Tension control method, device and system of rolling and unrolling equipment

A tension control, rewinding and unwinding technology, applied in transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve problems such as increased errors, increased costs, and inaccurate roll diameter measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

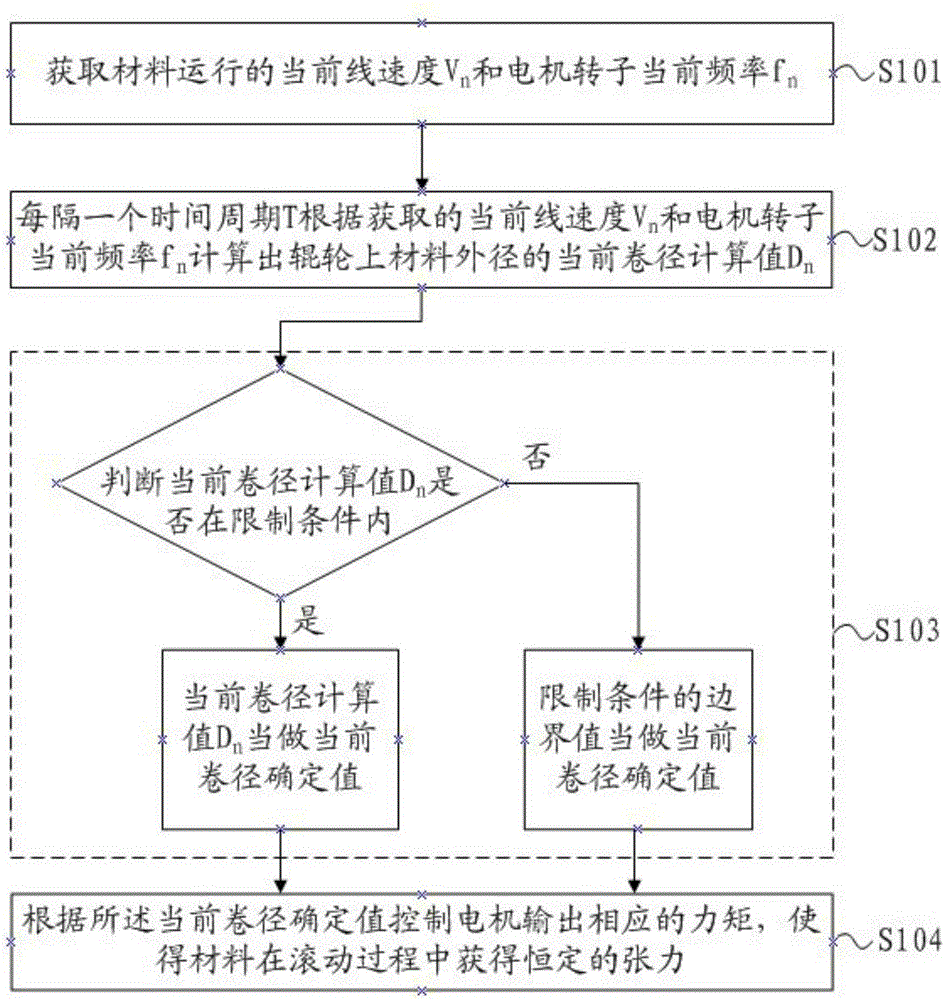

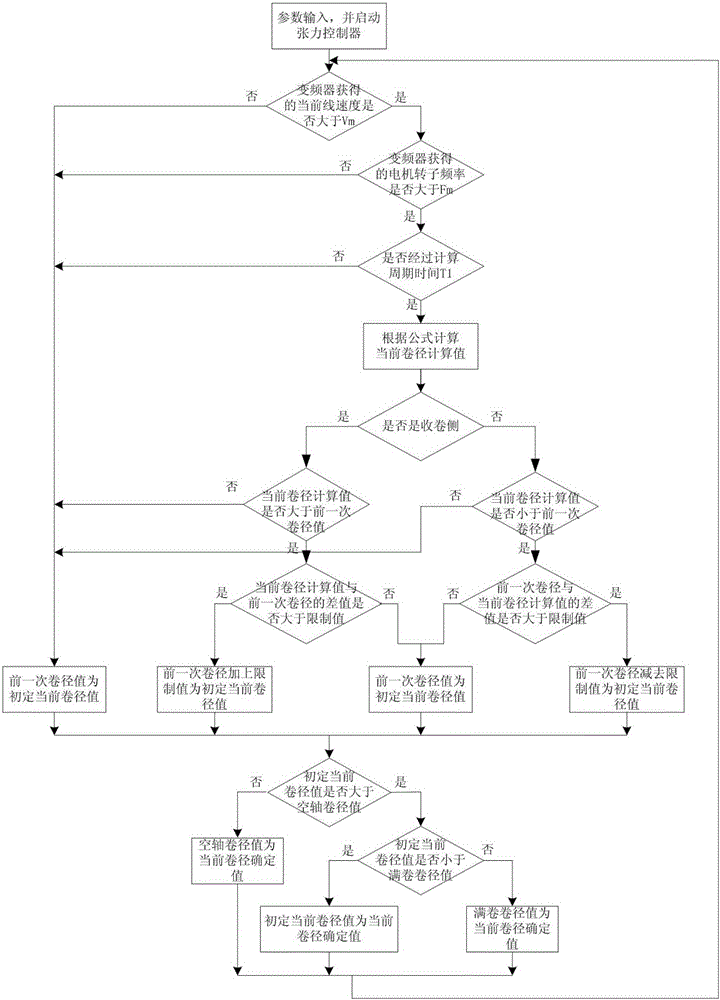

[0052] In this embodiment, a tension control method of the winding and unwinding equipment is provided. The method is executed by the tension control system of the winding and unwinding equipment. After calculating the diameter of the winding and unwinding equipment, the tension control system controls the motor to output the corresponding torque. Realize the control of the surface tension of the material on the unwinding and unwinding roller, so that the tension tends to a constant value, so as to ensure the good forming effect of the material on the roller. The present invention is only applicable to the strip tension control occasion where the rewinding and unwinding rotating shaft is cylindrical, and the value of the coil diameter is the value of the outer diameter after the material is wound by the roll on the rewinding and unwinding side.

[0053] Such as figure 1 As shown, the present invention provides a tension control method for winding and unwinding equipment, and t...

Embodiment 2

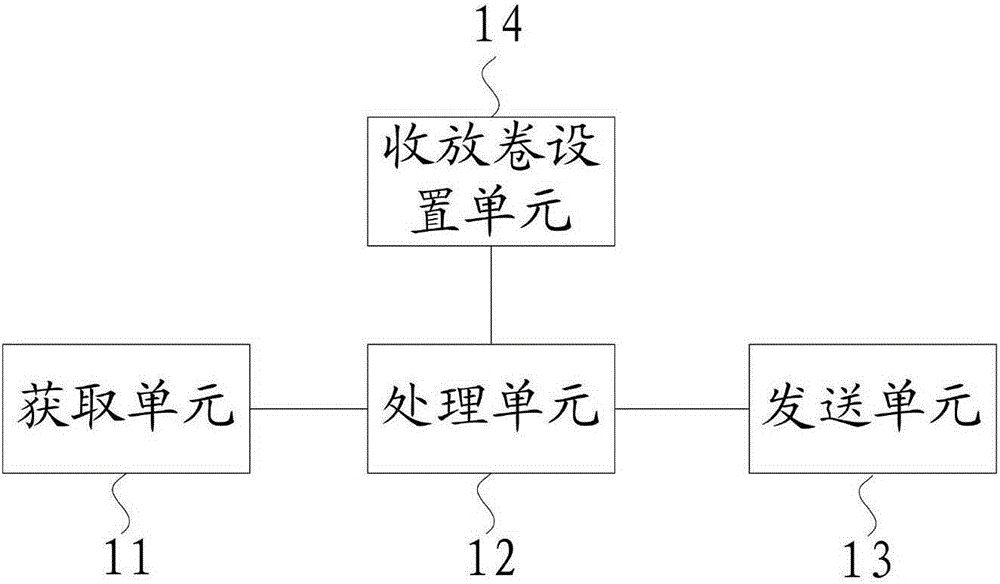

[0111] Such as image 3 As shown, this embodiment provides a tension control device for winding and unwinding equipment. Preferably, the tension control device in this embodiment is a tension control dedicated frequency converter connected to the traction motor. In other embodiments, the tension control device can also be a device independent of the frequency converter (ordinary frequency converter), which is connected to the frequency converter signal, and by controlling the frequency converter, the motor can output a corresponding torque according to the determined value of the current winding diameter, so that The material acquires a constant tension during rolling.

[0112] The frequency converter includes an acquisition unit 11, a processing unit 12 and a sending unit 13. The acquisition unit 11 and the sending unit 13 are respectively connected to the processing unit 12 with electrical signals, the acquisition unit 11 is connected to the traction side motor signal, and t...

Embodiment 3

[0130] Such as Figure 4 As shown, this embodiment provides a tension control device system for winding and unwinding equipment, which includes the tension control device 1 of the second embodiment and the frequency converter 2 on the traction side. Wherein the tension control device 1 is a frequency converter on the winding side, the frequency converter on the winding side is electrically connected to the frequency converter 2 on the traction side, and the frequency converter 2 on the winding side is electrically connected to the motor on the winding side.

[0131] The frequency converter on the winding side obtains the current linear velocity V n , and the frequency converter on the winding side itself has the current frequency f of the motor rotor n information, by obtaining the current linear velocity V of the material n and the current frequency f of the motor rotor n Calculate the outer diameter value of the material on the winding side roller, and calculate the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com