Patents

Literature

87results about How to "Accurate torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

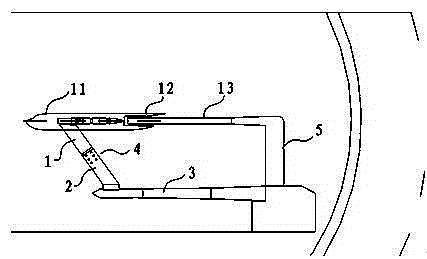

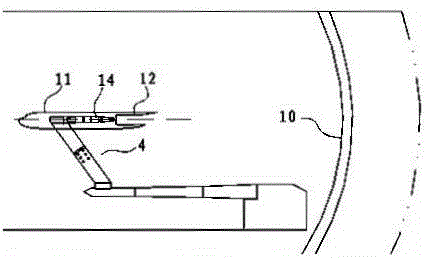

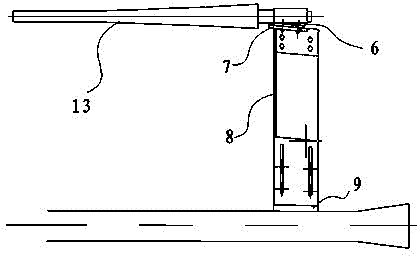

Method for correcting interference of high-speed wind tunnel tail support to lateral directional aerodynamic characteristics

ActiveCN105222984AReliable Model Aerodynamic Forces and MomentsAccurate torqueAerodynamic testingAngle of incidenceEngineering

The invention provides a method for correcting interference of high-speed wind tunnel tail support to lateral directional aerodynamic characteristics, which is a method for correcting interference of tail support in high-speed wind tunnel test to lateral directional aerodynamic characteristics. The method comprises the following steps: firstly, using a variable sideslip angle blade belly support device to enable a test model to be pre-deviated to a set sideslip angle, then using a fake tail support moving device to enable a fake tail support and the test model to keep synchronous sideslip angle pre-deviation so as to simulate true relative position relation in tail support test, and then obtaining the lateral directional aerodynamic characteristics interfered by the test model with the fake tail support; and subsequently, dismantling the fake tail support and an accessory device thereof, and carrying out wind tunnel test by keeping same test conditions to obtain the lateral directional aerodynamic characteristics of the test model without the tail support. At the same angle of incidence, the difference between the lateral directional aerodynamic coefficients of structures of two test models is considered to be the influence quantity of interference of the tail support at the set sideslip angle to the lateral directional aerodynamic characteristics, and then correction on the interference of the lateral directional support of data of tail support test can be completed, so that accurate model aerodynamic force and moment can be obtained.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

