Patents

Literature

34results about How to "Easy Tension Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

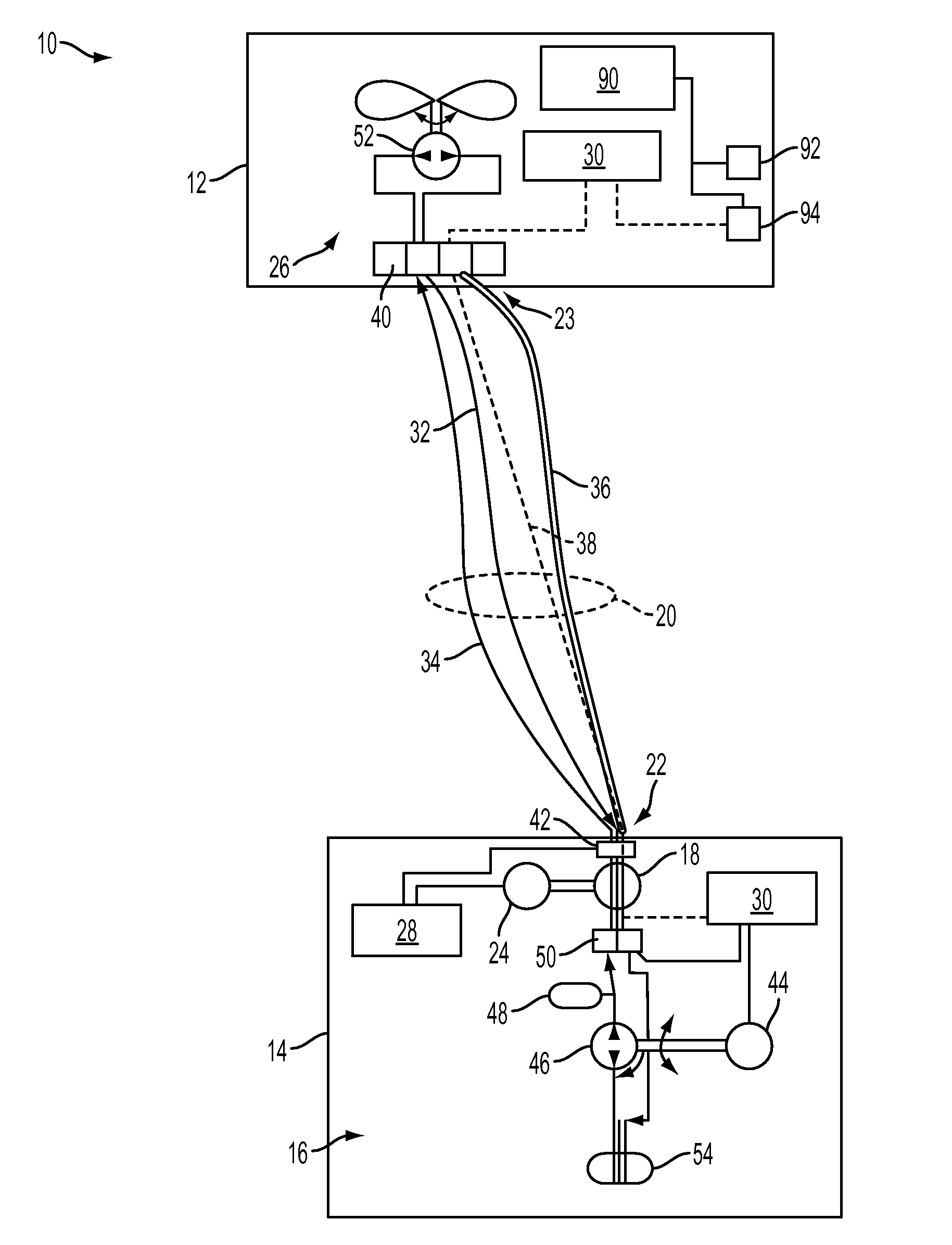

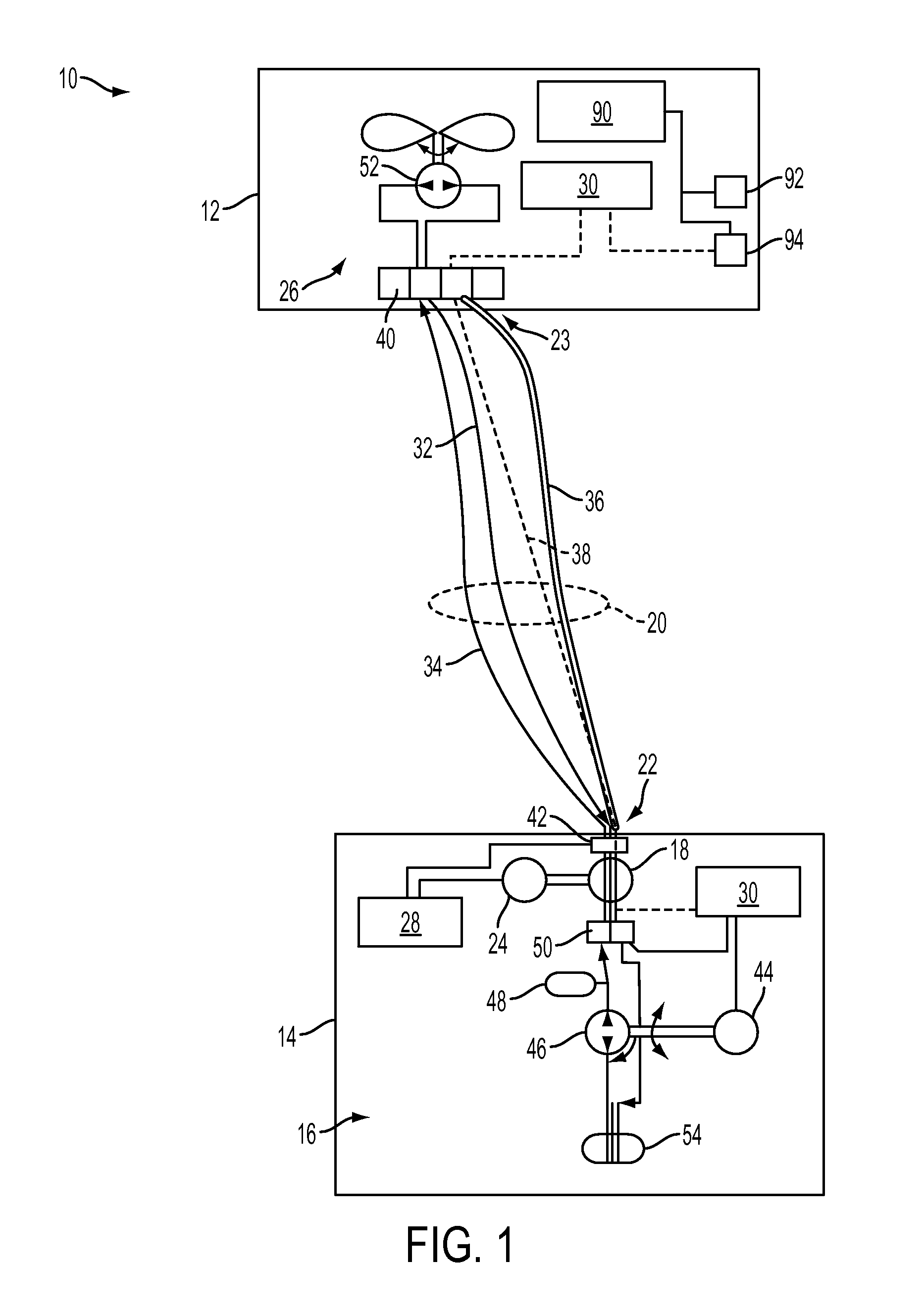

Tether energy supply system

InactiveUS20110180667A1Eliminate weightEliminate riskTethered aircraftPower plant fuel tanksDistributed control systemElectric machinery

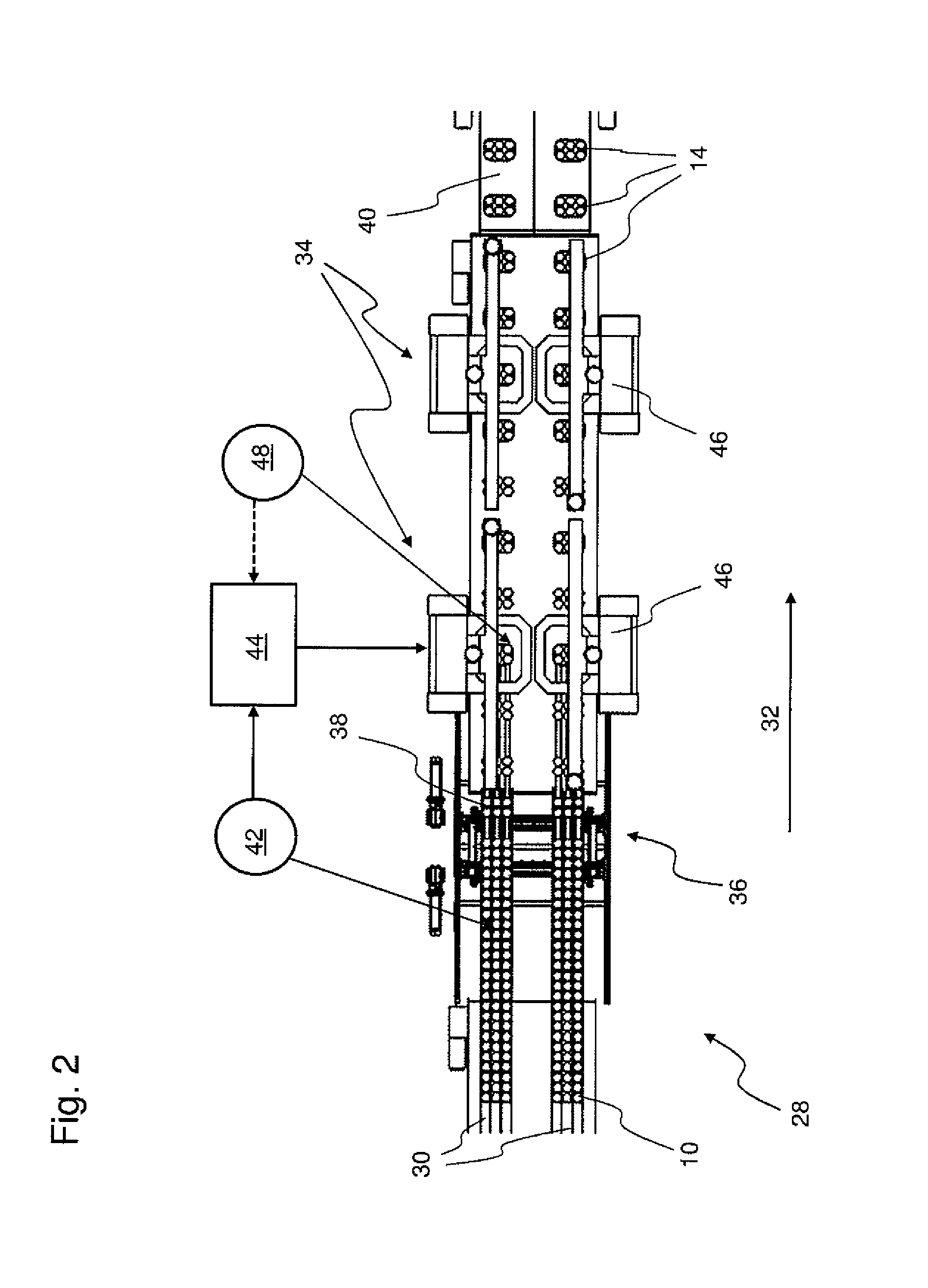

A tether continuous energy supply system for an unmanned aerial vehicle comprising: a ground station, a ground station energy system, a spool coupled to the ground station energy system at a rotating joint, a tether that is wound about the spool, wherein a first end of the tether is coupled to the rotating joint, a tension control motor coupled to both the spool and the ground station energy system, an unmanned aerial vehicle coupled to a second end of the tether, a UAV energy system, a fluid that moves throughout the tether continuous energy supply system, a tension control system that receives and transmits signals from a plurality of sensors contained within the tether continuous energy supply system, and a distributed controls system that receives and transmits signals from the plurality of sensors contained within the tether continuous energy supply system.

