Patents

Literature

442results about How to "Constant tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

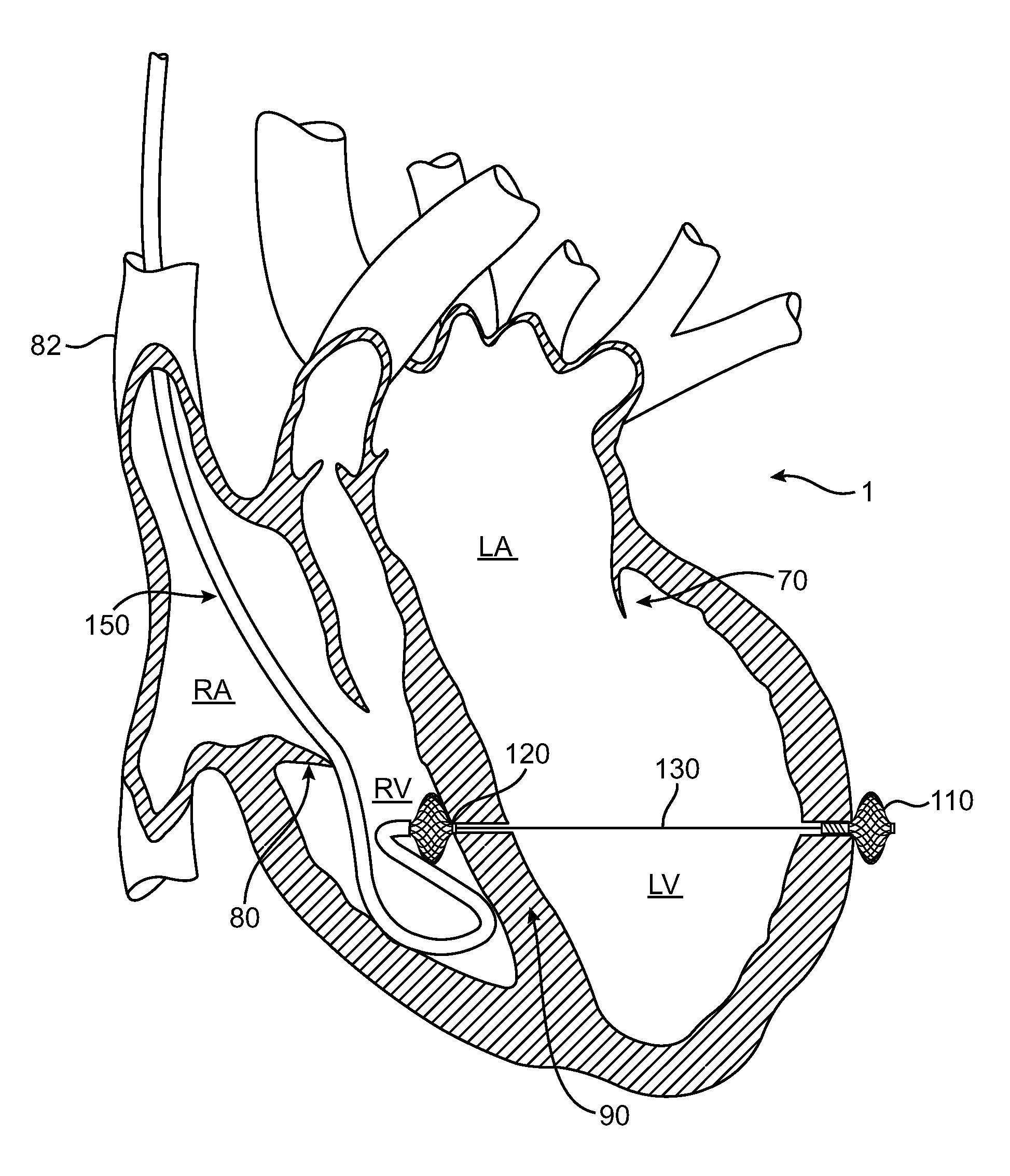

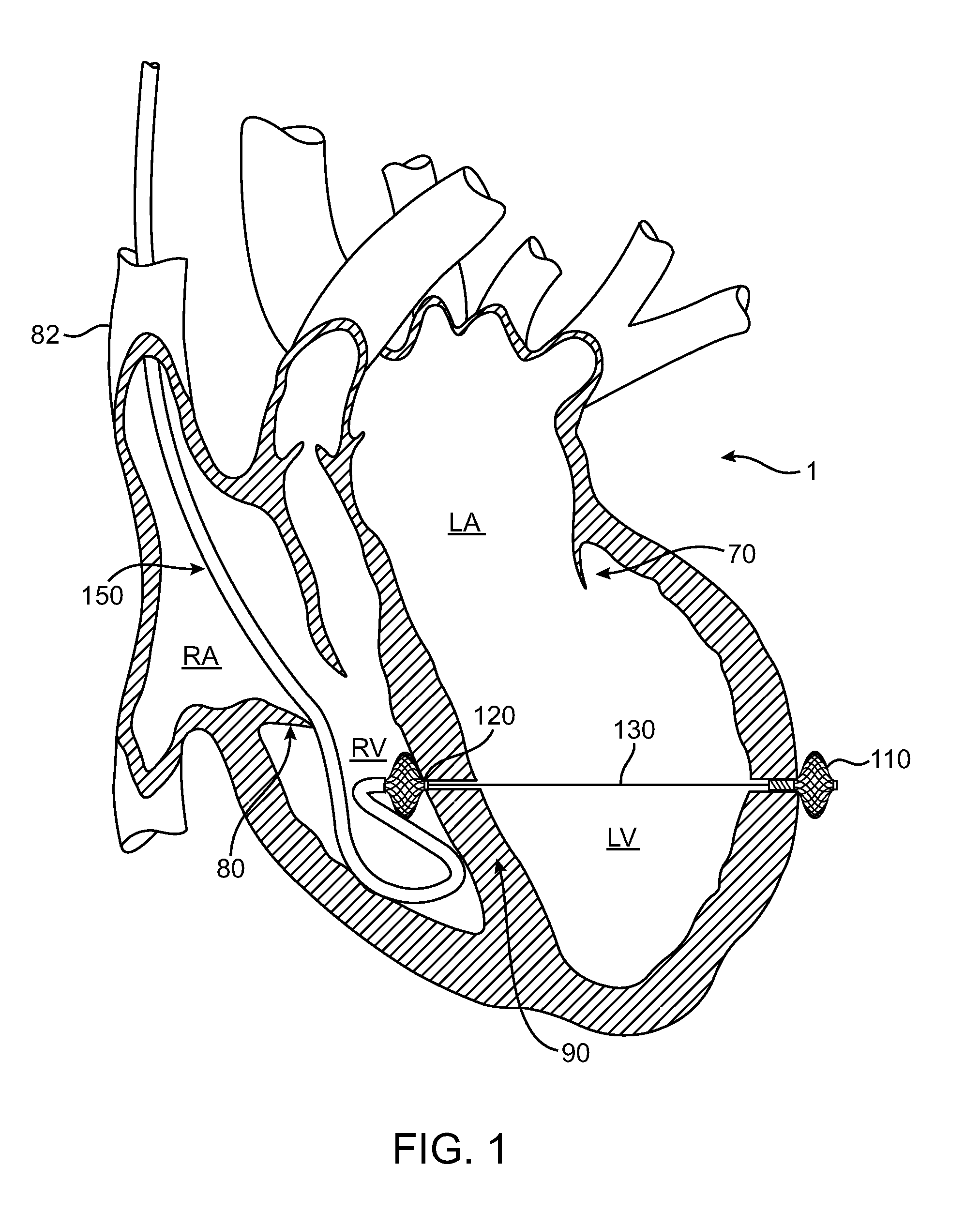

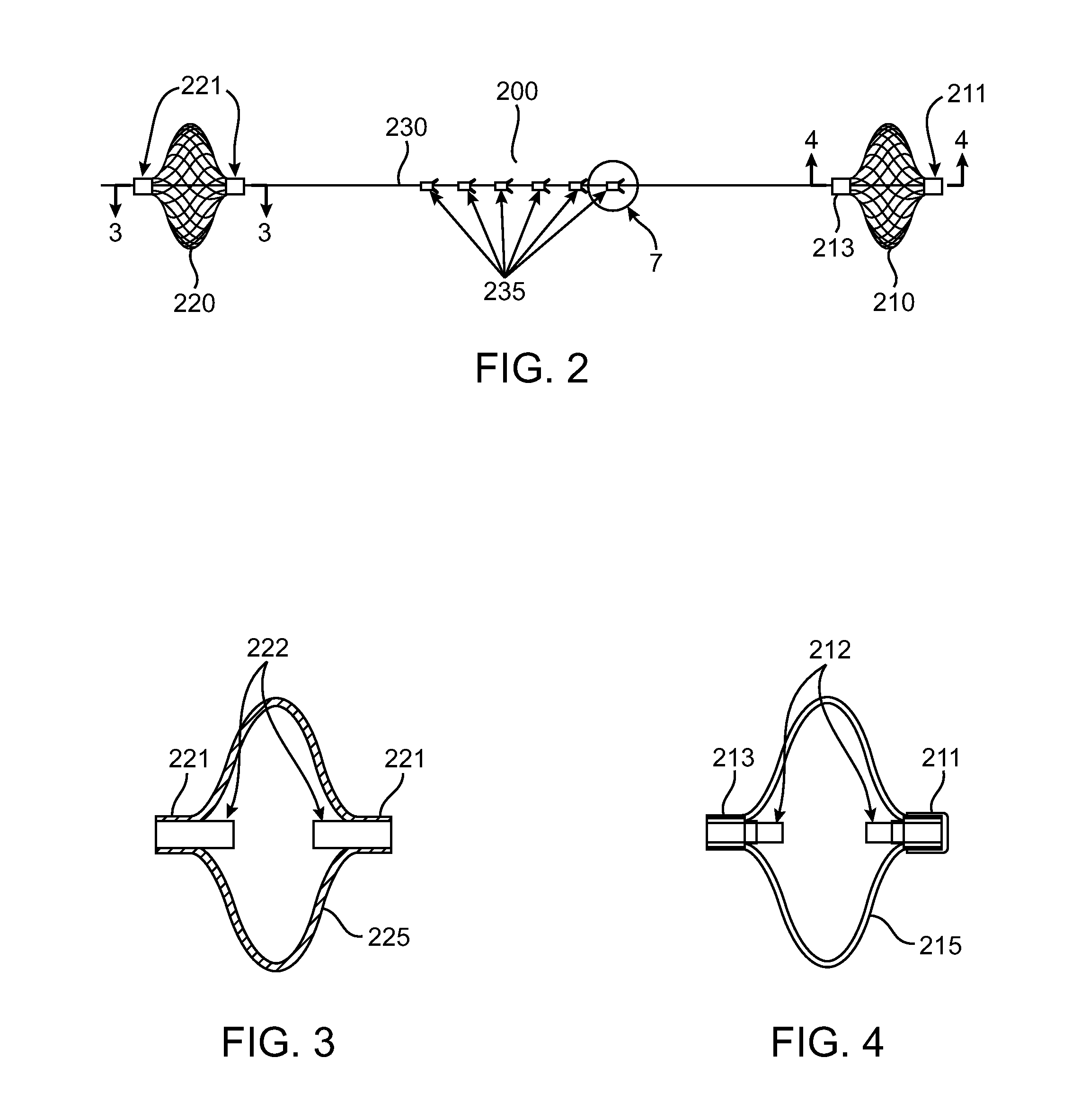

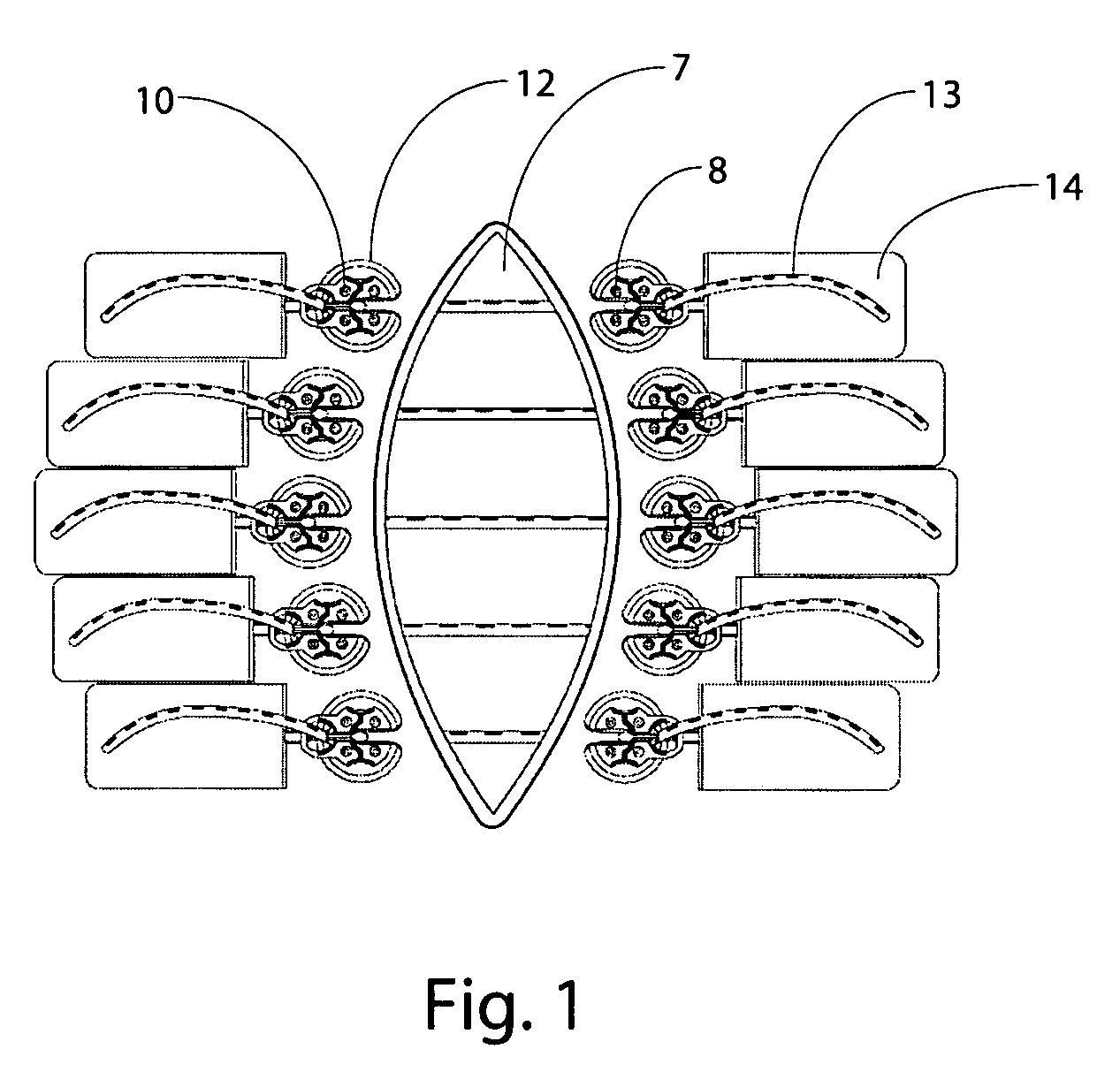

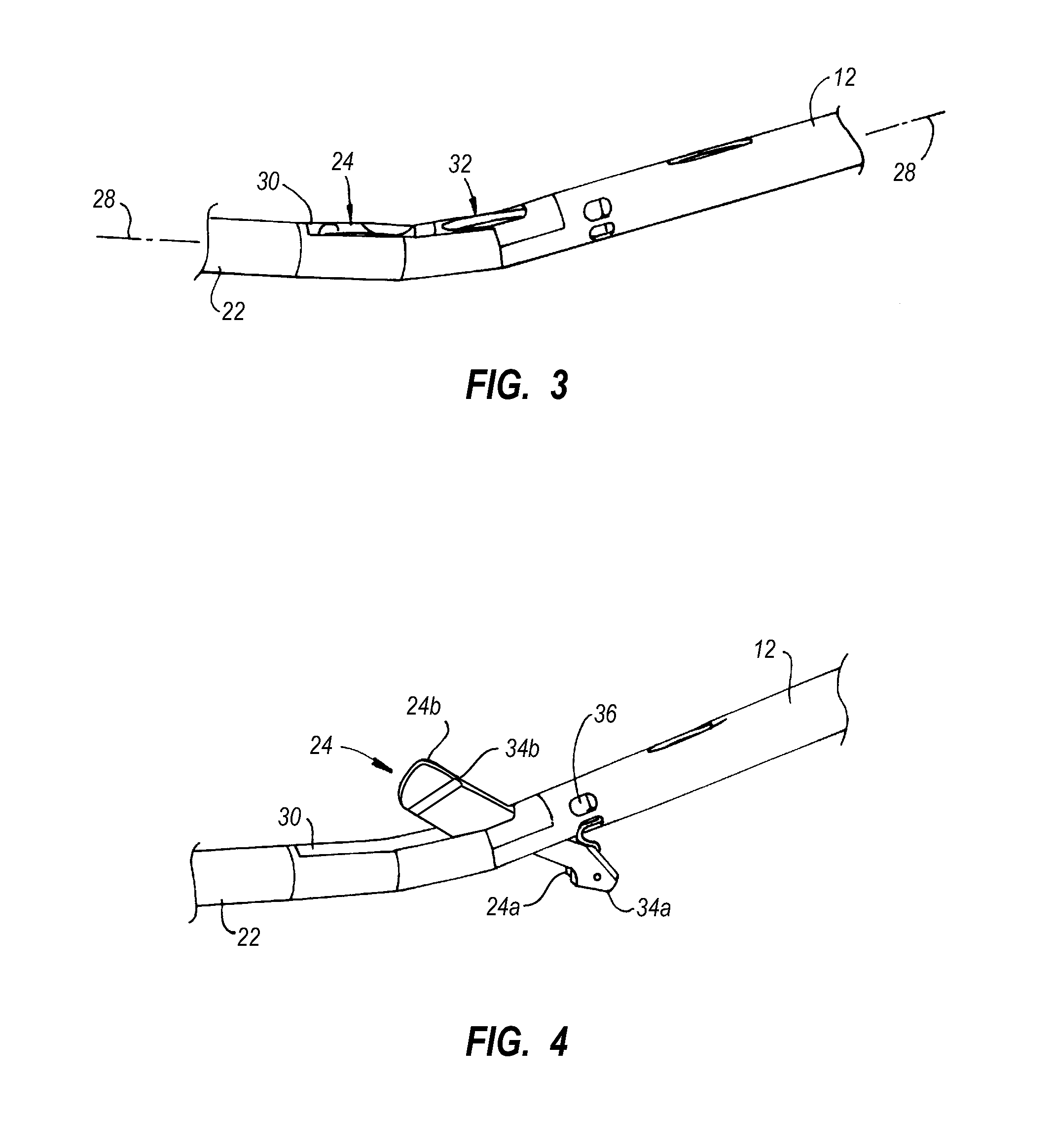

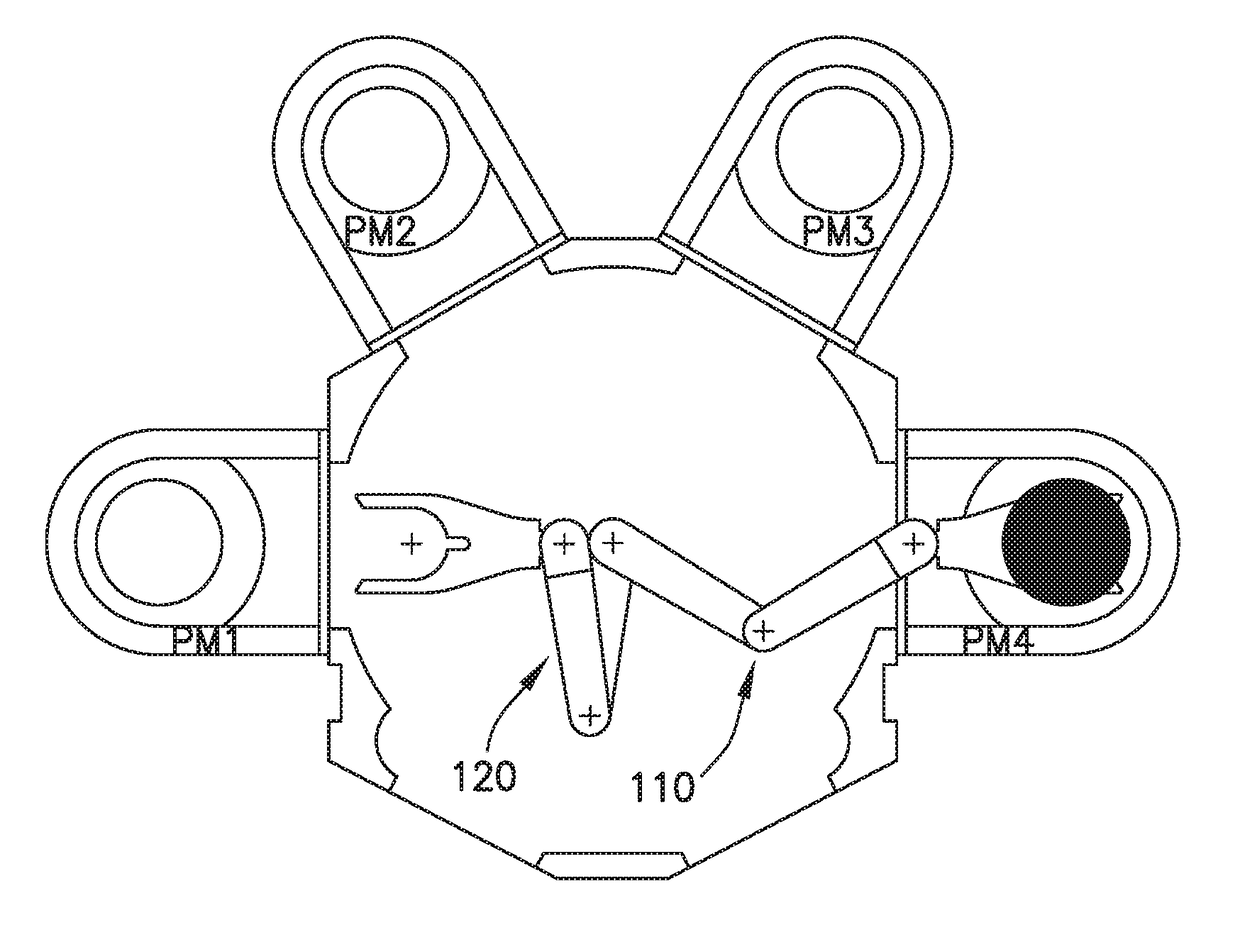

System for Treating Mitral Valve Regurgitation

InactiveUS20070203391A1Reduce lateral distanceConstant tensionSuture equipmentsSurgical needlesTension memberLeft Ventricles

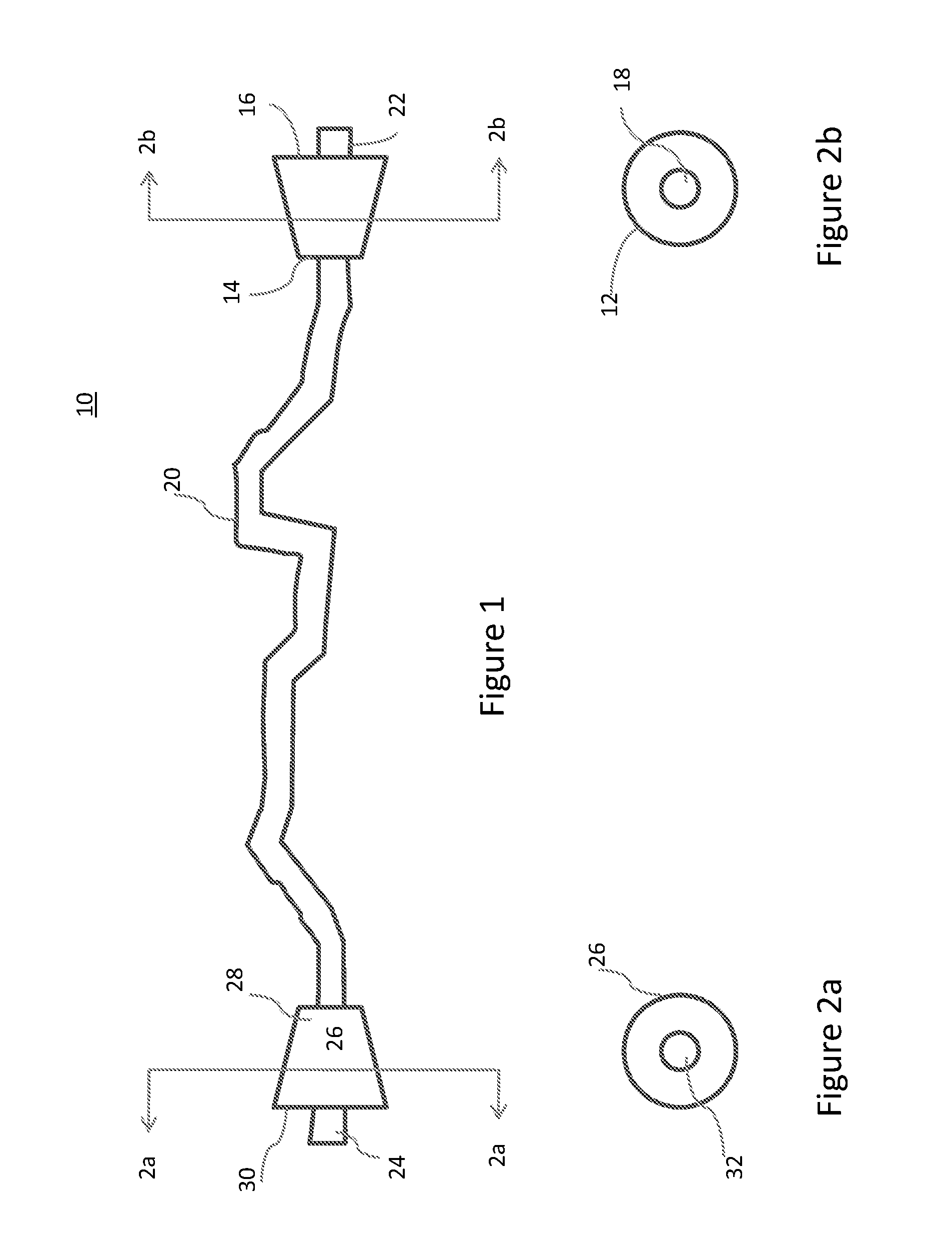

A system for treating mitral valve regurgitation comprising at least delivery catheters, puncture catheters, and tensioning devices. The devices include tension members linking a proximal anchor and distal anchor that can be constructed from a tubular braded material and have internal reinforcing members. In some embodiments, the anchors and tension members may flex in response to a heart beat. The system can also include temporary anchors so a clinician can review and adjust the vector of the tension member. Delivery catheters can also include temporary anchors to secure the catheter in position. When positioned across the left ventricle of a heart, the device can reduce the lateral distance between the walls of the ventricle and thus allow better coaption of the mitral valve leaflets thereby reducing heart valve regurgitation.

Owner:MEDTRONIC VASCULAR INC

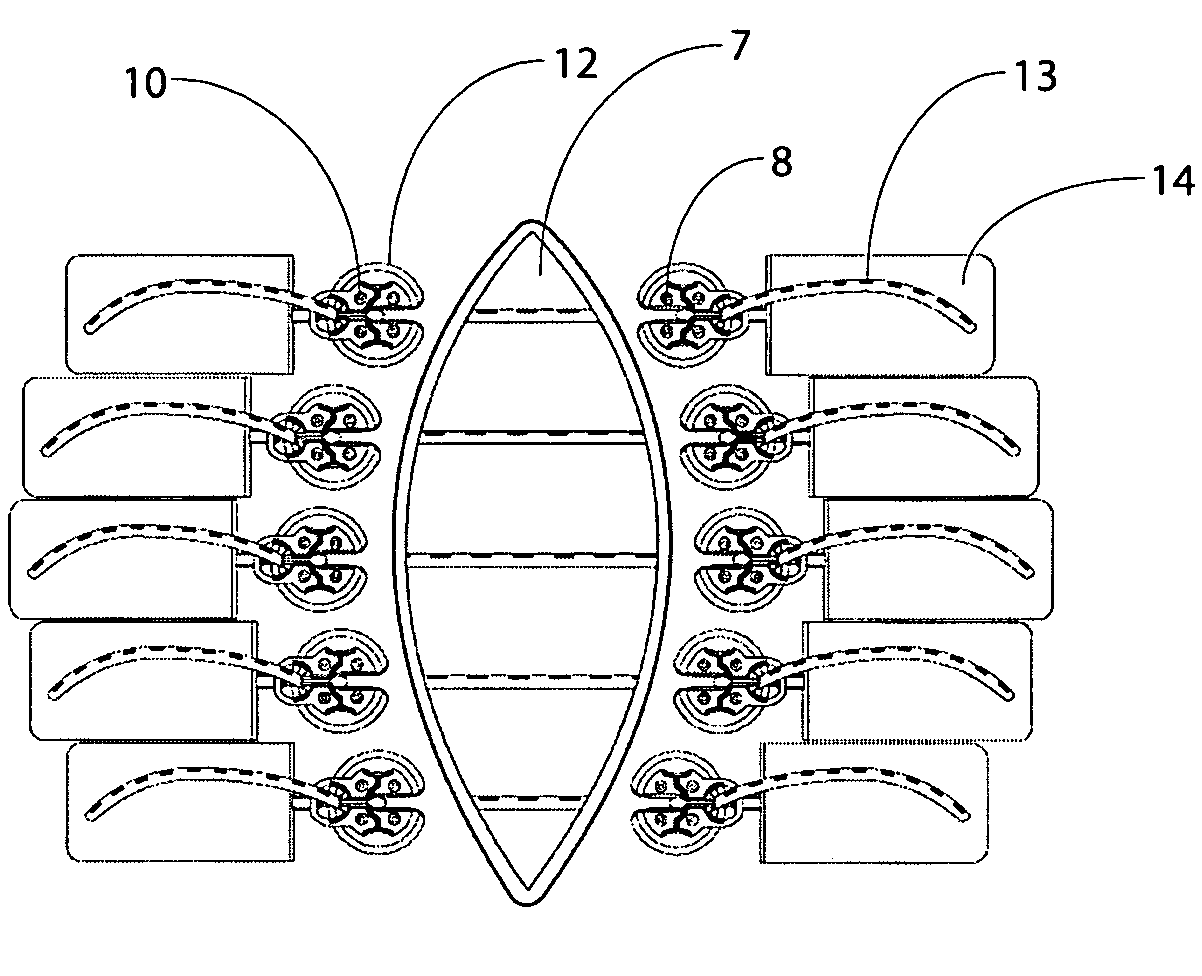

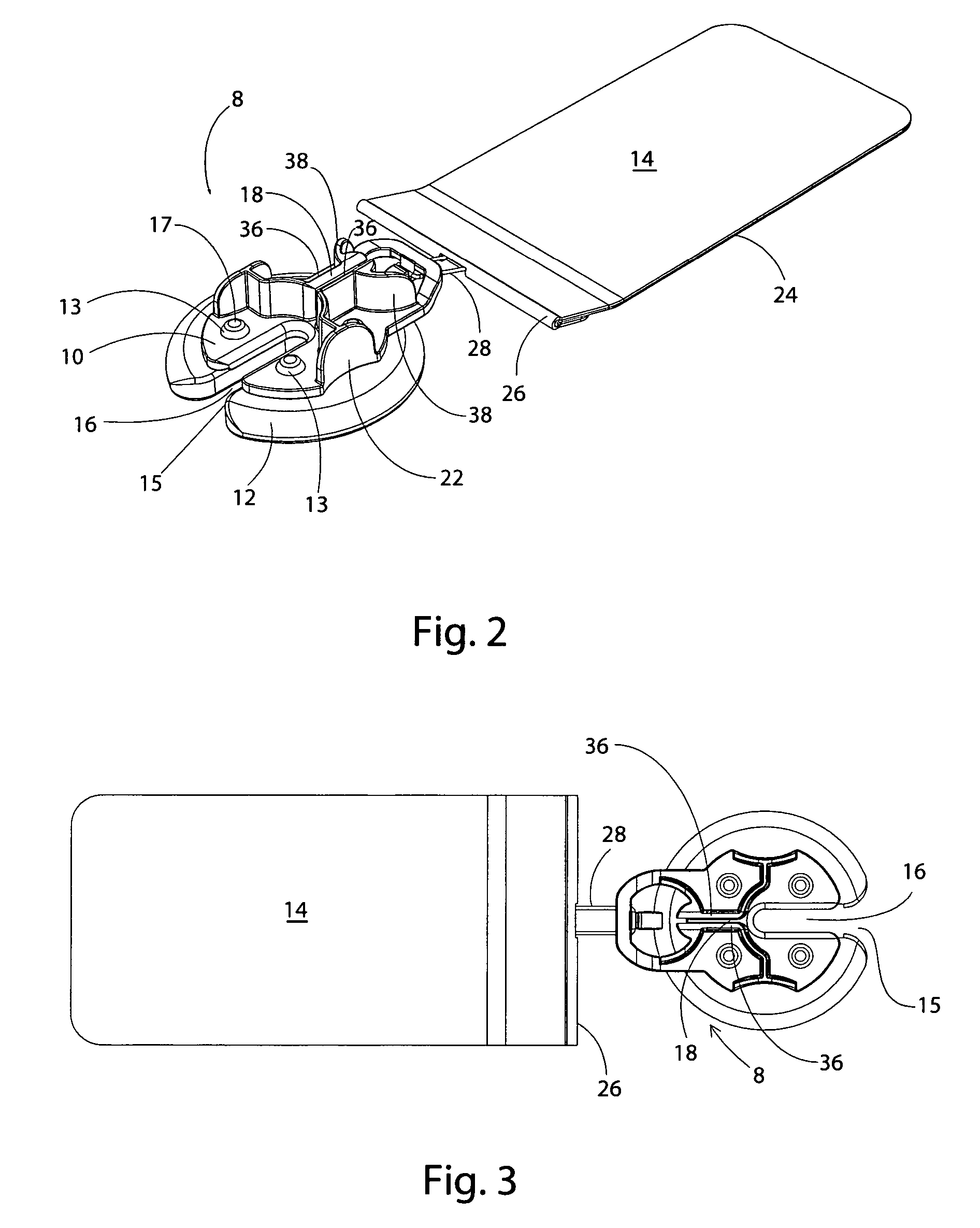

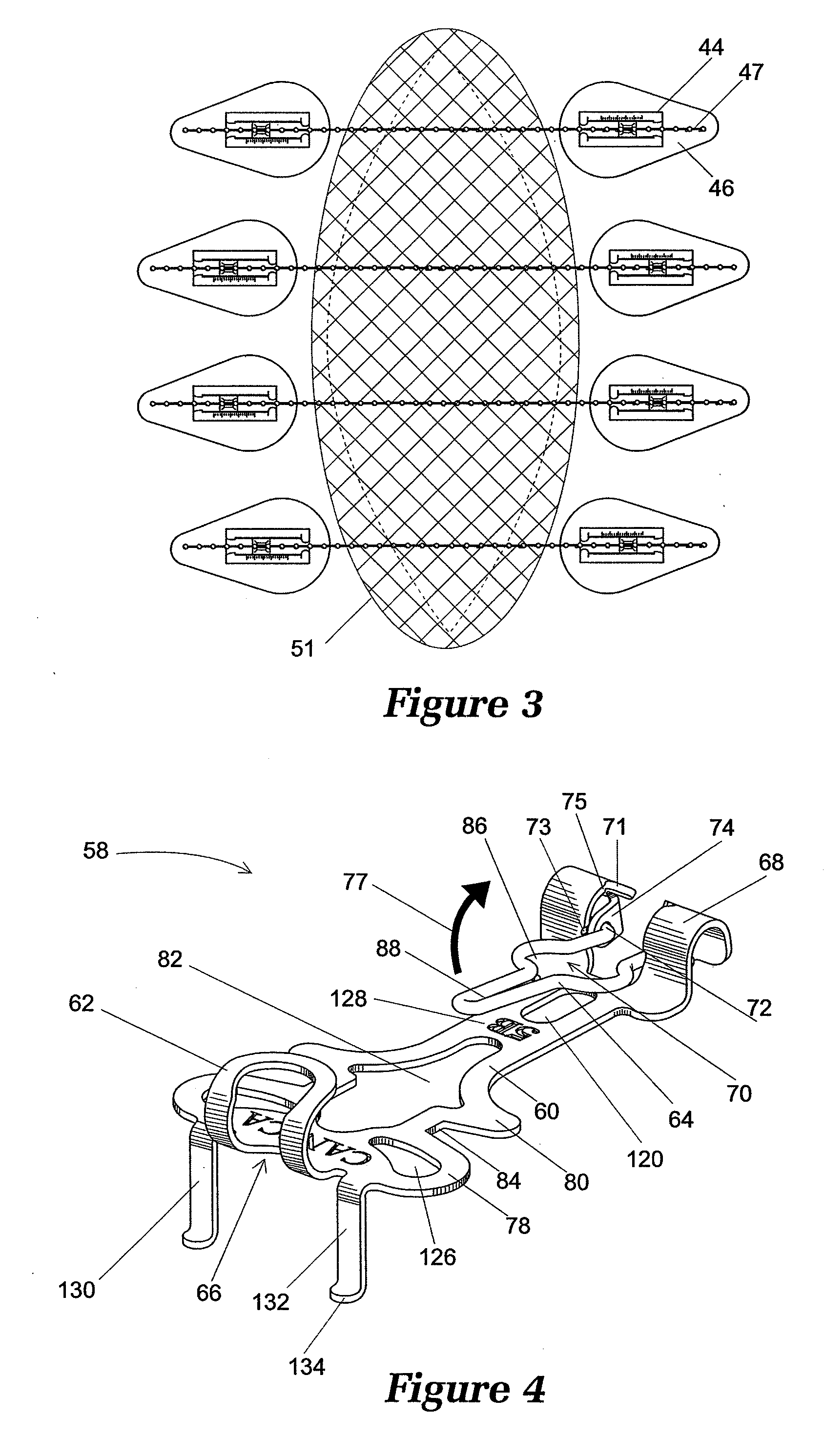

Button anchor system for moving tissue

InactiveUS20060064125A1Simple and easy to useCost-effectiveSuture equipmentsSurgical veterinaryReactive componentsFull thickness

A system of non-reactive components for moving or for moving and stretching plastic tissue that exerts a relatively constant dynamic force over a variety of distances and geometries, that is easily adjustable, and is self-adjusting. This system includes a “button anchor system” for moving tissue, particularly including deep fascia and muscle layers of the abdominal or thoracic cavity wall, in surgical, post surgical, and post traumatic reconstruction where the wound margins are beyond a distance that permits normal re-approximation. Button anchor assemblies allow re-approximation of severely retracted abdominal wall and full thickness thoracic wounds where a closure force is required to be applied to the sub-dermal layers. Systems of this invention allow for such a force to be applied and externally controlled during treatment.

