Automatic welding rod replacing device for rotor spot welding machine

A spot welding machine and welding rod technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of high requirements for the consistency of welding rod size and increase the labor intensity of workers, so as to ensure consistency and reduce labor. Strength, the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

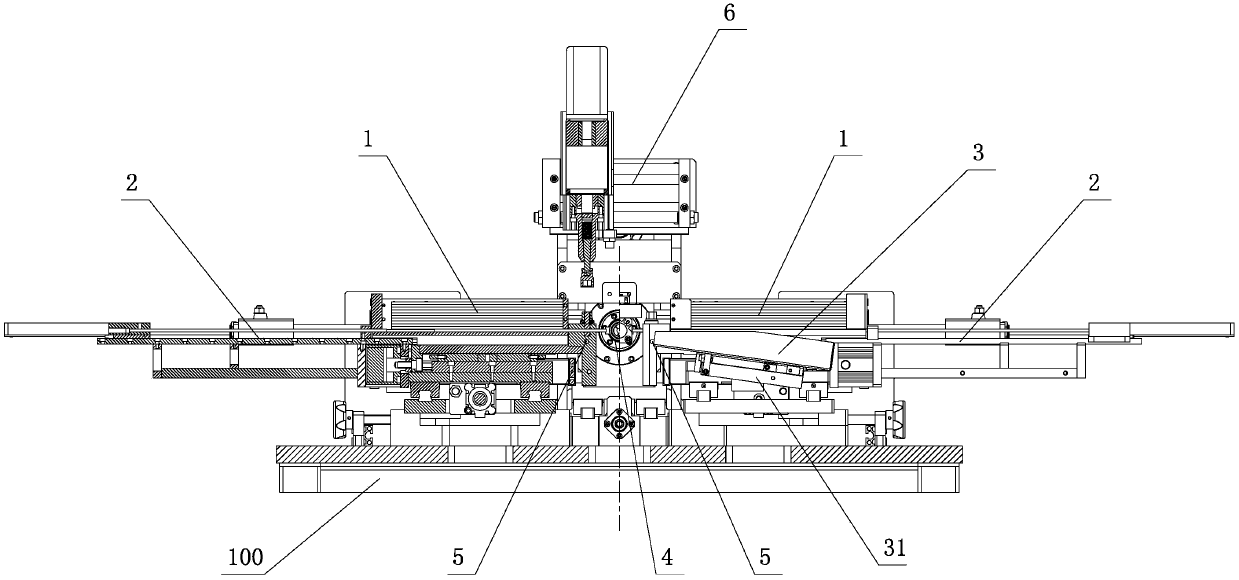

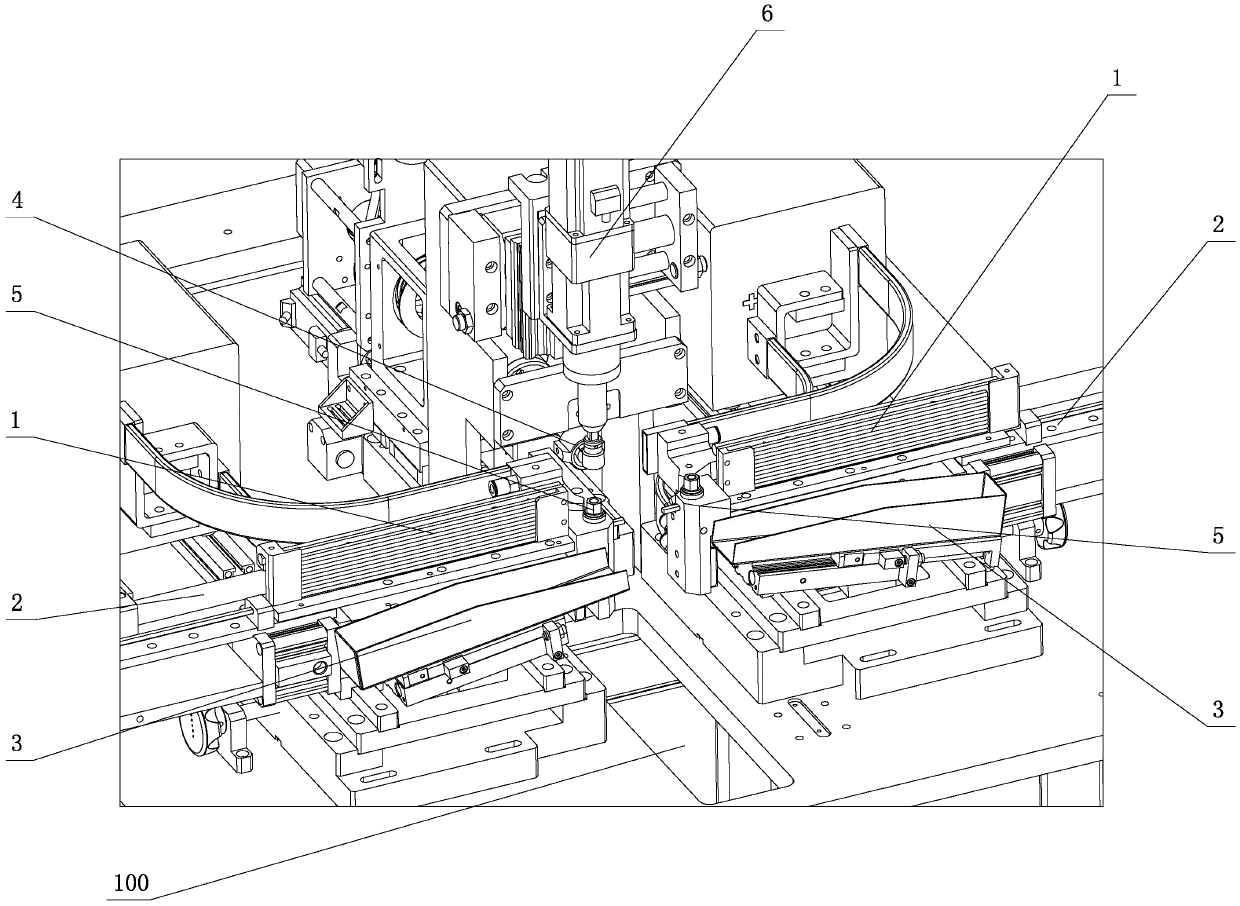

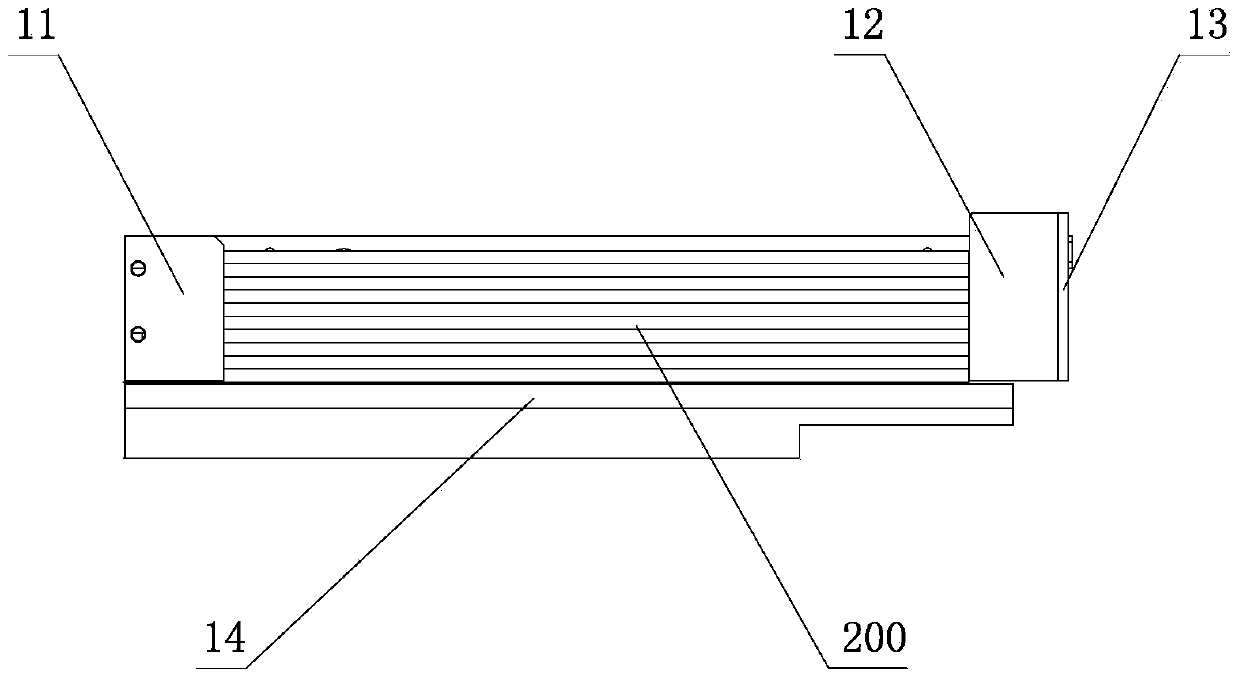

[0023] Refer to attached picture.

[0024] The automatic welding rod changing device of the rotor spot welding machine of the present invention comprises a frame 100, which is provided with a new welding rod storage folder 1, a welding rod pusher mechanism 2, an old welding rod receiving device 3, and a welding rod positioning Device 4, welding rod clamping seat 5 and tightening device 6, the new welding rod storage folder 1 is used to store spare welding rods, the welding rod pusher mechanism 2 is used to push the welding rod to the position required for welding, and the old welding rod is connected The material device 3 is used to collect incompletely used welding rods (discarded welding rods) to keep the working environment of the device clean and tidy. The welding rod positioning device 4 is used to position the welding rods pushed out by the welding rod pusher mechanism 2. The end face is in a suitable position for welding. The welding rod clamping seat 5 is used to clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com