Owner:HONEYWELL INT INC

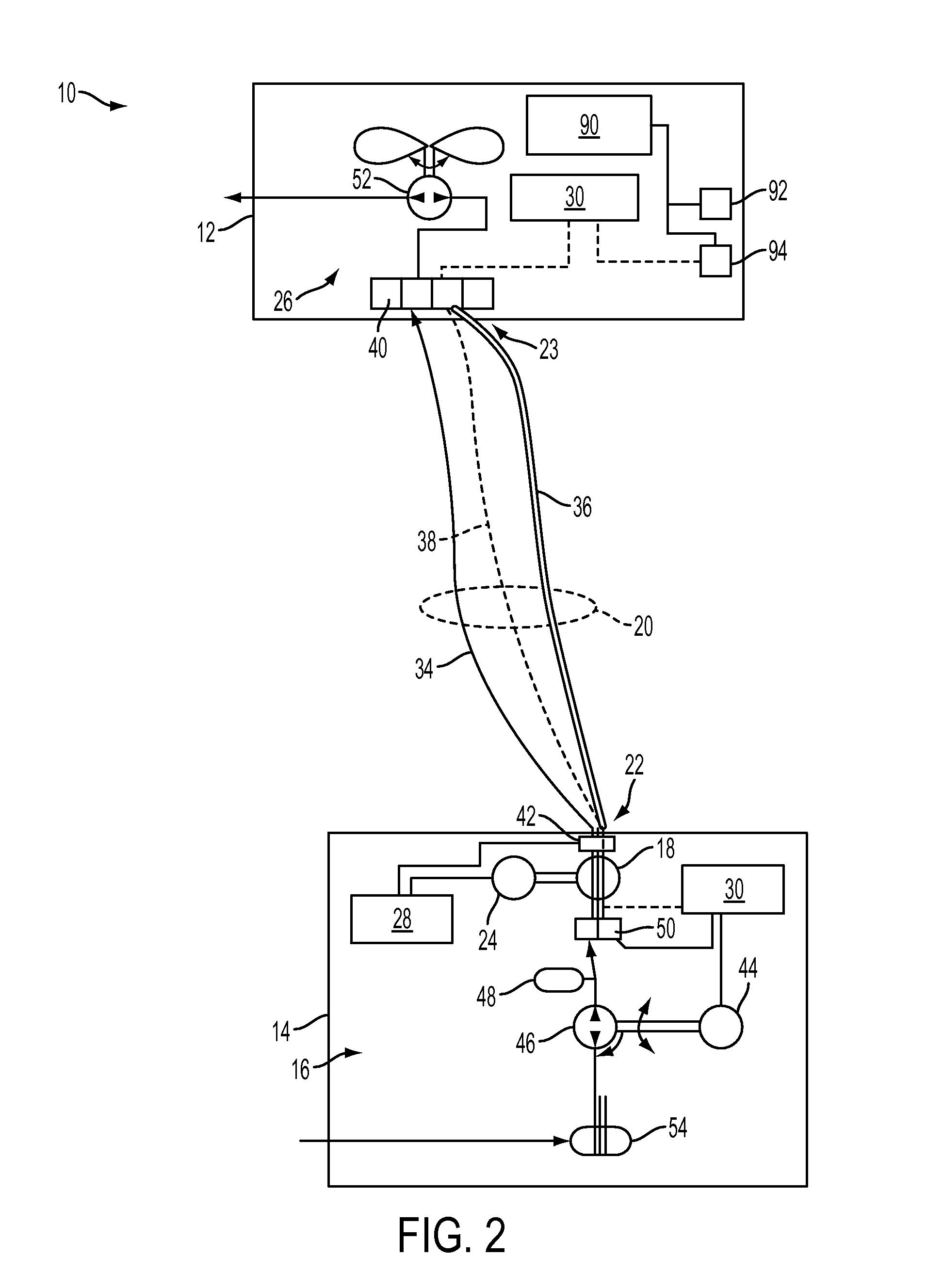

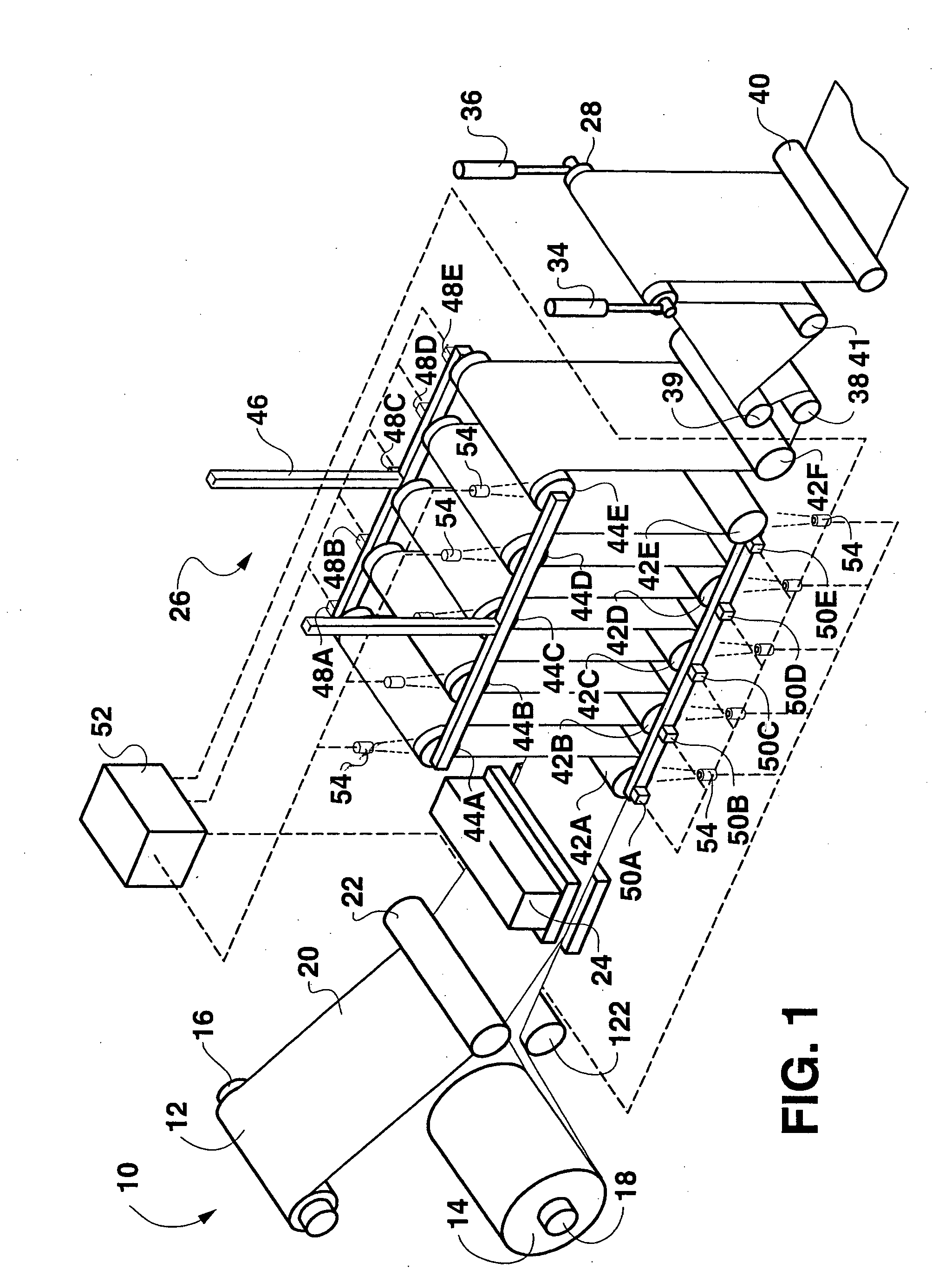

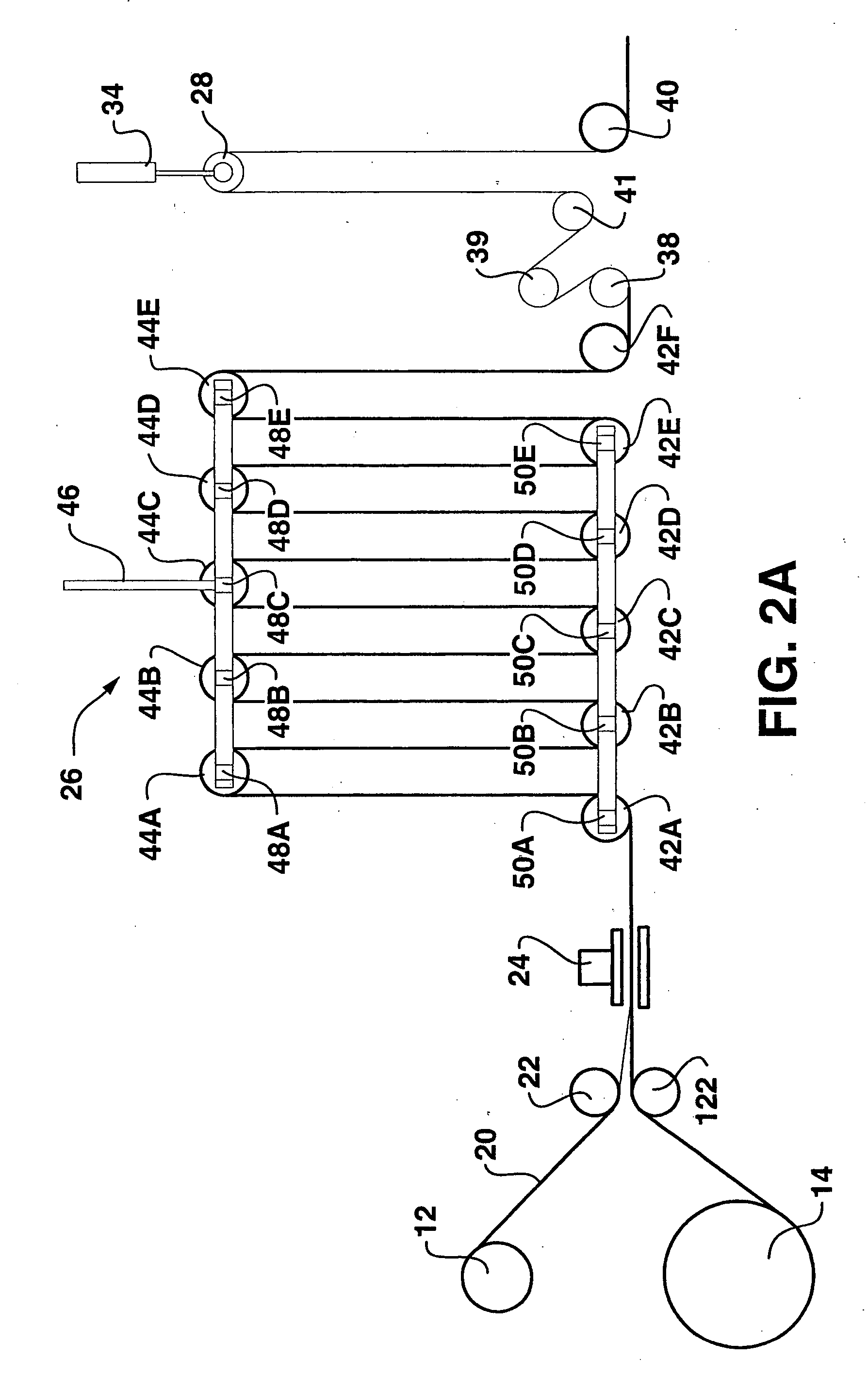

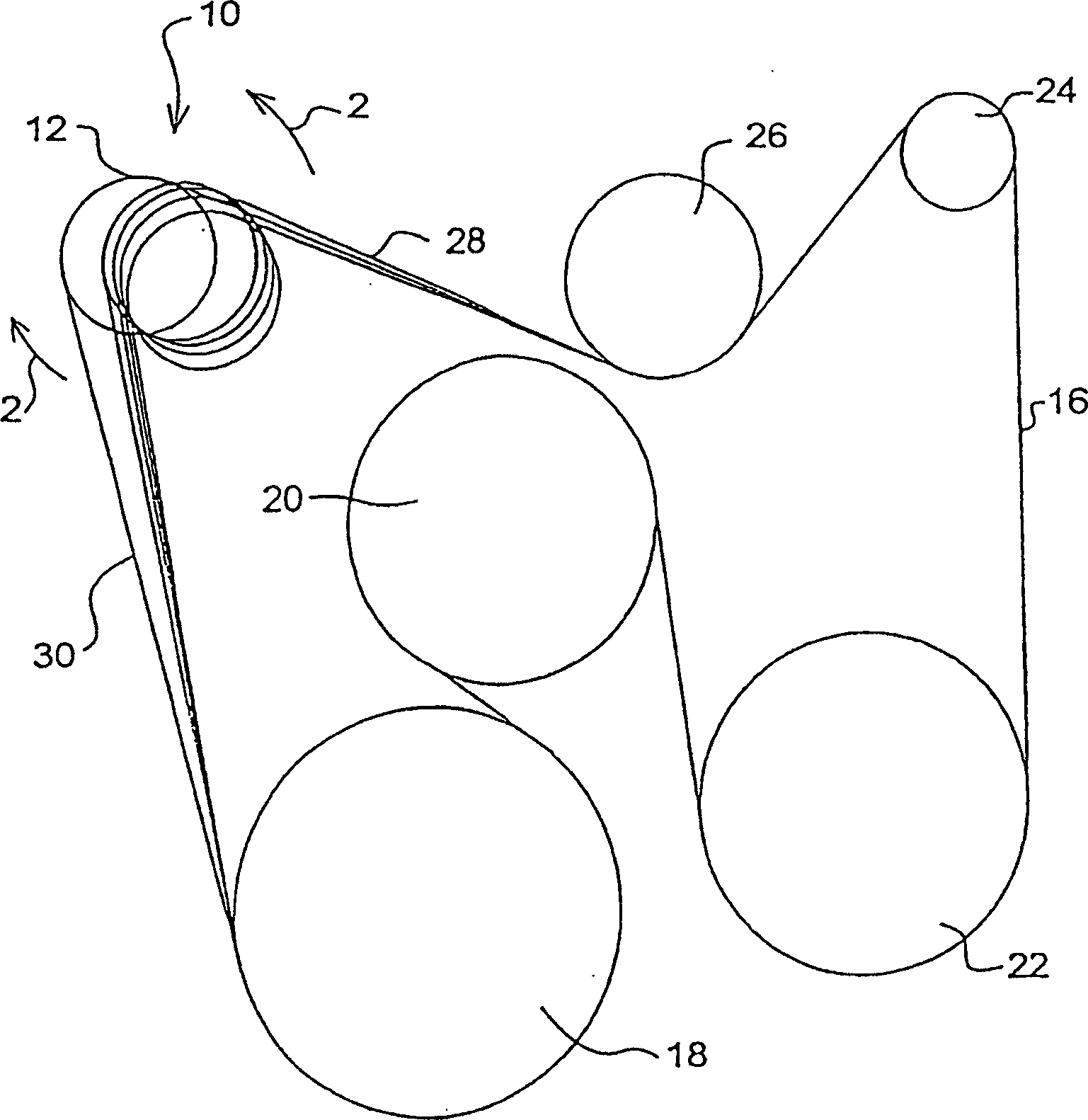

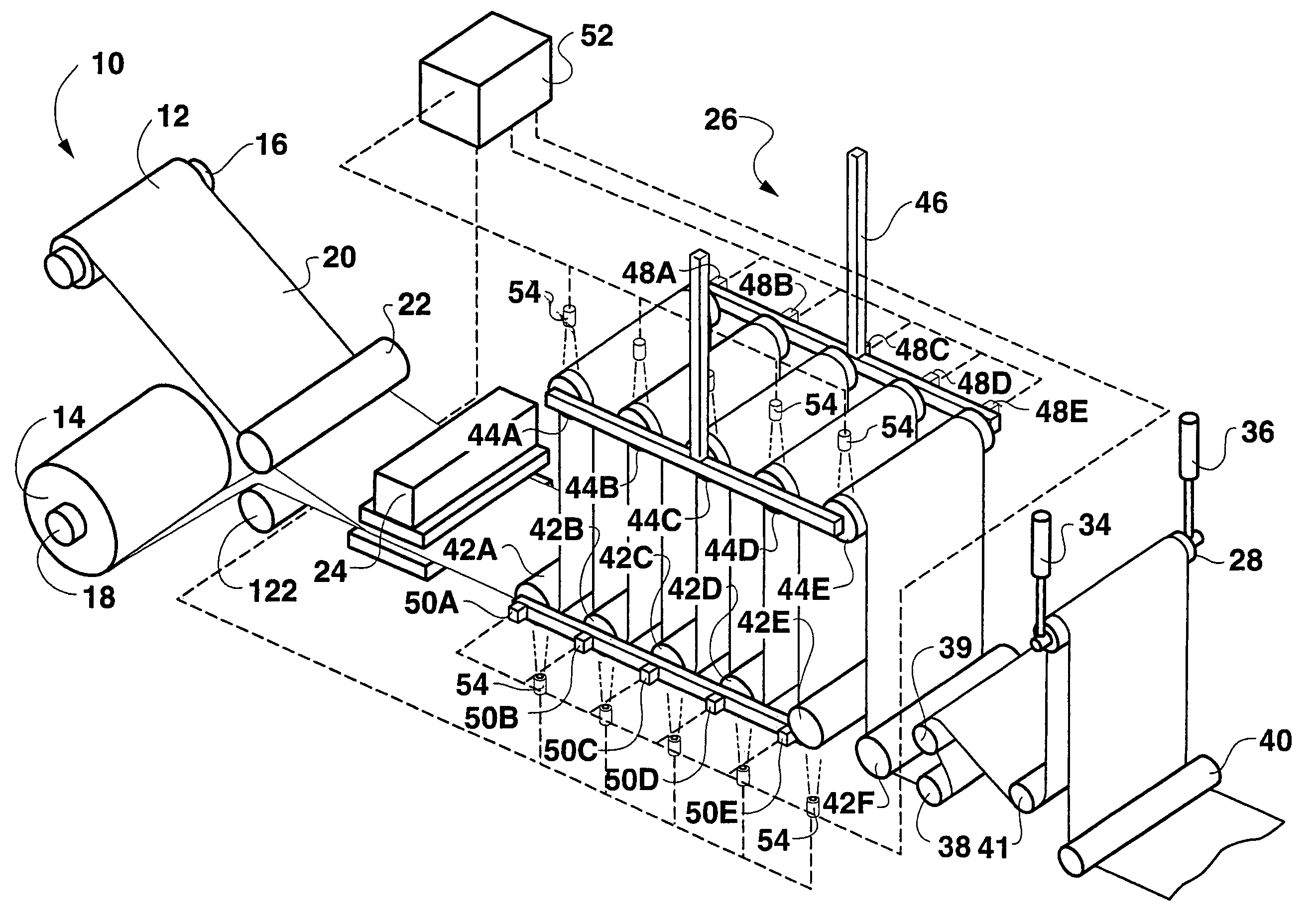

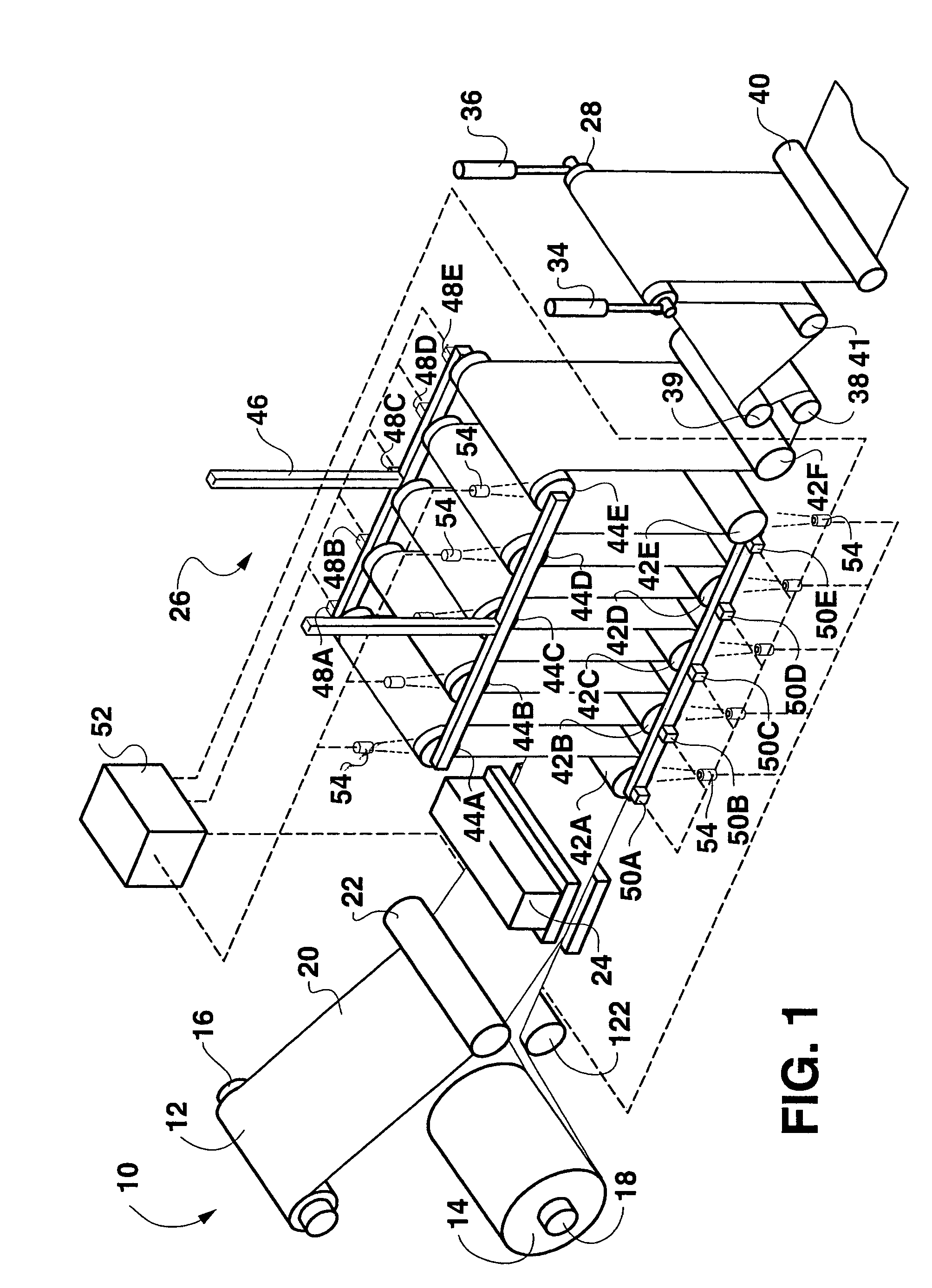

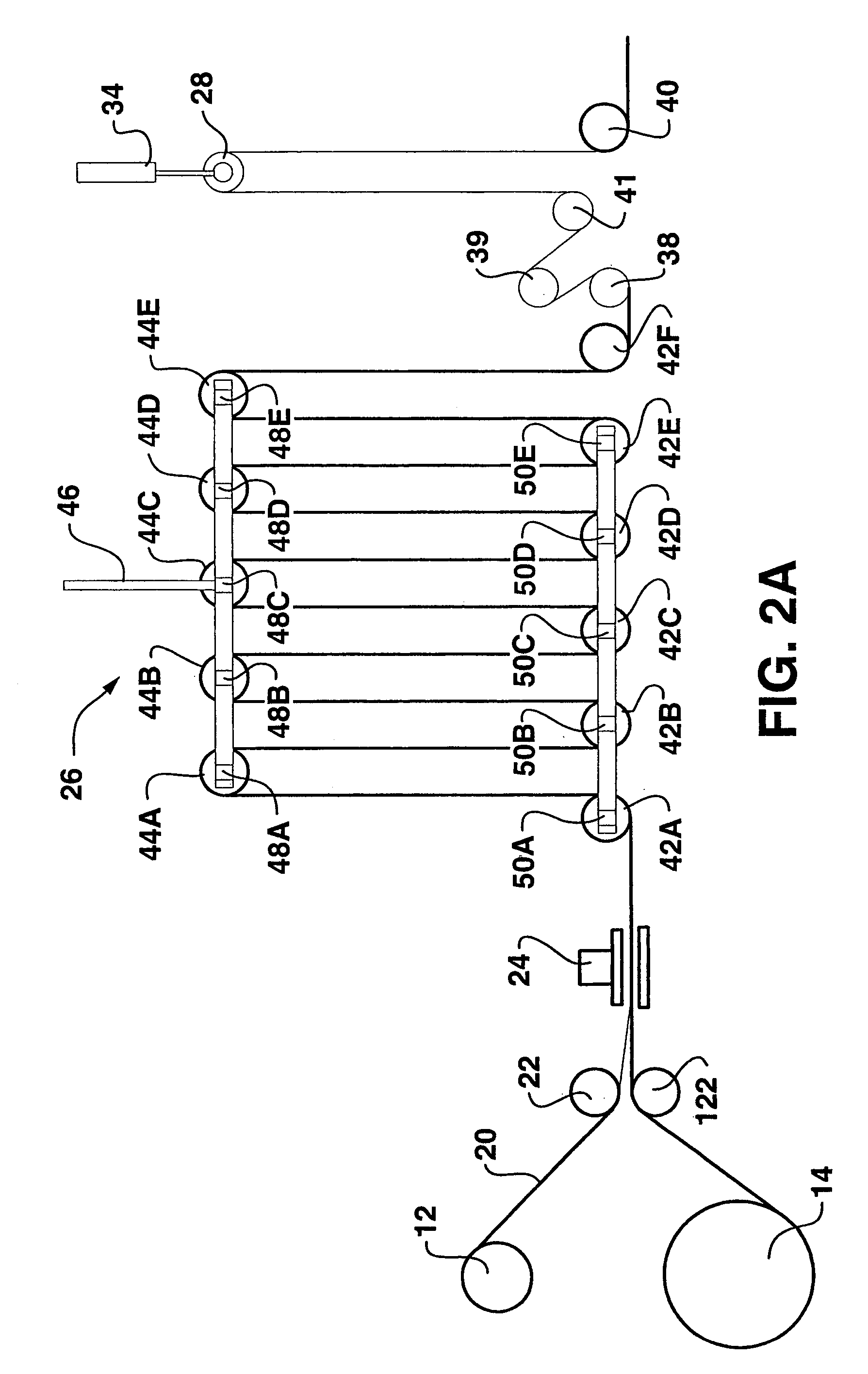

System and process for controlling the deceleration and acceleration rates of a sheet material in forming absorbent articles

ActiveUS20050139713A1Reduce tensionReduce probabilityFilament handlingRecord information storageEngineeringAcceleration rate

A system and process for unwinding materials in forming absorbent articles is described. The system includes an unwind device in association with a festoon. The festoon is for accumulating a determined length of material. The amount of material contained in the festoon is increased or decreased depending upon the rate at which a roll of material is unwound in relation to the rate at which the first material is fed into a downstream process. In order to minimize the capacity of the festoon and in order to minimize tension swings in the festoon, the festoon includes a plurality of drive devices associated with selected guide rolls contained in the festoon. The drive devices can accelerate and / or decelerate the guide rolls in response to rate increases or decreases occurring at the unwind device in relation to the downstream process speed. In one embodiment, each of the guide rolls is controlled independently of the remaining guide rolls in the festoon.

Owner:KIMBERLY-CLARK WORLDWIDE INC

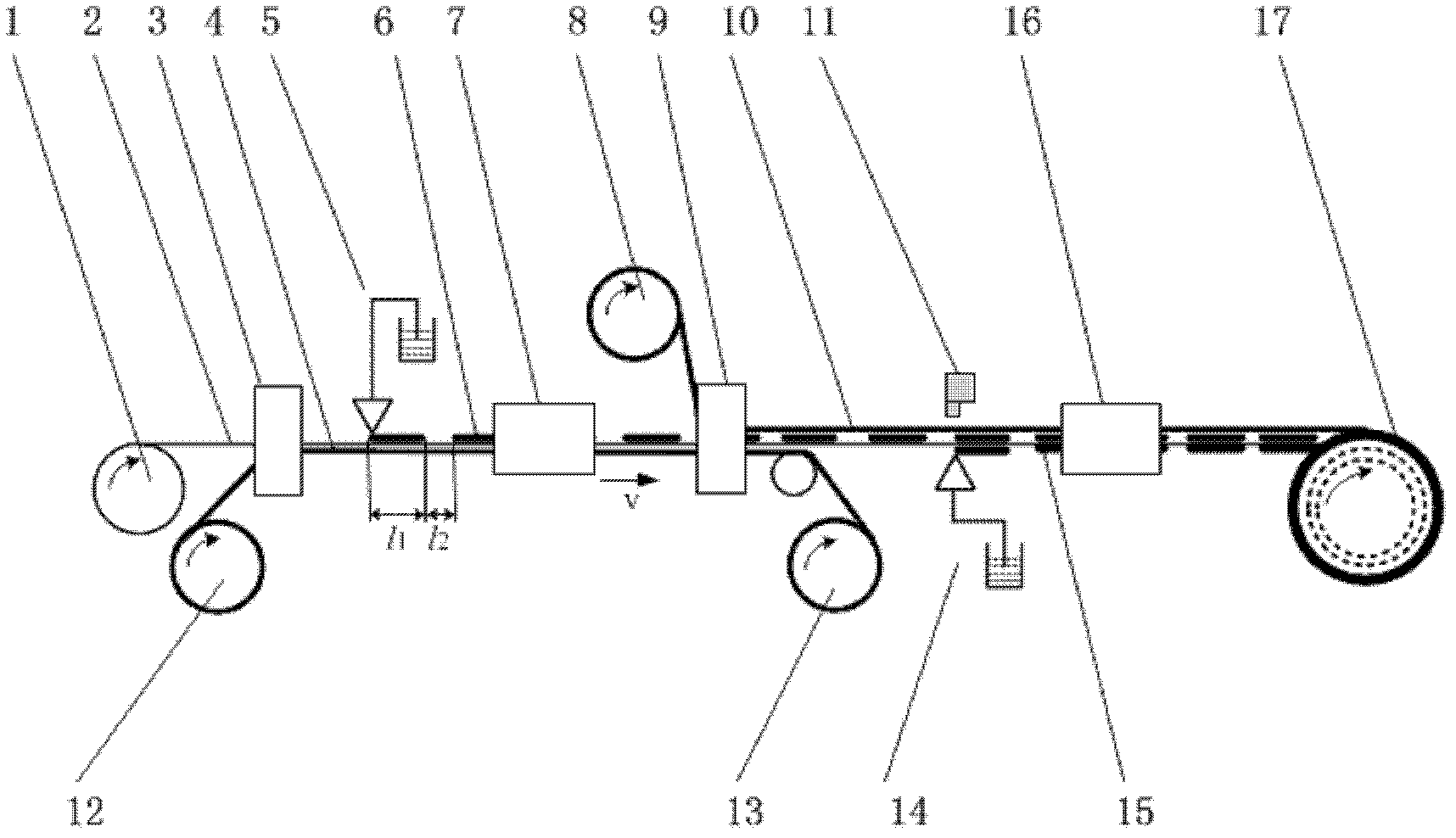

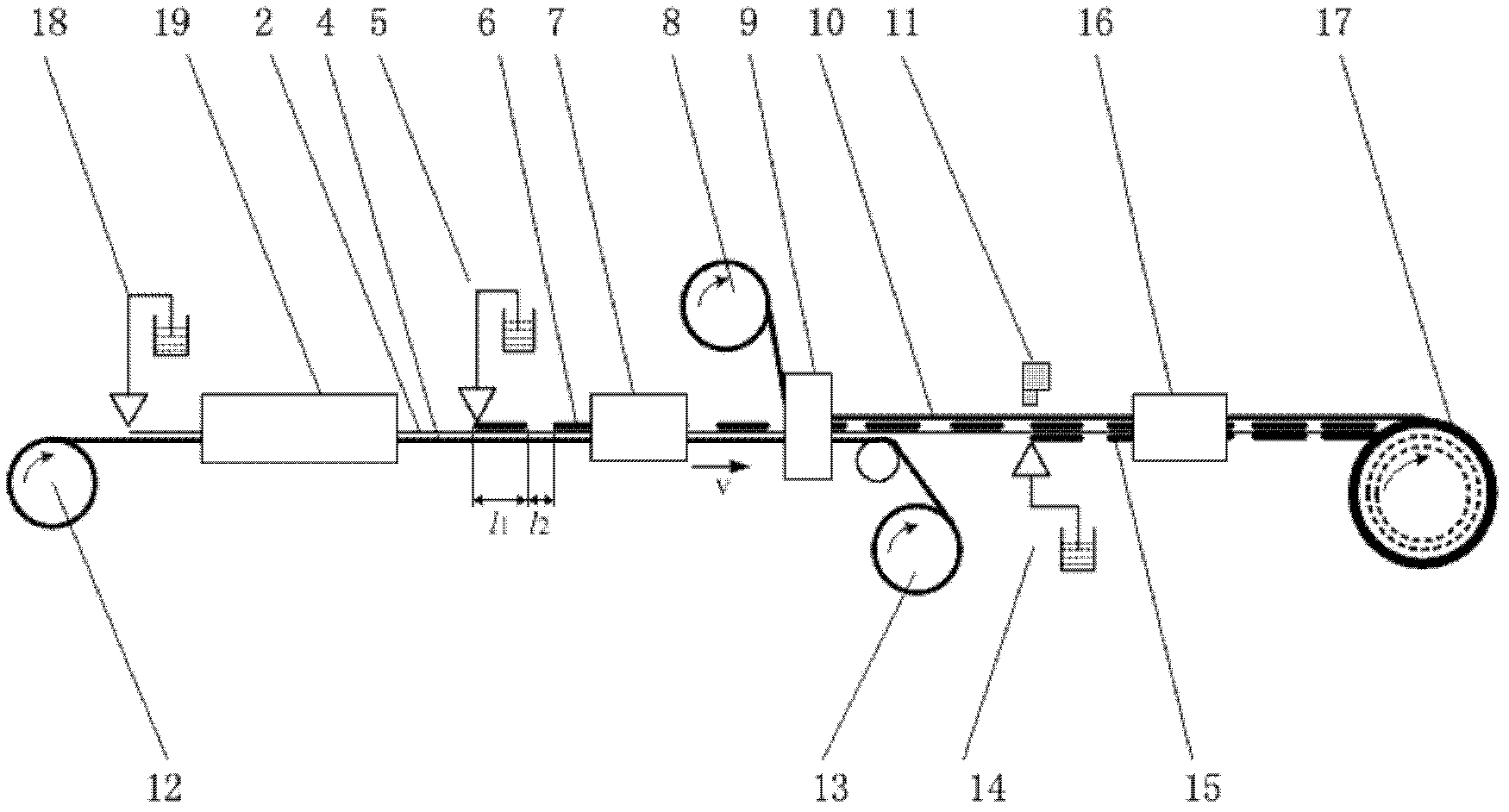

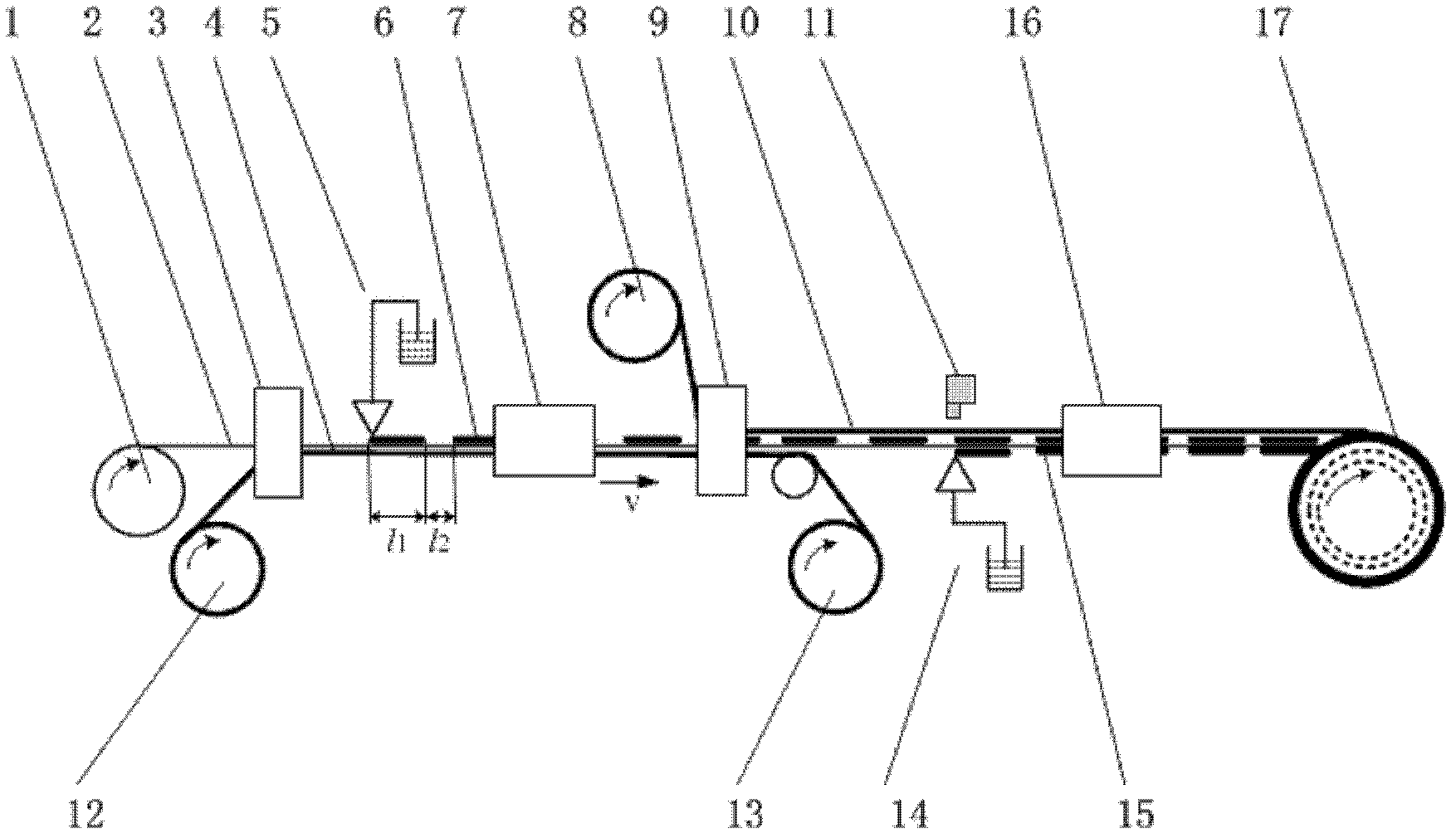

Method for continuously manufacturing 3-CCM (three Catalyst Coated Membranes) of fuel cell

InactiveCN102544558AEasy Tension ControlEasy towingFinal product manufactureSolid electrolyte fuel cellsTectorial membraneFuel cells

The invention discloses a method for continuously manufacturing 3-CCM (three Catalyst Coated Membranes) of a fuel cell. The method is characterized by comprising the following step of: under a condition that a protective membrane is adhered on one side of a proton exchange membrane, compositing a catalyst on the other side of the proton exchange membrane by utilizing a process manner, such as a direct coating manner, a printing manner, an indirect coating manner, a spray coating manner, a slit extrusion manner and a physicochemical deposition manner. The method for continuously manufacturing the 3-CCM of the fuel cell, disclosed by the invention, has the advantages that: (1) coil-to-coil easy continuous batch manufacturing can be realized; (2) the size precision is better and composite defects are fewer in the manufacturing procedure because the proton exchange membrane adhered with the protective membrane has excellent size stability in a compositing process of a catalyst layer and the proton exchange membrane; and (3) the manufacturing of the 3-CCM of the fuel cell with slotted catalyst layer can be continuously realized. When the 3-CCM are manufactured by utilizing the method for continuously manufacturing the 3-CCM of the fuel cell, disclosed by the invention, batch production is easier, and the yield is higher at the same time.