Owner:CANICA DESIGN

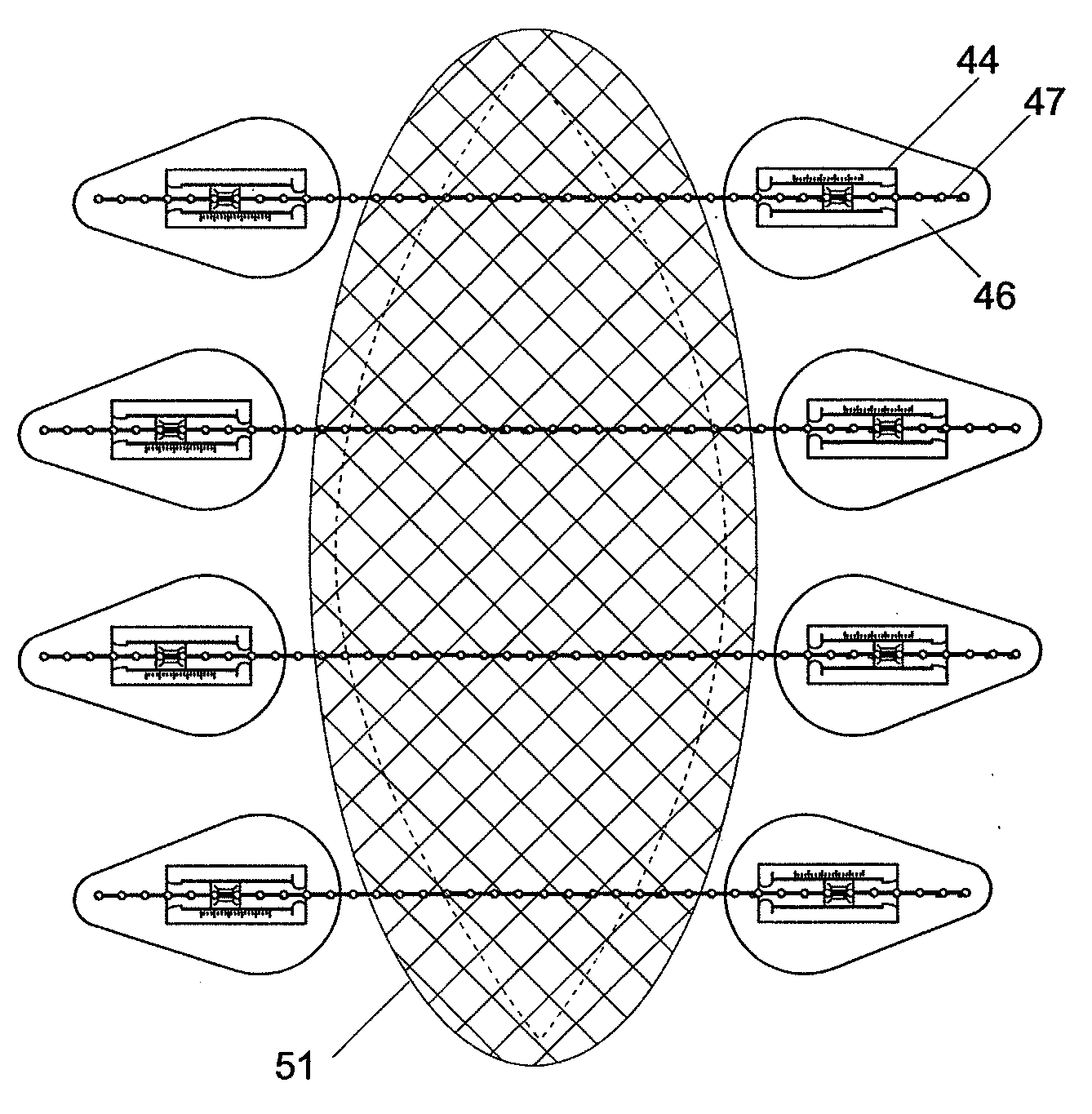

Clinical and Surgical System and Method for Moving and Stretching Plastic Tissue

InactiveUS20080147115A1Easy to useConstant forceSurgical veterinaryWound clampsBiomedical engineeringSelf adjusting

A system and method of moving and stretching plastic tissue using dynamic force. A preferably non-reactive force applying component is adjustably attachable to one or more tissue attachment structures for securing the force applying component to the plastic tissue, providing a self adjusting system that is capable of exerting relatively constant tension over a certain distance.

Owner:CANICA DESIGN

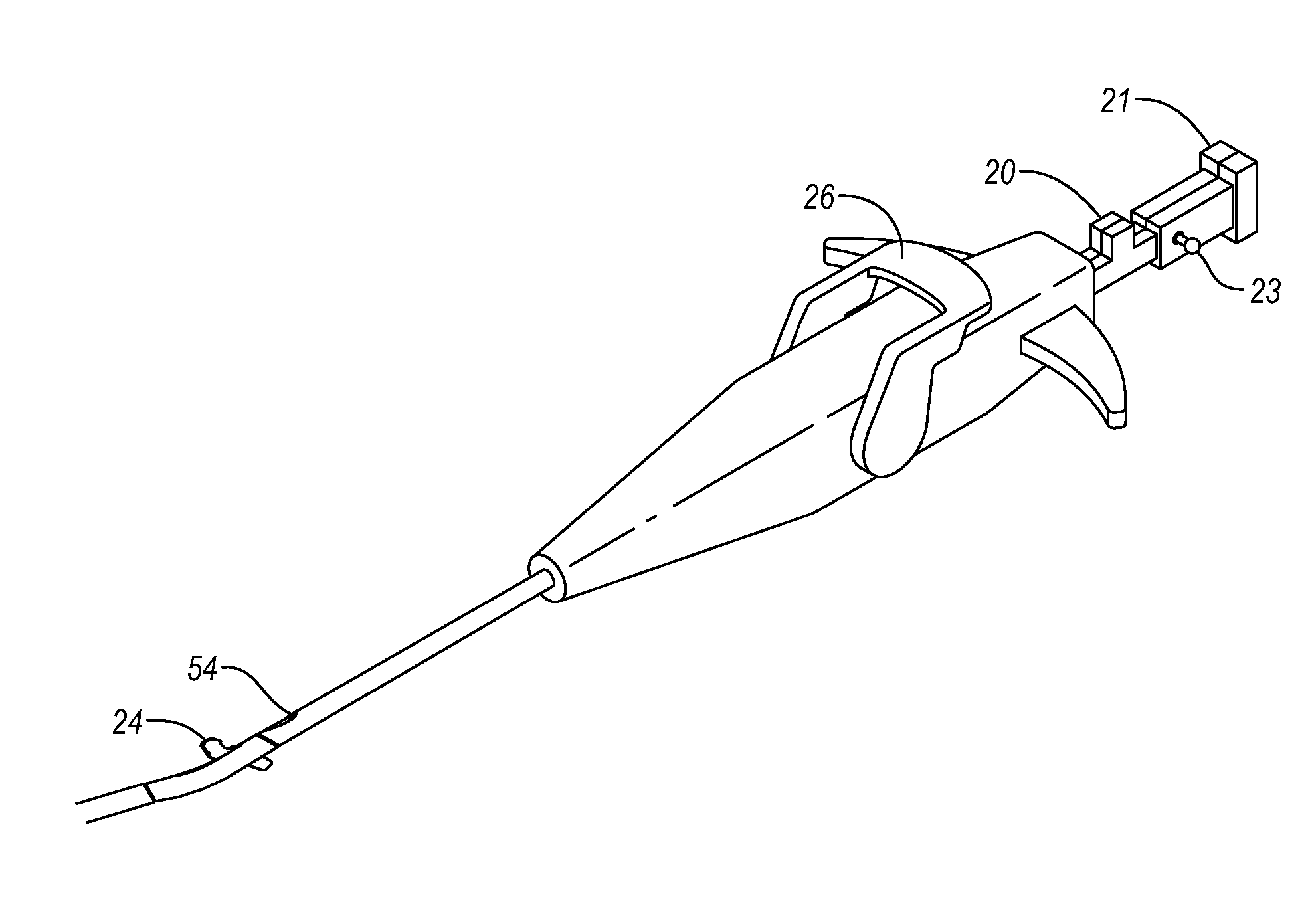

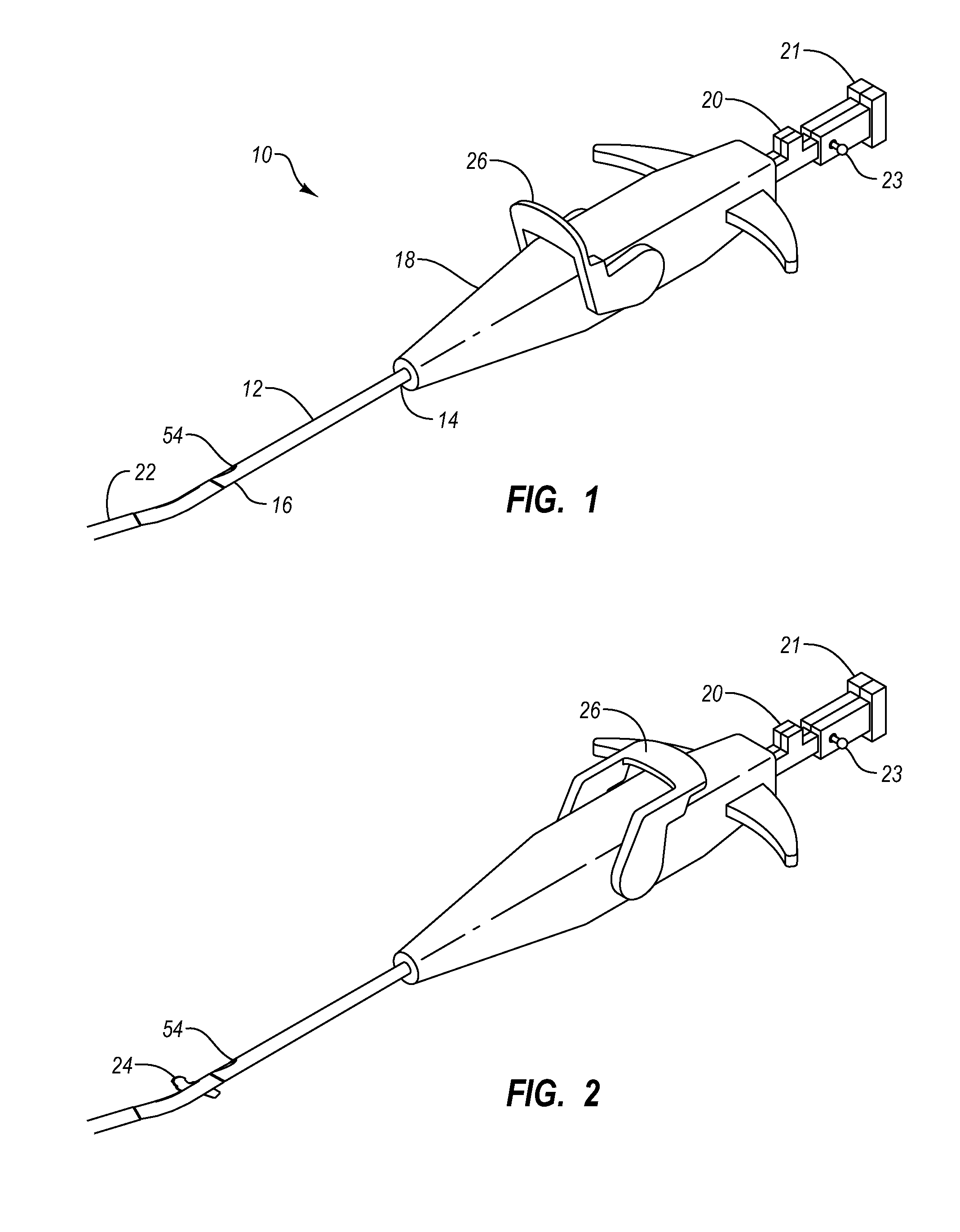

System for closing a puncture in a vessel wall

ActiveUS20080319458A1Close punctureConstant tensionSuture equipmentsSurgical needlesSurgeryBlood vessel

A device is provided herein for deploying a suture in a puncture through a vessel wall of a blood vessel, the puncture disposed within a tissue tract of a patient body. The device includes a shaft suitable for insertion along the tissue tract and into the vessel through a puncture, a plurality of needles, each needle having a proximal end and a distal end suitable for forming a needle path through the vessel wall, wires associated with each needle, each wire having a distal end and a proximal end, and hooks coupled to each of the distal ends of each wire, each hook being configured to anchor the wire to an interior portion of the vessel wall.

Owner:ABBOTT LAB INC

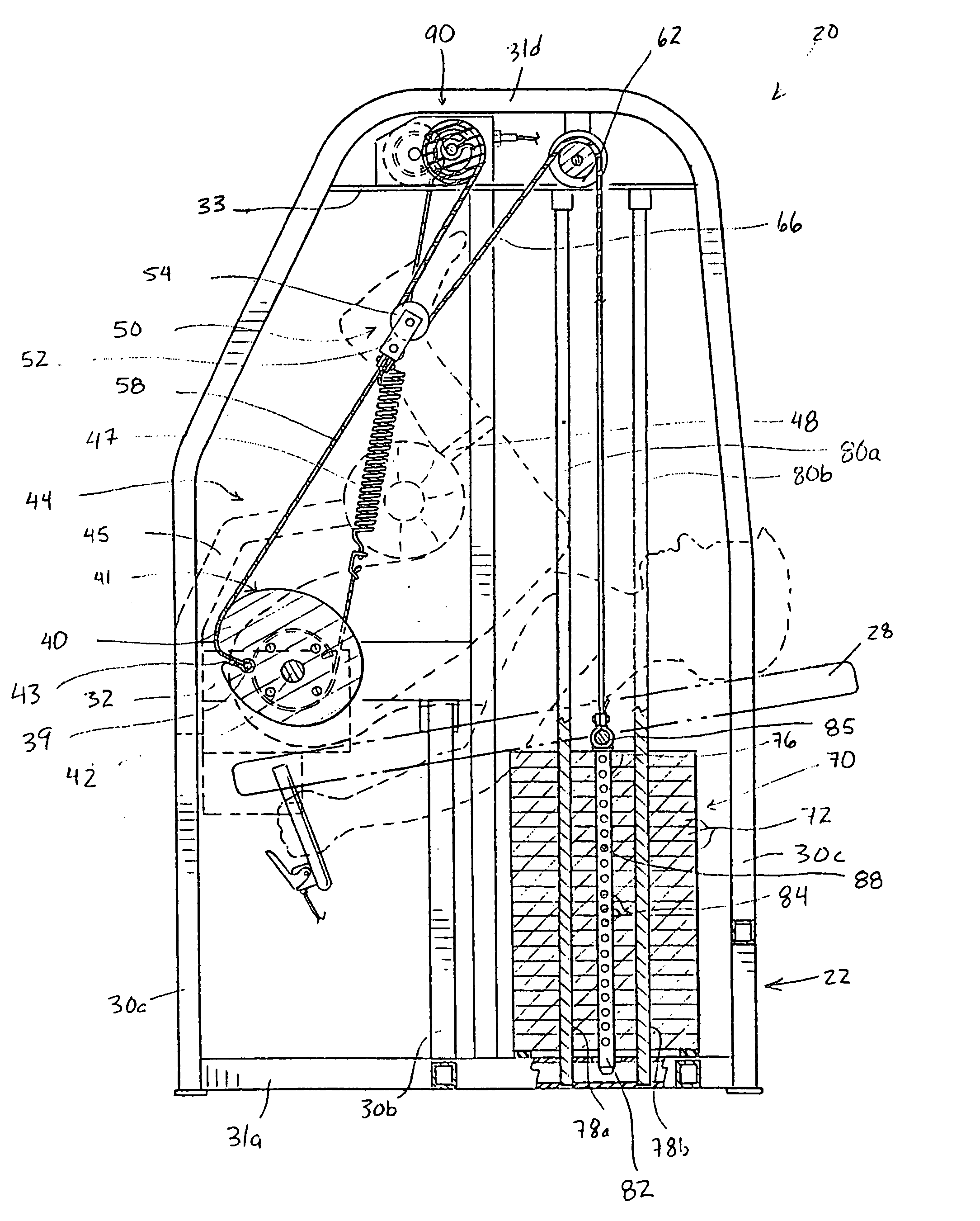

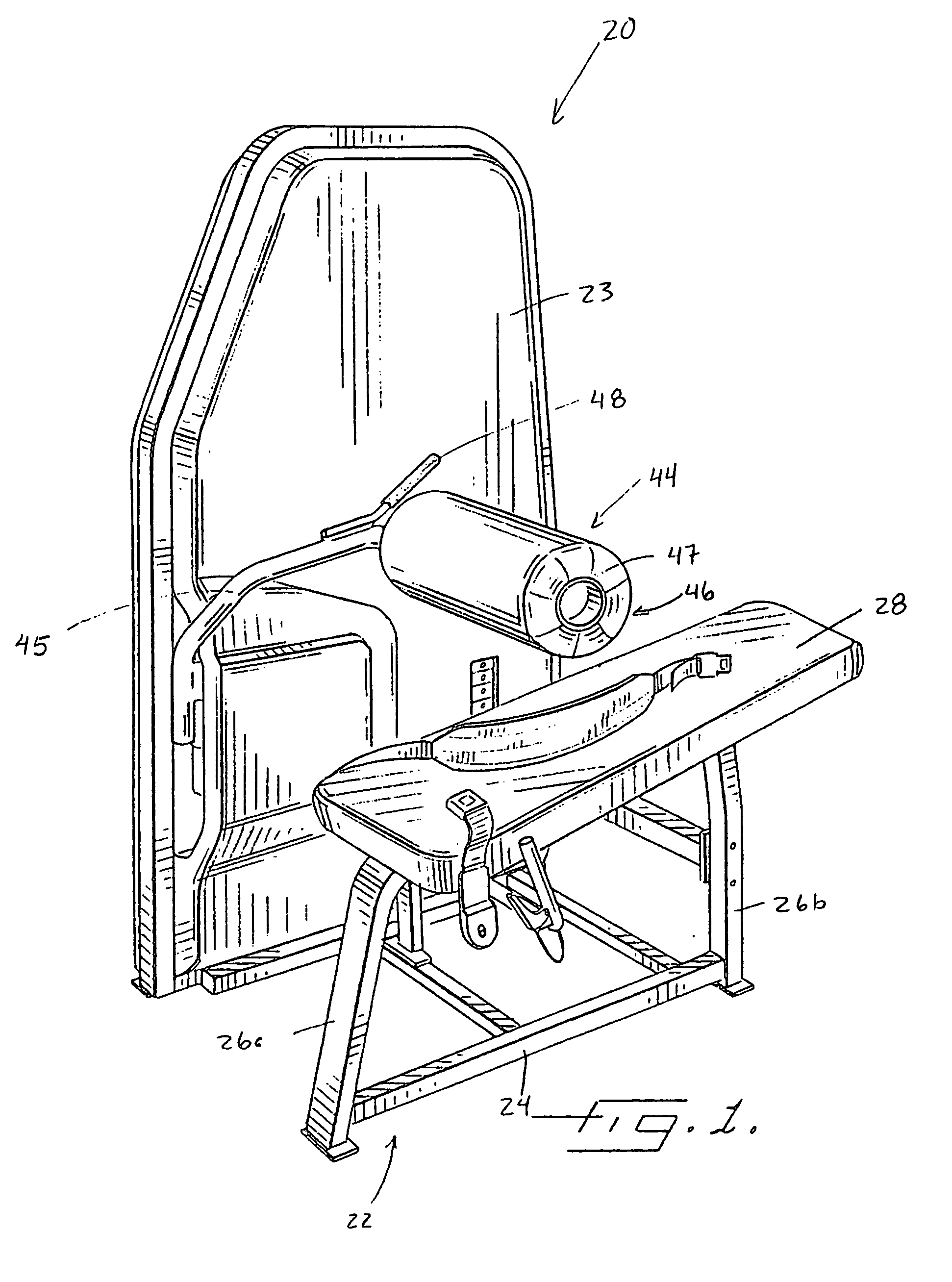

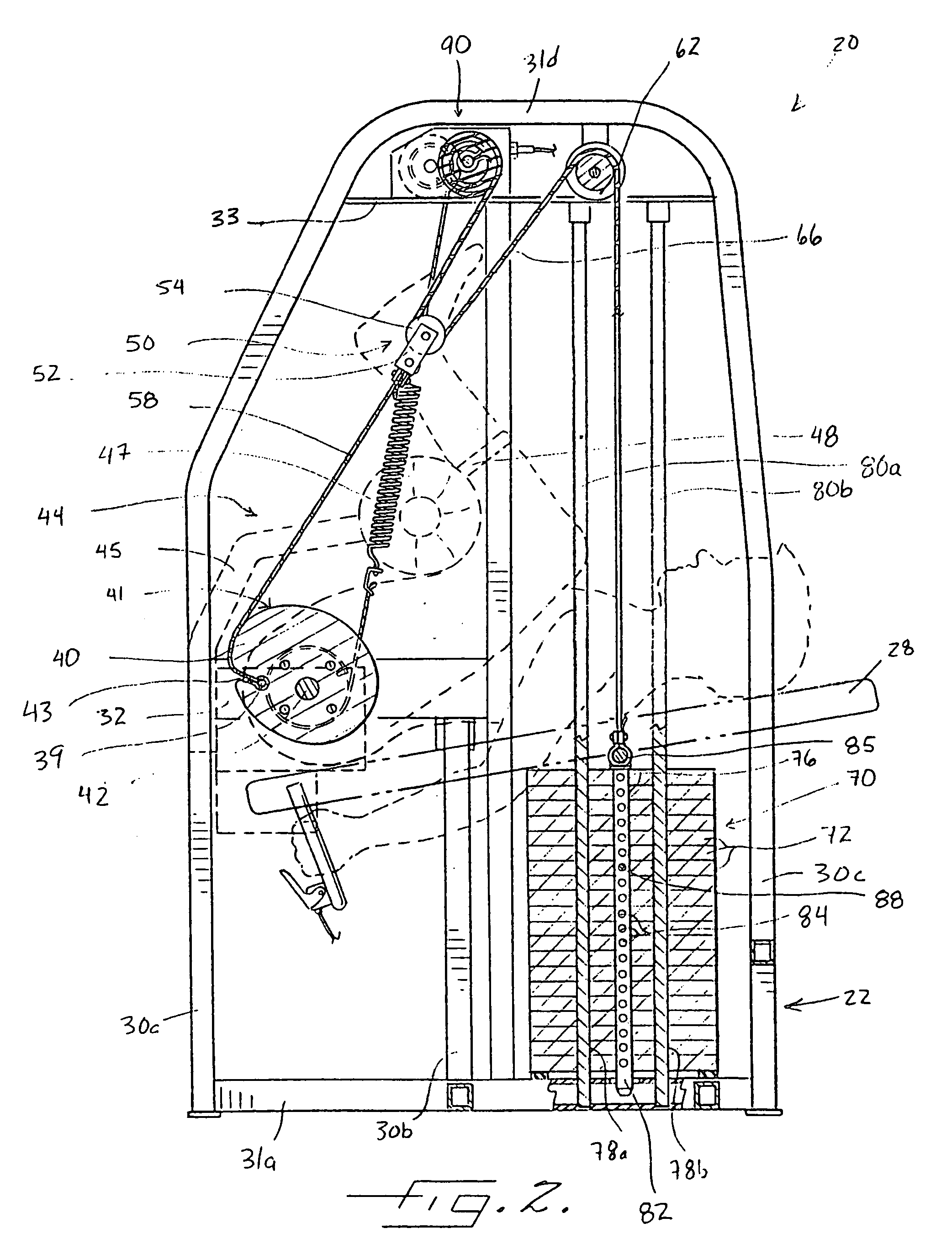

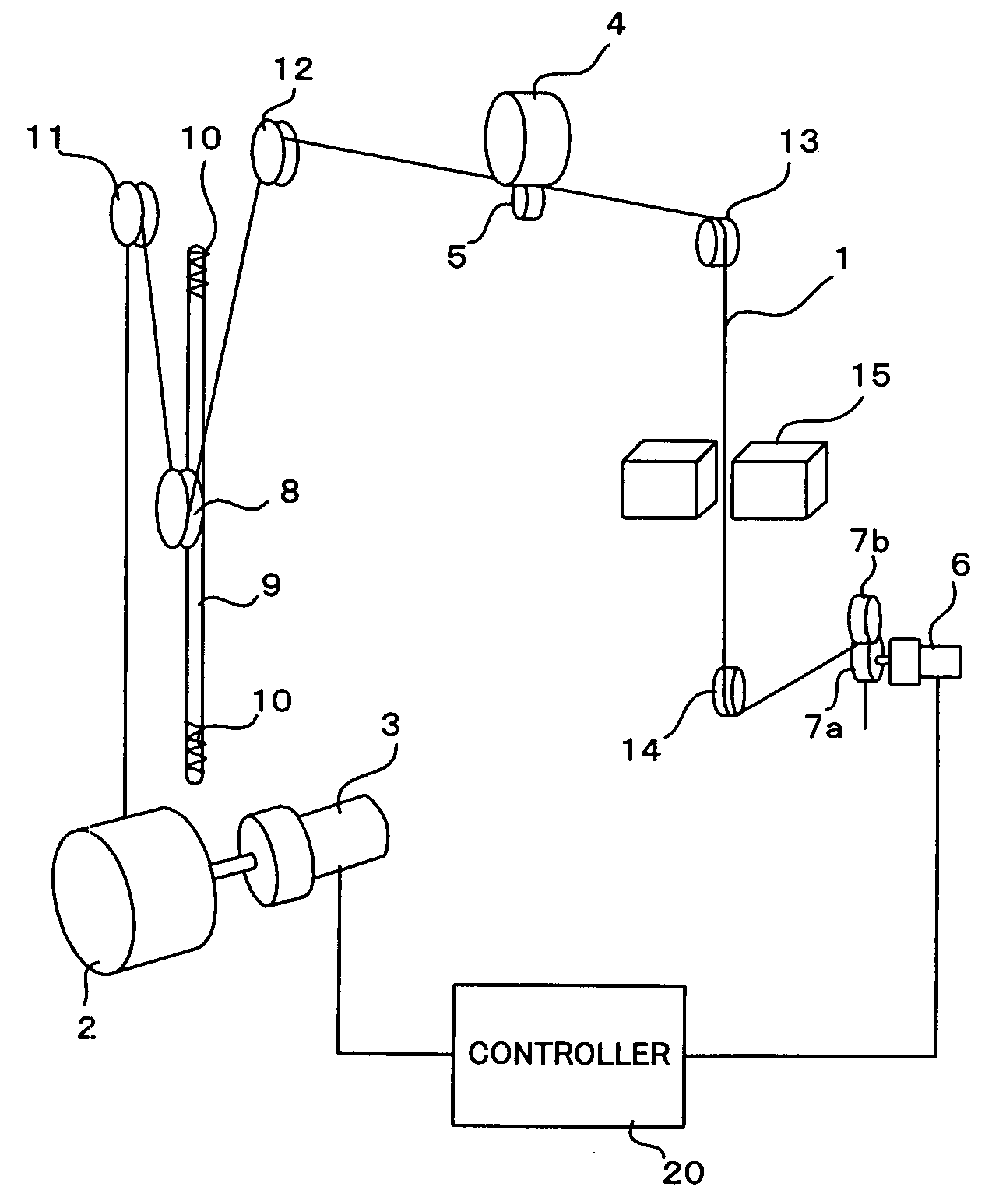

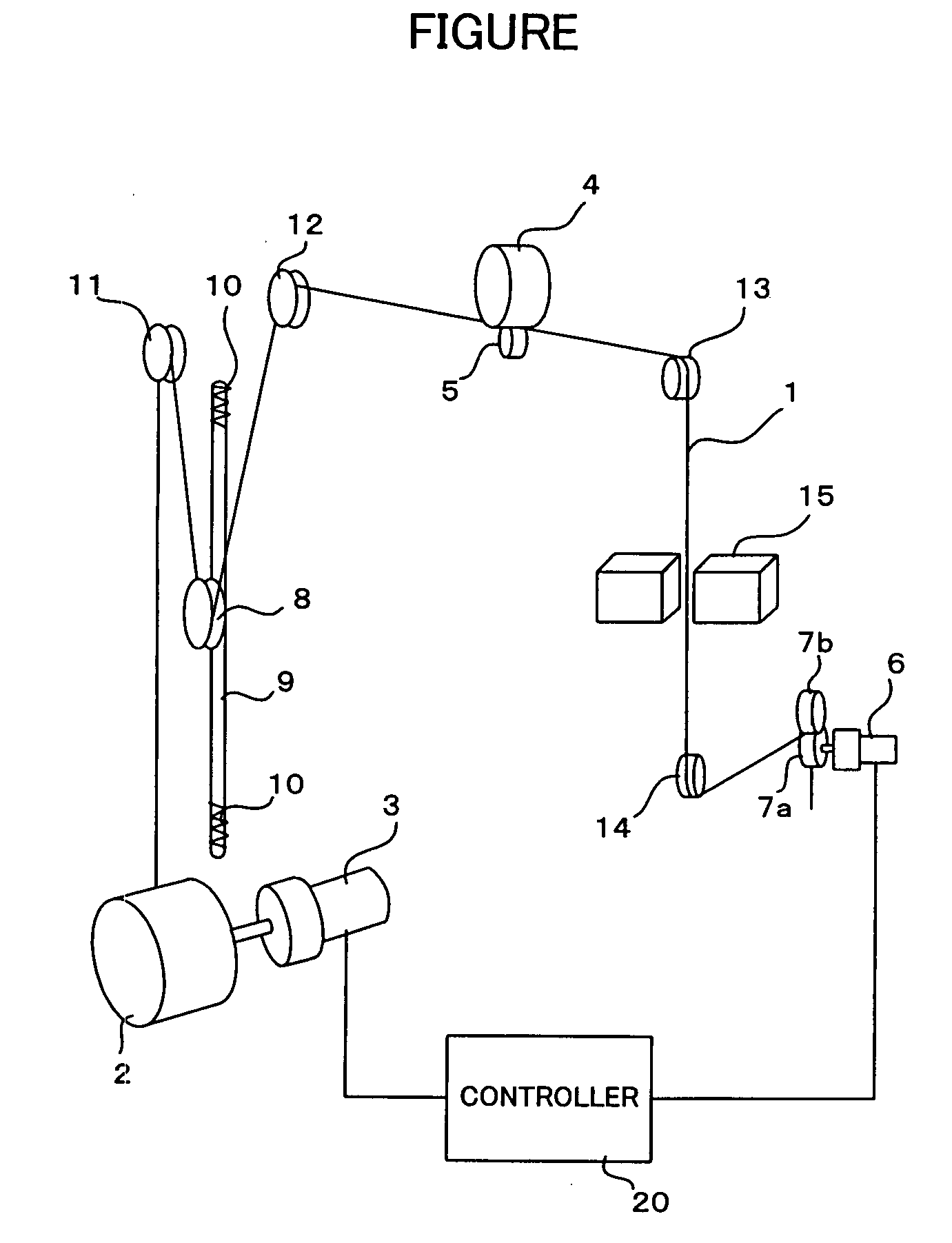

Exercise machine with infinite position range limiter and automatic belt tensioning system

InactiveUS7083554B1Simple setupIntuitive adjustmentStiltsMuscle exercising devicesEngineeringMotion system

An exercise machine having infinite range limiting capability comprises: a frame; a pivotable exercise arm mounted to the frame configured to engage an exercising user and moveable along a stroke path having a fully extended position and a fully flexed position; a movement-resisting system for resisting movement of the exercise arm along the stroke path; an interconnecting unit for interconnecting the exercise arm and the movement-resisting unit so that movement of the exercise arm causes a portion of the movement-resisting unit to move in response thereto; and a range-limiting unit for limiting the distance the exercise arm moves along the stroke path during exercise. The range-limiting unit is connected to the interconnecting unit and is configured to enable a user of the exercise machine to select a first partially flexed position at any desired location along the stroke path such that the exercise arm moves between the first partially flexed position and the fully extended position serving during exercise. The range limiting unit is also configured so that movement of the exercise arm away from the fully extended position past the first partially flexed position by the user selects a second partially flexed position such that the exercise arm moves between the second partially flexed position and the fully extended position during exercise.

