Polyethylene film modifying device

A polyethylene film modification technology, which is applied in the field of polyethylene film modification devices, can solve the problems of slow speed, low efficiency, and inability to realize controllable cross-linking modification of polyethylene film, and achieve the effect of constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

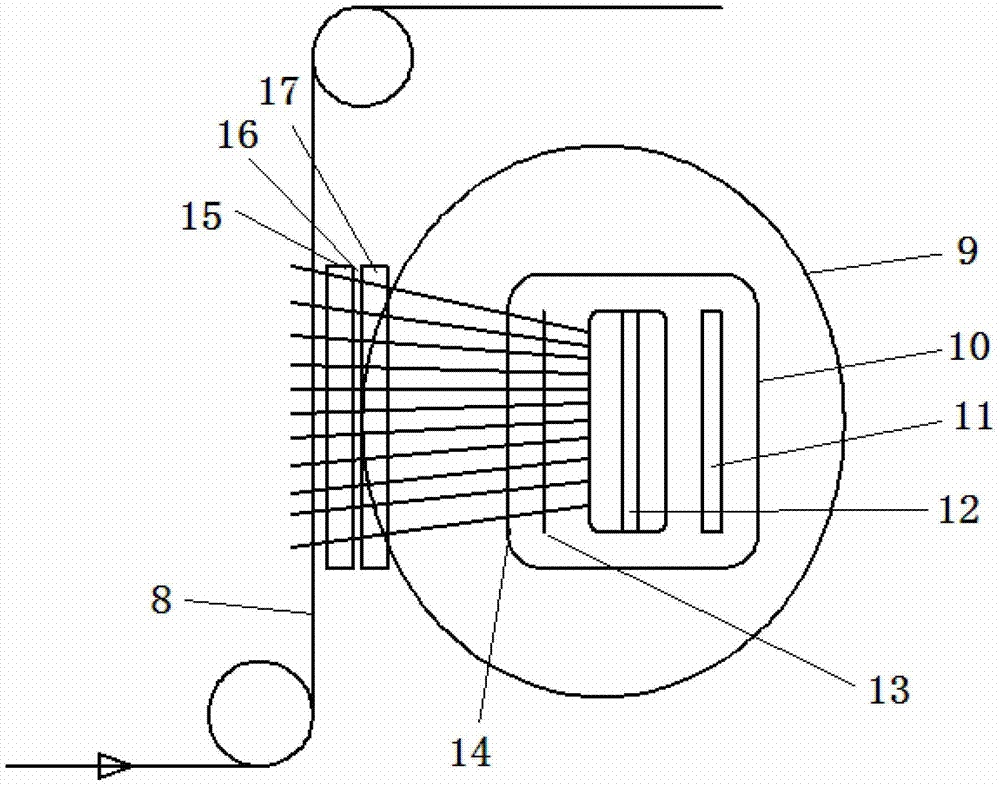

[0022] Semi-cross-linking modification means that the electron beam only penetrates half the thickness of the low-density polyethylene (LDPE) film, so that the upper half of the LDPE layer is cross-linked and the tensile strength of the LDPE is improved, while the lower half layer is not irradiated and cross-linked. Linked to maintain the original toughness and heat sealing performance of LDPE.

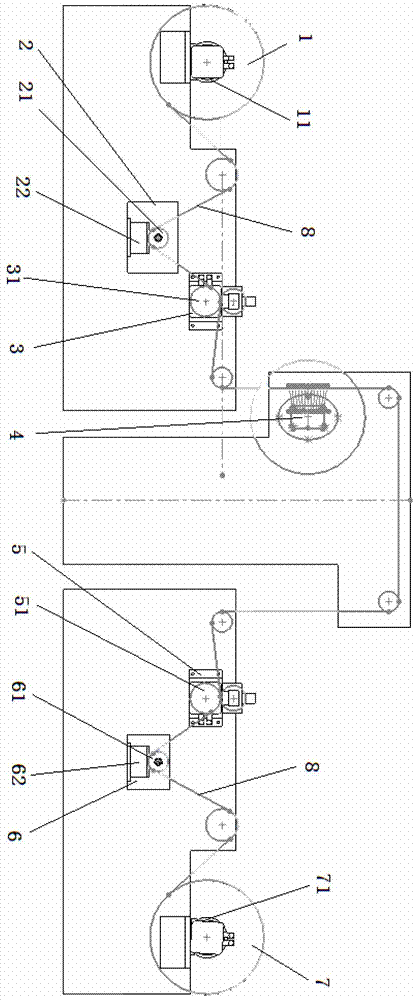

[0023] A polyethylene film modification device disclosed in the present invention sequentially includes an unwinding device, a front traction device, an electron beam irradiation device, a rear traction device, and a winding device, and is used to control the various devices and receive the The control device of the feedback sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com