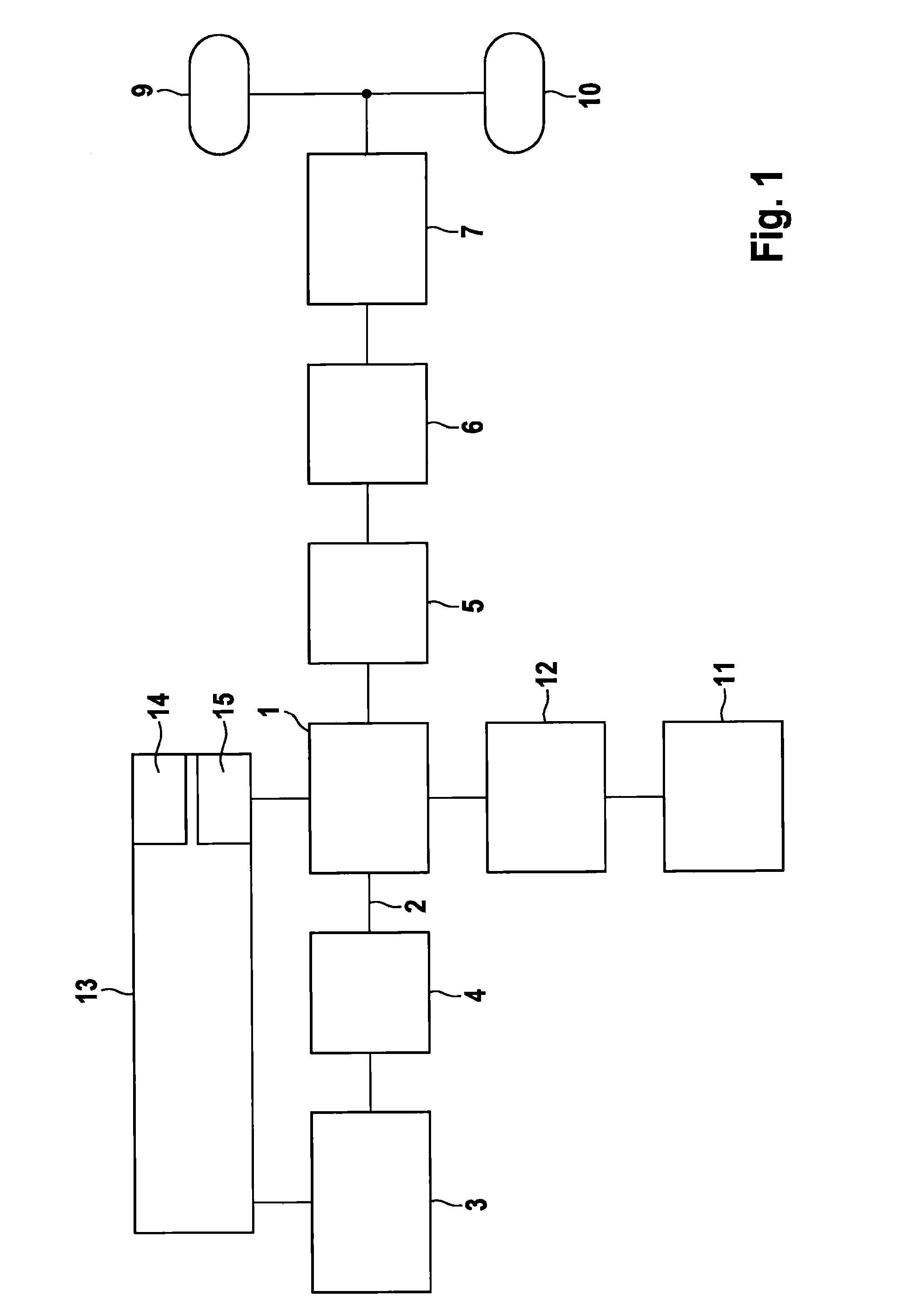

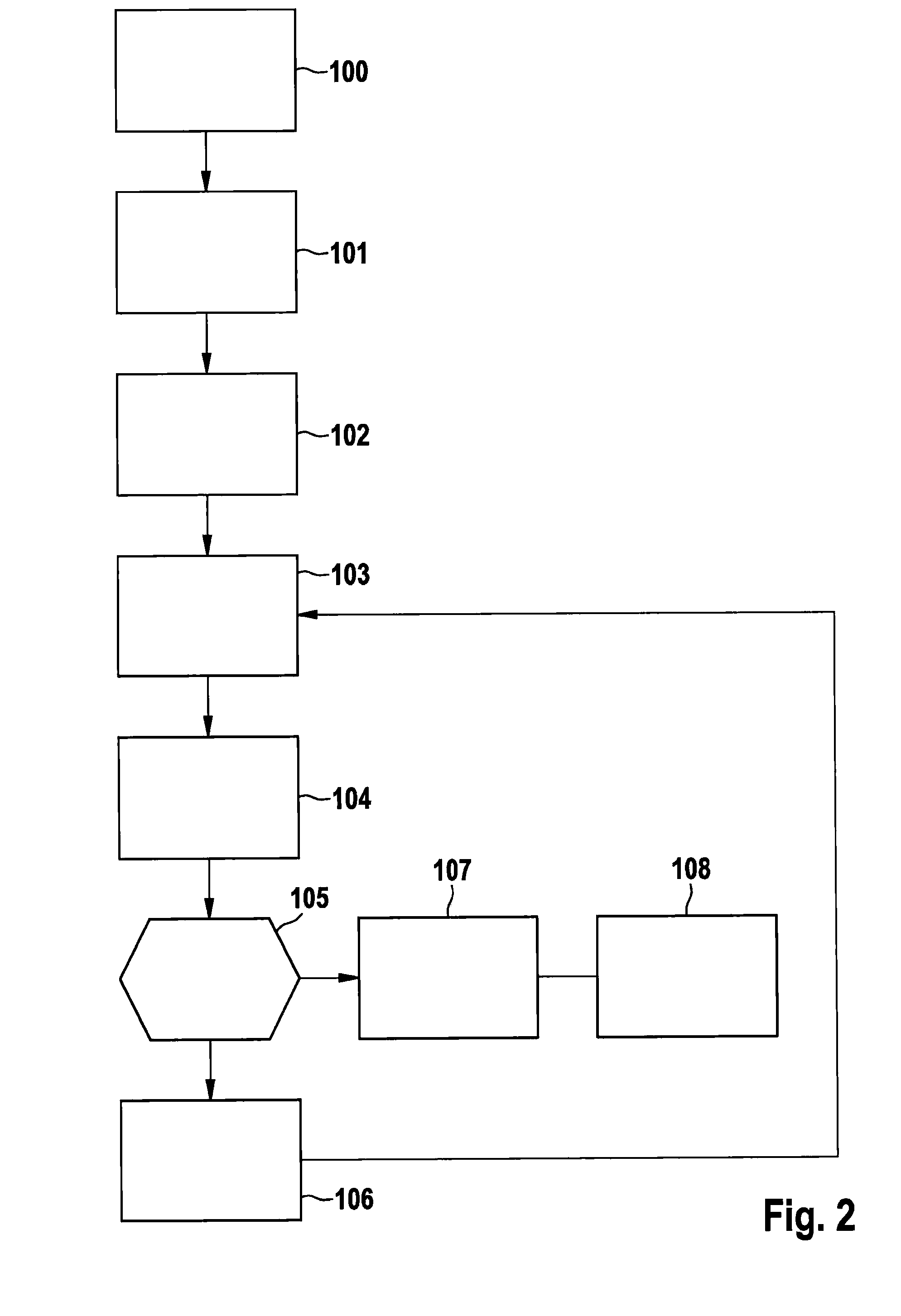

Method and device for verifying a drive torque applied by an electric machine in a hybrid drive of a motor vehicle

ActiveUS20120303196A1Accurate torqueTested rapidly and easilyDigital data processing detailsElectric machinesCombustionElectric machine

A method for verifying a drive torque applied by an electric machine in a hybrid drive of a motor vehicle, the motor vehicle being propelled by the electric machine and / or an internal combustion engine, and it being checked if the drive torque applied by the electric machine is determined accurately. In order to ensure that the operating strategy is correctly implemented and a shift in load level in the power train functions reliably during operation of the motor vehicle, the drive torque applied by the electric machine is evaluated with regard to its accuracy, using a drag torque generated by the combustion engine during an overrun fuel cut off.

