Patents

Literature

44results about How to "Stable tension control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

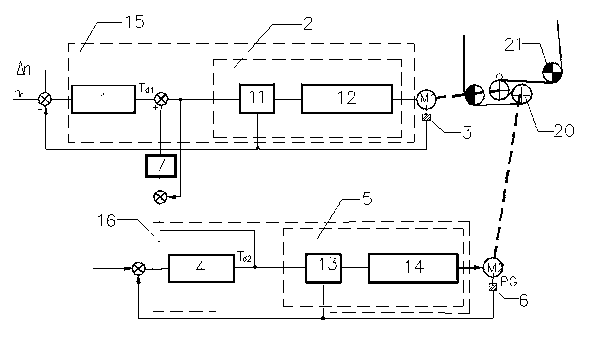

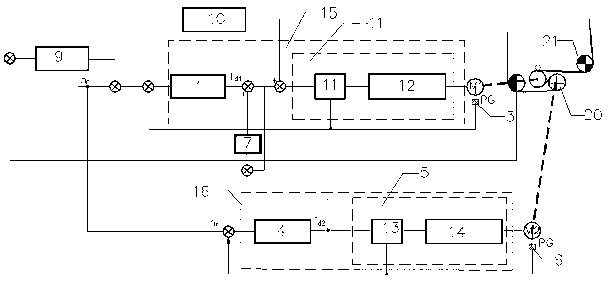

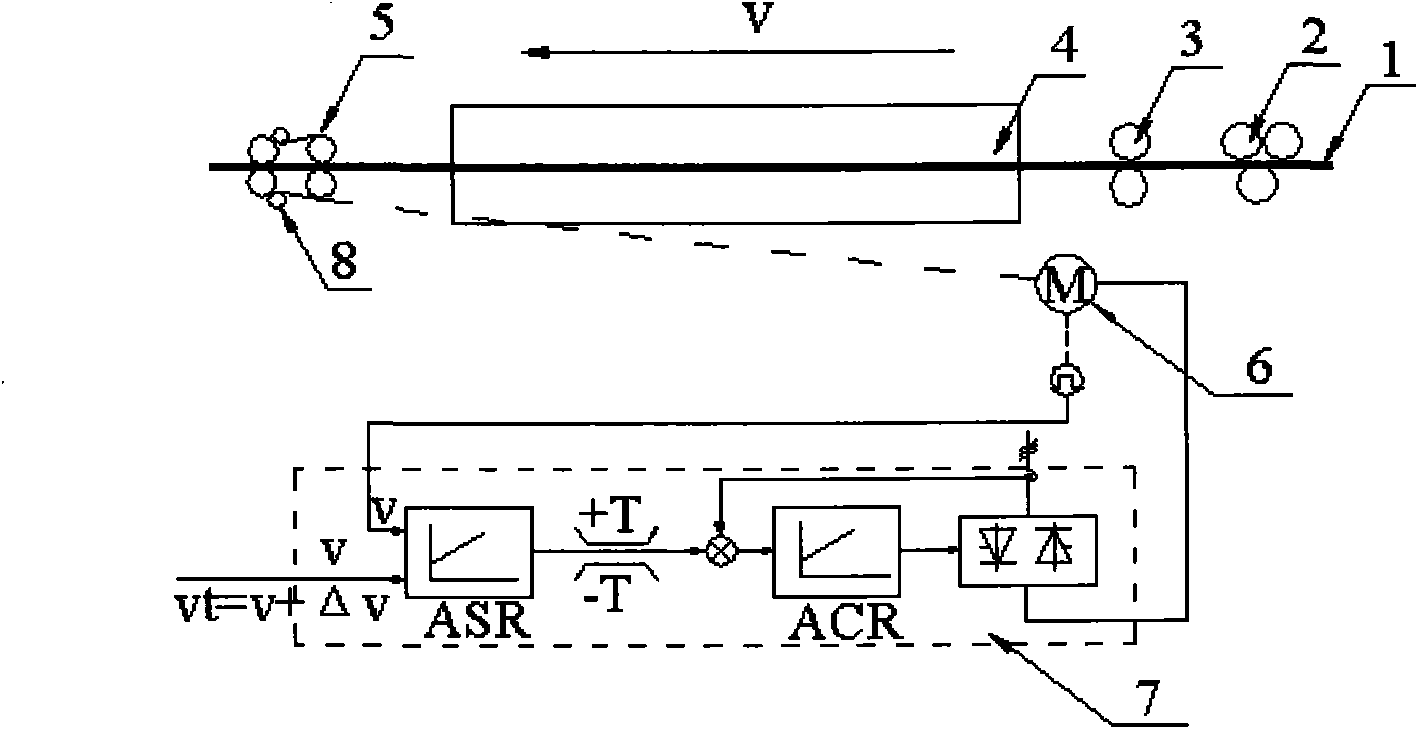

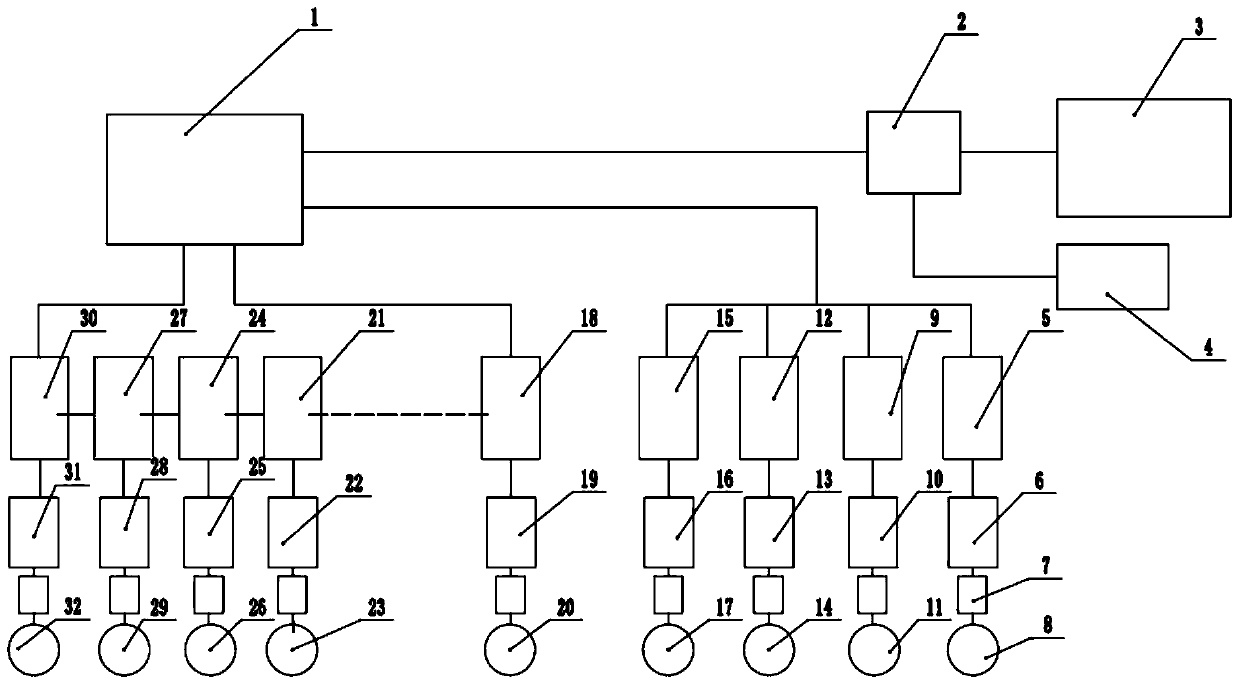

Tension roll control device for plate and strip processing line and tension control method

The invention discloses a tension roll control device for a plate and strip processing line and a tension control method, belonging to the field of tension control of tension rolls on the plate and strip processing line in the metallurgical industry. The tension roll control device comprises a tension roll group, an auxiliary roll frequency converter and a main roll frequency converter, and further comprises an auxiliary roll speed encoder, a main roll speed encoder, a load distributor, a tension regulator, a feedforward compensation unit and a tensiometer, wherein two ends of the load distributor are respectively connected with the auxiliary roll frequency converter and the main roll frequency converter; the auxiliary roll frequency converter comprises an auxiliary roll rotation speed control unit and an auxiliary roll torque control unit; and the main roll frequency converter comprises a main roll rotation speed control unit and a main roll torque control unit. The tension roll control device has the advantages of high control response speed and high control precision. A control method of the tension roll control device comprises the steps of: (1) main / slave load distribution for the tension rolls; (2) complex tension control of the tension rolls; and (C) dynamic compensation. The method has the advantages of small steady state error of a torque loop, short anti-disturbance recover time, constant rotation speed and good anti-disturbance performance.