Owner:武汉理工新能源有限公司

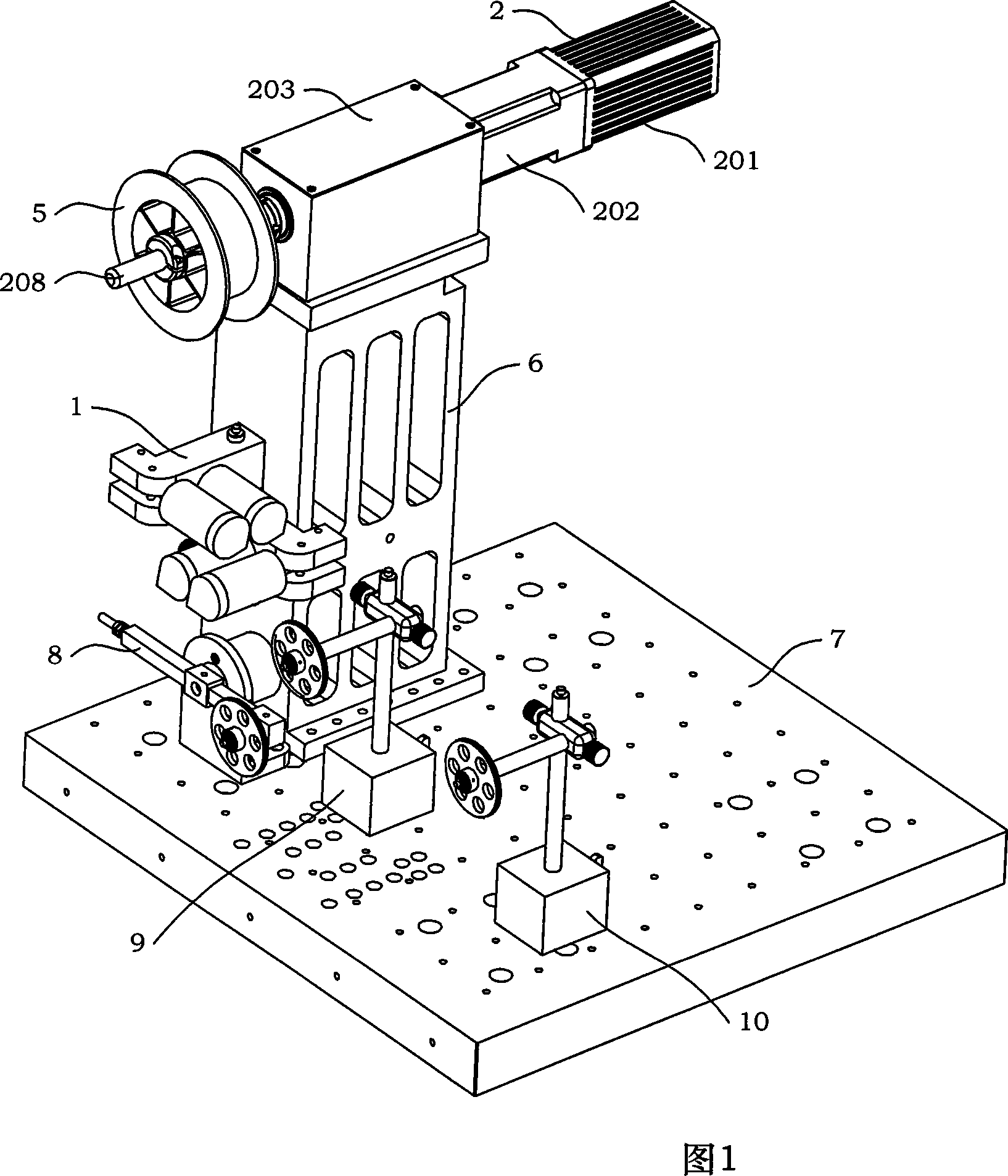

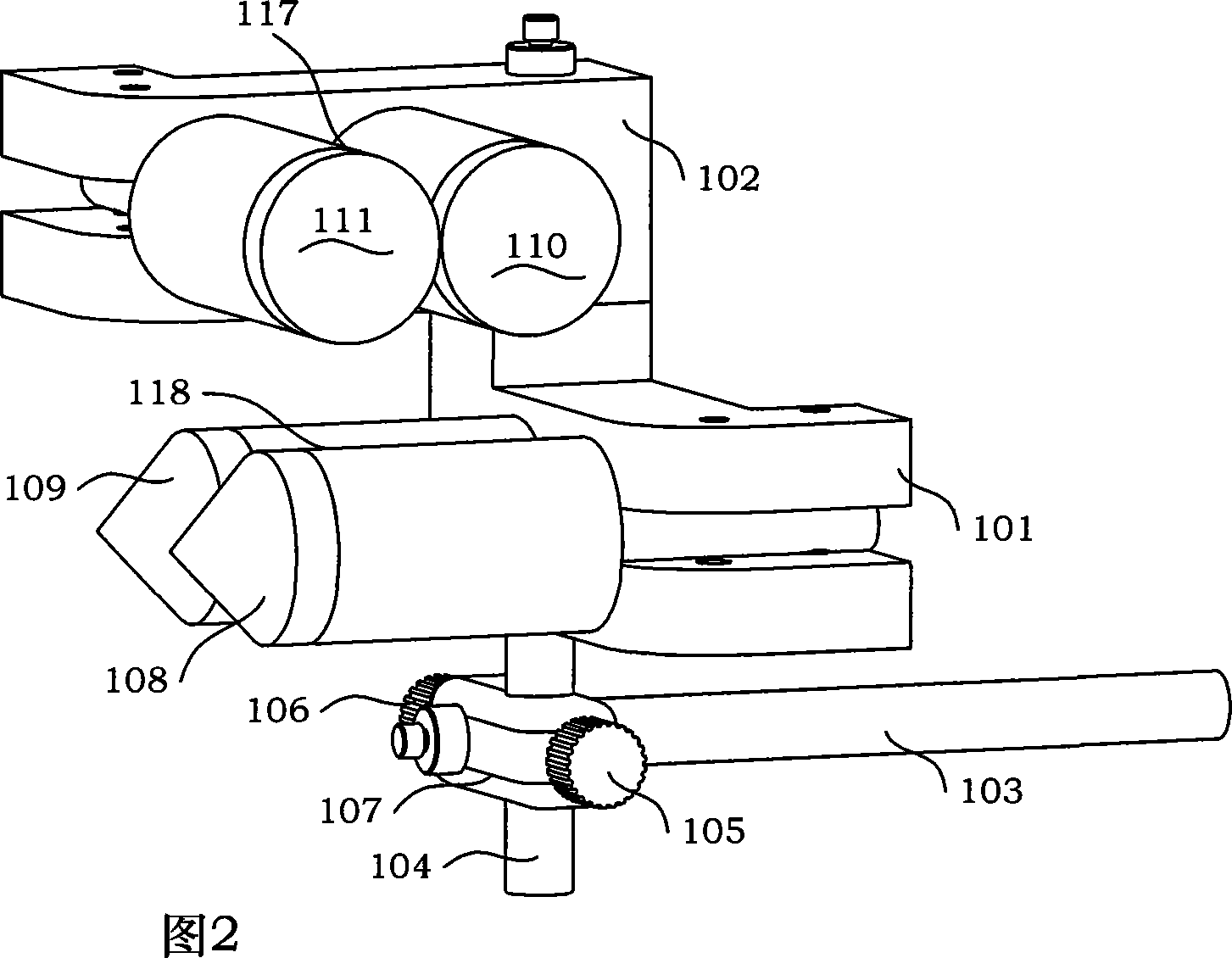

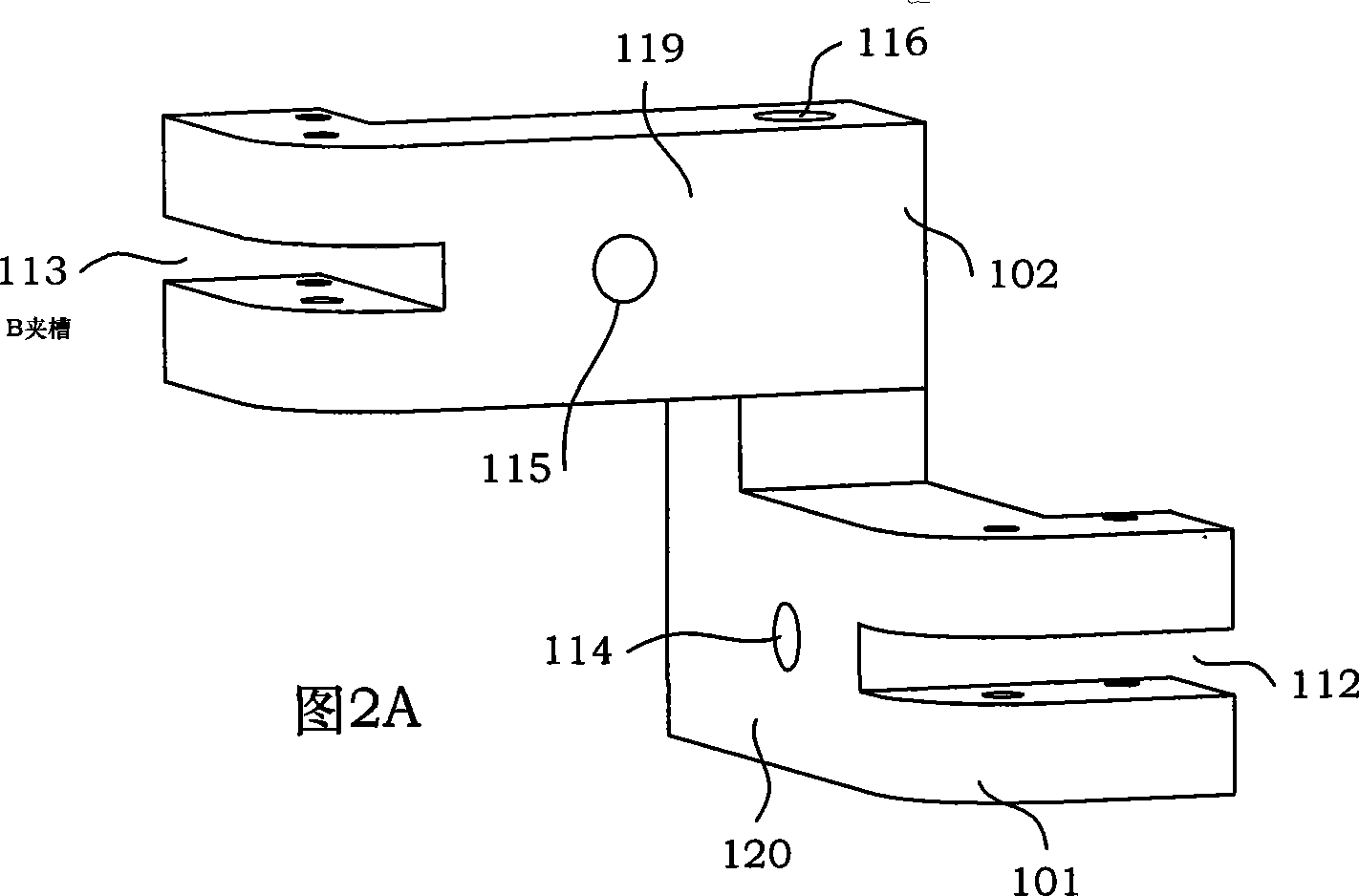

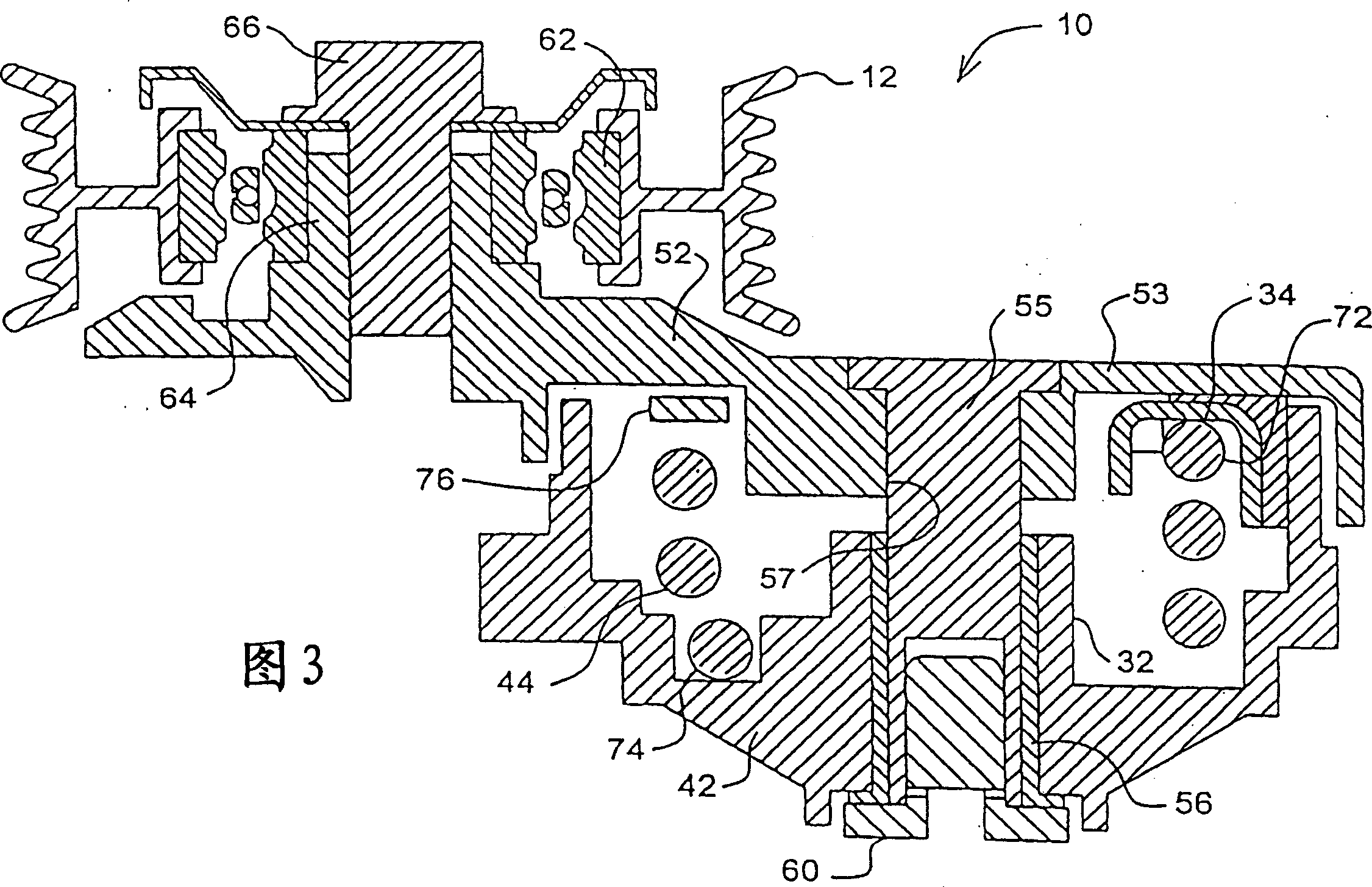

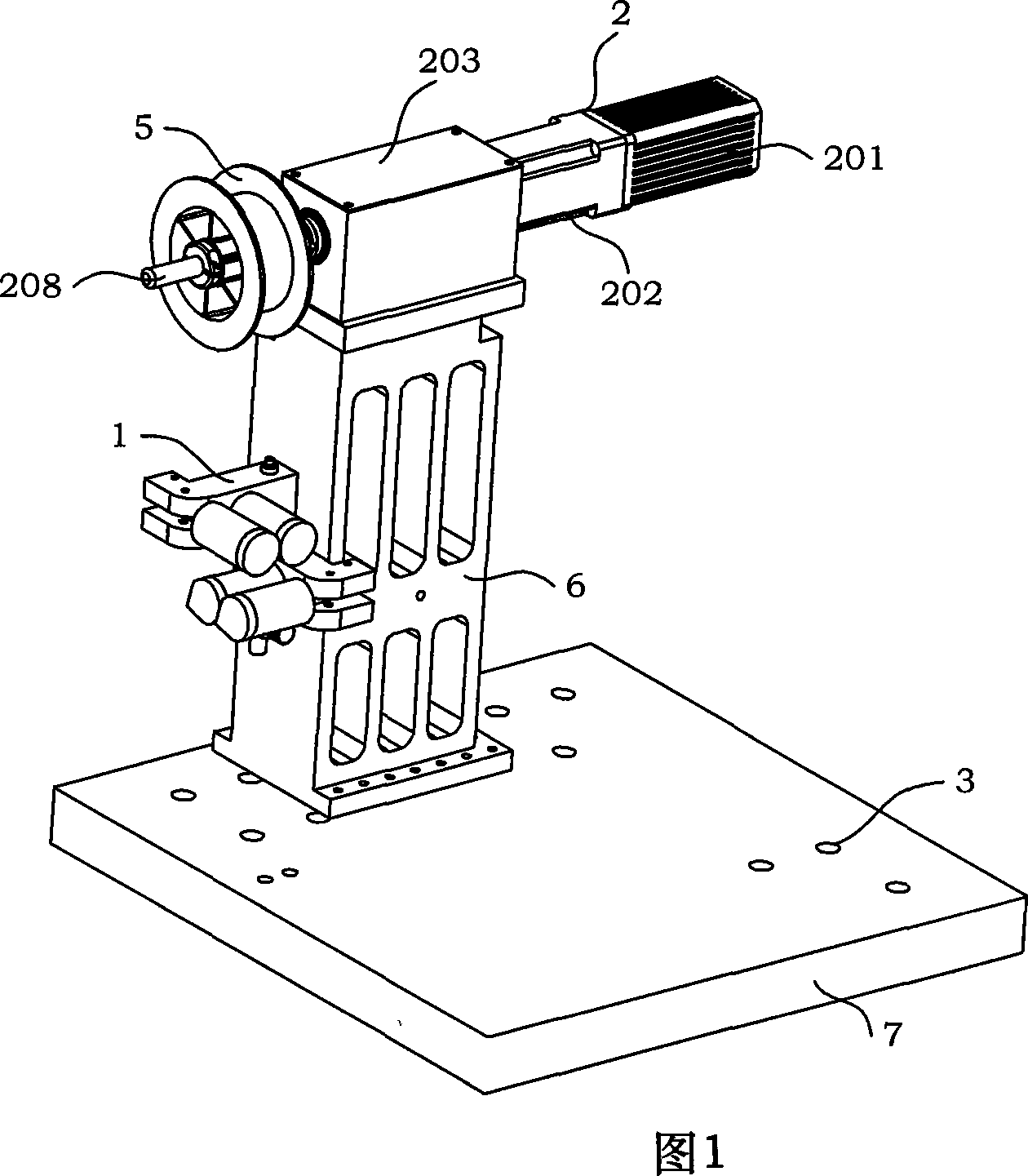

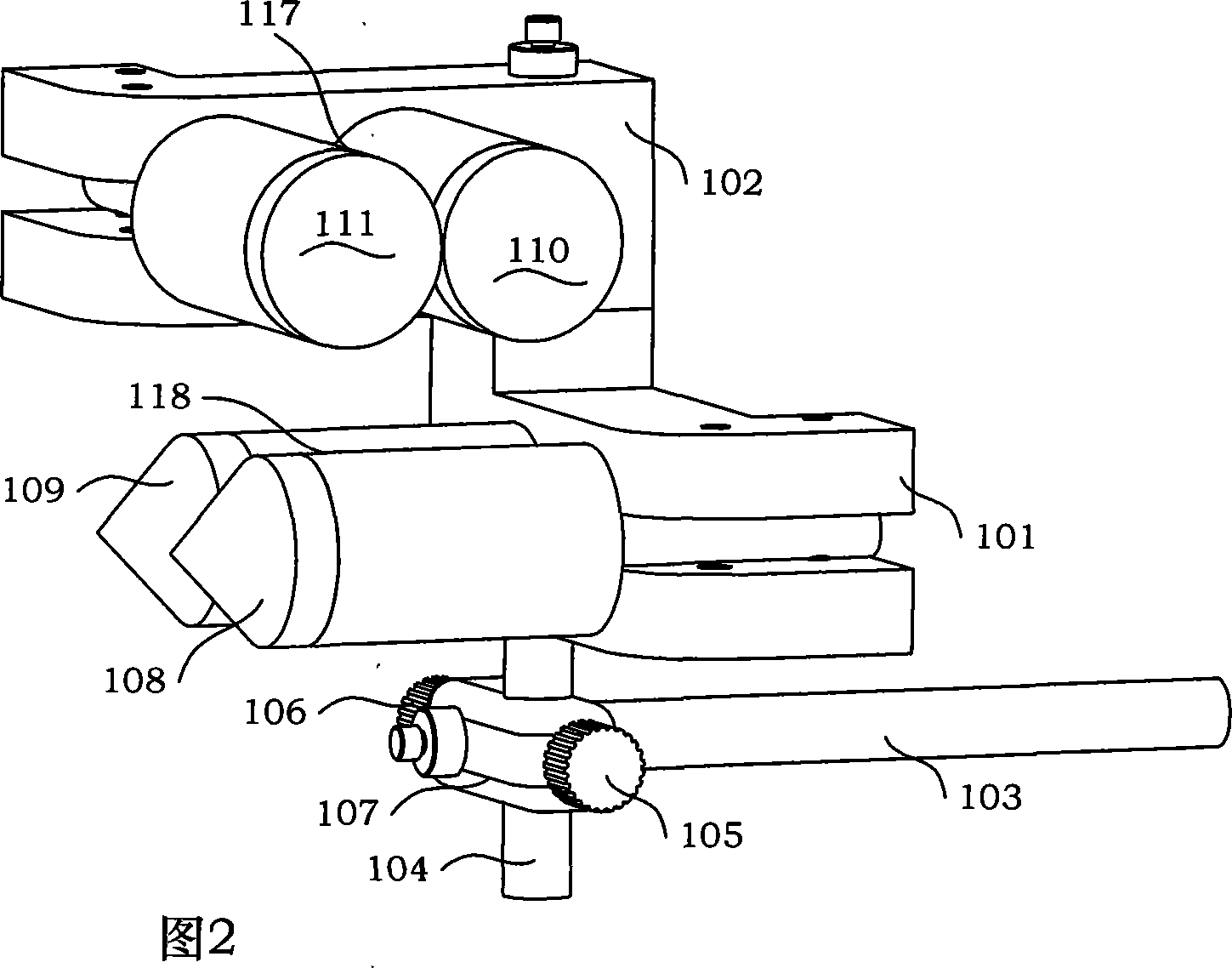

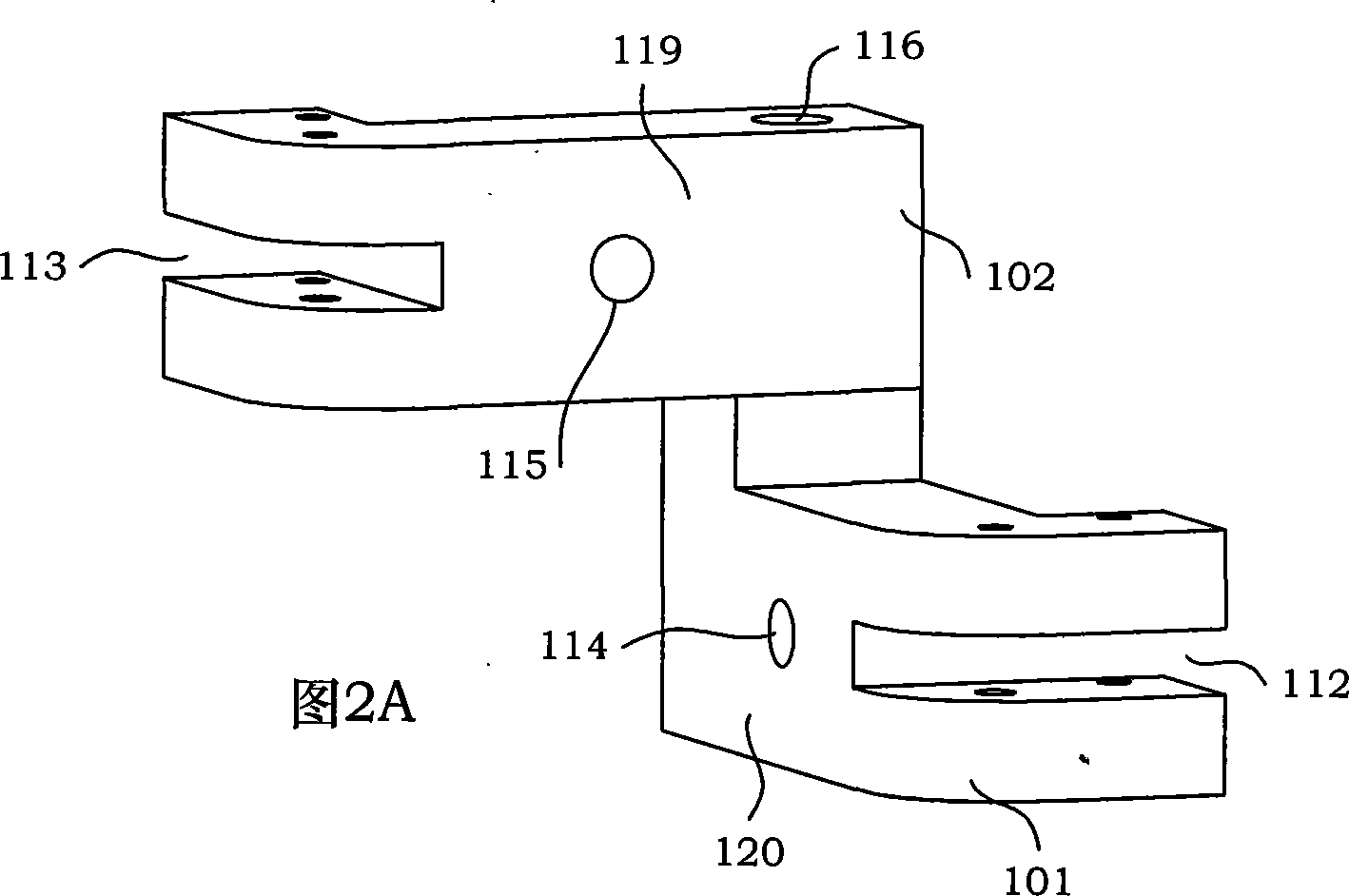

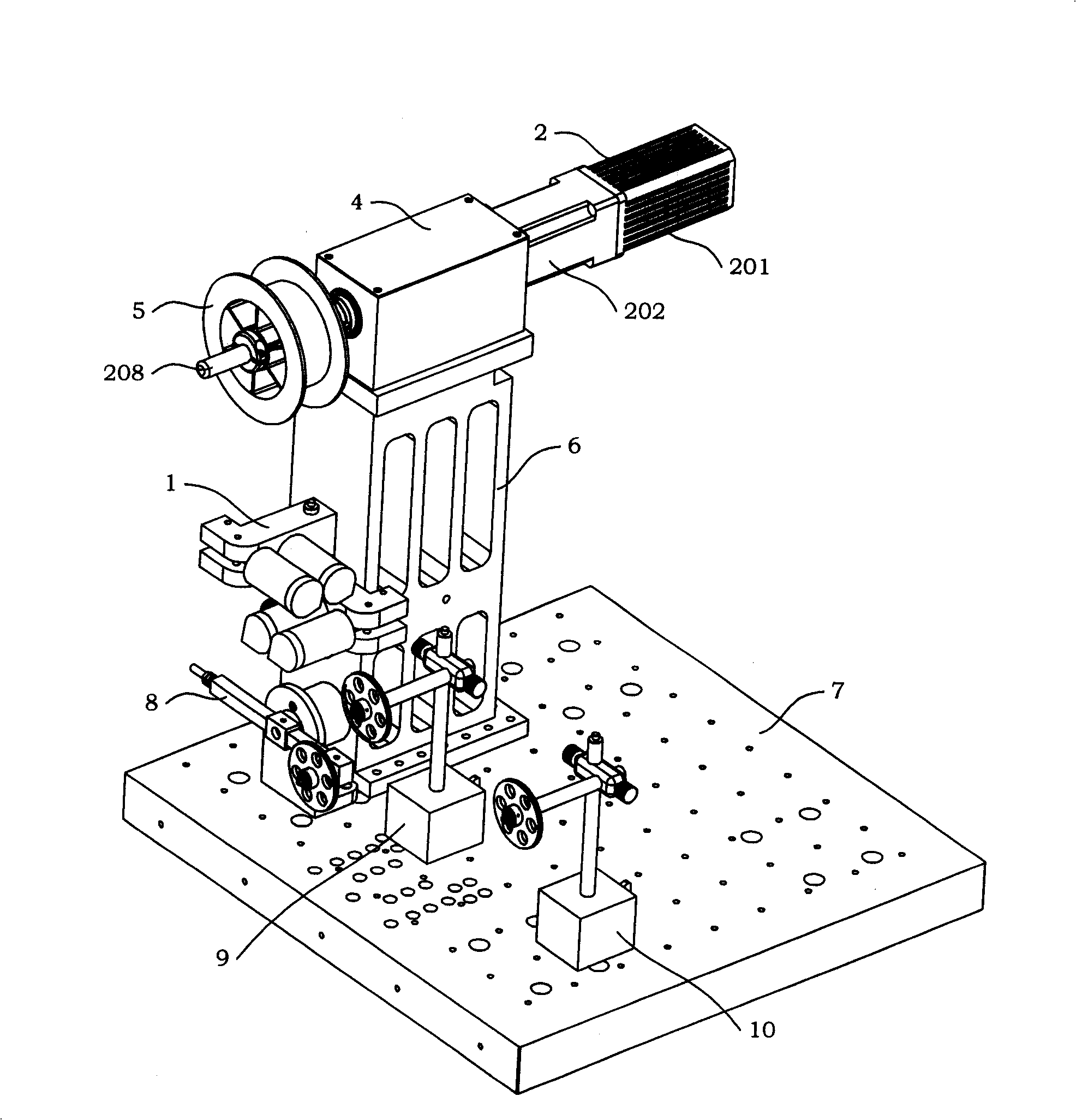

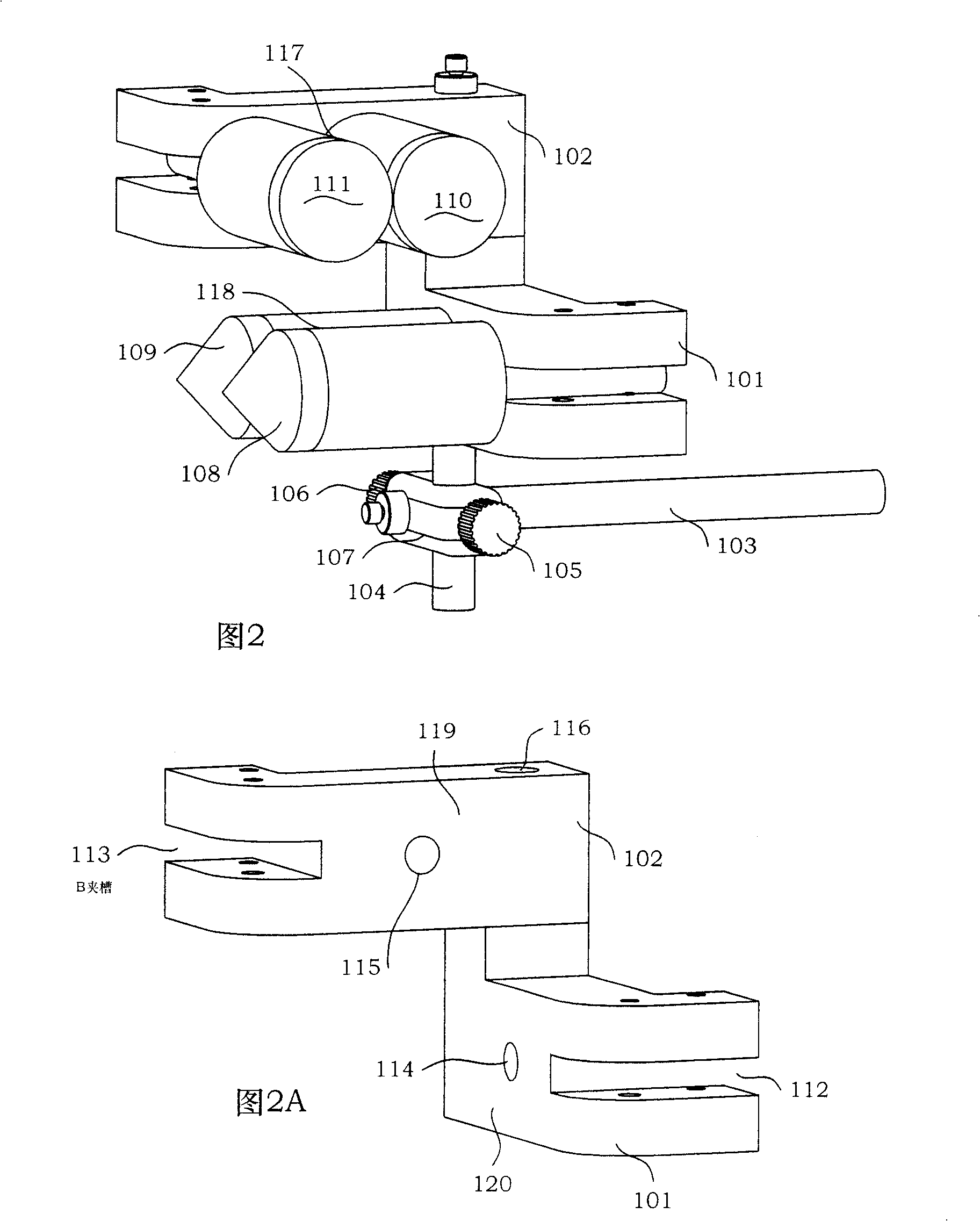

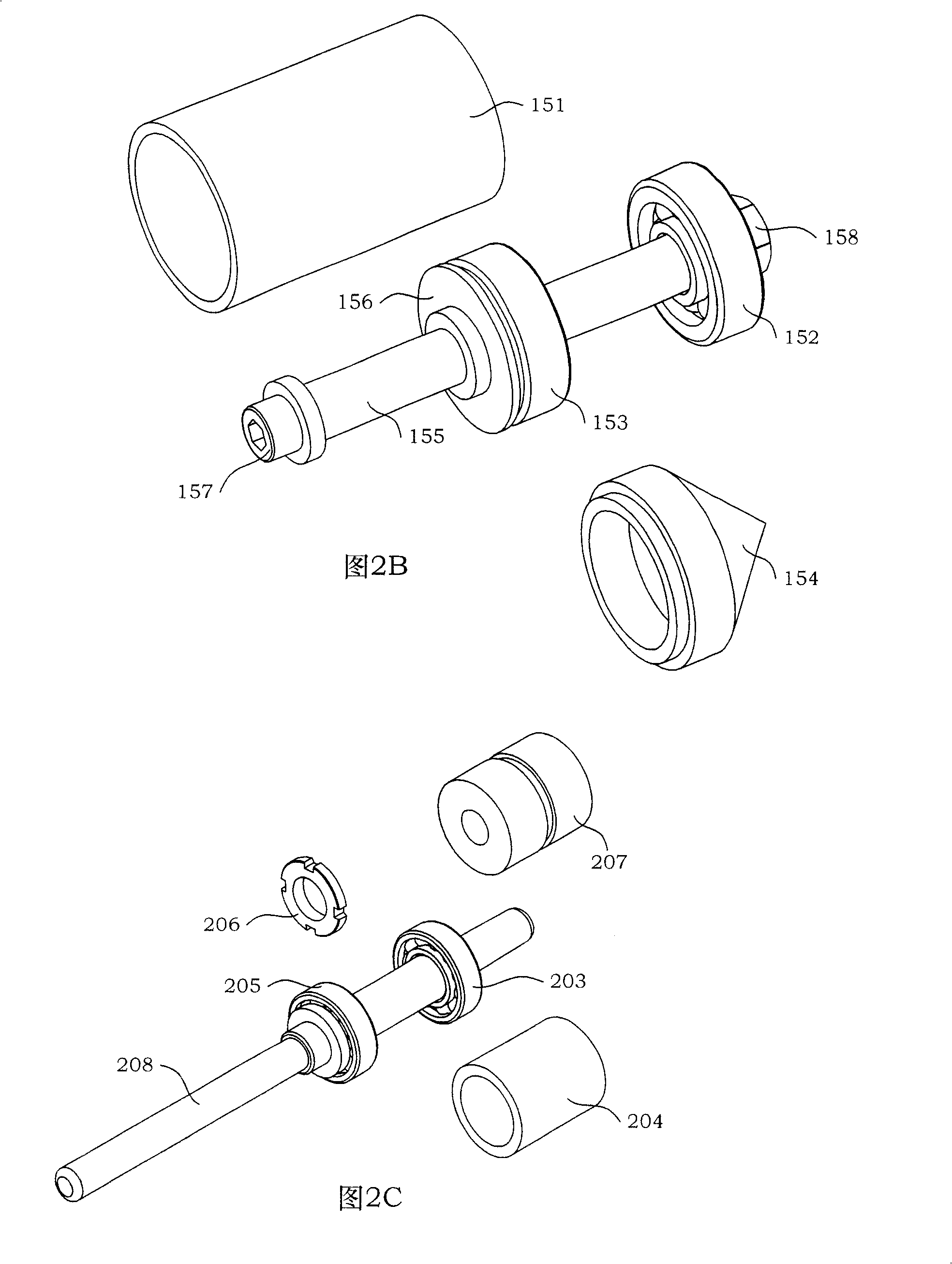

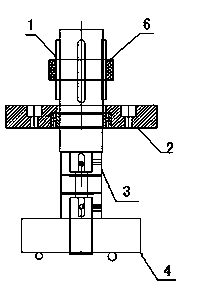

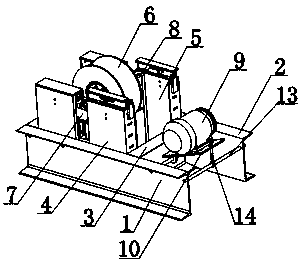

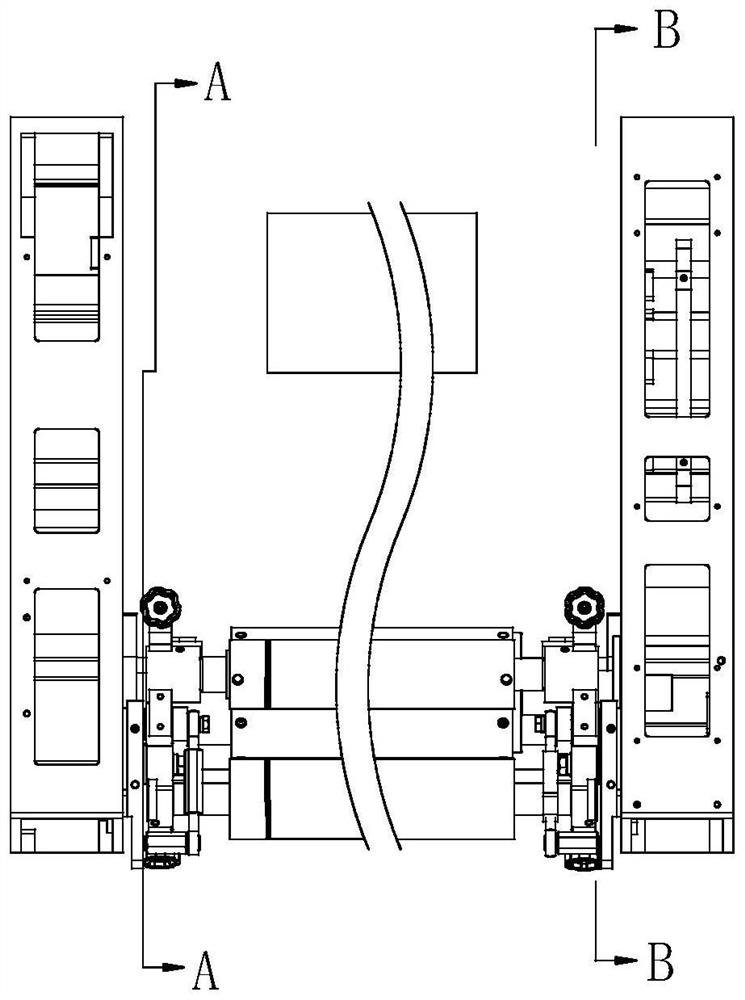

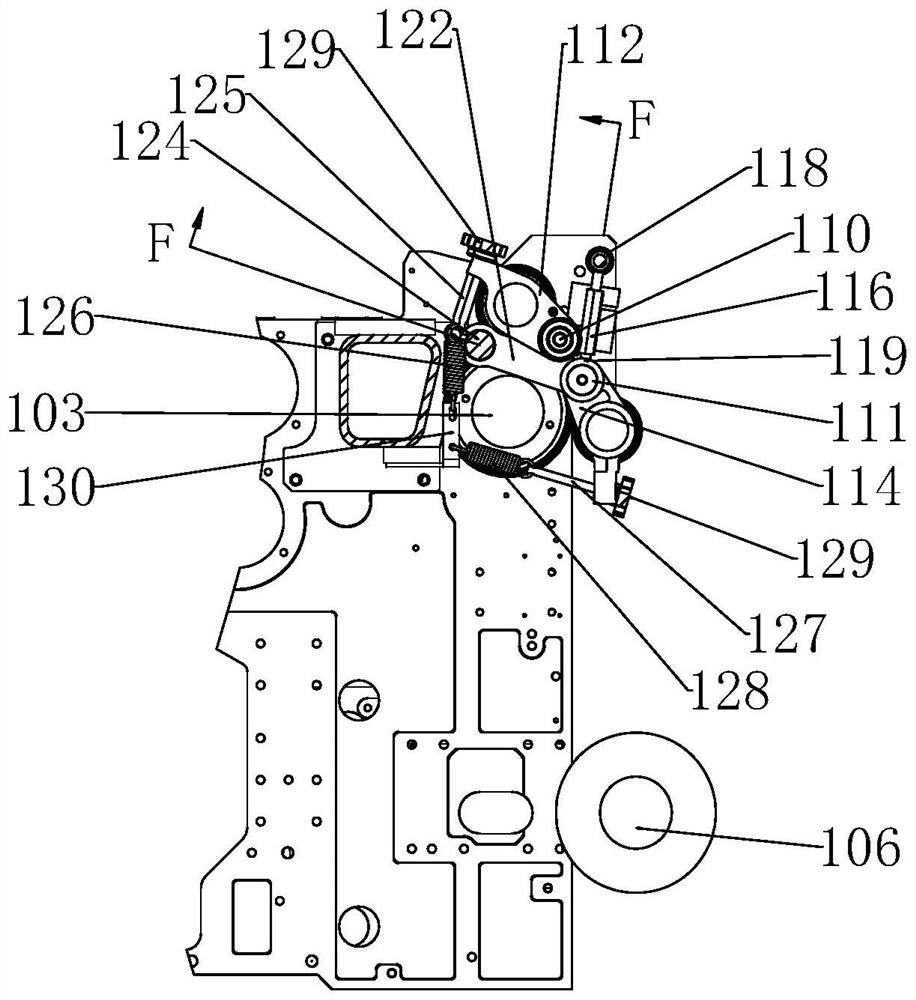

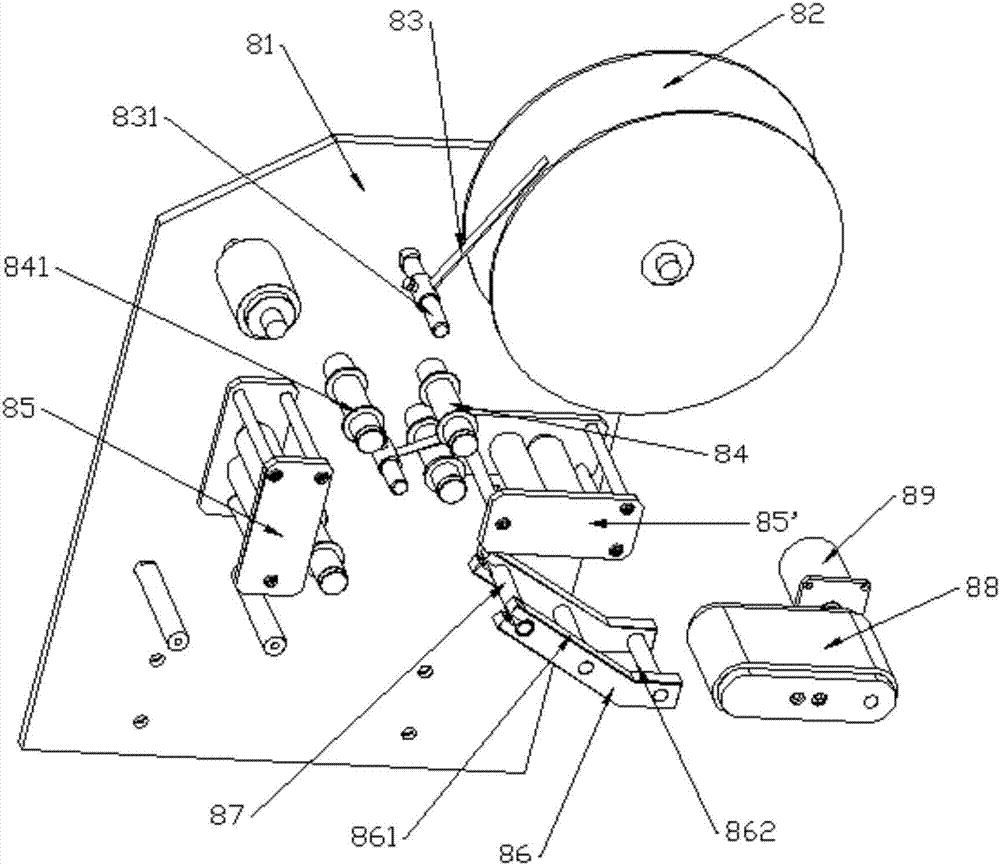

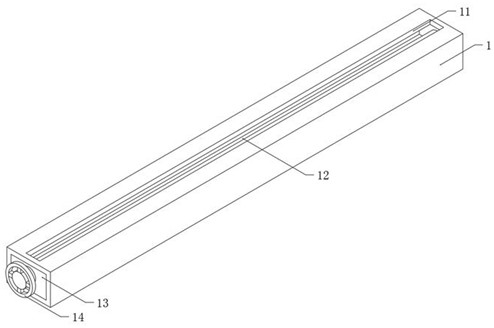

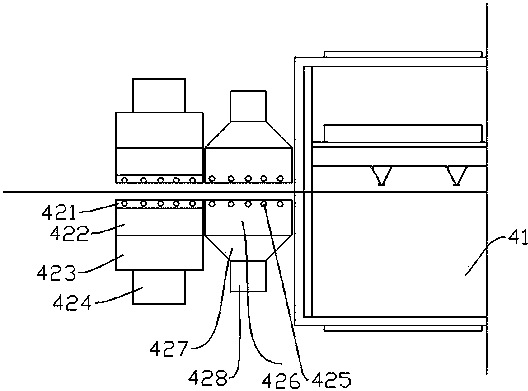

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN101059582ACompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a tension structure used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table tension element, a first fiber guider and a second fiber guider, wherein the lower end of the support base via nut and screw is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel, the sliding table is arranged with a plurality of mounting holes for fixing and mounting devices, the tension element, the first and the second fiber guiders via nut and screw are fixed on the sliding table, which guide grooves are in one plane. The inventive tension device has reasonable, compact and simple structure, without reverse dead area, but with stable transmission control, accurate tension control, non-zero-bias in force measurement, digit and closed tension control.

Owner:BEIHANG UNIV

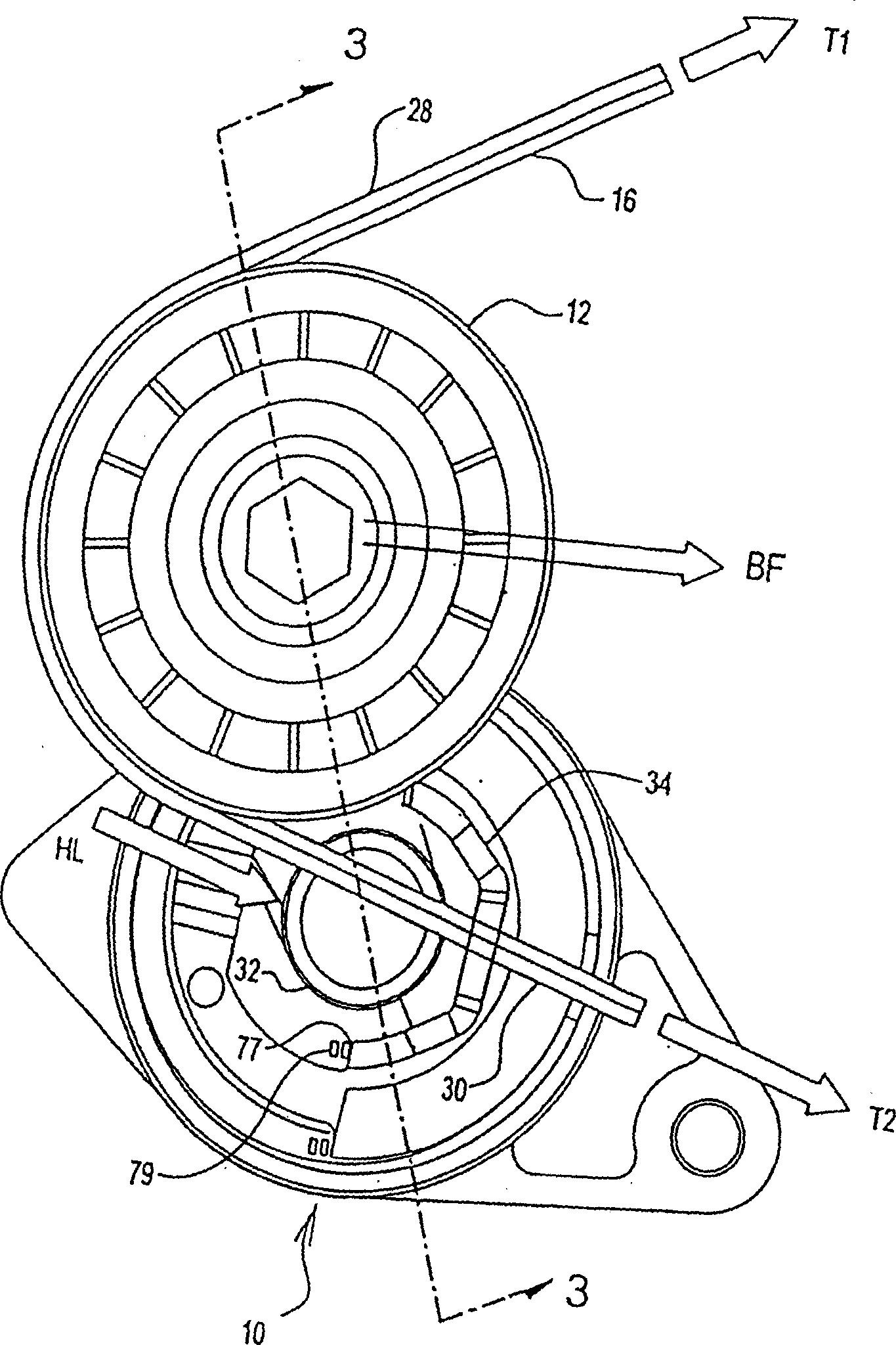

Asymmetric damping tensioner belt drive system

The invention comprises an asymmetric damping tensioner system for belt drives on an engine. A belt is connected between a driver pulley on a crankshaft and any number of driven pulleys. Each drive pulley is connected to an accessory such as an alternator, power steering pump, compressor or the like. The tensioner is placed anywhere before the first component of significant effective inertia, in the belt movement direction. A biasing member in the tentioner