Owner:ROBERT BOSCH GMBH

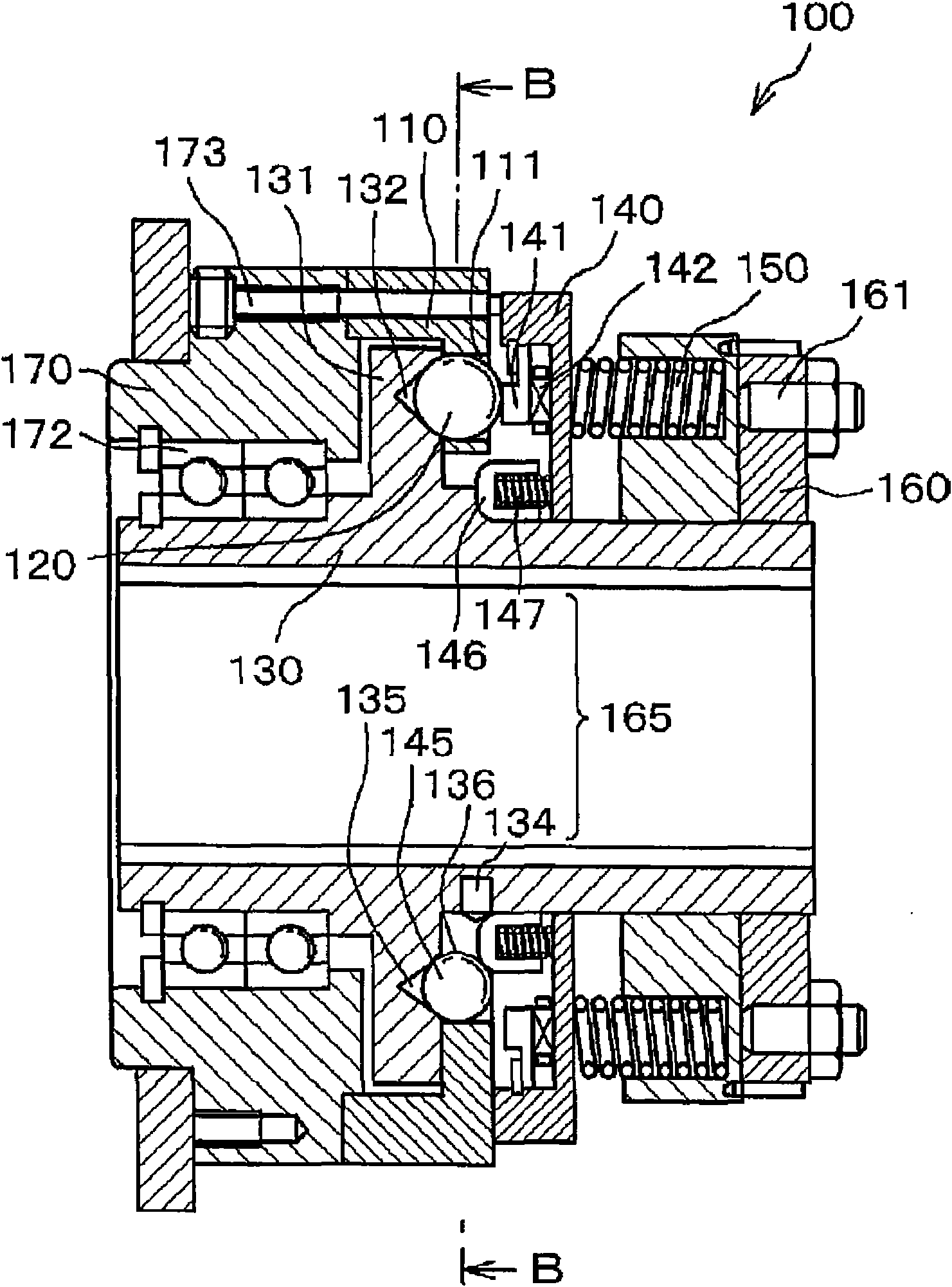

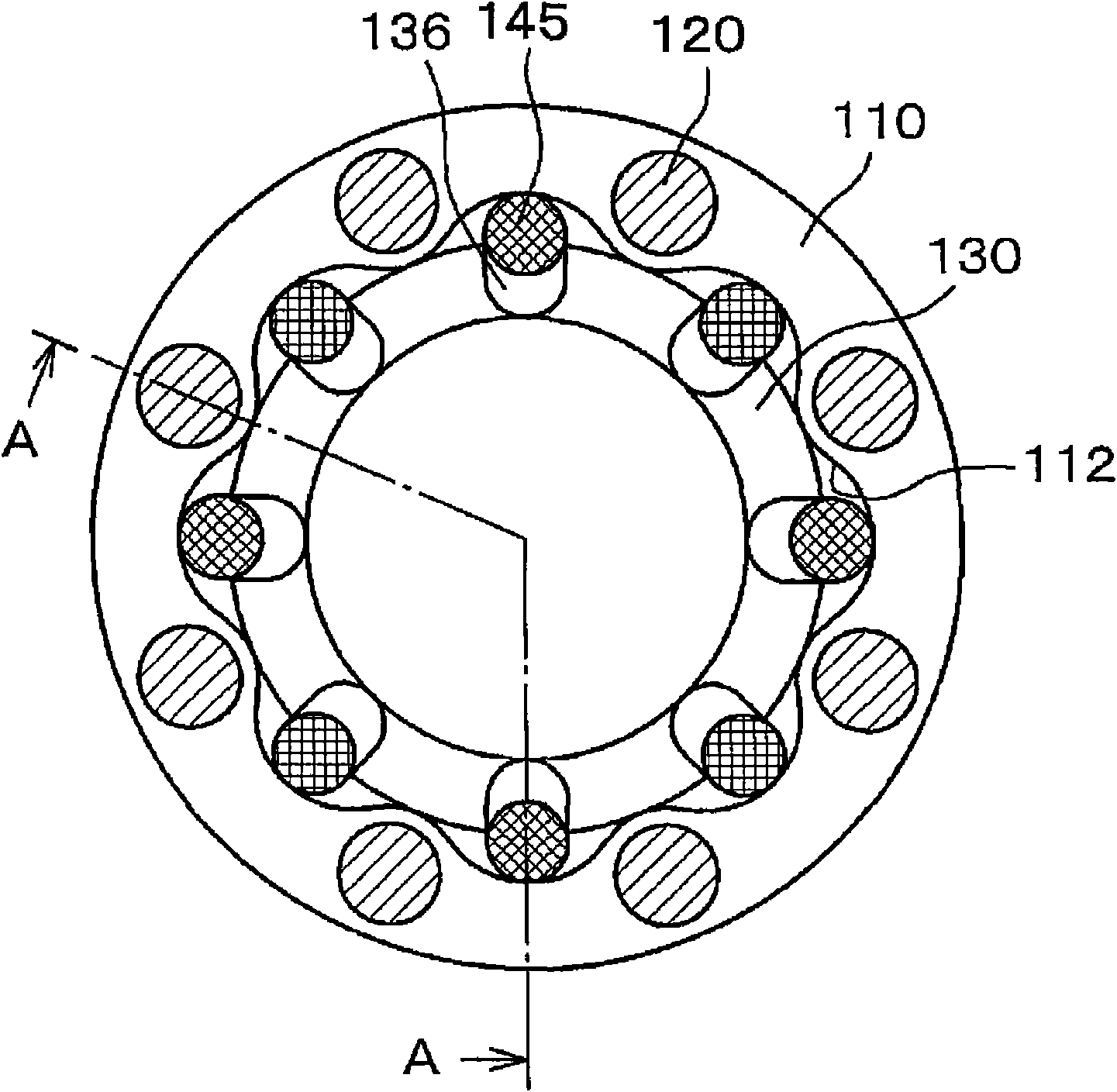

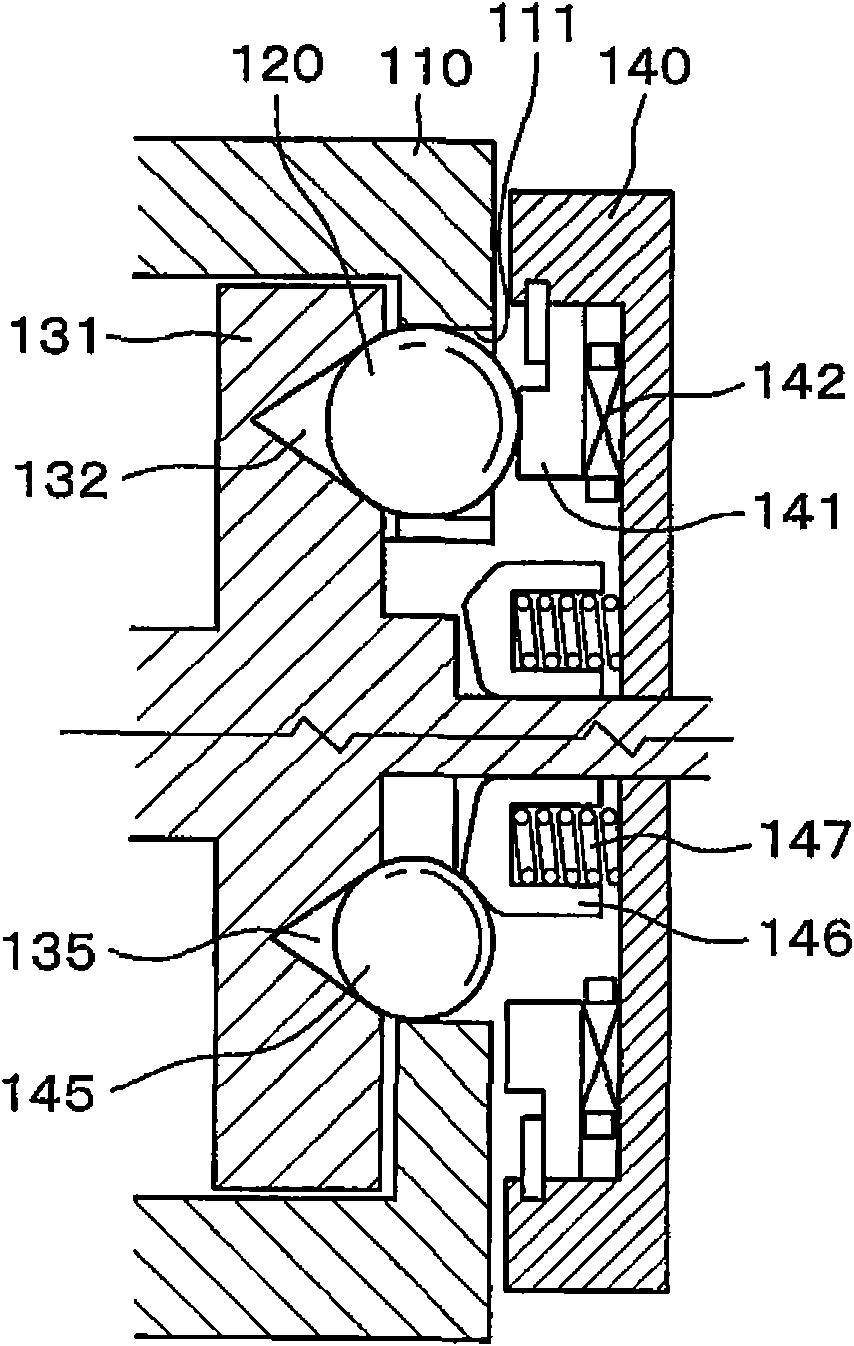

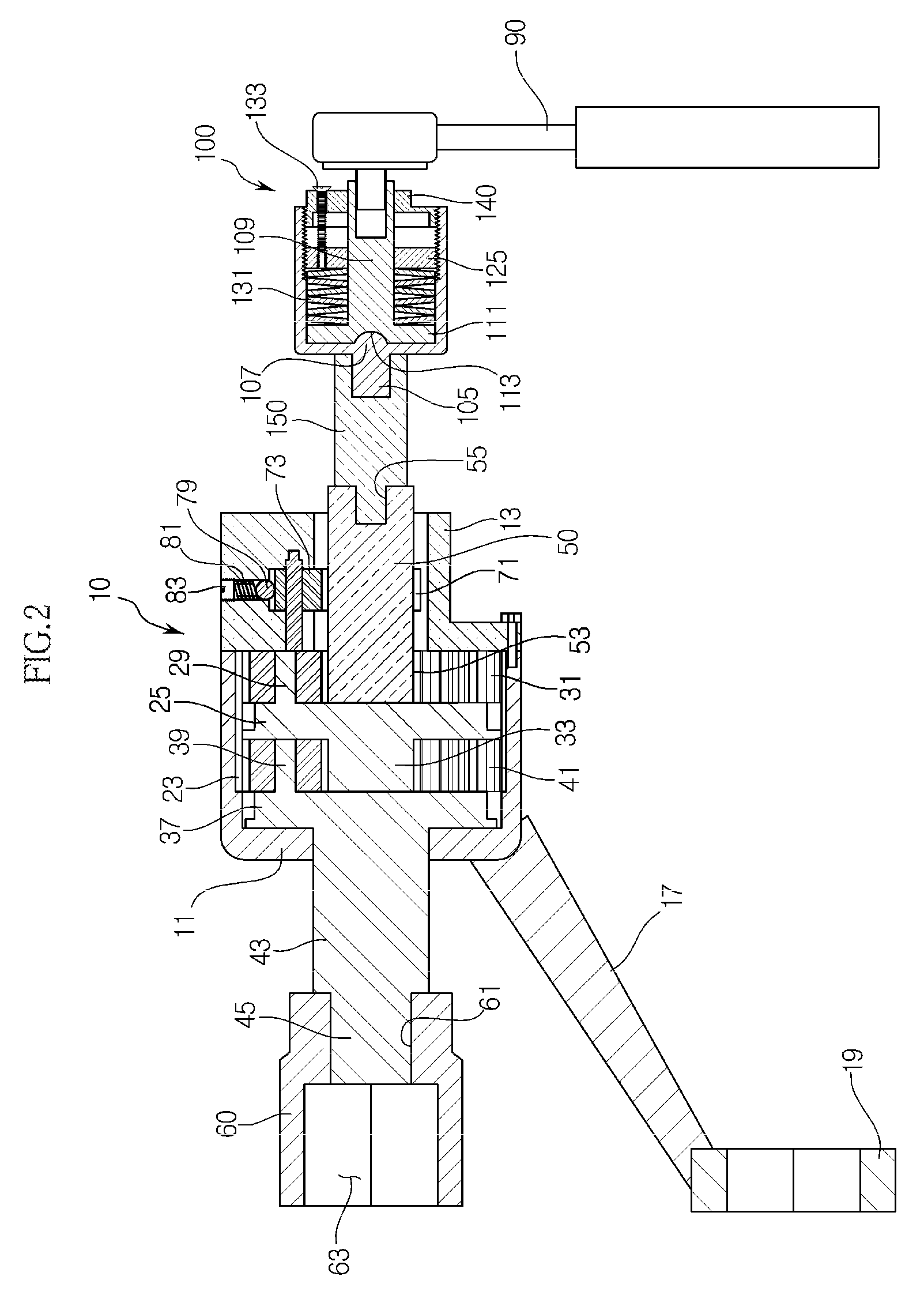

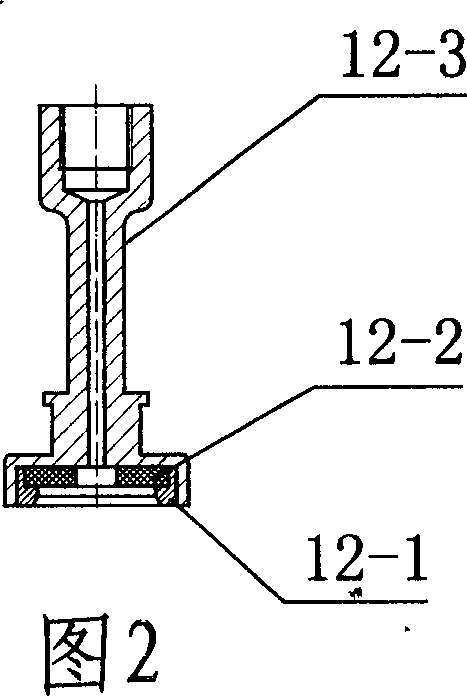

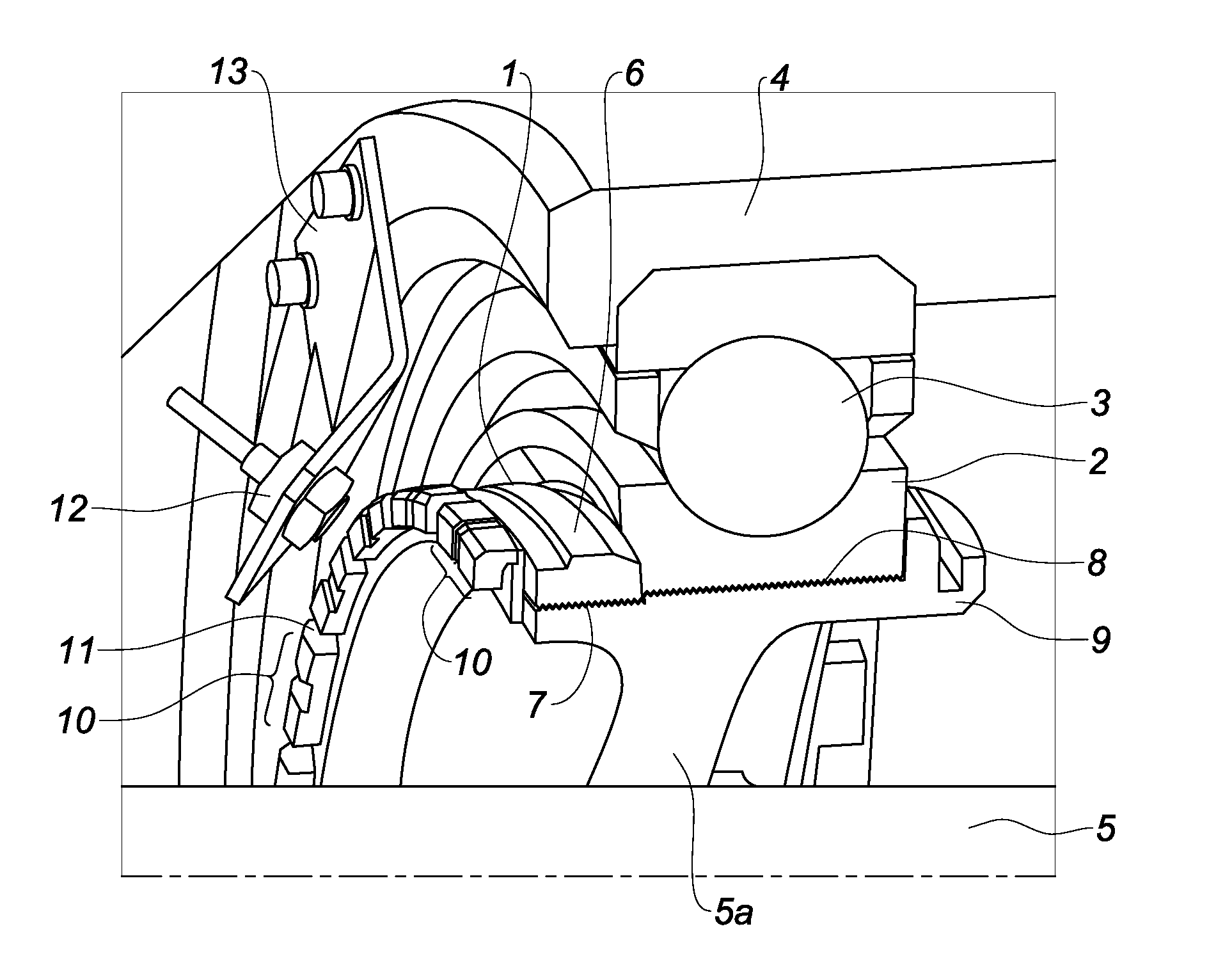

