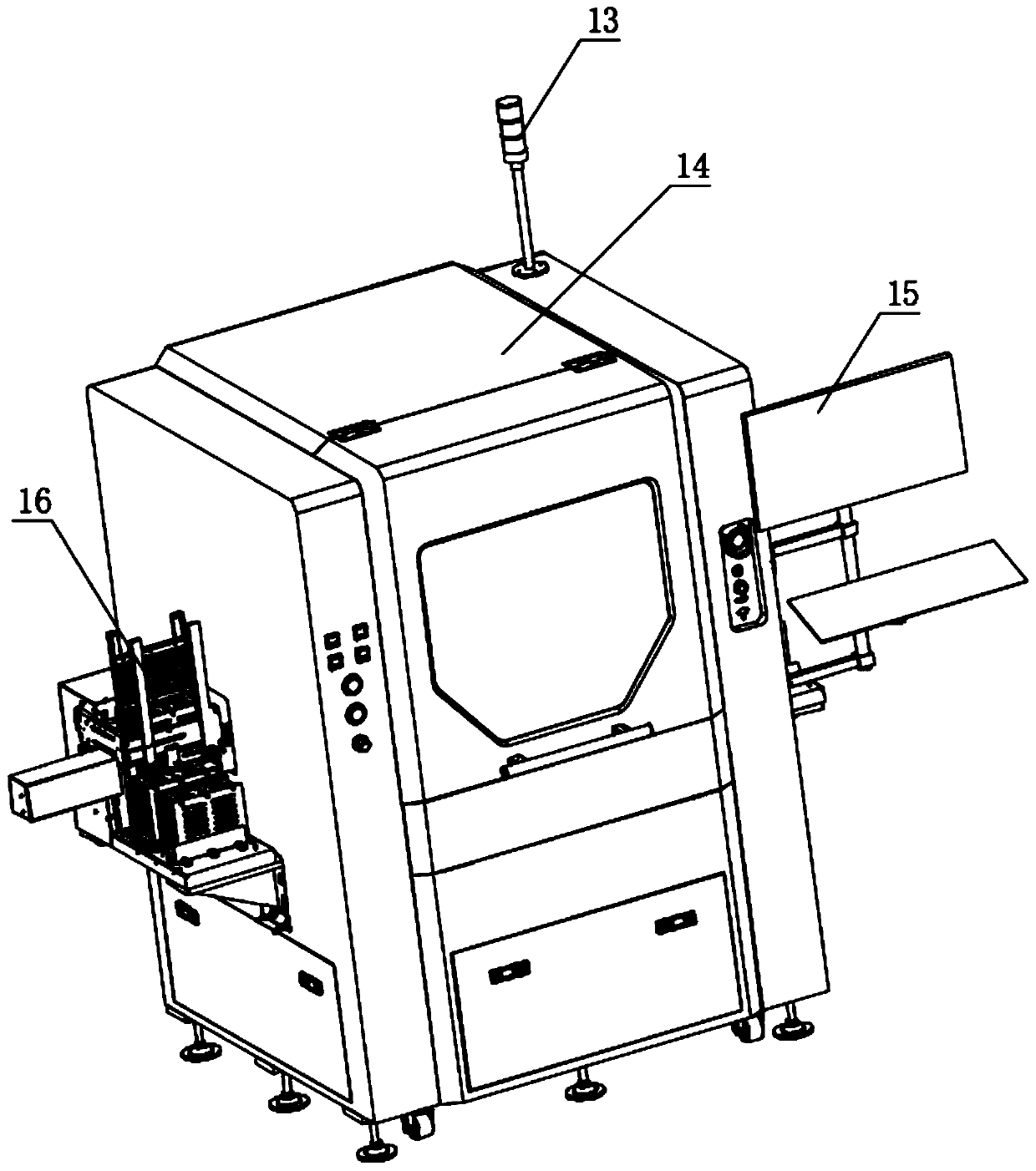

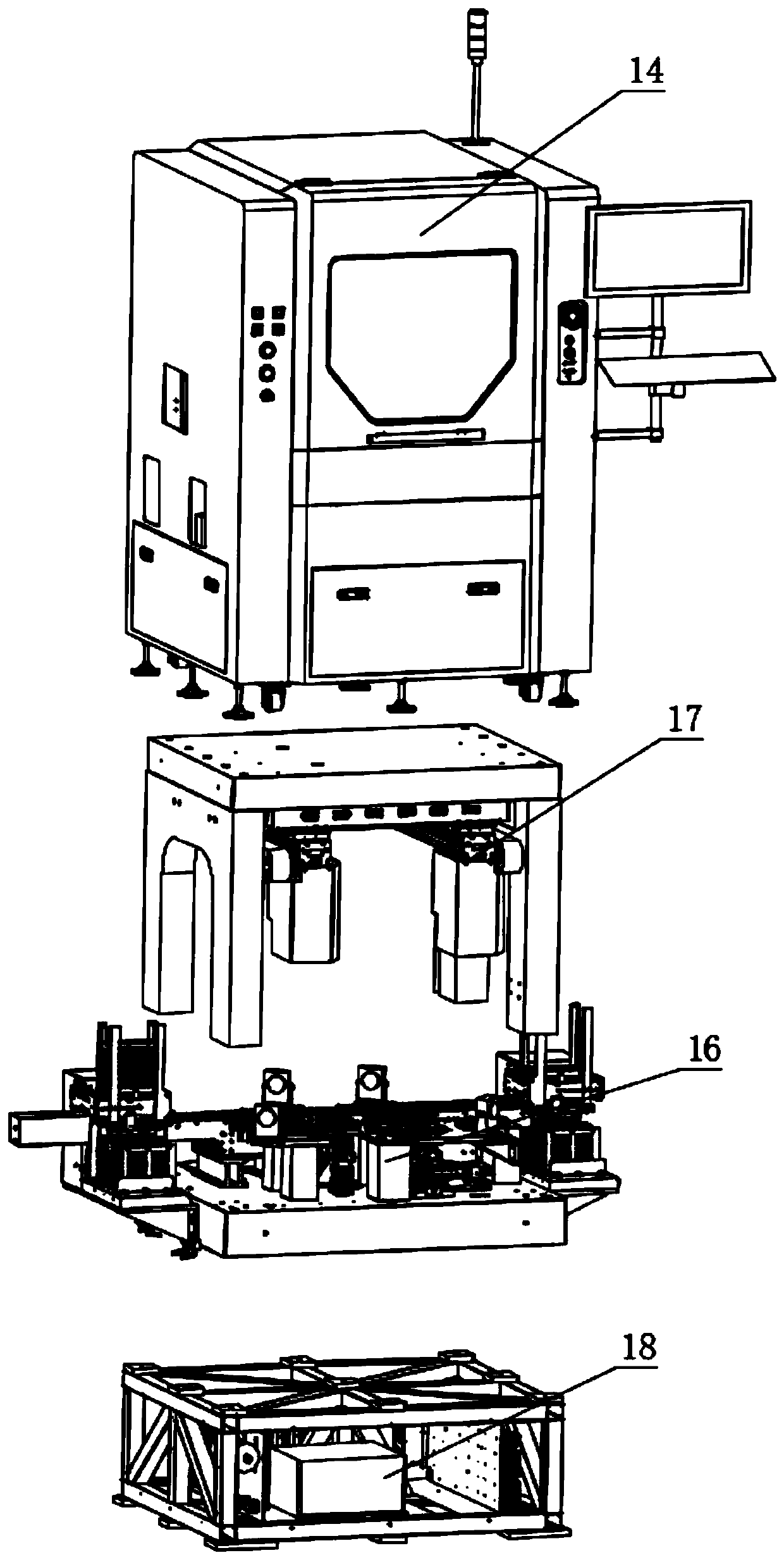

High-precision multifunctional chip mounter and using method thereof

A multi-functional, chip loader technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of slow speed, high operator requirements, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