is used to maintain a tention in the belt. The tensioner further comprises a damping mechanism to damp belt vibrations caused by the operation of the engine. Tensioner damping friction is unequal or asymmetric, depending upon the direction of movement of the tentioner arm. During acceleration the damping friction of the tentioner in the unloading direction is significantly lower than the damping friction in the opposite, or loading direction, as is the case during deceleration. Lower damping friction during acceleration allows the tensioner arm to quickly adjust to the increase in belt length caused by acceleration. Higher damping friction during deceleration prevents the tensioner arm from being moved too far in the loading direction thereby causing slipping and noise. Asymmetric damping also significantly diminishes overall vibration in the belt during all phases of operation.

Owner:THE GATES CORP

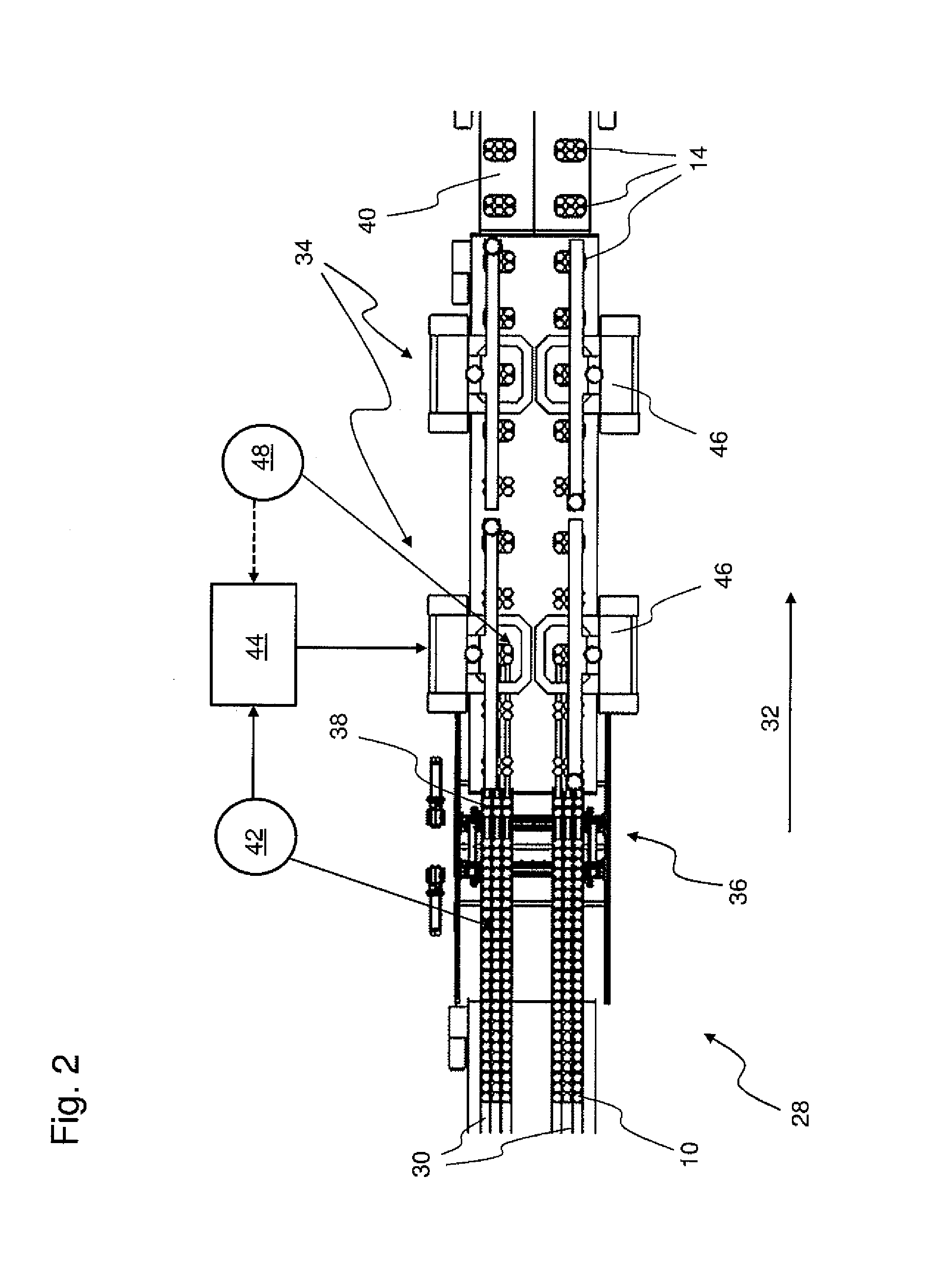

System and process for controlling the deceleration and acceleration rates of a sheet material in forming absorbent articles

ActiveUS7458540B2Rapid decelerationIncrease in sizeFilament handlingRecord information storageEngineeringAcceleration rate

A system and process for unwinding materials in forming absorbent articles is described. The system includes an unwind device in association with a festoon. The festoon is for accumulating a determined length of material. The amount of material contained in the festoon is increased or decreased depending upon the rate at which a roll of material is unwound in relation to the rate at which the first material is fed into a downstream process. In order to minimize the capacity of the festoon and in order to minimize tension swings in the festoon, the festoon includes a plurality of drive devices associated with selected guide rolls contained in the festoon. The drive devices can accelerate and / or decelerate the guide rolls in response to rate increases or decreases occurring at the unwind device in relation to the downstream process speed. In one embodiment, each of the guide rolls is controlled independently of the remaining guide rolls in the festoon.