Owner:NAUTILUS INC

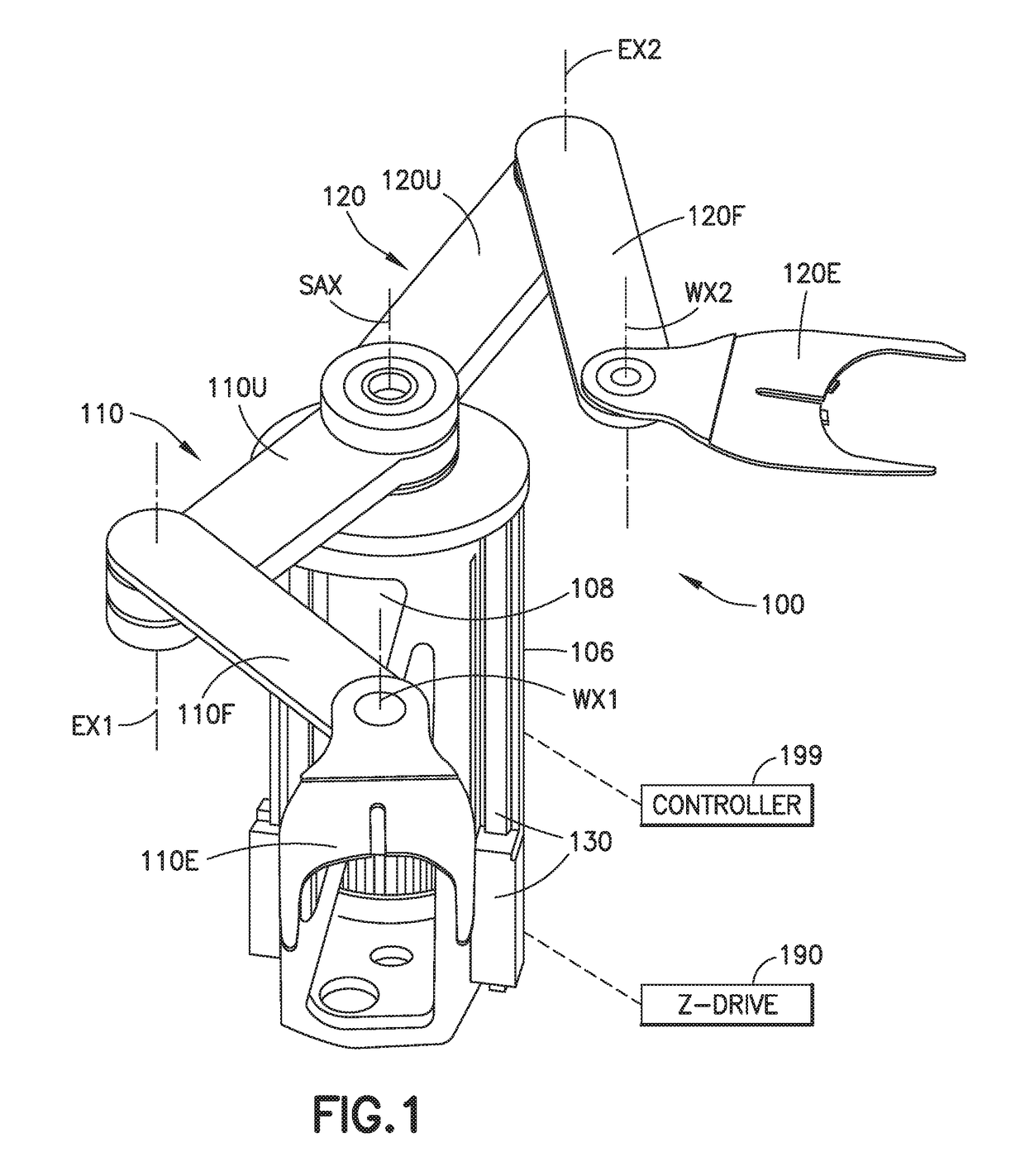

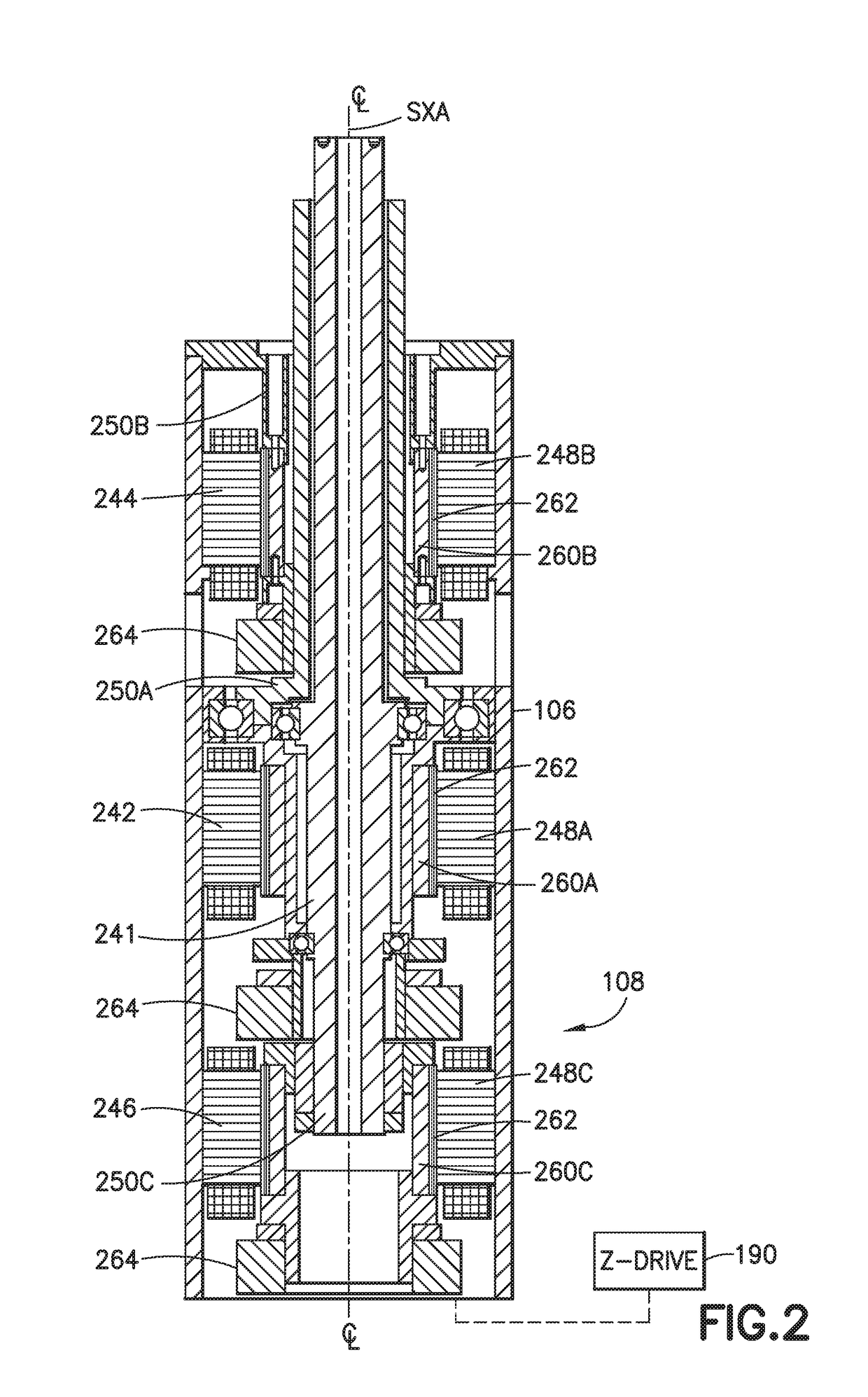

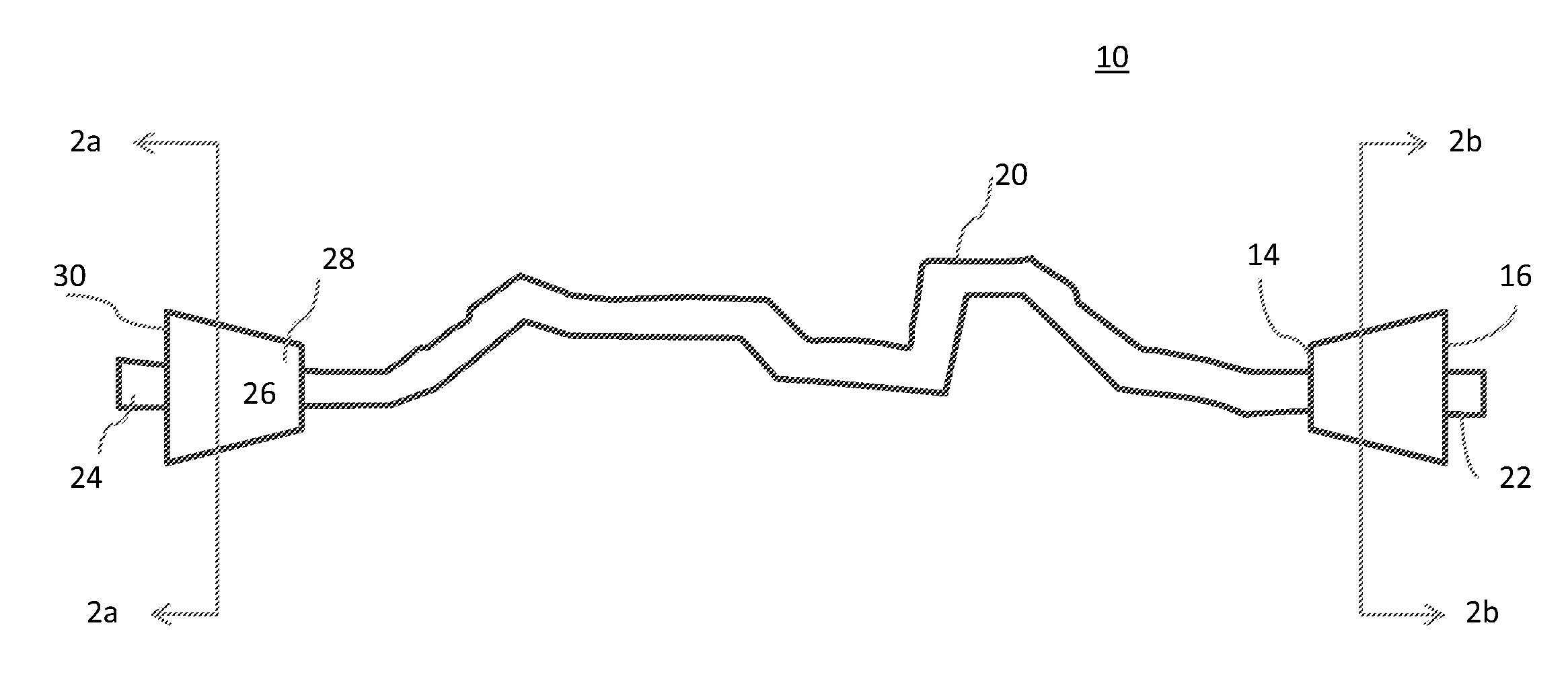

Substrate processing apparatus

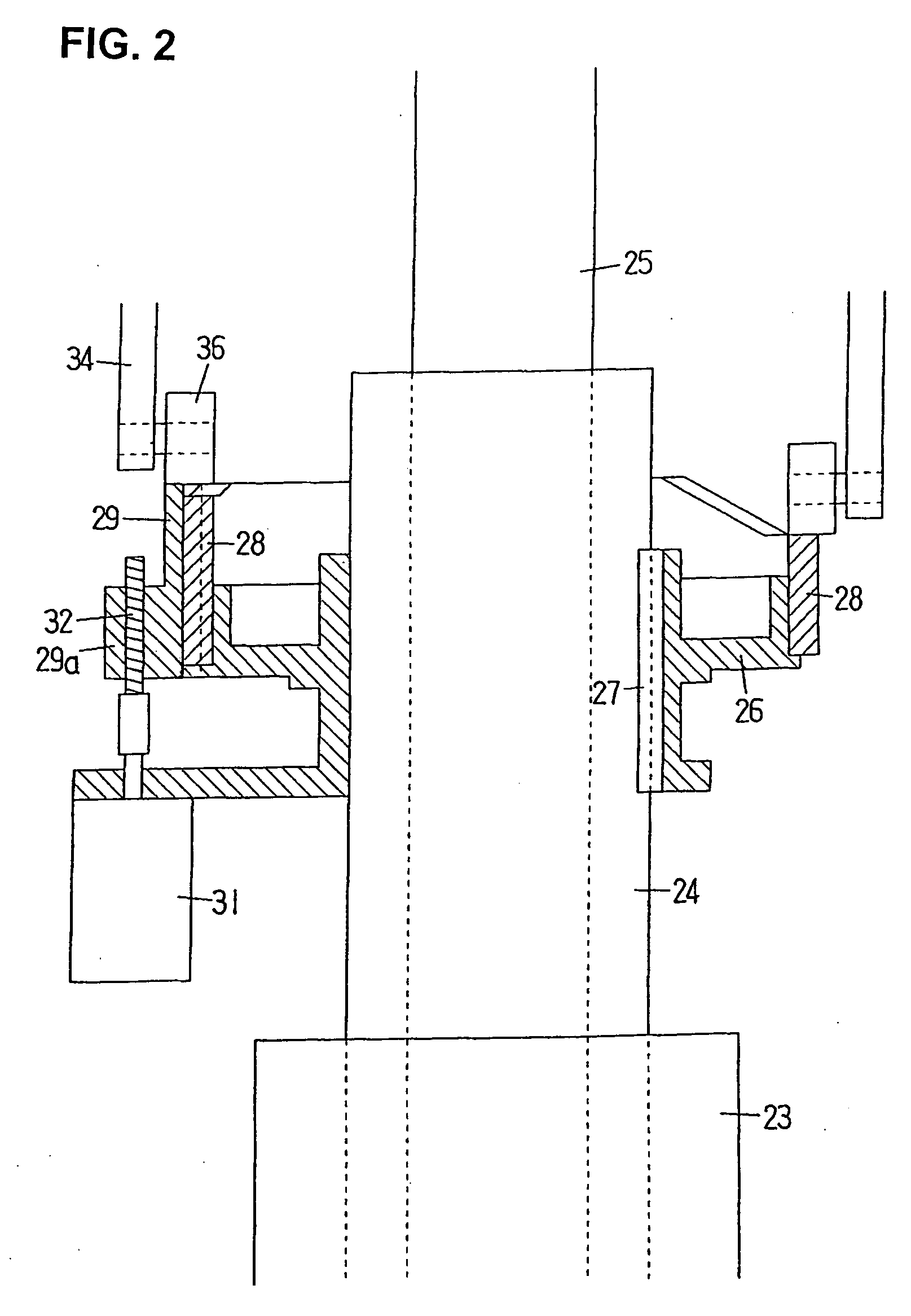

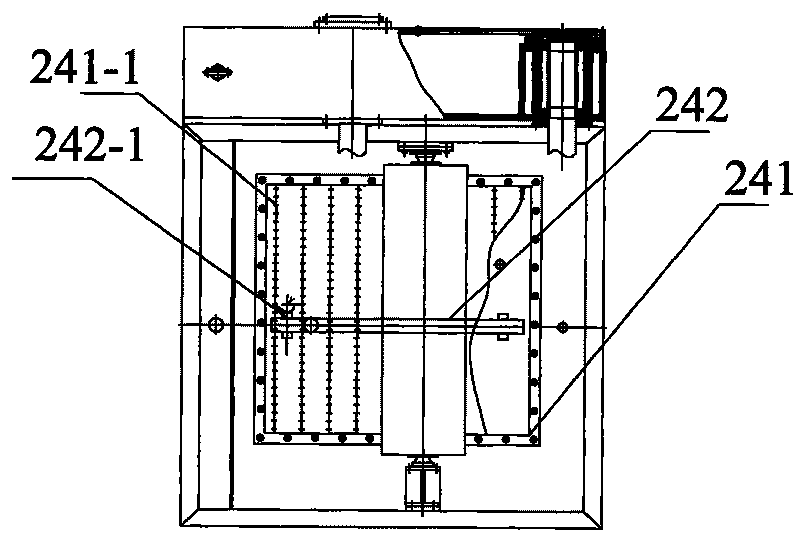

ActiveUS20180019155A1Reduce internal volumeReduce the overall heightProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingDegrees of freedomEngineering

A substrate processing apparatus including a frame, a first SCARA arm having an end effector and being configured to extend and retract along a first axis, a second SCARA arm having an end effector and being configured to extend and retract along a second axis, a drive section including a splitting drive pulley rotatably mounted to rotate at an axis of rotation of the drive section that is shared by the first and second SCARA arms, the splitting drive pulley being coupled to at least two idler pulleys by respective segmented transmission loops of separate band segments so that the splitting drive pulley is a common pulley splitting one degree of freedom of the drive section between the at least two idler pulleys so as to commonly drive the at least two idler pulleys, wherein at least one band of each respective transmission loop share a common band interface level.

Owner:BOOKS AUTOMATION US LLC

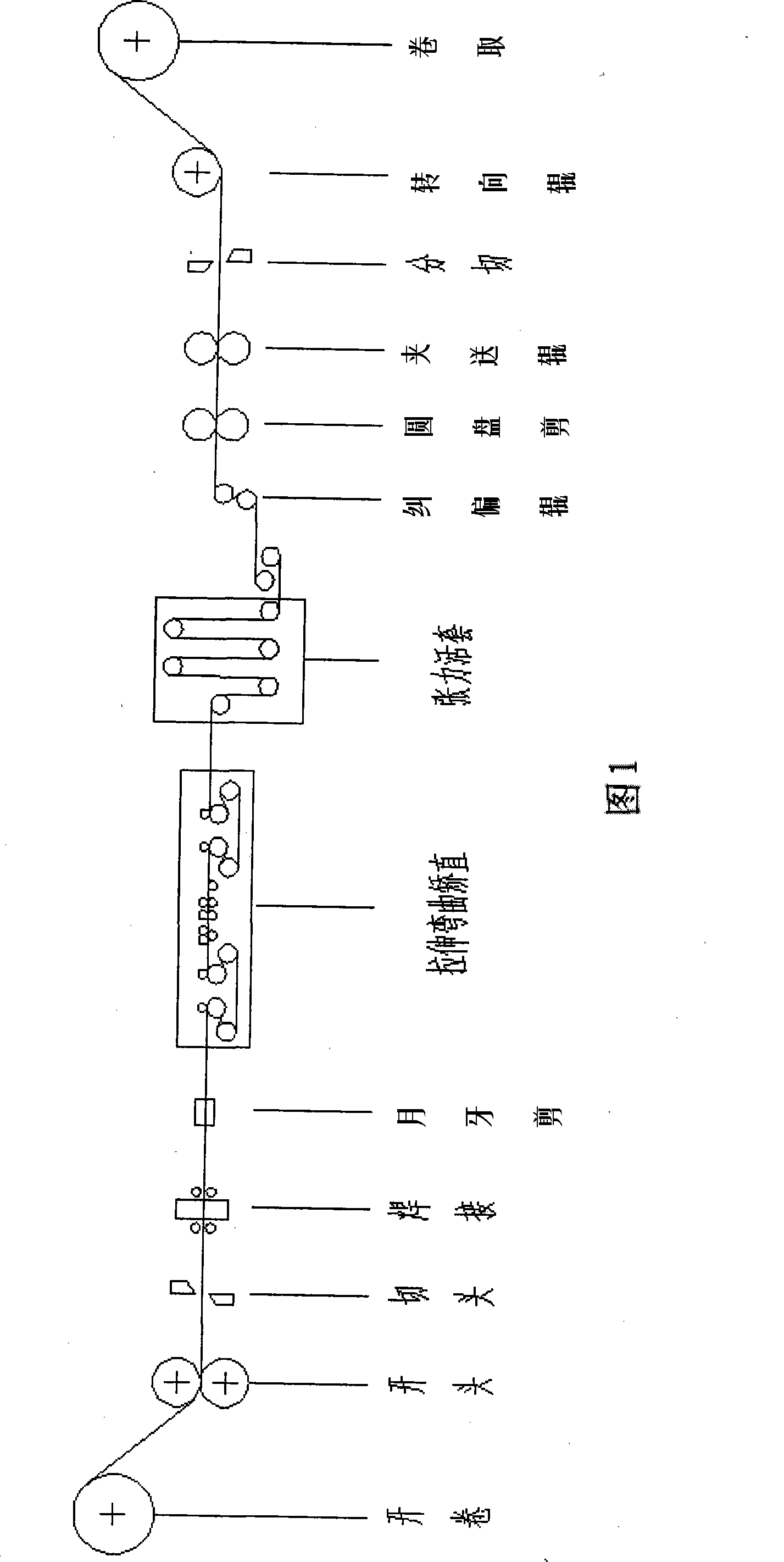

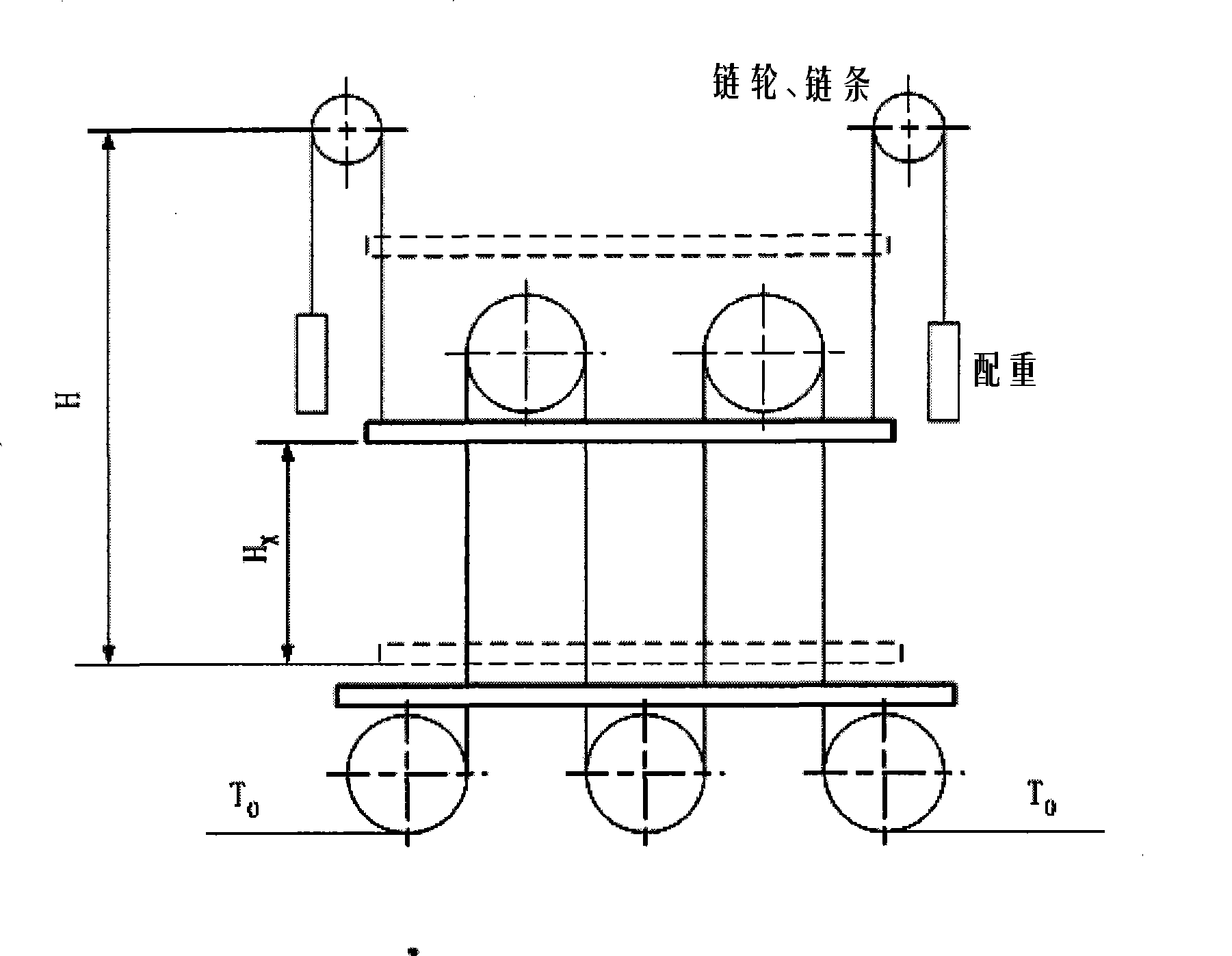

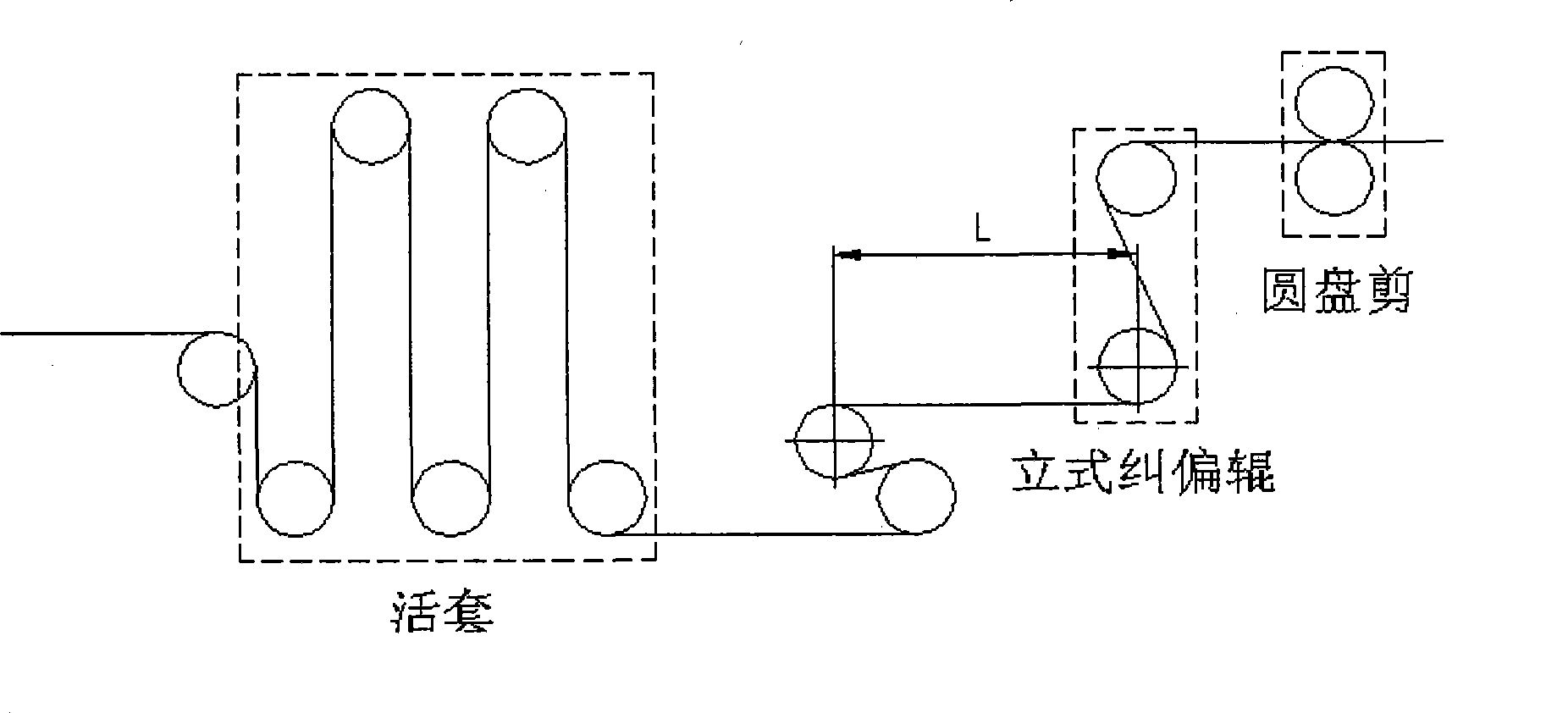

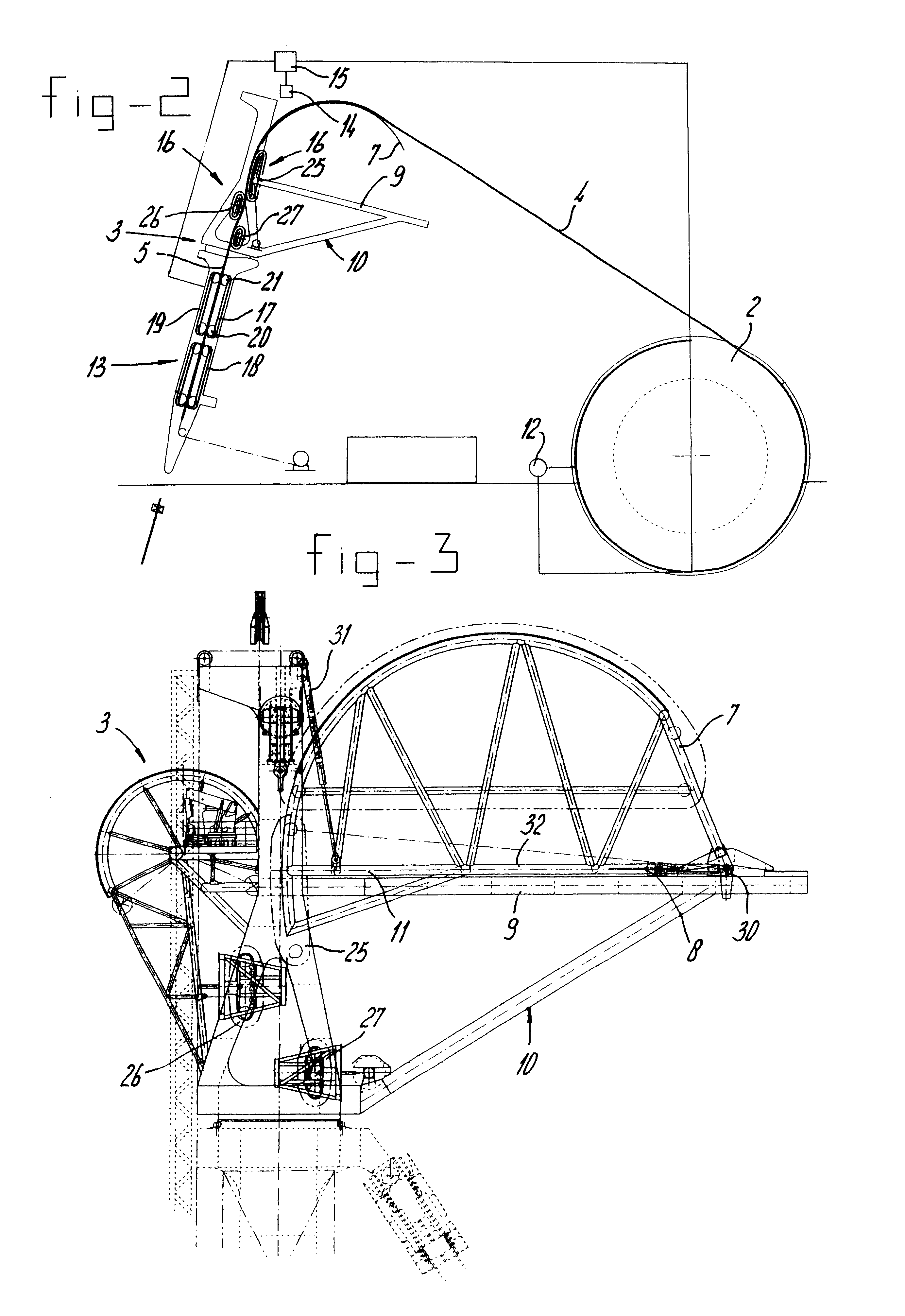

Machine unit process for stretch bending, straightening and rewinding

InactiveCN101439468AEliminate tension changesConstant tensionOther manufacturing equipments/toolsFlexible work arrangmentsCircular discLower limit

The invention provides a unit process used for finishing, tension-bending, straightening, and recoiling the metallurgical cold-rolling strips. The process is characterized in that the process comprises at least the steps as follows: roll-up, uncoiling, head cutting, welding, tension-bending and straightening, tensioning piston, rectification, trimming, separating, coiling and coil removing. When the unit produces normally, a coiler provides initial tension for an outlet tension roller; when the production line is shut down for coil separating, the coiler is shut down, the tensioning piston provides the initial tension equivalent to the coiling tension during the normal production for the outlet tension roller and a tension-bending, and straightening machine continues to straighten the strips; the straightened strips are stored in the tensioning piston; when the coiler removes the coils and re-produces the next finished coils, the straightened strips stored in the piston are coiled, the lifting roller unit of the movable sleeve falls to a lower limit position, the coiler loads the tension and shifts the initial tension of the tension-bending and straightening machine from the tensioning piston to the coiler at the same time, and then the whole unit produces at an accelerated speed. The process can overcome the defects generated on the disc shear by the strips when the tension is shifted between the coiler and the tensioning piston owning to the shutdown of the coil separating.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

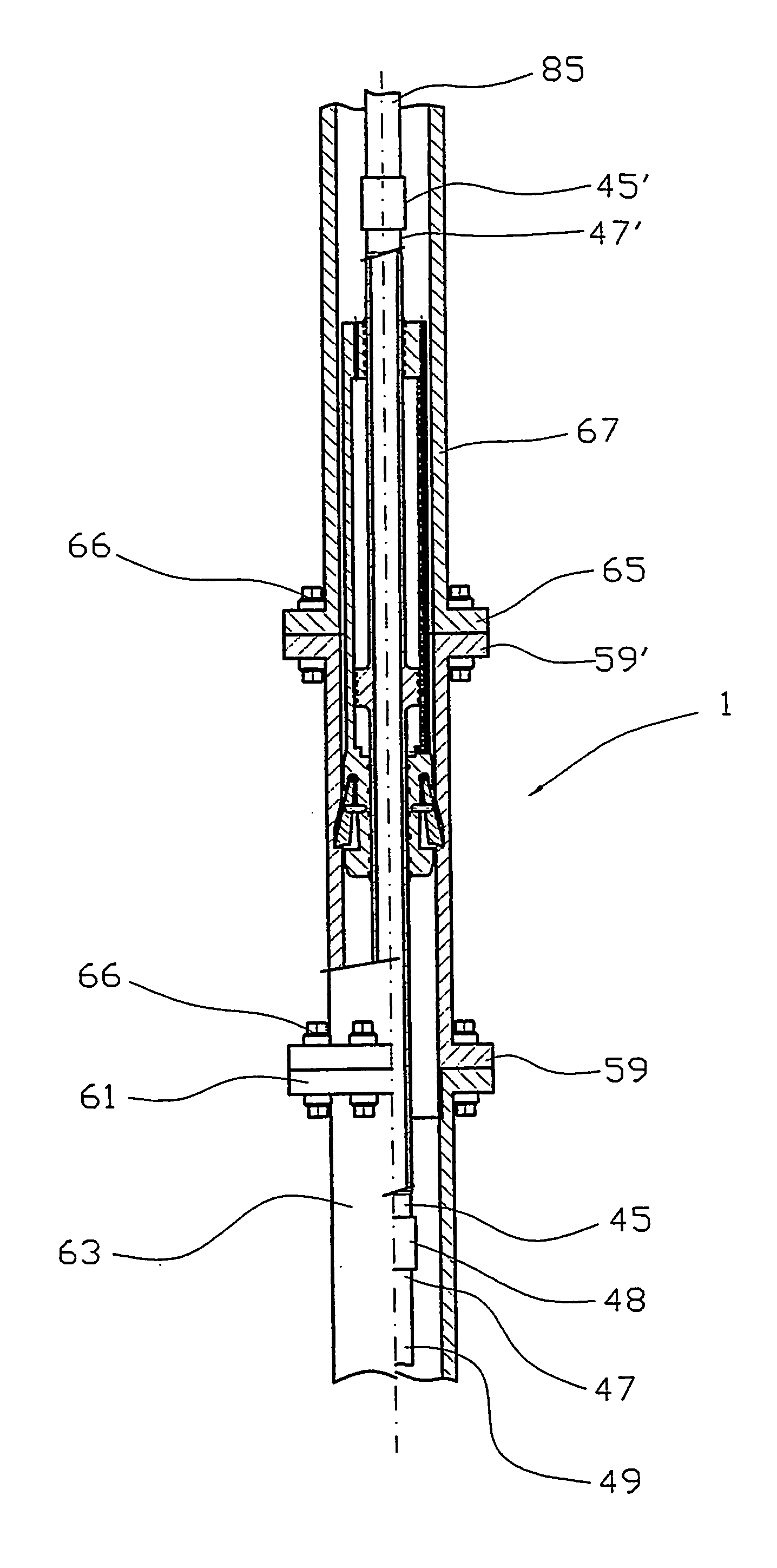

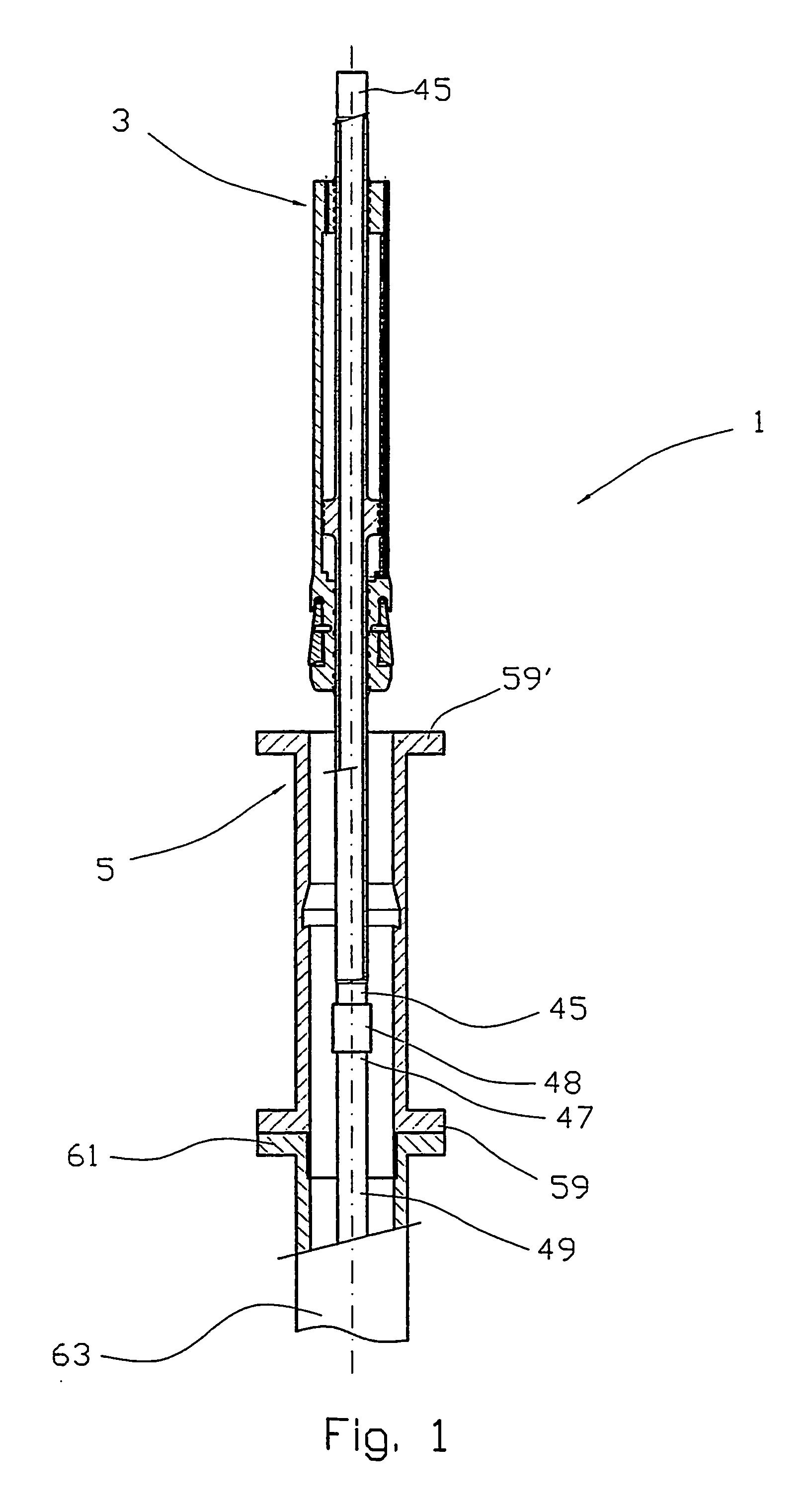

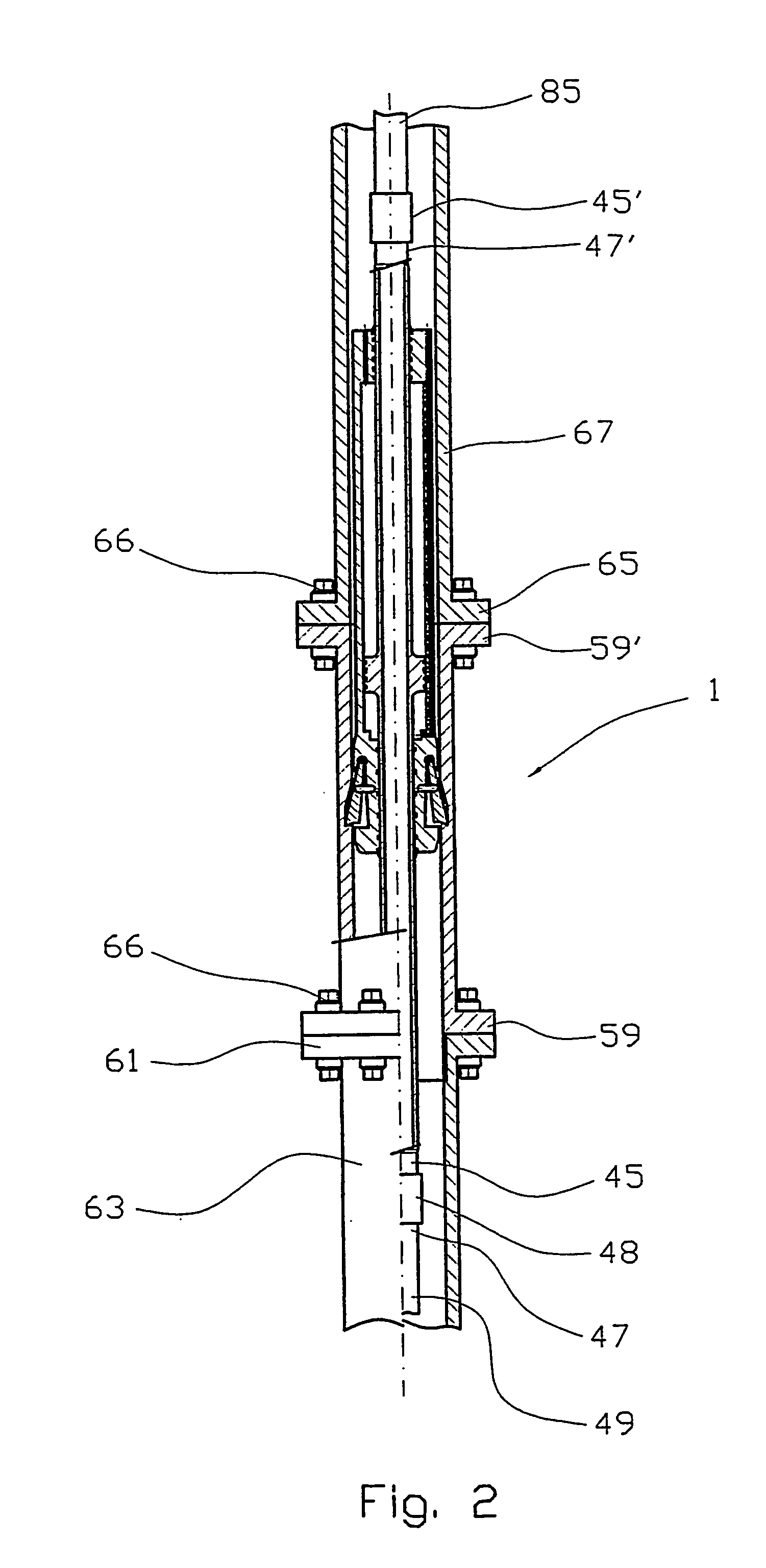

Tensioning system for production tubing in a riser at a floating installation for hydrocarbon production

A device for tensioning and relieving production tubing (49) extending from a subsea hydrocarbon well (107) up through a riser (63) to a floating installation (87), a continuous production tubing extension (85) passing through a telescopic unit (67) in the upper part of the riser (63), preferably extending above a production deck (89) on the floating installation (87), where the production tubing (49) is provided with a tubing tensioner unit (1) below and in the proximity of the lower end of the telescopic unit (67).