Owner:安徽马钢输送设备制造有限公司

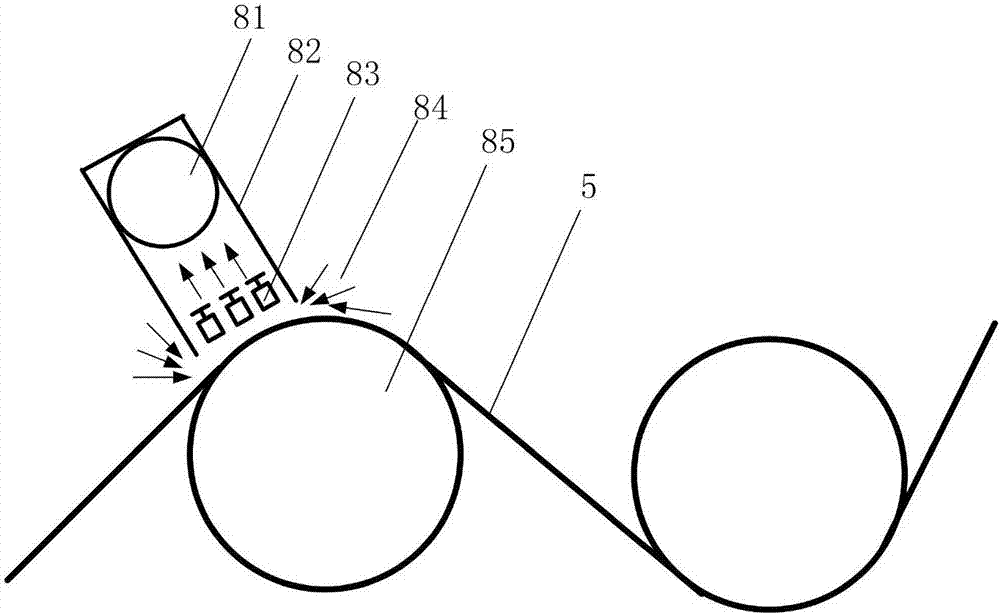

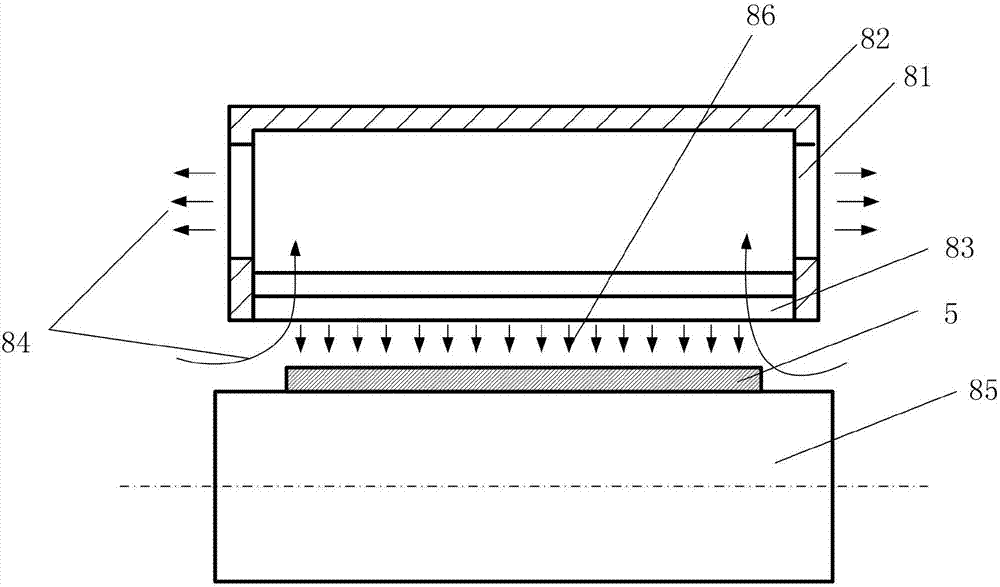

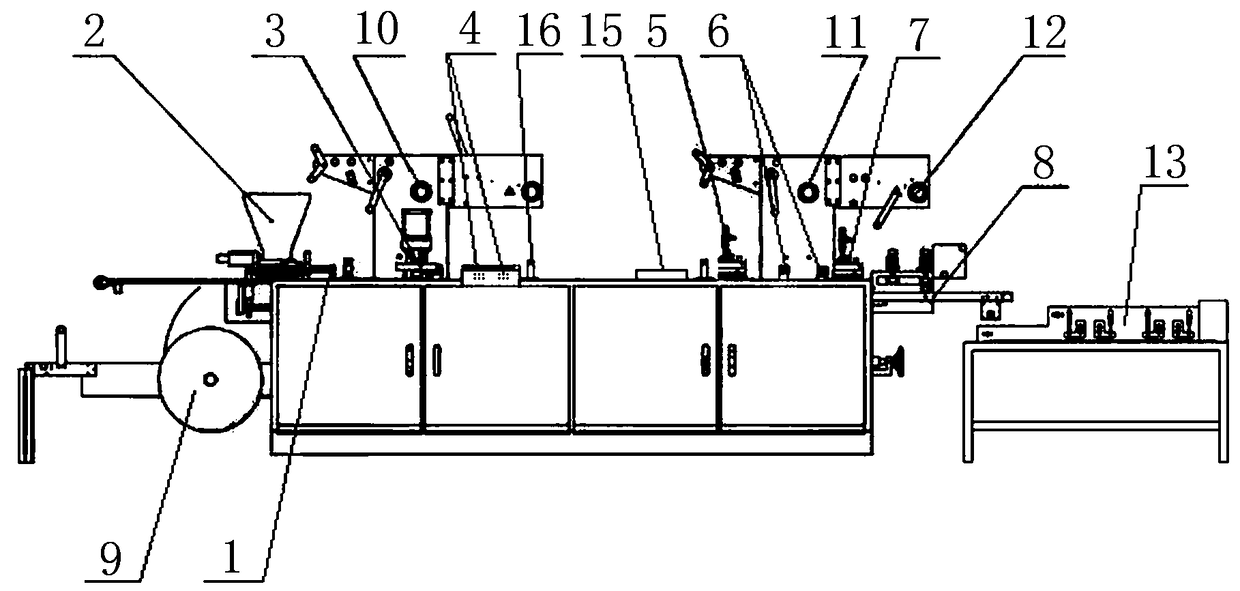

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

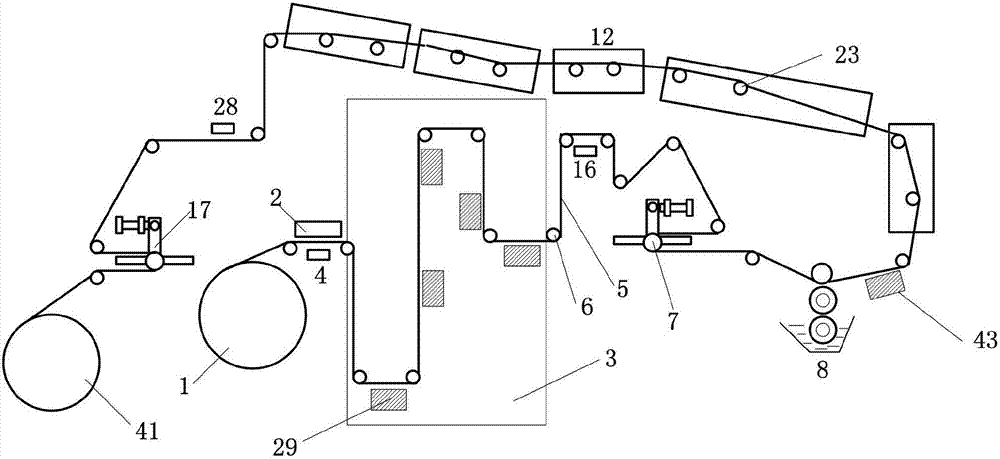

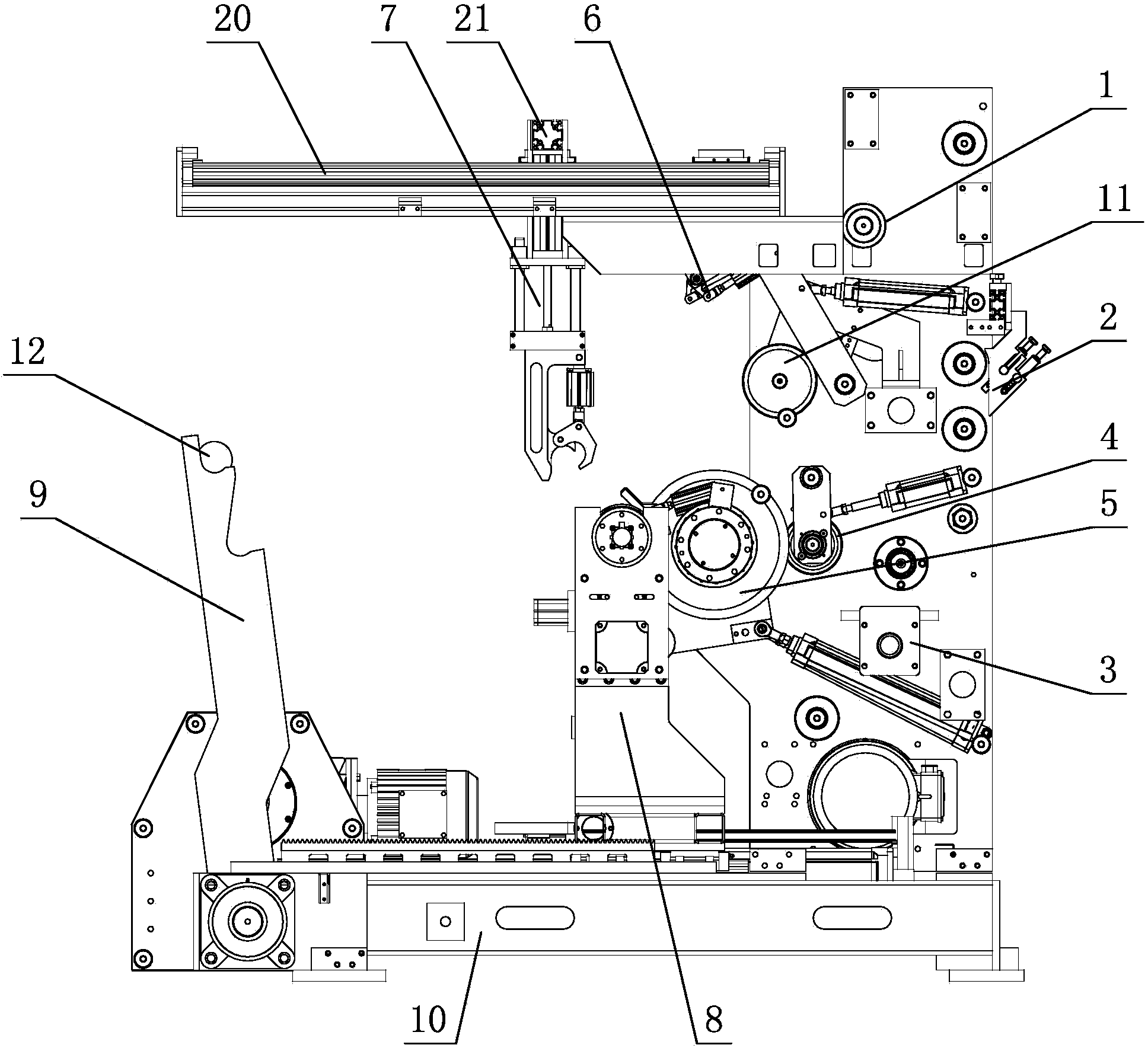

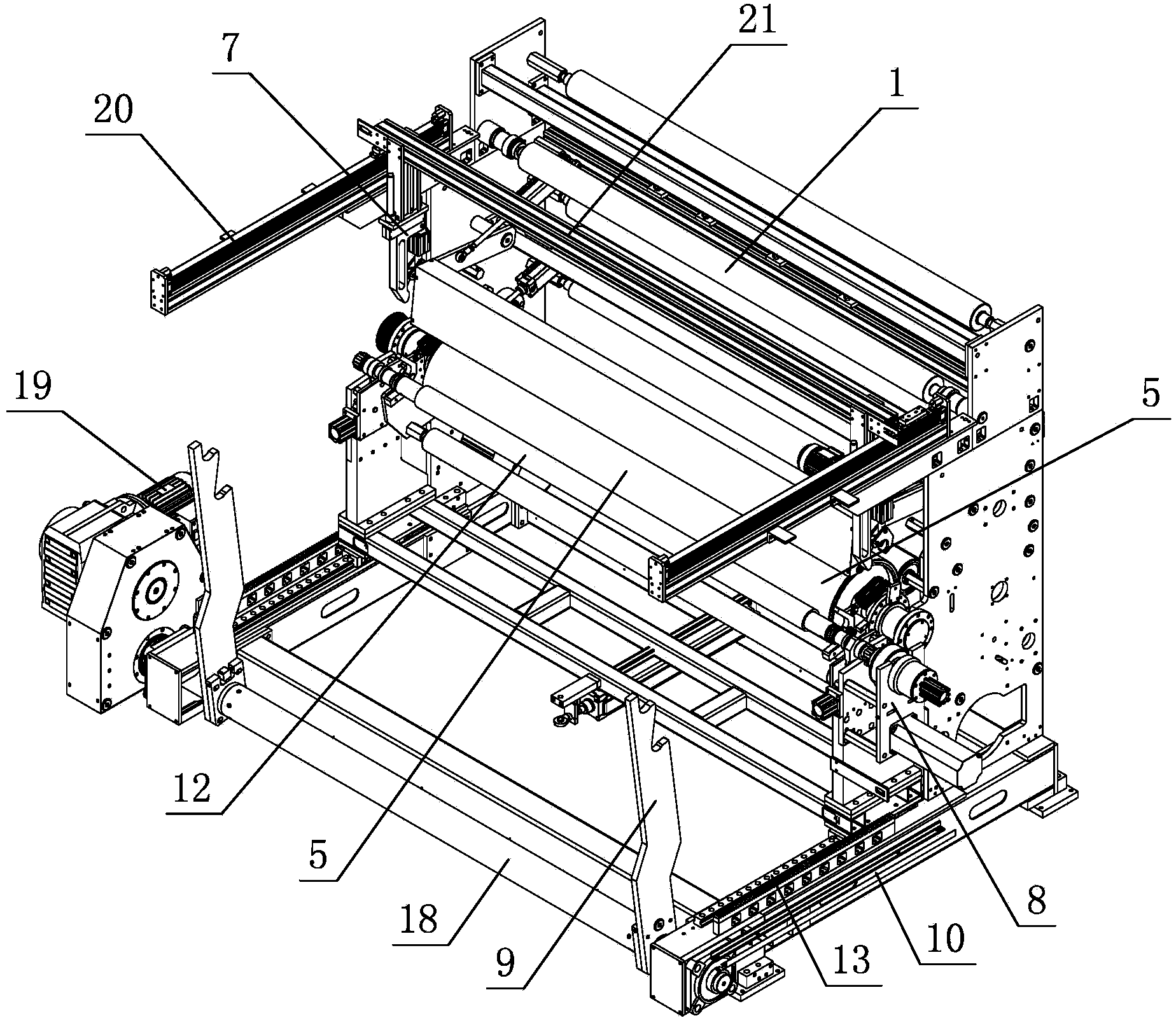

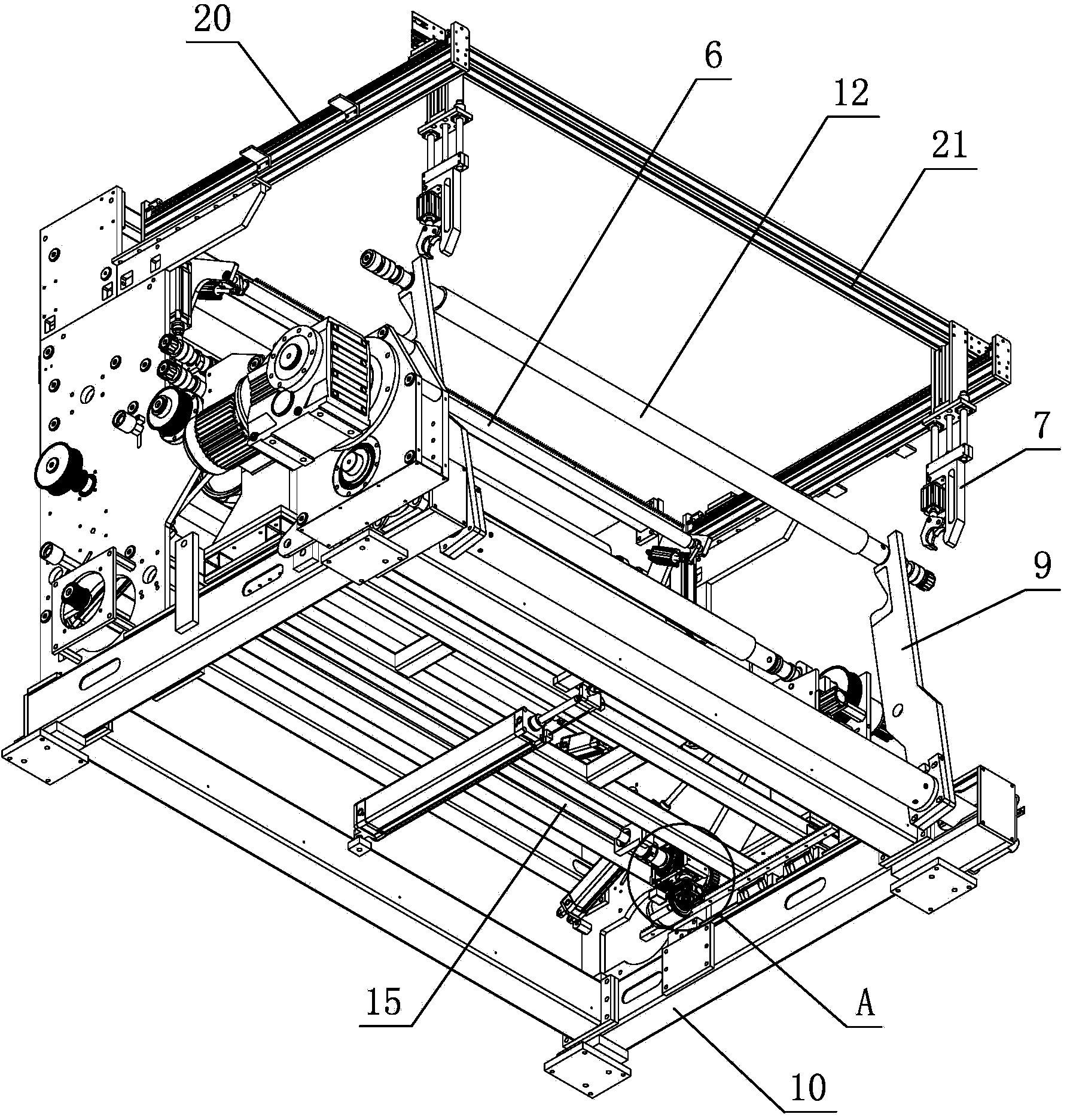

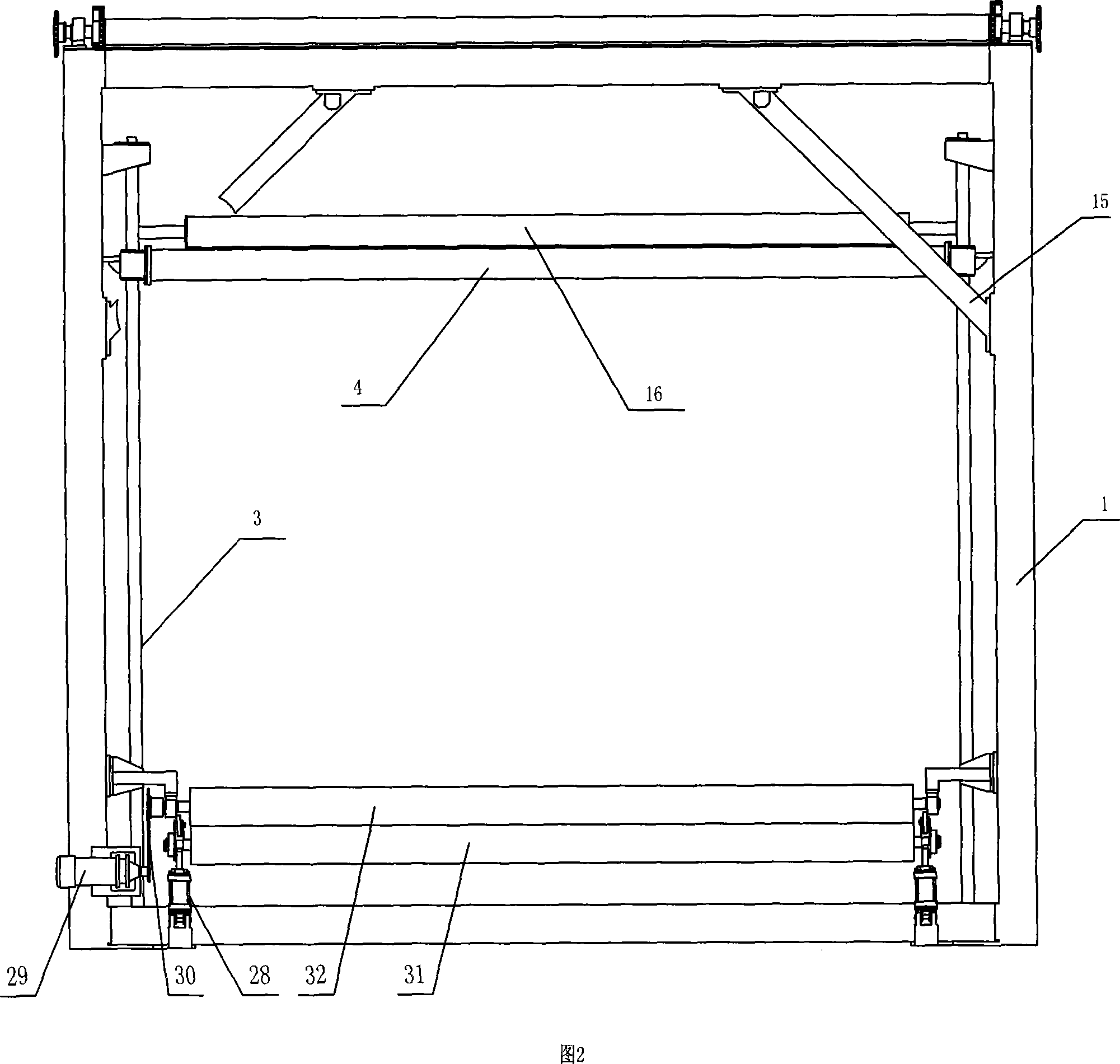

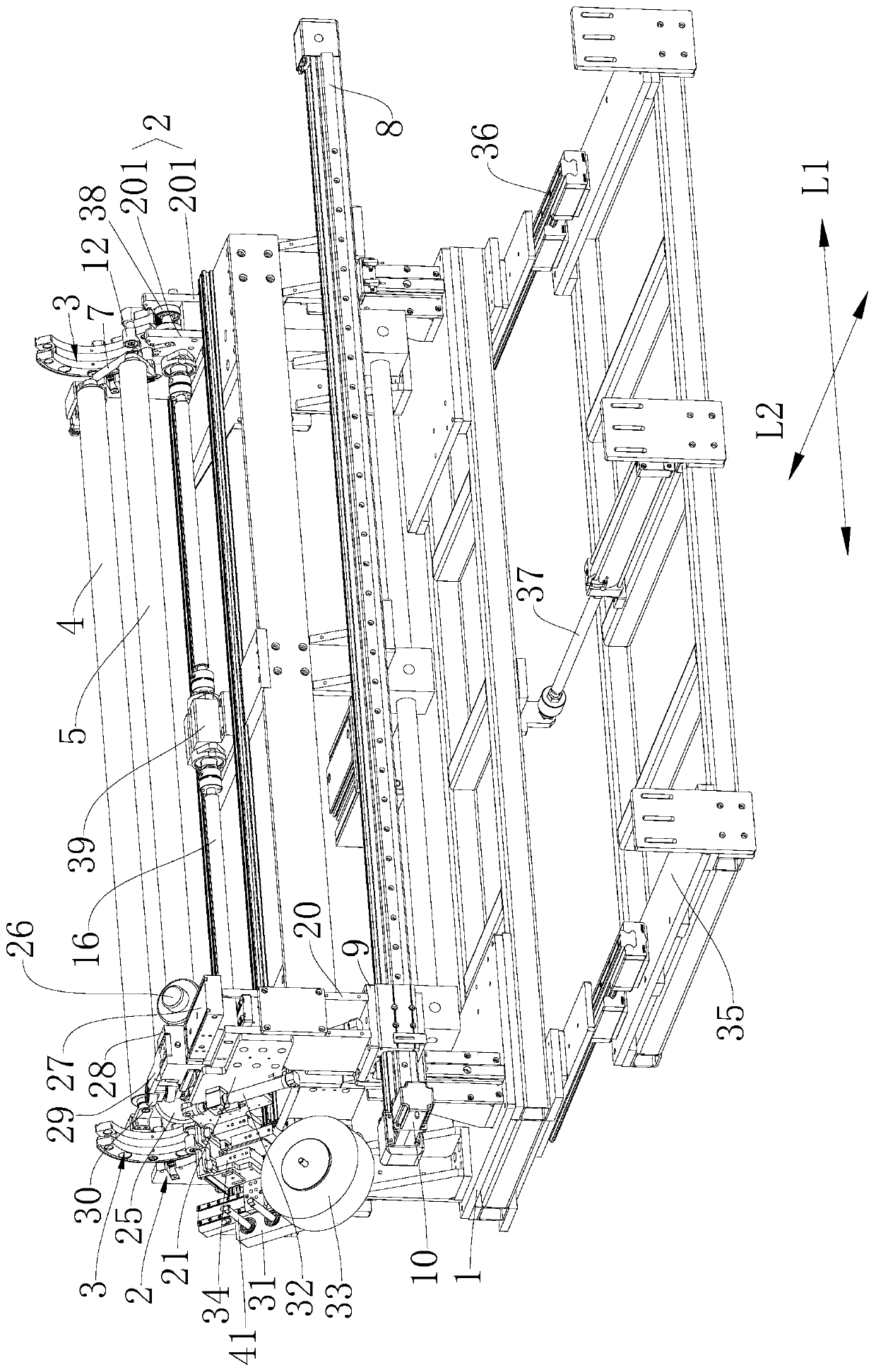

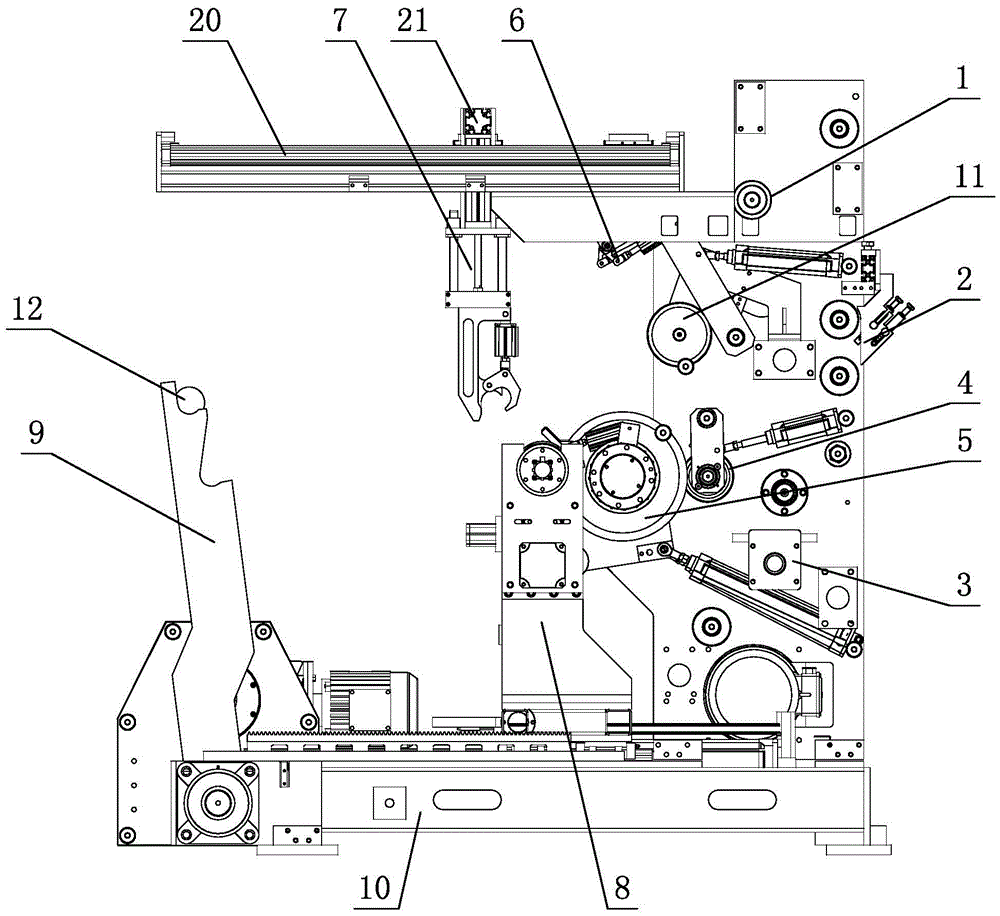

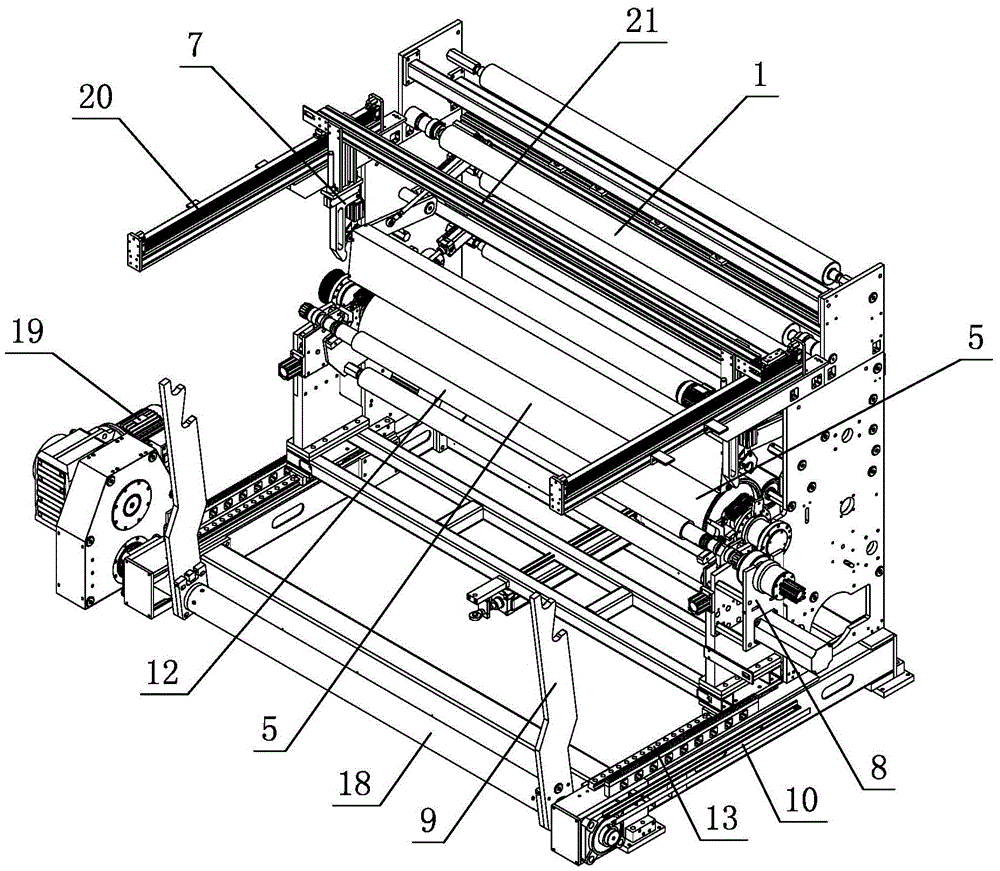

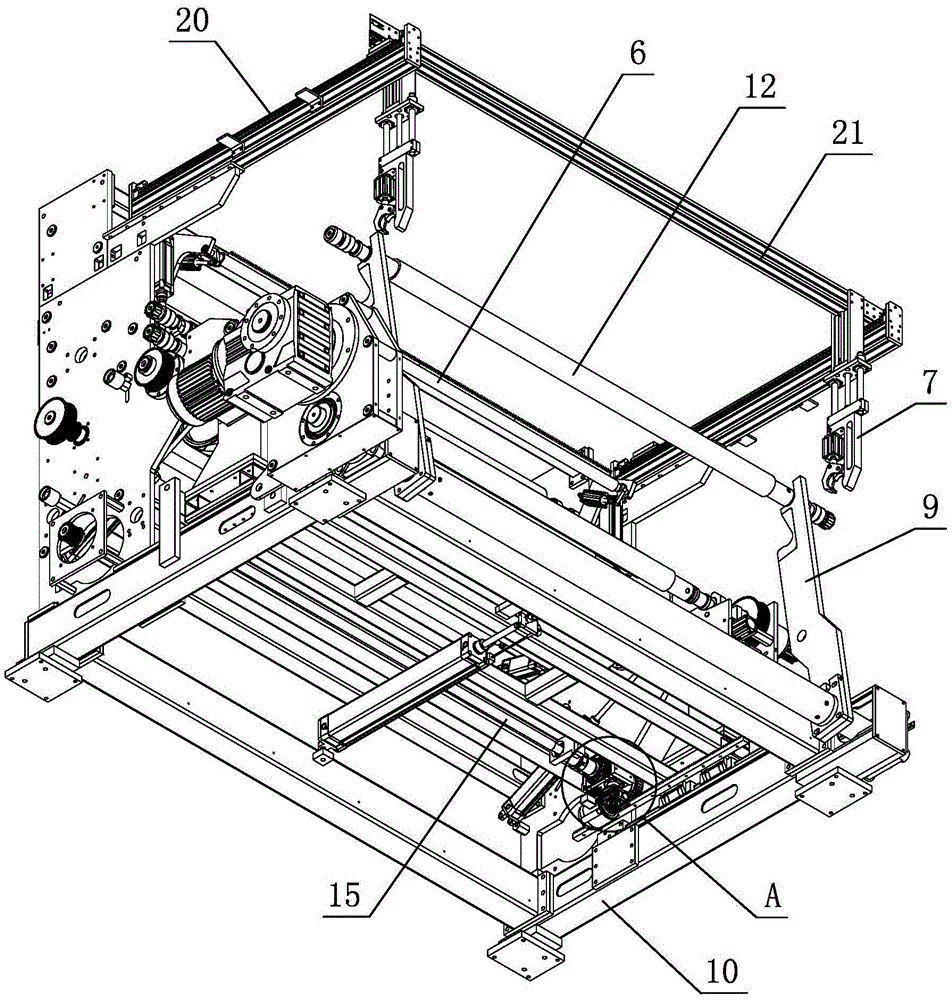

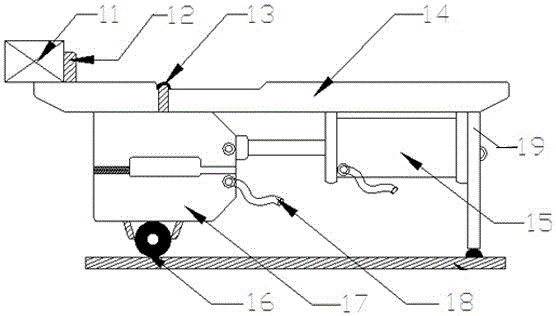

Thin film center and surface winding machine

The invention discloses a thin film center and surface winding machine which comprises a machine frame. An inflatable shaft, a tension roller, a cutter device, a flattening arc roller, a clamping roller, a large slotting rubber roller, a thin film cutting-off device, an inflatable shaft conveying device, a winding trolley device, a coil discharging device and an inflatable shaft accelerating device. A moving guide assembly is arranged between the machine frame and the winding trolley device, the winding trolley device moves on the machine frame in a linear mode through the moving guide assembly, and therefore the winding tension of the winding machine is controlled. Two parallel linear guide rails are arranged on the left side and the right side of the machine frame, and the winding trolley device moves on the machine frame in the linear mode through the two linear guide rails. The winding trolley device can achieve moving and horizontal adjusting functions, and the inflatable shaft placed on the winding trolley device can achieve the center winding and surface winding functions. The problem that the quality of wound finished products is poor due to the fact that a traditional thin film center and surface winding machine is integrated to a wall board is effectively solved, and flatness, smoothness and quality of the wound finished products are ensured.