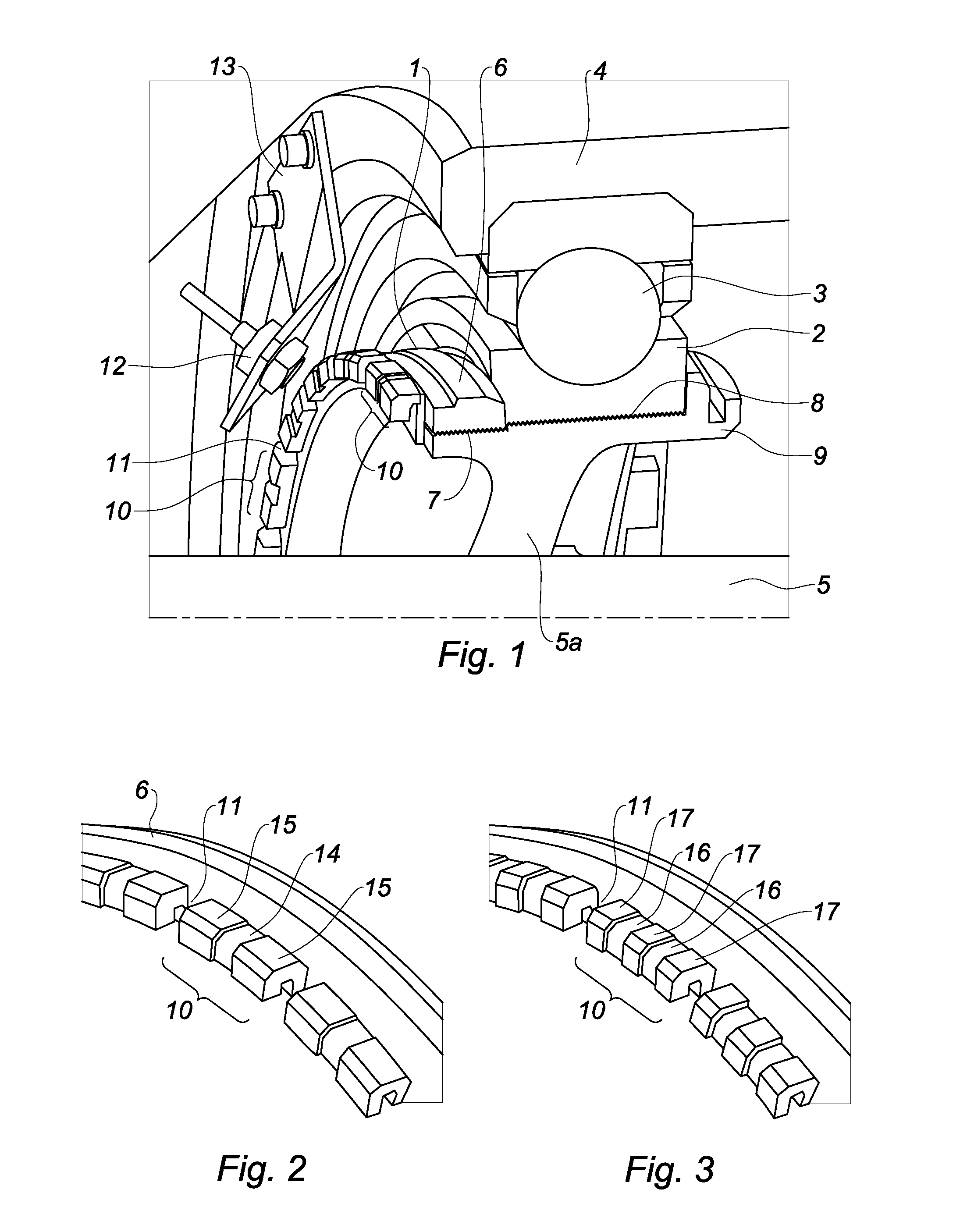

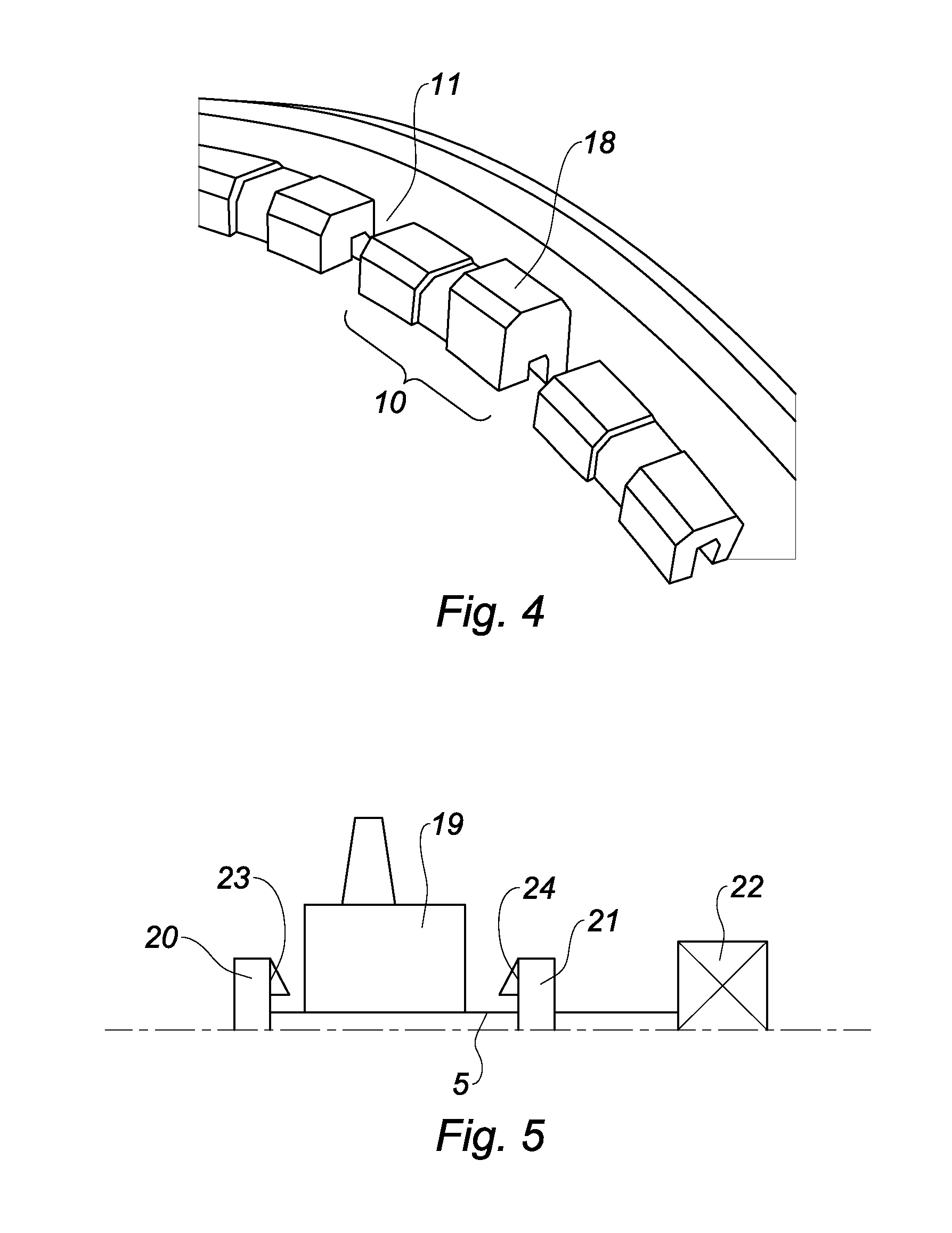

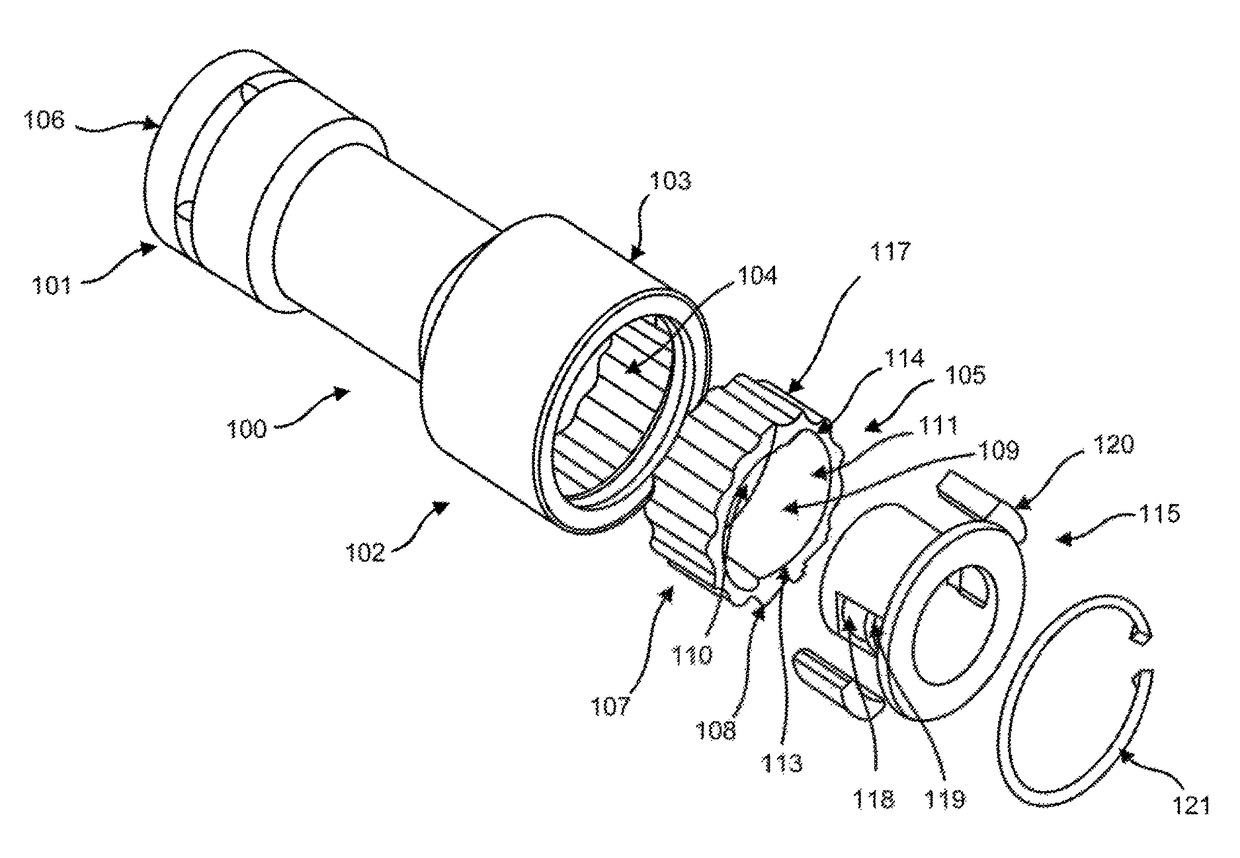

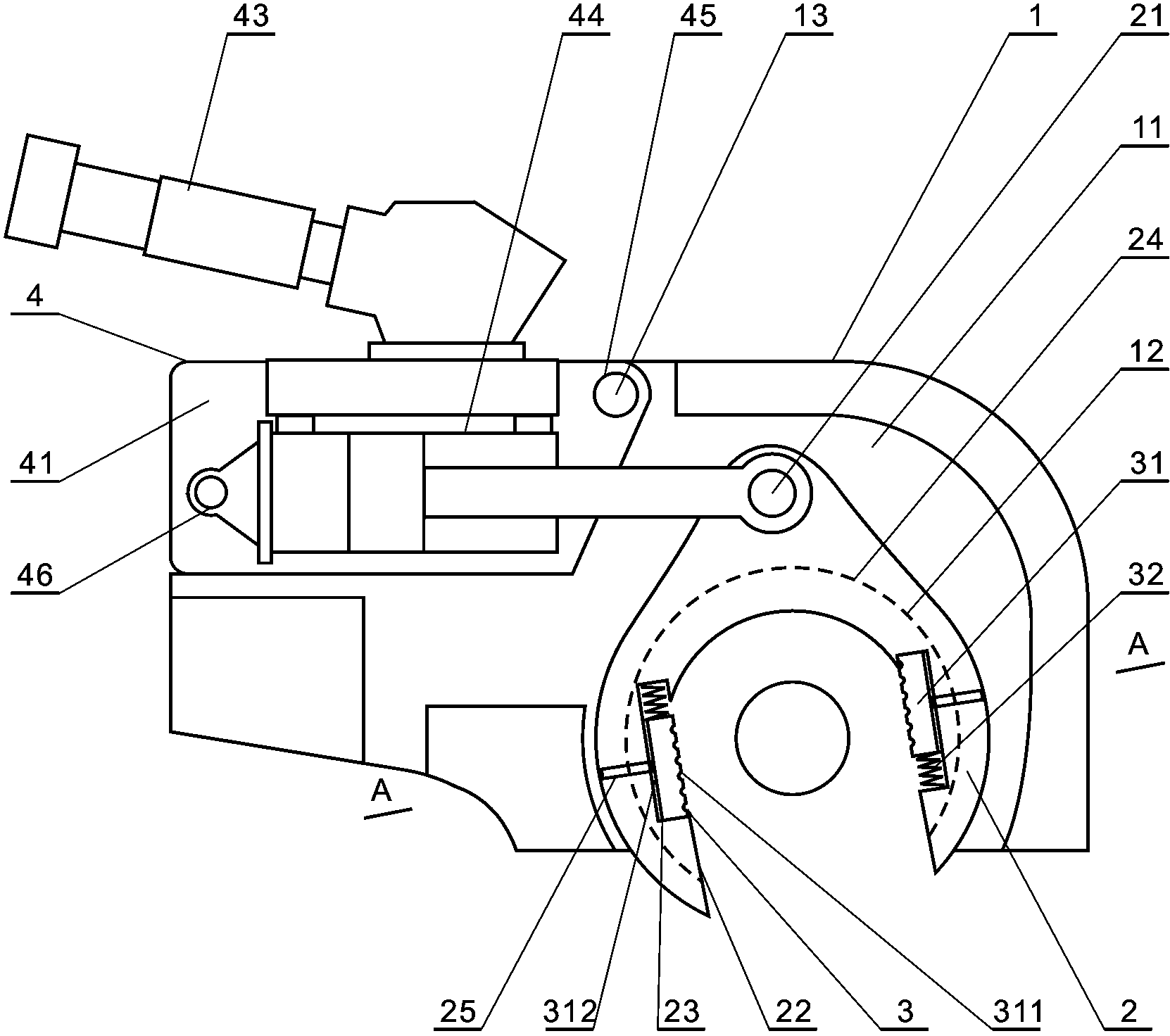

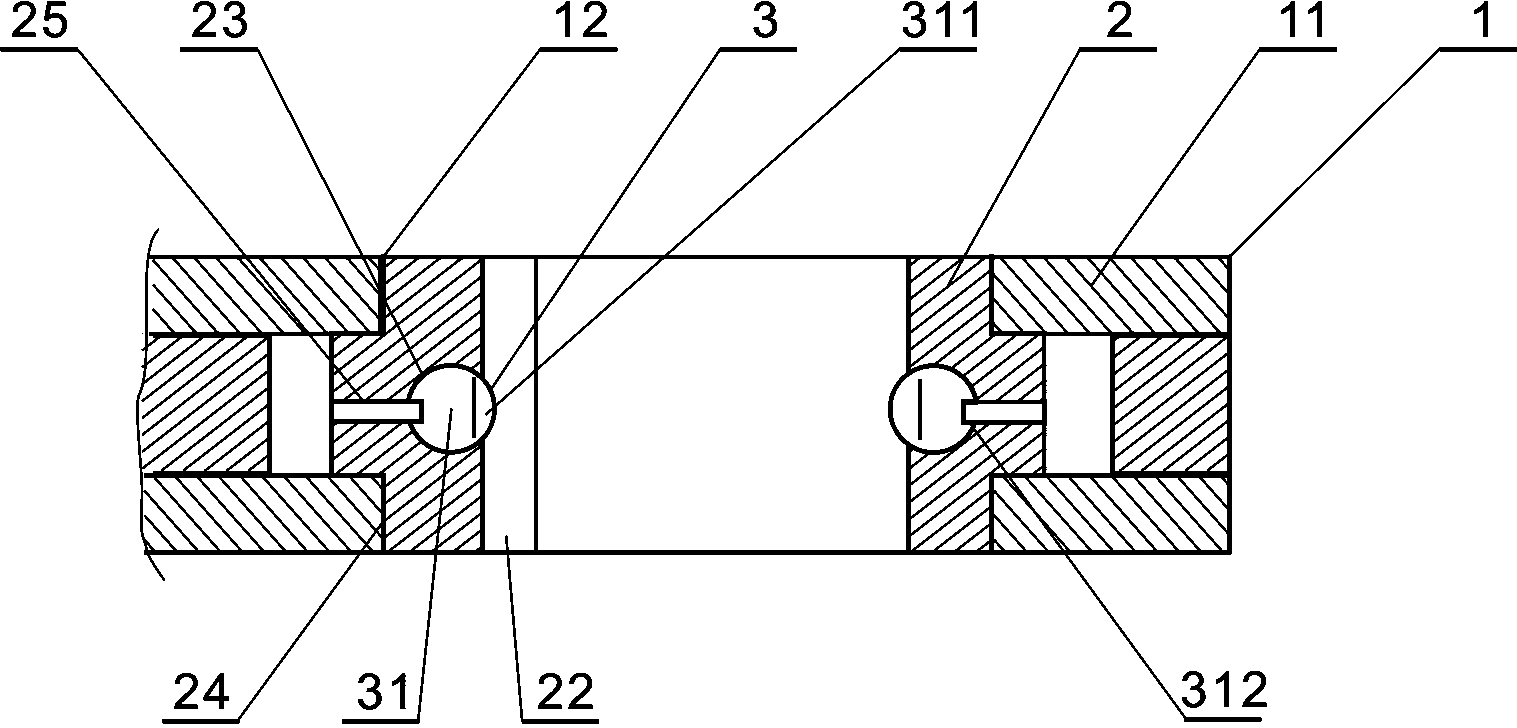

Overload protection device

InactiveCN101561020AAvoid vibration and noiseAccurate working torqueAutomatic clutchesRetaining ringFlange

The invention provides a overload protection device, capable of keeping the rotary drive partition state and preventing from generating the vibration and noise because of the transference the path of the push pressure and accurately setting the operation torque and making a holding mechanism work reliably. the overload protection device has a central flange (110), a hub flange (131) and a push compressed plate for pushing a steel ball (120) to rotate and drive, wherein a holding mechanism (165) for keeping the partition in the over loading comprises a retaining ring (146) mounted at the central flange side of the push pressure plate (140) and a holding ball (145) arranged at the internal circumstance side of the central flange (110).