Owner:GRANT PRIDECO LP

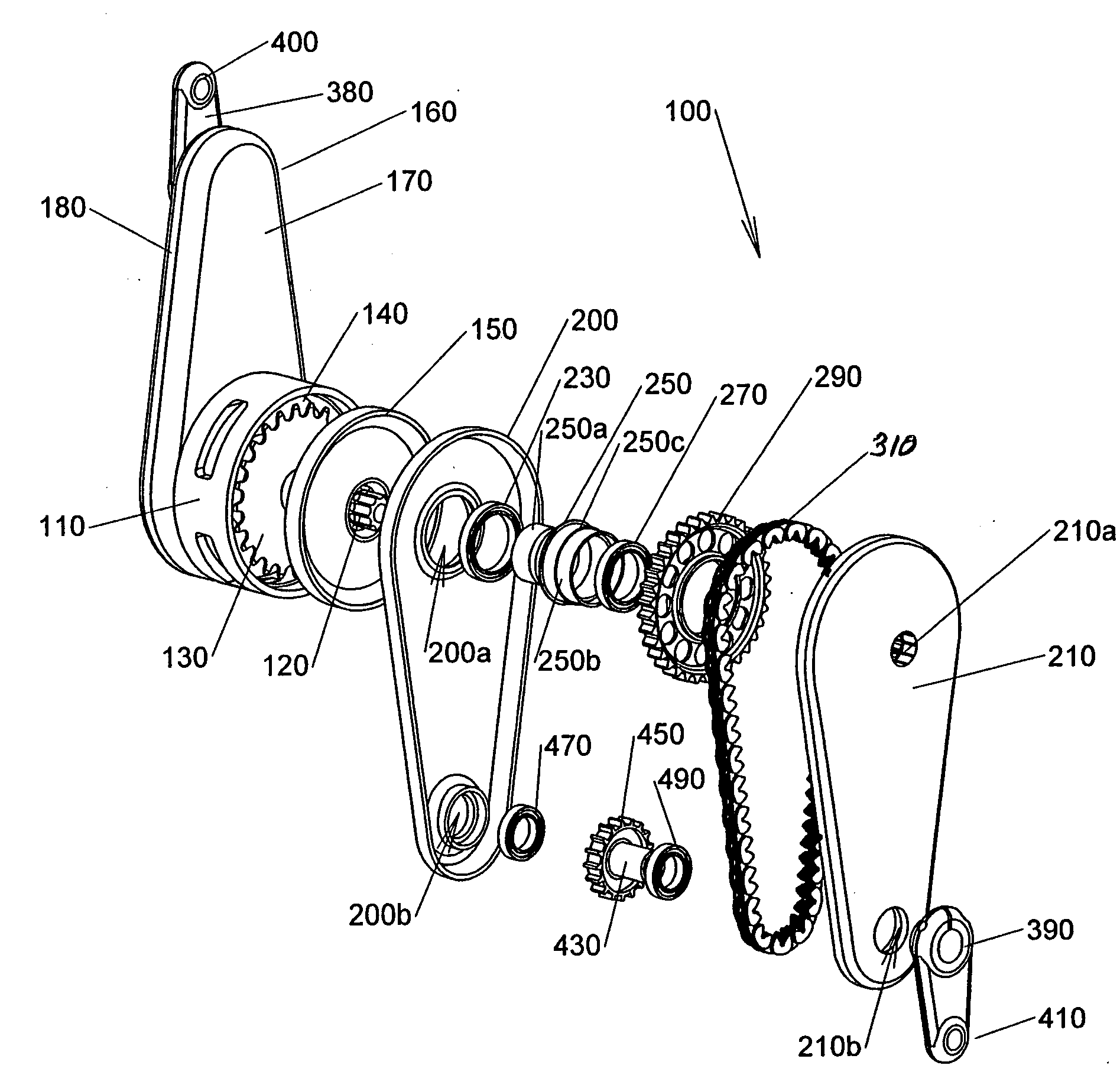

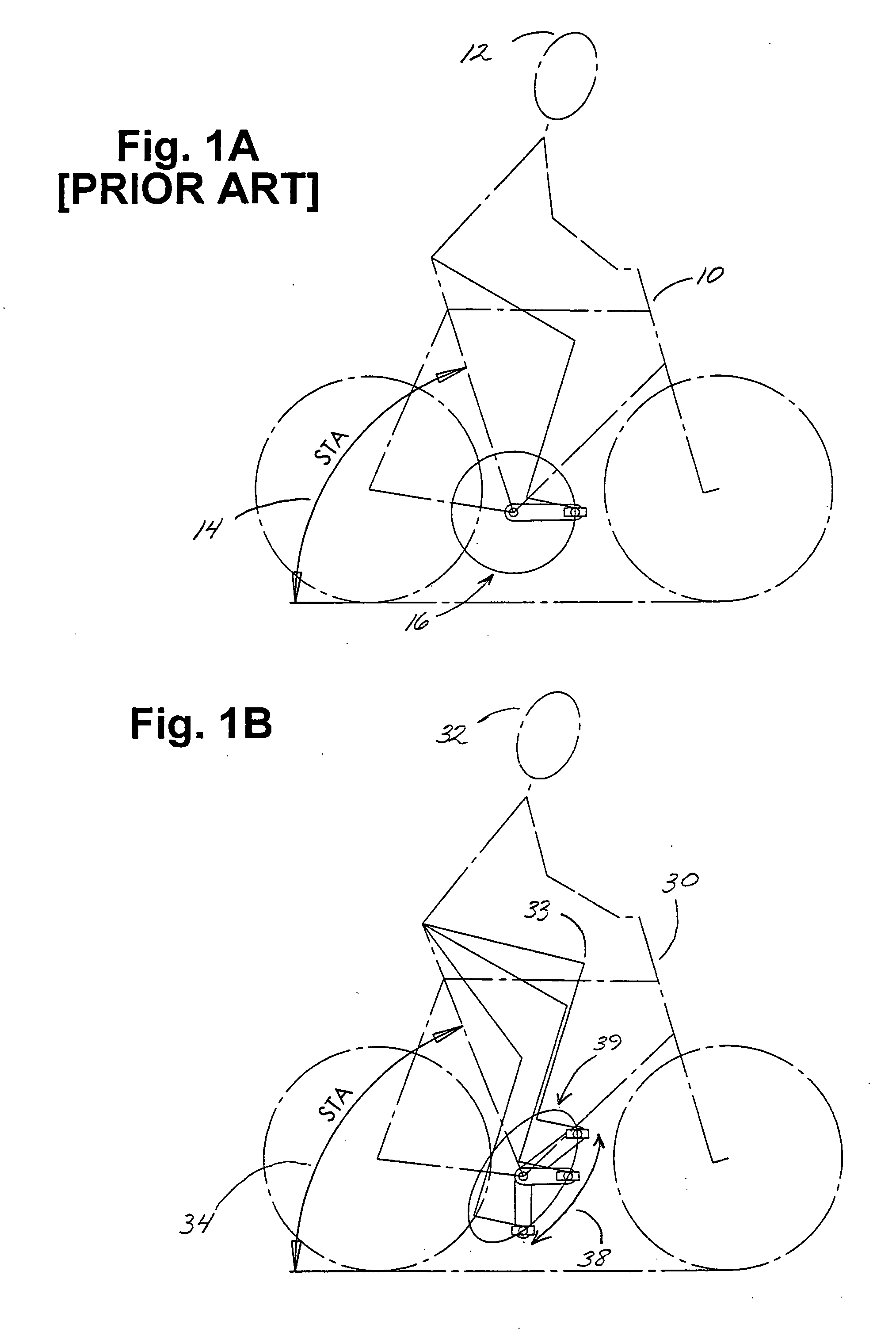

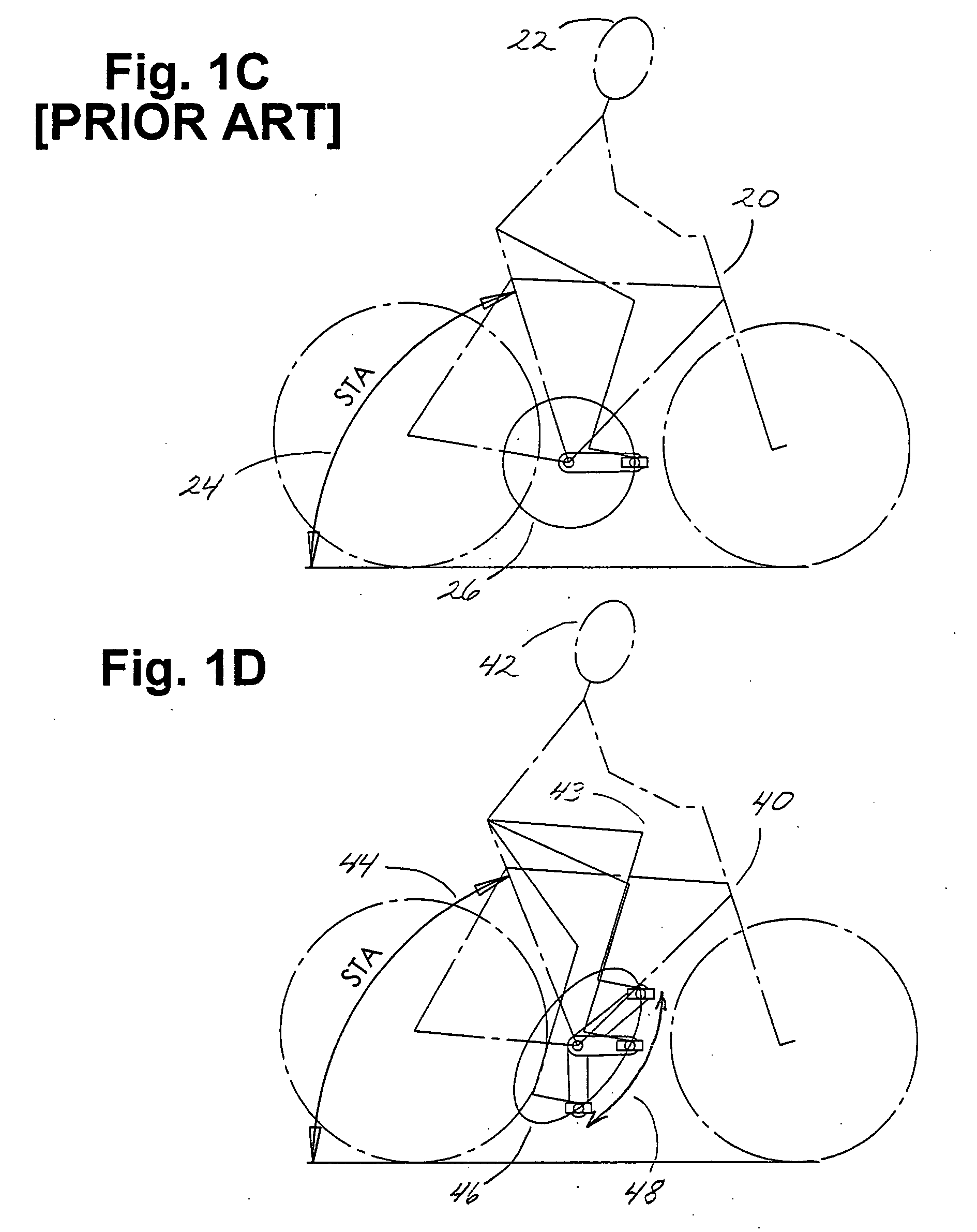

Bicycle having frame geometry, elliptical pedaling path, and seat configuration to increase efficiency and comfort

InactiveUS20050263978A1Easy to installGood lookingVehicle cranksChain/belt transmissionVehicle frameRange of motion

A bicycle having a frame geometry, elliptical pedaling system, and seat design and configuration which, in combination, moves the rider's body weight rearward relative to its location in conventional bicycle designs, increases the hip joint range of motion and maximum knee flex experienced during pedaling, increases the distance over which the rider's knee is directly over the pedal spindle during pedaling, provides a seating platform from which to brace and push during leg extension, and thereby increases overall efficiency and rider comfort.

Owner:ASCHER STEVEN G

Composite bone grafts, particulate bone-calcium sulfate constructs, and methods of treating joint injuries

InactiveUS20110208305A1Easy to handleEliminate needBone implantLigamentsSolid componentCalcium phosphate product

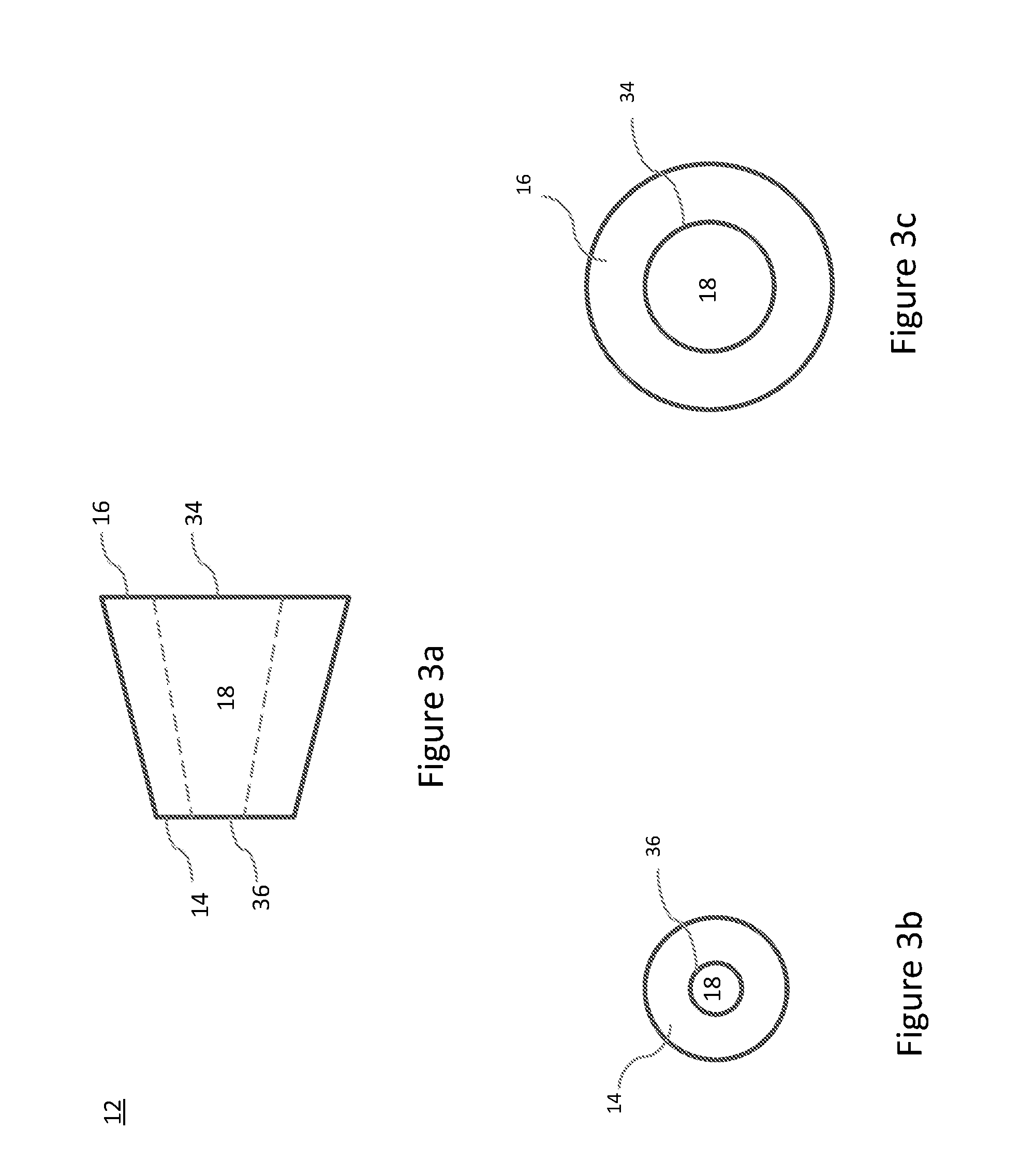

A solid implantable bone construct (12) shaped like a cylinder, a cone, or a frustum, for anchoring ligament implants. The bone construct (12) can include a bone component and a biocompatible solid component. The bone component can include particulate bone of between 75 and 600 microns, powdered bone of 75 microns or smaller in size, or both. The biocompatible solid component can include calcium sulfate hemihydrate, a calcium phosphate product, or both. The bone component can be between 5 and 50 wt-% of the construct (12) and the biocompatible solid component can be at least 50 wt-% of the construct (12). Also disclosed is a composite graft (10) comprising a first bone dowel (12) and a ligament (20) and a method of securing one bone to another using the composite graft (10).

Owner:VIVEX BIOLOGICS GRP INC

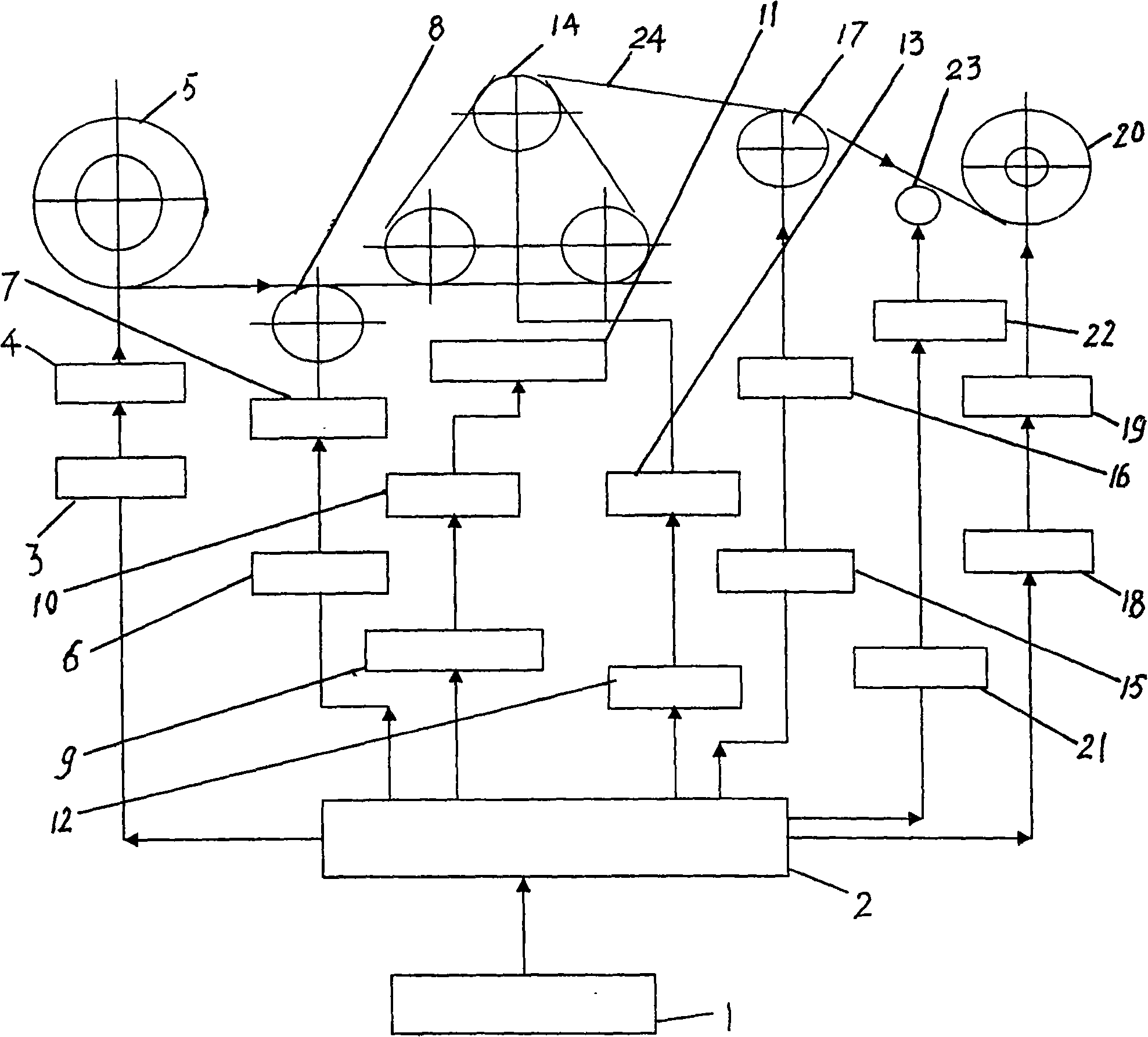

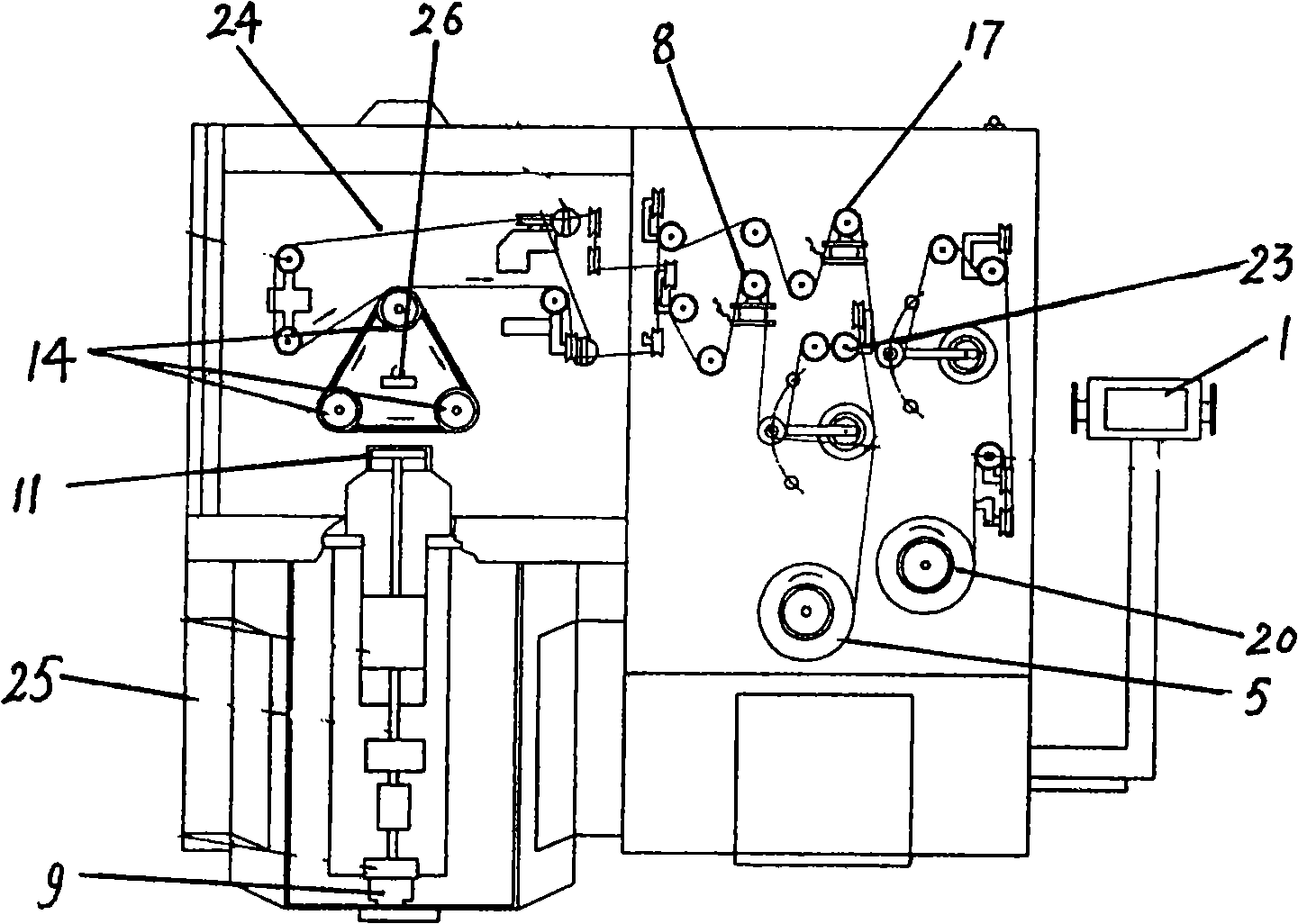

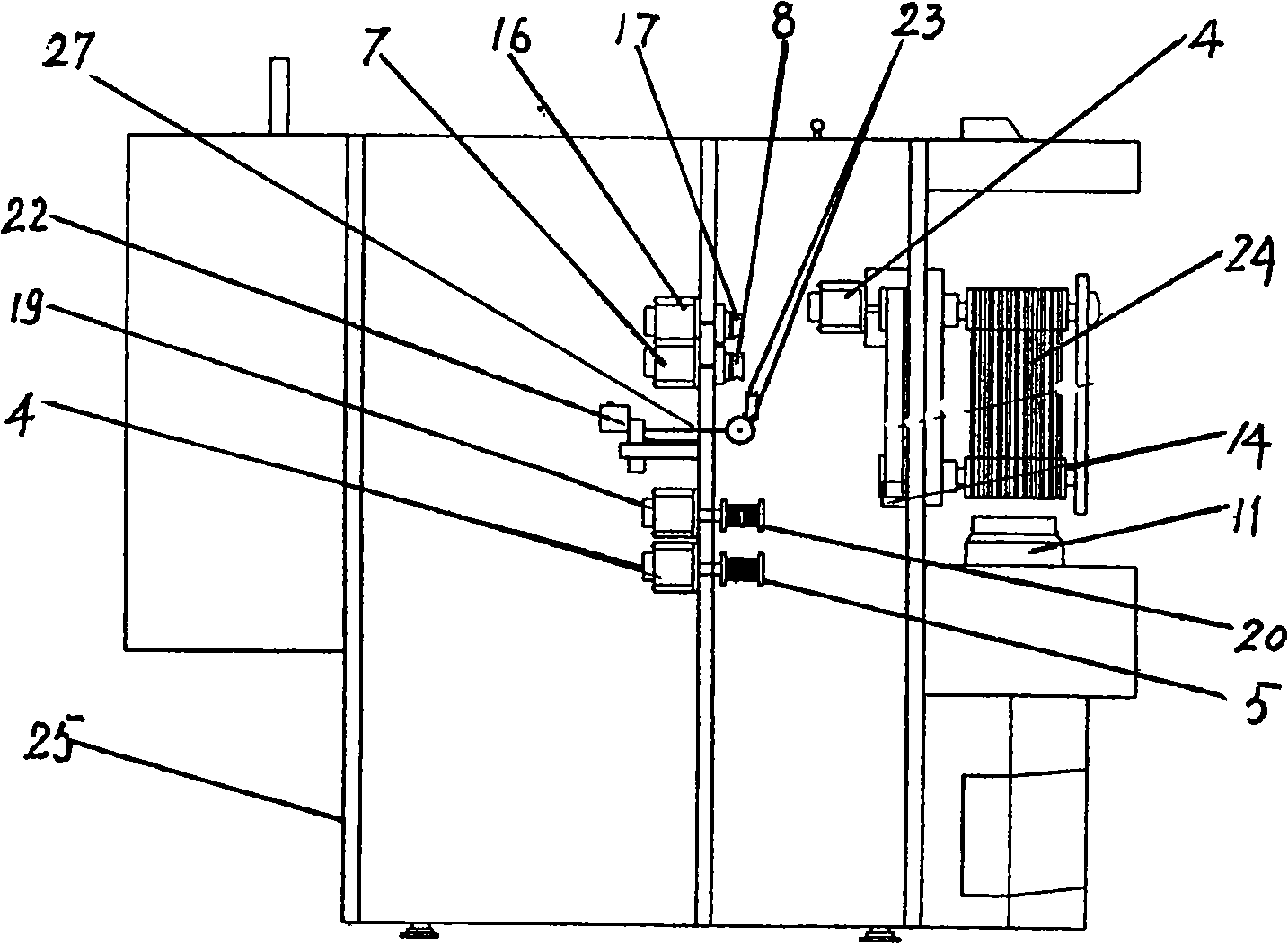

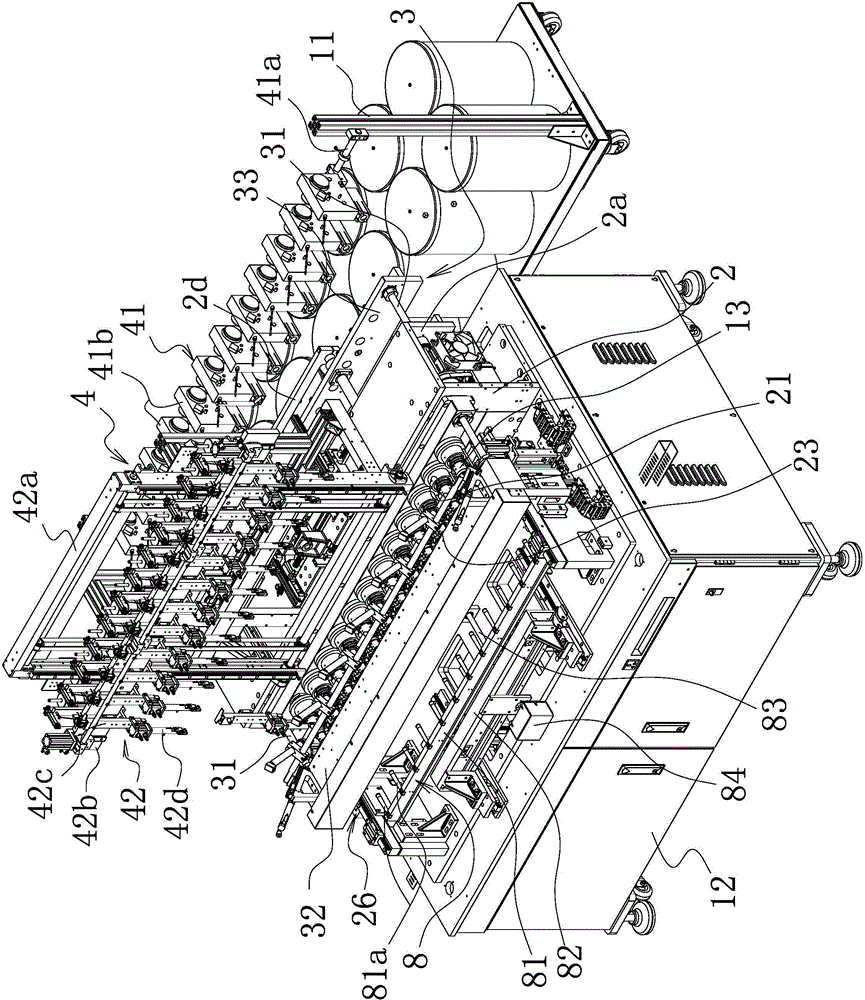

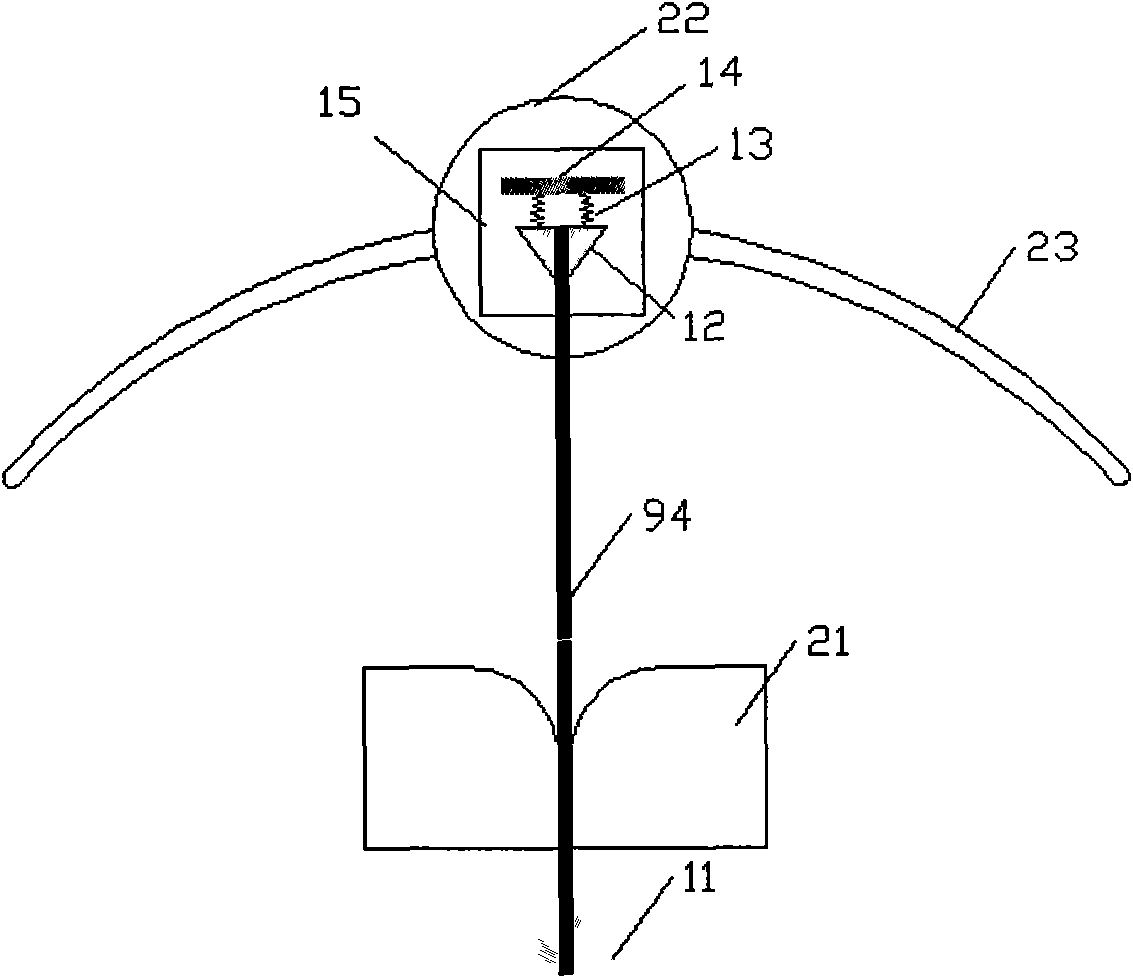

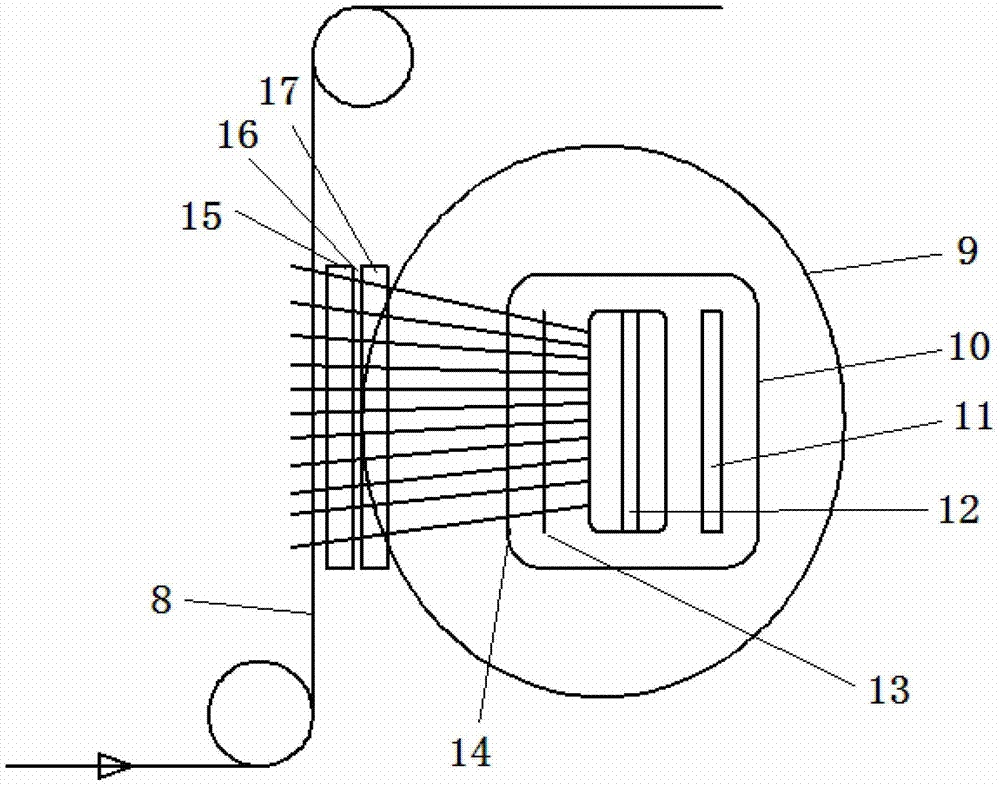

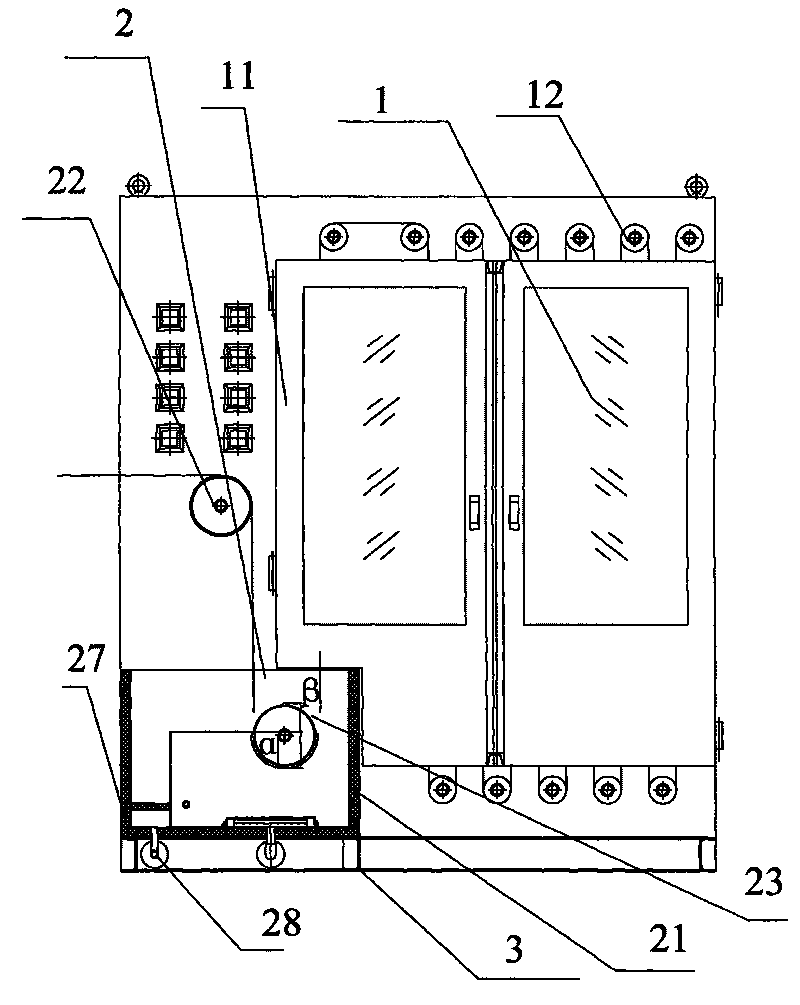

Microcomputer control multiline cutting machine

InactiveCN101301734AConstant tensionAchieve the purpose of being cutGrinding machinesFine working devicesAudio power amplifierWire wheel

The invention provides a micro-computer control multi-wire cutting machine, comprising a frame, a worktable, a metal wire, and a grinding lubricant supply mechanism; the control part of the micro-computer control multi-wire cutting machine adopts the programming of a main substrate to control a CPU module; the parameters of the CPU module are set by a touch display; furthermore, a servo amplifier is controlled by optical fibres; the servo amplifier controls a servo motor; a frame is internally provided with at least six servo amplifiers and six servo motors which respectively control the lifting of the worktable; the micro-computer control multi-wire cutting machine also comprises three rotation rollers, a wiring wheel, a wiring tensioning sensor, a stranding wheel, and a stranding tensioning sensor; the grinding lubricant supply mechanism leads out an emery liquid injection pipe; the outlet of the emery liquid injection pipe is in the middle of an isosceles triangle which is presented by three rotation rollers; the metal wire extends from wiring wheel passing through the wiring tensioning sensor and winding parallel hundreds of rounds on three rotation rollers to form a cut surface, the main substrate programming controls the CPU module so as to control the rotation / direction of the servo motors, thus leading the rotation rollers, stranding wheel and wiring wheel to reciprocate to rotate. The micro-computer multi-wire cutting machine has high cutting precision and working efficiency.