Owner:广东恒立电气自动化有限公司

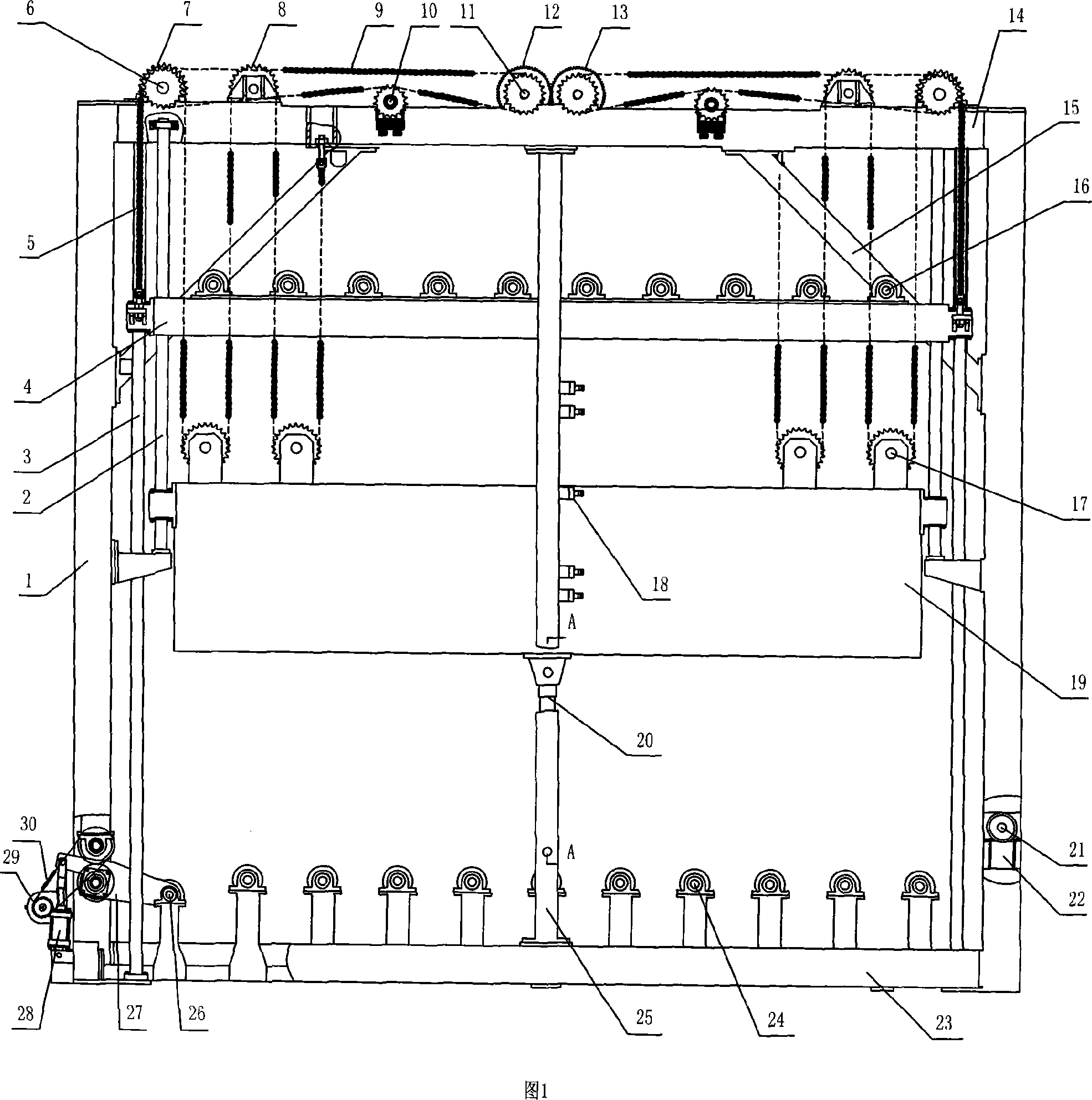

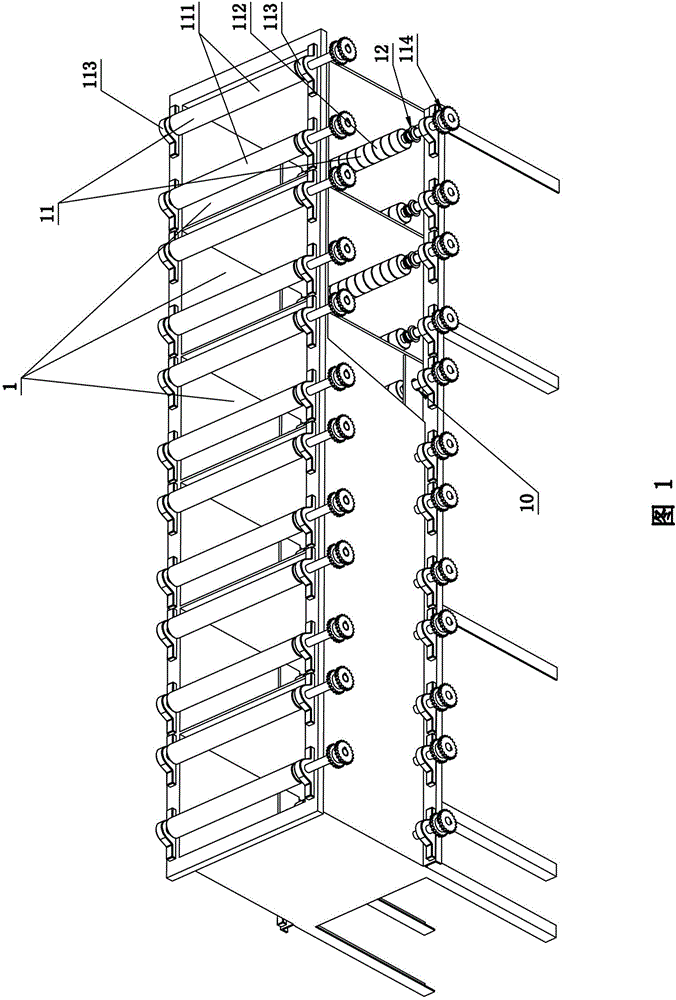

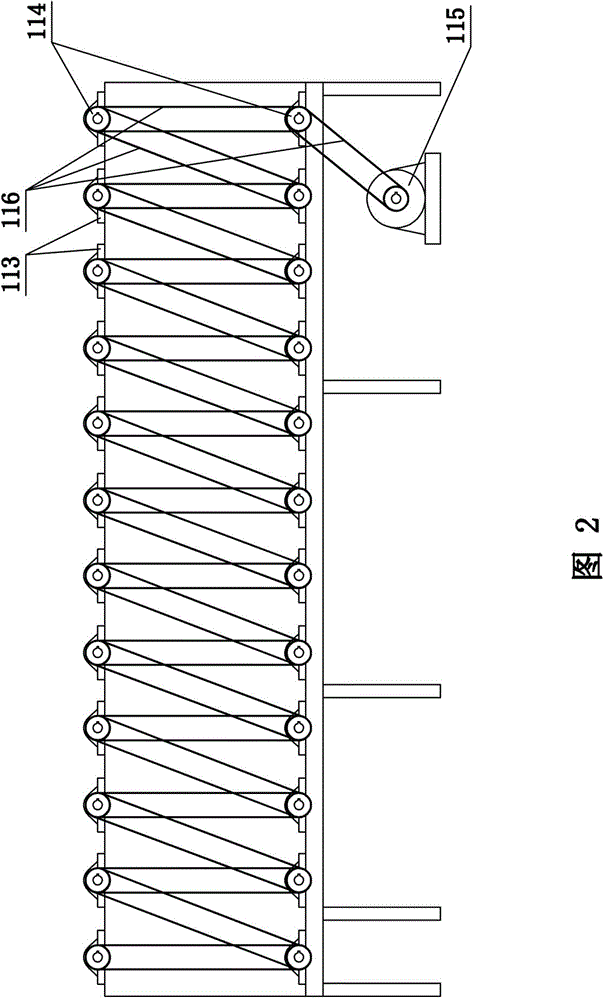

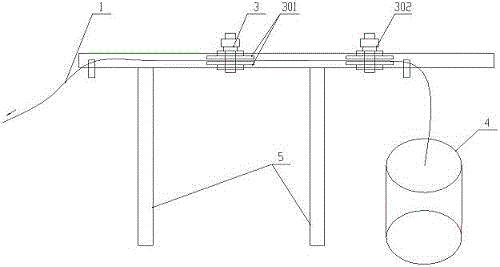

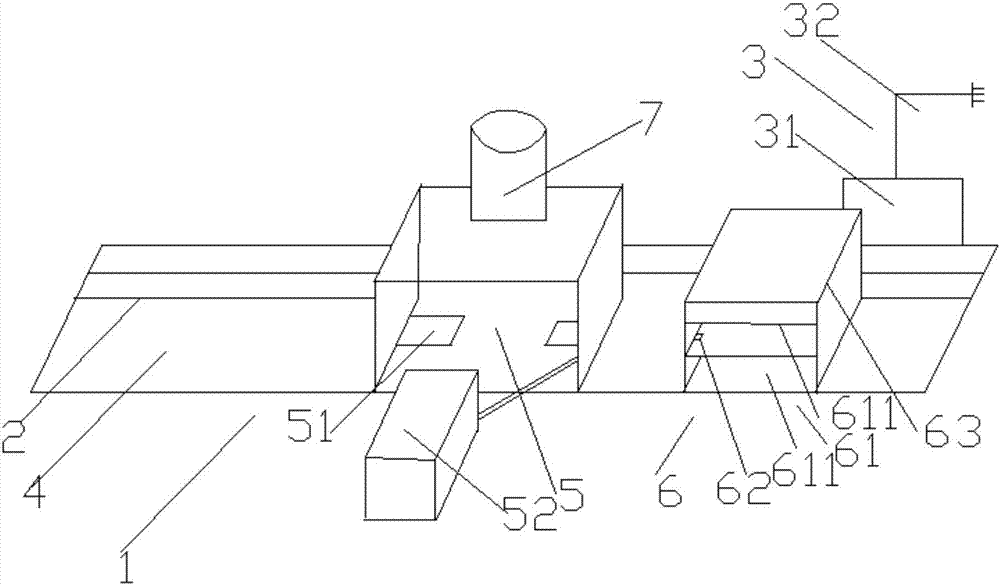

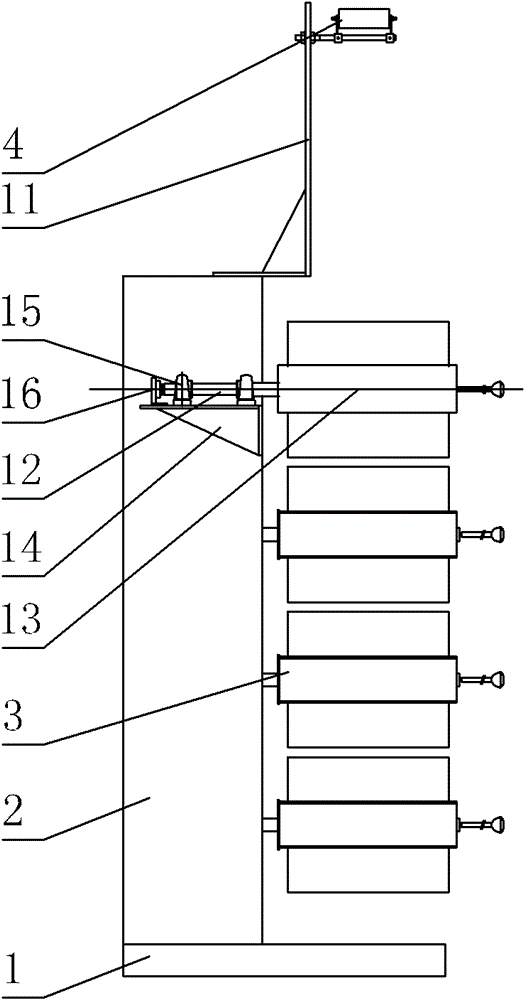

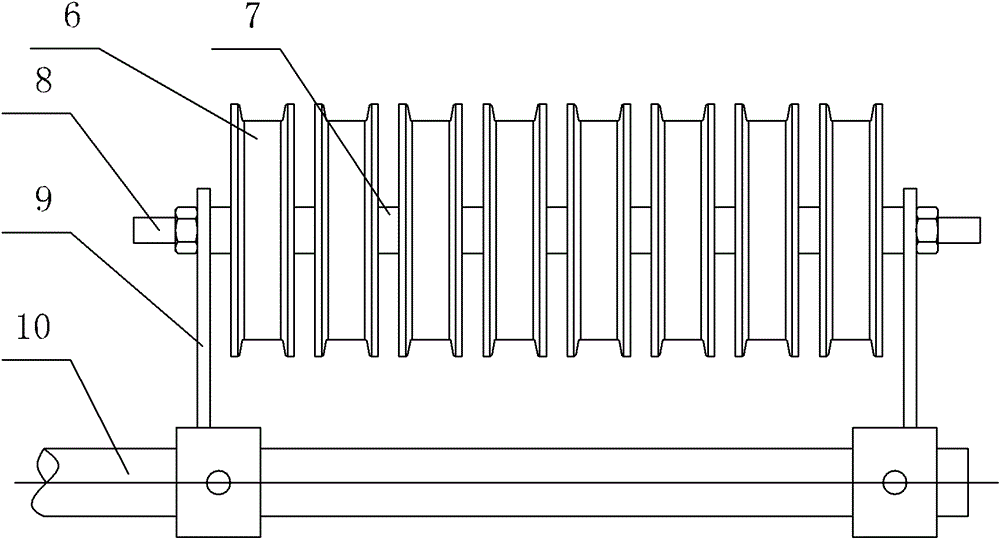

Roll material dynamic storing apparatus with tension control

InactiveCN101070130AStable tension controlLarge storage capacityGearingWebs handlingProduction lineDynamic storage

The invention relates to the coil dynamic storage device with the tension control function. It includes the main frame, the fixed array roller set in the bottom of the main frame, the input roller with the tension detector set in one end of the main frame, the other end of the main frame is set with the output roller components. The lifting array roller corresponded to the fixed array roller in the main frame which is connected with the lifting balance weight through the flexible gearing. The coil material passes through between the lifting array roller and the fixed roller to store the coil material, the lifting array roller is in floating state to keep the tension constant. The invention has the compact structure, proper set, high automatic, stable running and convenience operation. The invention can be used alone or online, especially proper for the big size, big tension coil product line to improve the productive efficiency.

Owner:HONGYANG MACHINERY FACTORY

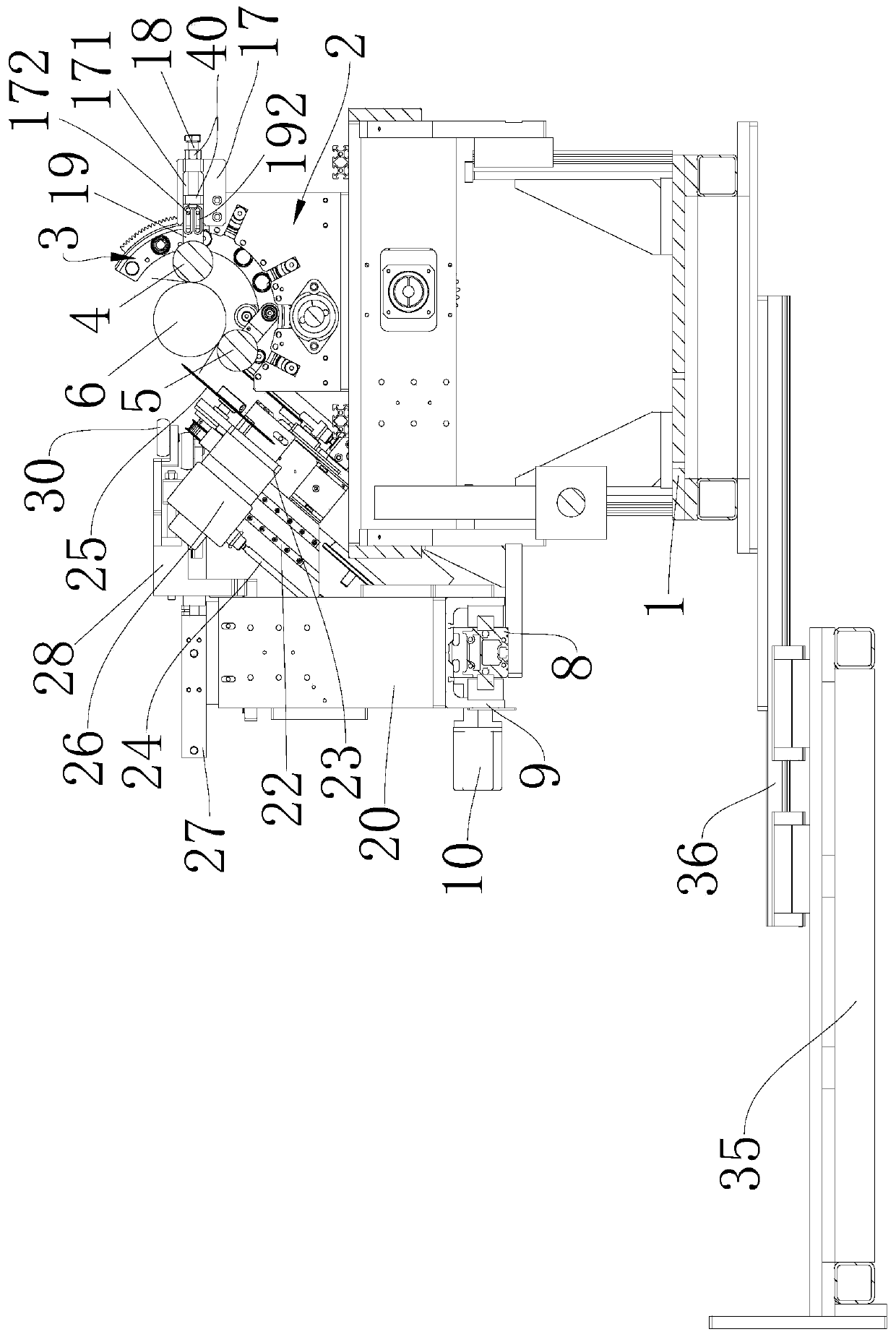

Three-roller coating printing unit for continuously coating surface of base material with viscous material

ActiveCN107350121AThin and uniform glue layerReduce usageLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a three-roller coating printing unit for continuously coating the surface of a base material with a viscous material. The unit comprises a pressing roller, a driving silica gel roller and a driving steel roller which are stacked from top to bottom. The driving silica gel roller and the driving steel roller rotate in opposite directions, and a micron order gap is kept; the driving steel roller is soaked with a colloid pond containing the viscous material, the base material is arranged between the pressing roller and the driving silica gel roller, and the base material is supported on the supporting roller and moves in the centrifugal force direction of the top vertex of the driving silica gel roller under power traction. Under the effect that the viscous material is extruded, stretched and extended through rotating rollers with the two different rotating speeds and the opposite directions, a rubber layer of the certain thickness is formed on the surface of the rubber covered roller, the material is transferred to the surface of the continuously running base material by means of the pressing roller, the thin and uniform coating is formed, and materials of the micro order and submicron order thickness and thinner materials can be uniformly sprayed to the surface of the base material.

Owner:陕西浩合机械有限责任公司

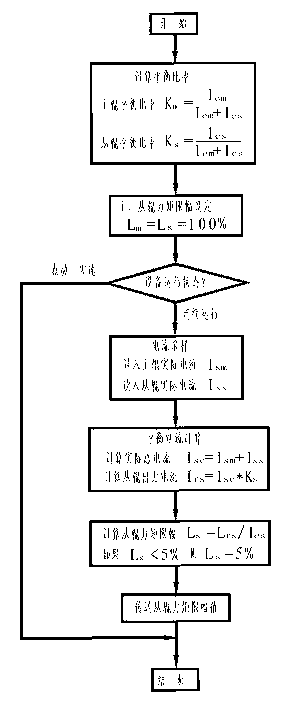

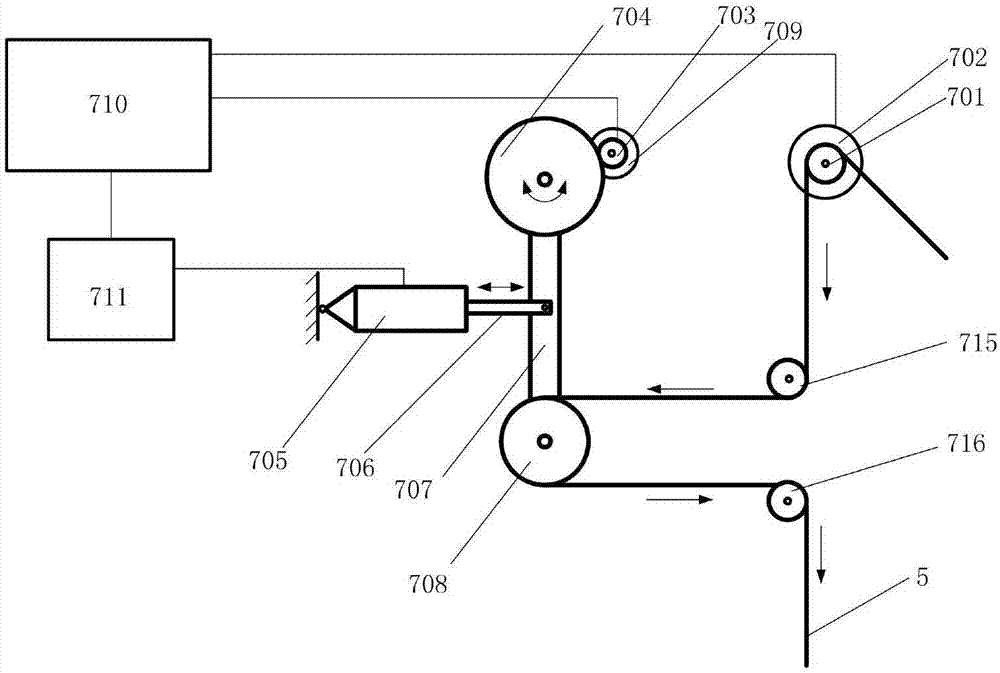

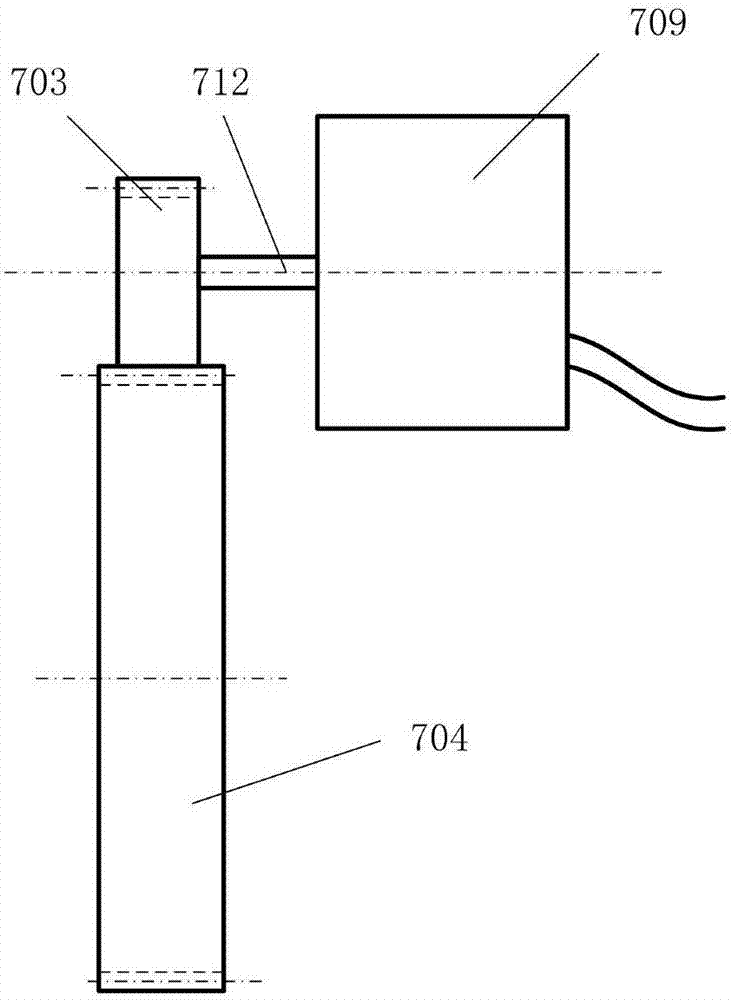

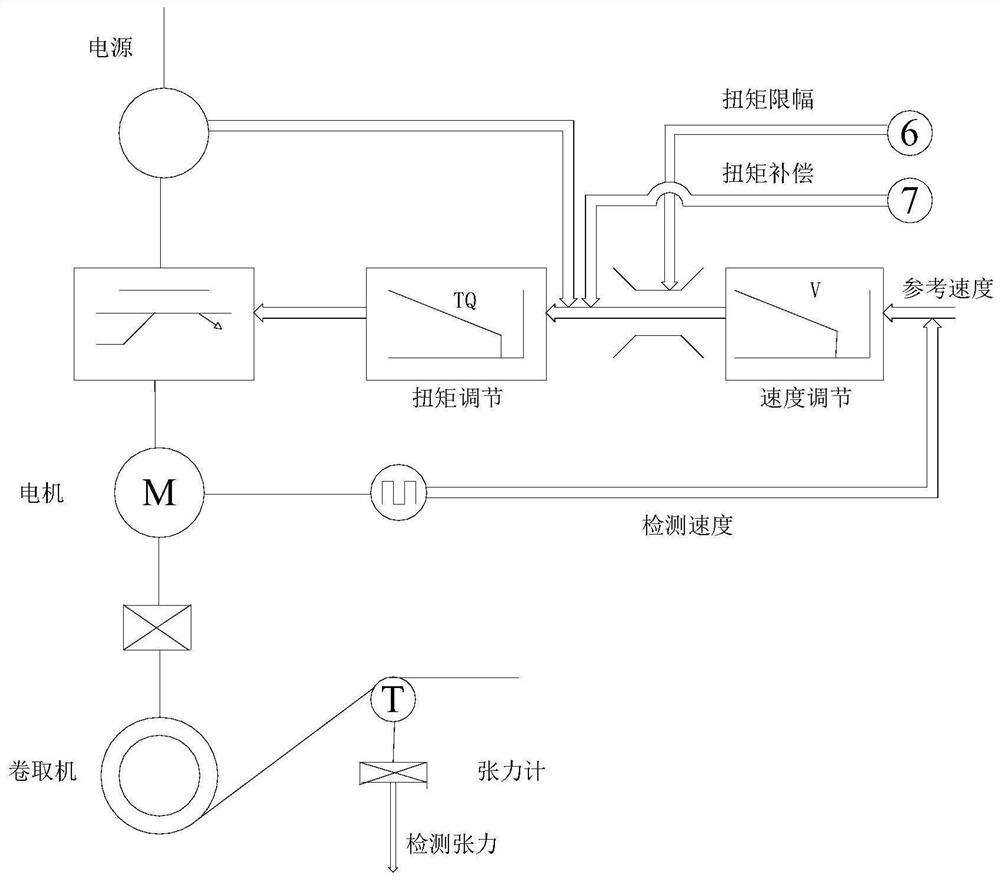

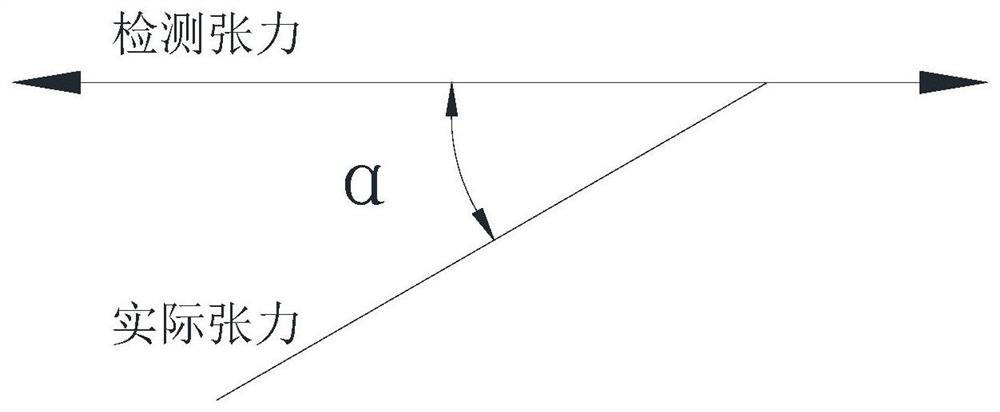

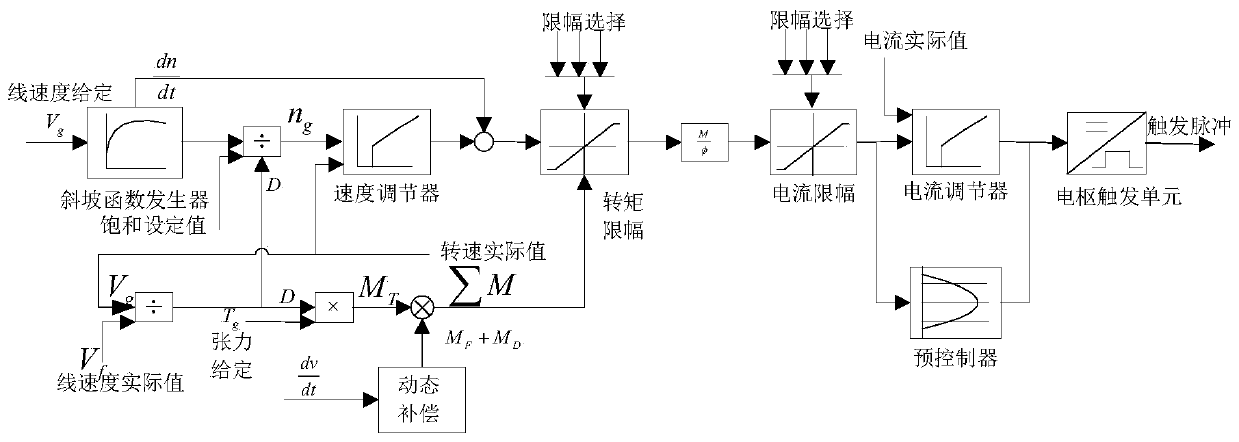

Ultra-thin steel strip coiling tension control method

ActiveCN113042540AGuaranteed tightGuaranteed to rollTensioning/braking arrangementsTension/compression control deviceFriction torqueLoad torque

The invention relates to an ultra-thin steel strip coiling tension control method. The technical problem that tension is difficult to control in the ultra-thin steel strip rolling process is solved. The tension control method comprises the following steps that firstly, static tension is established for an uncoiler and a coiler before a steel rolling unit operates; secondly, after the steel rolling unit operates, a tension value of a steel belt is detected, and a detection result is used for adjusting the output torque of a motor of the coiler; and thirdly, in the ultra-thin steel strip rolling process, torque compensation is conducted on the coiler, the tension of the steel strip is made to be constant, and the load torque MZ of the coiler comprises the steel strip tension torque MF, the rotational inertia torque MD, the steel strip bending torque Mw and the transmission system friction torque Mf. According to the technical scheme provided by the invention, strip drawing and strip breakage are avoided in the ultra-thin steel strip coiling process, so that a steel coil can be tightly and neatly coiled, the performance requirement of a product is met, and the production efficiency is also improved.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