Owner:KIMBERLY-CLARK WORLDWIDE INC

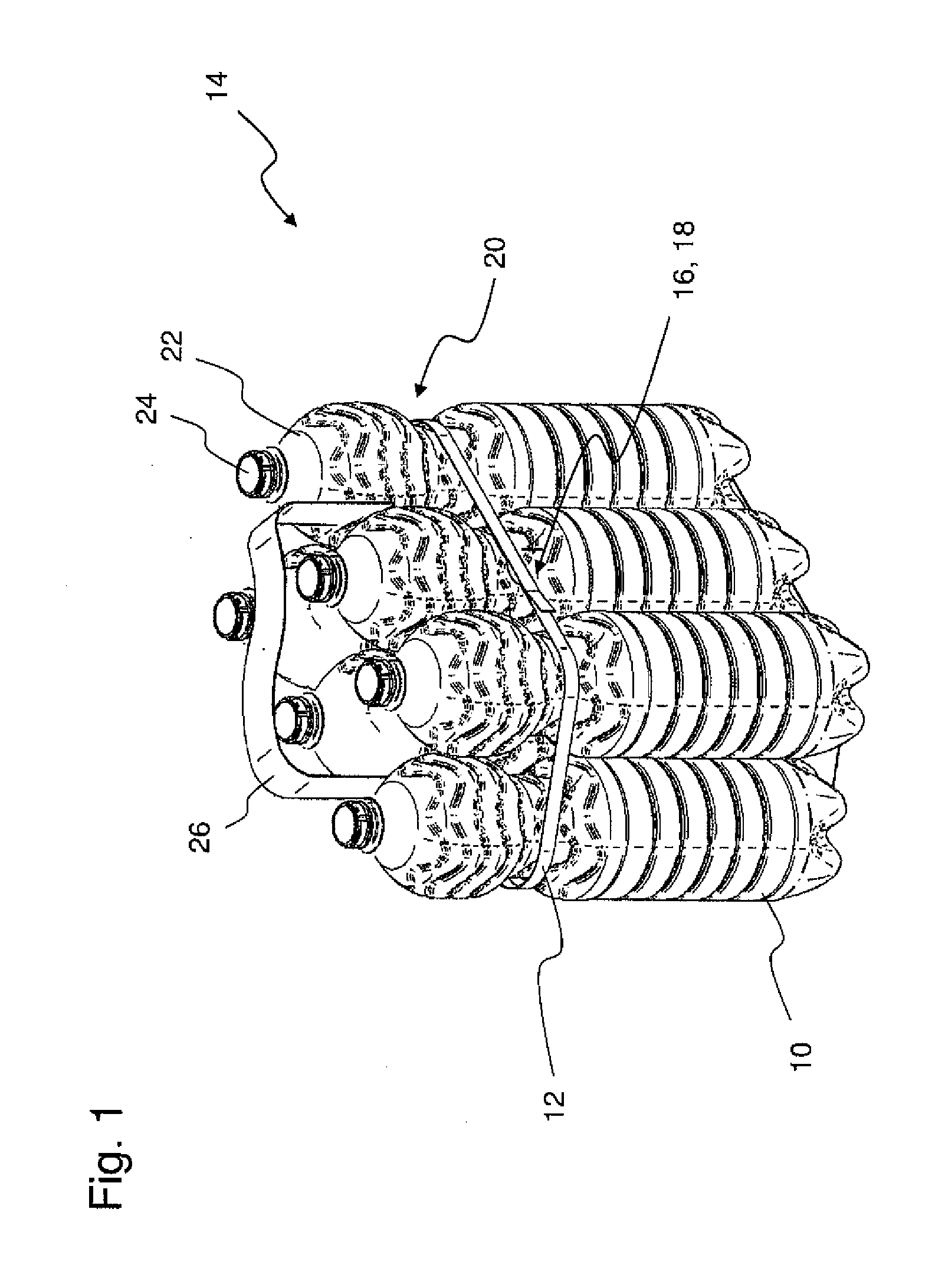

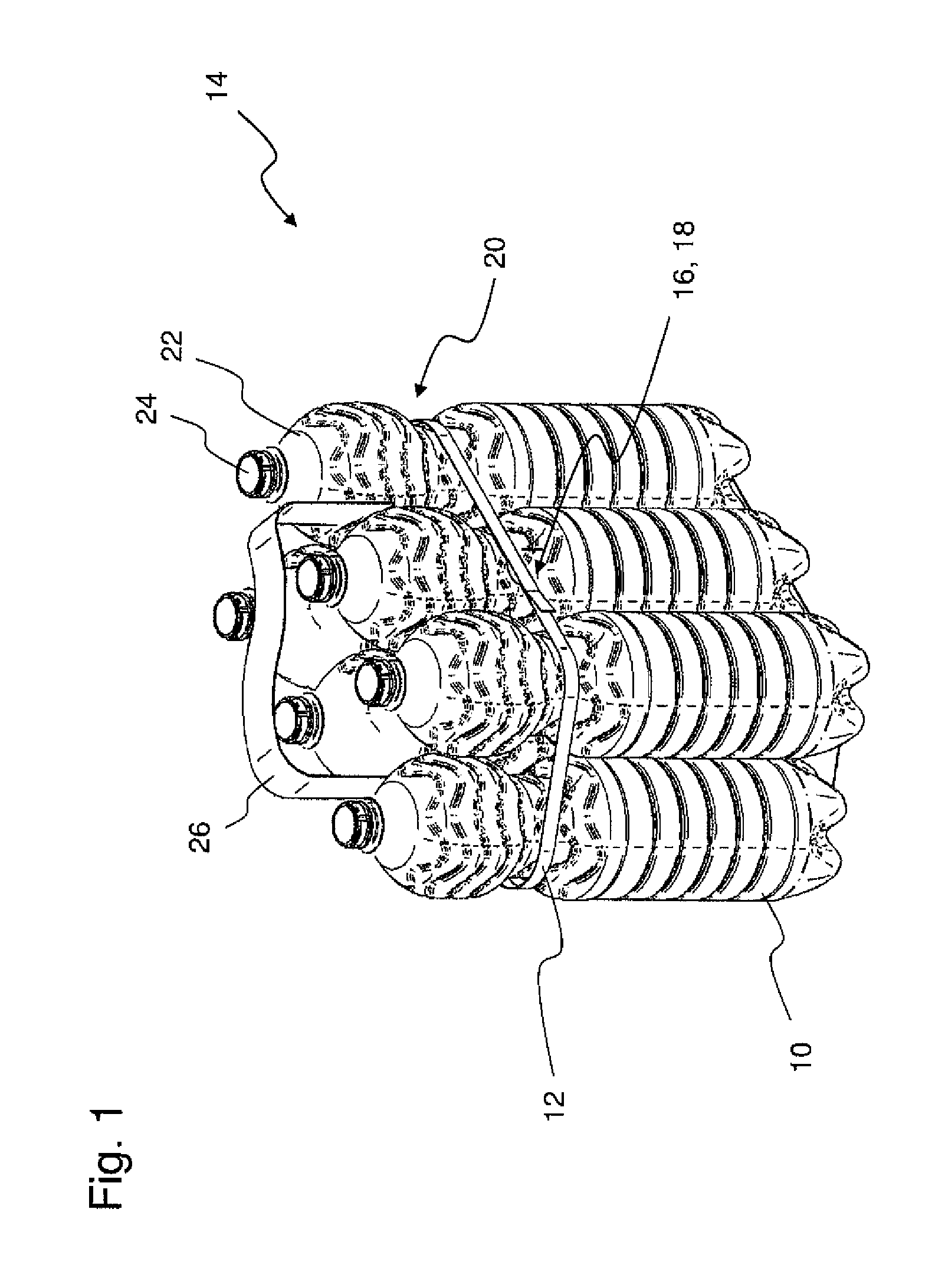

Device and method for manufacturing strapped packs and regulatory and/or control method for a strapping device

ActiveUS20120210674A1Avoid damageReduce tensionBinding material applicationBundling machine detailsStrappingEngineering

A device and method for the manufacturing of a pack including at least one article. The device includes a strapper for strapping a strip around the at least one article. The strapping is strapped around the outside of the article horizontally and / or vertically and / or cross-wise. A device generates a definable tensioning force of the strapping. A detector for the detection of properties of the article(s) is coupled and / or effectively connected to the device for generating a definable tensioning force of the strapping.A regulation and / or control method for a strapping device is also provided. Recorded properties of the articles to be wrapped and / or of the strapping material to be used are used as control values for the tensioning force and / or back tensioning force.

Owner:KRONES AG

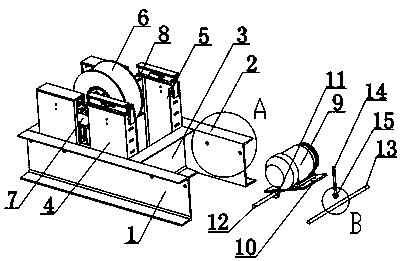

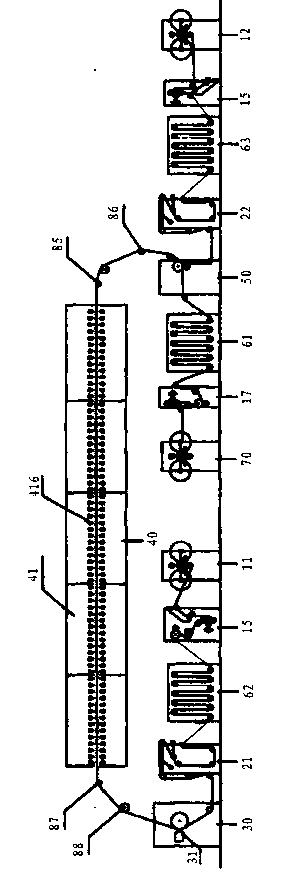

Subway tunnel construction railcar facilitating realization of regular cable laying

PendingCN110380360AConducive to laying efficiencyRealize regular layingFilament handlingApparatus for laying cablesPetroleum engineeringTunnel construction

The invention discloses a subway tunnel construction railcar facilitating the realization of regular cable laying. The railcar includes a railcar body provided with a pay-off arm. The railcar also includes a cable restraint device installed on the pay-off arm. The cable restraint device includes a support, a bracket, a cable guide and a binding machine. The support is fixed on the pay-off arm, andthe bracket can be rotationally connected to the support. The railcar also includes a locking piece for fixing the bracket relative to the support. The cable guide and the binding machine are fixedlyinstalled on the bracket, and the cable input end of the cable guide is connected with the cable input end of the binding machine. By adopting the structure design of the railcar, multiple stands ofcables can be laid synchronously, and regular cable wiring can be obtained on the cable bracket.

Owner:SOUTHWEST JIAOTONG UNIV

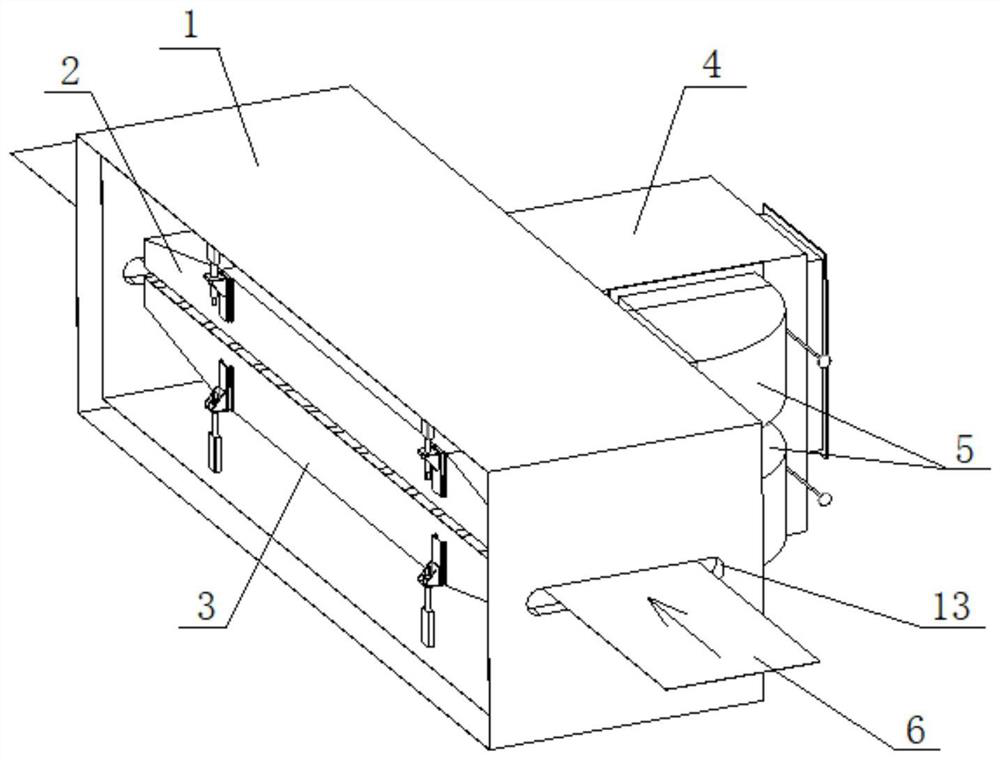

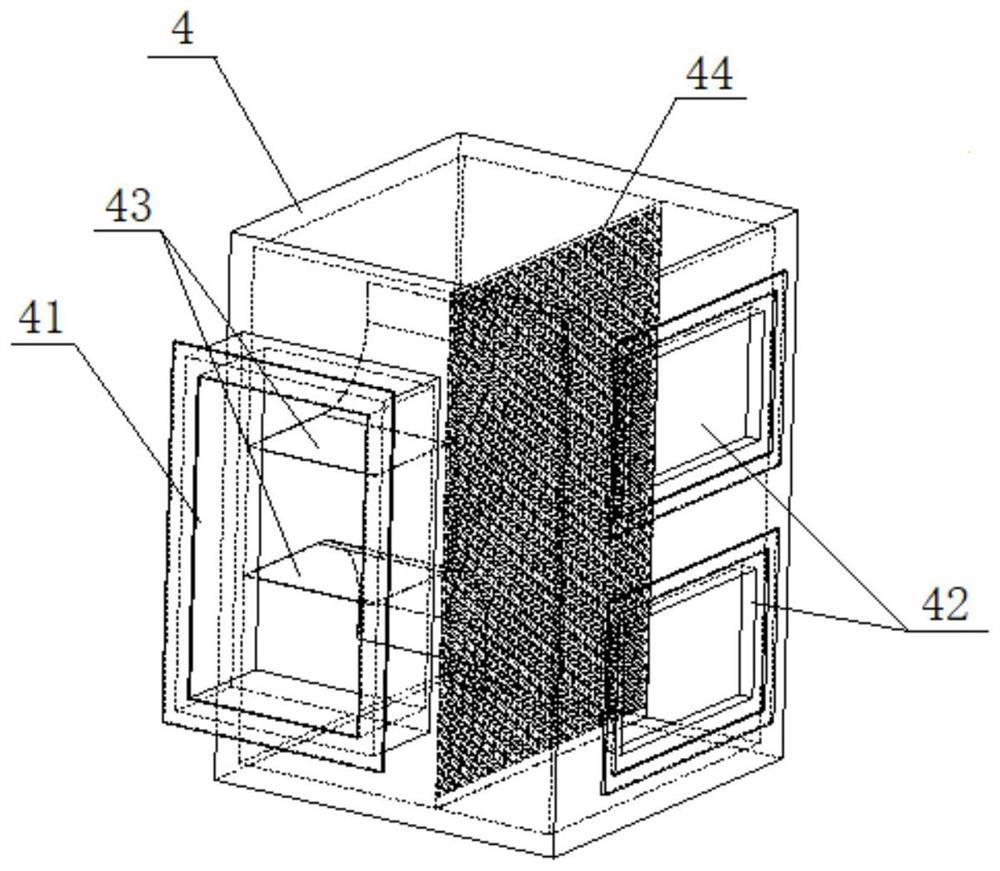

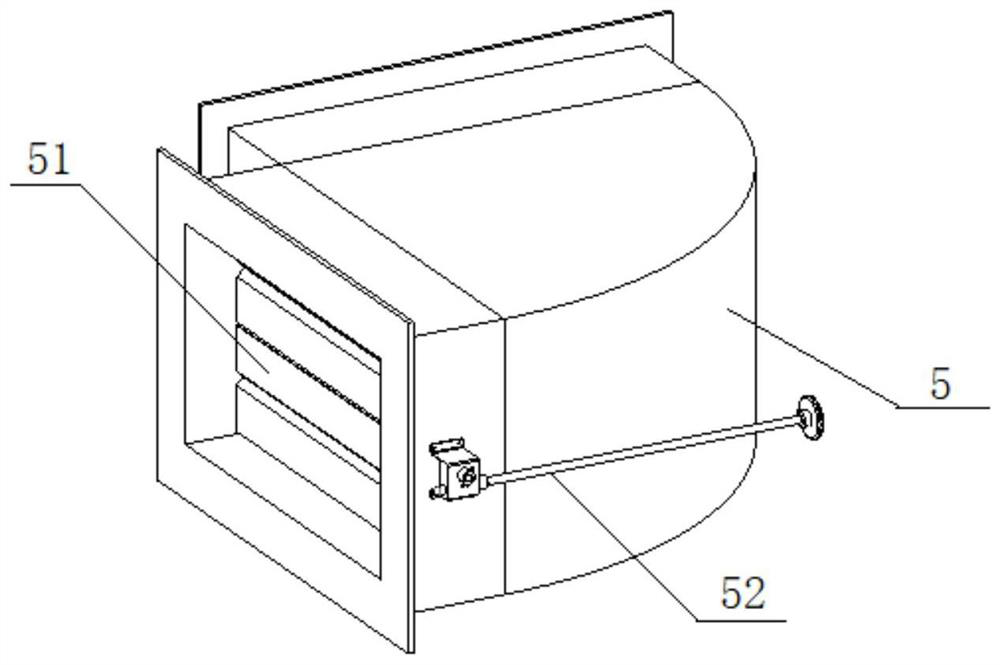

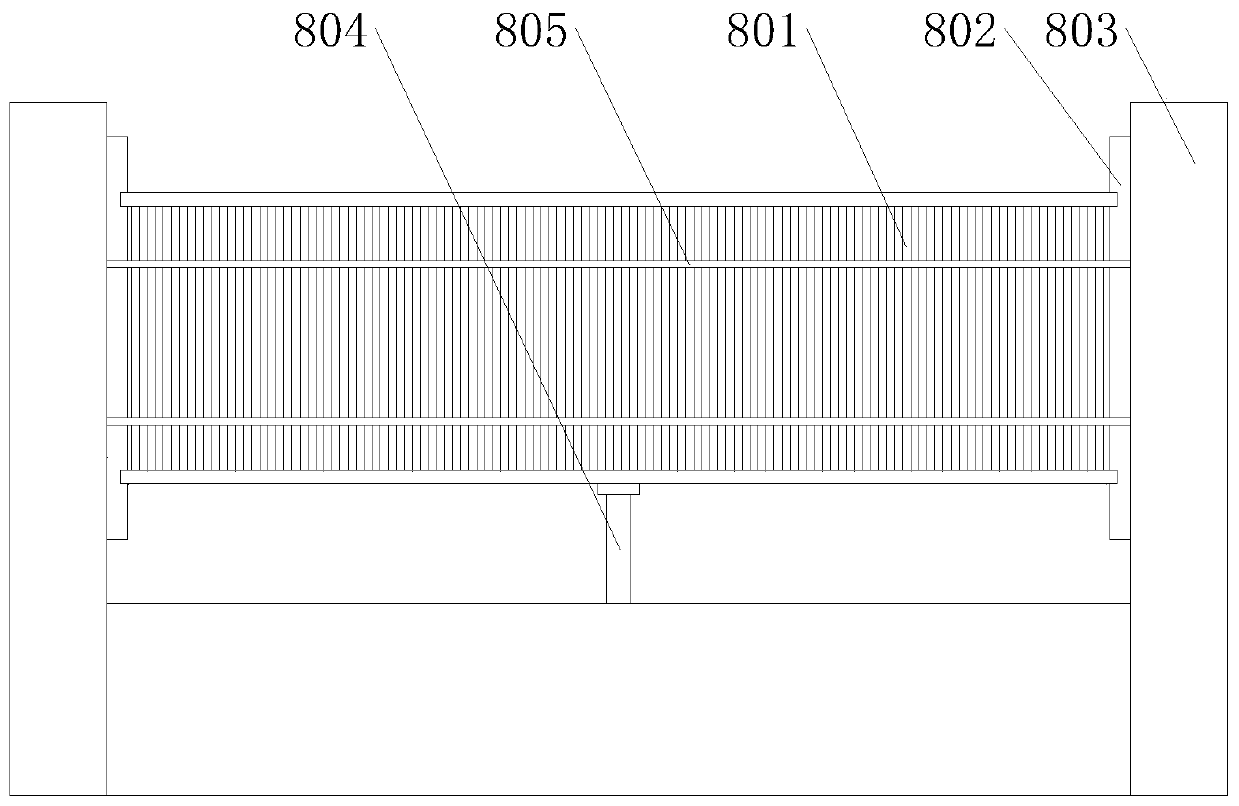

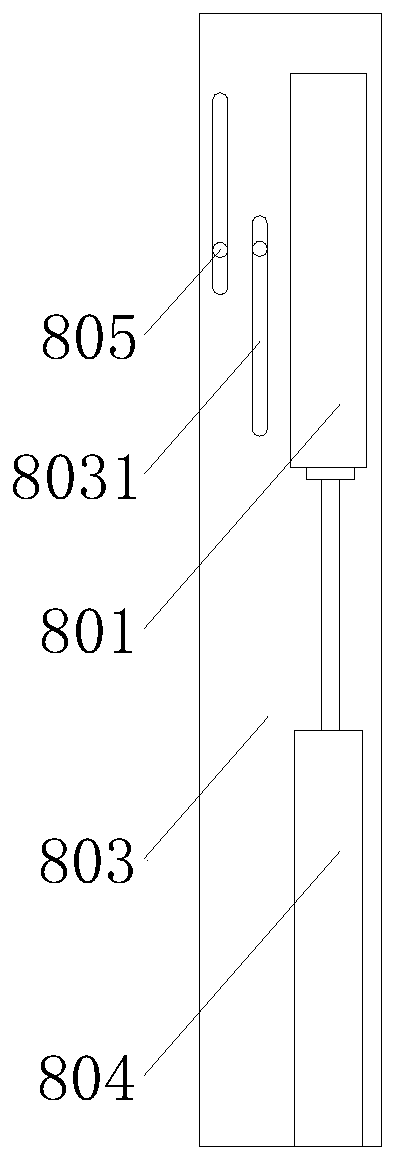

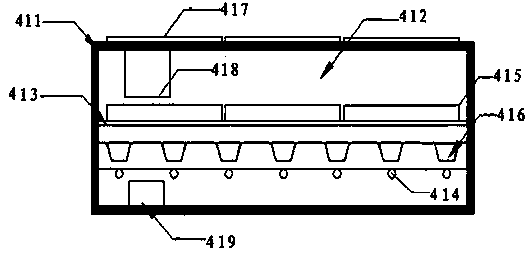

Uniform drying mechanism of coating oven

ActiveCN111905999AAvoid getting lostAdjustable distancePretreated surfacesCoatingsEngineeringLaboratory oven

The invention discloses a uniform drying mechanism of a coating oven. The uniform drying mechanism of the coating oven comprises an oven body, an upper air chamber, a lower air chamber and an oven static pressure chamber body, wherein the upper air chamber and the lower air chamber are arranged in the oven body; and the oven static pressure chamber body is arranged outside the oven body and respectively communicates with the upper air chamber and the lower air chamber. According to the uniform drying mechanism of the coating oven provided by the invention, through the primary steady flow air equalization of an oven static pressure chamber and the secondary steady flow air equalization of the upper air chamber and the lower air chamber, hot air blown out of the upper air chamber and the lower air chamber can evenly and rapidly dry two faces of a pole piece, so that the pole piece is ensured to be evenly heated; and the uniform drying mechanism of the coating oven is simple in structure,convenient to operate and reliable in operation.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

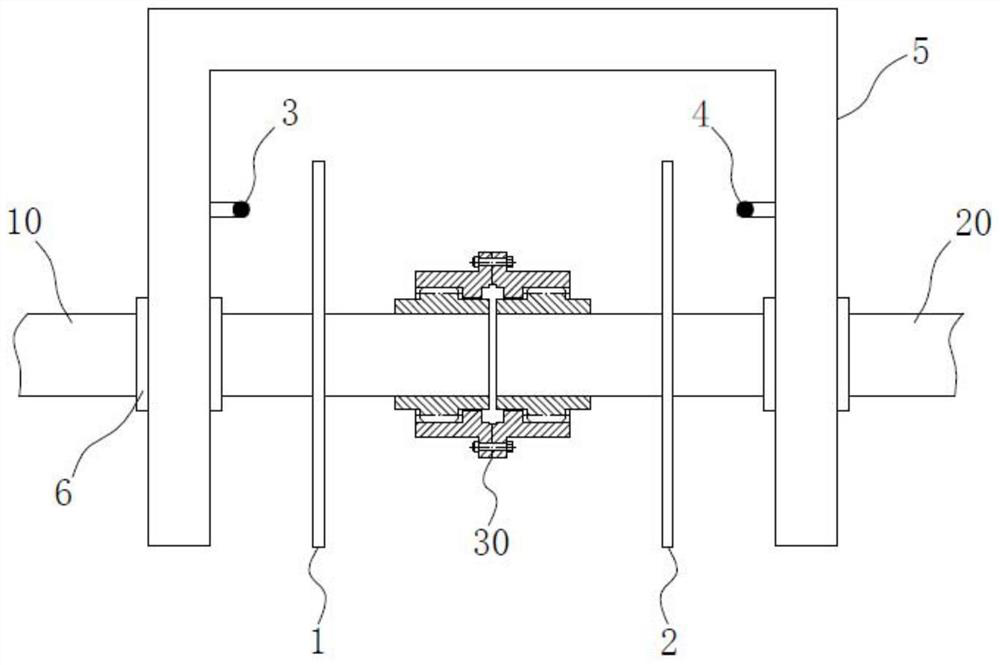

Continuous annealing line gear coupling fault detection device, system and method

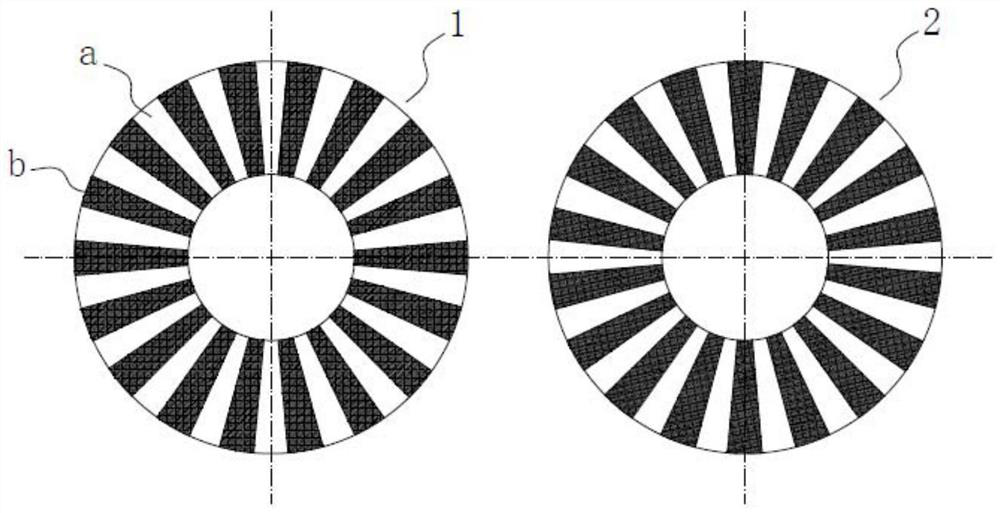

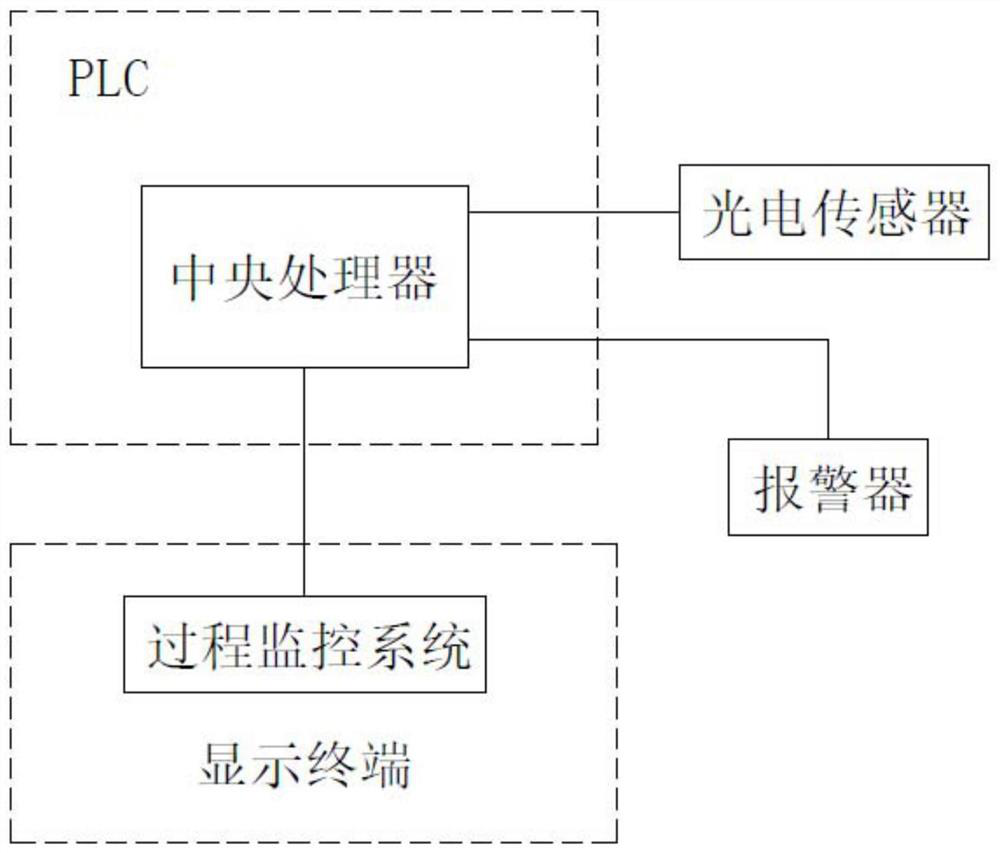

ActiveCN111982508AImprove troubleshooting efficiencyImprove maintenance efficiencyMachine part testingProduction lineGrating

The invention discloses a continuous annealing line gear coupling fault detection device, system and method, and relates to the field of continuous annealing production lines. The device comprises twoannular gratings with the same structure, and each annular grating is provided with a shading area and a light-transmitting area which are uniformly and alternately distributed around the axis of theannular grating; the device further comprises a photoelectric sensor which is provided with a light source transmitting end and a light source receiving end; the two annular gratings are coaxially matched and fixedly connected with a driving shaft and a driven shaft which are connected with the two ends of a gear coupling respectively, the shading area on one annular grating coincides with the light-transmitting area on the other annular grating in the axial direction, and the light source transmitting end and the light source receiving end are oppositely fixed to the outer sides of the two annular gratings. The system comprises a plurality of detection devices in one-to-one correspondence with gear couplings in a continuous annealing line, and a PLC control system, the method performs real-time remote monitoring on the continuous annealing line based on the system. According to the invention, the fault of the continuous annealing line gear coupling can be detected in time, the product quality is ensured, and the safety is high.

