 Thereby control the water level in the water tank and keep it in a certain normal working range; the housing 1 has four sides, three of which are provided with air inlets, and nylon mesh is installed at the air inlets as a preliminary filter structure, which can also be Metal mesh 15 is used instead, and the other side is provided with an air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com