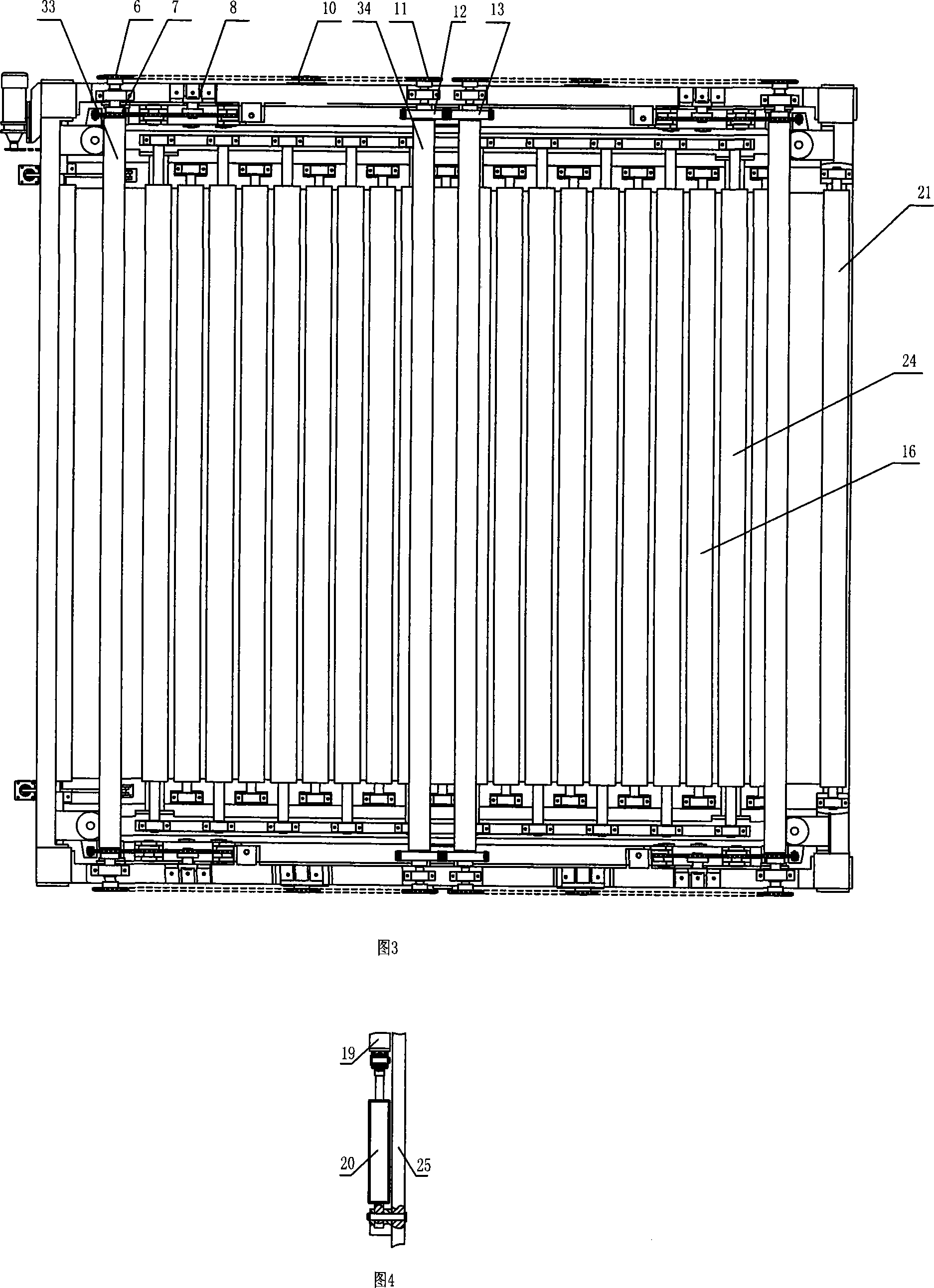

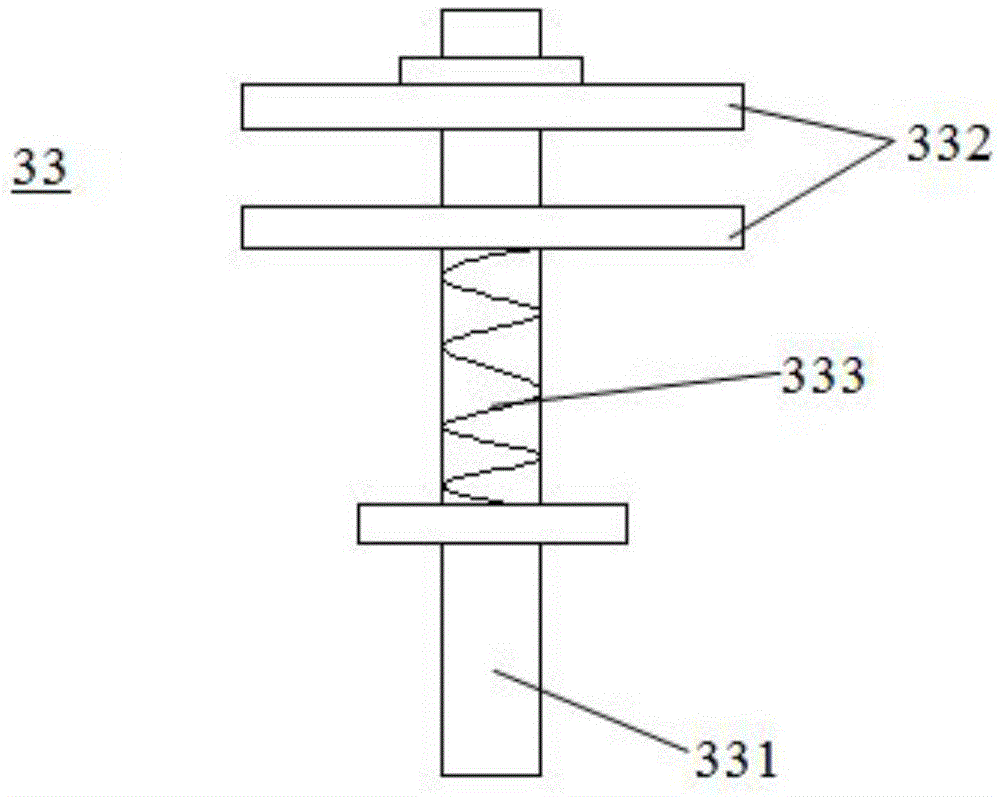

Device for controlling tension dynamic balance of warp thread of loom

InactiveCN101581000ATo achieve the purpose of dynamic adjustmentReduce swingLoomsDynamic balanceEquilibrium control

The invention belongs to the fitting device of a loom and particularly relates to a device for controlling tension dynamic balance of warp threads of the loom. The device comprises a resistance disc (5), a resistance rope (6), a spring (9) and a fixed bracket (7); the resistance rope (6) is connected with the resistance disc (5); the fixed bracket (7) is shaped like T or 7; two ends of a transverse rod of the fixed bracket (7) are connected with a stander (1) and a guide roller (8) respectively; the lower end of a vertical rod of the fixed bracket (7) is connected with a tension balance bracket (2); the vertical rod body is connected with a displacement adjusting device (4); one end of the resistance rope (6) is connected with the displacement adjusting device (4) and the other end thereof is connected with the external end of the tension balance bracket (2); the tail end of the external end of the tension balance bracket (2) is connected with a tension balance roller (12); and the tension balance bracket (2) is connected with the fixed bracket (7) by a spring displacement adjusting device (10) and the spring (9). The device achieves the object of dynamically adjusting balance, generates an error of less than 0.25 percent during the operation process, and has small swing amplitude and stable tension control.

Owner:张木辉

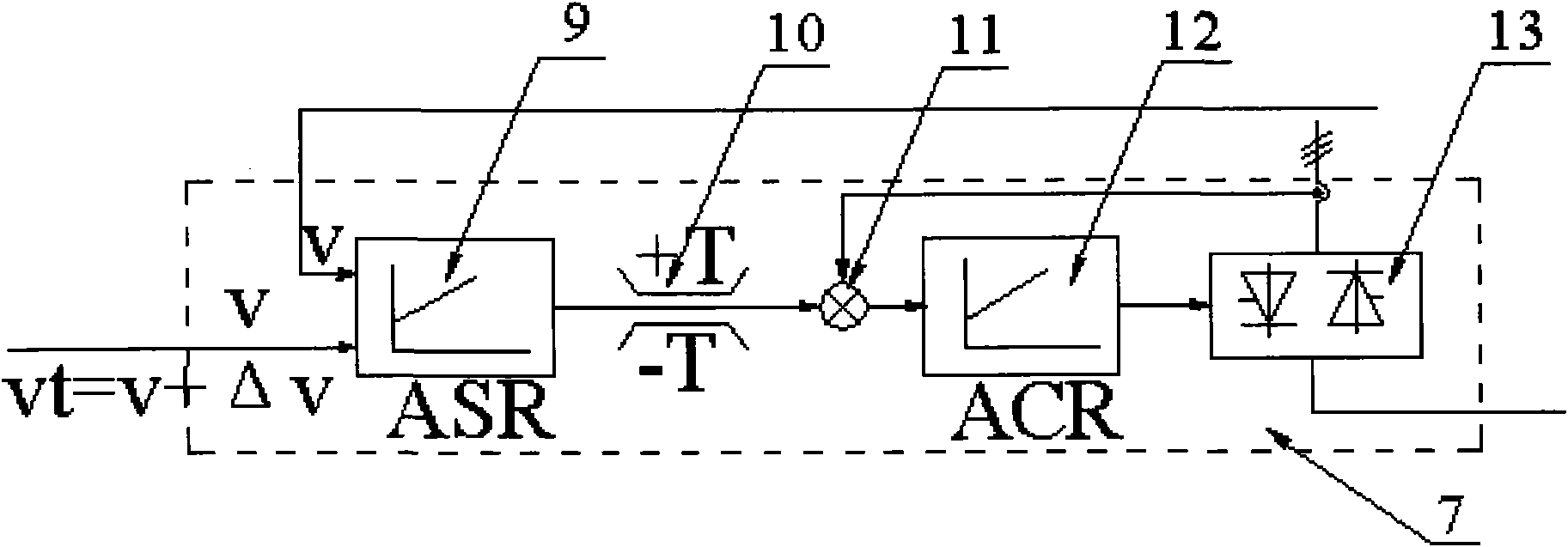

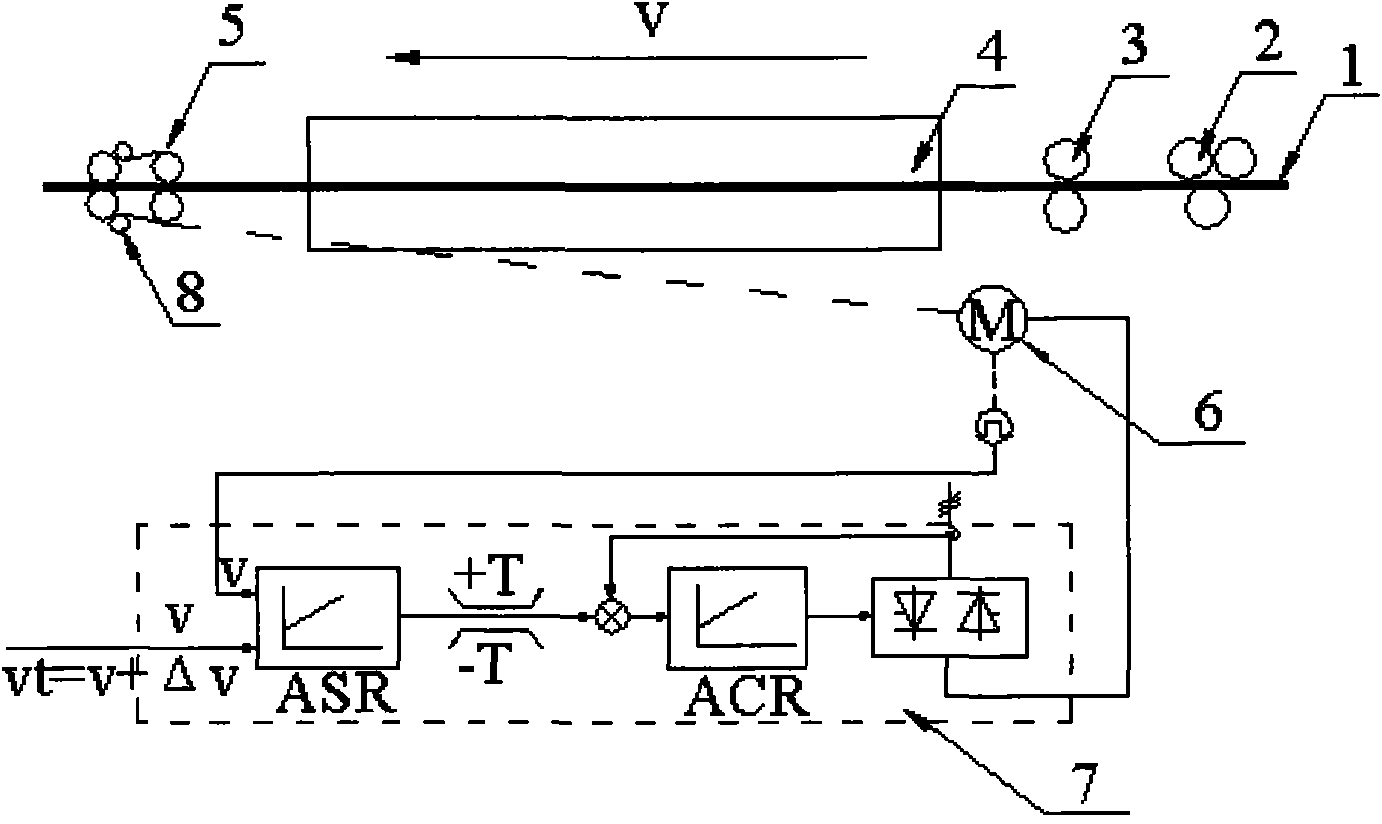

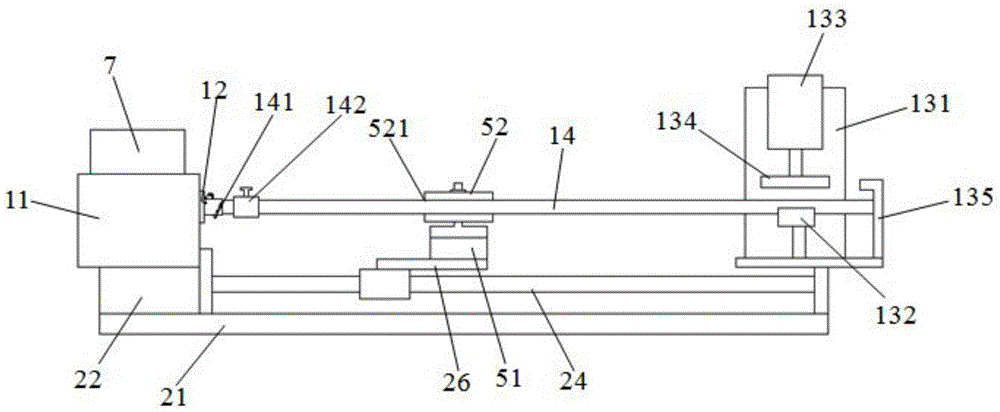

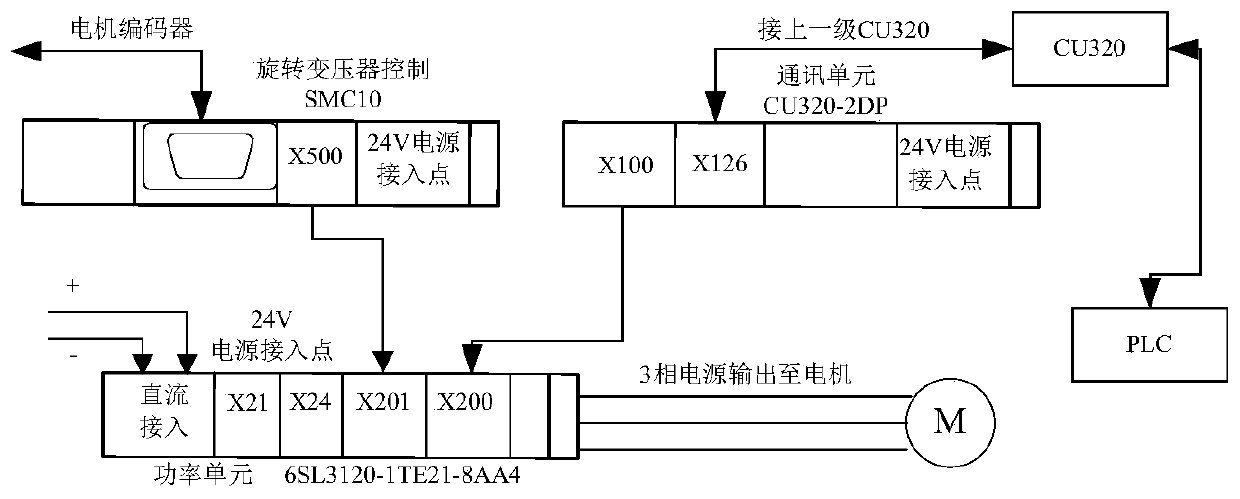

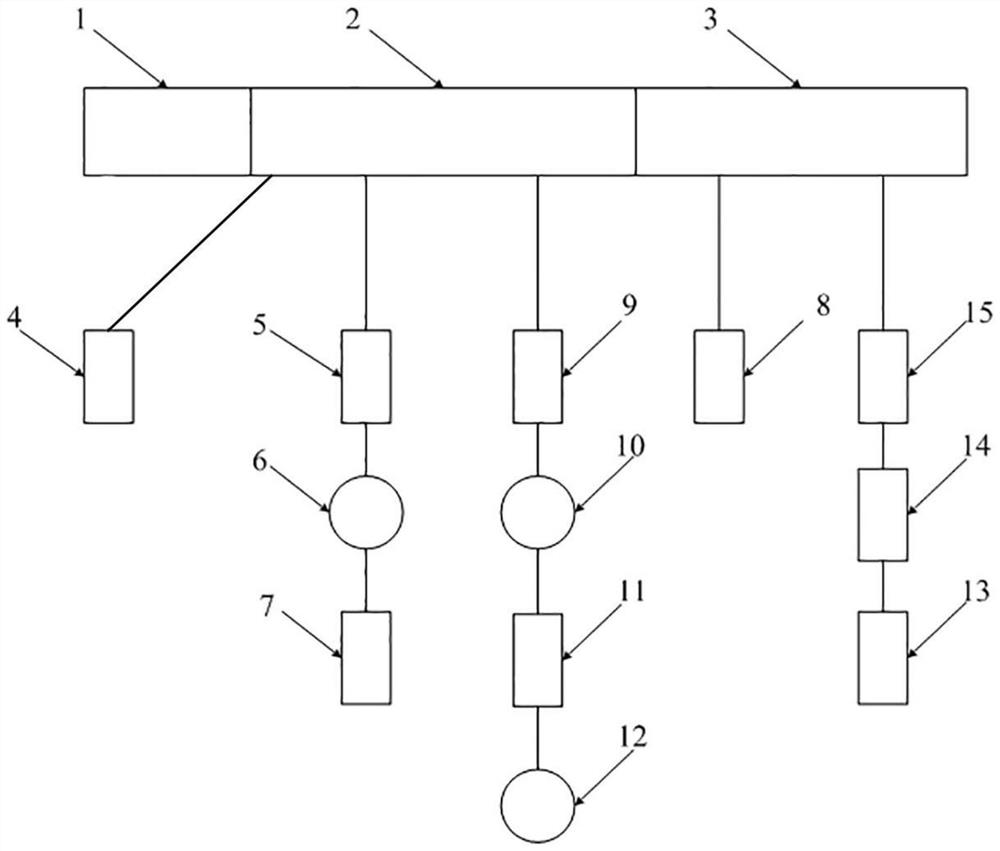

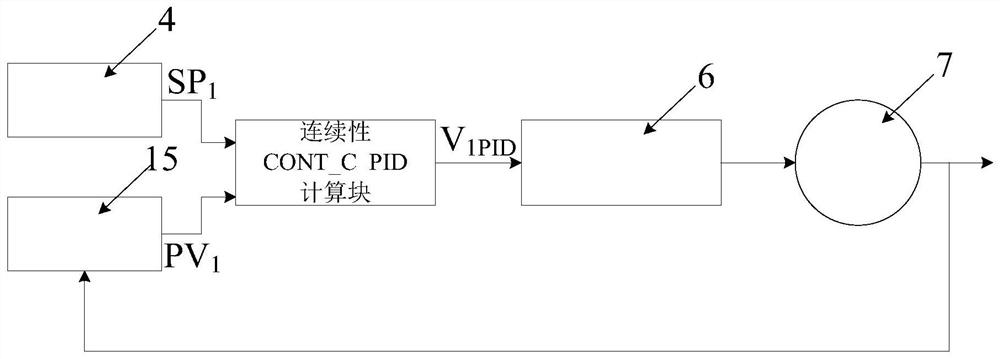

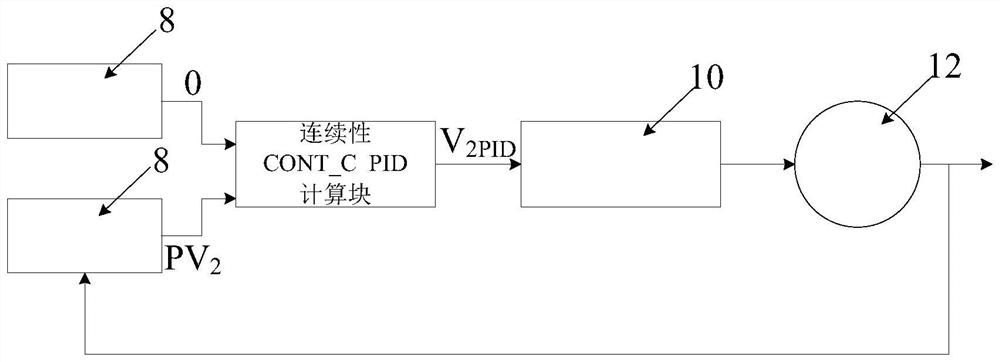

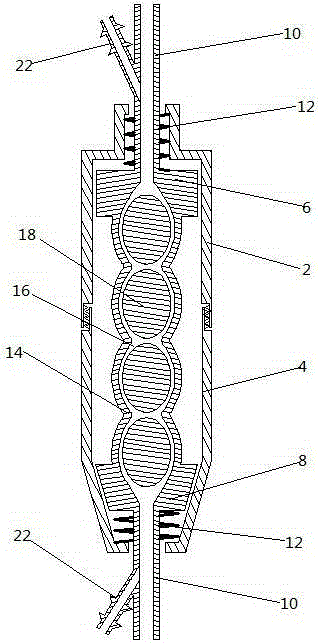

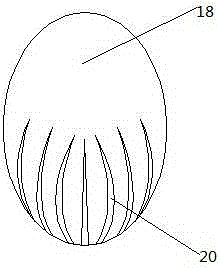

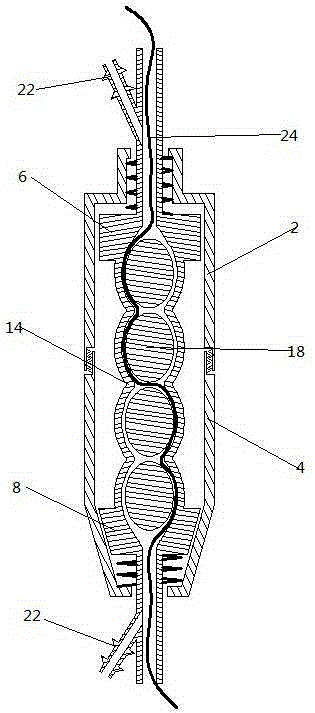

Micro-tension control system of copper-pipe high-speed continuous induction annealing furnace

InactiveCN101921978ARealize automatic buildingReduced control accuracyIncreasing energy efficiencyFurnace typesProgrammable logic controllerEngineering

The invention provides a micro-tension control system of a copper-pipe high-speed continuous induction annealing furnace, which comprises a pinch mechanism, a speed measurement device, an annealing furnace, a traction tension device and a programmable logic controller, wherein the traction tension device and the speed measurement device are located at the two sides of the furnace chamber of the annealing furnace respectively; the pinch mechanism is located in front of the speed measurement device; and the programmable logic controller is connected with the pinch mechanism, the speed measurement device and the traction tension device respectively. The invention causes the copper pipe to pass through the induction annealing furnace stably and uniformly within the full speed range of continuous induction annealing, without causing stretching deformation, suspension scratch or stacking contraction; and the actually measured annealing speed control precision is less than 1%.