Owner:MAANSHAN IRON & STEEL CO LTD

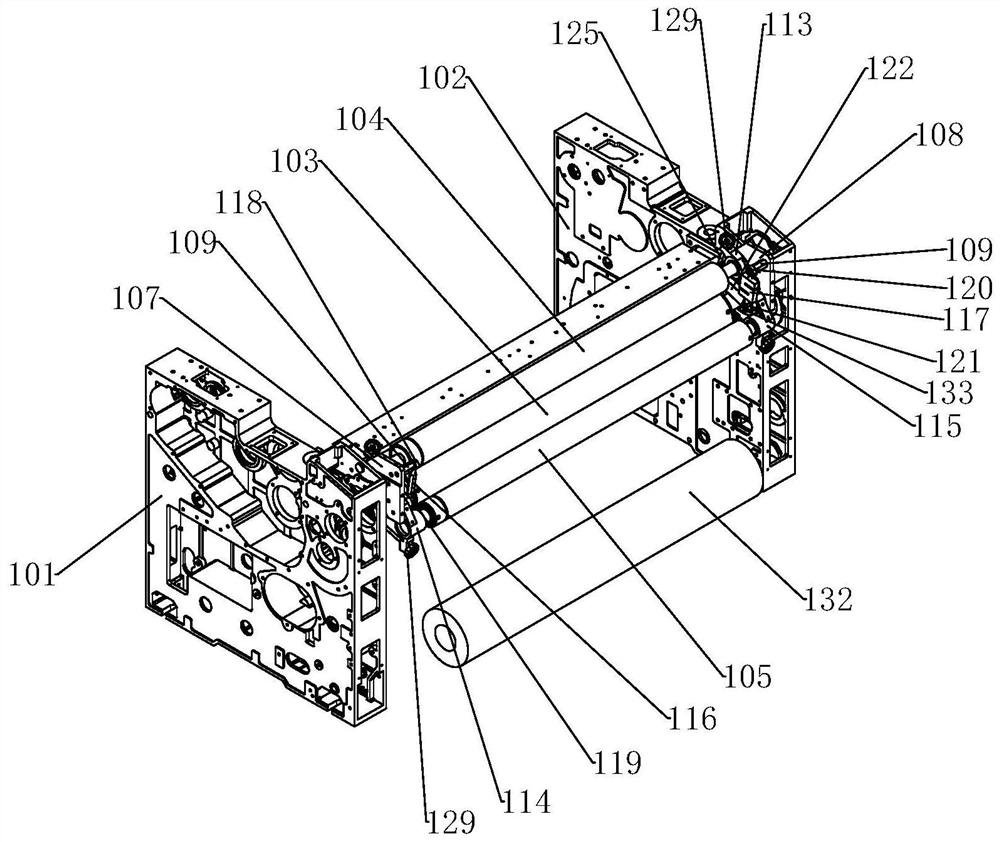

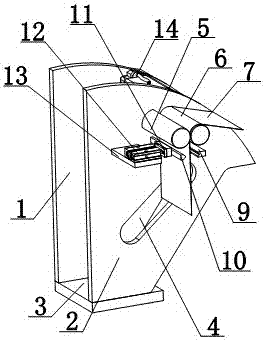

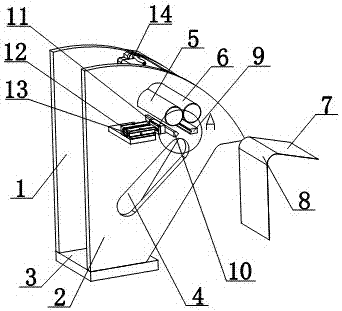

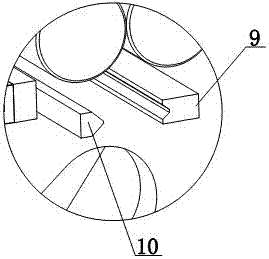

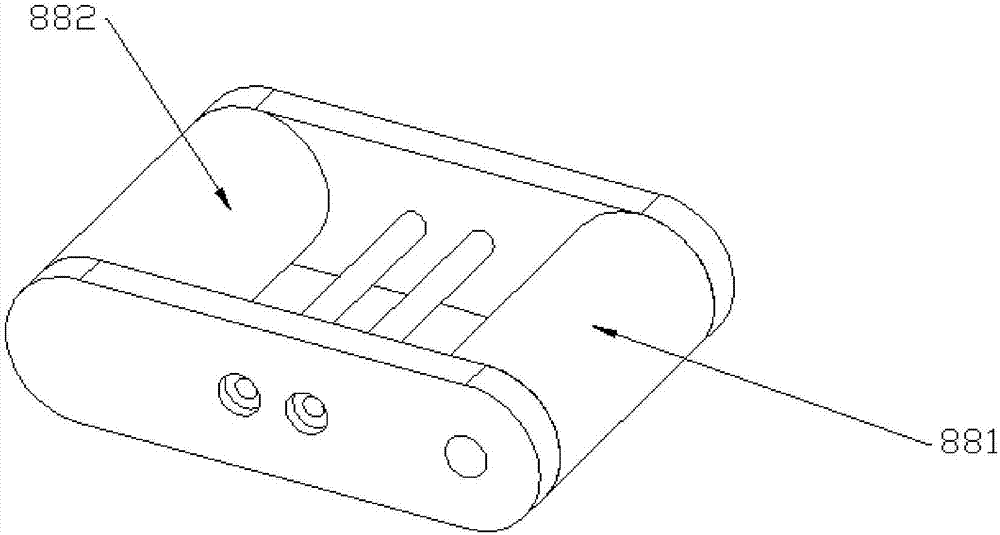

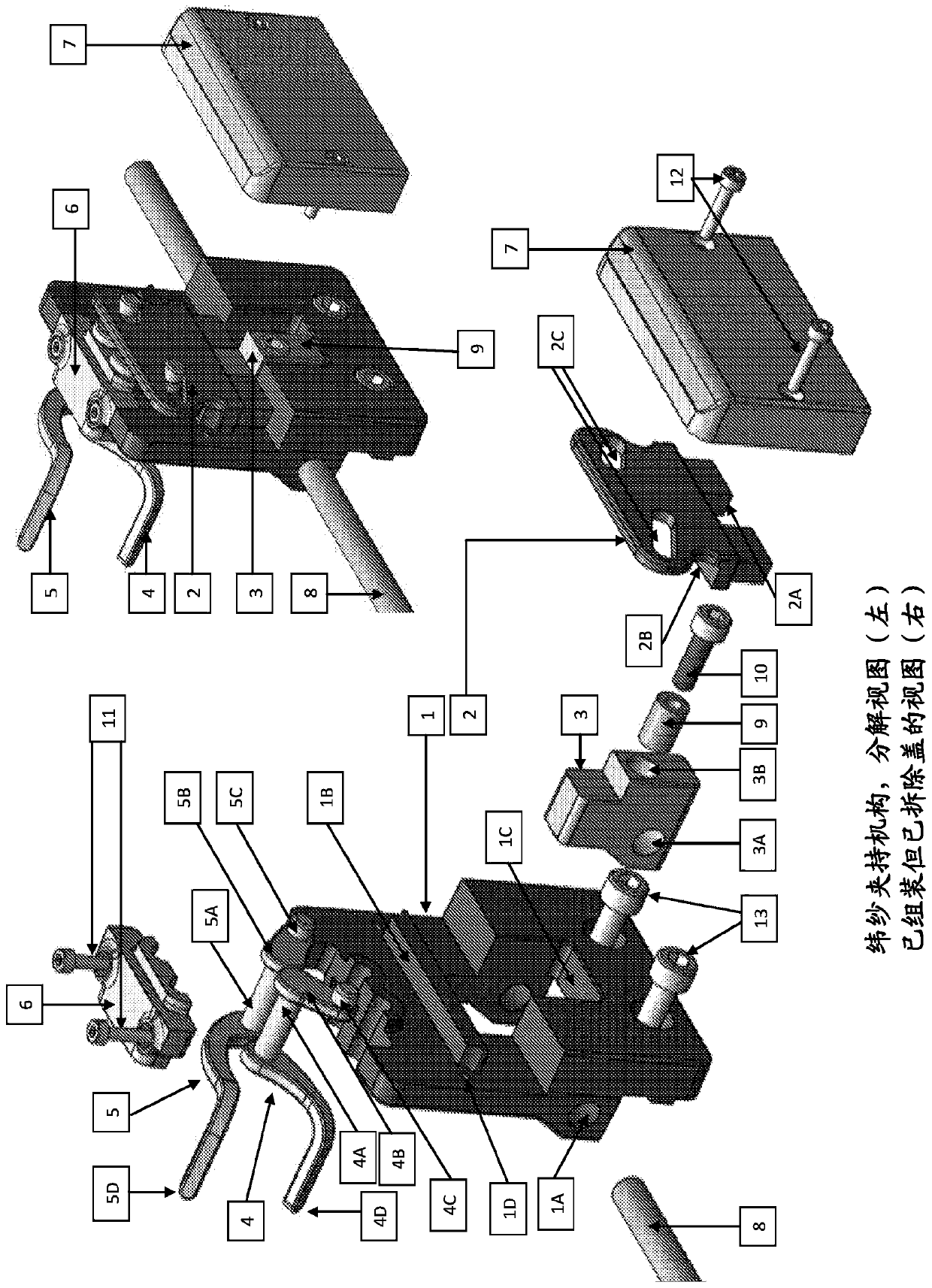

Fiber supply device of automatic optical fiber winding machine

InactiveCN101059583APrecise rotationStable controlFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a fiber feeder used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table, wherein the support base is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel. The invention can feed fiber in various automatic fiber coilers, and in the machine as fiber repeat coiler and fiber selector. The invention uses the accurate suspended shaft to vertically support the fiber discharge wheel to discharge fiber, and arranges the fiber collector under the wheel to collect the fiber output by the wheel into a fixed point to be moved out, thereby confirming the feeding direction consistence of the tension wheel and confirming the tension consistence in the fiber coiling process.

Owner:BEIHANG UNIV

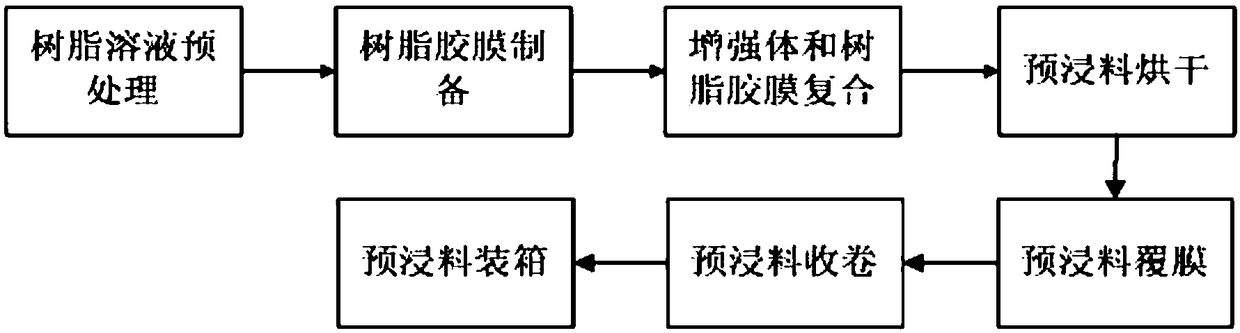

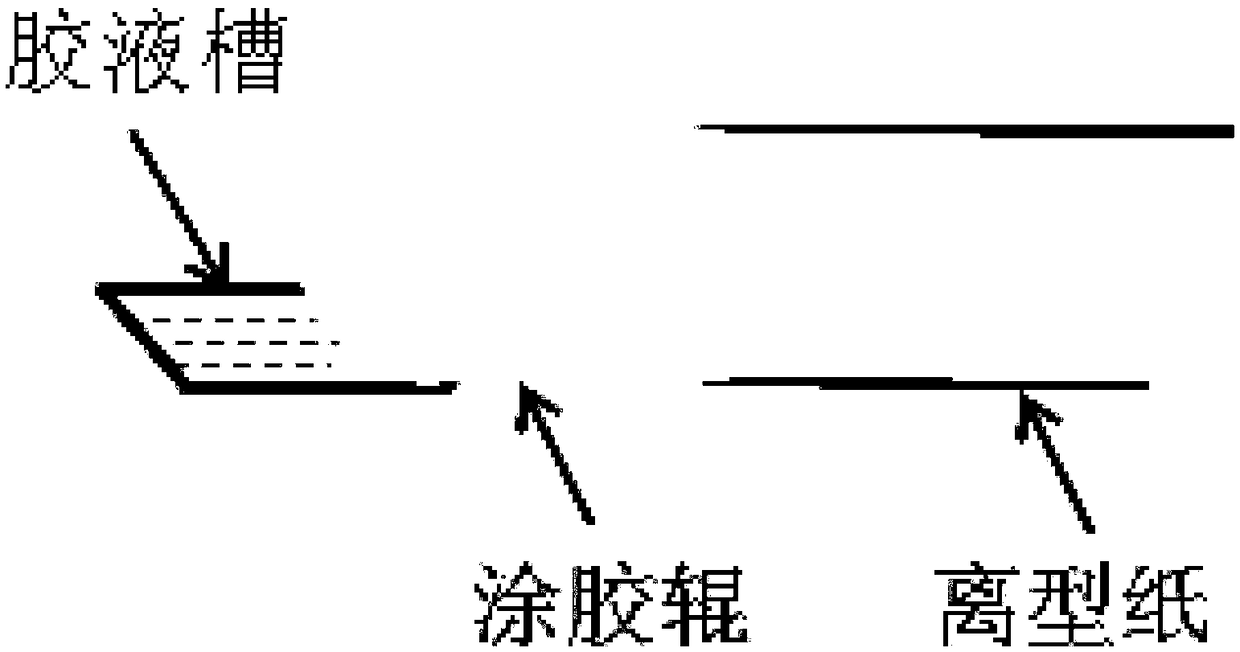

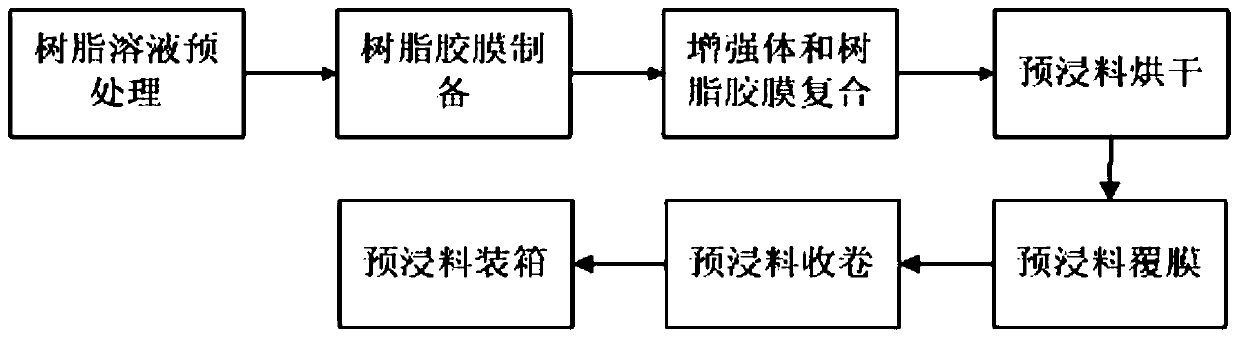

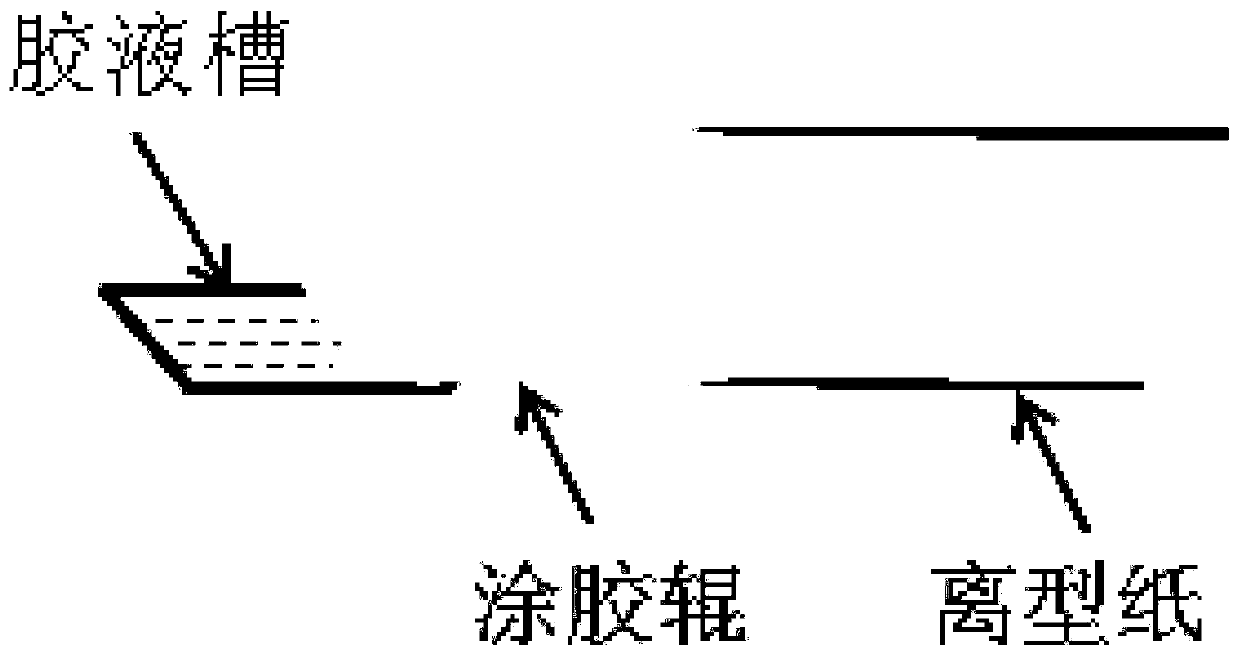

Preparation method of polyimide prepreg

The invention relates to a preparation method of polyimide prepreg, and belongs to the technical field of prepreg preparation. The method comprises the steps that proper resin solution viscosity is firstly contained through resin solution pretreatment, after release paper is coated with resin glue liquid through a tape casting process, a fiber enhancement body is paved, a pressure roller is utilized for achieving dipping of resin to the fiber enhancement body, then redundant volatile matter is removed through drying, and finally membrane coating and rolling are carried out. According to the preparation method, the technical problem about efficient impregnation of a low-viscosity polyimide resin solution is effectively solved by adopting the dual-roller engagement tape casting process, batched and stable preparation of the polyimide prepreg is achieved, and a good foundation is laid for engineering popularization and application of the polyimide prepreg.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

