Method for continuously manufacturing 3-CCM (three Catalyst Coated Membranes) of fuel cell

A core component, fuel cell technology, used in fuel cells, solid electrolyte fuel cells, sustainable manufacturing/processing, etc., can solve the impact on performance and cost, reduce the stability of mass manufacturing, and do not solve the size of the proton exchange membrane, etc. problem, to achieve the effect of high yield and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

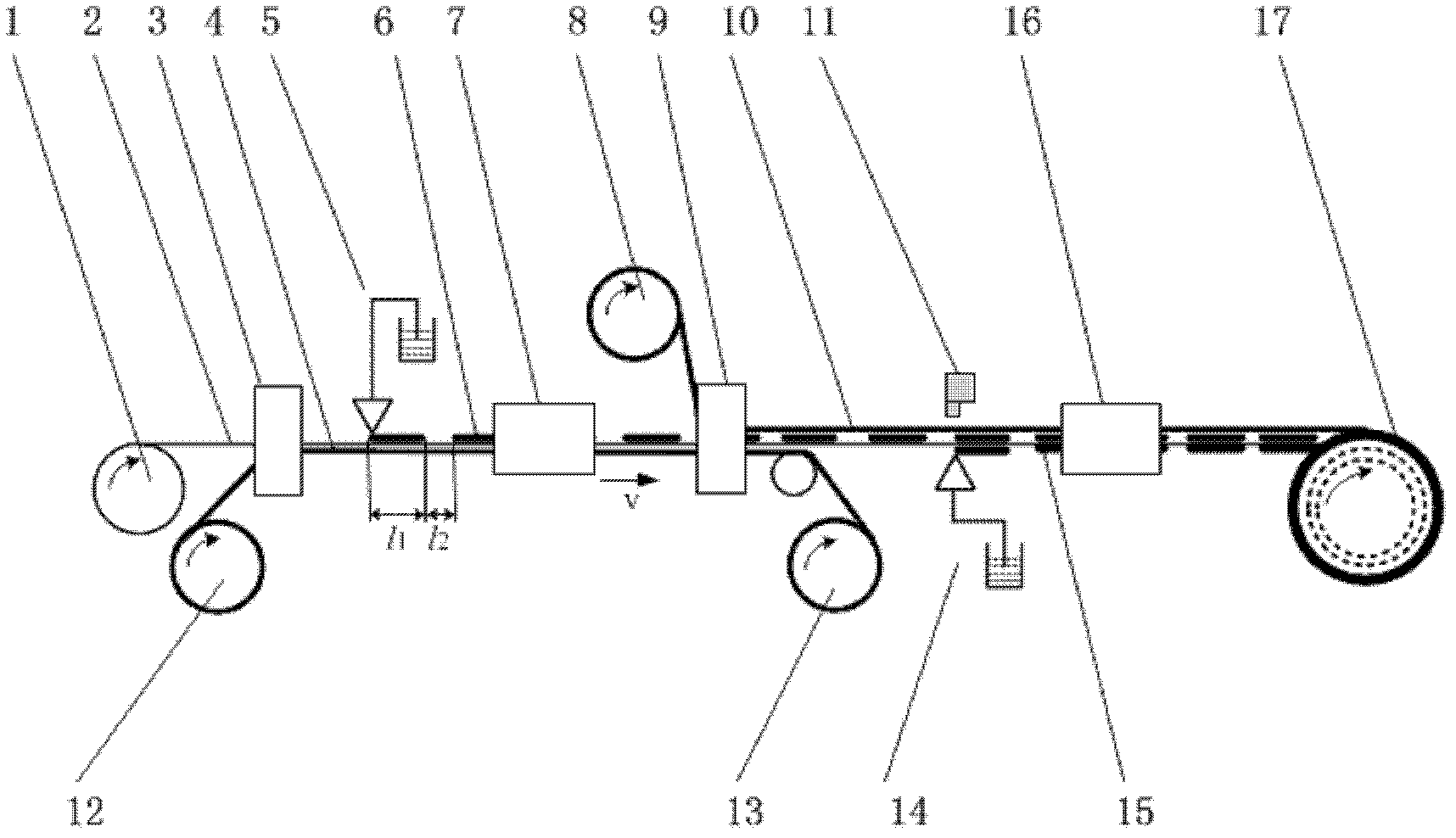

[0039] figure 1 An exemplary embodiment of the invention is described, as shown in the drawings. The manufacturing method system includes: two sets of unwinding systems, three sets of winding systems, two sets of composite systems, two sets of bonding systems and a process control system.

Embodiment approach

[0041] First, the proton exchange membrane is treated with 2wt% hydrogen peroxide and 0.02M dilute sulfuric acid to remove surface pollutants, and then it is washed with deionized water for more than 3 times, dried and wound to obtain the proton exchange membrane for use; catalyst slurry The preparation of the material is to use deionized water: 5wt% perfluorosulfonic acid solution: Pt / C (Pt loading 10wt%) catalyst to mix according to the mass ratio of 6:5:1, obtain after ultrasonic stirring, and set aside;

[0042] Put the proton exchange membrane 2 through the above-mentioned pretreatment into the proton exchange membrane unwinding station 1, put the weakly viscous PET-like first protective film 4 into the first protective film unwinding station 12, and unwind the two. Roll action, the two are pasted by the ground 1 pasting station 3; and then the pasting of the two is carried out by catalyst coating through the first catalyst composite station 5 equipped with a catalyst, so ...

