Tensioning device of conveyer belt of sealing machine

A technology of tensioning device and conveyor belt, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of low elasticity, slippage and poor adaptability of the belt, and achieve the effect of compensating the slack of the conveyor belt, stable transmission and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

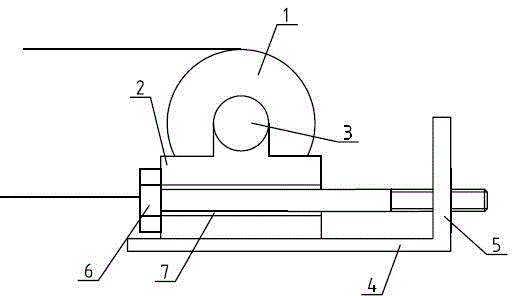

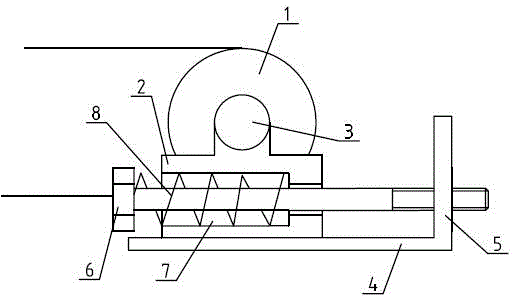

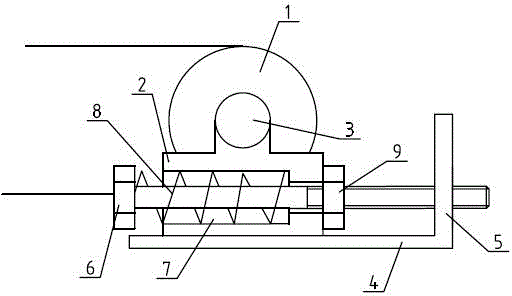

[0018] Such as figure 1 As shown, a sealing machine conveyor belt tensioning device includes a tensioning wheel 1, the tensioning wheel 1 is arranged on the inner side of the conveyor belt, and also includes a movable frame 2, and the tensioning wheel 1 is hinged on the On the movable frame 2, the movable frame 2 is arranged on the support 4 through the guide rail, the movable frame 2 can slide along the guide rail, the support 4 forms a protrusion 5 to the movable frame 2 side, and the adjusting bolt 6 Pass through the hole 7 on the movable frame 2 and connect with the protrusion 5 .

Embodiment 2

[0020] Such as figure 1 As shown, on the basis of the first embodiment, the hole 7 is a stepped hole, and the spring 8 is arranged between the head of the adjusting bolt 6 and the step of the hole 7 .

Embodiment 3

[0022] Such as figure 1 As shown, on the basis of the second embodiment, the adjusting bolt 6 is further provided with a limit nut 9 , and the limit nut 9 is arranged on the side of the movable frame 2 close to the protrusion 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com