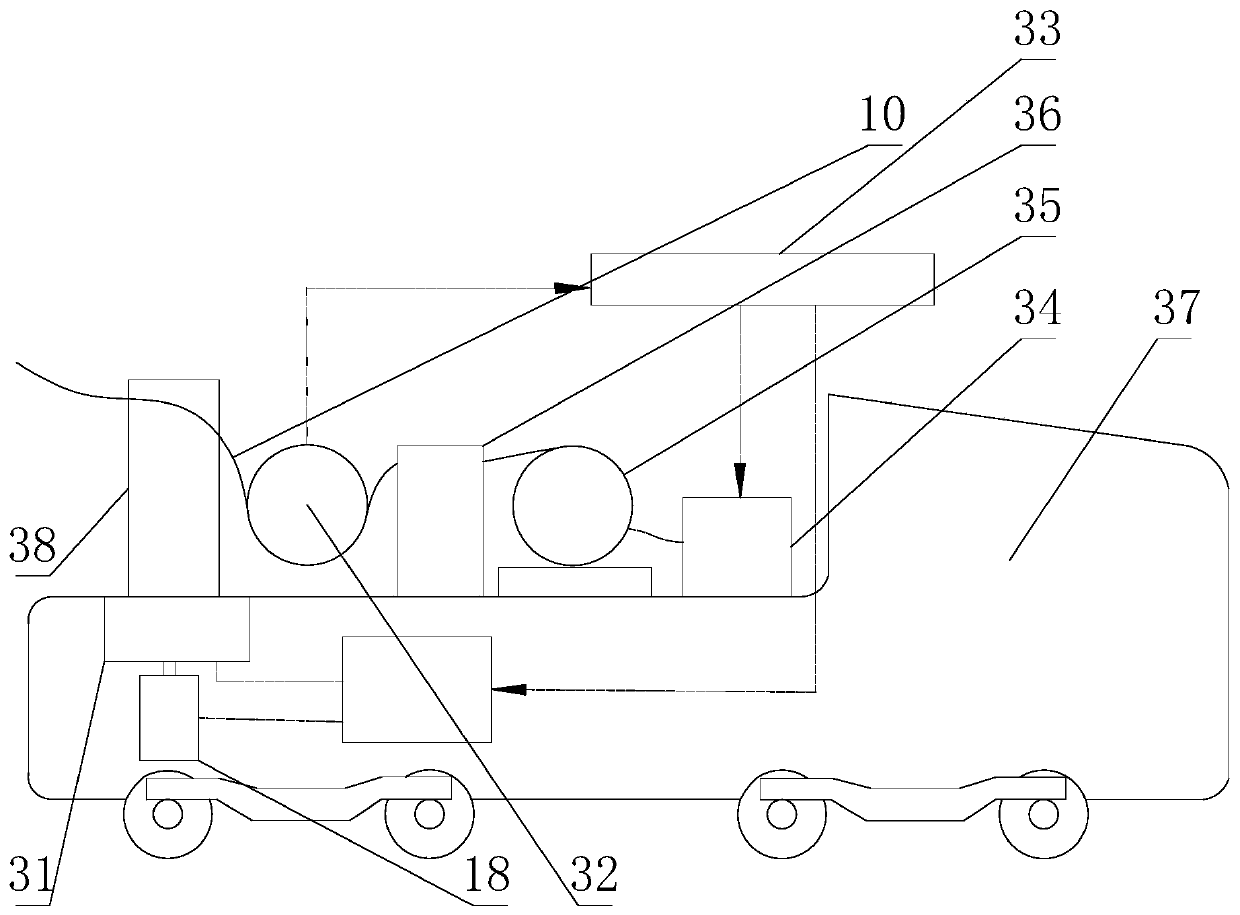

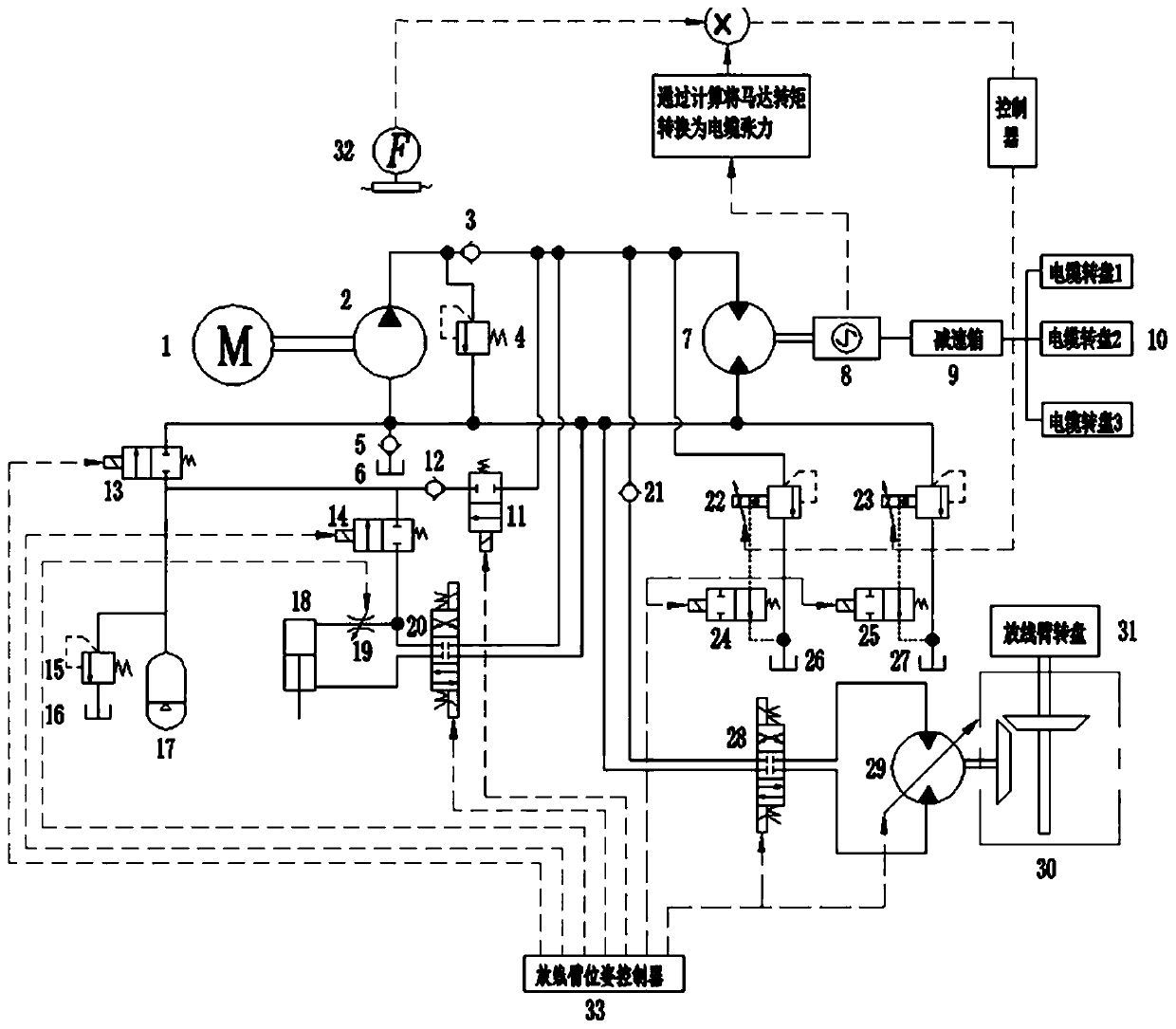

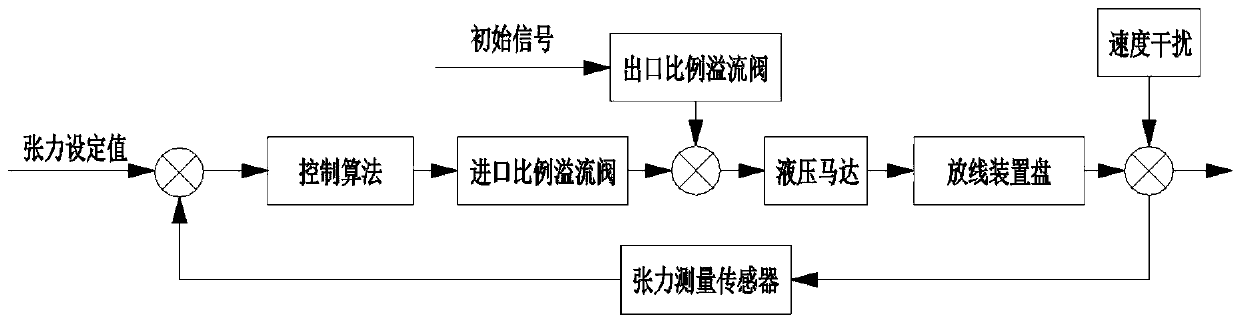

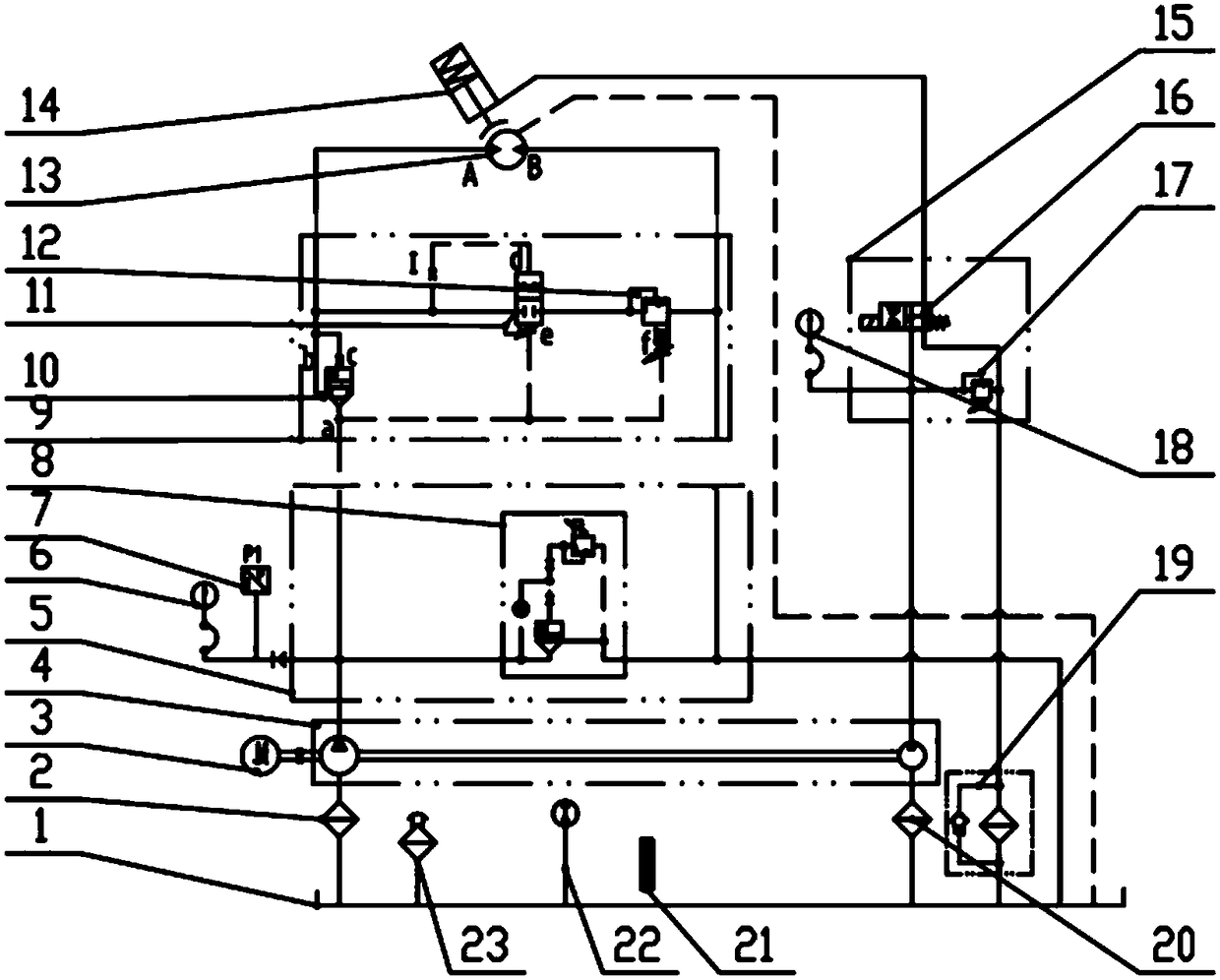

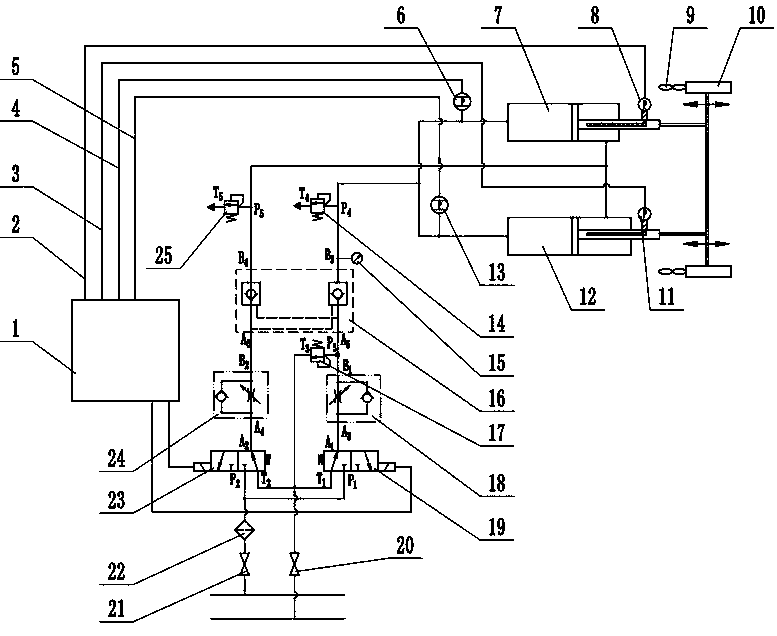

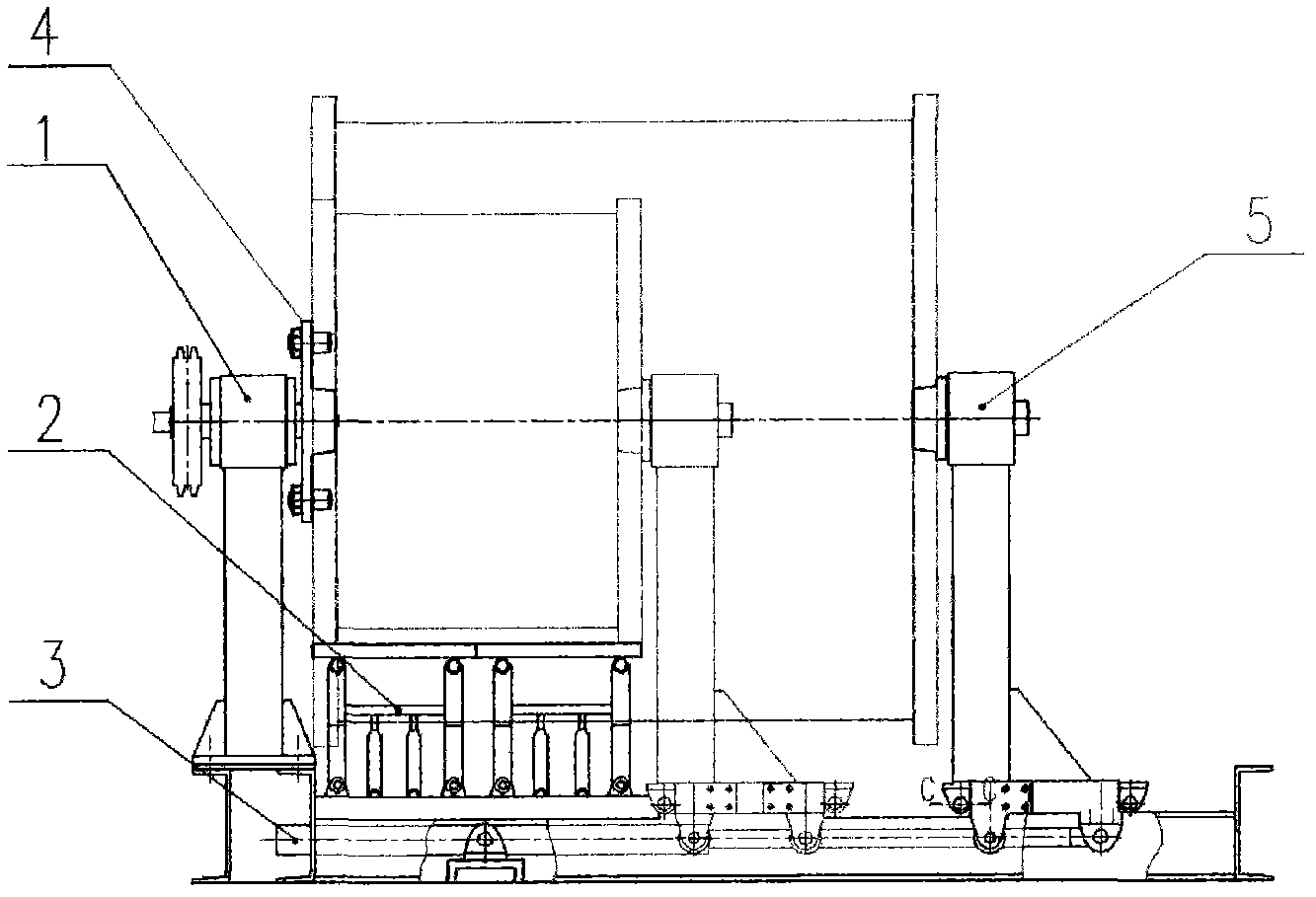

A hydraulic control system of automatic tensioning and free-releasing rope winch

ActiveCN106167233BImprove startup response speedImprove delivery efficiencyServomotorsWinding mechanismsFailure rateWinch

The invention discloses a winch hydraulic control system achieving automatic tensioning and free reeling off. The winch hydraulic control system comprises an oil tank, an electric motor, a double pump and a motor, wherein the motor is connected with a winch drum; the winch hydraulic control system further comprises a pressure control system, an automatic reeling off control assembly, a braking system assembly and a controller; the pressure control system comprises a first pressure gauge, a pressure transmitter and a proportional overflow valve; the automatic reeling off control assembly comprises a one-way valve, a two-position hydraulic control reversing valve and a pilot overflow valve; the braking system assembly comprises a brake used for conducing braking on the motor and a brake valve group, and the brake valve group is composed of a magnetic exchange valve, an overflow valve and a second pressure gauge. The winch hydraulic control system is high in automation degree and capable of accurately achieving stepless control of a tensioning force of a belt conveyor in real time, impact of start and stop of a winch can be effectively reduced, and therefore the failure rate can be reduced; meanwhile, the winch hydraulic control system can achieve a rapid response of start of the winch, therefore, the conveying efficiency of the belt conveyor can be improved, and energy consumption can be effectively saved.

Owner:XUZHOU WUYANG TECH

Process for sizing hard twisted yarns on warping and sizing combination machine

InactiveCN101768843ALittle loss of strengthLess chance of twistingFibre treatmentWarping machinesYarnSlurry

The invention relates to a process for sizing hard twisted yarns on a warping and sizing combination machine. The process combines a warping procedure and a sizing procedure into one. The process has the following technical points: (1) sizing process: dipping twice and pressing twice, putting slurry into a back slurry tank, holding yarns by a front slurry tank, sizing at a low temperature and keeping the slurry at the temperature of between 65 and 75 DEG C, wherein an out-of-box twist is 8' and a sizing coverage factor is 70 percent; and (2) slurry prescription, wherein 20 kilograms of Nanpi-8 and 1 kilogram of CS-58 are used and the slurry contains 10 percent of solids. The process has the advantages of shortening the process flow, improving the work efficiency and reducing the manpower and material investment; and besides, the process is mature and stable, guarantees the product quality, and reduces waste.

Owner:TIANJIN TEXTILE ENG RES INST

Telescopic machine tail self-adaptive adjustment electro-hydraulic composite control system and method

InactiveCN110134057ASimple designBest tension stateProgramme control in sequence/logic controllersSelf adaptiveElectro hydraulic

The present invention relates to the technical field of equipment design and manufacture of coal mine underground fully mechanized mining face, in particular to a telescopic machine tail self-adaptiveadjustment electro-hydraulic composite control system and method. A piston rod of the tensioning cylinder I and a piston rod of the tensioning cylinder II are connected with a telescopic machine tailframe, a travel sensor I and a travel sensor II are respectively arranged inside the piston rod of the tensioning cylinder I and inside the piston rod of the tensioning cylinder II, the travel sensorI and the travel sensor II are respectively connected with a PLC calculation control center through a travel signal transmission line I and a travel signal transmission line II, the tensioning cylinder I and the tensioning cylinder II are connected with a double-hydraulic-control one-way valve, a pressure sensor I and a pressure sensor II are respectively arranged on a pipeline which is connectedwith the tensioning cylinder I and the tensioning cylinder II and the double-hydraulic-control one-way valve, and the pressure sensor I and the pressure sensor II are respectively connected with thePLC calculation control center through a pressure signal transmission line I and a pressure signal transmission line II. The system and method is safe and reliable, has a simple mechanism, and adoptsmicrocomputer control and information feedback.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN100454056CCompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

Owner:BEIHANG UNIV

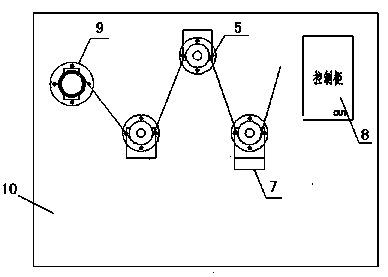

Electroplating film supplying device for automatically adjusting tension of sticking film

The invention discloses an electroplating film supplying device for automatically adjusting the tension of a sticking film. The device comprises a rack (10), a sticking film unreeling device fixedly arranged on the rack (10), and a plurality of guiding idler wheels (5) in upper and down staggered distribution, and is characterized in that the device also comprises a control cabinet (8), the sticking film unreeling device comprises a tensioner (9) and a magnetic powder clutch (4) connected with the tensioner (9), one guiding idler wheel is provided with a twisting sensor (7), and the twisting sensor (7) and the magnetic powder clutch (4) are in signal connection with the control cabinet (8). The electroplating film supplying device is convenient for tension control, manual adjustment is not needed, and the production efficiency and the product percent of pass are improved.

Owner:铜陵宇阳广告有限公司

Device and method for manufacturing strapped packs and regulatory and/or control method for a strapping device

ActiveUS9051071B2Reduce tensionReduce the amount of solutionBinding material applicationBundling machine detailsEngineeringStrap device

A device and method for the manufacturing of a pack including at least one article. The device includes a strapper for strapping a strip around the at least one article. The strapping is strapped around the outside of the article horizontally and / or vertically and / or cross-wise. A device generates a definable tensioning force of the strapping. A detector for the detection of properties of the article(s) is coupled and / or effectively connected to the device for generating a definable tensioning force of the strapping. A regulation and / or control method for a strapping device is also provided. Recorded properties of the articles to be wrapped and / or of the strapping material to be used are used as control values for the tensioning force and / or back tensioning force.

Owner:KRONES AG

A kind of preparation method of polyimide prepreg

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Tension adjusting device for traction of transmission belt

The invention discloses a tension adjusting device for traction of a transmission belt. The device comprises a first supporting rack and a second supporting rack, wherein a butt joint rack is arrangedbetween the first supporting rack and the second supporting rack, a first supporting seat is arranged on the end part of the first supporting rack, a second supporting seat is arranged on the end part of the second supporting rack, and a belt wheel is arranged between the second supporting seat and the second supporting rack; and a tensioning mechanism is arranged between the first supporting rack and the second supporting rack and comprises a tensioning roller, the tensioning roller is arranged on an adjusting plate, a fixed shaft is arranged at the bottom of the adjusting plate, the fixed shaft is mounted between the first supporting rack and the second supporting rack, a positioning shaft is arranged between the first supporting rack and the second supporting rack, an insertion shaft is arranged on the positioning shaft, and the upper end of the insertion shaft penetrates through the adjusting plate. According to the tension adjusting device disclosed by the invention, the tensioning roller can be moved to be finely adjusted conveniently, so that tension of the transmission belt is controlled conveniently.

Owner:王玲芳

Novel batching tension control device of glass fiber weaving machine

The invention discloses a novel cloth rolling tension control device of a glass fiber weaving machine. The novel cloth rolling tension control device comprises a rack, an upper cloth pressing roller, a winding roller and a tension roller. The rack comprises a left wallboard and a right wallboard, and a left fixing plate and a right fixing plate are correspondingly mounted on the inner side walls of the two wallboards; the winding roller is rotationally mounted between the left wallboard and the right wallboard through mounted fixed bearings at the two ends of the winding roller; the upper cloth pressing roller is rotationally mounted between the left fixing plate and the right fixing plate through upper cloth pressing roller arms at the two ends of the upper cloth pressing roller and located above the winding roller; the tension roller is rotationally mounted between the left and right fixing plates through tension roller arms at two ends of the tension roller and is positioned in front of and below the winding roller; meanwhile, a first tension connecting rod and a second tension connecting rod are further arranged on the two end sides of the tension roller and form stable triangular support with the corresponding lower connecting arms. An original lower cloth pressing roller and an original tension roller are combined into a whole, the structure is simpler and more compact, the space in a weaving machine is saved, the slippage phenomenon caused by insufficient pressing force of an independent tension roller and a cloth cover is effectively avoided, and the cloth cover wrinkling problem is solved.

Owner:青岛天一红旗特种织机科技有限公司

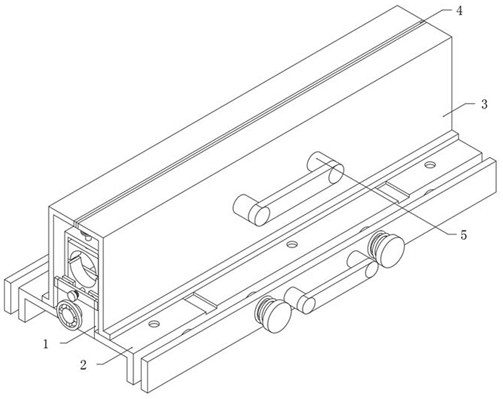

Tensioning device for conveyer belt of paper feeding machine driving mechanism

InactiveCN107399624AEasy Tension ControlFlexible tension adjustmentArticle feedersMechanical engineeringEngineering

The invention discloses a tensioning device for a transmission belt transmission mechanism of a paper feeder, which comprises a fixed plate; the fixed plate is arranged on a base; the outer wall of the fixed plate is provided with adjustment rollers; A tension piece is provided between the rollers, and a bending portion is provided in the middle of the tension piece; the tension piece passes between the limit blocks; the outer wall of the fixed plate is provided with a cylinder, and the cylinder is provided with a telescopic shaft, and the telescopic shaft A moving block is arranged at the end of the roller, and the moving block is arranged between the adjusting roller and the limit block. The invention can control the tension sheet to control the tension of the transmission belt, which facilitates the flexible adjustment of the tension of the transmission belt on the paper feeder.

Owner:陈沛

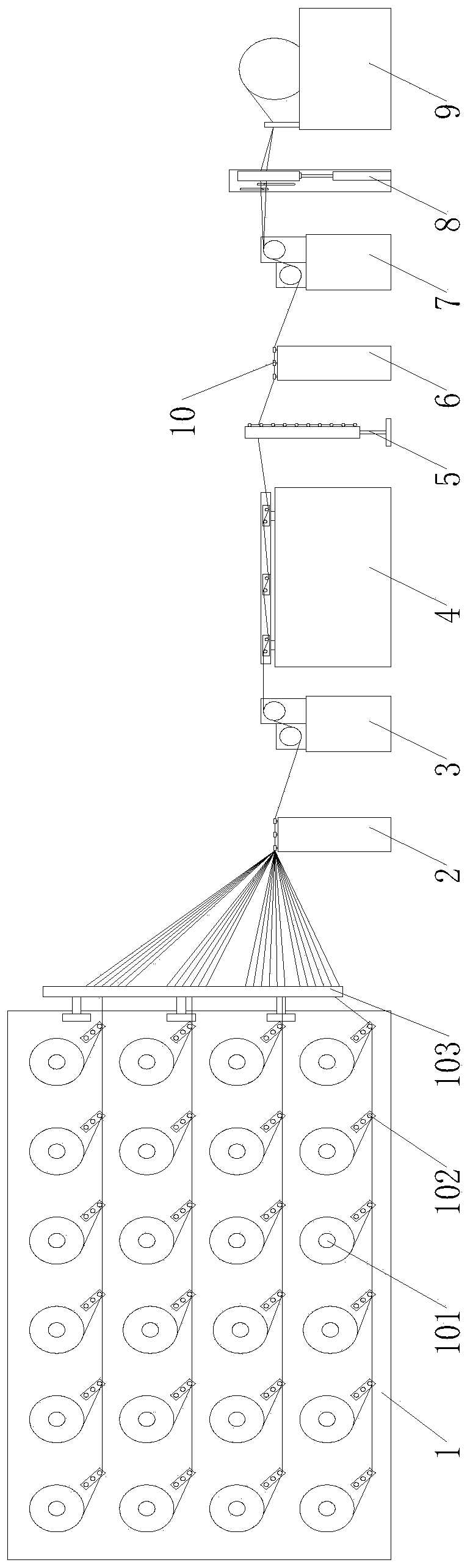

Nylon mother yarn warping method and nylon mother yarn warping device

The invention discloses a chinlon mother yarn warping method and a chinlon mother yarn warping device. The method comprises the steps of firstly, mutually twisting 10 chinlon son yarns to form a mother yarn and then winding the mother yarn on a cylinder to obtain a mother yarn spindle; then respectively arranging the mother yarn spindle on a fixed roller of an electric-control spindle frame, sequentially penetrating one end of each mother yarn through a yarn threading frame, a mother yarn locating frame, a mother yarn tension roller and an adjusting base; then separating the son yarns from the mother yarn and penetrating the son yarns into a yarn dividing frame side by side; then sequentially penetrating the son yarns through a son yarn locating frame and a son yarn tension roller, layering by a leasing rod and then penetrating the son yarns through a reed; finally penetrating the son yarns into a warping machine to finish warping. The chinlon mother yarn warping method disclosed by the invention not only can achieve once forming of spindles, but also achieves whole-process control on yarn tension in a chinlon warping process and has the advantages of high production efficiency and good stability.

Owner:HUZHOU HENGXIN TRADEMARK MAKING BRINGING

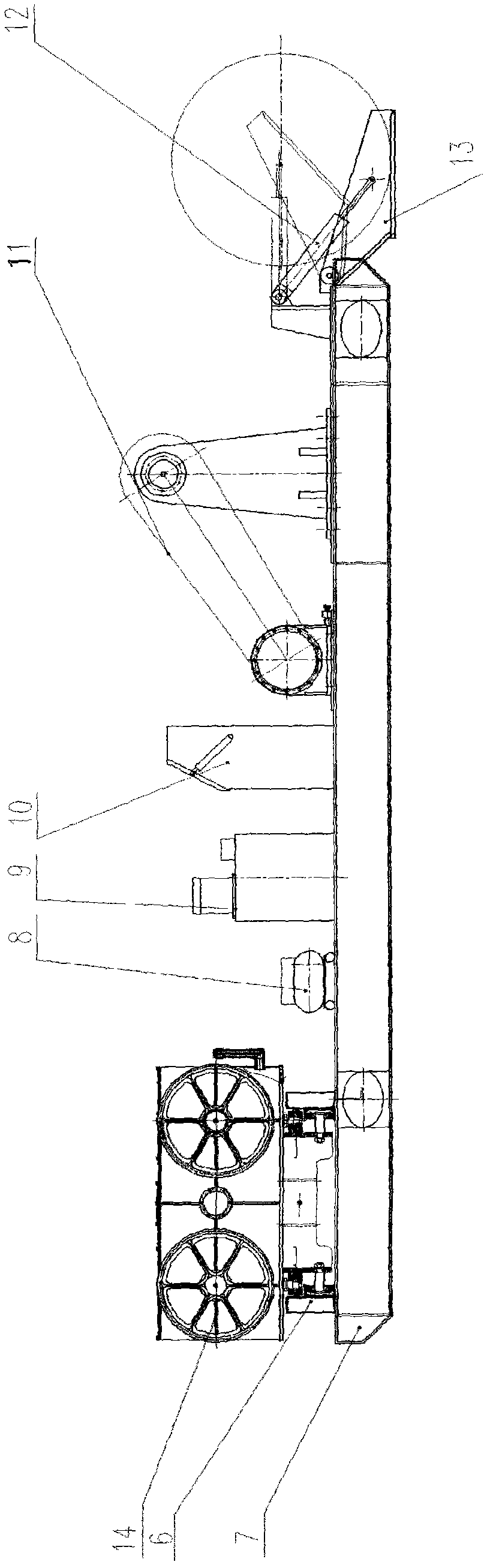

Automatic cable inverting machine of logging cable

ActiveCN102674076BNeat tensionSmall footprintFilament handlingAutomatic controlAutomated control system

The invention provides a cable inverting machine of an oilfield logging cable. The automatic cable inverting machine comprises a fixed bracket, a small shear type lifter, an oil cylinder, a supporting head, a movable bracket, a cable arranging device assembly, a prying frame, an air compressor, a hydraulic station, an operation control console, a lifting bucket and other devices. The logging cable inverting machine can loading a certain tension to a cable of thousands of meters; the cables can be evenly arranged during both winding the cable and unwinding the cable; compared with the original method, the cable inverting machine has the advantages of small space usage, time and labor conservation and better tension control. The cable in a winding drum is prevented from being hoisted to cable inverting equipment by hoisting equipment during cable inverting operation. According to the invention, a cable lifting device, a tension device, a cable arranging device and an automatic control system are integrated with each other; therefore, the cable inverting machine provided by the invention has the advantages of simplicity in operation, orderliness for arranging cables, stable tension and high degree of automation.