Owner:苏州建莱机械工程技术有限公司

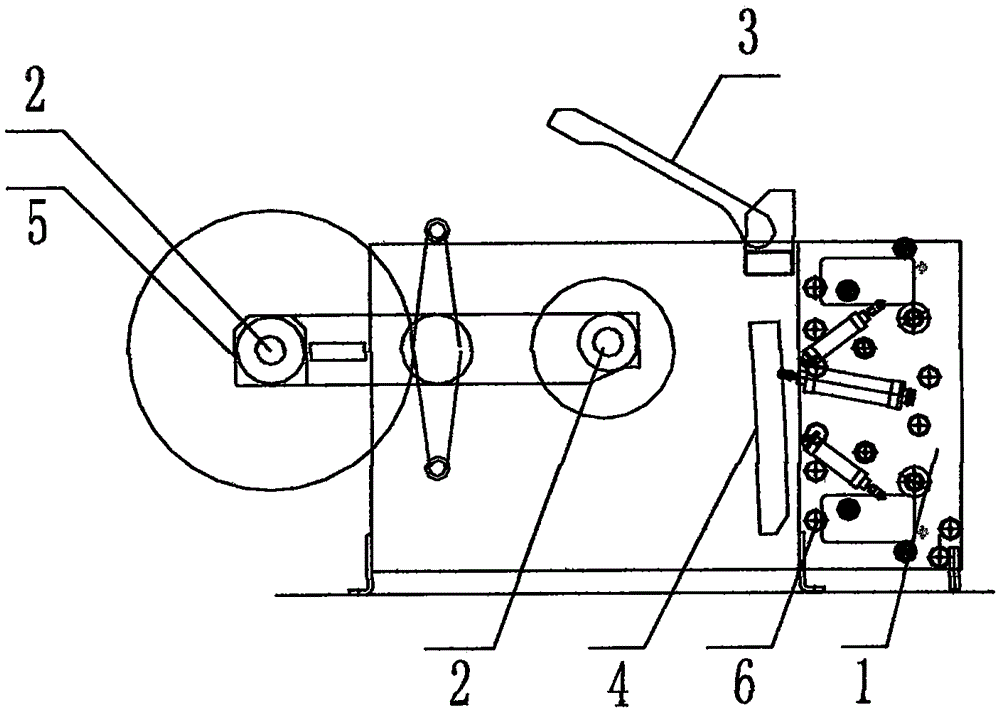

Paper-saving type same-speed paper supply machine and using method thereof

ActiveCN105584869AReasonable structural designStable tension controlWebs handlingTension controlTransverse beam

The invention relates to a paper-saving type same-speed paper supply machine and a using method thereof. The same-speed paper supply machine comprises a machine frame, transverse beams arranged on the two sides of the machine frame, a main paper supply device, a standby paper roll paper supply device and a control device; the main paper supply device and the standby paper roll paper supply device are installed on the machine frame; the control device is installed on one side of the machine frame; the main paper supply device comprises a main paper supply driving unit, and the standby paper roll paper supply device comprises a standby paper roll paper feeding device and a paper feeding driving unit; and the control device is in control connection with the main paper supply driving unit and the paper feeding driving unit to achieve same-speed paper supply. The paper-saving type same-speed paper supply machine has the beneficial effects that structural design is reasonable, the production cost is low, running is stable and reliable, the paper receiving success rate is high, the defective index of paper replacing each time is low, tension control is stable, and the automatic degree is high; and it is guaranteed that when the machine is applied, the printing efficiency and the printing quality are greatly improved.

Owner:WIN UNION BEIJING EQUIP

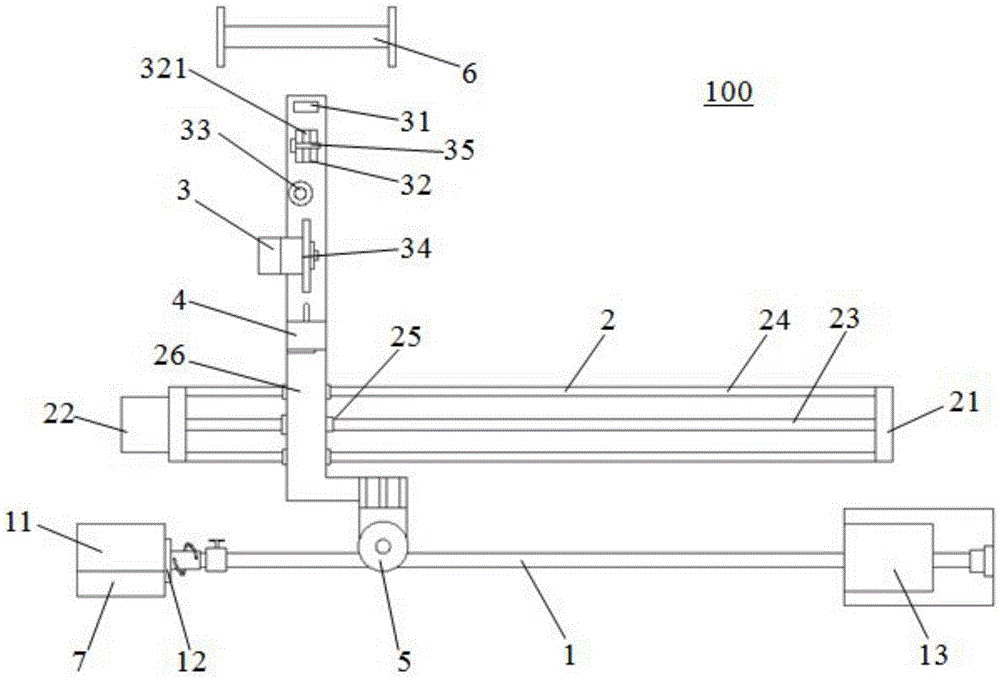

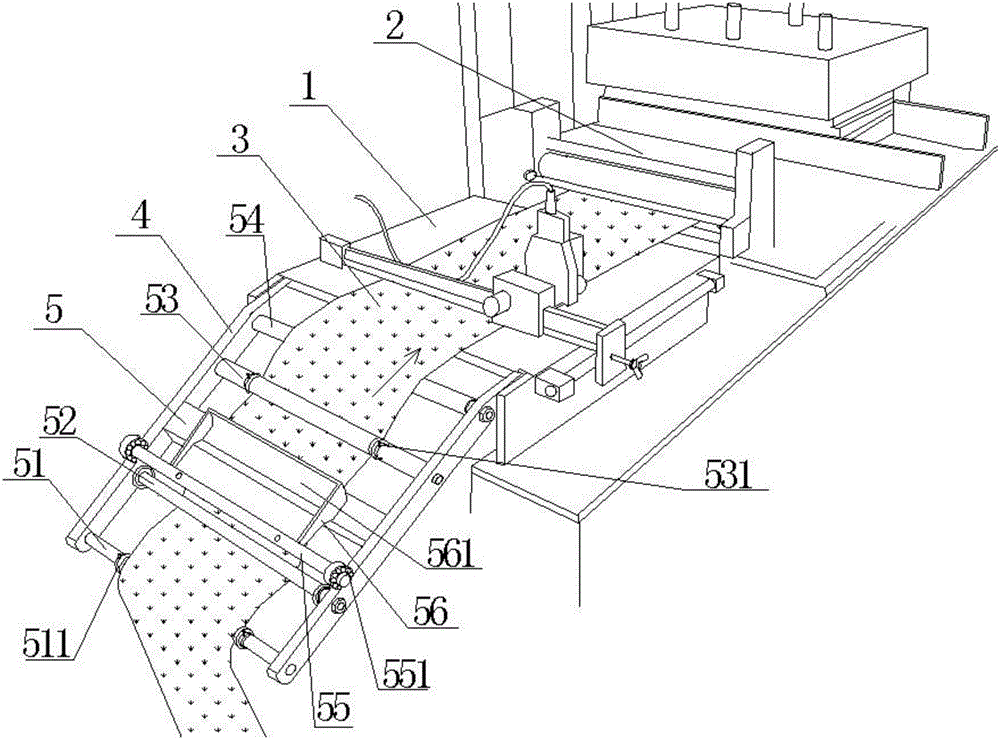

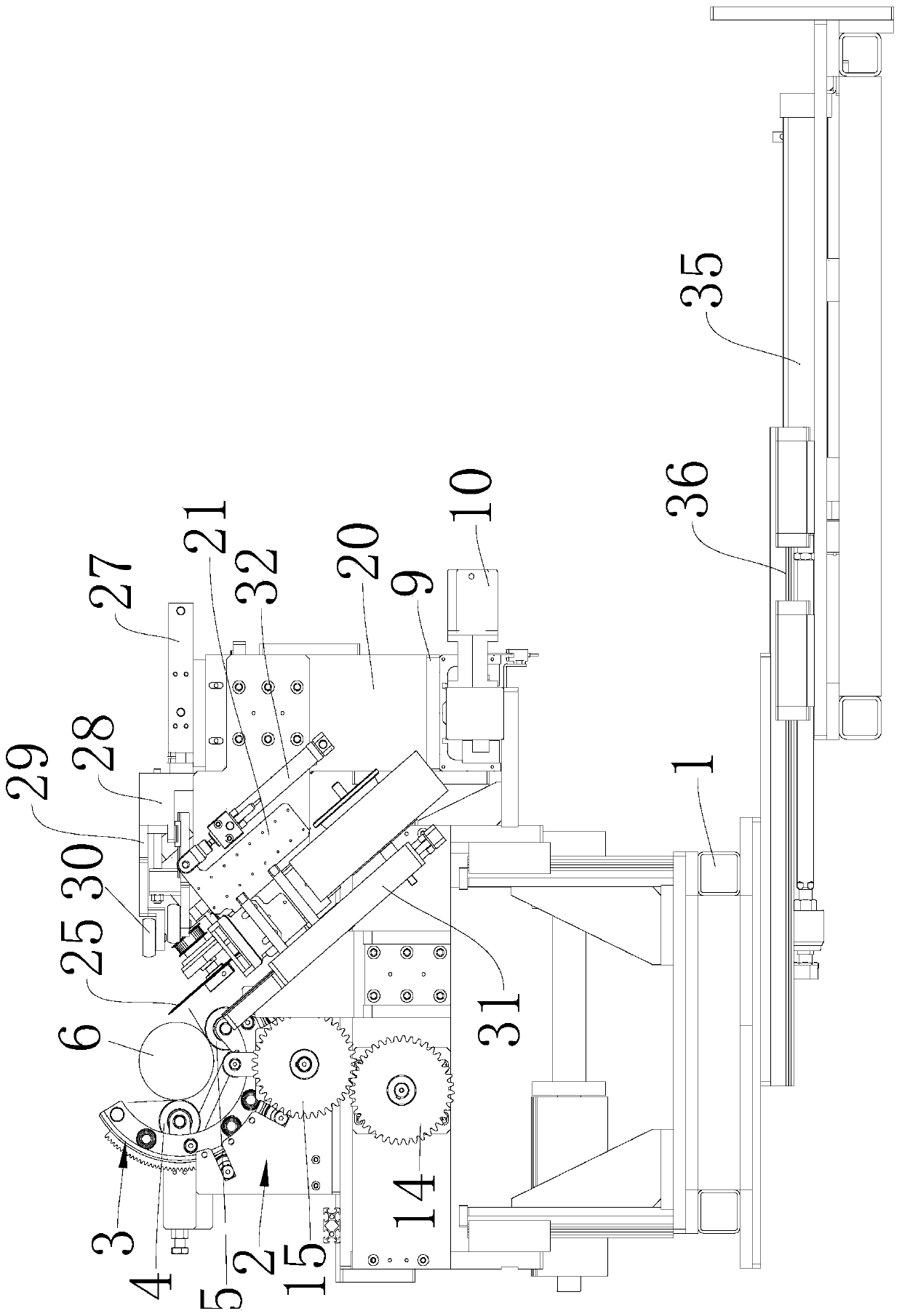

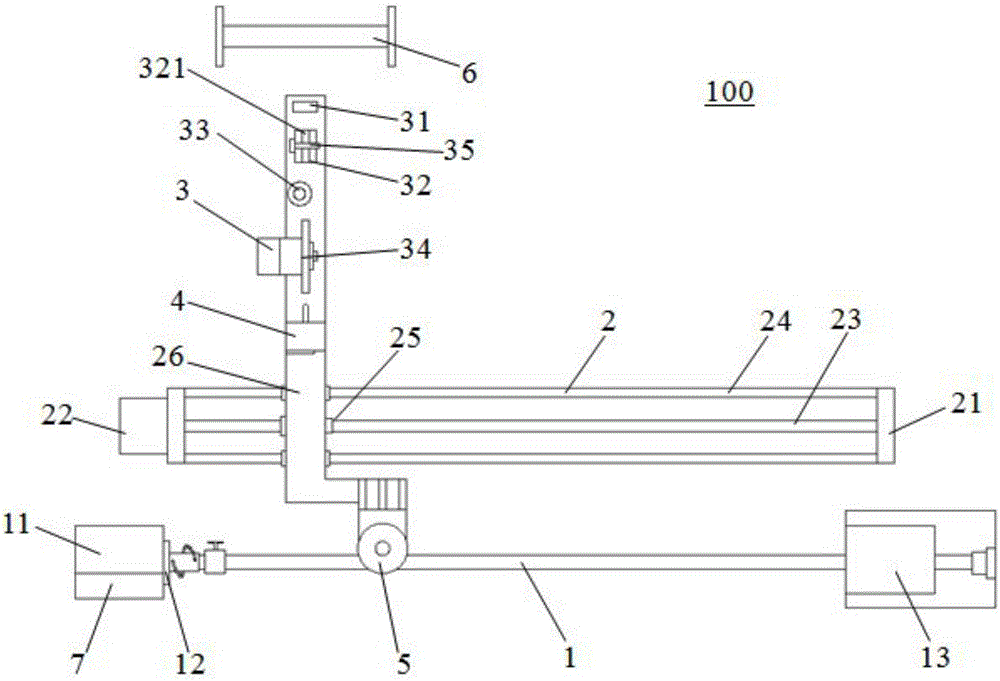

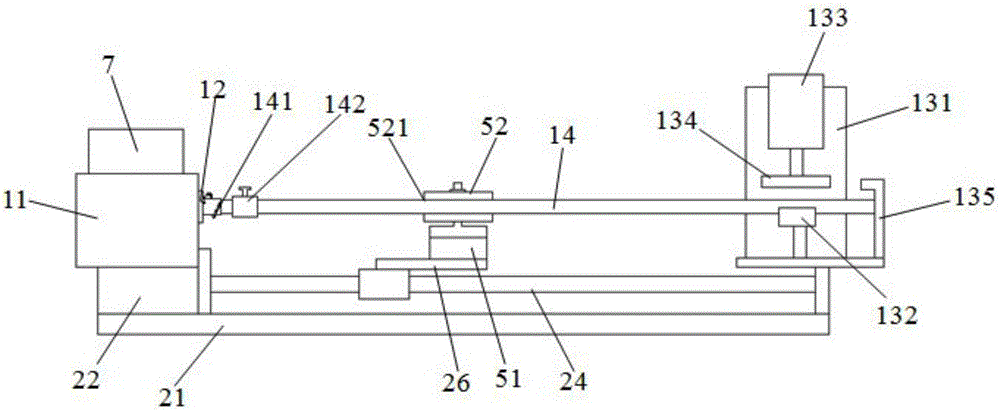

Automatic wire winding machine for spring wires

ActiveCN105665586AEnsure consistencyStable tension controlNon-rotating vibration suppressionElectricityWinding machine

The invention discloses an automatic wire winding machine for spring wires. The automatic wire winding machine comprises a wire winding drive device, a transfer device which is horizontal with the wire winding drive device, a wire cable guide device, a cut-off device, a vibration damping device. The wire cable guide device, the cut-off device and the vibration damping device move on the transfer device., a pay-off rack used for supporting cable coil stock, and a control unit, wherein the control unit is electrically connected to the wire winding drive device, the transfer device, the cut-off device, and the wire cable guide device. According to the automatic wire winding machine, the wire cable guide device, the cut-off device and the wire cable guide device are arranged on the transfer device, and are kept to be synchronous with the movement speed, on a wire winding shaft, of the wire cables, so that the wire cables are guaranteed to be perpendicular to the wire winding shaft all the time during the conveying process. Therefore, the automatic wire winding machine is beneficial for stabilizing tension control, and also guarantees the consistency of elastic force of a spring; the vibration damping device is arranged beside the wire winding shaft, and is synchronous with a cable to move along the wire winding shaft, so that the vibration of the wire winding shaft is further reduced, and therefore, the precision is improved.

Owner:SUZHOU CABLEPLUS ELECTRIC

Feeding device of die cutting machine

InactiveCN105014730AStable tension controlNot easy to swingMetal working apparatusBiochemical engineeringTension control

The invention discloses a feeding device of a die cutting machine. The feeding device comprises support arms on the two sides and a connecting rod for connecting the support arms. A first round rod, a second round rod, a third round rod, a fourth round rod and an auxiliary rod are arranged between the two support arms. The auxiliary rod is provided with an externally-arranged pressing plate. The pressing plate is provided with a pressing trough. The feeding device of the die cutting machine is arranged on one side of a feeding table, and a die cutting device is arranged on the other side of the feeding table. The first round rod is provided with two slideable first fixing rings. The third round rod is provided with two slideable second fixing rings. The first fixing rings are fixed to the first round rod through bolts, and the second fixing rings are fixed to the third round rod through bolts. The lower side of the pressing plate is in a smooth arc shape, and the pressing plate is fixed to the auxiliary rod through bolts. The feeding device of the die cutting machine is simple, applicable and convenient to use. The tension of die-cutting raw materials is controlled stably, the die-cutting raw materials are not prone to swinging, and the die cutting precision is high.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

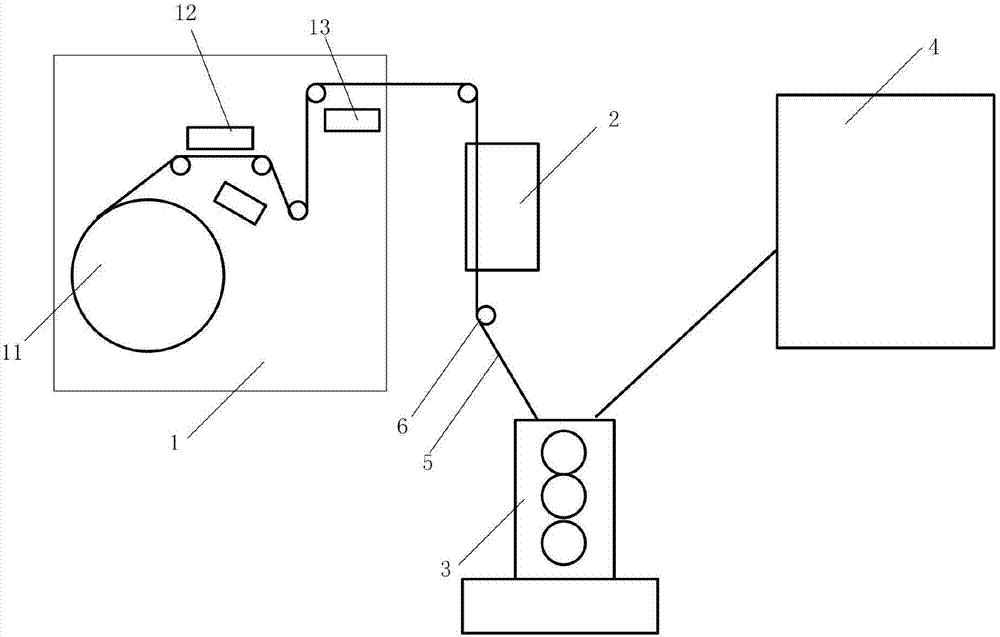

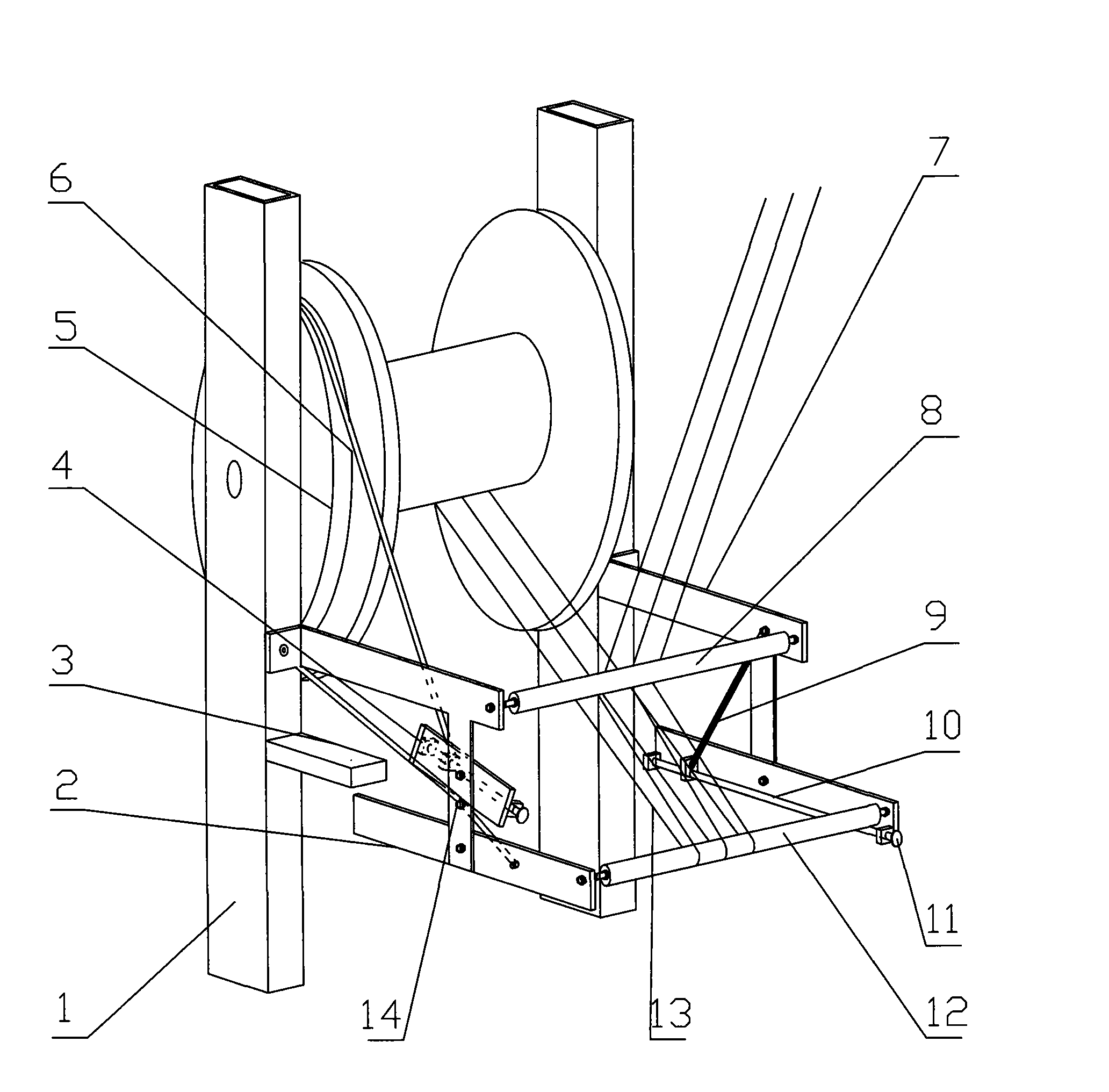

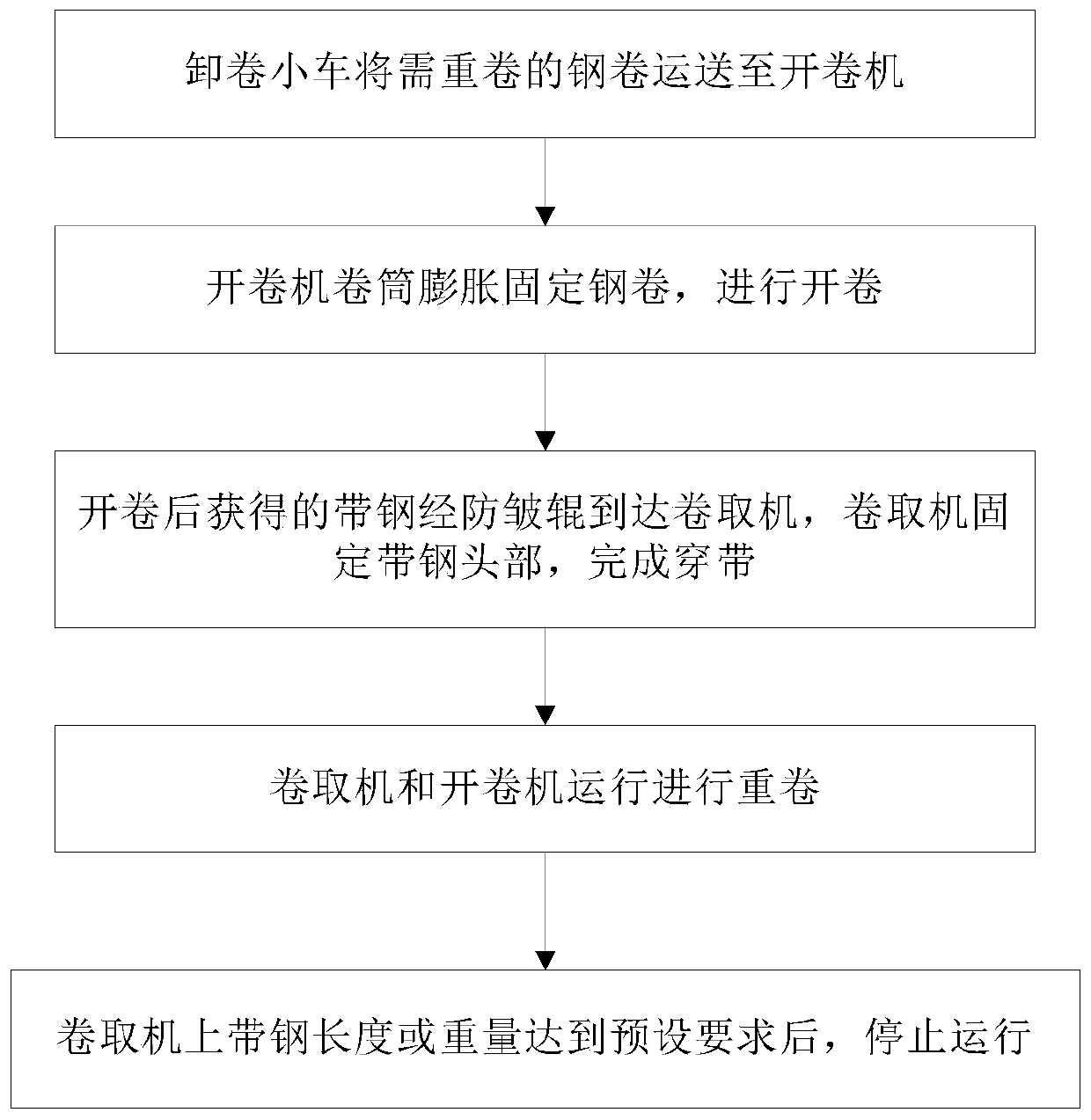

Control system and method for changing diameters by coiling ultra-thin stainless steel strips

