Scroll filter and automatic control method thereof

A filter and reel technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of excessive replacement, inaccurate replacement time of filter cotton, and incomplete replacement, so as to overcome the problems of excessive replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

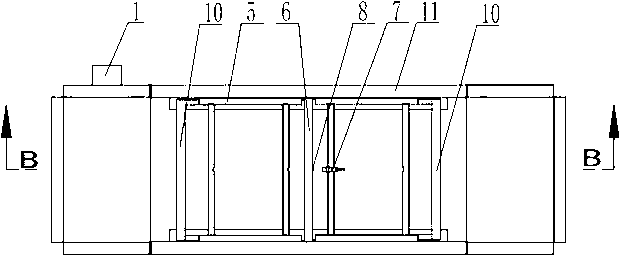

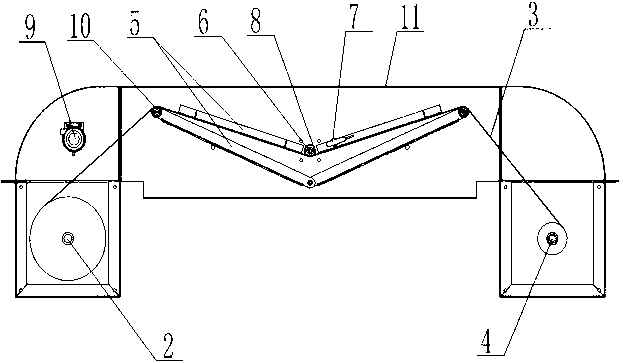

[0022] Such as Figures 1 to 2 As shown, the scroll filter of the present invention includes a housing 11, the housing 11 can be split or integral, and two scrolls are arranged in the housing 11, one of which is used as the driving scroll 2 and is installed with The reel motor 1, the other reel is used as the driven reel 4 for placing the whole roll of filter cotton 3, a support 5 is installed between the active reel 2 and the driven reel 4, the support 5 of the present embodiment is a V-shaped structure, Two ends of support 5 are provided with cylinder 10, and rolling bar 6 is installed in the middle part of support, and the girth of rolling bar 6 is 4.5cm, and the total length of whole filter cotton 3 through filter surface is 90cm, roll bar 6 A magnetic steel 8 with a Hall sensor is installed on the top, and a probe 7 of a Hall sensor matching the magnetic steel is also installed on the bracket 5. The filter cotton 3 is pulled out from the driven reel 4 and passed through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com