A hydraulic control system of automatic tensioning and free-releasing rope winch

A hydraulic control system and tensioning technology, applied in the direction of fluid pressure actuators, servo motors, hoisting devices, etc., can solve the problems of poor accuracy and real-time performance of the control process, simple working conditions, slow start-up response, etc., to achieve Improve the start-up response speed, improve the conveying efficiency, and facilitate the effect of tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

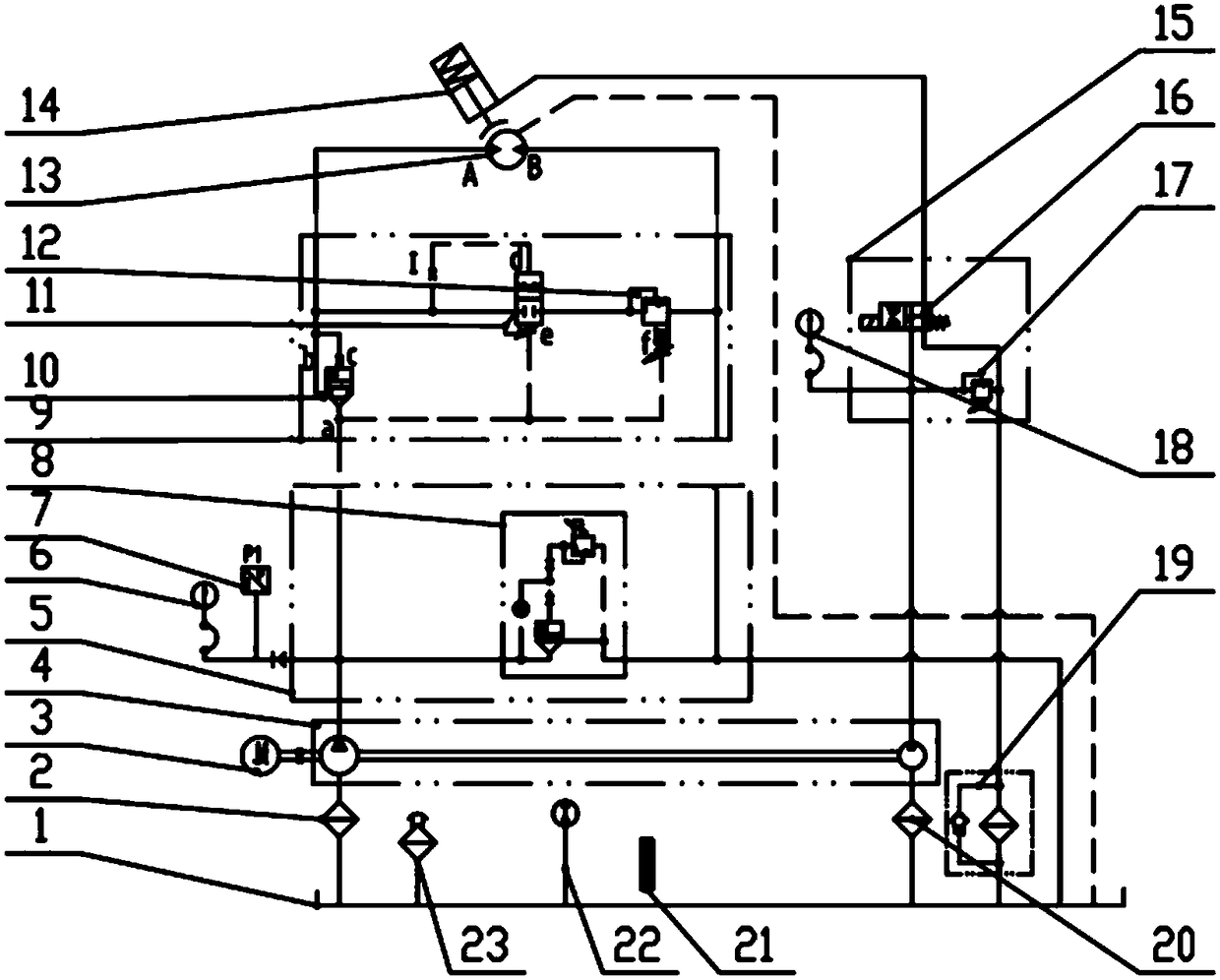

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] Such as figure 1 As shown, the automatic tensioning and free-releasing winch hydraulic control system includes a fuel tank 1, an electric motor 3, a double pump 4 and a motor 13, and the motor 13 is connected to the winch drum, and also includes a pressure control system 5, an automatic rope-releasing Control assembly 9, braking system assembly and controller, pressure control system 5 includes first pressure gauge 6, pressure transmitter 7 and proportional overflow valve 8; control reversing valve 11 and pilot relief valve 12; brake system components include a brake 14 and a brake valve group 15 for braking the motor 13, and the brake valve group 15 is composed of an electromagnetic reversing valve 16, a relief valve 17 and the second pressure gauge 18 form;

[0019] The duplex pump 4 is composed of a large displacement pump and a small displacement pump connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com