Full-static pressure clean optical thin film coating machine

A technology of optical film and coating machine, which is applied to the device, lamination and coating of surface coating liquid, which can solve the problems affecting the development of precision optical coating, the inability to make fully qualified products, and the cleanliness not up to the standard and other issues, to achieve stable anti-shake ability, easy for employees to operate, and prevent damage by wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

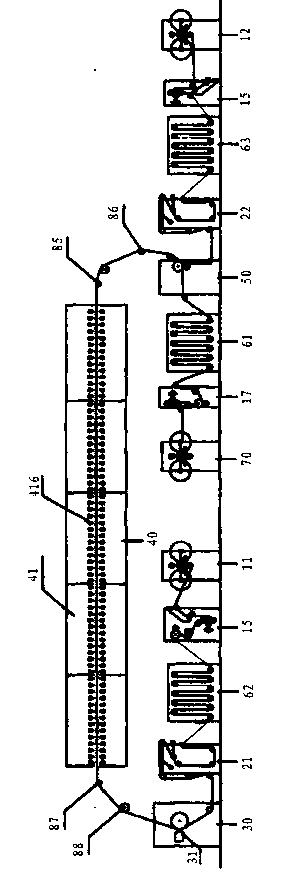

[0023] see figure 1 , the embodiment of the present invention includes:

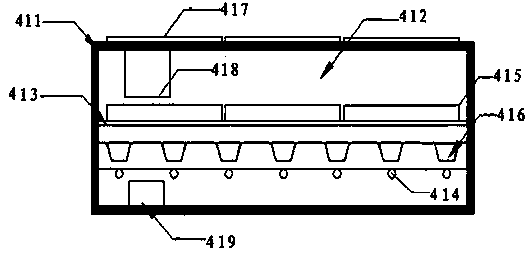

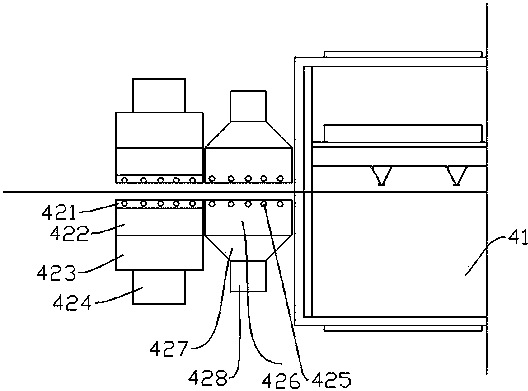

[0024] A full static pressure clean optical film coating machine, comprising: a first film material unwinding unit 11, a first dust removal and static elimination unit 15, a first film material storage unit 62, a first film material traction unit 21, a high Precision coating unit 30, 100-level clean drying and curing unit 40, second film material unwinding unit 12, second dust removal and static elimination unit 15, second film material storage unit 63, second film material traction unit 22, composite unit 50. The composite film material storage unit 61 and the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com