InactiveCN110355235AMeet needsMeet the requirements of coiling diameter reductionGeometric CADSpecial data processing applicationsControl systemStrip steel

The invention discloses a control system and method for changing diameters by coiling ultra-thin stainless steel strips. The method comprises the following steps: steel coils which need to be recoiledare transported to an uncoiling machine by a coil stripping car; coiling blocks of the uncoiling machine expand to fix the steel coils, and uncoiling is performed; strip steel obtained after uncoiling reaches a coiling machine via a crease-resistant roller, and the head part of the strip steel is fixed by the coiling machine to finish strip threading; the coiling machine and the uncoiling machinerun to perform recoiling; and the coiling machine and the uncoiling machine stop running after the length or weight of the strip steel on the coiling machine reaches the preset requirement. Accordingto the control system and method for changing the diameters by coiling the ultra-thin stainless steel strips, by coiling and recoiling the steel strips, the coil diameters of the steel coils can be changed; the steel coils of preset coil diameters are obtained to meet the needs of different clients, and the application range is relatively broad; direct tension control is employed; direct tensioncreation is performed on the uncoiling machine and the coiling machine; the dynamic torque and the mechanical loss torque of the uncoiling machine are compensated in real time; drawn or broken stripsare not generated in the whole process; tension control is stable; the requirement of changing the diameters by coiling is met; and the production efficiency is increased.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

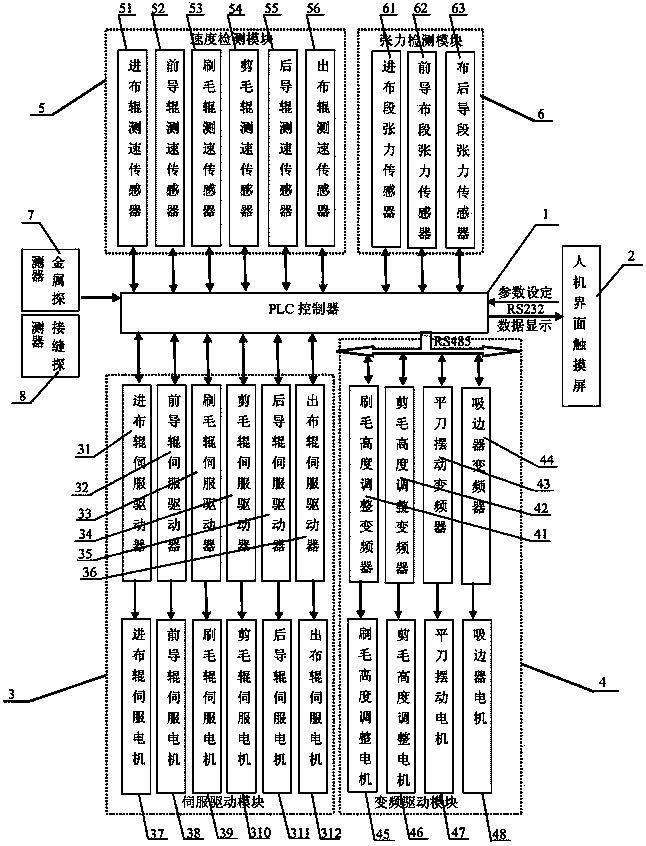

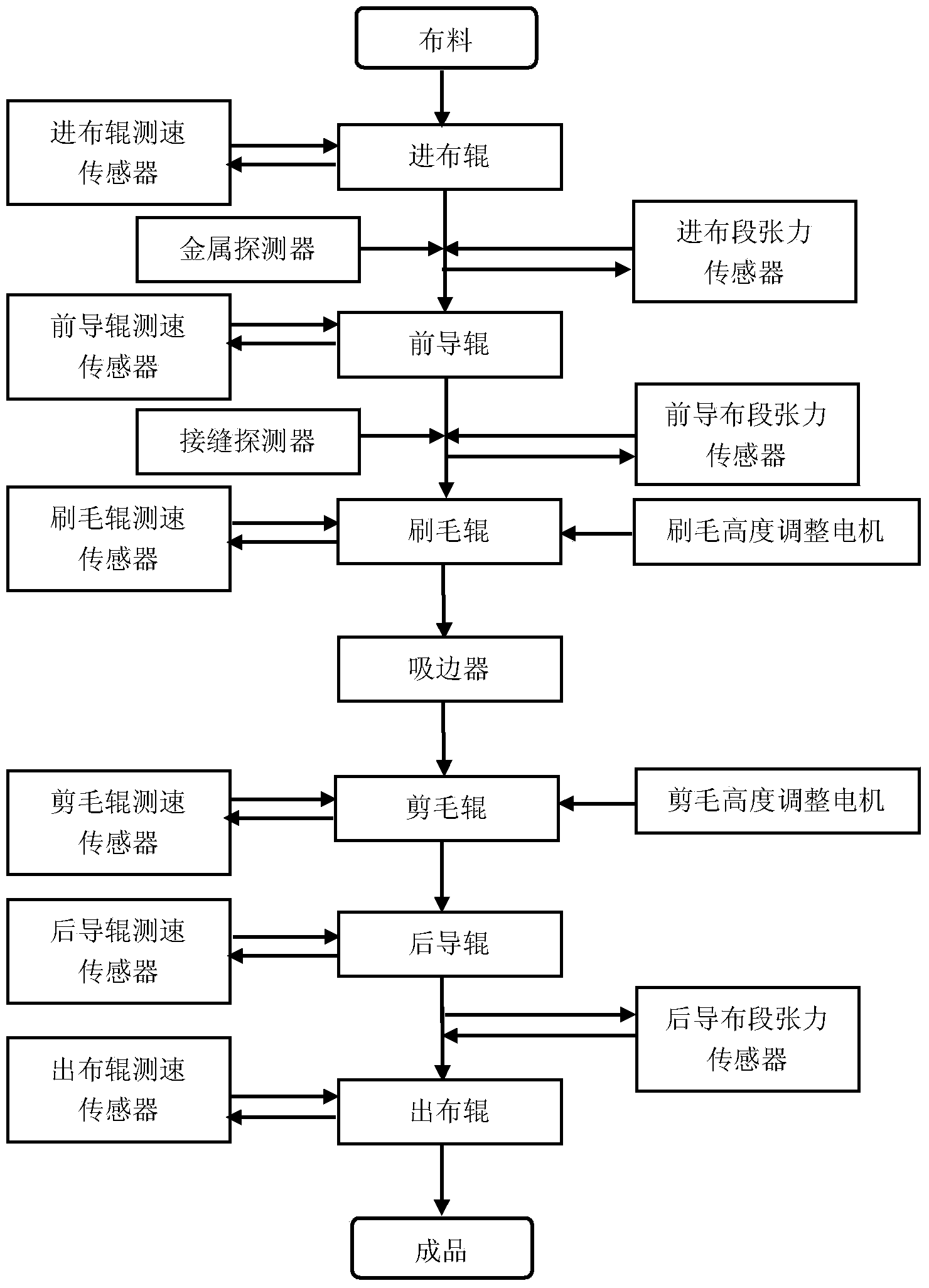

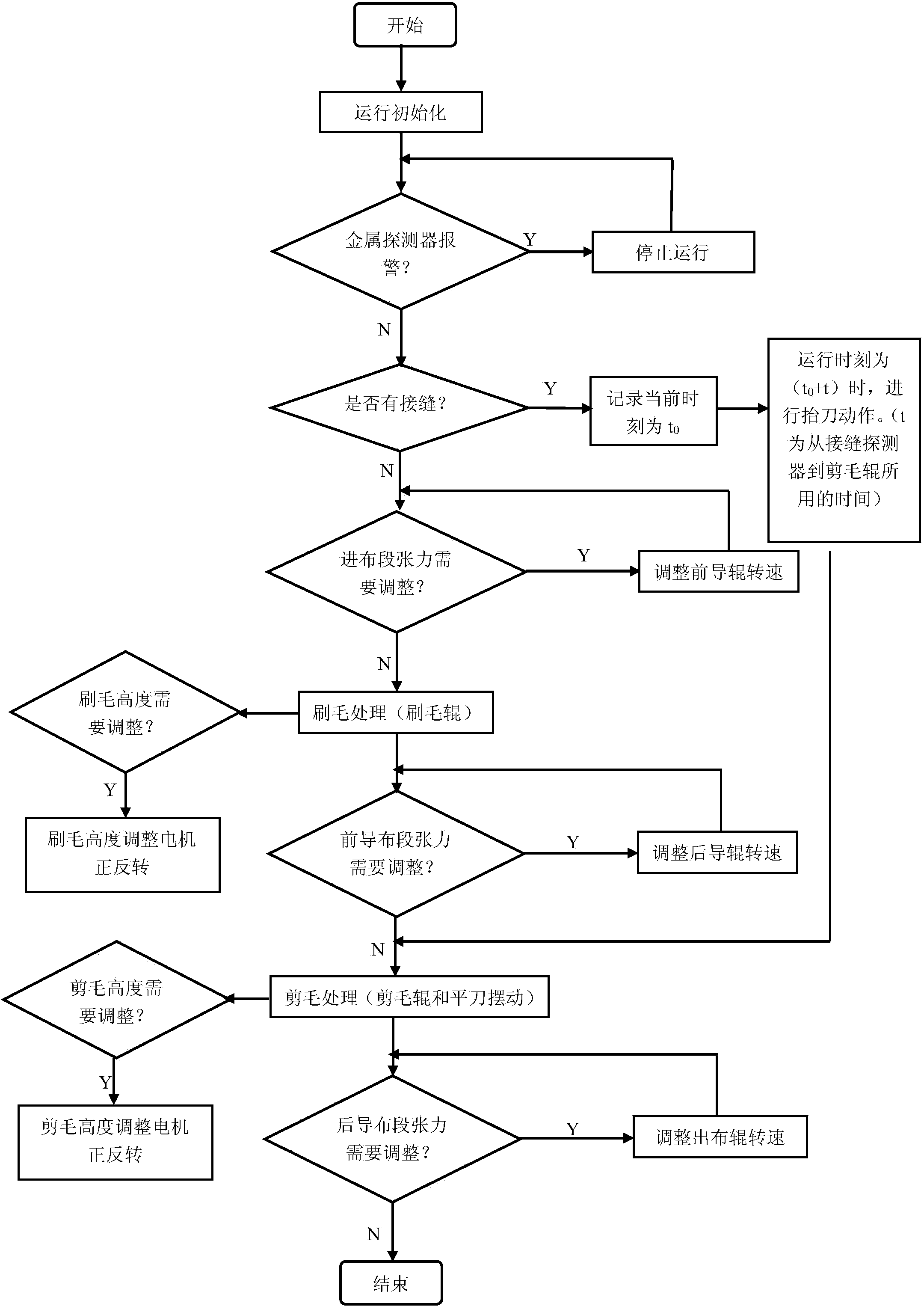

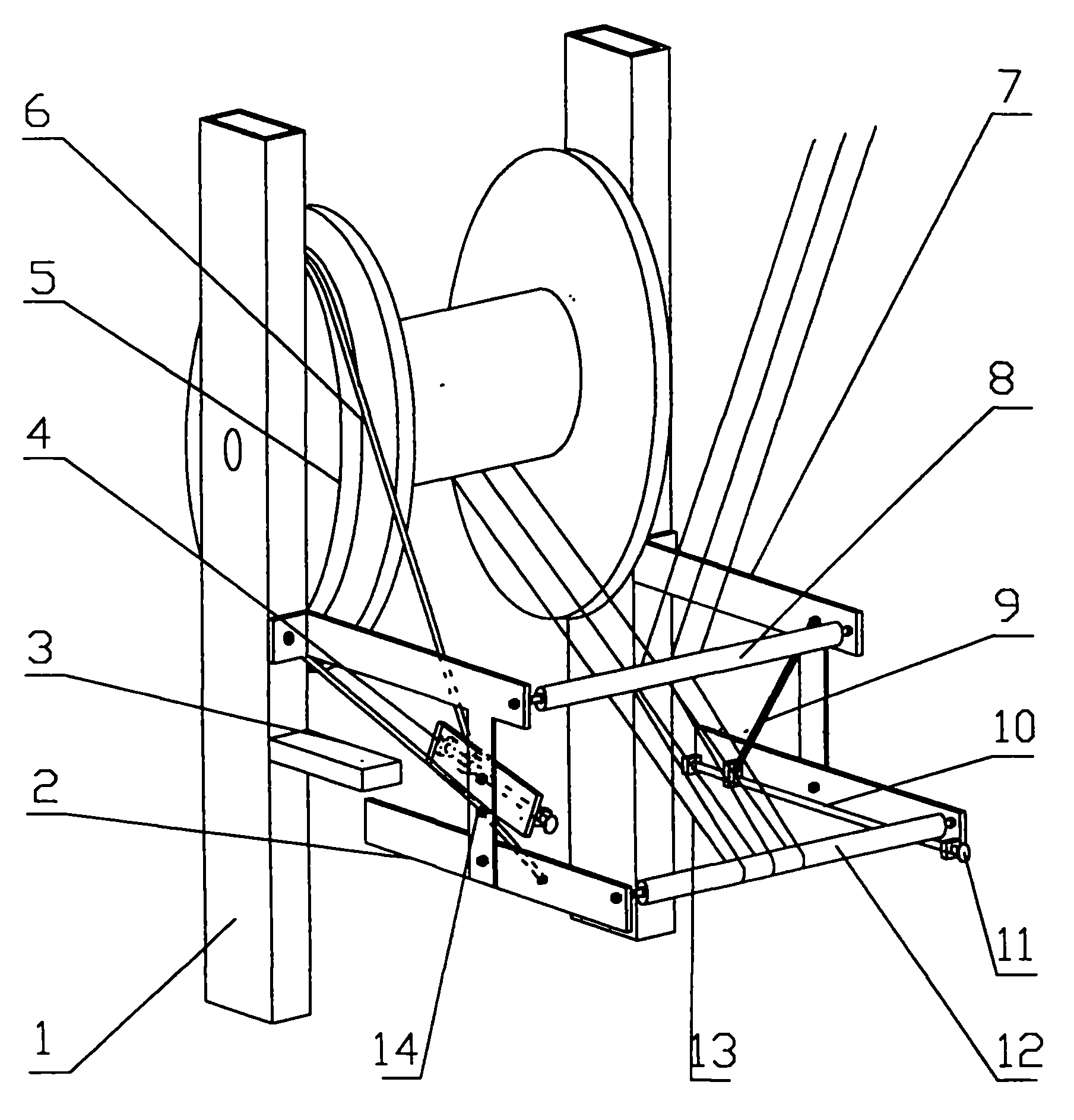

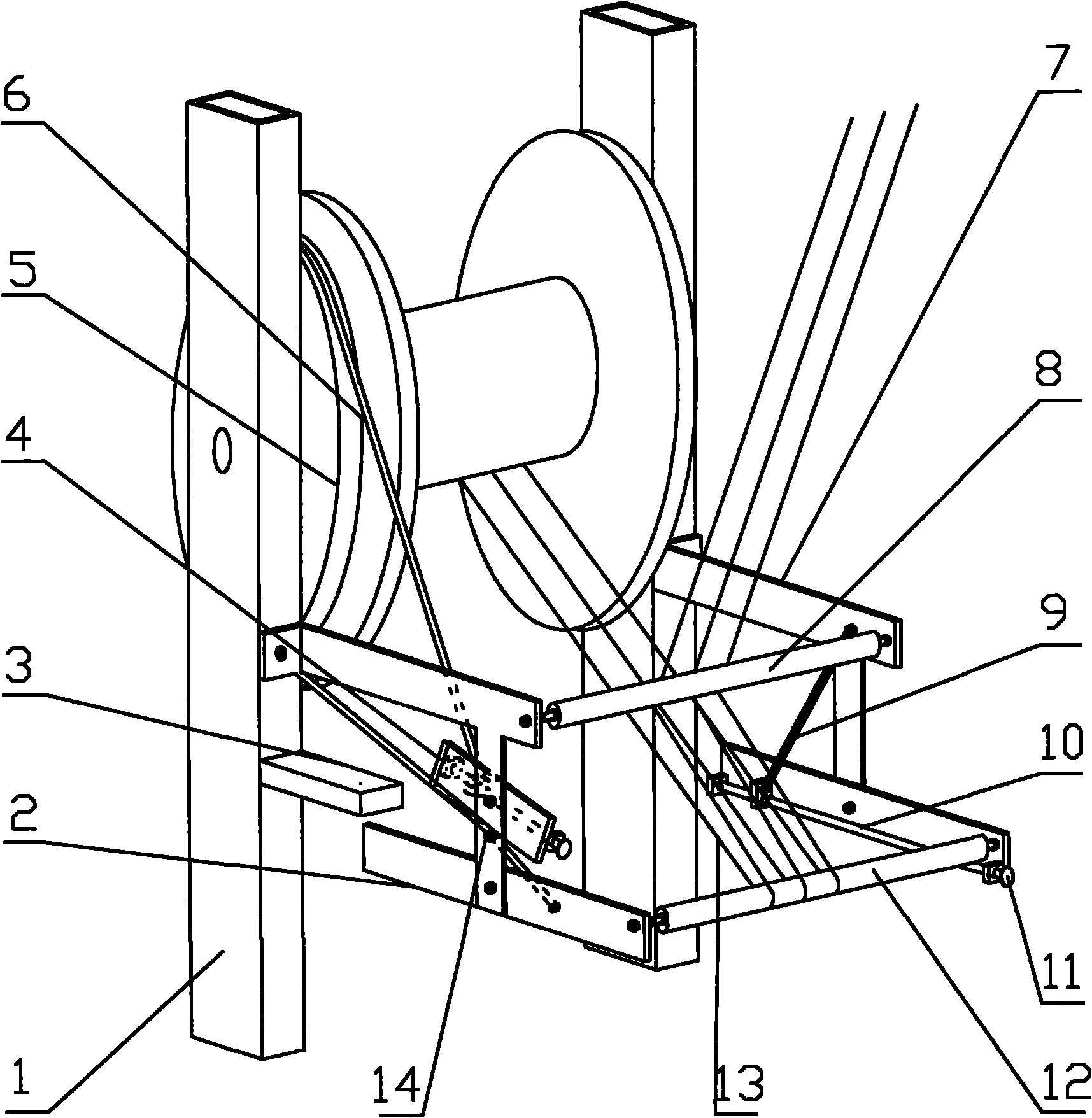

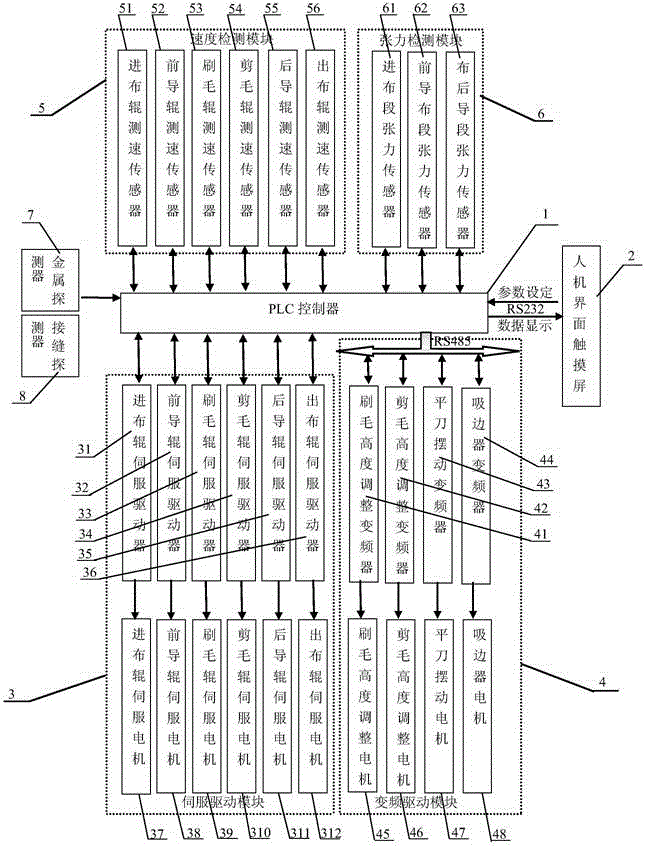

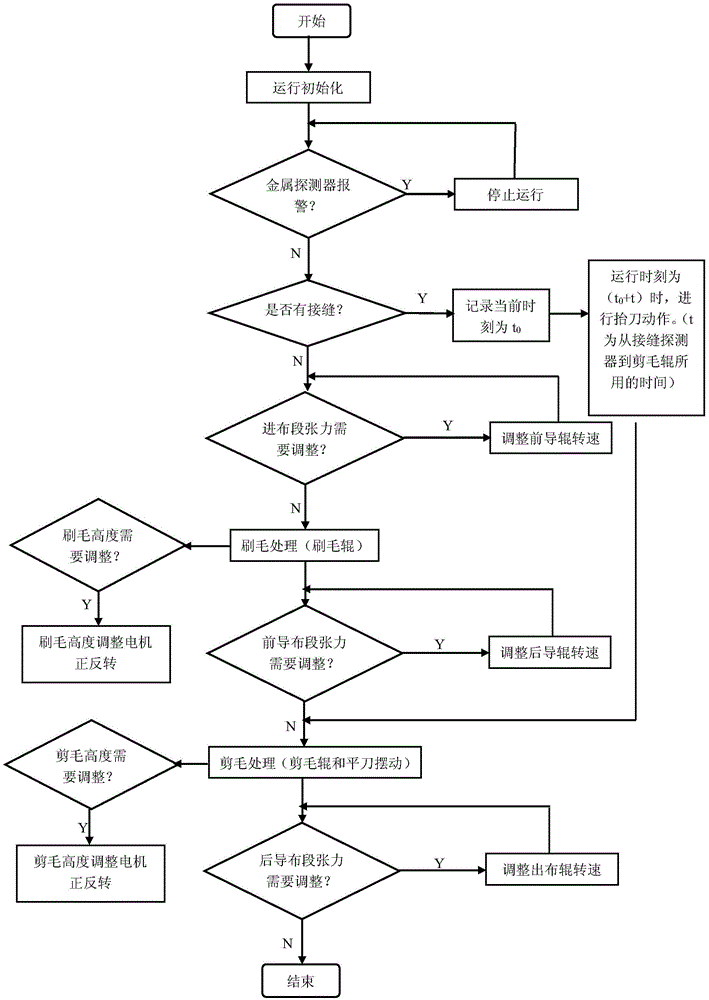

Real-time control system and method for tension of wool shearing machine

ActiveCN103938405AConstant tensionConstant tension controlMechanical pressure/force controlTextile shapingHuman–machine interfaceTouchscreen

The invention discloses a real-time control system and method for tension of a wool shearing machine. The real-time control system comprises a PLC (Programmable Logic Controller), wherein the PLC is connected with a human-computer interface touch screen through an RS232 serial communication wire; a high-speed pulse output port of the PLC is connected with a servo driving module through a circuit; the PLC is connected with a variable-frequency driving module through an RS485 bus; the PLC is also respectively connected with a speed detecting module, a tension detecting module, a metal detector and a seam detector through circuits. Through real-time control on rotating speeds of a cloth feeding roller, a front guide roller, a brush roller, a cloth guider, a wool shearing roller, a rear guide roller and a cloth discharging roller, the precise control and stepless regulation on the tension of a fabric is realized, the wool shearing height is more precise, and the height error is reduced.