Owner:乐清市新晶电子器件有限公司 +1

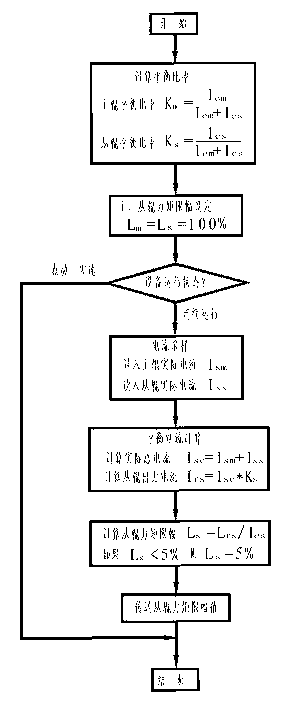

Tension roll control device for plate and strip processing line and tension control method

The invention discloses a tension roll control device for a plate and strip processing line and a tension control method, belonging to the field of tension control of tension rolls on the plate and strip processing line in the metallurgical industry. The tension roll control device comprises a tension roll group, an auxiliary roll frequency converter and a main roll frequency converter, and further comprises an auxiliary roll speed encoder, a main roll speed encoder, a load distributor, a tension regulator, a feedforward compensation unit and a tensiometer, wherein two ends of the load distributor are respectively connected with the auxiliary roll frequency converter and the main roll frequency converter; the auxiliary roll frequency converter comprises an auxiliary roll rotation speed control unit and an auxiliary roll torque control unit; and the main roll frequency converter comprises a main roll rotation speed control unit and a main roll torque control unit. The tension roll control device has the advantages of high control response speed and high control precision. A control method of the tension roll control device comprises the steps of: (1) main / slave load distribution for the tension rolls; (2) complex tension control of the tension rolls; and (C) dynamic compensation. The method has the advantages of small steady state error of a torque loop, short anti-disturbance recover time, constant rotation speed and good anti-disturbance performance.

Owner:安徽马钢输送设备制造有限公司

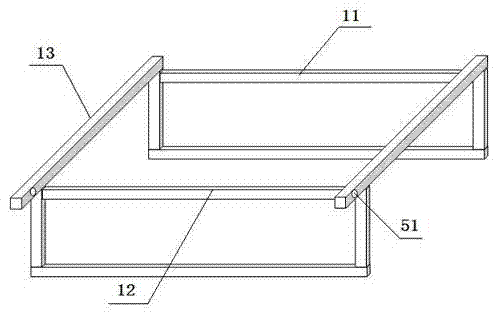

Gluing fixed support for tensile property tests on fiber multifilaments and fiber multifilament sample preparing method

ActiveCN102759479AConstant tensionImprove pass ratePreparing sample for investigationStrength propertiesFiberInsertion stent

The invention relates to a gluing fixed support for tensile property tests on fiber multifilaments and a fiber multifilament sample preparing method. The gluing fixed support comprises a fixed support body, one end of the fixed support body is provided with a plurality of fixed round rods, the other end of the fixed support body is correspondingly provided with separating round rods (the number of the separating round rods is the same as the number of the fixed round rods), each glue-dipped fiber multifilament after being hung on one fixed round rod is formed into two mutually-parallel parts, the two ends of each glue-dipped fiber multifilament are respectively located on both sides of one separating round rod and connected with a heavy object (hung in the air) through a fixture, and the masses of the heavy objects are the same so as to ensure that the cured tensile forces of the glue-dipped fiber multifilaments are completely the same. The fiber multifilament is fixed at one end of the gluing fixed support for tensile property tests on fiber multifilaments disclosed by the invention, and the other end of the gluing fixed support ensures that a fiber always has a constant tensile force in the process of glue dipping and curing by way of hanging weights, therefore, bent sample bands or sample bands with glue beads do not occur, and the yield rate of the sample band is 100%, thereby greatly improving the qualified rate of the sample band.

Owner:BEIJING UNIV OF CHEM TECH

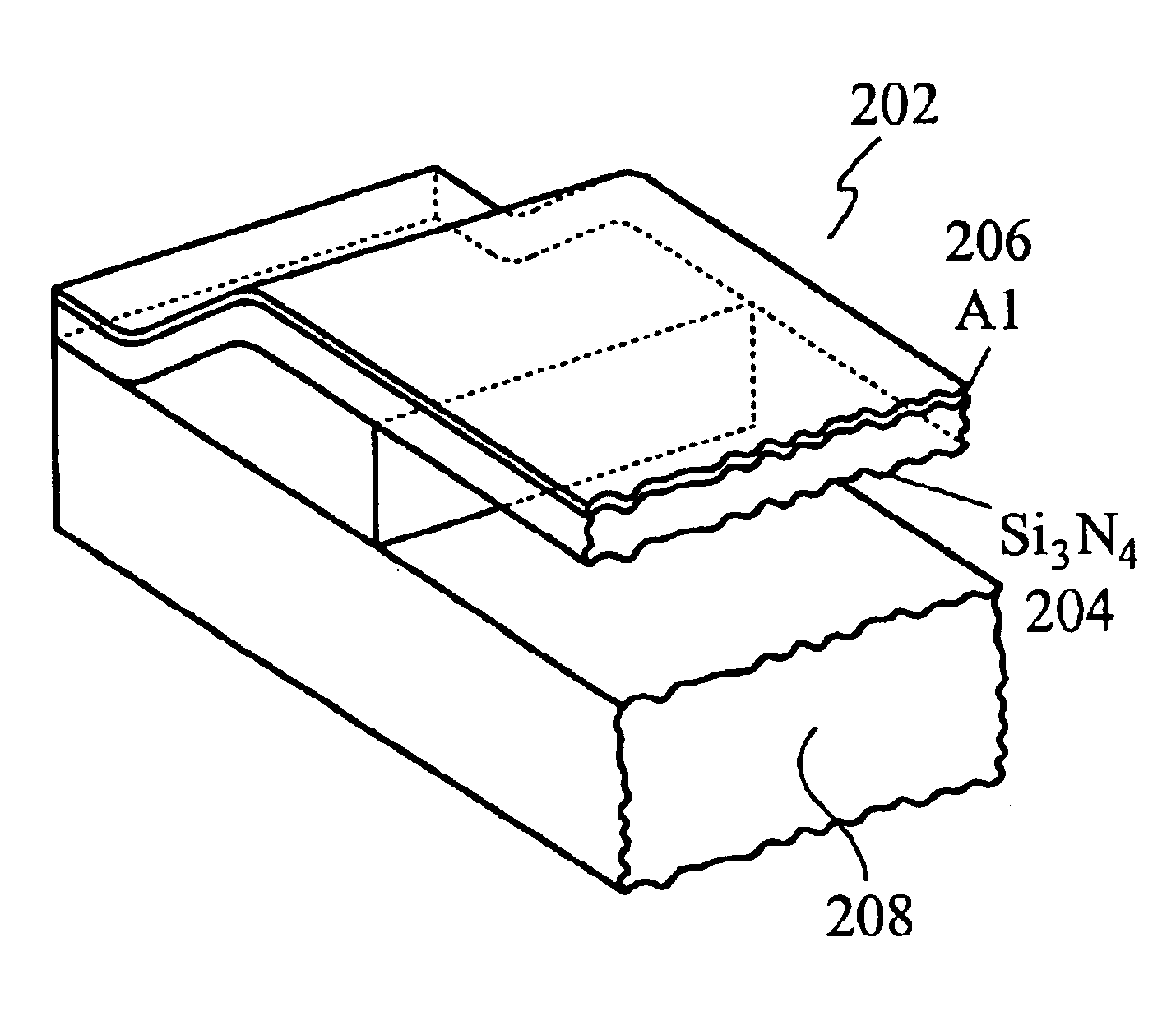

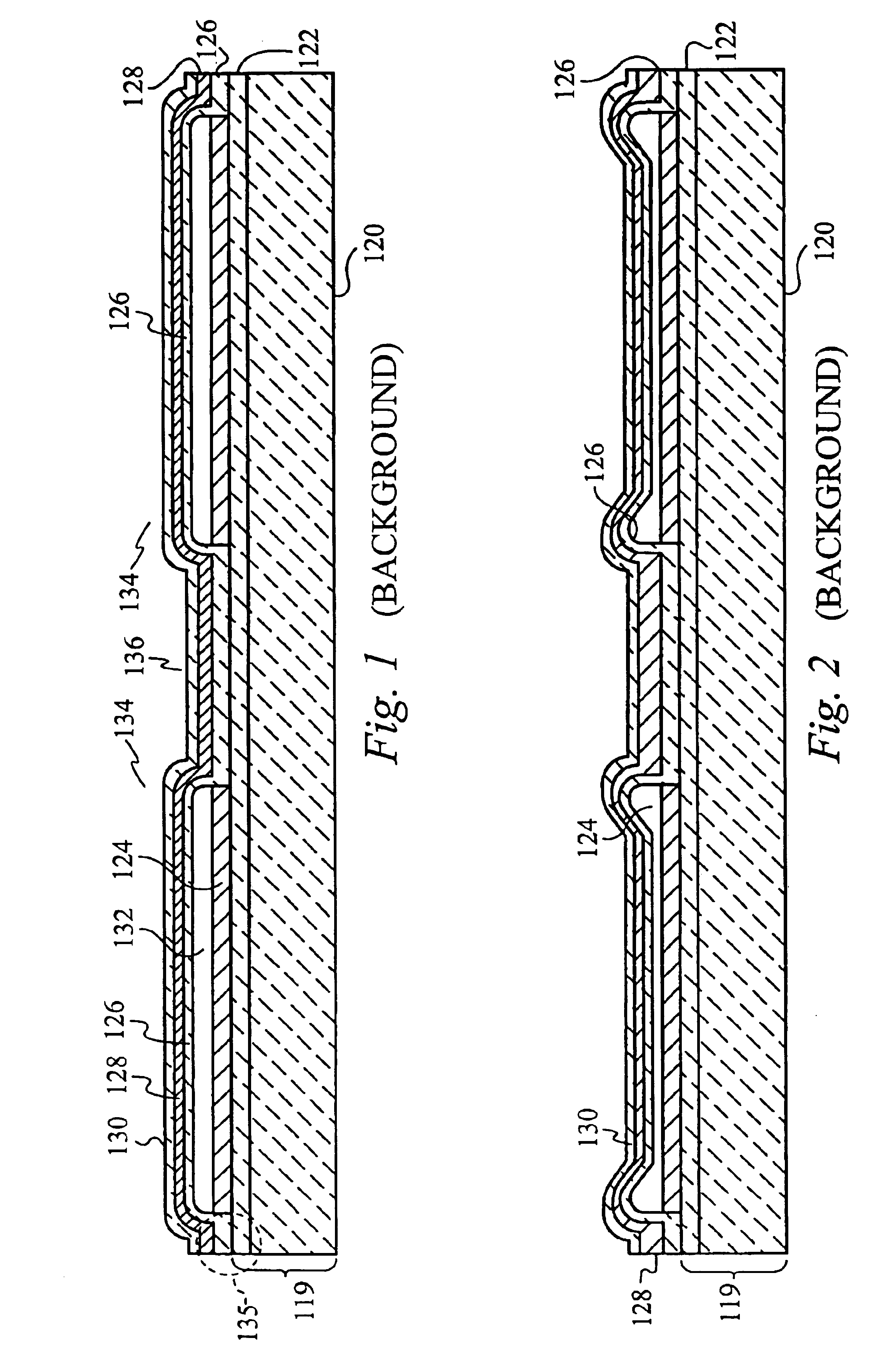

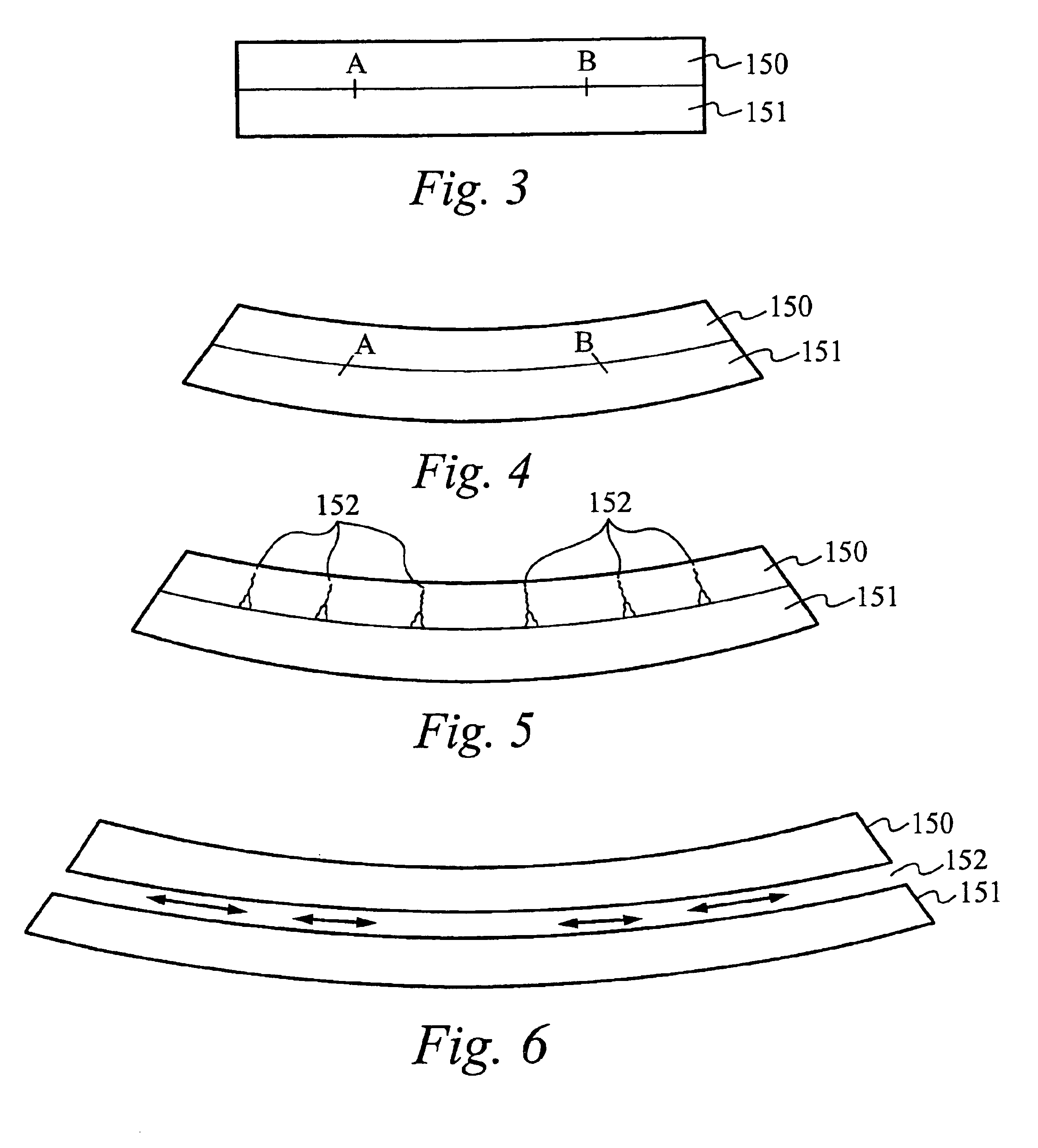

Method and apparatus for leveling thermal stress variations in multi-layer MEMS devices

InactiveUS6922272B1Reduce variationProcess stabilityDecorative surface effectsSemiconductor/solid-state device detailsThermal coefficientStress variation

A MEMS device such as a grating light valve™ light modulator is athermalized such that the force required to deflect the movable portion of the MEMS device remains constant over a range of temperatures. In MEMS embodiments directed to a grating light valve™ light modulator, a ribbon is suspended over a substrate, and the ribbon tension is kept constant over a temperature range by adjusting the aggregate thermal coefficient of expansion of the ribbon to match the aggregate thermal coefficient of expansion of the substrate. Various opposition materials have an opposite thermal coefficient of expansion as the aluminum layer of a grating light valve™ light modulator ribbon, using the thermal coefficient of expansion of the substrate as a zero coefficient reference. The adjustment of the thermal coefficient of expansion of the ribbon can be performed variously by thickening existing layers of opposition material or adding additional layers of new opposition material to the ribbon, or reducing the aluminum in aluminum layer. The aluminum layer may be reduced variously by reducing the thickness of the aluminum layer, or reducing the surface area that the aluminum covers, or reducing both the surface area and the thickness. Embodiments may combine the reduction of aluminum with the use of opposition materials.

Owner:SILICON LIGHT MACHINES CORP

Bag filling and packaging method and bag filling and packaging apparatus

InactiveUS20070204570A1Maintains the degree of tension in the bags constantConstant tensionSolid materialLiquid materialSet distanceCam

A bag filling and packaging system including gripper pairs around a rotating table so that the grippers of each gripper pair grip two side edges of a bag on which various packaging processes are performed. A gripper distance adjustment auxiliary cam is provided to ascend and descend relative to a gripper distance setting cam for setting distance between grippers. A roller rolls on the two cams as the table rotates, and the distance between the grippers changes in response to the height of the roller by a transmission mechanism. An apparent bag width is measured prior to gripping a bag, the height of the gripper distance adjustment auxiliary cam is controlled according to this measured value, and the distance between grippers in a bag supply process is adjusted accordingly, the amount of part gripped by the grippers at side edges of a bag thus being constant for all bags.

Owner:TOYO JIDOKI CO LTD

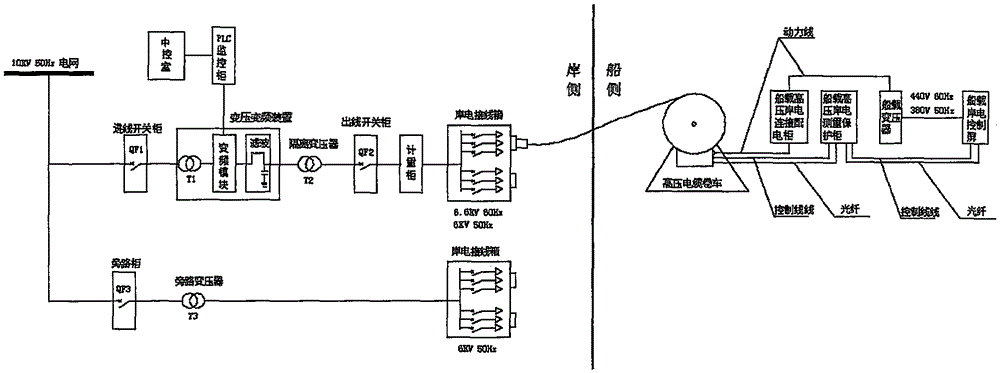

Shipping high-voltage shore power system

PendingCN105490264ARealize remote settlementMeet power requirementsAc network circuit arrangementsElectricityEngineering

The invention provides a shipping high-voltage shore power system. The output power adopts AC6.6KV / 60Hz or AC6KV / 50Hz; the shipping high-voltage shore power system comprises a shore-based part and a shipborne part, wherein the shore-based part comprises a high-voltage wire-inlet switch cabinet, a high-voltage frequency converter, an isolating transformer, a wire-outlet switch cabinet, a measuring cabinet, a high-voltage shore power junction box and a PLC monitoring cabinet; the shipborne part comprises a high-voltage cable reel, a shipborne high-voltage shore power connection power distribution cabinet, a shipborne high-voltage shore power measuring protection cabinet, a shipborne transformer and a shipborne shore power access control screen. The shipping high-voltage shore power system adopts a high-voltage boarding manner, and the output power adopts AC6.6KV / 60Hz or AC6KV / 50Hz; therefore, the shipping high-voltage shore power system is suitable for shore-based power supply for ports, and can be applied in a convenient, rapid and effective manner; power supply for ships in berthing periods is realized; and the shipping high-voltage shore power system is energy-saving, environment-friendly, and regarded as a part of green ports.

Owner:LIAONING LVGANG TECH CO LTD

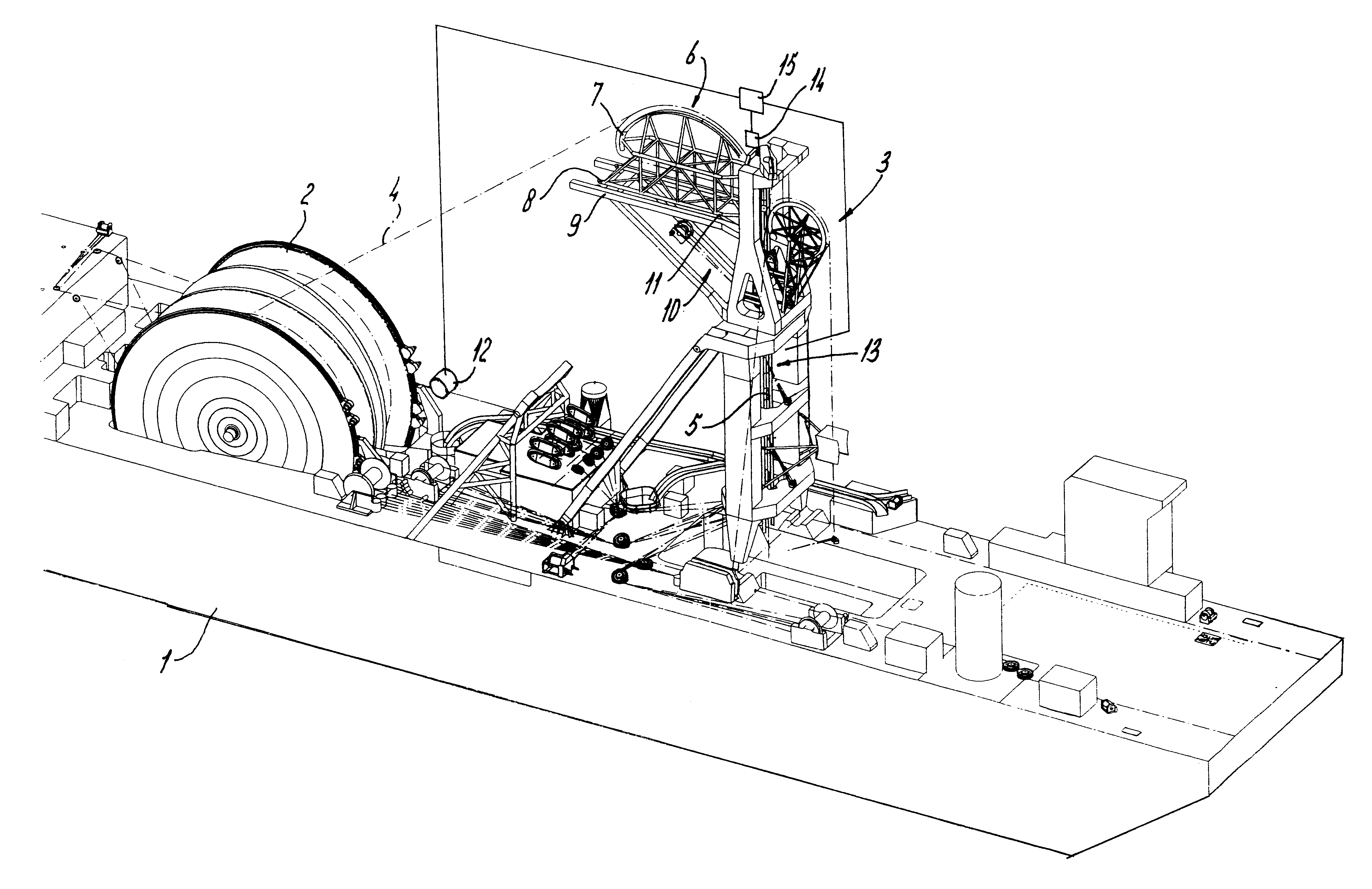

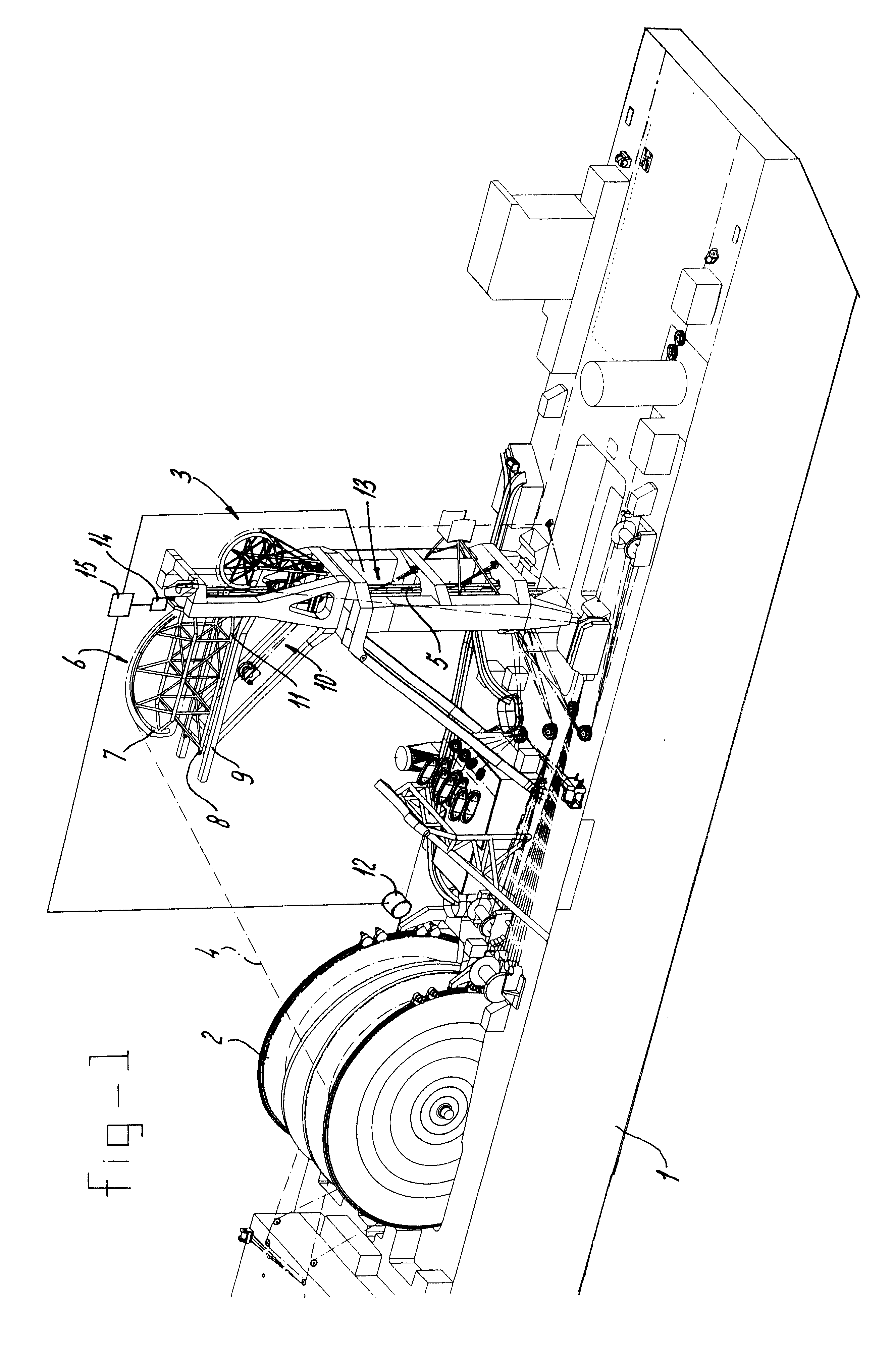

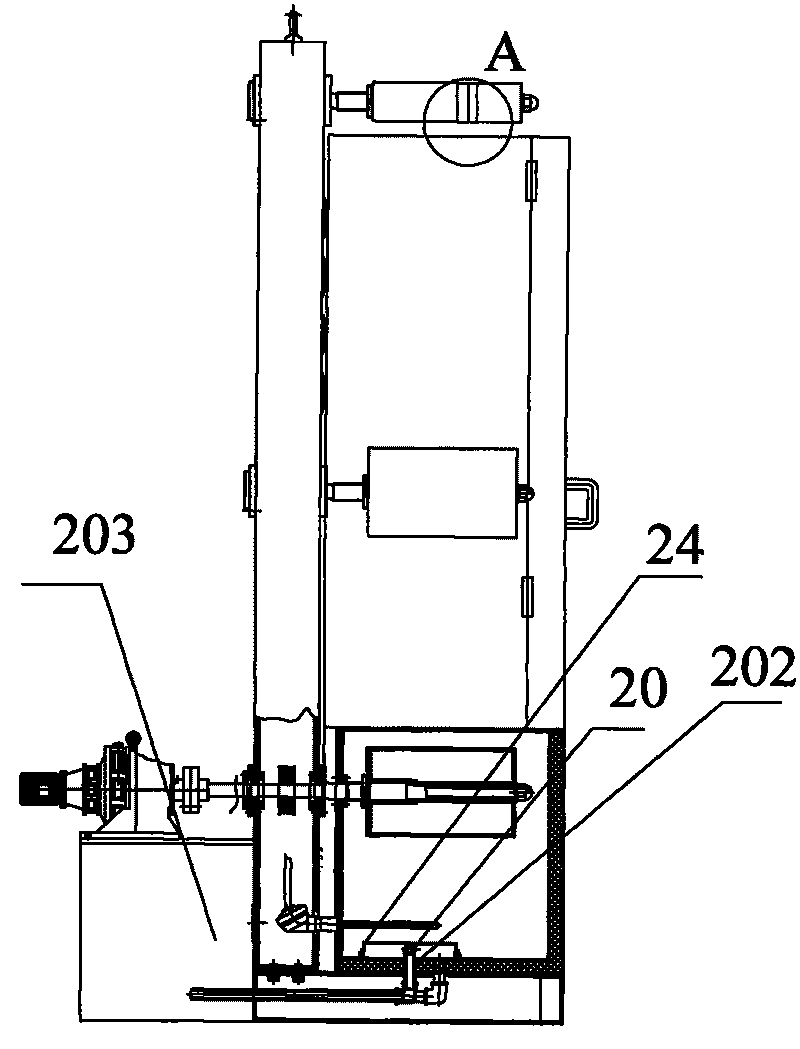

Pipe lay system with tension compensator

InactiveUS6761506B2Maintain tensionConstant tensionPipe laying and repairFilament handlingLength variationConductor Coil

A pipe lay vessel with a reel for carrying a length of pipe and first drive part for controlling rotation of the reel. A substantially vertical guide structure includes at its upper end a deflection member for deflecting the pipe from a first trajectory extending between the reel and the guide structure to a second, substantially vertical trajectory. A clamping member carries the vertical pipe section and has second drive for feeding the pipe along the vertical trajectory. A movable tension compensator (7) is provided at the first pipe trajectory for lengthening or shortening the first pipe trajectory to maintain a substantially constant tension of the pipe along the first trajectory during unwinding of the reel. By displacing the tension compensator, the first pipe trajectory can be lengthened or shortened to compensate for variations in speed due to non-uniform winding of the pipe and varying diameter of the spooled pipe and to compensate for sagging of the pipe due to its own weight and length variations upon unspooling in view of occuring plasticity and partial straightening of the pipe.