Embodiment 2

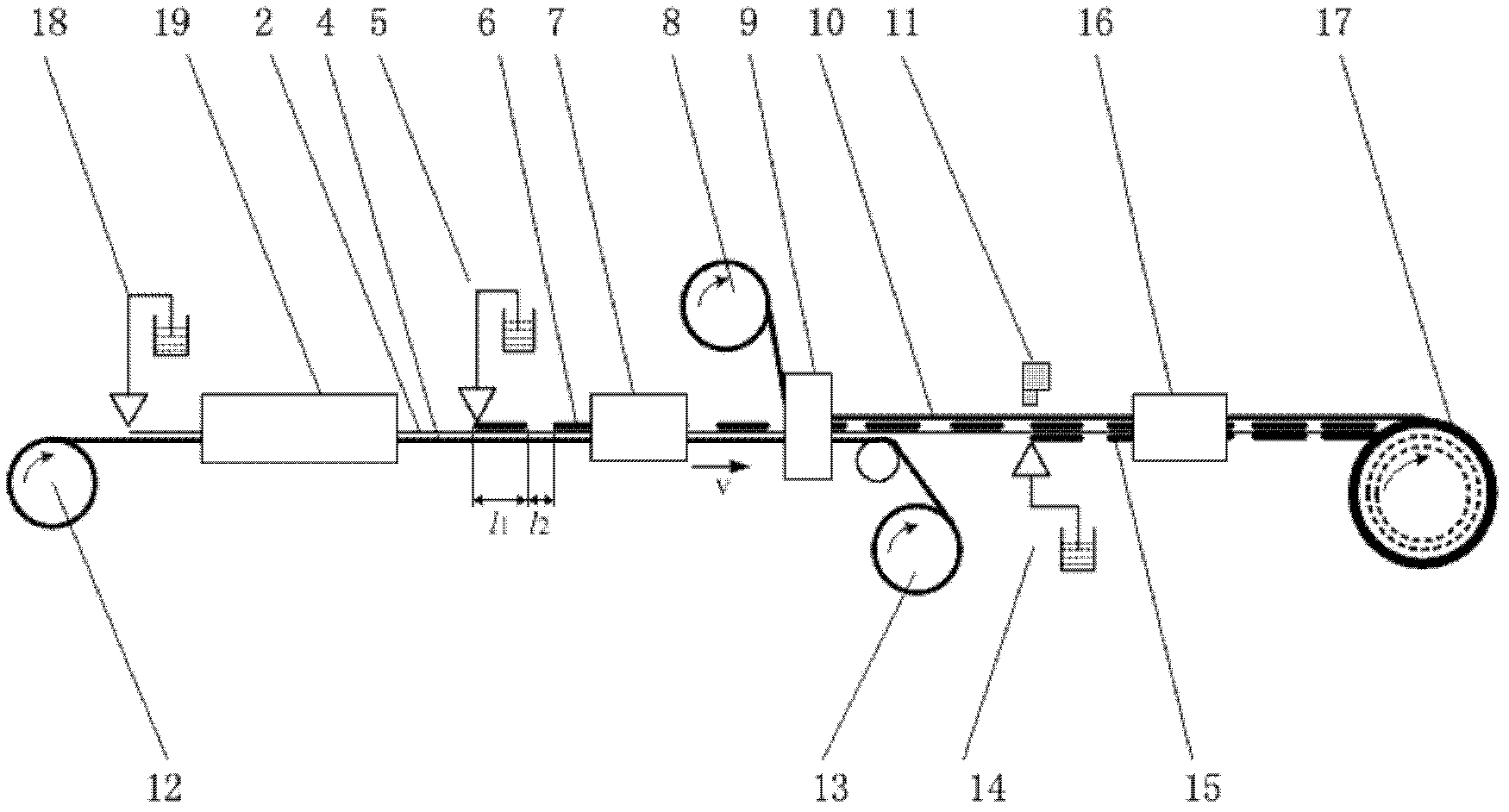

[0044] figure 2 Described the typical embodiment in the 2nd of the present invention, as shown in the figure, compared with embodiment 1, its difference is that proton exchange membrane 2 is to utilize proton exchange membrane solution online coating station, i.e. tape casting Bit 18 is obtained.

[0045] The implementation method is as follows:

[0046] Concentrate the 5wt% perfluorosulfonic acid solution to 7wt%~10wt% under vacuum at a temperature of 40~100°C, set aside, and then prepare the catalyst slurry: use deionized water: 5wt% perfluorosulfonic acid solution: Pt / C (Pt loading 20wt%) catalyst is mixed according to the mass ratio of 6:5:1, obtained after ultrasonic stirring, and is ready for use;

[0047] Put the PET-type first protective film 4 into the first protective film unwinding station 12 to perform the unwinding action, add the concentrated perfluorosulfonic acid solution to the tape casting station 18, through the tape casting process Form a film on the 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com