Owner:HANGZHOU XUREN TEXTILE MACHINERY

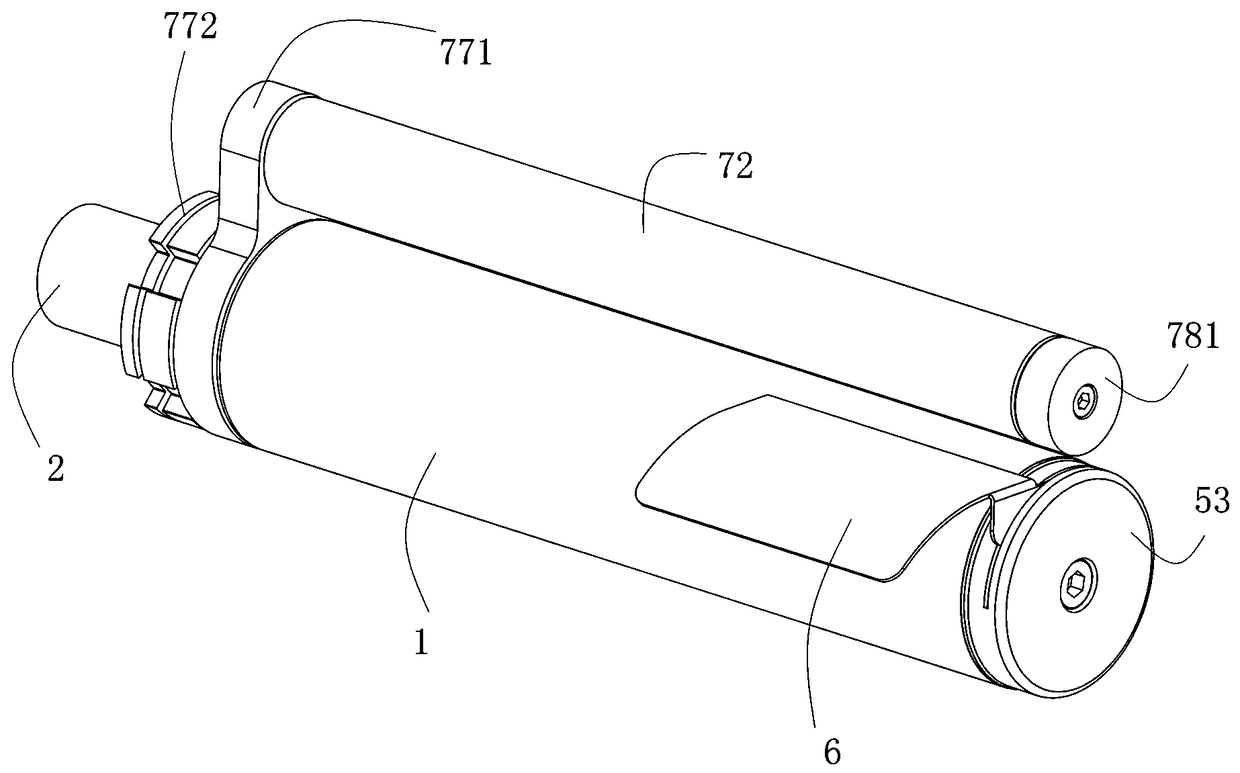

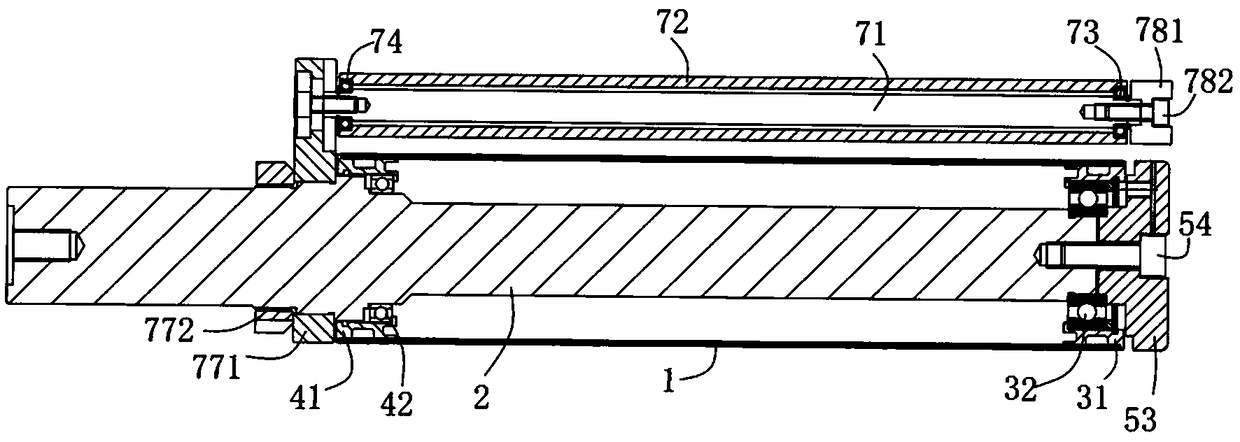

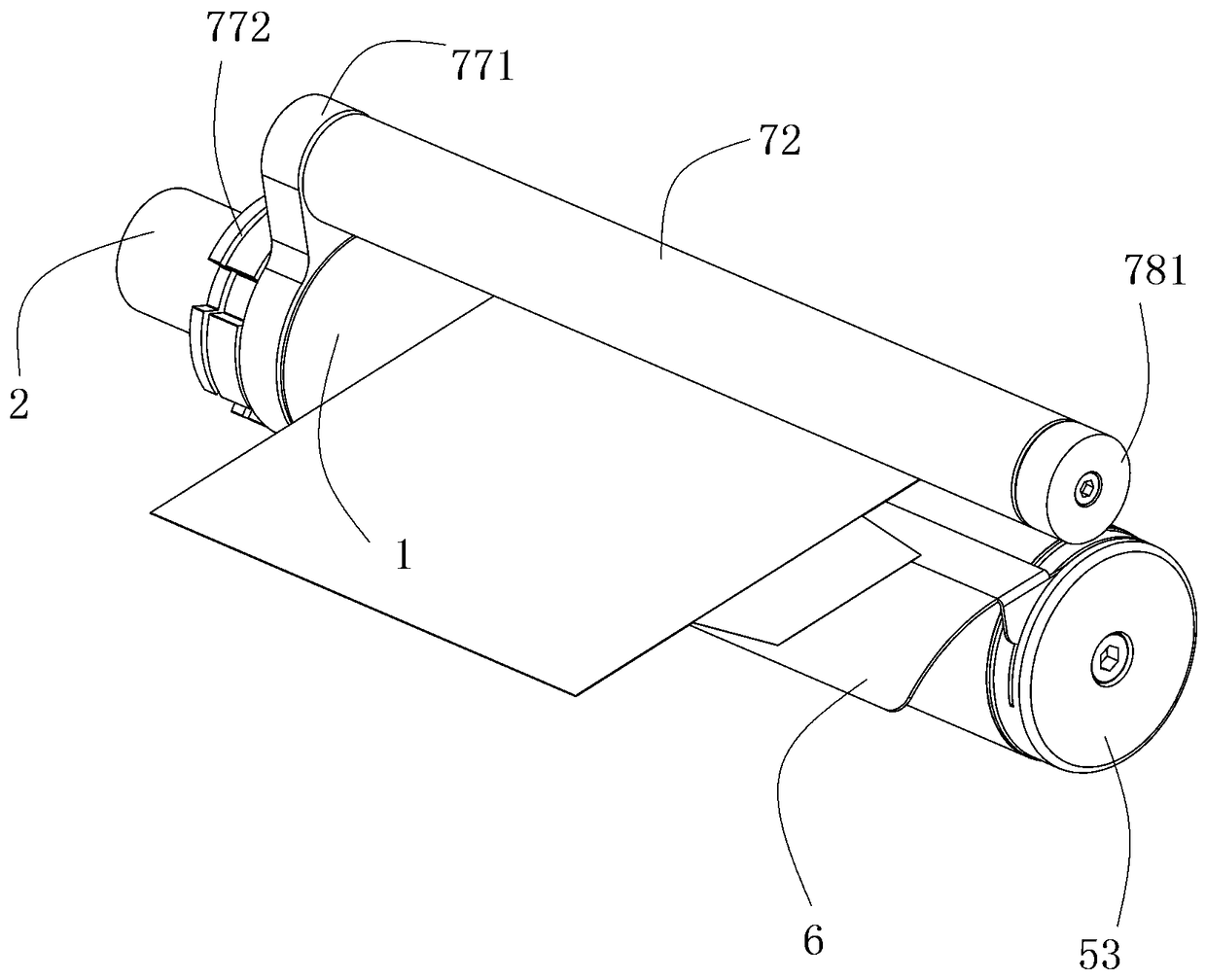

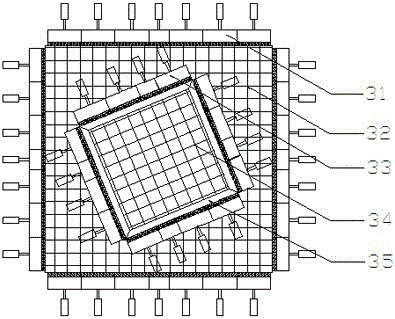

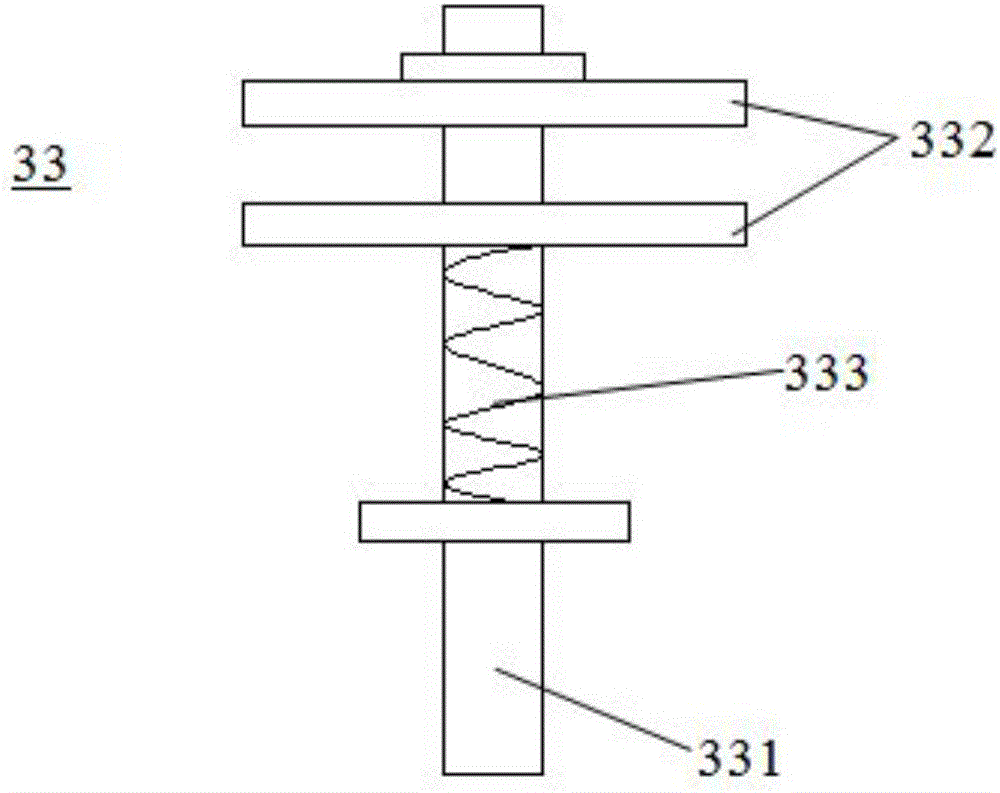

A pole plate passing roller structure

PendingCN108987797AReduce frictionSmall moment of inertiaElectrode manufacturing processesFinal product manufactureAxial pressureEngineering

A pole piece passing roller structure is disclosed, It comprises a first passing roller, a first central shaft and a first fixing assembly, wherein one end of the first passing roller inner wall is provided with a first rolling assembly, the other end of the first passing roller inner wall is provided with a second rolling assembly, the first passing roller is connected with the first central shaft through the first rolling assembly and the second rolling assembly, the second rolling assembly is connected with the first central shaft, and the first fixing assembly is connected with one end ofthe first central shaft. The pole piece passing roller structure realizes that the first bearing is not subjected to axial pressure and ensures that the first bearing is in a zero clearance state, sothat the first passing roller is subjected to less frictional force when rotated, the inertia of the first passing roller is small, avoiding the broken belt or wrinkling caused by excessive moment ofinertia of the pole piece, The axial movement of the first passing roller is reduced, a gap is arranged between the second bearingand the second step of the first central shaft, and the axial pressuregenerated by squeezing the second bearing is avoided, so that the second bearing is only used for supporting the first passing roller, so that the resistance of the first passing roller is smaller, and the quality and the yield of the lithium battery cell production are greatly improved.

Owner:GUANGDONG JITI SMART EQUIP CO LTD

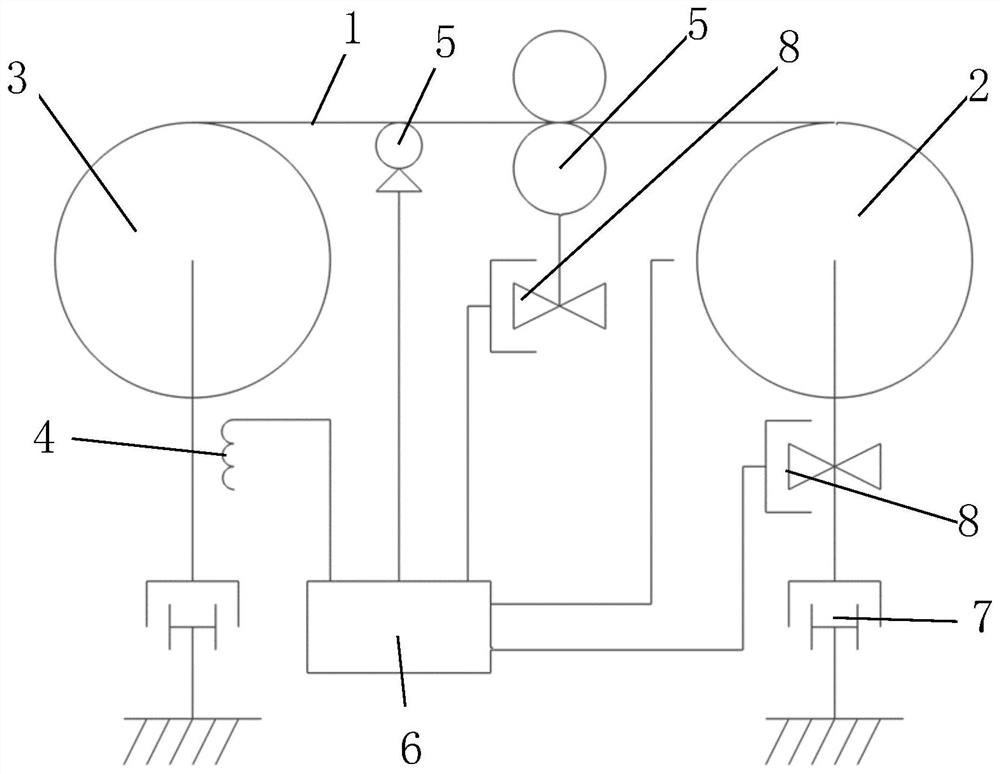

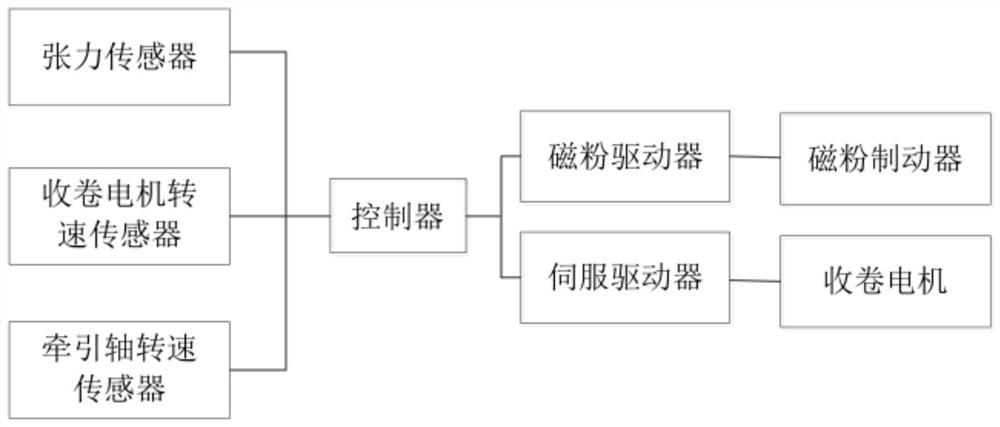

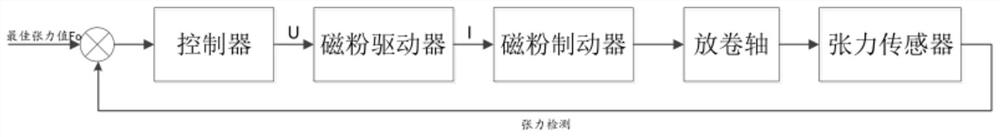

Tension adjusting method for film splitting machine based on discrete PID and taper tension control

PendingCN112919216AAvoid wrinklesStable tension controlArticle deliveryWebs handlingBrakeElectric machinery

The invention discloses a tension adjusting method for a film splitting machine based on discrete PID and taper tension control. The tension adjusting method comprises the following steps that S1, the real-time tension value F of a film is measured; S2, the real-time diameter D of a winding shaft is measured; S3, an optimal tension value F0 is obtained through a segmented taper tension model; S4, the torque of an unwinding shaft is controlled through a magnetic powder brake, so that the real-time tension value F of the film between the unwinding shaft and a traction shaft is adjusted to the optimal tension value F0; and S5, difference comparison is conducted on the real-time tension value F and the optimal tension value F0 to obtain a tension deviation value delta F, a tension deviation value delta F signal is transmitted into a discrete PID controller, and the torque of a winding motor is controlled through the discrete PID controller, so that the real-time tension value F of the film between the traction shaft and the winding shaft is adjusted to the optimal tension value F0. According to the method, tension control is stable, and reliability is high.

Owner:SHANGHAI INST OF TECH

Zipper tooth oxidation line with shafts and bearing seats having longer service lives

The invention discloses a zipper tooth oxidation line with shafts and bearing seats having longer service lives, and the zipper tooth oxidation line comprises at least one oxidation tank, wherein each oxidation tank is provided with at least one rotating shaft group; the rotating shaft groups comprise upper shafts and lower shafts that are arranged in parallel; bearing seats are assembled at the two ends of the upper shafts and the lower shafts respectively; the bearing seats are assembled on the oxidation tanks; the lower shafts are assembled in the oxidation tanks; through holes are formed in tank walls of the oxidation tanks; the two ends of the lower shafts penetrates through the through holes and are assembled on the bearing seats respectively; the through holes are provided with mechanical sealing devices; and the lower shafts are assembled at the mechanical sealing devices in a sealing manner. According to the zipper tooth oxidation line, the two end parts of the lower shafts and the bearing seats are arranged outside the oxidation tanks and prevented from being soaked in liquid to be corroded; the service lives of the lower shafts and the bearing seats are prolonged; the maintenance frequency is reduced effectively; the equipment maintenance is easier; the production efficiency is improved; and the costs for purchasing the lower shafts and the bearing seats are lowered.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Hot compress steam mask forming machine

PendingCN108785057AImprove fixation stabilityImprove passabilityBathing devicesSurface layerEngineering

The invention discloses a hot compress steam mask forming machine, which comprises a stand, wherein a discharging device, a hot sealing device, a first gas holder conveying device, a first blanking device, a second gas holder conveying device, a second blanking device and a product conveying device, wherein a mask bottom layer uncoiling device is arranged at the lower side of the front end of thedischarging device; at the back of the discharging device, a middle layer uncoiling device, a mask surface layer uncoiling device and a mask waste coiling device are arranged at the upper side of thestand; a guide shaft by which a mask bottom layer, a mask middle layer and a mask surface layer are gathered is arranged at the front of the hot sealing device; a conveying and flattening mechanism isarranged at the back end of the product conveying device; the conveying and flattening mechanism comprises a bracket as well as an upper belt conveying device and a lower belt conveying device whichare opposite in conveying direction; the upper layer of a conveying belt of the lower belt conveying device is tightly pressed by the lower layer of a conveying belt of the upper belt conveying device; and a plurality of flattening devices are additionally arranged in the belt conveying devices. With the application of the device (the steam mask forming machine) provided by the invention, formingprocessing and flattening of hot compress steam masks can be completed.

Owner:HENAN SUPER ASIA MEDICAL EQUIP

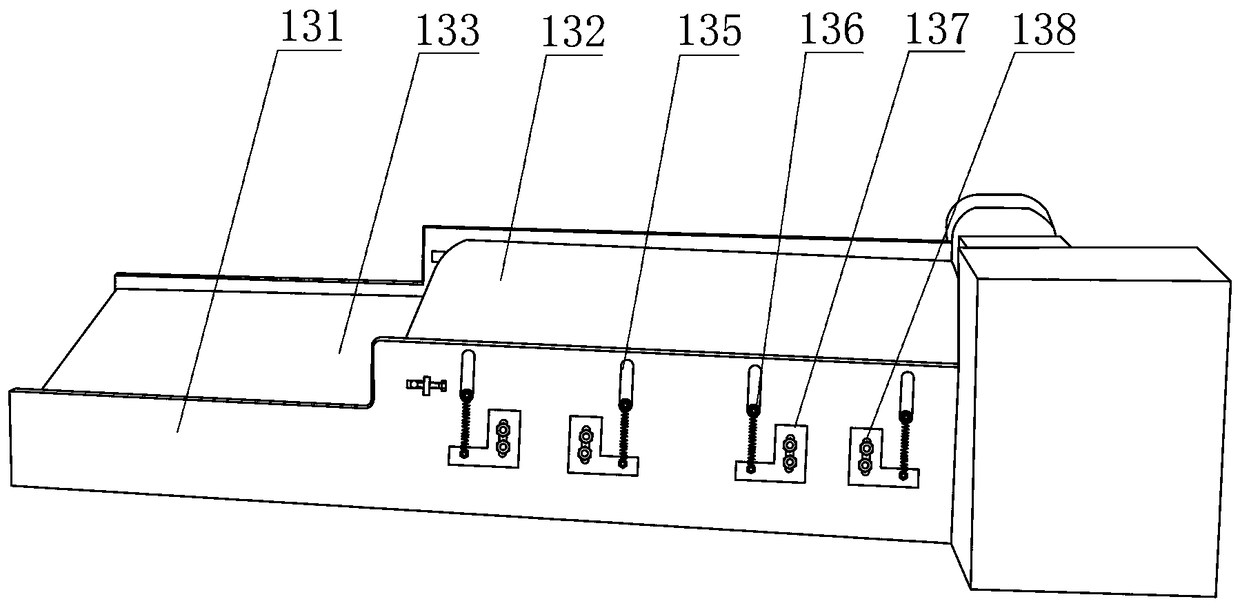

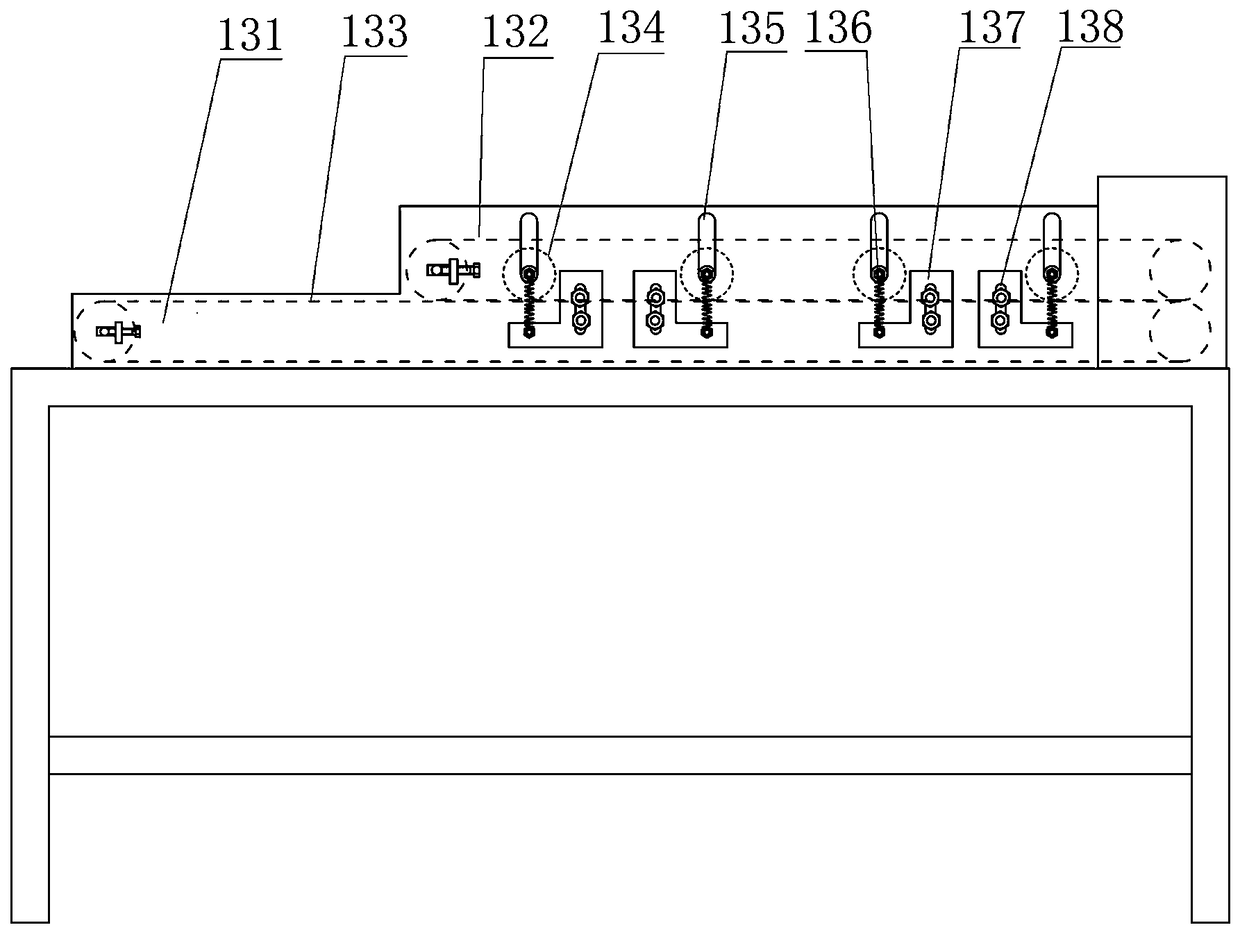

Micro-tension control system and control method for GDL fragile material

PendingCN114392885ASolve the technical problem that the micro-tension control of GDL materials cannot be realizedStable tension controlLiquid surface applicatorsCoatingsControl systemControl engineering

The invention discloses a micro-tension control system for a GDL fragile material. The micro-tension control system comprises a controller, a detection mechanism and an execution mechanism, the controller comprises a power supply module, a CPU module and an analog quantity input and output module which are connected in sequence; the execution mechanism comprises a floating swing roller servo driver, a floating swing roller servo motor and a floating swing roller which are connected in sequence, and further comprises a driving roller servo driver, a driving roller servo motor, a speed reducing mechanism and a driving roller which are connected in sequence, and the detection mechanism comprises a linear potentiometer, a tension roller, a tension sensor and a tension amplifier. Tension is controlled and displayed by the floating swing roller driven by the servo motor, and the problem that existing equipment cannot achieve GDL fragile material micro-tension control is solved. The invention further discloses a micro-tension control method of the GDL fragile material, the tension of the material film is controlled through a double-speed closed loop, the tension control is stable and high in precision, the operation is convenient and fast, time is saved, and the control efficiency is high.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Routing mechanism of winding machine

InactiveCN104157446ASimple structureReduce failureManufacturing dynamo-electric machinesCoils manufactureWinding machineEngineering

The invention discloses a routing mechanism of a winding machine. A wire passing mechanism is arranged on a holding frame, an enamel covered wire is led out from an enamel covered wire plate, passes through the wire passing mechanism and enters the winding machine, the wire passing mechanism is composed of a plurality of pieces of wood felt which are arranged in an up-and-down mode, each piece of wool felt is provided with an adjusting nut, and the enamel covered wire penetrates through the wool felt which is arranged in the up-and-down mode. According to the routing mechanism of the winding machine, the structure is simple, faults are few, maintaining is convenient, noise pollution is reduced, stable tension control is provided, the winding process of products is improved, and production efficiency is improved.