Owner:SINGLE BUOY MOORINGS INC

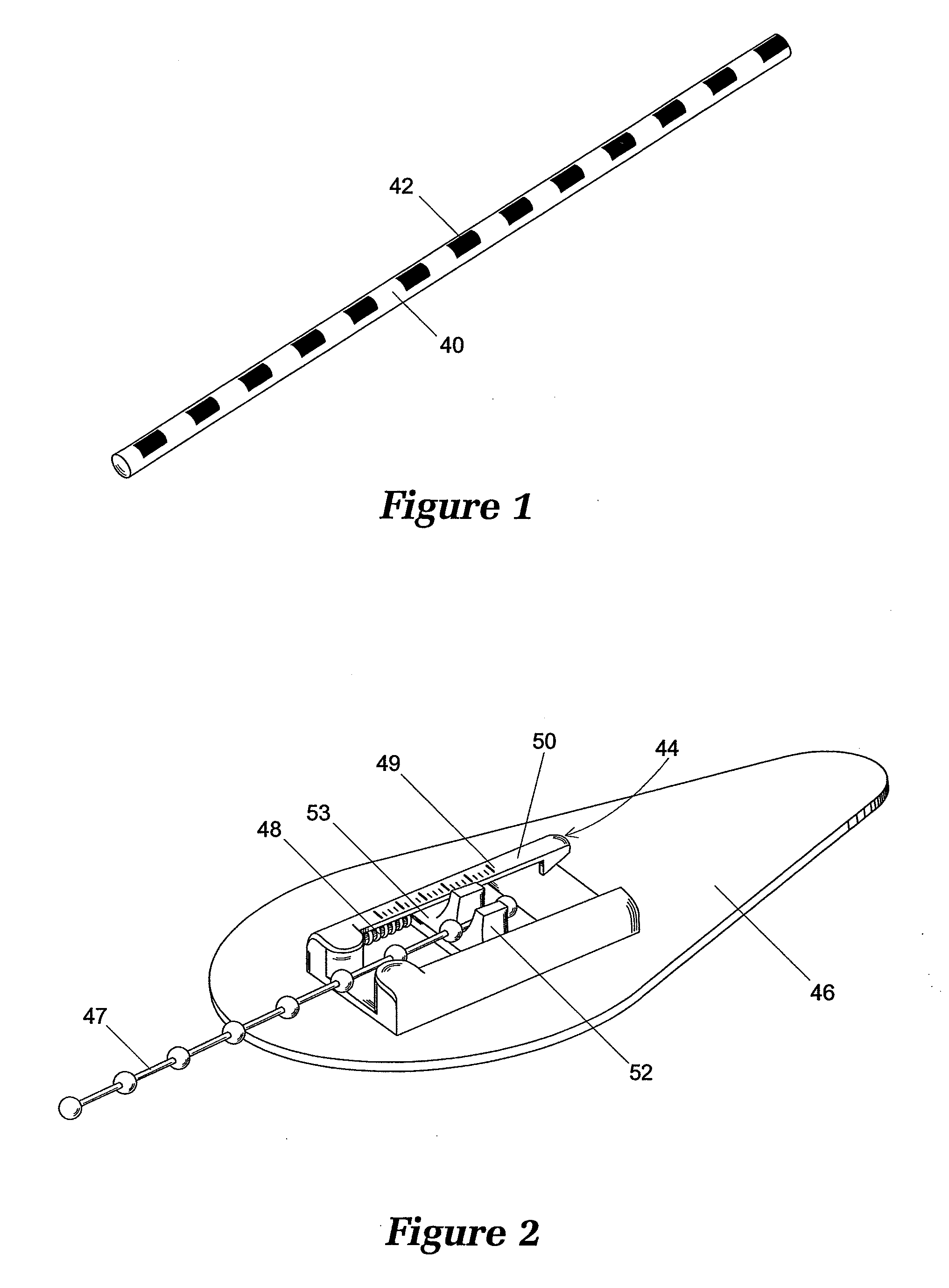

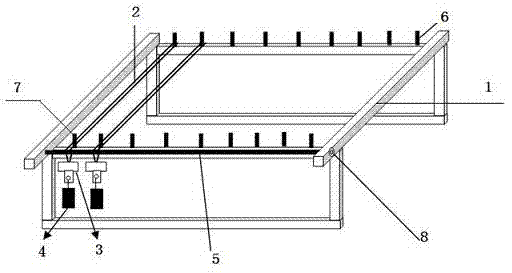

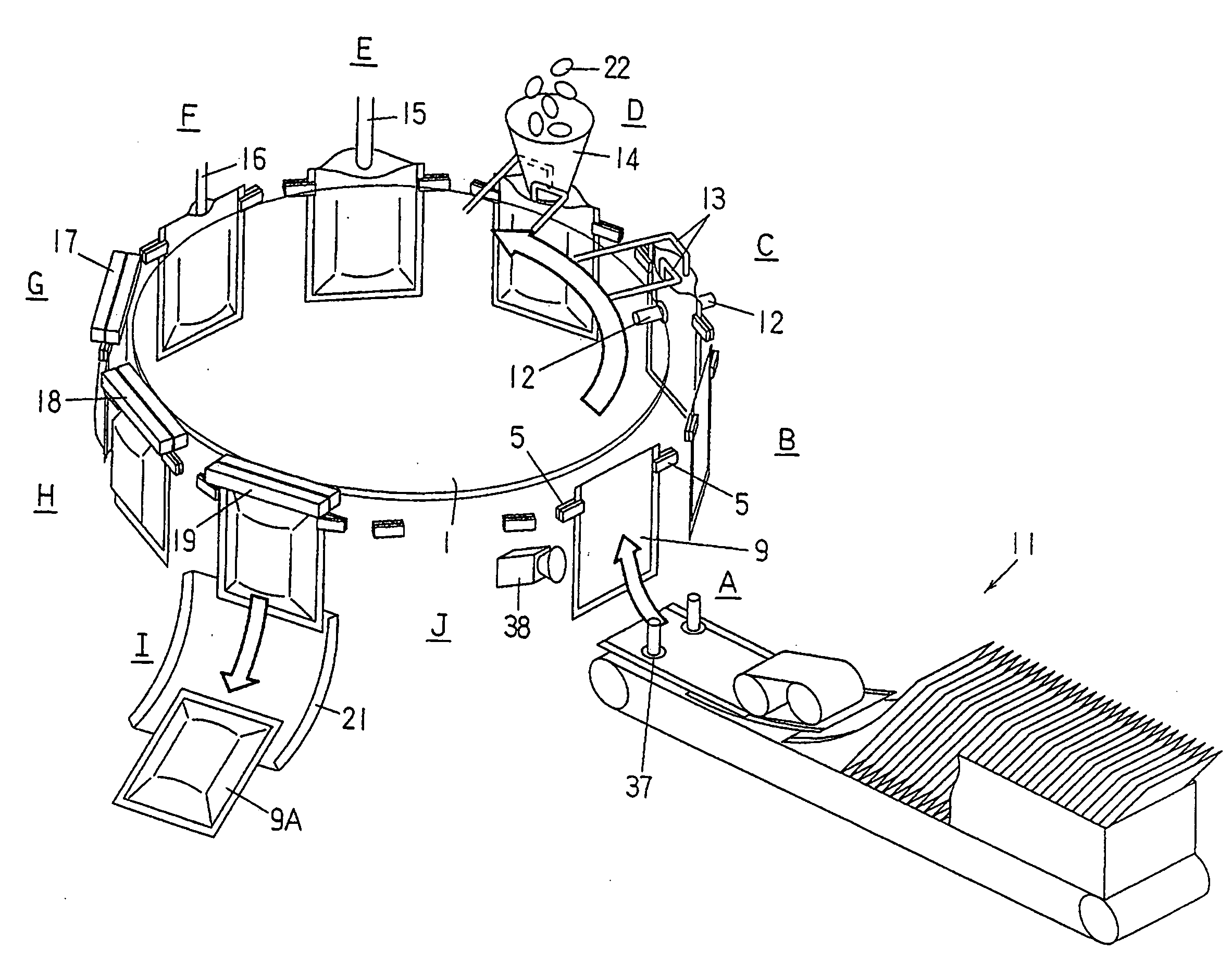

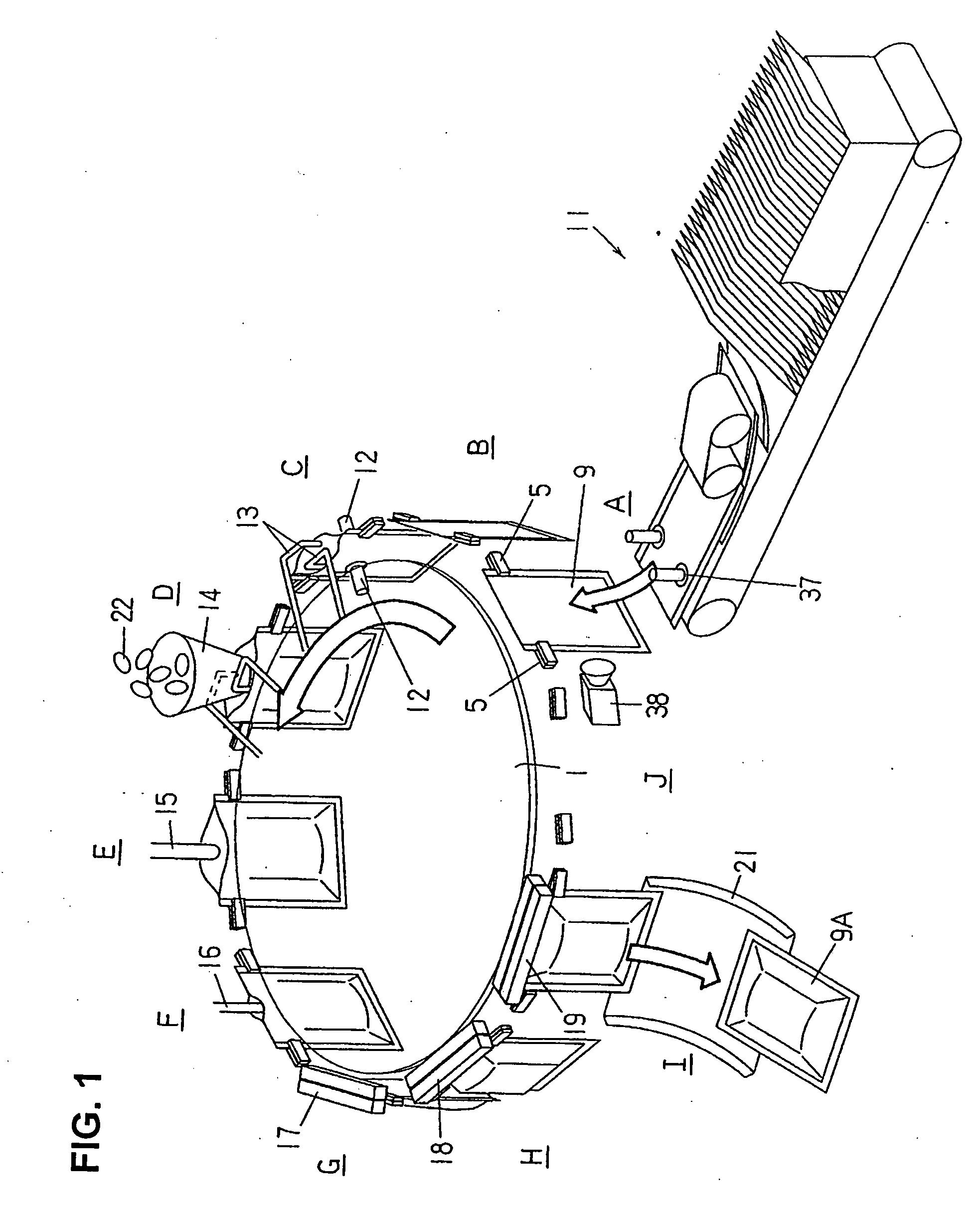

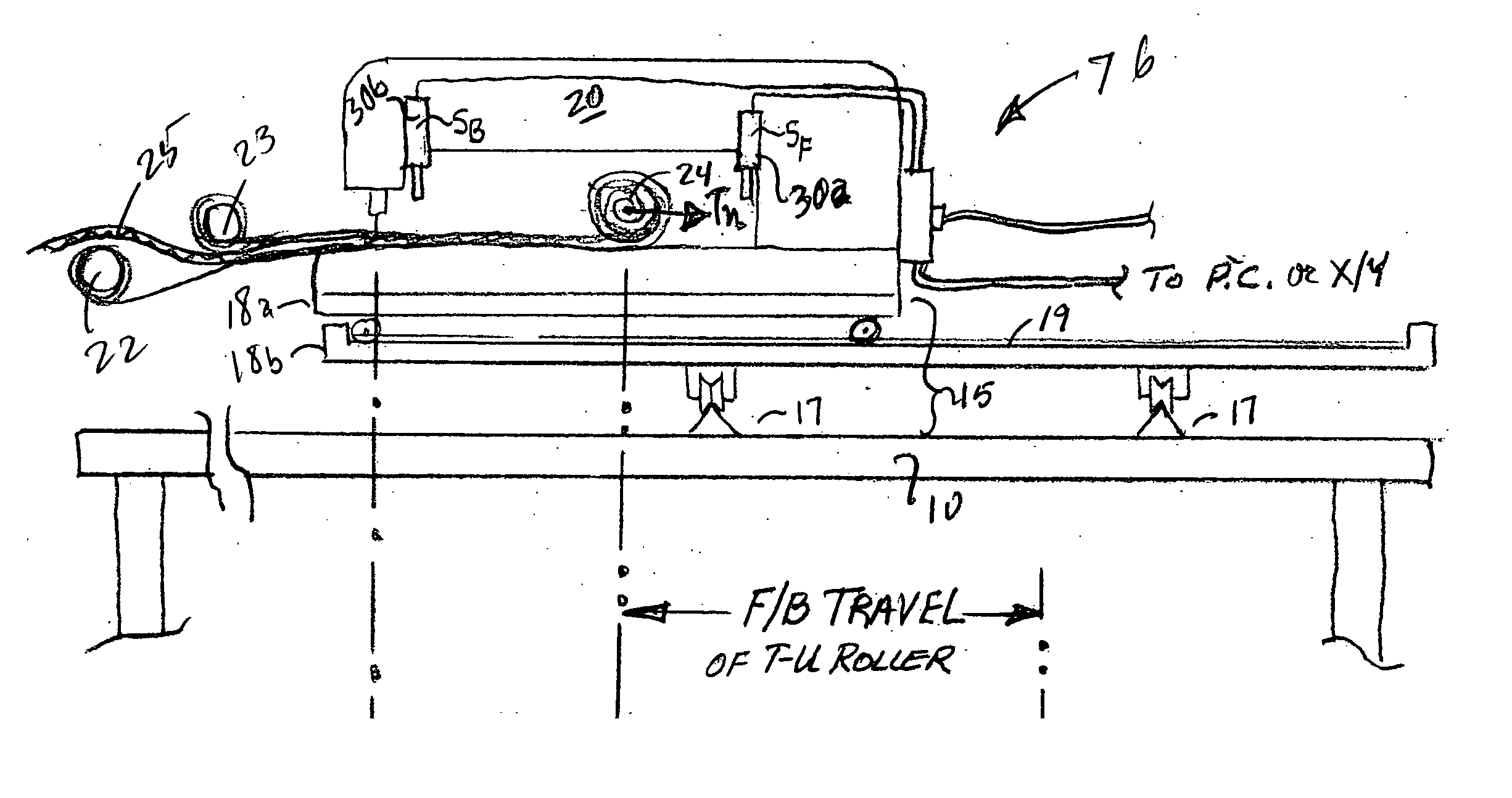

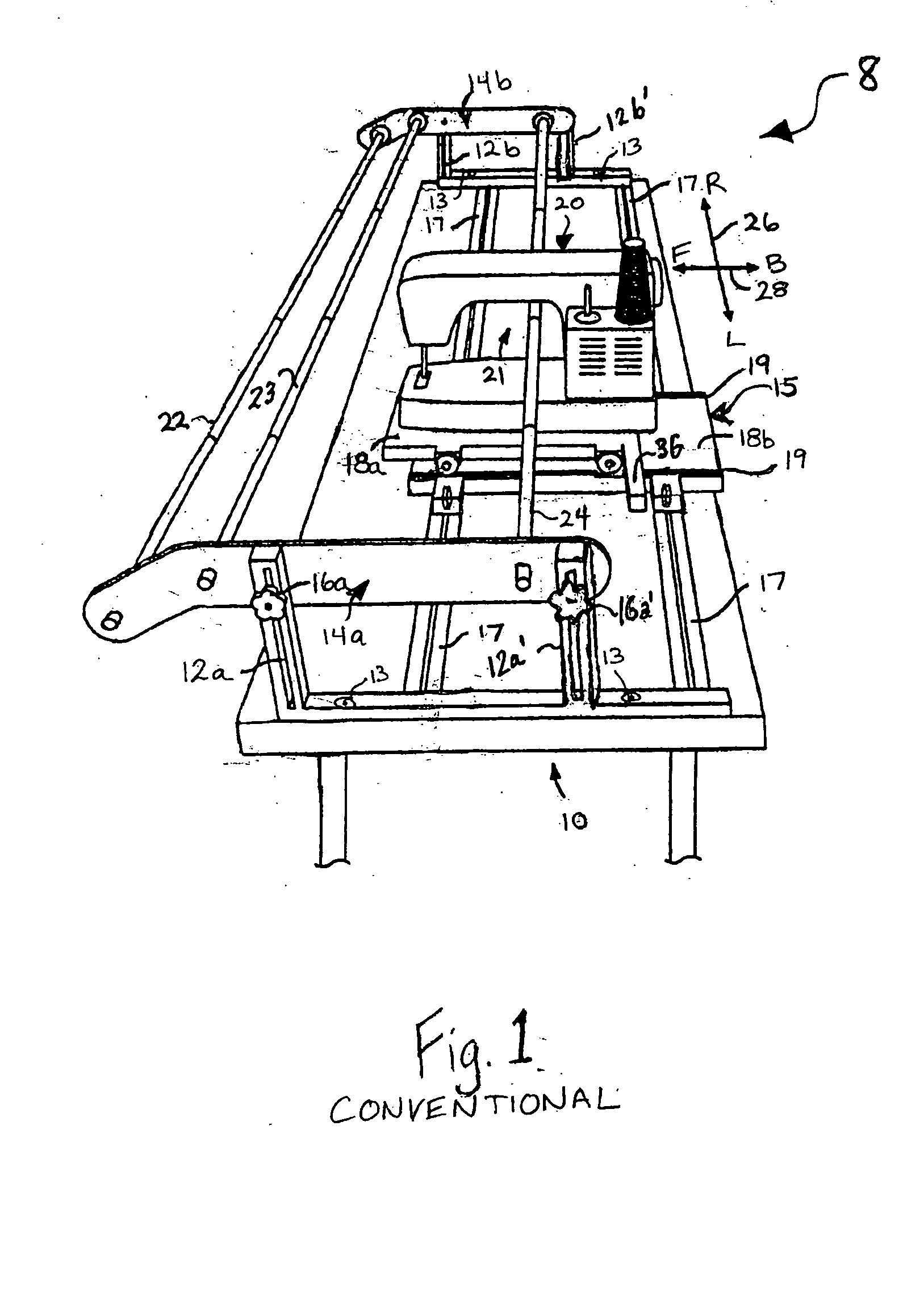

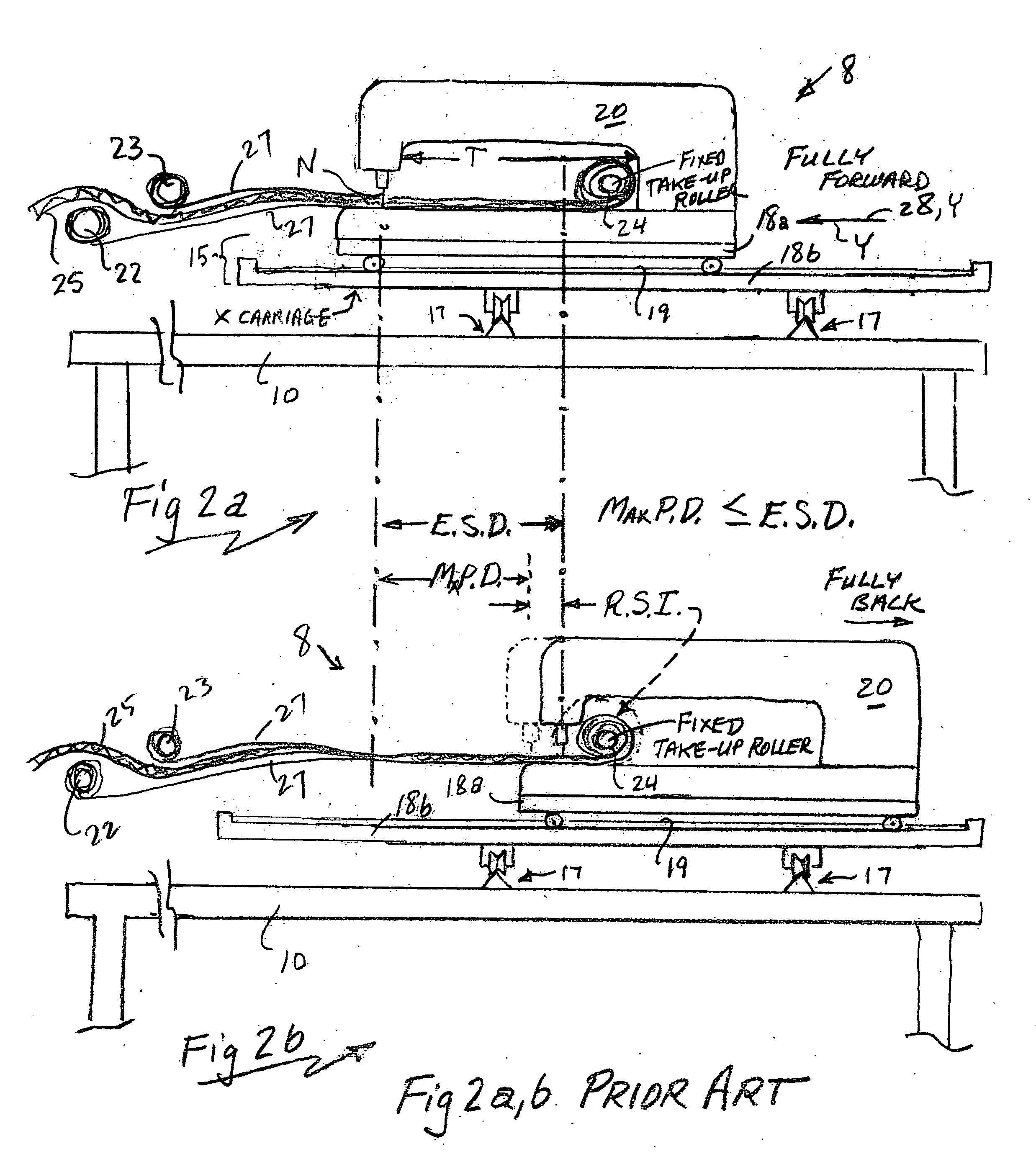

Movable quilting work area system and method

InactiveUS20050045083A1Increased lateral pattern coverageWide rangeWork-feeding meansMattress sewingMicroprocessorSewing machine

An improved quilting apparatus and method for automatically providing a variable sewing area (VSA) independent of the throat depth of the sewing machine used and X / Y carriages on which the sewing machine is mounted, comprising a rotatably-powered take-up roller mounted on laterally movable carriages, a tension system for continuous tension on fabric and batting, arm-mounted or sewing machine-mounted sensors that detect proximity or engage fabric on the take-up roller and cause rotation of the take-up roller so that it is out of the way of the advancing or returning sewing machine. The inventive VSA system includes a microprocessor-based controller for automatic operation, which controller interfaces with PC operated quilting programs that drive powered X / Y carriage systems to allow sewing of quilting patterns much larger than the throat depth of conventional sewing machines.

Owner:MCMUFFIN & SNUFFLES

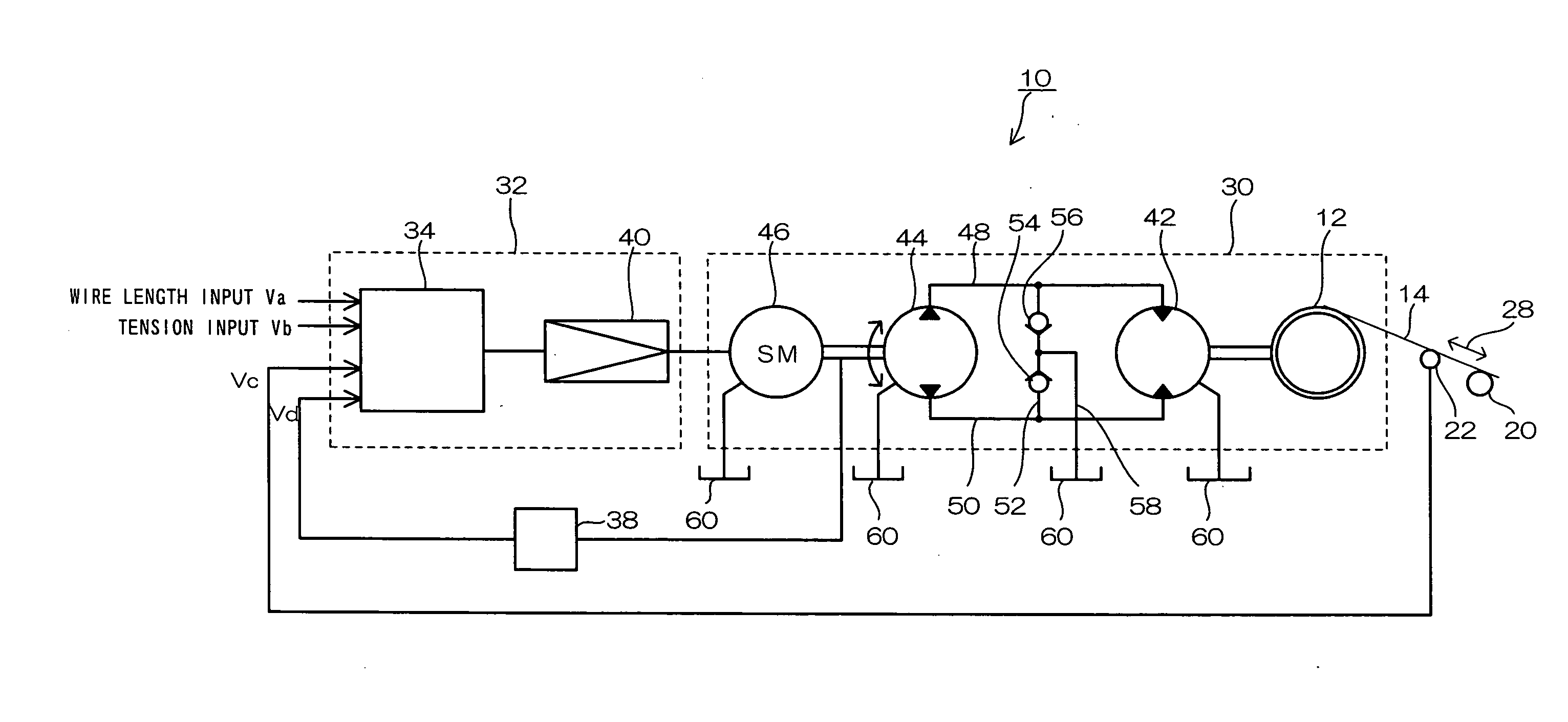

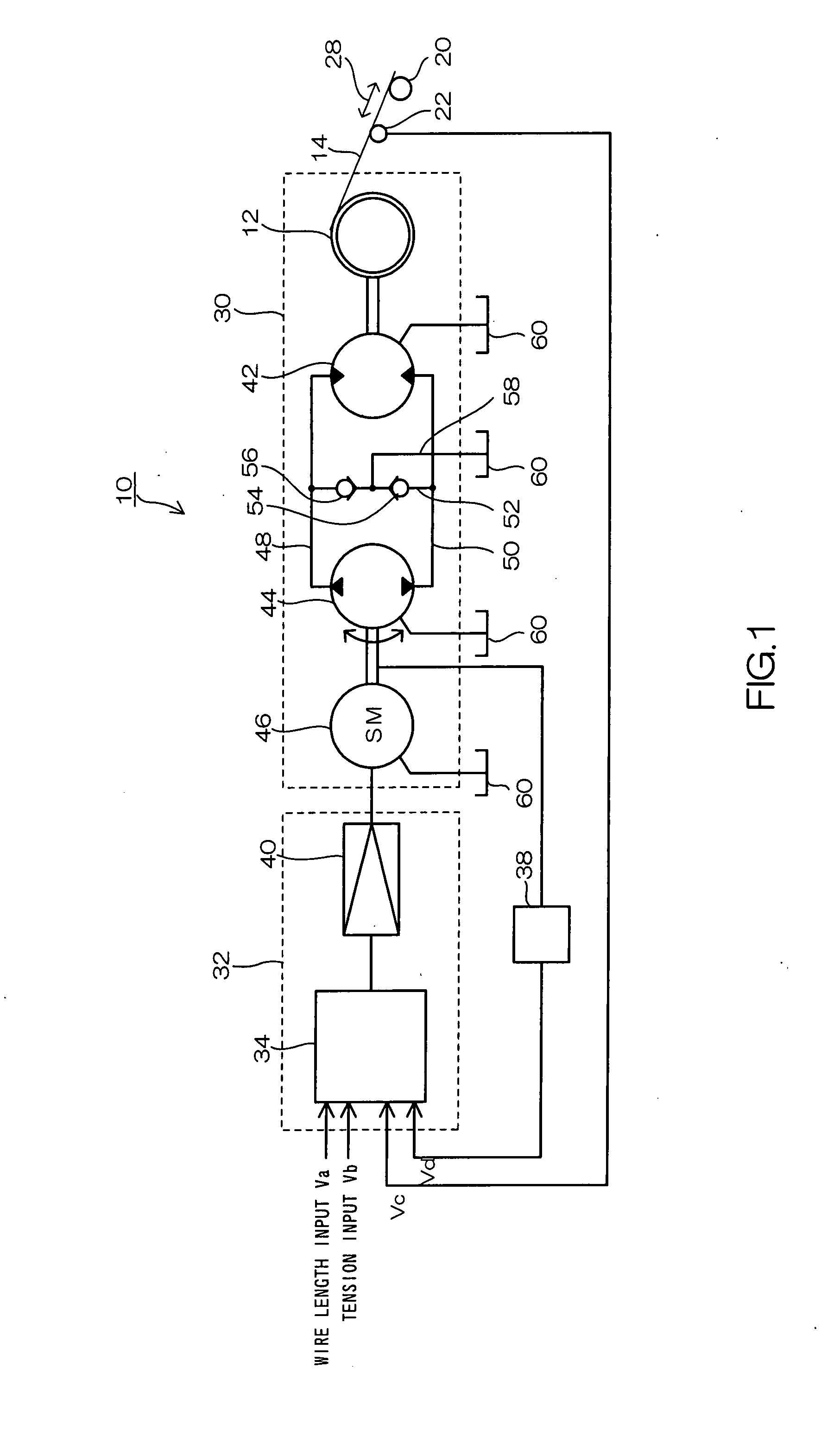

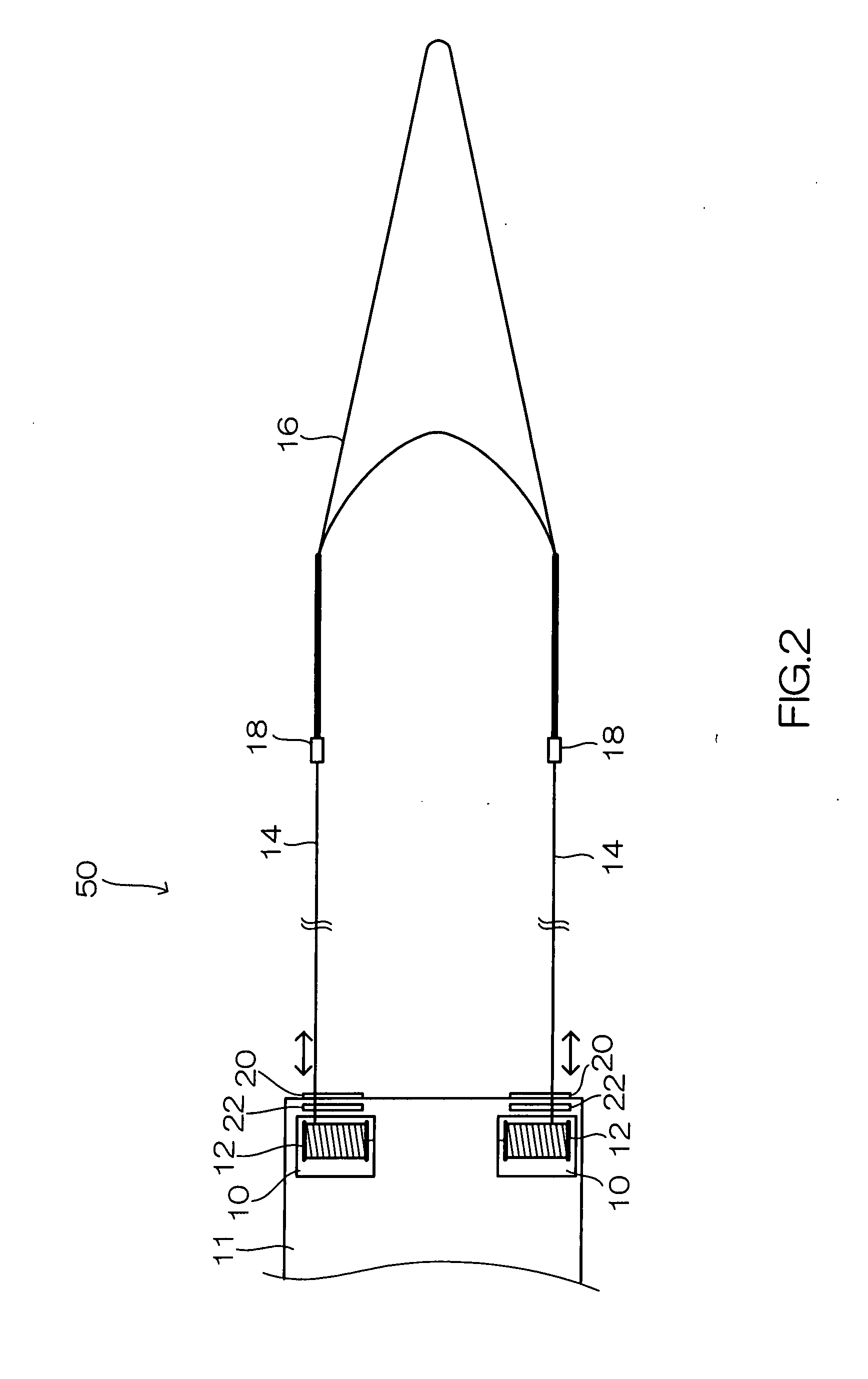

Winding Mechanism with Tension Control Function and Trawling Apparatus

InactiveUS20080164365A1Keep the tensionConsumption energy can be savedTowing/pushing equipmentFishing netsPower flowHydraulic pump

To provide a winding mechanism and a trawling apparatus capable of eliminating an excessive tension or slack generated in a wire wound around a drum and keeping the tension or wire length of the wire constant.A winding mechanism with tension control function includes a reversibly rotatable liquid-pressure motor rotating a drum having a wire wound therearound, a liquid-pressure pump coupled directly with the liquid-pressure motor and supplying hydraulic oil, and an electric motor rotating to drive the liquid-pressure pump. The winding mechanism further includes a control unit controlling a torque of the electric motor based on a variation in load current of the electric motor and winding off or winding up the wire to keep the tension of the wire at a set value.