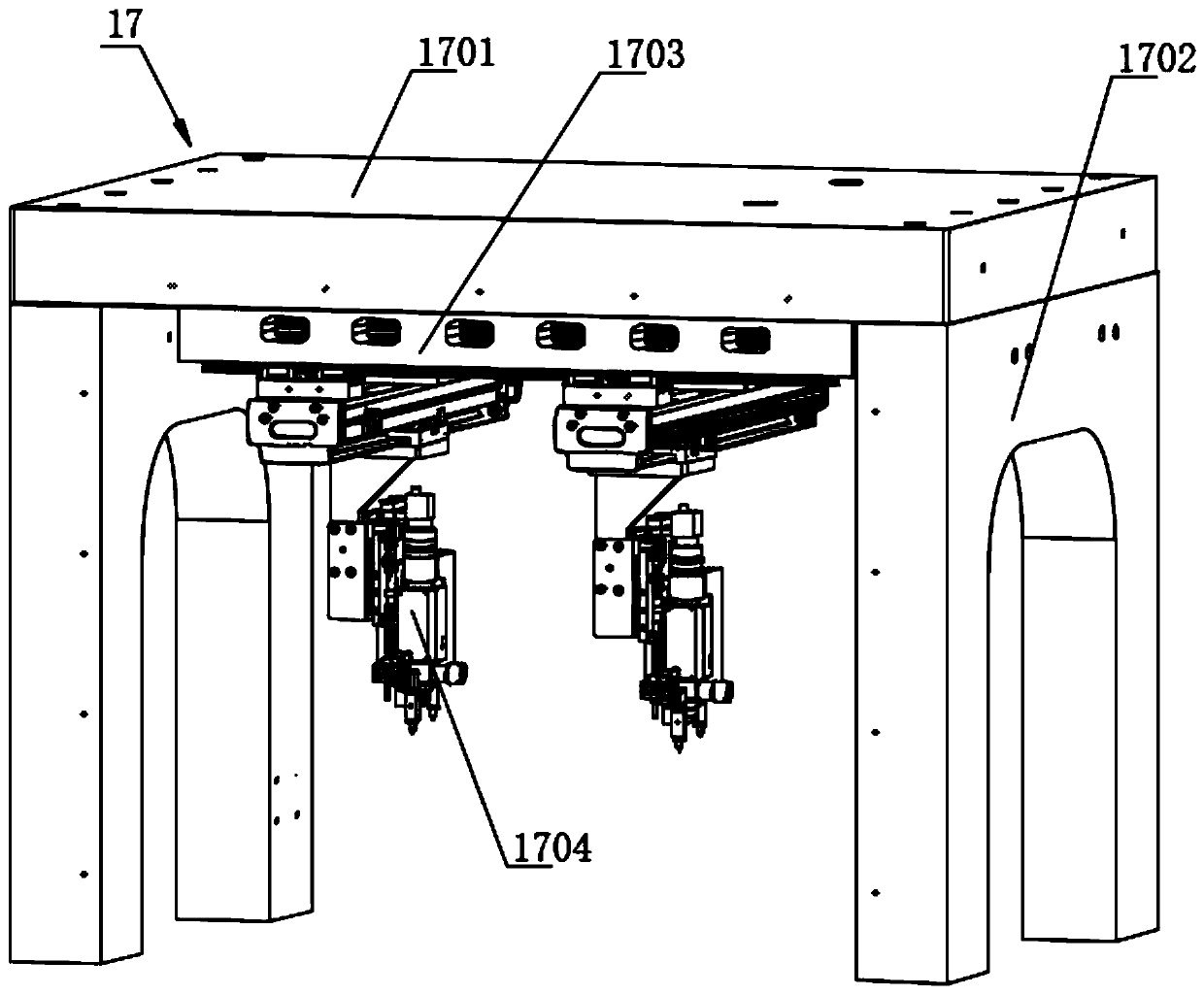

[0160] Embodiment 1: Take a chip pasted as an example for illustration

[0161] Manually install the same suction nozzle 17443 and glue dipping needle 174614 on the suction nozzle assembly 1744 and the glue dipping assembly 1746 of the two welding head mechanisms 1704; In the sheet feeding mechanism 2; place two empty sheet material boxes at the same position of the unloading mechanism 3; same as the above step 3, place the jig 57 with the chip magazine 58 on the jig base of station one seat 52;

[0162] Through the display screen 15 to start the program, the pushing system 203 pushes the tablet from the tablet magazine onto the rail conveying mechanism 12, and transports it forward along the track; when the first tablet is delivered to the middle track assembly 1205, The ejecting mechanism ejects and fixes the tablet 19, and when the second tablet is delivered to the front track assembly 1206, it is also fixed by the same ejecting mechanism;

[0163] Repeat the above step s...

Embodiment 2

[0166] Embodiment 2: Take two kinds of chips as an example for illustration.

[0167] The difference from Embodiment 1 is that different suction nozzles 17443 and different glue dipping needles 174614 are manually installed on the suction nozzle assembly 1744 and the glue dipping assembly 1746 of the two welding head mechanisms 1704, and the station one and station two respectively Place different chips.

Embodiment 3

[0168] Embodiment 3: take three types of chips as an example for illustration.

[0169] The difference with Embodiment 1 is:

[0170] Manually install different suction nozzles 17443 and different glue dipping needles 174614 on the suction nozzle assembly 1744 and the glue dipping assembly 1746 of the two welding head mechanisms 1704;

[0171] Manually place the suction nozzle 17443 and the glue-dipping needle 174614 that will be used in the process on the quick-change mechanism 8;

[0172] Manually place different chips into station 1 and station 2 according to assembly requirements;

[0173] Carry out the chip mounting action with the above steps; when it is necessary to replace the suction nozzle 17443 or the glue dipping needle 174614, the welding head mechanism 1704 moves to the quick change mechanism 8 under the drive of the linear motion component 1703, and the suction nozzle component 1744 Hang the suction nozzle 17443 and the glue dipping needle 174614 on the glue dip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com