Owner:环一军

Device for controlling tension during production of flexible materials

The embodiment of the invention provides a device for controlling tension during the production of flexible materials. The device comprises a turnover mechanism arranged on a workbench frame, a tension control mechanism and a first linear guide rail arranged on the workbench frame, and wherein the turnover mechanism comprises a supporting seat, an arc-shaped turnover part and a power assembly; thearc-shaped turnover part is embedded into an arc-shaped groove of the supporting seat; the power assembly drives the arc-shaped turnover part to rotate in the arc-shaped groove; the tension control mechanism comprises a fixed roller and a floating roller which are used for clamping a raw material core rod, the fixed roller is fixedly connected with the supporting seat, and the floating roller ismovably connected with the arc-shaped turnover part; and a sliding table is arranged on the first linear guide rail, and the sliding table is driven by a driving mechanism and has a working stroke anda returning stroke. According to the device, the raw material core rod is clamped by the matching of the fixed roller and the floating roller, and the stable tension control can be achieved under theconditions that the diameter of the raw material core rod, the conveying tension of an external roller and the thickness of the flexible materials are uneven.

Owner:苏州红橙蓝机器人有限公司

Thermoplastic sheet forming machine

The invention provides a thermoplastic sheet forming machine and particularly relates to the technical field of carbon fiber sheet production. The thermoplastic sheet forming machine comprises a rack, a rail and a mechanical arm, wherein the rail and the mechanical arm are arranged on the rack. The rack is provided with a storage area, a die area and a baking area in sequence, the storage area is connected with the baking area through the rail, and the baking area is connected with the die area through the rail. The baking area is provided with a ceramic heater and a temperature sensor, the die area is provided with a plurality of dies and an extremely-cold extremely-hot device connected with the dies, and the mechanical arm is placed on the baking area and slides on the rail. By means of the thermoplastic sheet forming machine, a series of actions from baking and transferring to pressing can be automated so that a thermoplastic sheet can be produced efficiently, heated uniformly and cooled rapidly, and tension control can be stable.

Owner:上伟(江苏)碳纤复合材料有限公司

A control method for integrated printing and embossing of rotary screen gravure printing

InactiveCN105109221BSimple mechanical structureImprove controlRotary pressesOther printing apparatusProgrammable logic controllerControl system

The invention discloses a rotary screen gravure integrated printing embossing control method, based on the rotary screen gravure integrated printing embossing control system, the specific structure of the rotary screen gravure integrated printing embossing control system is: the motion controller passes through the Ethernet switch They are respectively connected with the PLC programmable logic controller and the HMI touch screen, and the motion controller also controls the plate roller shaft, the circular servo Mesh shaft, water-cooled shaft, embossing shaft, sending and pulling shaft, the motion controller also controls the feeding shaft and pulling shaft by controlling the frequency converter for feeding, unwinding, water cooling for embossing, and pulling in. , embossing water-cooled shaft, take-up shaft, the combination of rotary screen, gravure, and embossing to realize precise overprinting among any three. The invention solves the problem of single overprinting method in the prior art.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

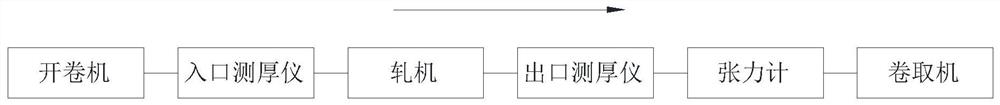

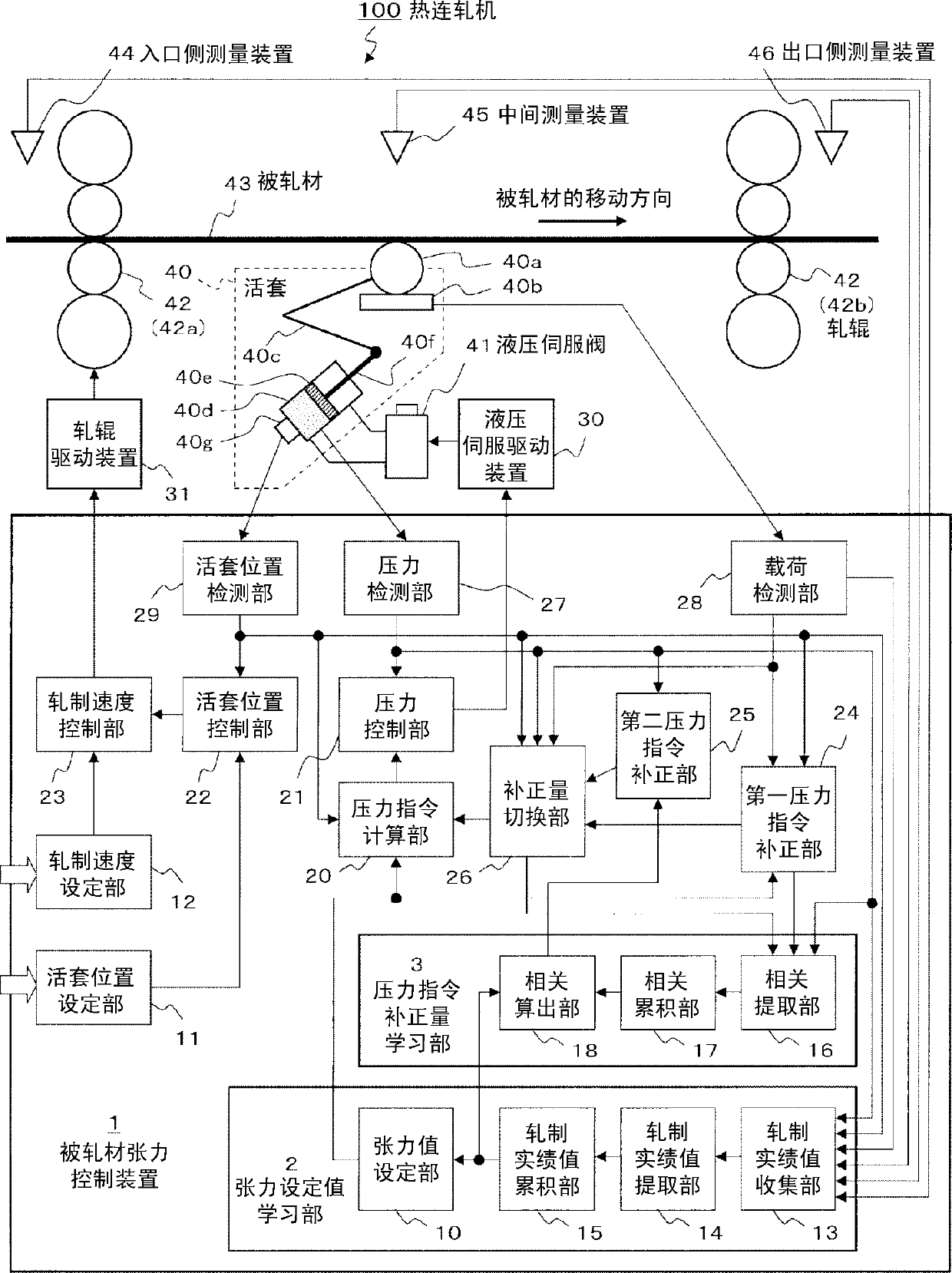

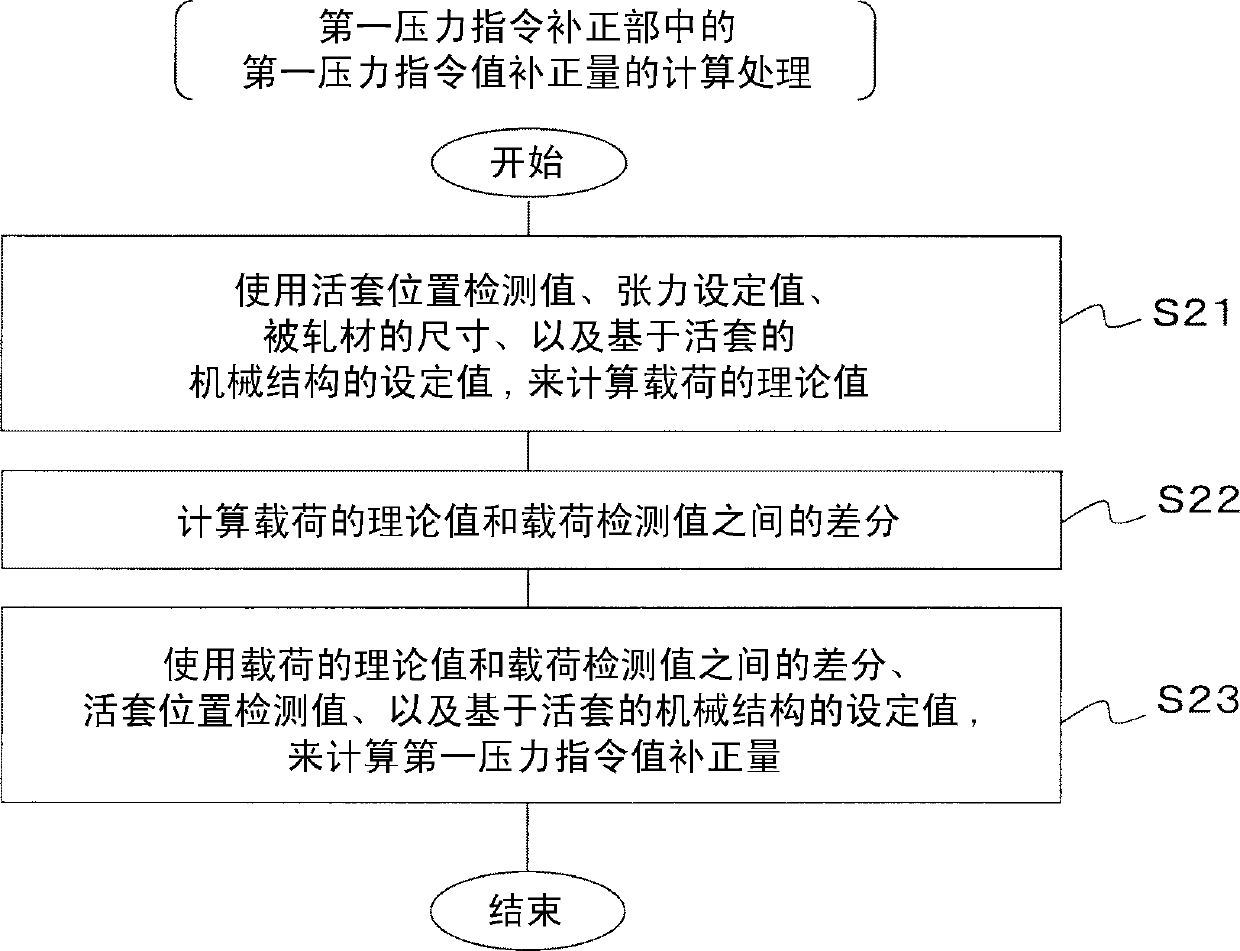

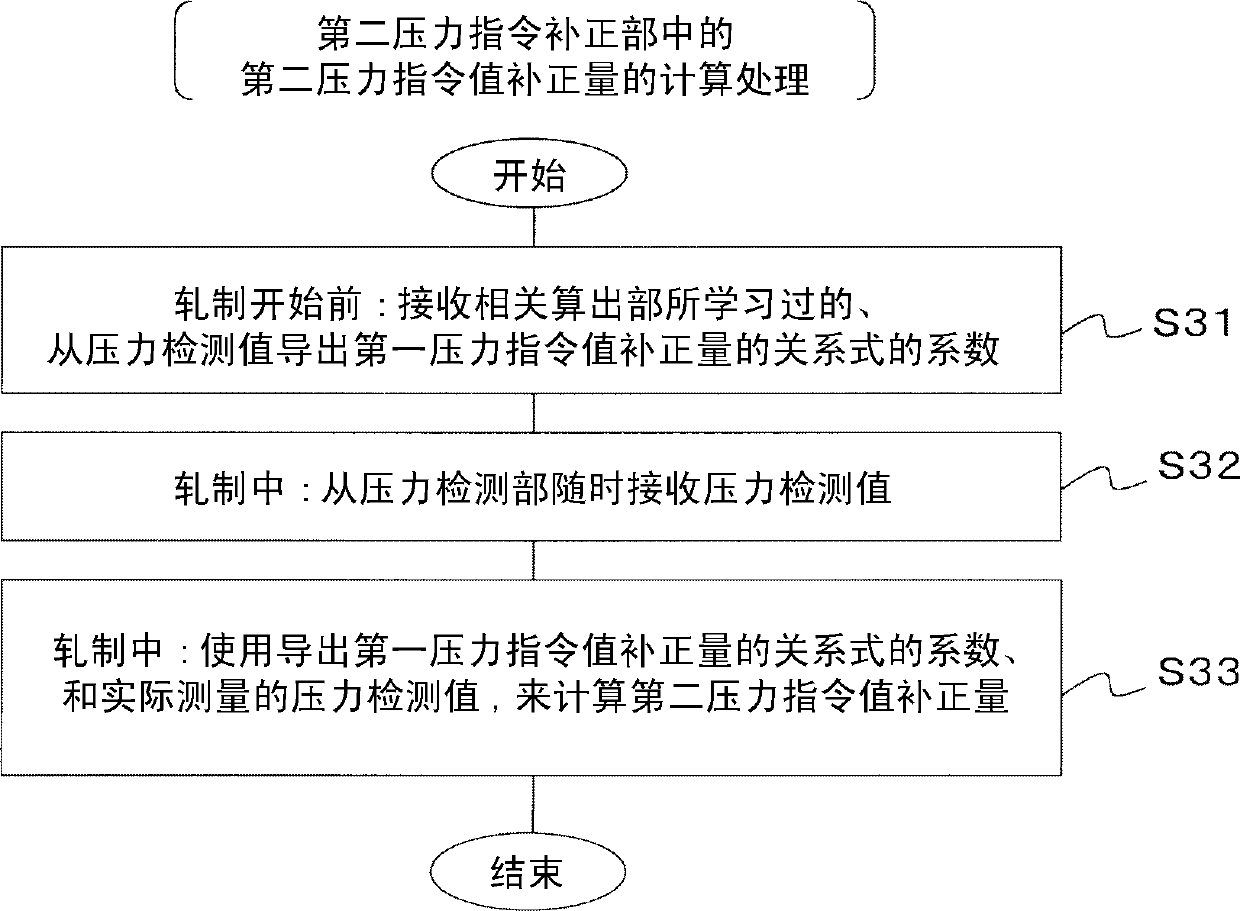

Rolled product tension control device, rolled product tension control method and hot strip mill

ActiveCN102451837BStable tension controlReduce the amount of variationTension/compression control deviceNormal loadTension control

The invention relates to a rolled product tension control device, a rolled product tension control method and a hot strip mill, wherein the tension on rolled products can be stably controlled. When a load detection value obtained from a load detection part (28) is normal, a pressure command correction quantity learning part (3) indicates the relation coefficient of the correlativity between a pressure detection value obtained from a pressure detection part (27) and a first pressure command correction quantity calculated through a first pressure command correcting part (24). When the load detection part can not obtain a normal load detection value, a rolled product tension control device (1) switches the pressure command correction quantity adopted by a pressure command calculating part (20) from a first pressure command correction quantity to a second pressure command correction quantity calculated through a second pressure command correcting part (25). Since the above correction quantities are related to each other, the change of the correction quantities during the switching process is not large. Therefore, the tension on rolled products can be stably controlled.

Owner:HITACHI LTD

A film center surface winder

The invention discloses a thin film center and surface winding machine which comprises a machine frame. An inflatable shaft, a tension roller, a cutter device, a flattening arc roller, a clamping roller, a large slotting rubber roller, a thin film cutting-off device, an inflatable shaft conveying device, a winding trolley device, a coil discharging device and an inflatable shaft accelerating device. A moving guide assembly is arranged between the machine frame and the winding trolley device, the winding trolley device moves on the machine frame in a linear mode through the moving guide assembly, and therefore the winding tension of the winding machine is controlled. Two parallel linear guide rails are arranged on the left side and the right side of the machine frame, and the winding trolley device moves on the machine frame in the linear mode through the two linear guide rails. The winding trolley device can achieve moving and horizontal adjusting functions, and the inflatable shaft placed on the winding trolley device can achieve the center winding and surface winding functions. The problem that the quality of wound finished products is poor due to the fact that a traditional thin film center and surface winding machine is integrated to a wall board is effectively solved, and flatness, smoothness and quality of the wound finished products are ensured.

Owner:广东恒立电气自动化有限公司

Tensioner with air brake function

Owner:WUJIANG KESHIDA TEXTILE

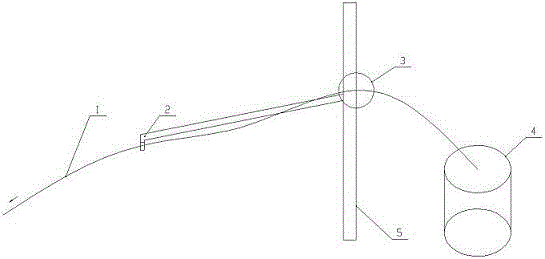

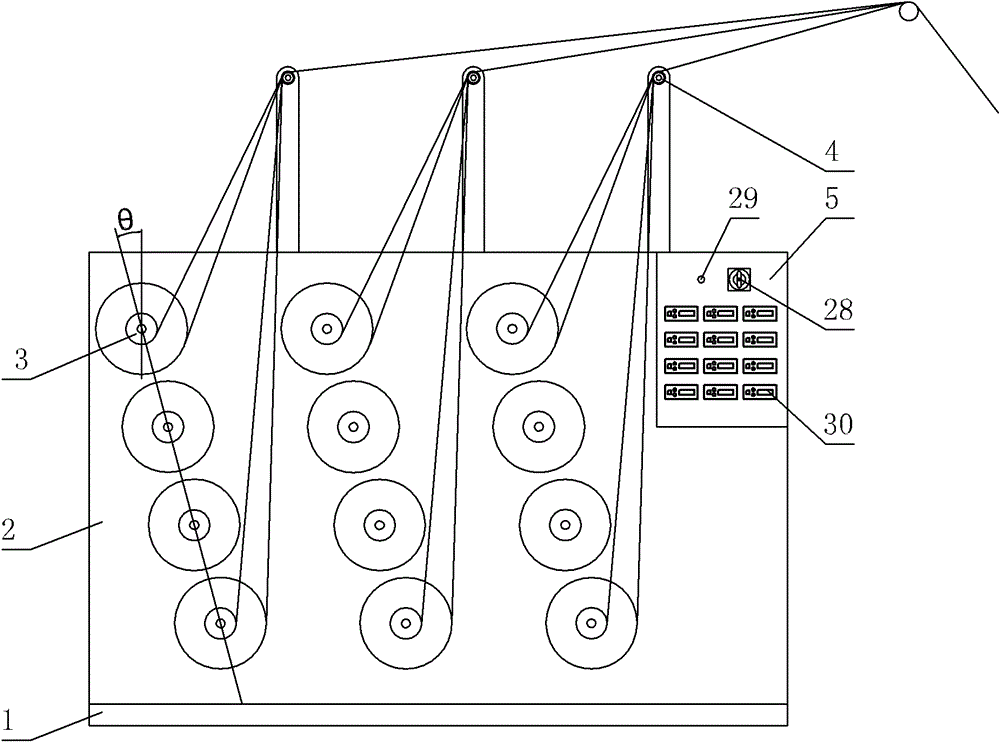

Wire-releasing machine for manufacturing continuous carbon fibers

The invention relates to a wire-releasing machine for manufacturing continuous carbon fibers, which comprises a case, a plurality of wire-releasing racks arranged on the side of the case in an array manner, a plurality of godet assemblies arranged at the top of the case through an installation rack, and a control case, wherein each godet assembly corresponds to a row of wire-releasing racks. The invention solves the technical problem that the wire-releasing rack of the conventional wire-releasing machine is unreasonably arranged and the fiber tension is unstable. Protofilament tows can be continuously delivered to the subsequent process for manufacturing carbon fibers through matching the wire-releasing racks with the godet assemblies so as to ensure that the fibers have stable tension in the wire-releasing process; tows slack and wire-releasing jumping are avoided; state consistency in the fiber wire-releasing process is improved; and the quality of the carbon fibers is improved.

Owner:西安航科等离子体科技有限公司

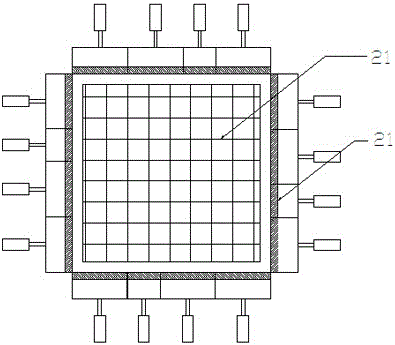

A high-stability composite screen making device

ActiveCN104325775BShort production timeStable tension controlForme preparationPolyesterScreen printing

The invention discloses a high-stability composite screen printing plate manufacturing device which comprises a base, wherein a bracket which is driven by power of a cylinder or an air cylinder is arranged on the base. The high-stability composite screen printing plate manufacturing device is characterized in that a lifting table surface is arranged on the bracket; a net frame pre-stressed device and an operation table which is positioned on the outer side of the net frame pre-stressed device are arranged on each side of the lifting table surface respectively; a polyester gauze and a net frame positioned above the polyester gauze are arranged among the net frame pre-stressed devices; a pneumatic or mechanical net pull machine is arranged on the operation table; a composite net gauze positioned above the net frame is arranged in the pneumatic or mechanical net pull machine. The high-stability composite screen printing plate manufacturing device is short in production time, stable in tension control, high in production efficiency, particularly applicable to large-scale production, wide in applicability, applicable to manufacturing of screen printing plates of different specifications and types and particularly applicable to manufacturing of high-stability composite screen printing plates, the pass percent of a product is increased, and the quality of the product is greatly improved.

Owner:FUZHOU UNIV

Automatic winding machine for spring wire

ActiveCN105665586BEnsure consistencyStable tension controlNon-rotating vibration suppressionWinding machineEngineering

The invention discloses an automatic wire winding machine for spring wires. The automatic wire winding machine comprises a wire winding drive device, a transfer device which is horizontal with the wire winding drive device, a wire cable guide device, a cut-off device, a vibration damping device. The wire cable guide device, the cut-off device and the vibration damping device move on the transfer device., a pay-off rack used for supporting cable coil stock, and a control unit, wherein the control unit is electrically connected to the wire winding drive device, the transfer device, the cut-off device, and the wire cable guide device. According to the automatic wire winding machine, the wire cable guide device, the cut-off device and the wire cable guide device are arranged on the transfer device, and are kept to be synchronous with the movement speed, on a wire winding shaft, of the wire cables, so that the wire cables are guaranteed to be perpendicular to the wire winding shaft all the time during the conveying process. Therefore, the automatic wire winding machine is beneficial for stabilizing tension control, and also guarantees the consistency of elastic force of a spring; the vibration damping device is arranged beside the wire winding shaft, and is synchronous with a cable to move along the wire winding shaft, so that the vibration of the wire winding shaft is further reduced, and therefore, the precision is improved.

Owner:SUZHOU CABLEPLUS ELECTRIC

Device for controlling tension dynamic balance of warp thread of loom

InactiveCN101581000BTo achieve the purpose of dynamic adjustmentReduce swingLoomsDynamic balanceEngineering

The invention belongs to the fitting device of a loom and particularly relates to a device for controlling tension dynamic balance of warp threads of the loom. The device comprises a resistance disc (5), a resistance rope (6), a spring (9) and a fixed bracket (7); the resistance rope (6) is connected with the resistance disc (5); the fixed bracket (7) is shaped like T or 7; two ends of a transverse rod of the fixed bracket (7) are connected with a stander (1) and a guide roller (8) respectively; the lower end of a vertical rod of the fixed bracket (7) is connected with a tension balance bracket (2); the vertical rod body is connected with a displacement adjusting device (4); one end of the resistance rope (6) is connected with the displacement adjusting device (4) and the other end thereofis connected with the external end of the tension balance bracket (2); the tail end of the external end of the tension balance bracket (2) is connected with a tension balance roller (12); and the tension balance bracket (2) is connected with the fixed bracket (7) by a spring displacement adjusting device (10) and the spring (9). The device achieves the object of dynamically adjusting balance, generates an error of less than 0.25 percent during the operation process, and has small swing amplitude and stable tension control.

Owner:张木辉

A kind of real-time control system and control method of shearing machine tension

ActiveCN103938405BHigh degree of mechatronicsConstant speedMechanical pressure/force controlTextile shapingReal-time Control SystemHuman–machine interface

The invention discloses a real-time control system and method for tension of a wool shearing machine. The real-time control system comprises a PLC (Programmable Logic Controller), wherein the PLC is connected with a human-computer interface touch screen through an RS232 serial communication wire; a high-speed pulse output port of the PLC is connected with a servo driving module through a circuit; the PLC is connected with a variable-frequency driving module through an RS485 bus; the PLC is also respectively connected with a speed detecting module, a tension detecting module, a metal detector and a seam detector through circuits. Through real-time control on rotating speeds of a cloth feeding roller, a front guide roller, a brush roller, a cloth guider, a wool shearing roller, a rear guide roller and a cloth discharging roller, the precise control and stepless regulation on the tension of a fabric is realized, the wool shearing height is more precise, and the height error is reduced.

Owner:HANGZHOU XUREN TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com