Owner:MITSUI ENG & SHIPBUILD CO LTD +2

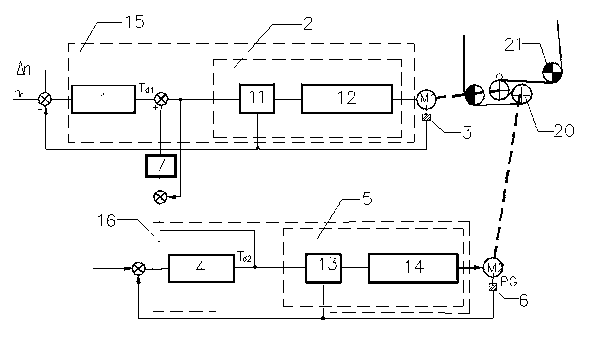

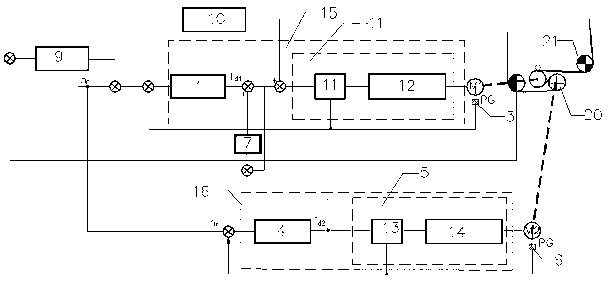

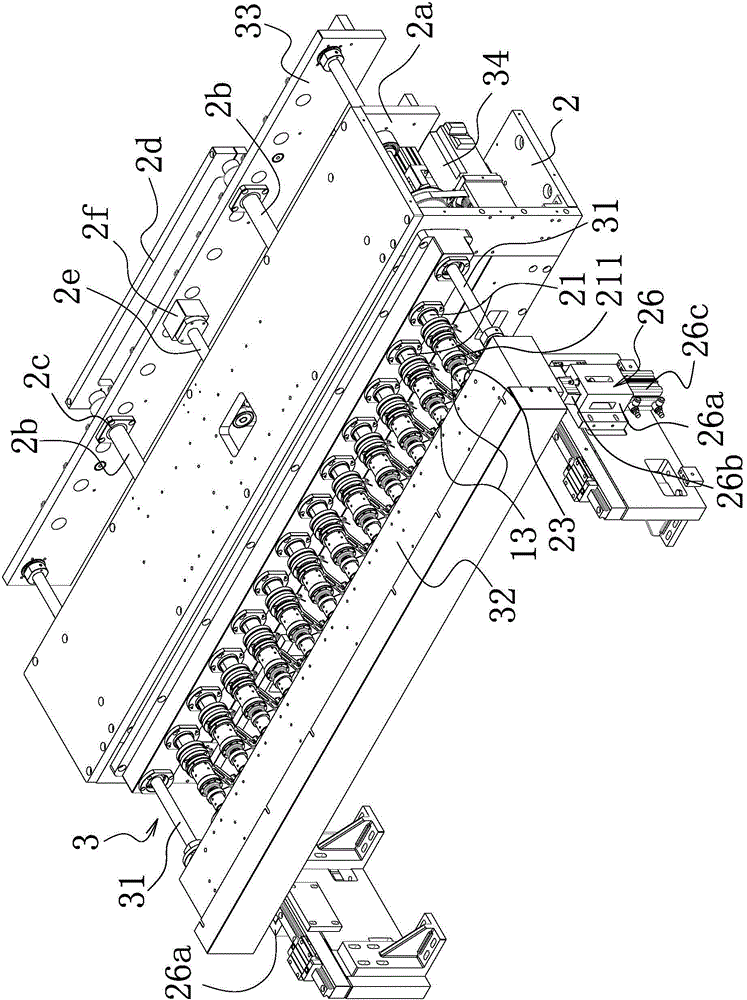

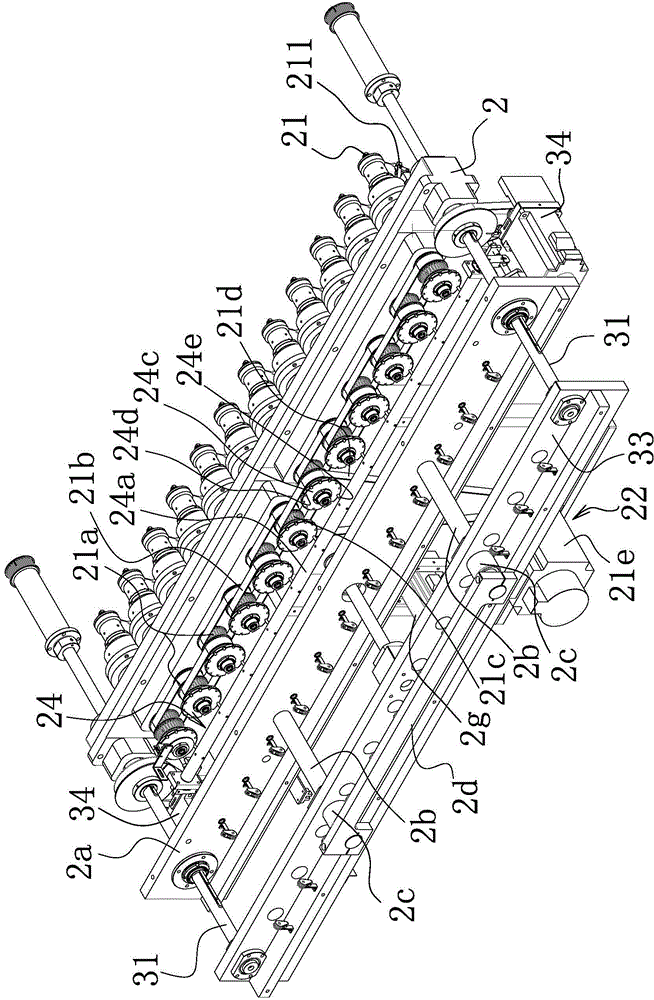

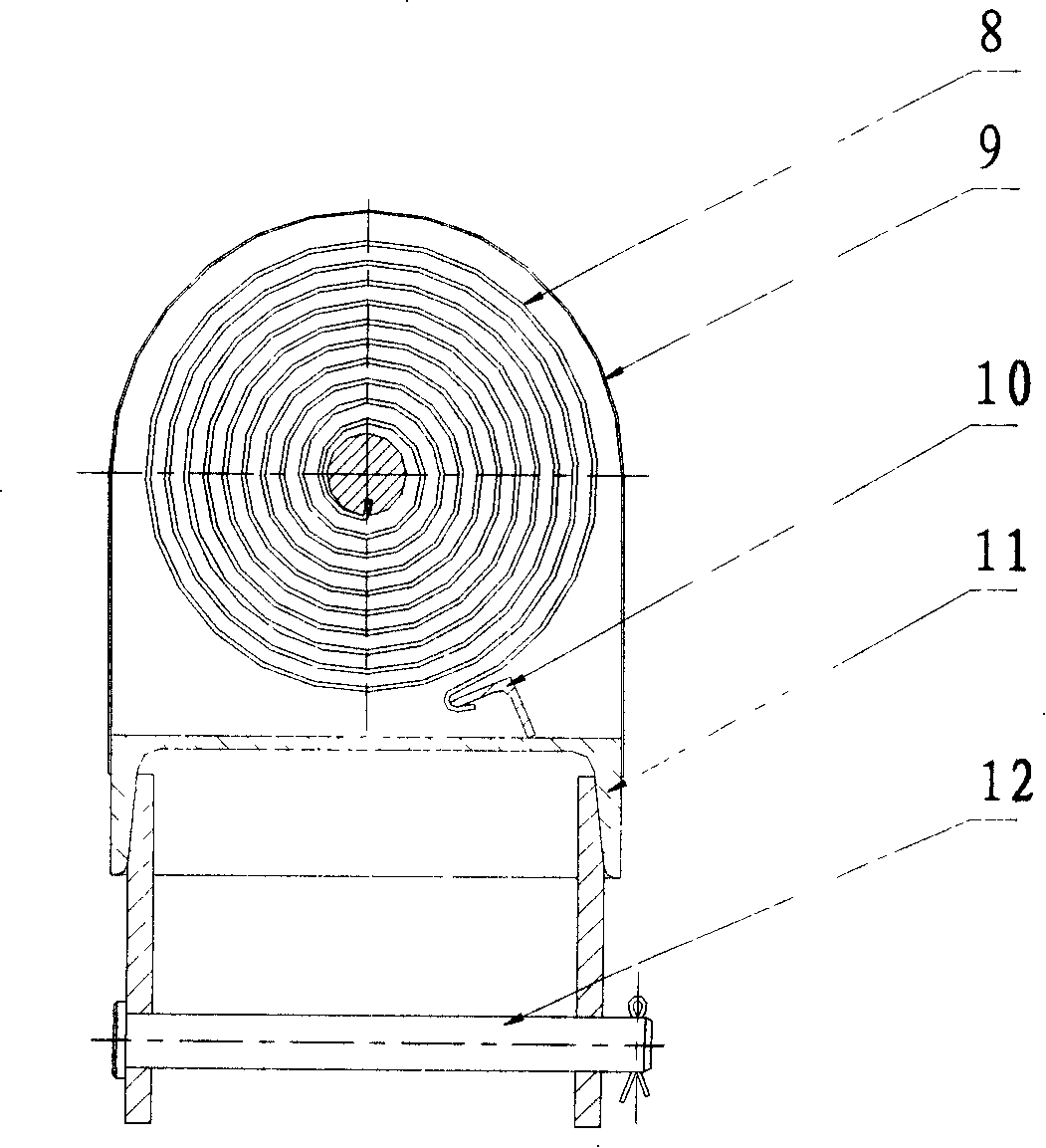

Hollow coil winding equipment

ActiveCN104916427AShorten heating timeLow powerFilament handlingCoils manufactureHeating systemHeating time

The invention relates to hollow coil winding equipment, which solves the technical problem that the heating time is long and the cost is high in the prior art. The hollow coil winding equipment comprises a bobbin unit, a stand arranged at one side of the bobbin unit and a plurality of winding fixtures. A mounting base is arranged on the stand. A plurality of main shafts which correspond to the winding fixtures one to one and which are connected with the winding fixtures in a rotary manner are arranged on the mounting base. A plurality of counter shafts which correspond to the winding fixtures one to one and which can be used for driving the winding fixtures to rotate are arranged on the mounting base. The equipment further comprises a heating system which can be used for heating the two ends of wound coils and the wound coils wound on the winding fixtures. The equipment further comprises a tension control system for enabling the two ends of the wound coils to have constant tension while the wound coils are continuously wound on the winding fixtures. The invention has the advantages that the hollow coil winding equipment could greatly reduce the heating time, and is low in cost and stronger in practicability.

Owner:TANAC AUTOMATION

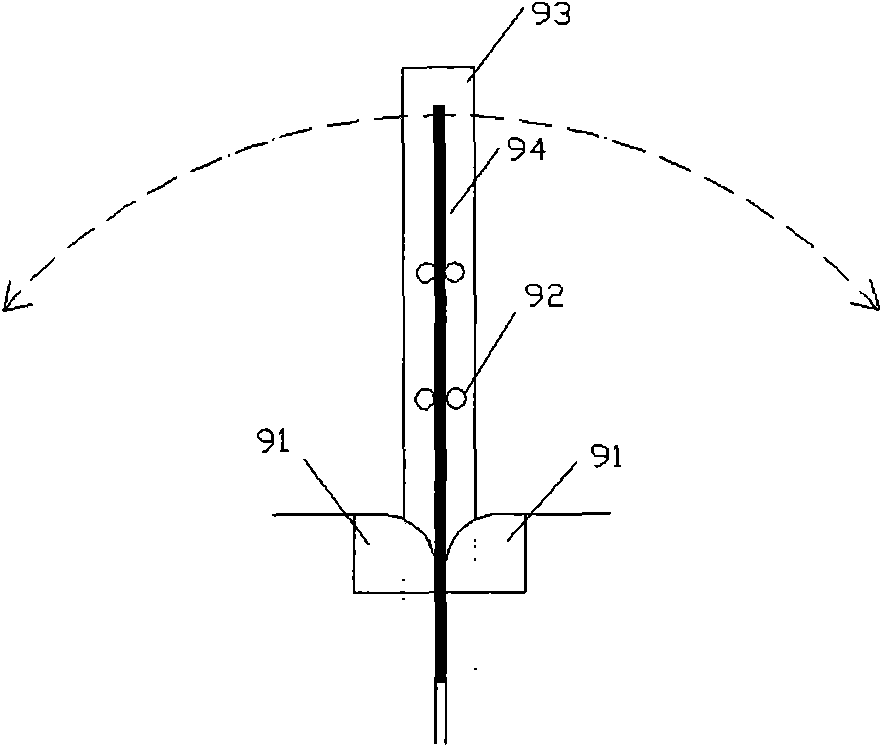

Repeated bending testing equipment under constant load and method

ActiveCN101639430AAccurate performanceConstant tensionMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesConstant loadFree rotation

The invention relates to repeated bending testing equipment under constant load and a method, belonging to the field of detection technique. The equipment comprises a drawing system and a bending system, wherein the drawing system is provided with a second clamping device connected with an elastic device and a drawing loading platform capable of rotating freely so as to realize the purposes of applying constant load to the sample and ensuring that bilateral bending occurs at effective parts; the bending system comprises a bending die, a bending working platform and a sliding groove with special track, realizes the equal-amplitude reciprocating movement of the bending working platform along the sliding groove and drives the sample to occur repeated bending at the arc of the bending die. Theinvention also discloses a testing method for carrying out repeated bending under constant load by the equipment, which can carry out repeated bending performance test under constant load on even materials and materials with welding seams.

Owner:SHOUGANG CORPORATION

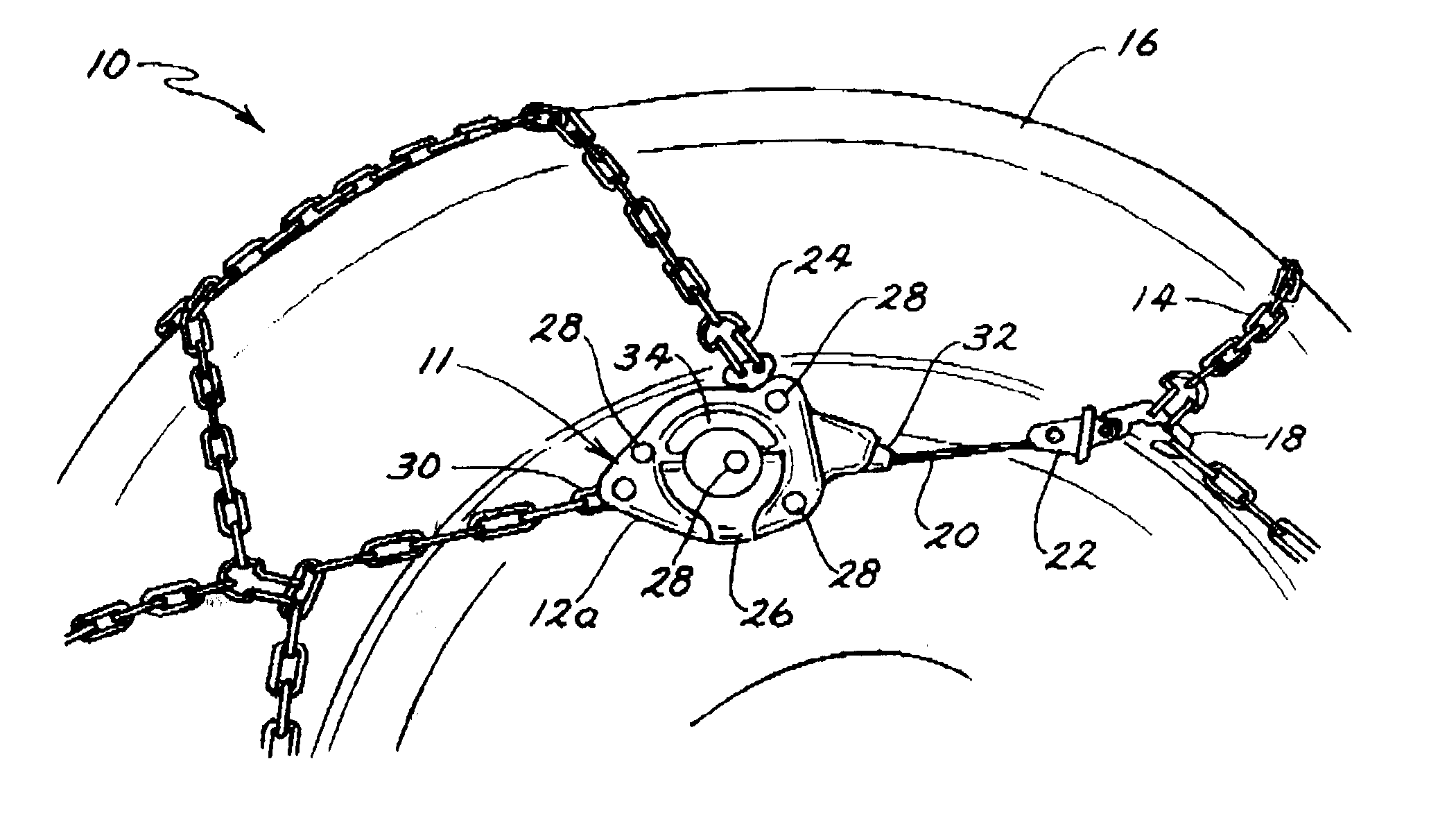

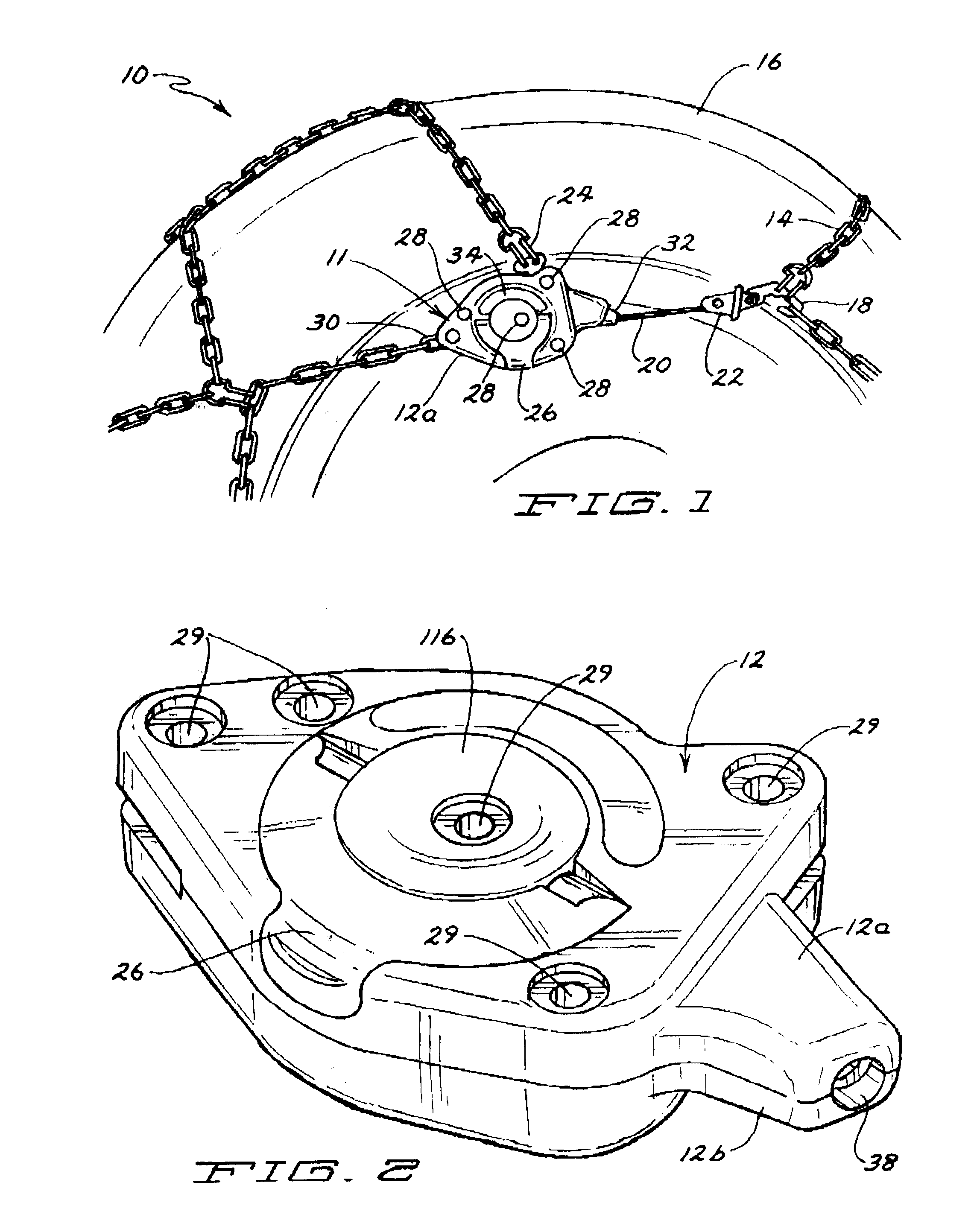

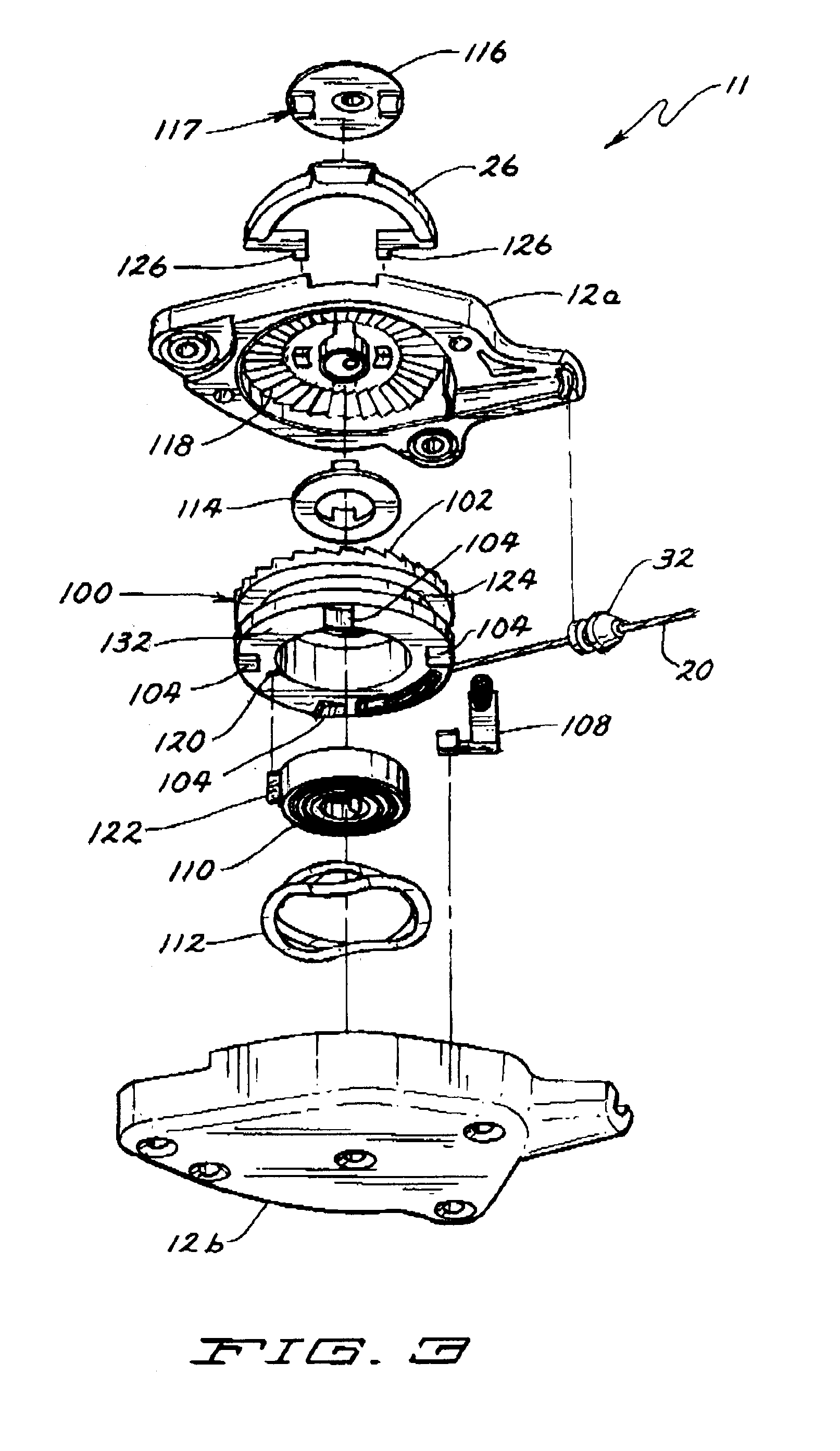

Self-Tightening Snow Chain and Methods of Use

ActiveUS20070199635A1Effectively tightensEasy to installBelt retractorsTyre tread bands/patternsEngineeringGrommet

Self-tightening snow chain for attachment to a vehicle wheel to provide traction. The preferred self-tightening snow chain includes a traction cable and a tensioning device including a housing having a top including a set of housing teeth, a bottom and at least one aperture; a lever interconnected to the housing; a ratchet spool within the housing having a set of ratchet teeth that mate with the housing teeth and a channel between upper and under surfaces to receive a cord that is interconnected with the ratchet spool; a tension spring that places a bias on the ratchet spool toward a wind-up direction; and a wave spring. A preferred tensioning device includes a cord sub-unit having two knobs, one on each end, and a grommet encircling the cord. A method of assembling the tensioning device is also disclosed.

Owner:PEERLESS CHAIN COMPANY

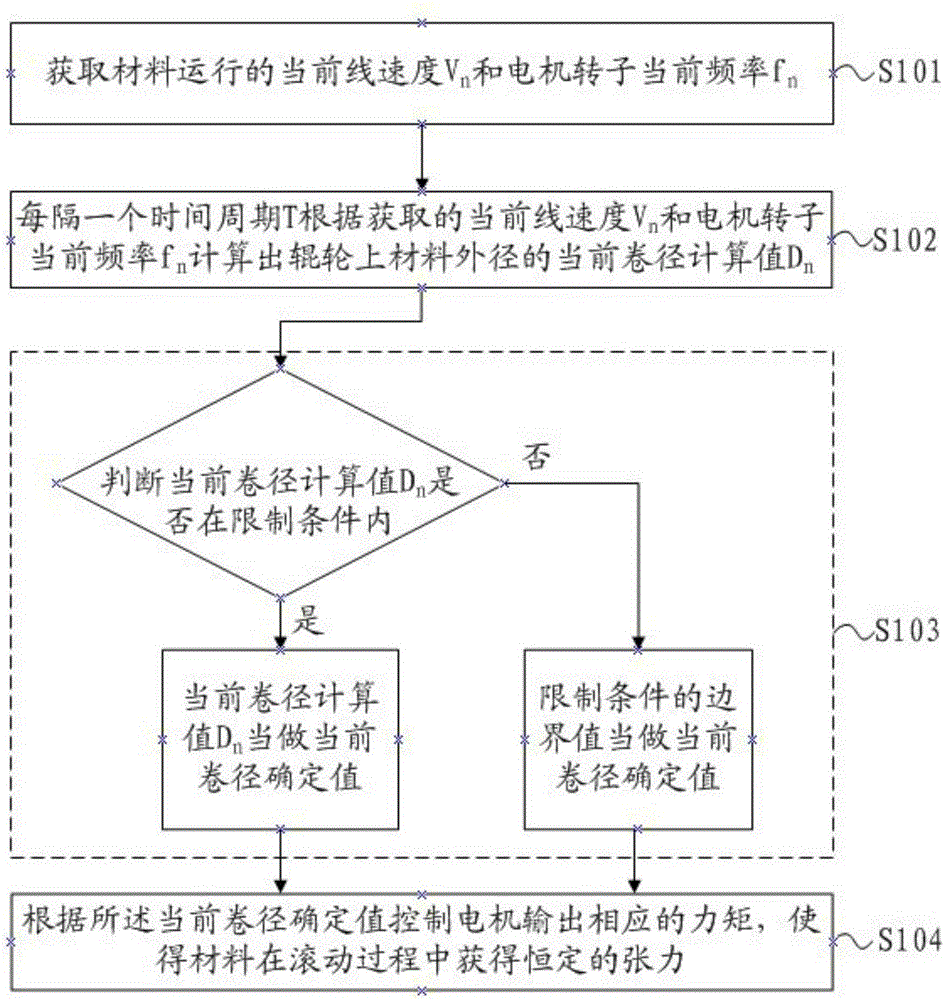

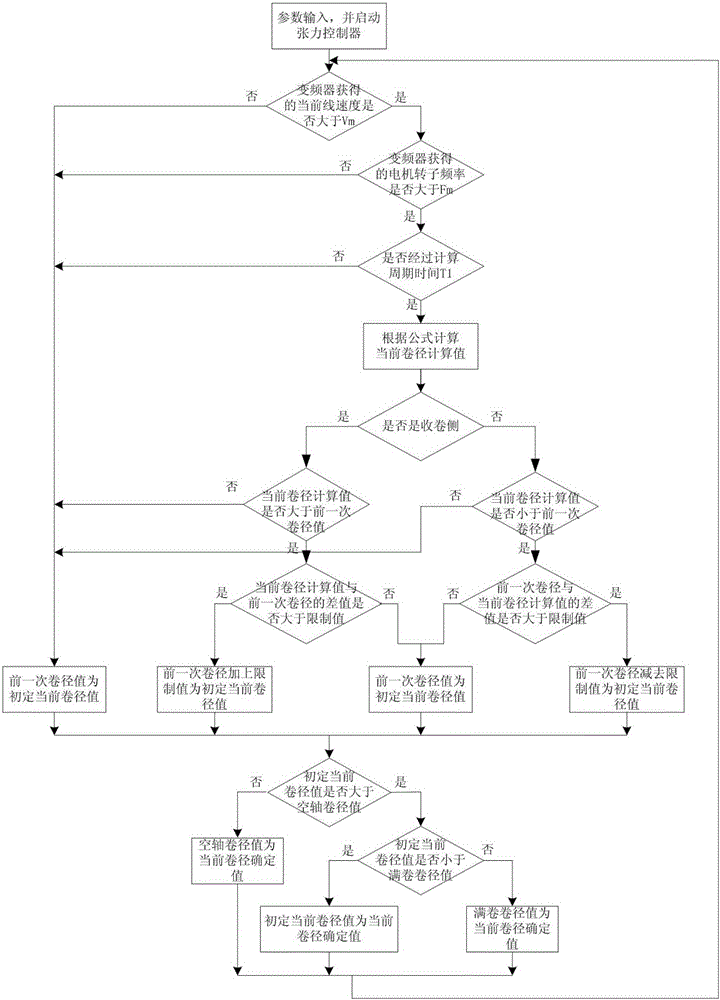

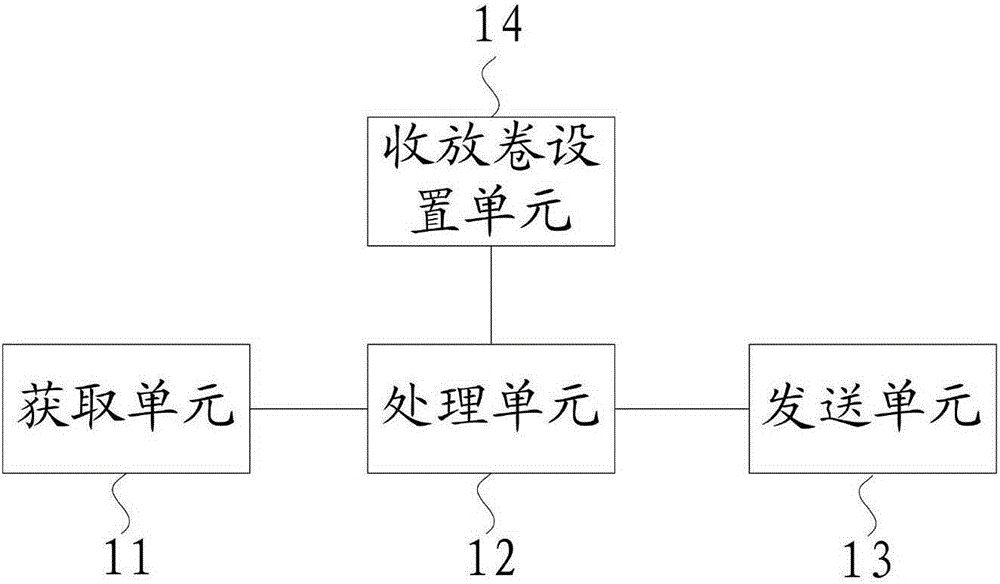

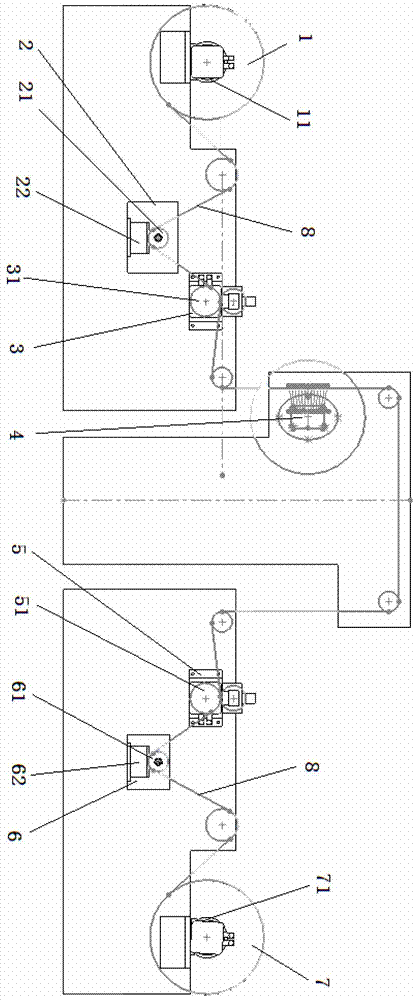

Tension control method, device and system of rolling and unrolling equipment

ActiveCN105197685AConstant tensionGood retractable effectFilament handlingFrequency changerTime cycles

The invention discloses a tension control method, device and system of rolling and unrolling equipment. The tension control method comprises the steps of obtaining the current linear velocity V<n> of operation of a material and the current frequency f<n> of a motor rotor; calculating out the current rolling diameter calculated value D<n> of the outer diameter of the material on a roller wheel every other time cycle T according to the obtained current linear velocity V<n> and the current frequency f<n> of the motor rotor; comparing the current rolling diameter calculated value D<n> with a predetermined limiting condition, and determining the current rolling diameter determined value; according to the current rolling diameter determined value, controlling a motor to output a corresponding force moment. According to the tension control method, device and system of the rolling and unrolling equipment, due to the fact that a tension controller calculates out the current rolling diameter calculated value by obtaining the material operation linear velocity, then conducts error judgment on the current rolling diameter calculated value obtained through calculation, conducts judgment by comparing the current rolling diameter calculated value with the limiting condition and finally controls a frequency converter to output the corresponding force moment according to the current rolling diameter determined value obtained through calculation and judgment, the material on the roller wheel can obtain constant tensile force all the time, the material can be rolled and unrolled more stably, and the rolling and unrolling effect is better.

Owner:SHENZHEN INVT ELECTRIC

Polyethylene film modifying device

The invention discloses a polyethylene film modifying device, which comprises an unwinding device, a front traction device, an electronic beam radiation device, a back traction device, a winding device and a control device in sequence, wherein the control device is used for controlling each device and receiving signals fed back by each device; the unwinding device and the winding device are used for conveying and receiving a polyethylene film respectively; the front and back traction devices are used for leading the conveying of the polyethylene film; and the electronic beam radiating device is used for radiating the polyethylene film passing through the electronic radiating device to modify the polyethylene film. Due to the adoption of the polyethylene film modifying device provide by the invention, the time of radiation crosslinking modification can be shortened; and the radiating high pressure of an electronic accelerator is adjusted for changing the radiation penetration depth, so that half crosslinking modification or gradient crosslinking modification of the polyethylene film is realized.

Owner:海南经济特区中质猎鹰智能勘测科技有限公司

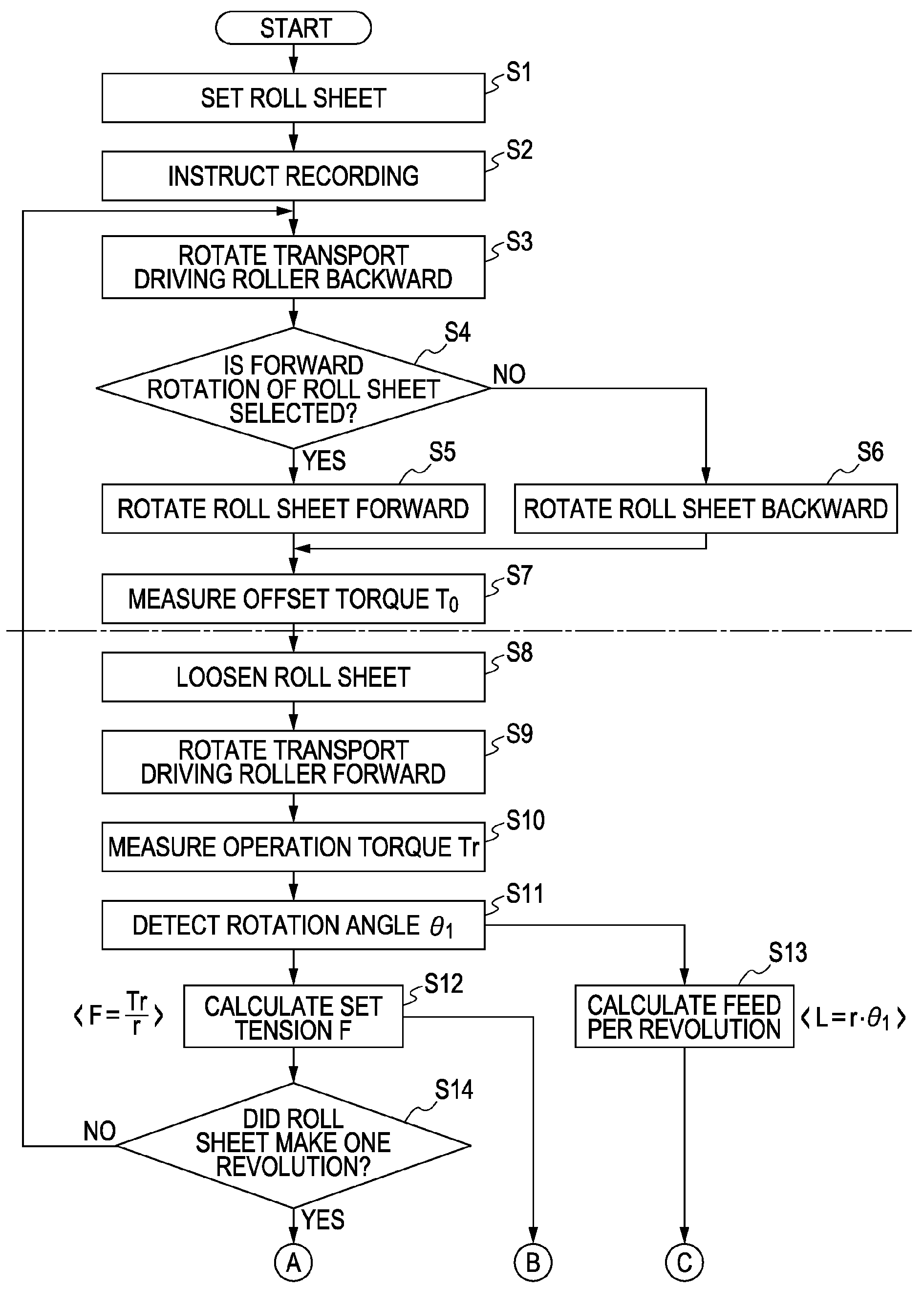

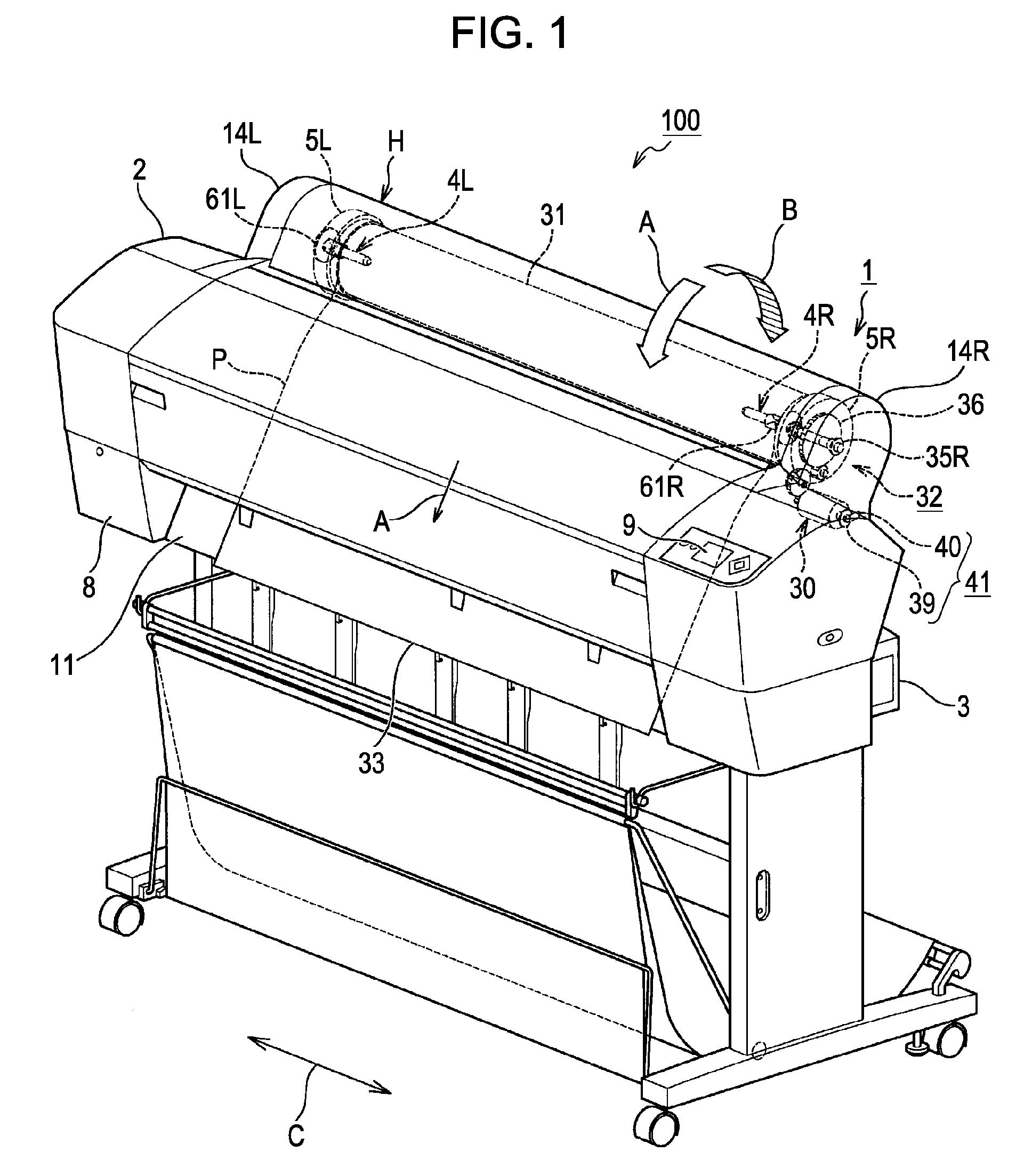

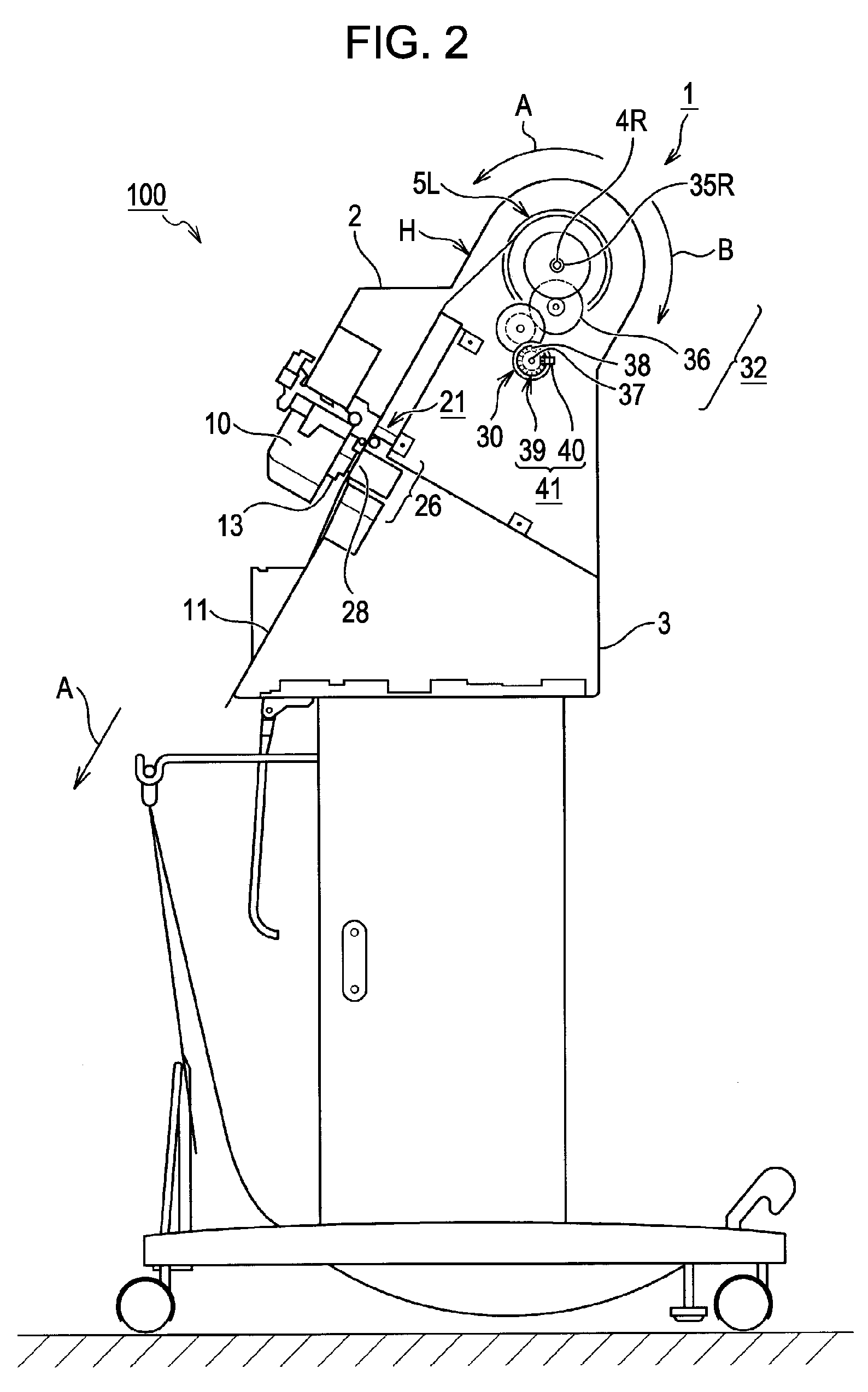

Transport device for transporting roll-shaped recording medium and recording apparatus

InactiveUS20090242603A1Reduce the number of partsSimple structureFilament handlingOther printing apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Wire electrode supply device for wire-cut electric discharge machine

InactiveUS20070228016A1Easy constructionPrevent slack in and snappingElectrical-based machining electrodesBobbinElectric discharge

A wire electrode supply device capable of preventing slack and snapping of a wire electrode even using a heavy wire bobbin without using a wire electrode tension detector. A pulley is provided between the wire bobbin driven by a torque motor and a brake roller. The wire electrode unwinds from the wire bobbin, passes through the pulley, brake roller and a workpiece work area, and is taken up by a wind-up roller. When the wire electrode traveling speed is changed from fast to slow, the pulley descends to prevent the wire electrode from slackening between the wire bobbin and the brake roller. When the traveling speed is changed from slow to fast, the back tension from the torque motor is reduced for a predetermined period of time, reducing tension on the wire electrode and preventing it from snapping. Also, the pulley descends, rotating the wire bobbin in the feeding direction and quickening tracking of the shift to fast feed speed, enabling snapping of the wire electrode to be prevented even when a heavy wire bobbin is used.

