Real-time control system and method for tension of wool shearing machine

A real-time control system, shearing machine technology, applied in the control/adjustment system, mechanical pressure/force control, non-electric variable control and other directions, can solve the problems of unstable tension control, affecting product quality, many failures, etc., to achieve constant tension , Improve the degree of mechatronics and the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

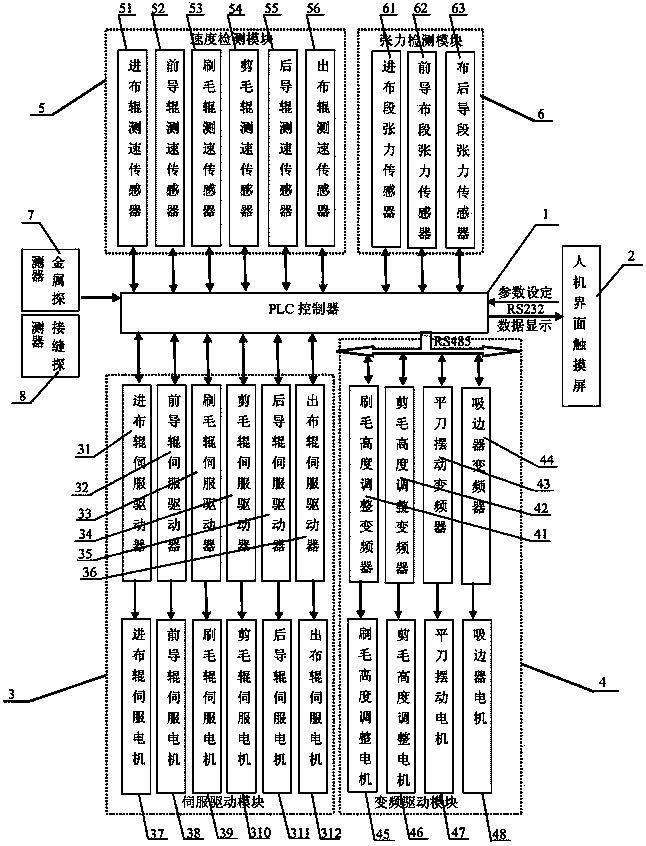

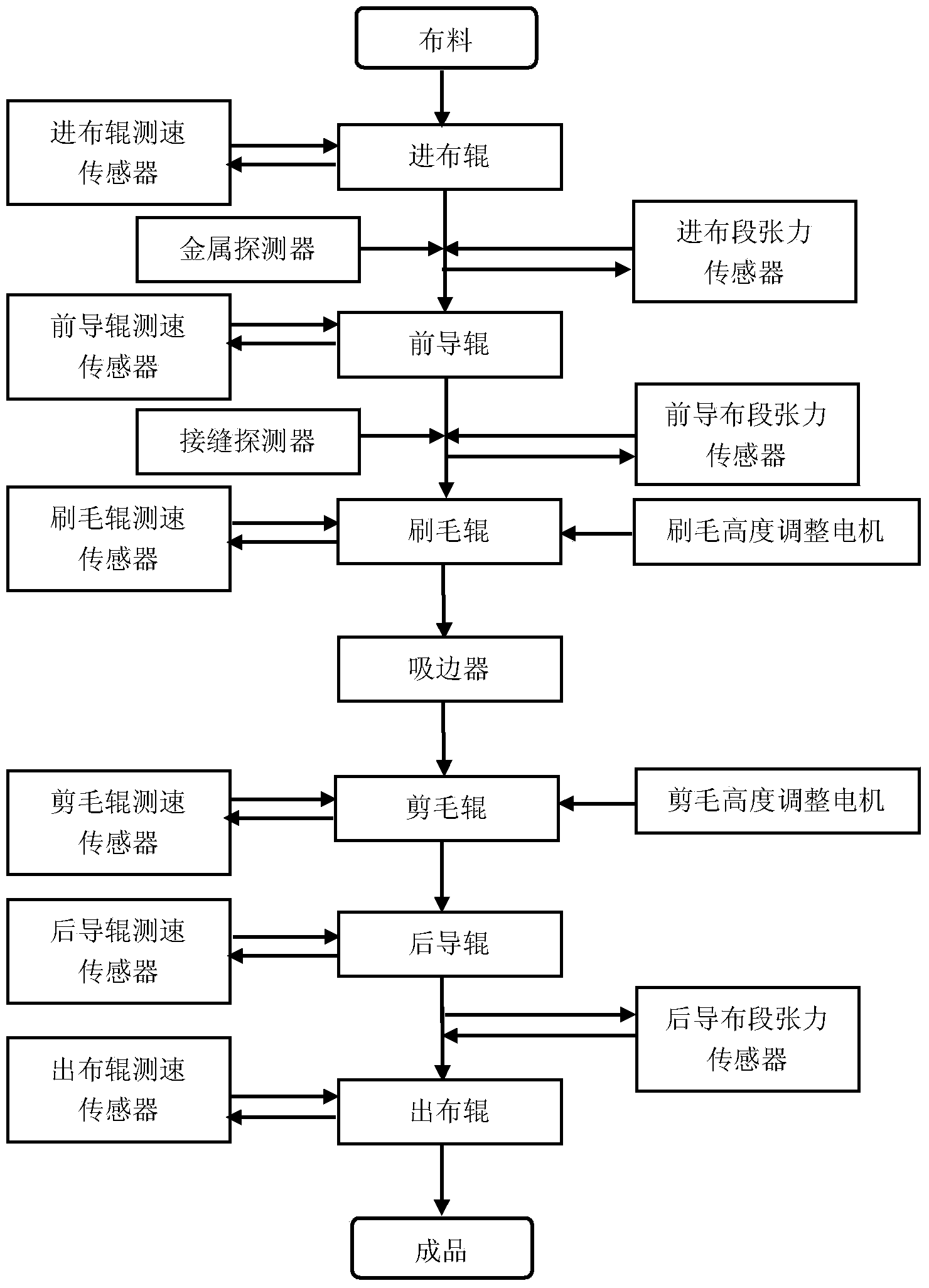

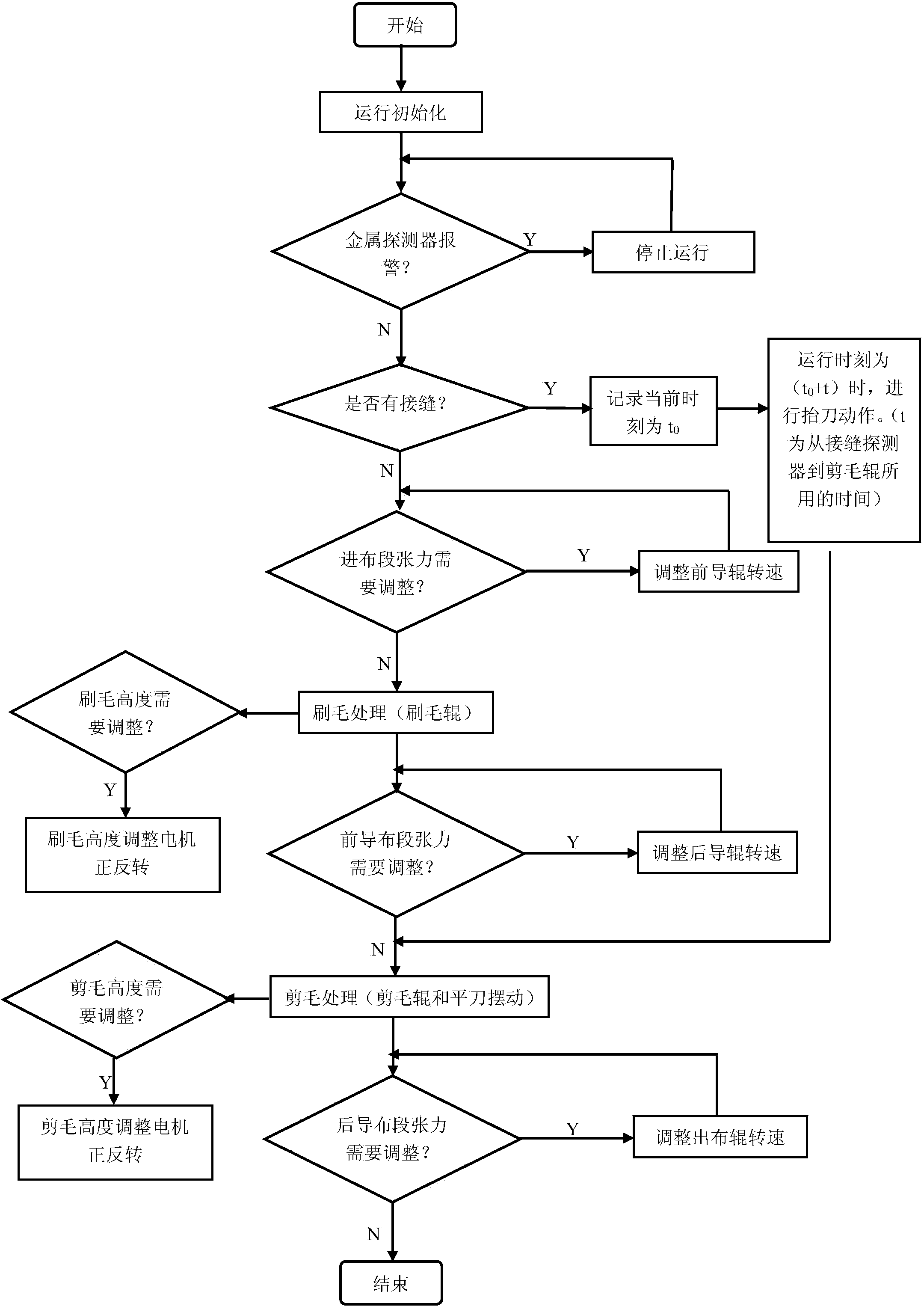

[0018] A kind of shearing machine tension real-time control system of the present embodiment, such as figure 1 As shown, it includes a PLC controller 1, the PLC controller 1 is connected with the man-machine interface touch screen 2 through the RS232 serial port communication line, the input and output of the PLC controller 1 is realized through the man-machine interface touch screen 2, and the man-machine interface The interface touch screen 2 realizes the control of the PLC controller 1 by setting operating parameters, and monitors the operating status of the PLC controller 1 in real time; the high-speed pulse output port of the PLC controller 1 is connected with the servo drive module 3 through a line; The PLC controller 1 is connected to the variable frequency drive module 4 through the RS485 bus; the PLC controller 1 is also connected to the speed detection module 5, the tension detection module 6, the metal detector 7 and the seam detector 8 through lines respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com