Weft gripping mechanism for shuttleles weaving machines

A technology of weft yarn and loom is applied in the field of weft yarn clamping mechanism and weft yarn tensioning device, which can solve the problems of no similar existing technology, and achieve the effects of improving clamping force, eliminating friction action and good tension control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

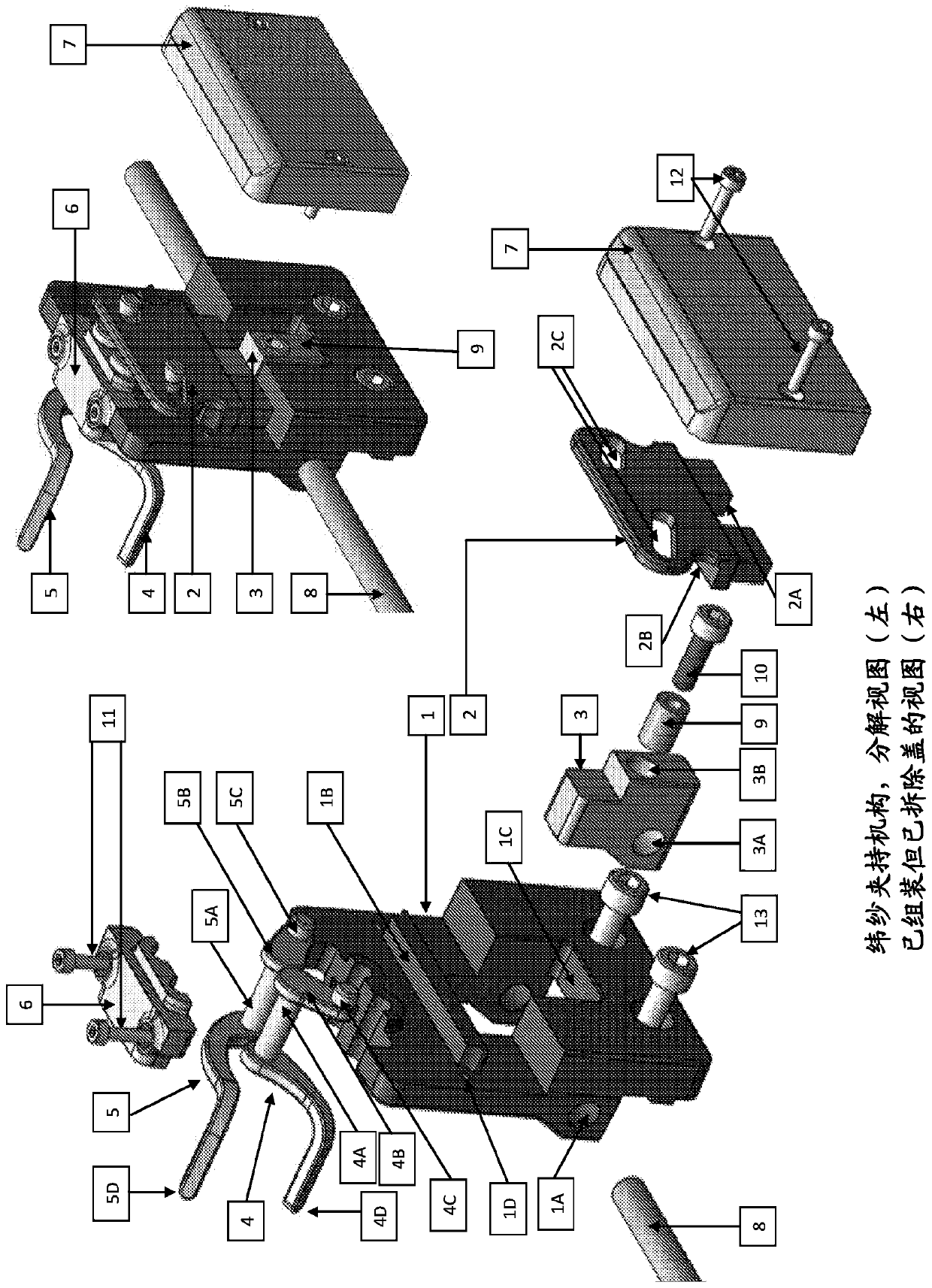

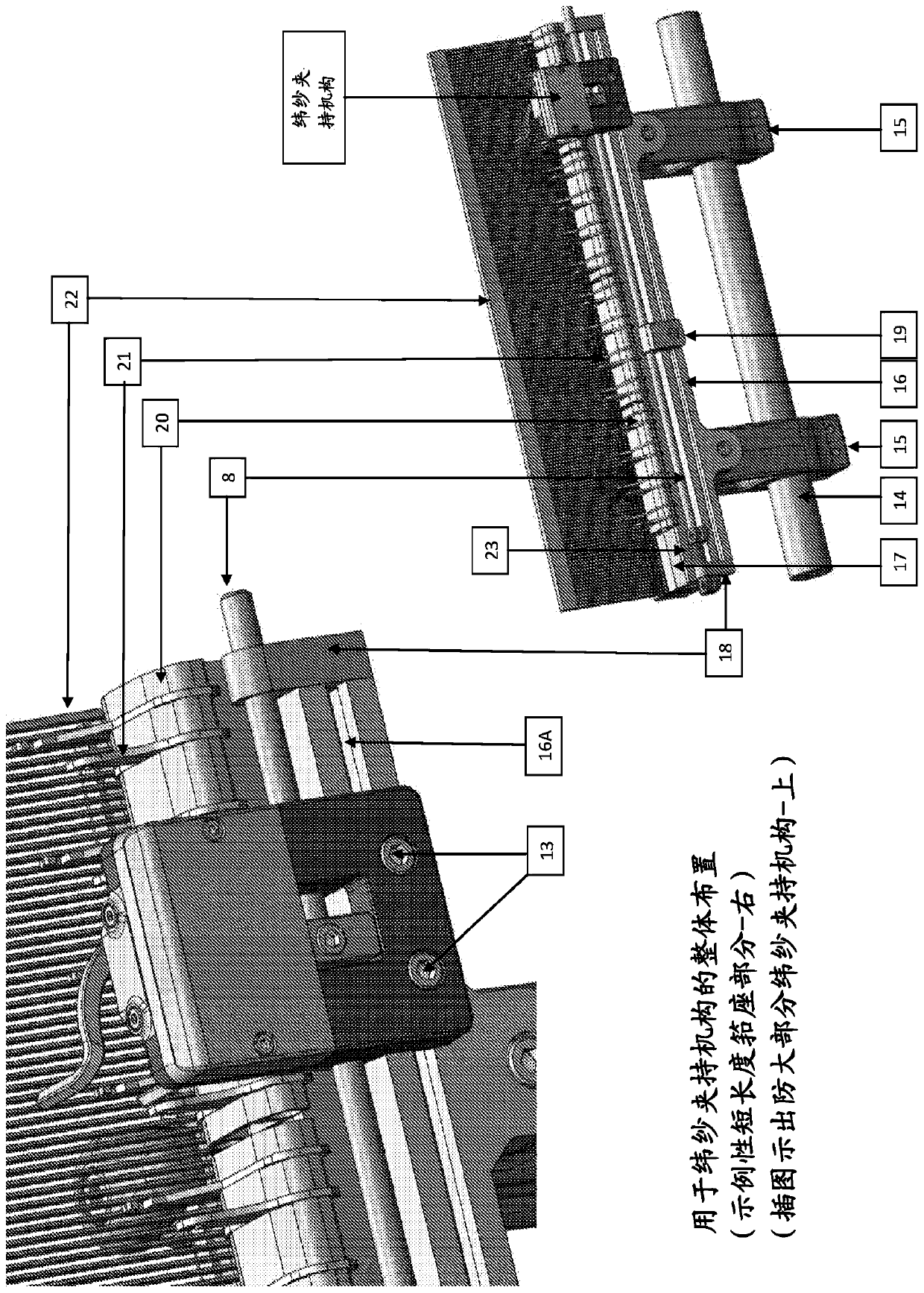

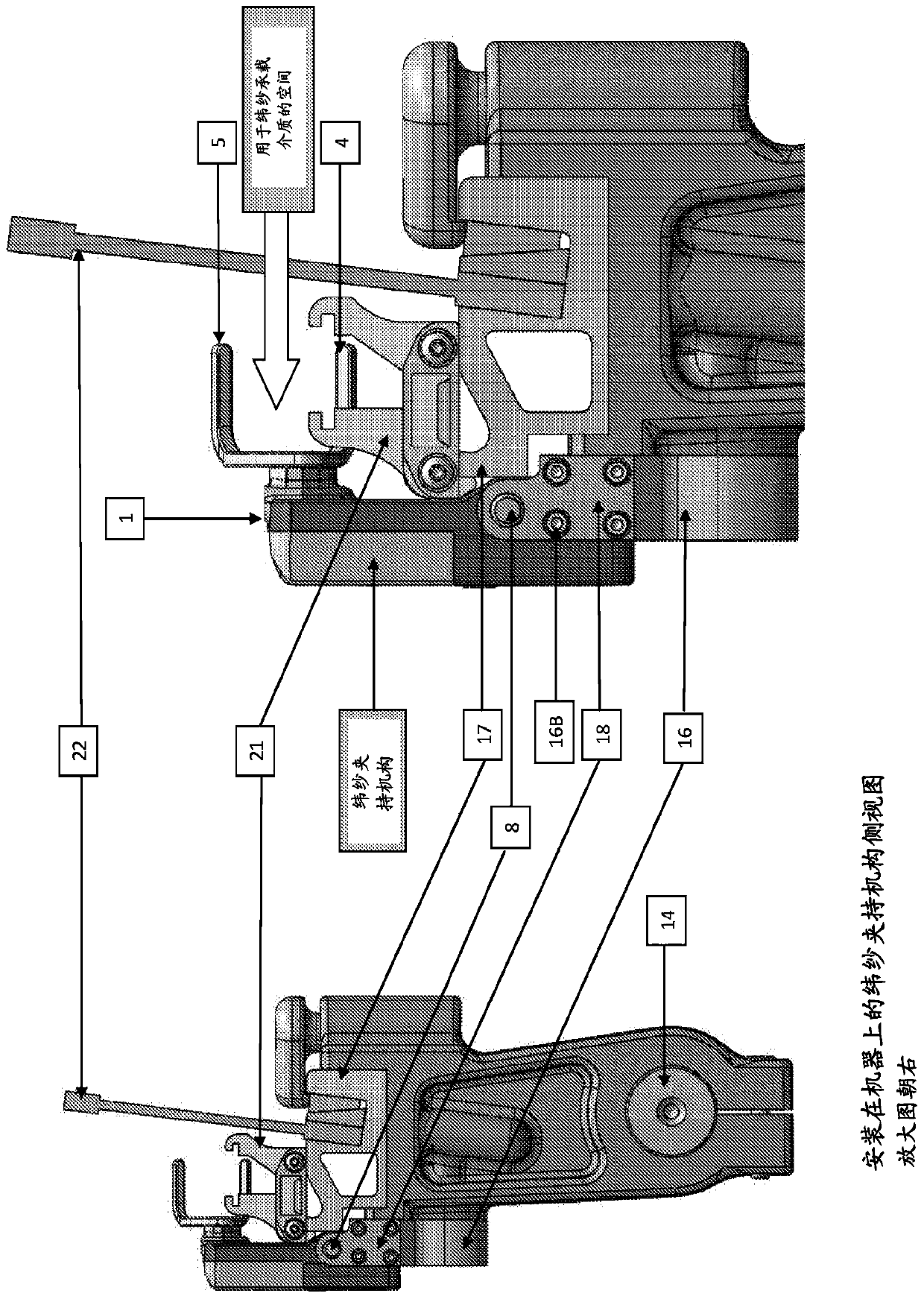

[0020] Patent description figure 1 : Weft clamping mechanism, exploded view (left), assembled but cover removed view (right).

[0021] The main body (1) of the weft clamping mechanism is firmly mounted on a part (numbered 16 and further explained), which is directly mounted on the sley support of the loom so that it can be woven relative to the fabric being woven. The side moves sideways in the desired position and can be locked in place for operation. This is better explained in the description of Patent Note 2 below. The main body (1) has the following details built-in, the hole (1A) for the shaft (8) is provided in the main body (1) of the weft clamping mechanism, and the protrusion (1B) is provided on the main body (1) for braking The plate cam (2) is allowed to move sideways to the plate cam (2), and a small space (1C) for the slider part (3) is provided on the main body (1). A suitable number of holes (1D) are provided in the main body in order to install the fasteners (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com