Owner:FANUC LTD

Carbon fiber starching machine

InactiveCN101694044ASizing achievedConstant tensionSucessive textile treatmentsTextile treatment carriersFiberCarbon fibers

The invention discloses a carbon fiber starching machine comprising a drying device, a starching device and a base, wherein the drying device and the starching device are arranged on the base; the drying device comprises a drying oven and driving roller sets in wrapped connection with carbon fiber, wherein the driving roller sets are respectively rotatably arranged on the upper end and the lower end of the drying oven; the starching device comprises a starching slot, a first driving roller in wrapped connection with the carbon fiber and a submerged roller in wrapped connection with carbon fiber, wherein the first driving roller is rotatably arranged above the starching slot and the submerged roller is arranged in the starching slot; and the first driving roller, the submerged roller and the driving roller sets form a carbon fiber conveying line. The invention realizes the starching of carbon fiber and continuous drying production and ensures that the carbon fiber keeps constant tension, thereby ensuring the treatment effect of the carbon fiber and improving the working efficiency.

Owner:镇江奥立特机械制造有限公司

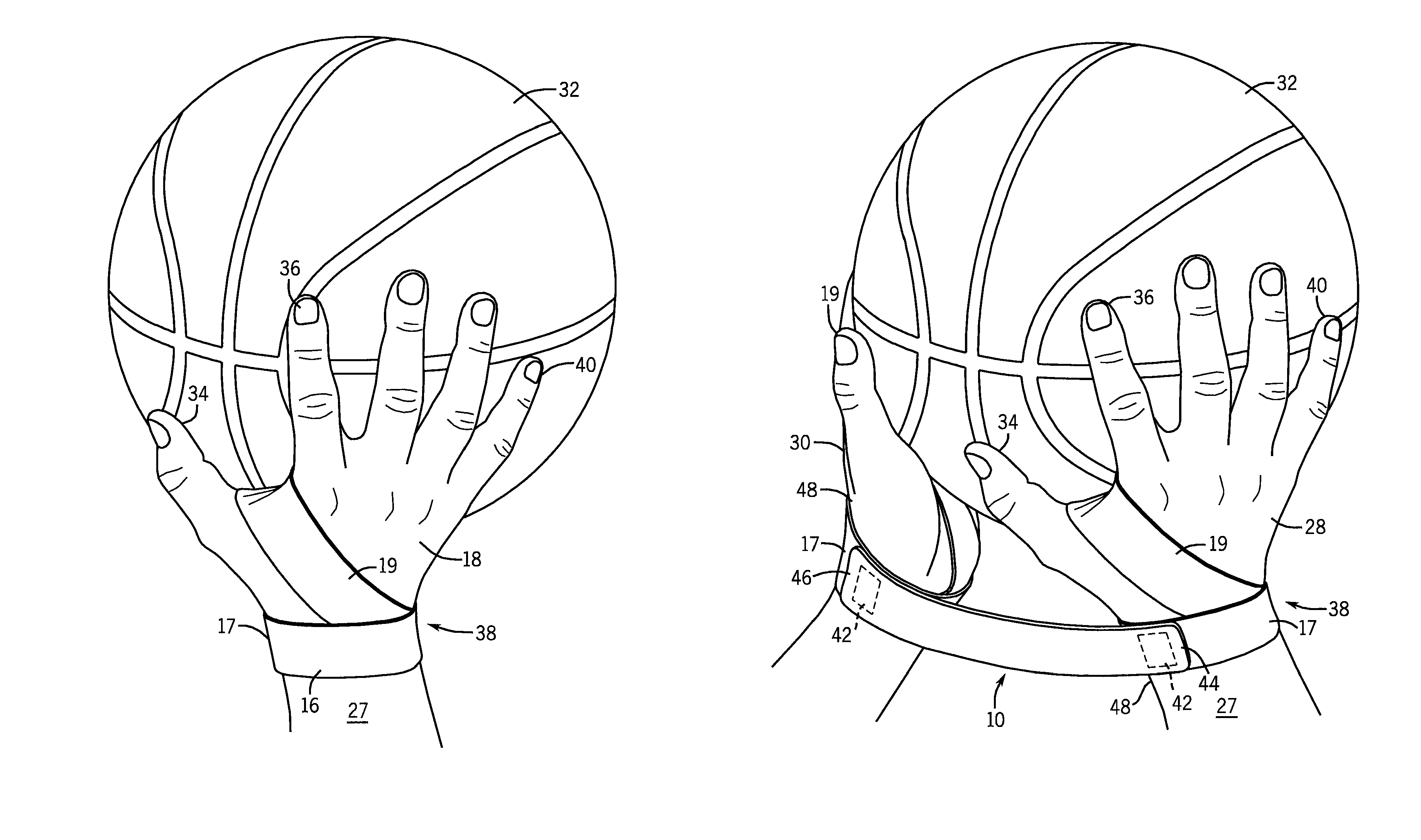

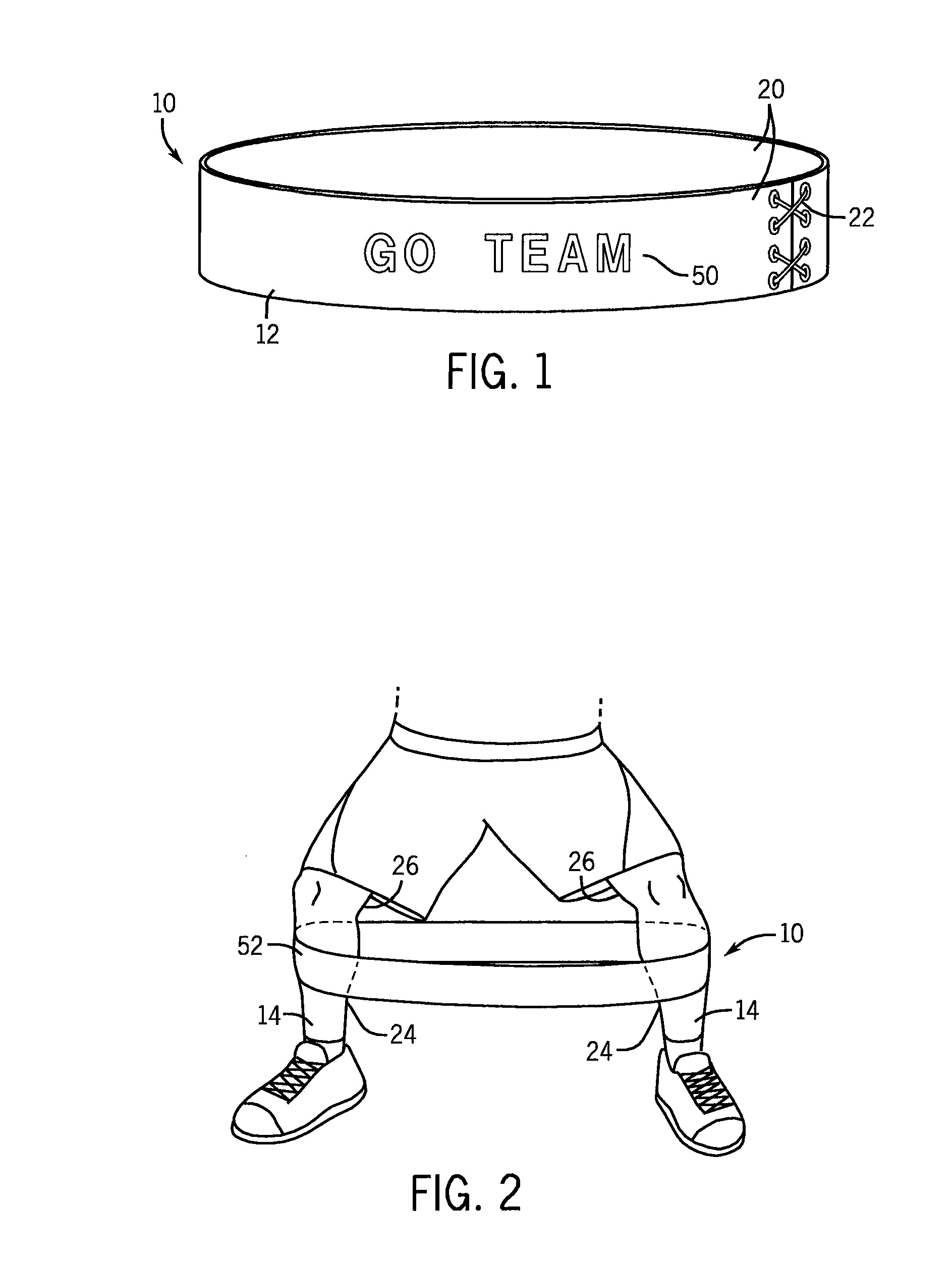

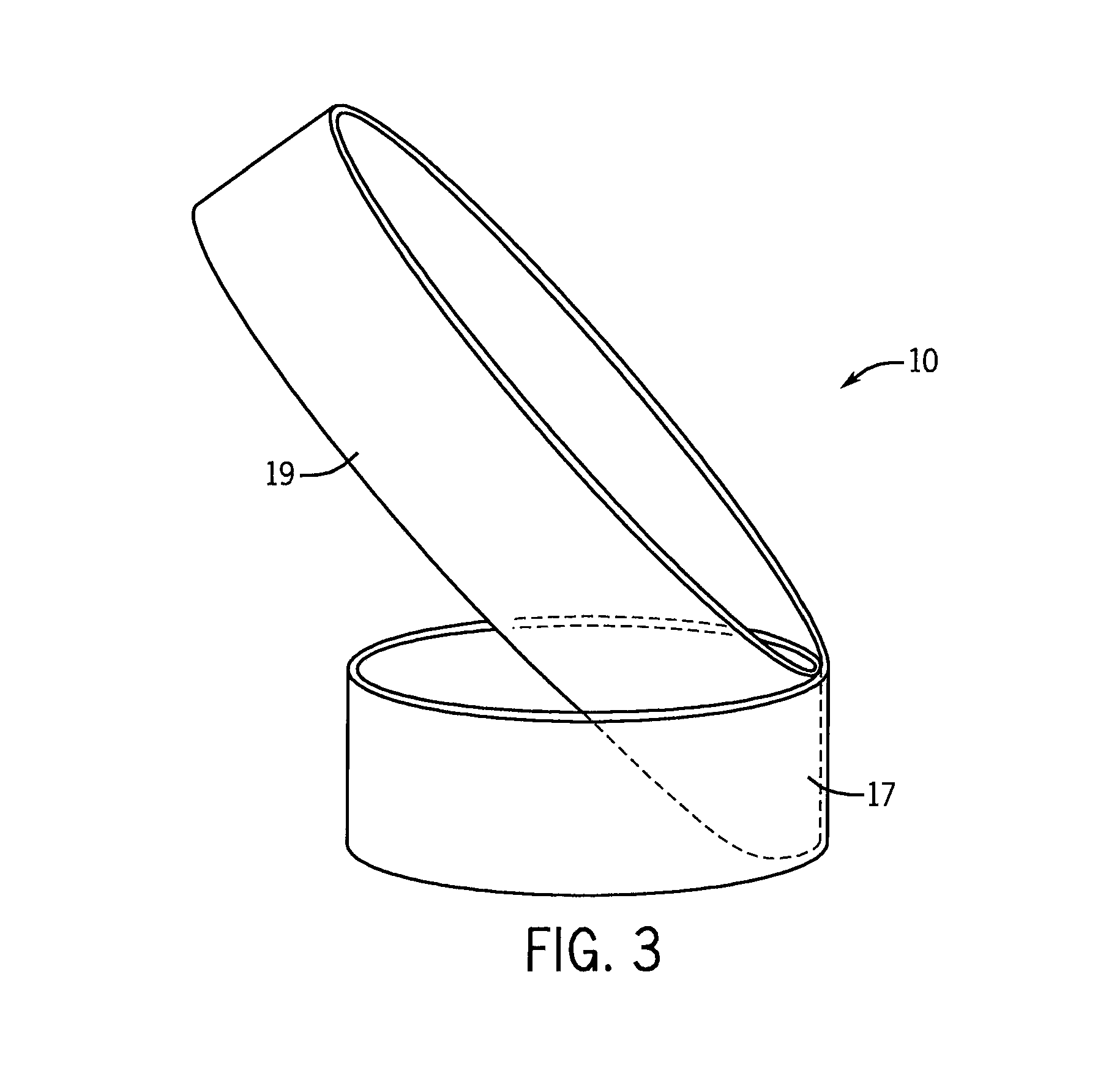

Basketball skill guide

ActiveUS7399240B2Constant tensionRestraining devicesNon-surgical orthopedic devicesSkill setsEngineering

The invention is a basketball training device for training players of all ages and skill levels how to shoot a basketball and / or how to play defense. The device comprises at least one elongated piece of substantially flexible material having two opposing ends, the ends secured together to define a substantially circular flexible device, the device being worn around a player's legs, wrists and / or hands. The device provides tension and support to the player's legs, wrists and / or hands, wherein the tension keeps the player's legs, wrists and / or hands in a desired basketball position. In a preferred version, the tension further provides at least some degree of feedback to the player when the player's legs, wrists and / or hands assume an undesired basketball position. The device may be used to train a player in offense (i.e., shooting) as well as defense.

Owner:PAUKERT MICHAEL S +1

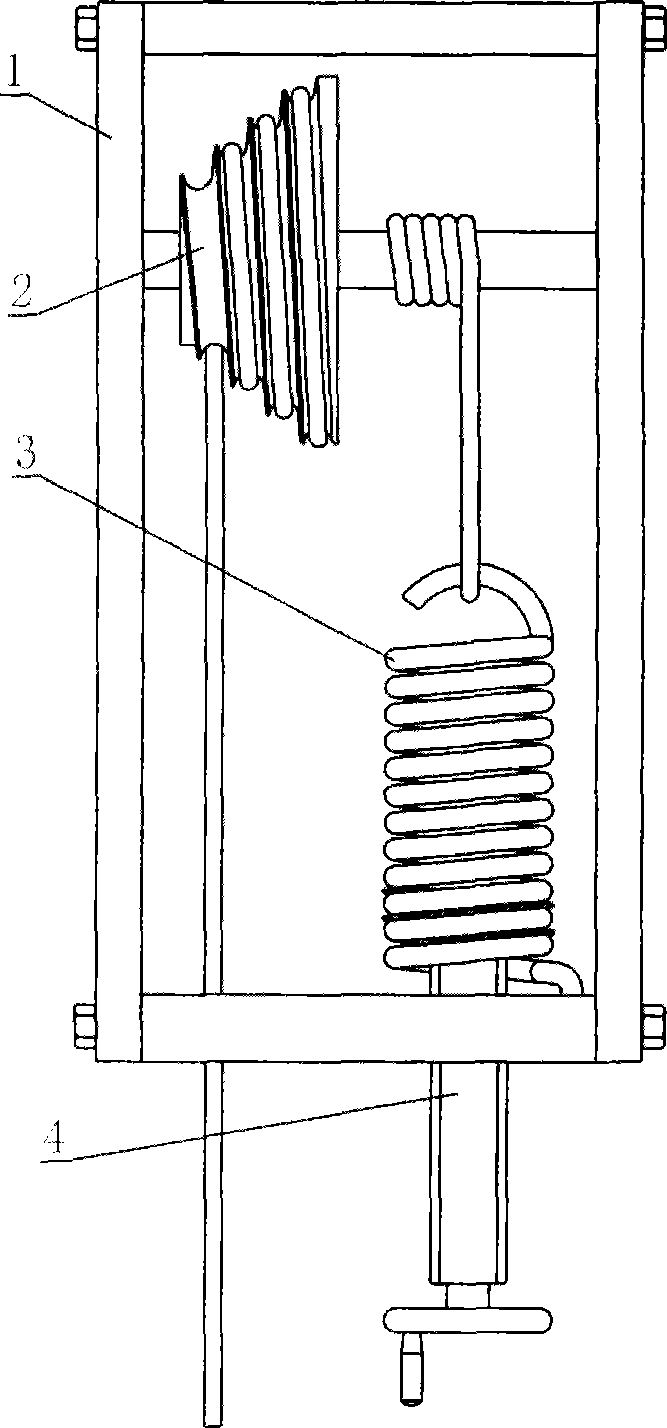

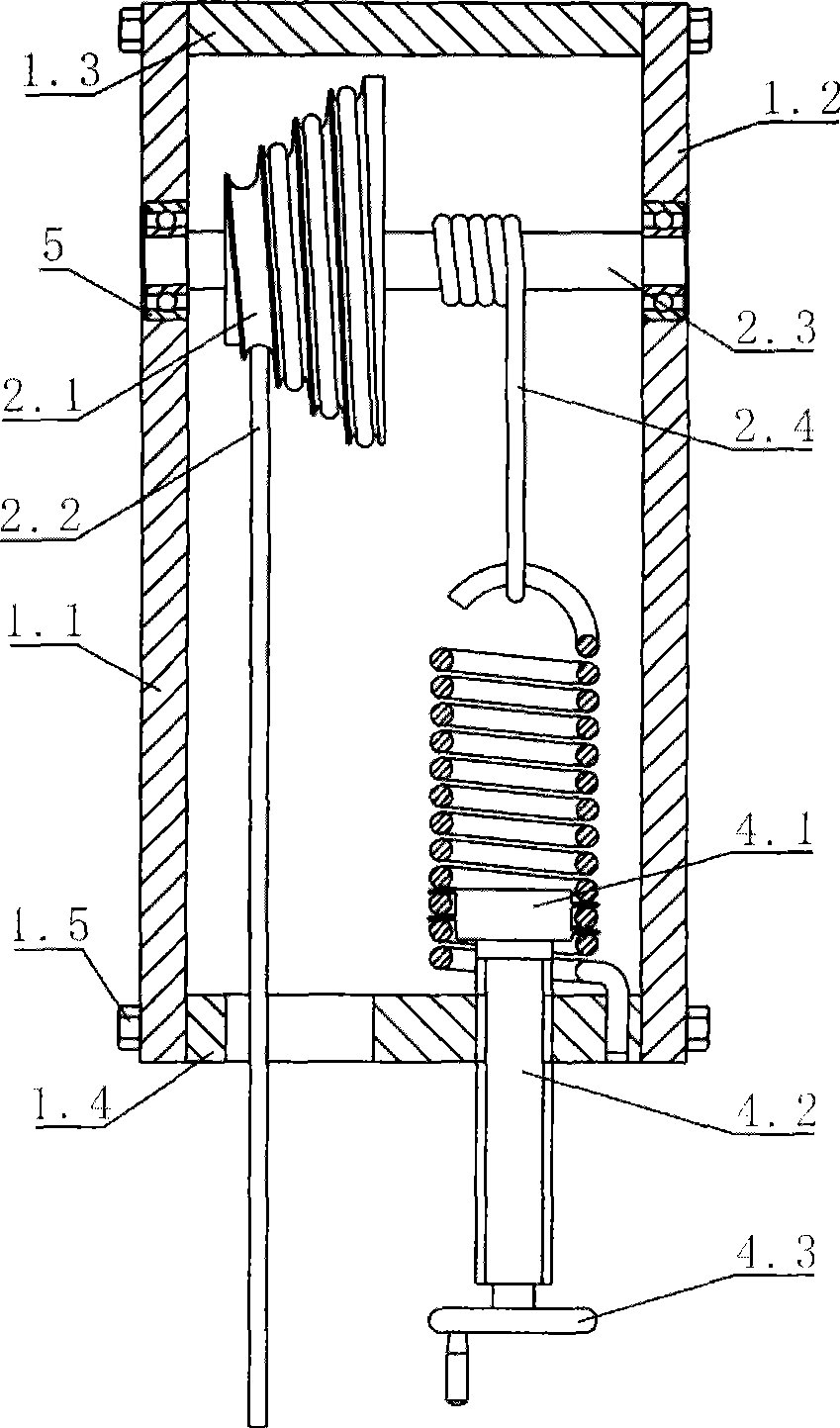

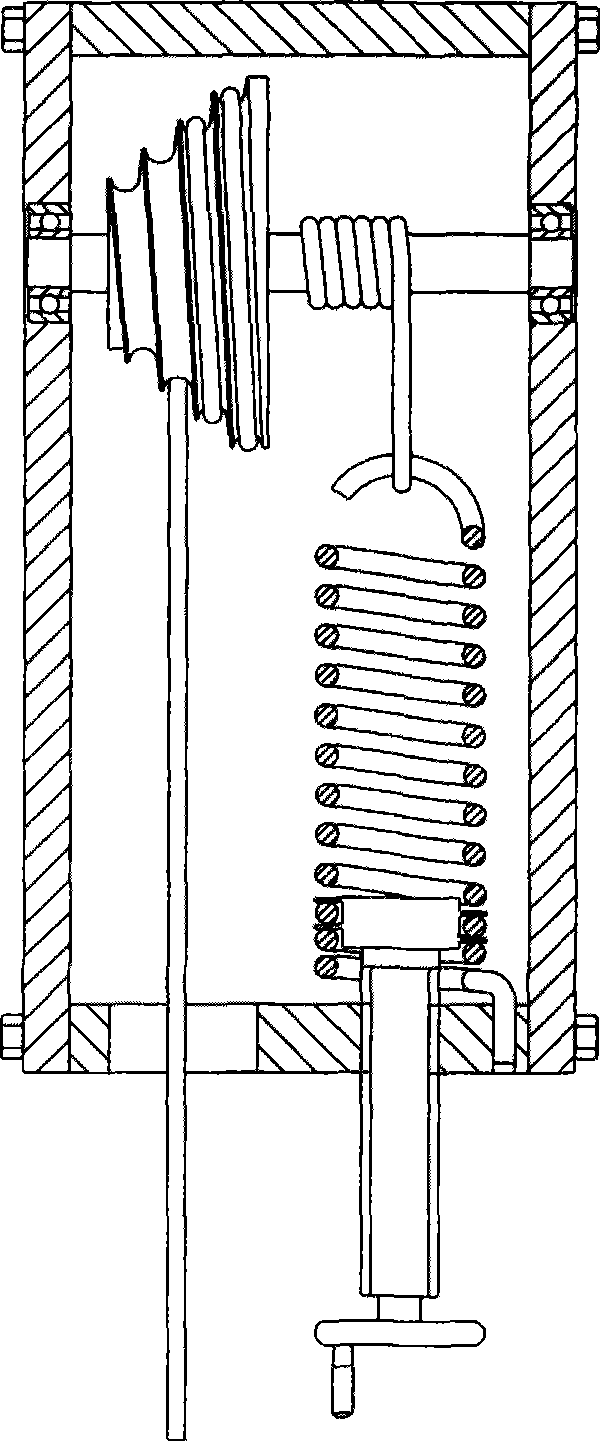

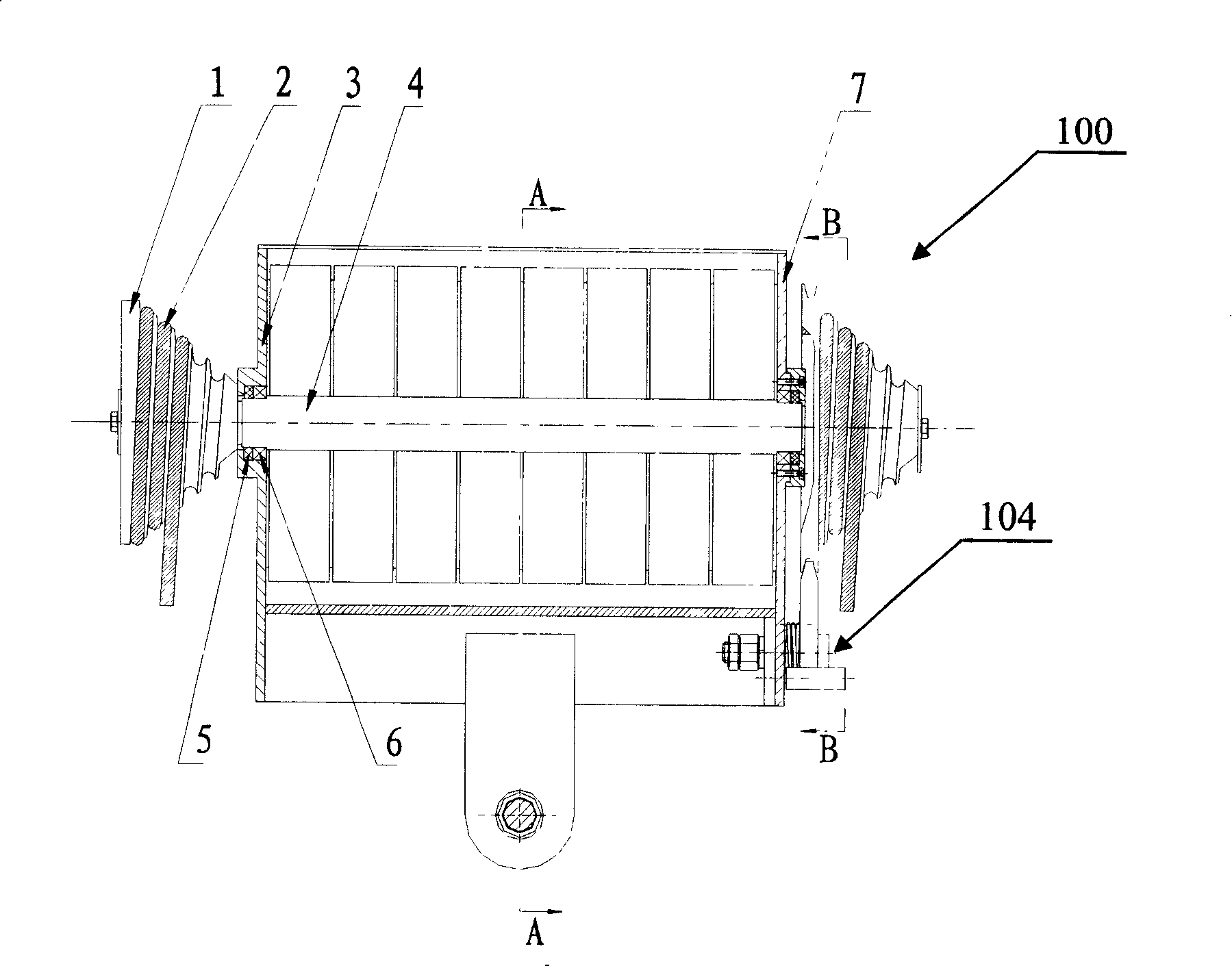

Constant-force chest developer

InactiveCN101507871AConstant tensionAdjustable tensionMuscle exercising devicesPull forceEngineering

The invention provides a constant force spring exerciser. The constant force spring exerciser has the advantages of no counterweight, simple structure and light weight, and can provide constant pulling force, and the magnitude of the pulling force can be adjusted. The constant force spring exerciser mainly comprises a machine frame, a spring, a twisted rope mechanism and an adjustment mechanism, wherein two end shaft supporting positions of a rope winding shaft of the twisted rope mechanism are arranged in bearing arrangement holes on a left supporting plate and a right supporting plate of the machine frame; a connecting rope of the twisted rope mechanism is fixed on a connecting hook at the upper end of the spring, while the lower end of the spring is inserted and fixed in a positioning hole of a lower connecting plate of the frame; a supporting block of the adjustment mechanism is screwed in the spring, a screw rod of the adjustment mechanism is screwed in a screw hole of the lower connecting plate of the frame, and the adjustment mechanism moves up and down by rotating the screw rod; the upper part of the screw rod is fixedly arranged in a middle hole of the supporting block; the twisted rope mechanism comprises a tower-shaped twisted rope disc, a pulling force rope, the connecting rope and a rope winding shaft; and the adjustment mechanism comprises the supporting block, the screw rod and a hand wheel.

Owner:HUAZHONG NORMAL UNIV

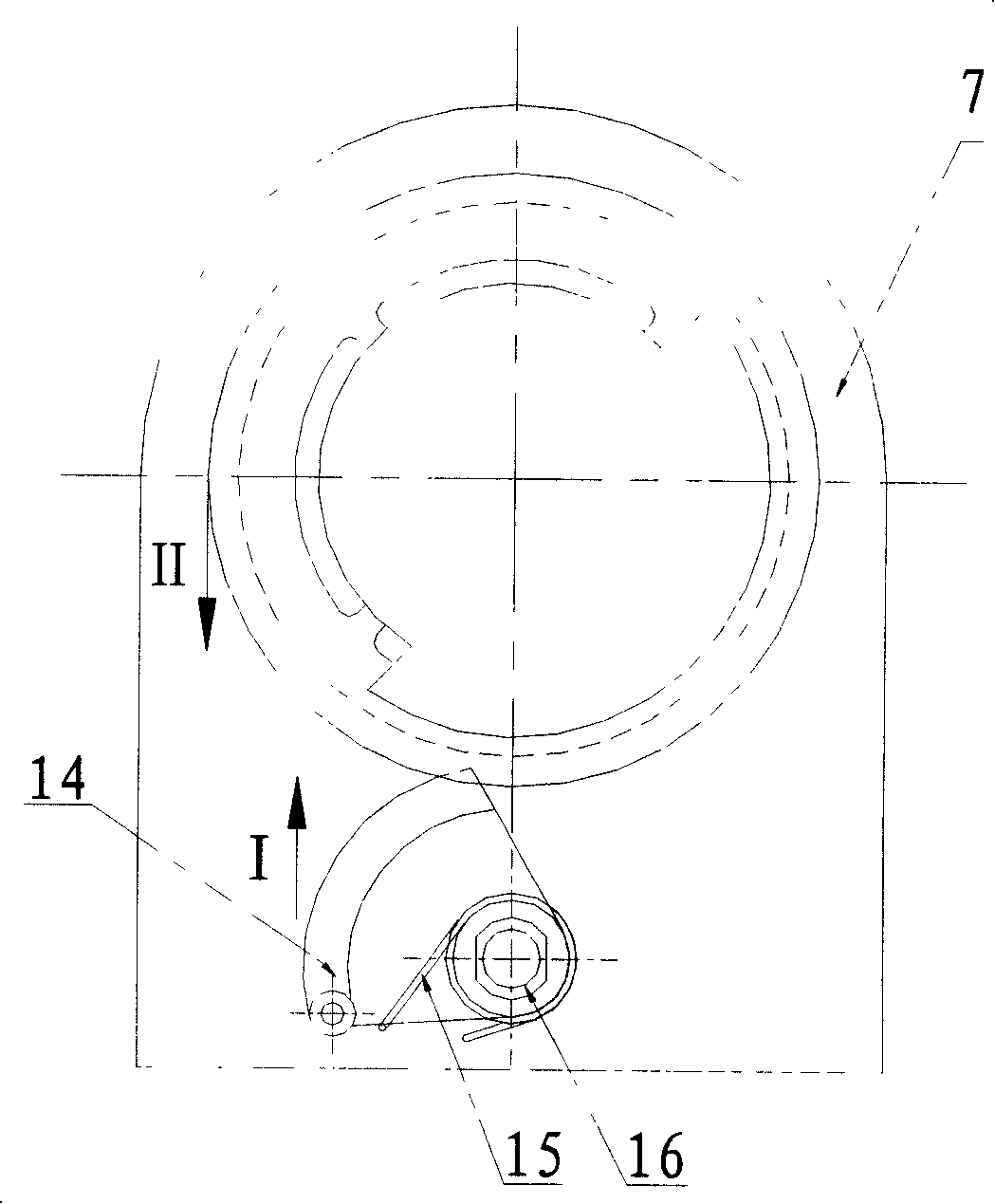

Constant tension spring compensating unit

The invention relates to a compensation device of a spring with constant tension, which essentially comprises a grooved pulley, a compensation rope, a left end plate, a main shaft, an oil seal, a bearing, a right end plate, a contact plane volute spring, an external cover, a fixed angle iron, an installation bottom plate, a hinge pin and a broken wire stopping device; wherein, the grooved pulley is fixed on the main shaft; the compensation rope is coiled and has an end fixed on the grooved pulley and the other end connected with an external contact net; the main shaft is supported on the left end plate and the right end plates by the oil seal and the bearing; the left end plate and the right end plate, the external cover, the fixed angle iron and the installation bottom plate form an enclosed box base; the hinge pin is connected to one side on the installation bottom plate far from the box base which is internally provided with the contact plane volute spring with an inner end bent hook connected with the main shaft and an outer end bent hook connected with the fixed angle iron on the box base. The compensation device of the spring with constant tension provided by the invention is compact in structure, small in size and light in weight. The invention can cause an electrified railway network to keep certain tension and reduce the loss catenary rate of the pantagraphs.

Owner:帖荣俊 +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com