Owner:HUBEI PETROKH MACHINE MFG

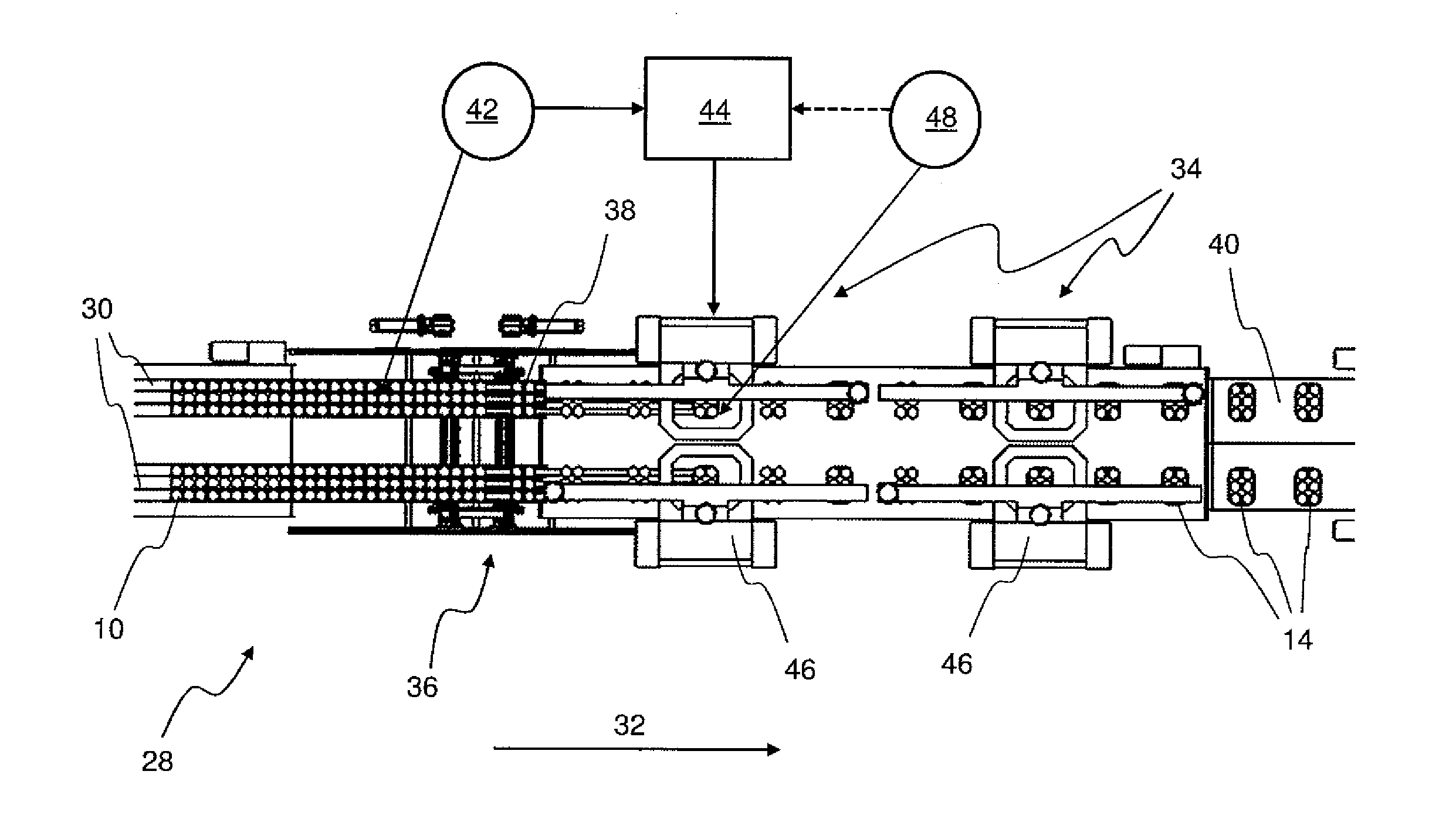

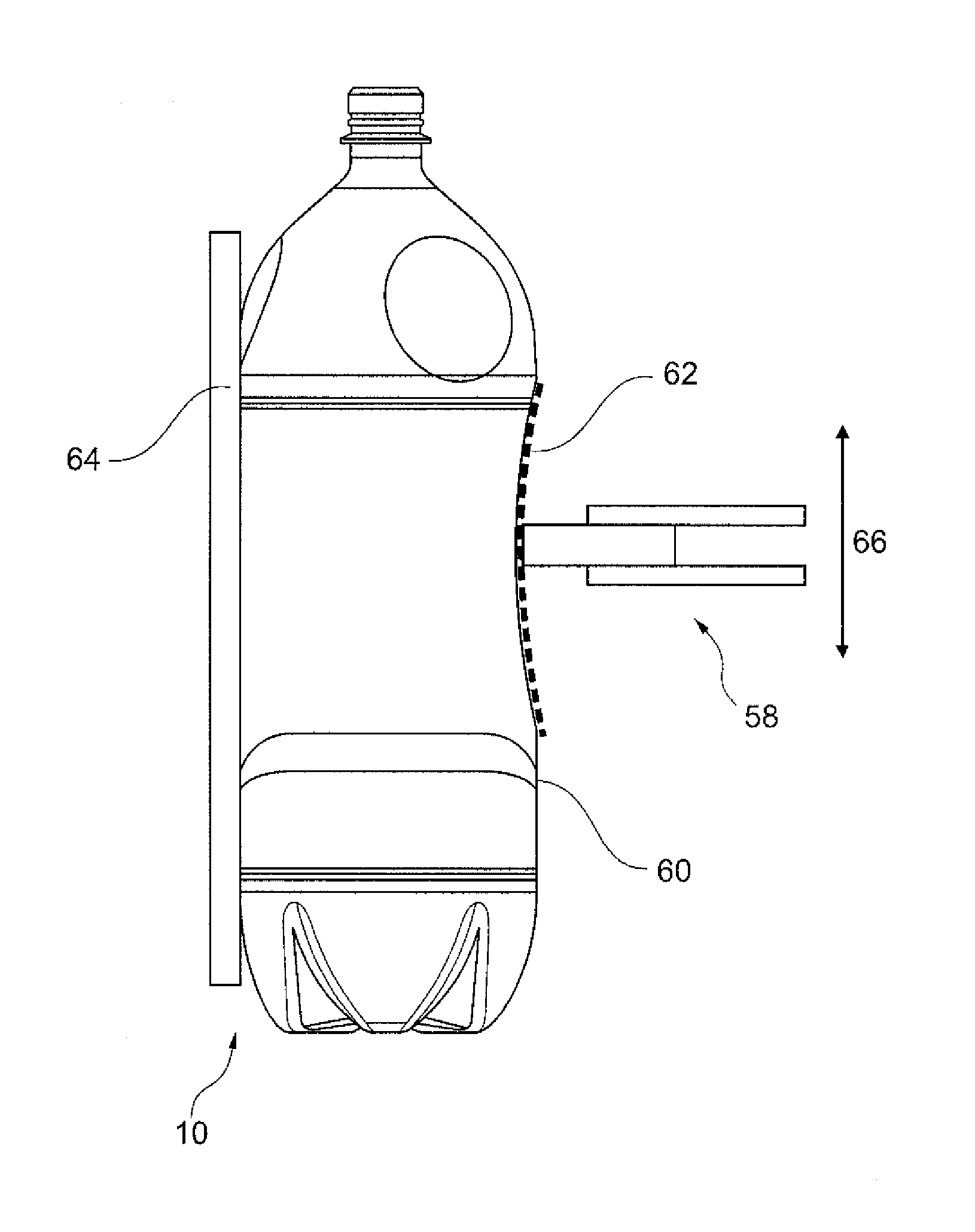

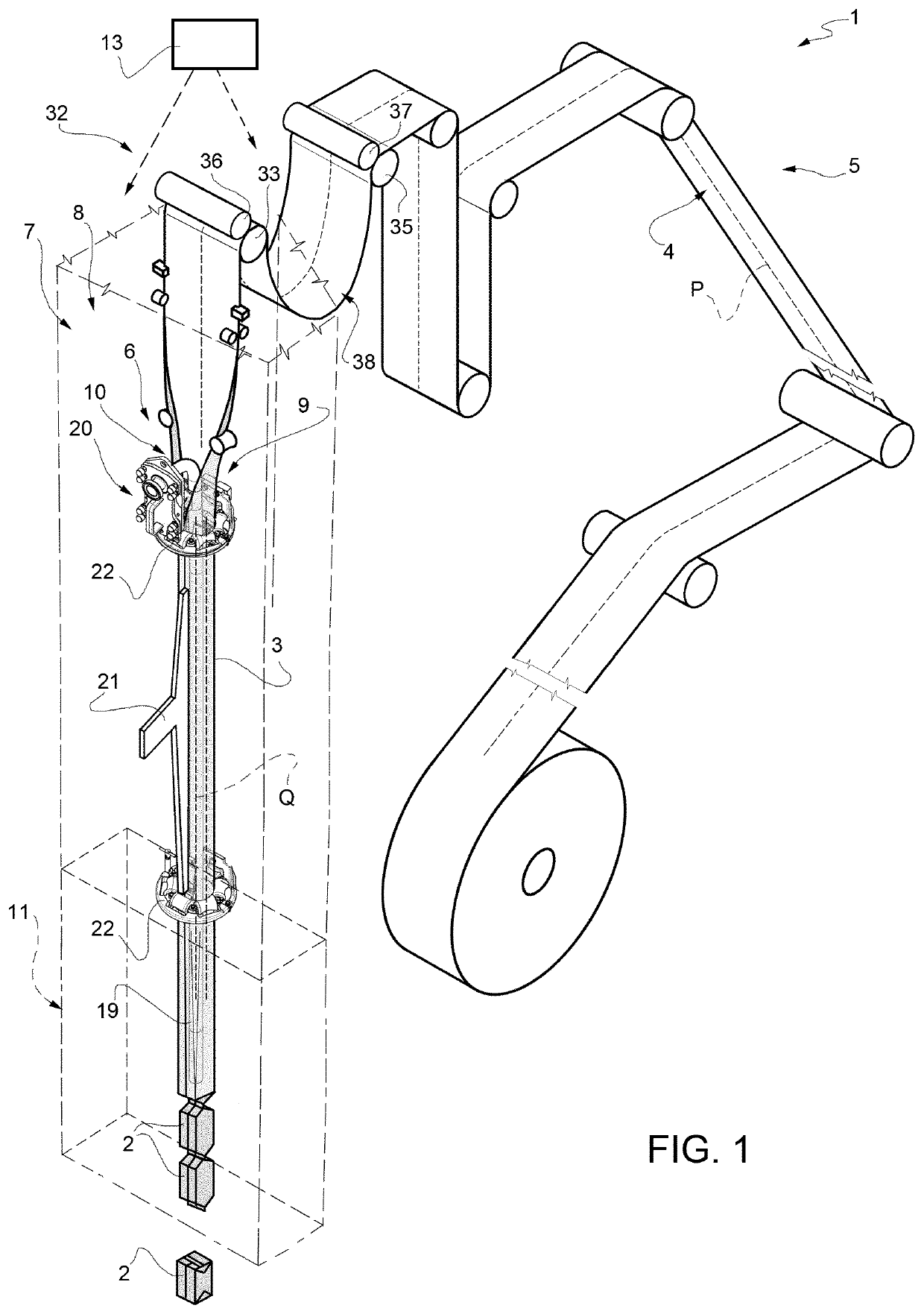

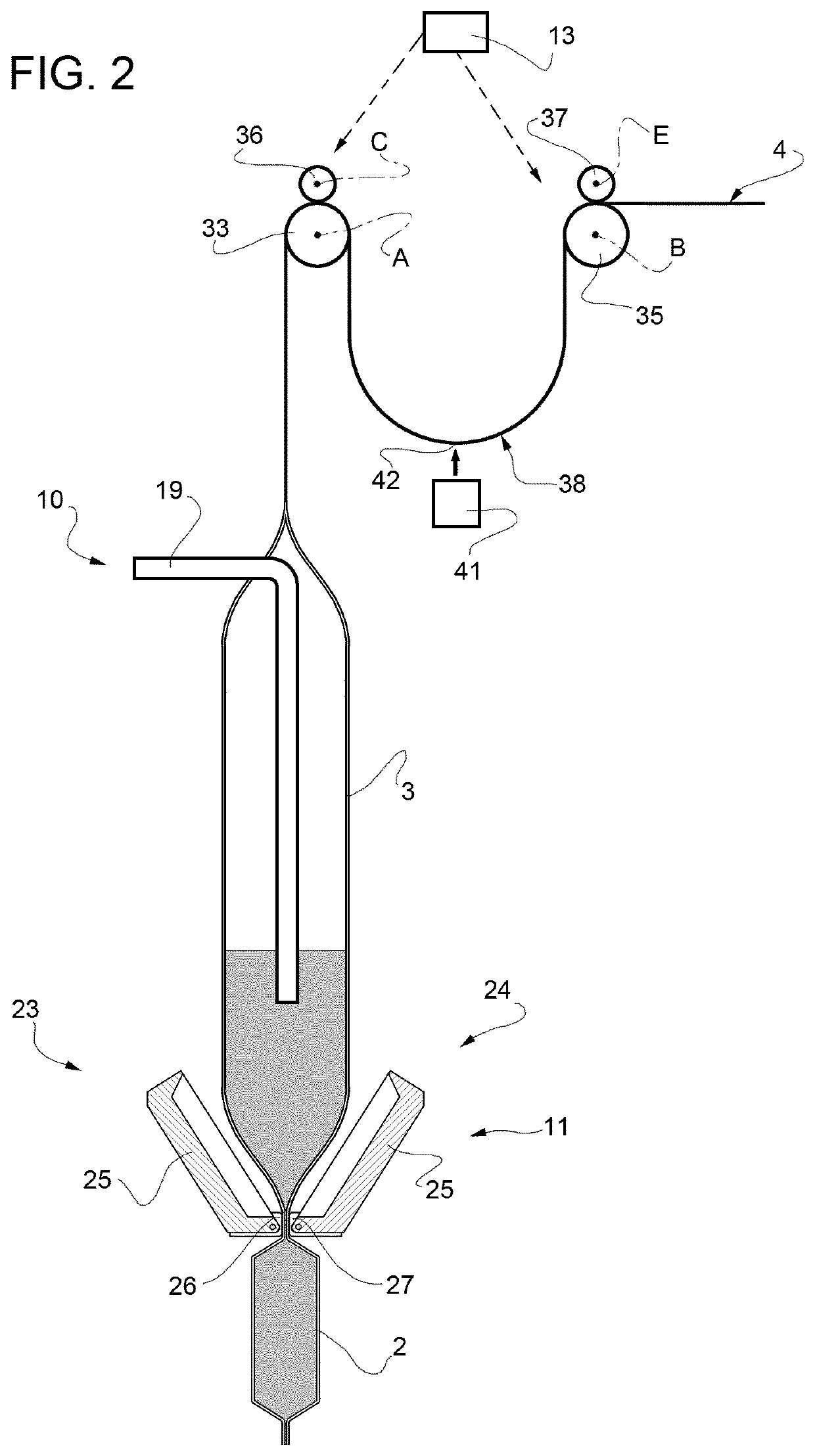

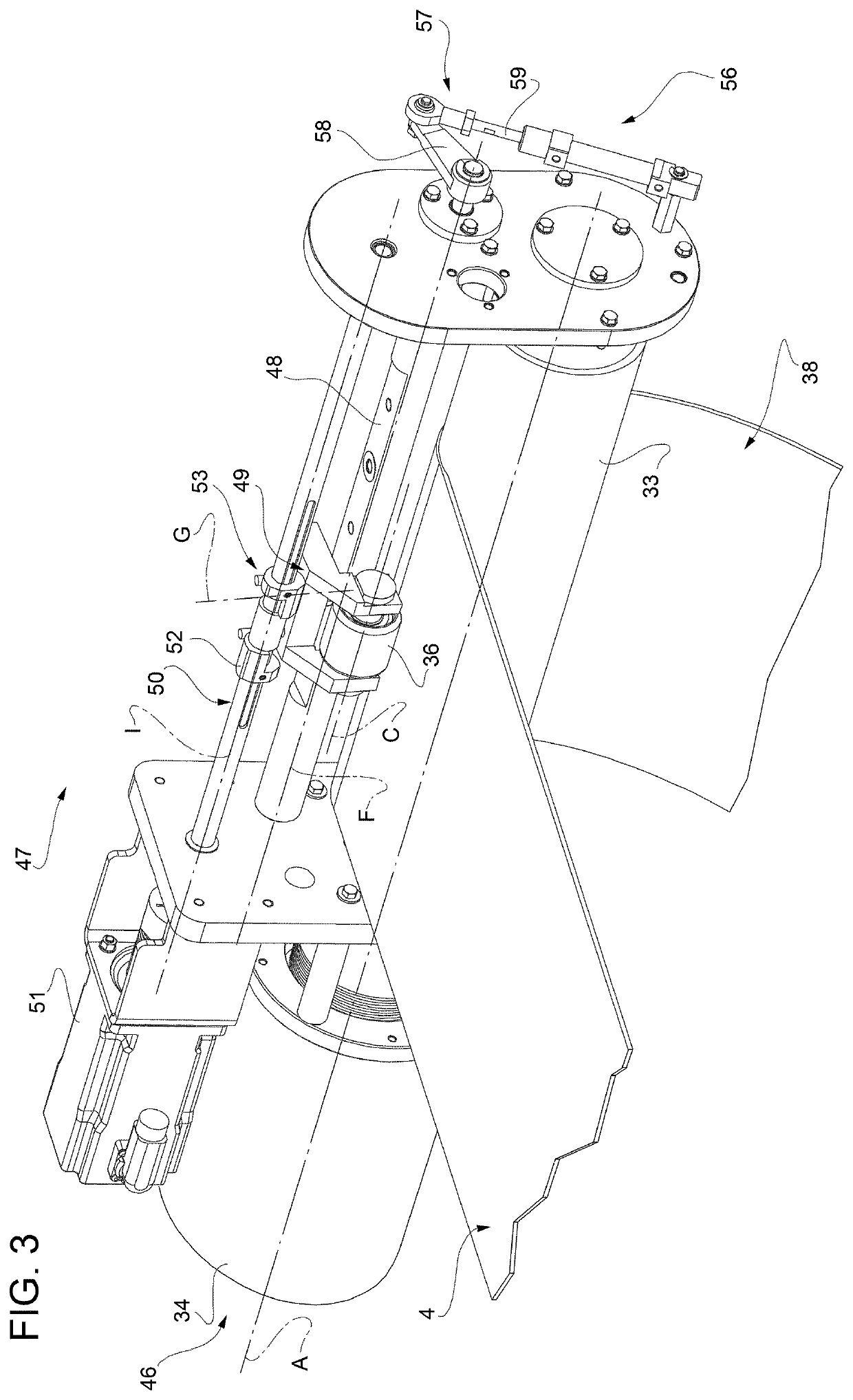

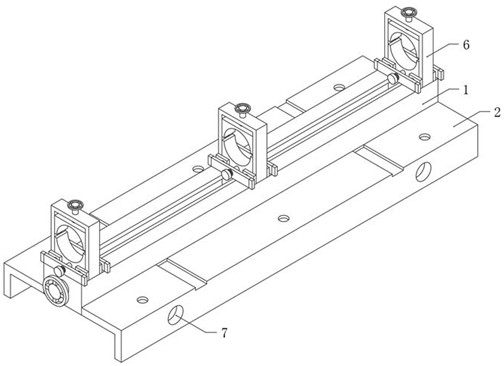

Packaging machine and method for producing sealed packages

PendingUS20220194639A1Easy Tension ControlWrapping material feeding apparatusFunction indicatorsRotational axisElectric machinery

A packaging machine comprises a conveying device for advancing a web along a web advancement path at least to a tube forming station where the web is formed into a tube and for advancing the tube along a tube advancement path, a tube forming and sealing device configured to form and to longitudinally seal the tube, a tensioning device upstream of the tube forming station and configured to control the tension of the tube and a control unit configured to control packaging machine operation. The tensioning device comprises a main drive roller rotatable around a main rotation axis and a main drive motor configured to actuate rotation of the main drive roller around the main rotation axis. The control unit is configured to control the main drive motor such that angular speed and / or angular acceleration of the main drive roller is cyclically varied to control the tension of the tube.

Owner:TETRA LAVAL HLDG & FINANCE SA

Film tension adjusting device

InactiveCN108001778APrevent movementPrevent looseningLabelling machinesEngineeringMechanical engineering

The invention provides a film tension adjusting device. The film tension adjusting device comprises a feeding wheel. A tangent first pressing plate is arranged on one side of the feeding wheel, and the first pressing plate is vertically arranged on a fixing plate through a first supporting rod. The first pressing plate can rotate relative to the first supporting rod. A plurality of guiding rods are arranged below the first supporting rod. A first drive frame is arranged on the left sides of the guiding rods, a second drive frame is arranged on the right sides of the guiding rods, and the firstdrive frame and the second drive frame are driven by a servo motor. By means of the film tension adjusting device, stable tension in the film feeding process can be guaranteed, and transmission is stable.

Owner:新昌县小毅家电子商务有限公司

Cable clamp with controllable lateral tension of cable and its clamping method

ActiveCN113422336BEasy Tension ControlImprove practicalityElectrical apparatusStructural engineeringControl theory

The invention discloses a cable clamp with controllable transverse tension of cables and a clamping method thereof, which comprises a positioning frame, a through groove is opened at the middle position of the top of the positioning frame, positioning blocks are fixed at both ends of the positioning frame, two positioning The middle positions on one side of the blocks are all rotated with first screw rods, and the middle positions on one side of the two positioning blocks are respectively connected to the two ends of the first screw rods in rotation; the present invention makes the first positioning handles Drive the first screw rod fixed at one end to rotate, so that the two moving blocks respectively drive the positioning seat and the cable fixed at the top to approach one end of the positioning frame, so that the cable is positioned at the same time as it is convenient for tension control, so that the cable can be positioned according to the position of the cable clamp And move, avoid making the cable work under the situation that the tension is uncontrollable for a long time, reduce the damage rate of the work to the cable, increase the service life of the cable, and improve the practicability of the cable clamp.

Owner:南通华众液压机械有限公司

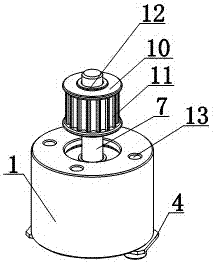

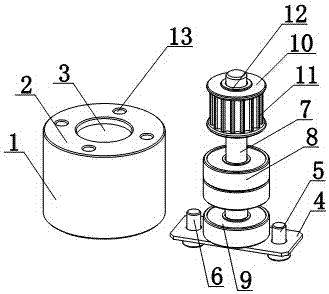

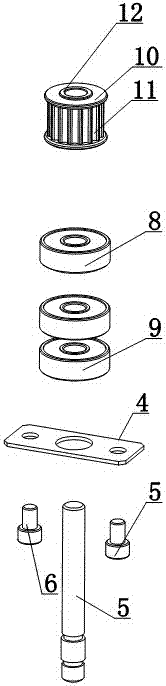

Belt wheel for conveying belt tensioning

InactiveCN107542901AEasy Tension ControlEasy to installPortable liftingGearing elementsTransmission beltConveyor belt

The invention discloses a belt pulley for tensioning a transmission belt, which comprises a protective tube, and a tensioning mechanism is arranged inside the protective tube. There is a plane bearing group, a plane bearing is arranged between the lower end of the rotating shaft and the fixed plate, and the plane bearing is set on the outer peripheral surface of the rotating shaft; a rotating wheel is arranged at the end of the rotating shaft, and several racks are arranged on the outer peripheral surface of the rotating wheel , the rack is parallel to the axial position of the rotating wheel; the rotating wheel is arranged in the protective tube; the upper part of the protective tube is provided with a buckle, and the center of the shaft of the buckle is provided with an opening, and the rotating shaft passes through the opening. The invention can protect the plane bearing group through the casing; the rotating wheel can be set on the inner side wall of the transmission belt, and the transmission belt can drive the rotating wheel through the rack, so as to facilitate the tension control of the transmission belt.

Owner:刘康

Full-static pressure clean optical thin film coating machine

ActiveCN102825893BEasy Tension ControlStable tensionLamination plant layoutLamination ancillary operationsComposite filmOptical thin film

Owner:浙江欣麟新材料技术有限公司

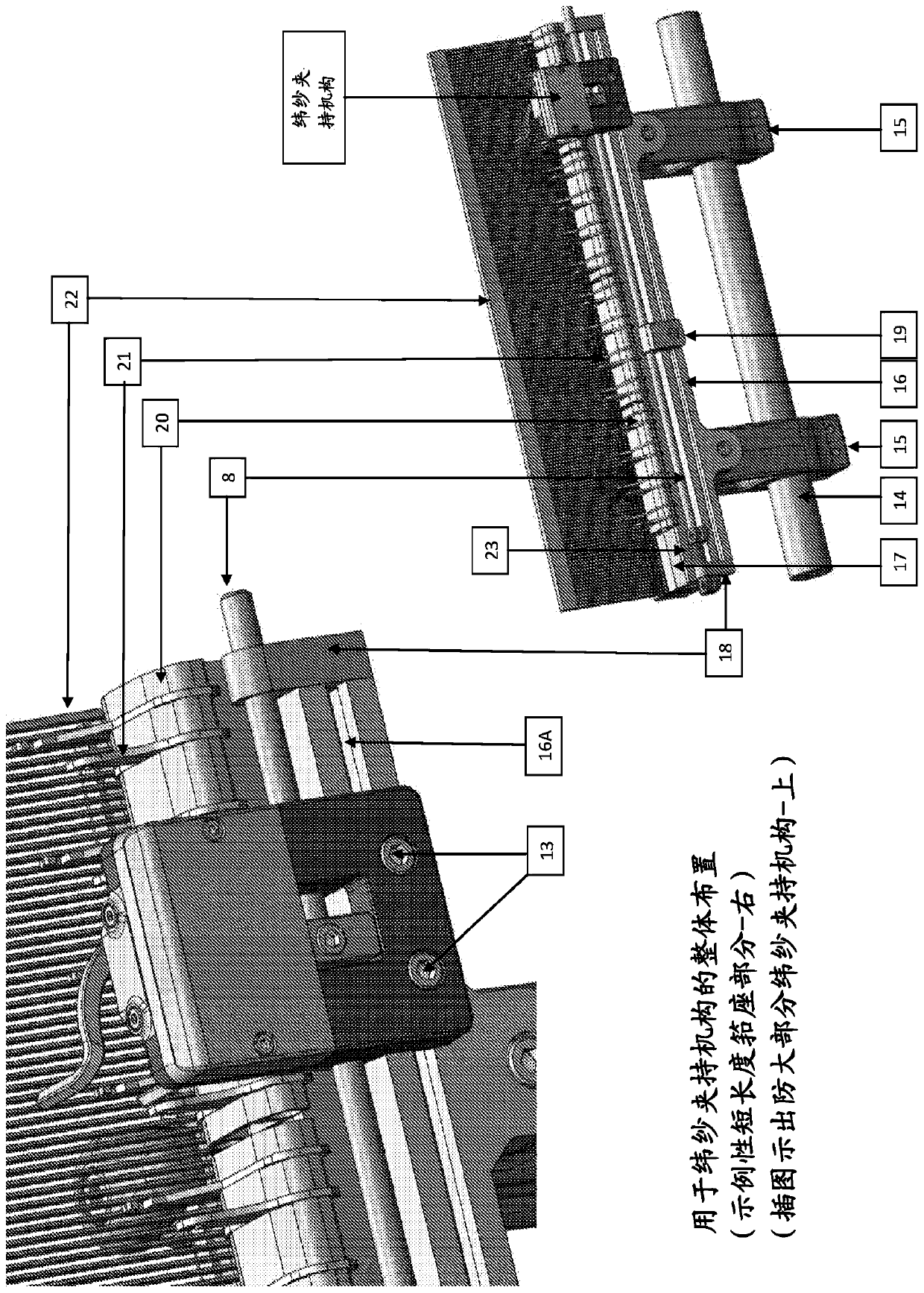

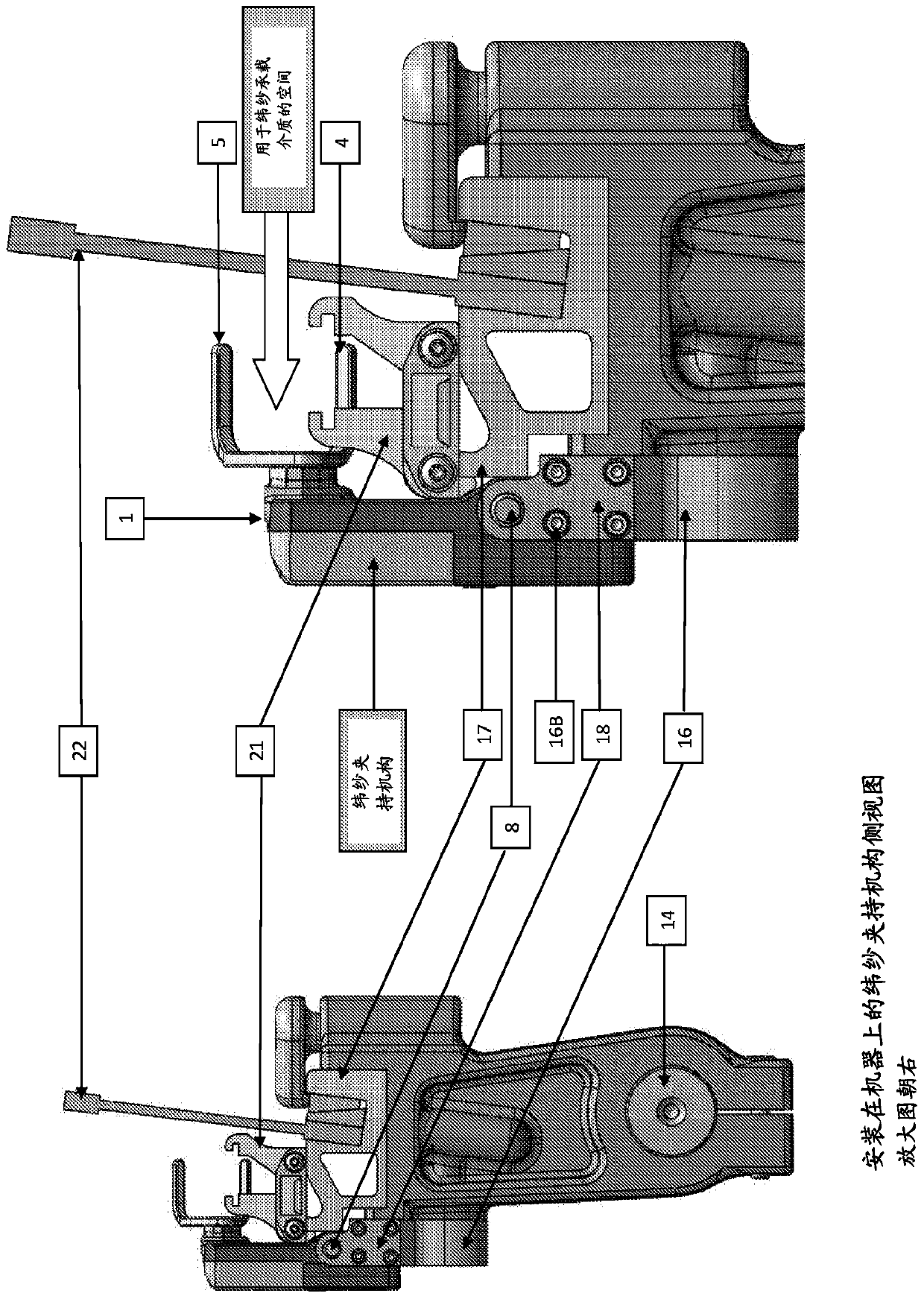

Weft gripping mechanism for shuttleles weaving machines

The invention refers to a path breaking and pioneering effort to art a Weft Gripping mechanism for use on shuttle-less weaving machines. There is no such or similar device in existence today and the need for such a mechanism arises from the key points of disadvantages of the existing systems. With the advent of the Weft Gripping mechanism, the rubbing action between the weft insertion media and boundary selvedge threads is totally eliminated and so will be the breakages arising due to the rubbing. It not only facilitates precision timing of positive grip but also improves the gripping force exerted on the weft yarn and brings about a better tension control of the weft thread, which is known to be the key element for a better fabric appearance. The novel weft grip mechanism allows a more precision timing setting of weft grip, which in turn means exact or optimum weft protruding length, which obviously means lesser wastage of precious weft yarns.

Owner:桑贾伊库尔库特

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com