Cross-flow fan blade welding robot

A welding robot and cross-flow fan blade technology, applied in the field of cross-flow fan blade welding robots, can solve problems such as the advent of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

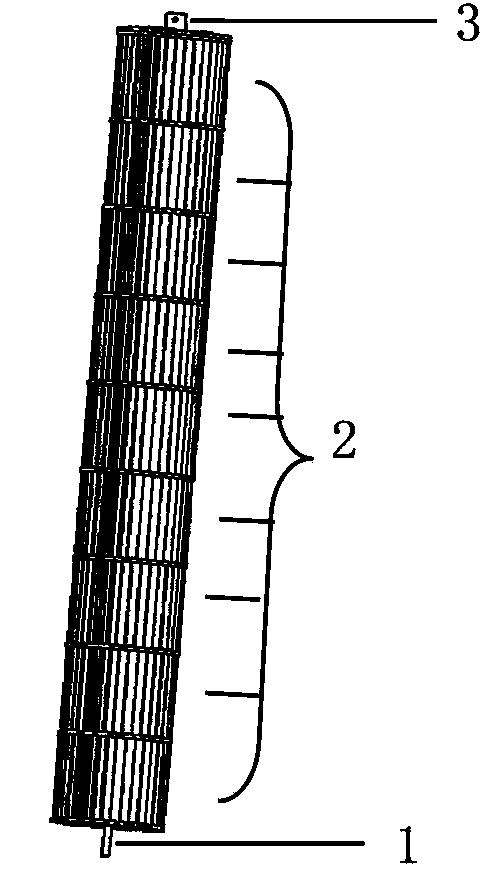

[0061] Example 1 Such as figure 1 As shown, the entire cross-flow fan blade is formed by a single shaft cover 1, a plurality of middle sections 2 and a single end cover 3 which are cascaded in sequence through an ultrasonic welding process. Among them, the shaft cover 1 is at the lowest end and the multiple middle sections 2 (From bottom to top, first to last) is in the middle and end cap 3 is at the top. Unless otherwise specified, the shaft cover, middle section and end cover are referred to as workpieces in the description of the present invention.

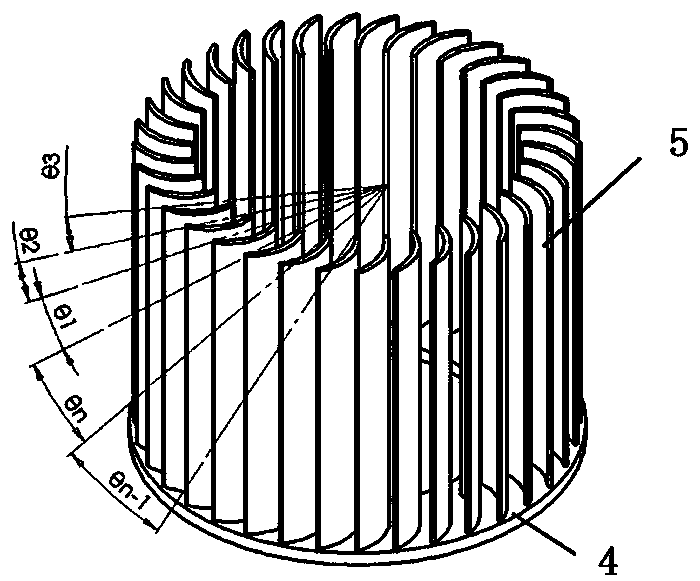

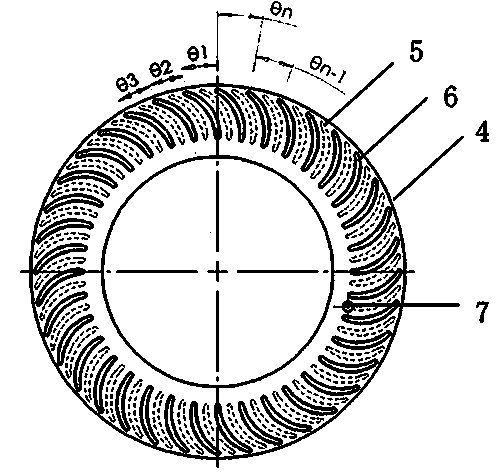

[0062] Such as figure 2 with image 3 The middle section 2 shown is composed of an A circular disk 4 and a plurality of A blades 5. The cross section of the A blade 5 is arc-shaped, and the rear end of the A blade 5 is connected to the lower surface of the circular disk 4, The upper surface of the A circular wheel 4 is provided with the same number of A positioning lobes 6 as the A blades 5, which are used to insert another mi...

Embodiment 2

[0095] Example 2 Picture 10 A preferred embodiment suitable for internal repair end caps is shown. versus Figure 8 In comparison, the difference is that the inner repair end cover belt line feeding mechanism replaces the outer repair end cover vibration plate feeding mechanism 28. The inner repair end cover belt line feeding mechanism includes a storage belt line 33 and a storage belt line 33 For the connected feeding belt line 34, the other embodiments are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com