Owner:TSUBAKI E&M +1

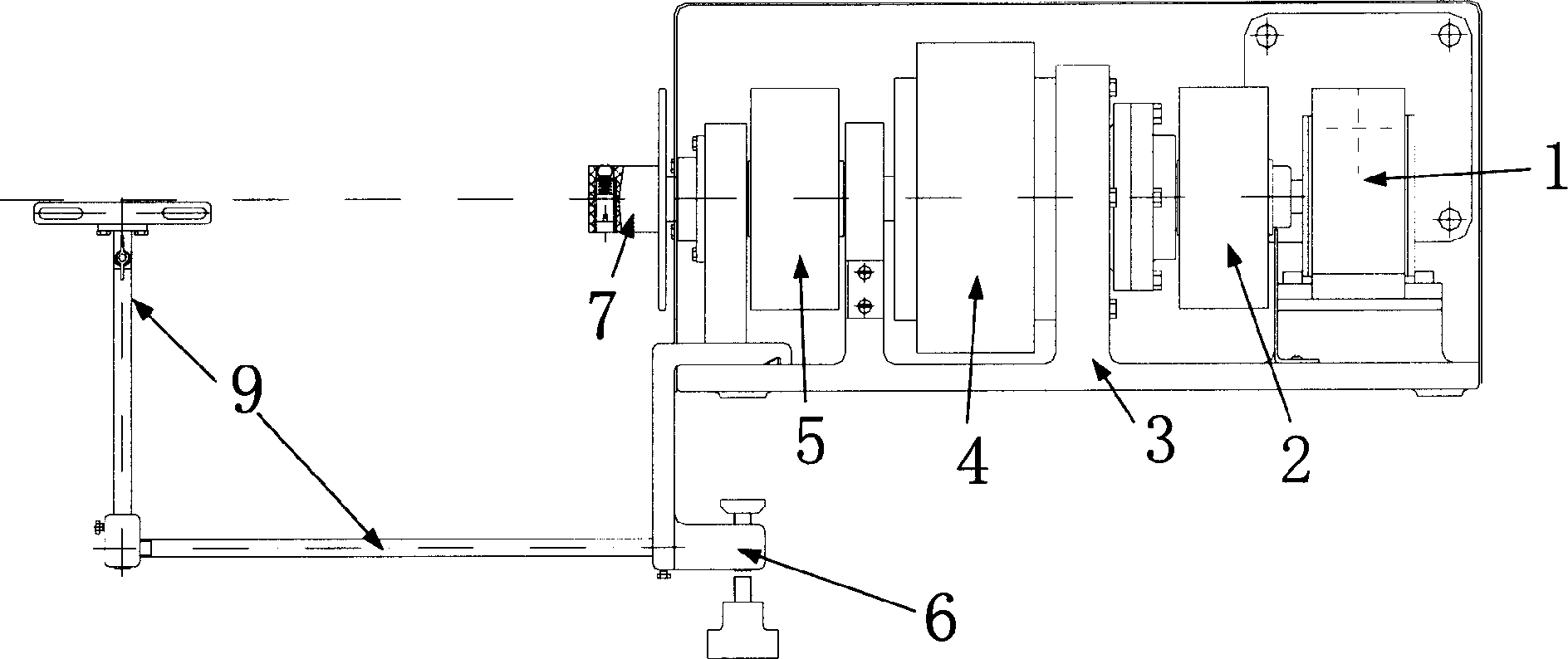

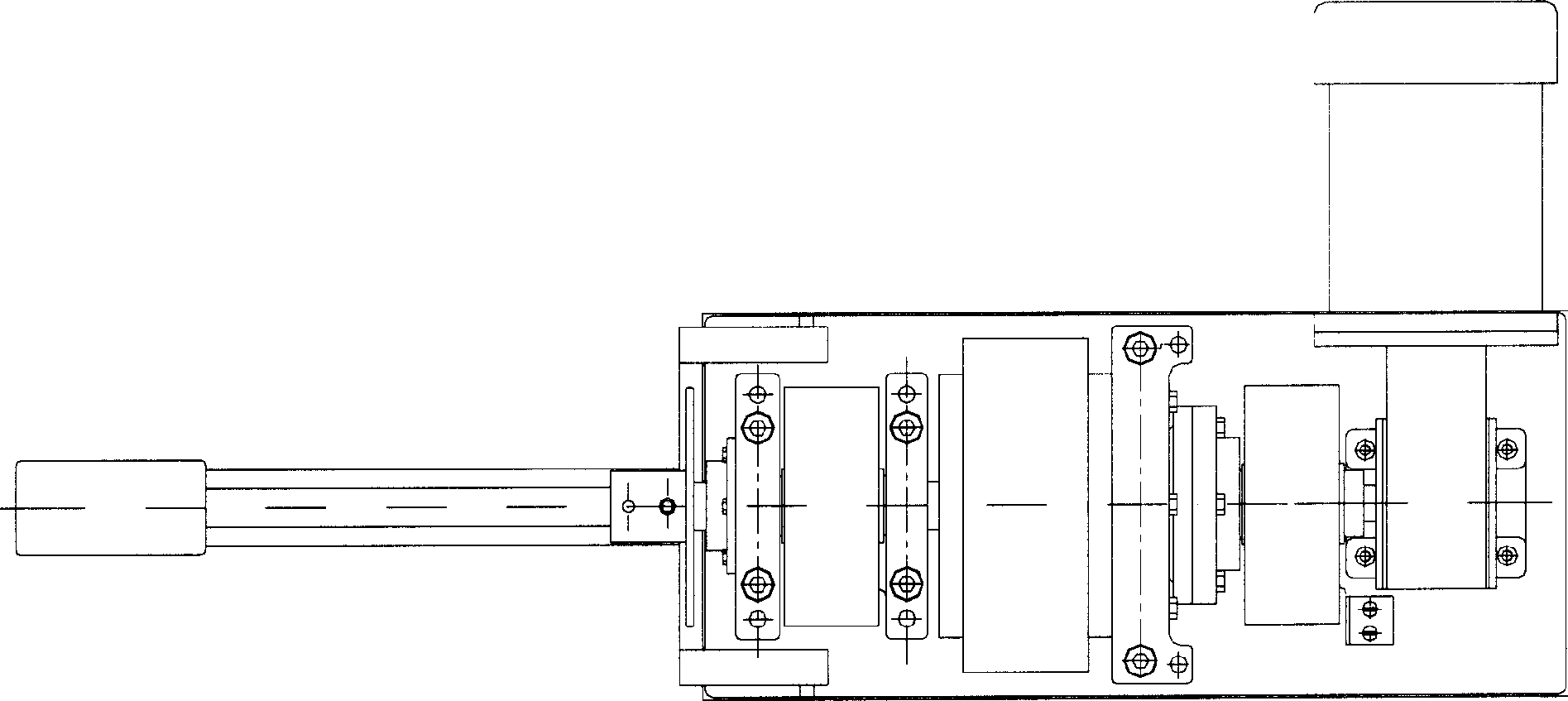

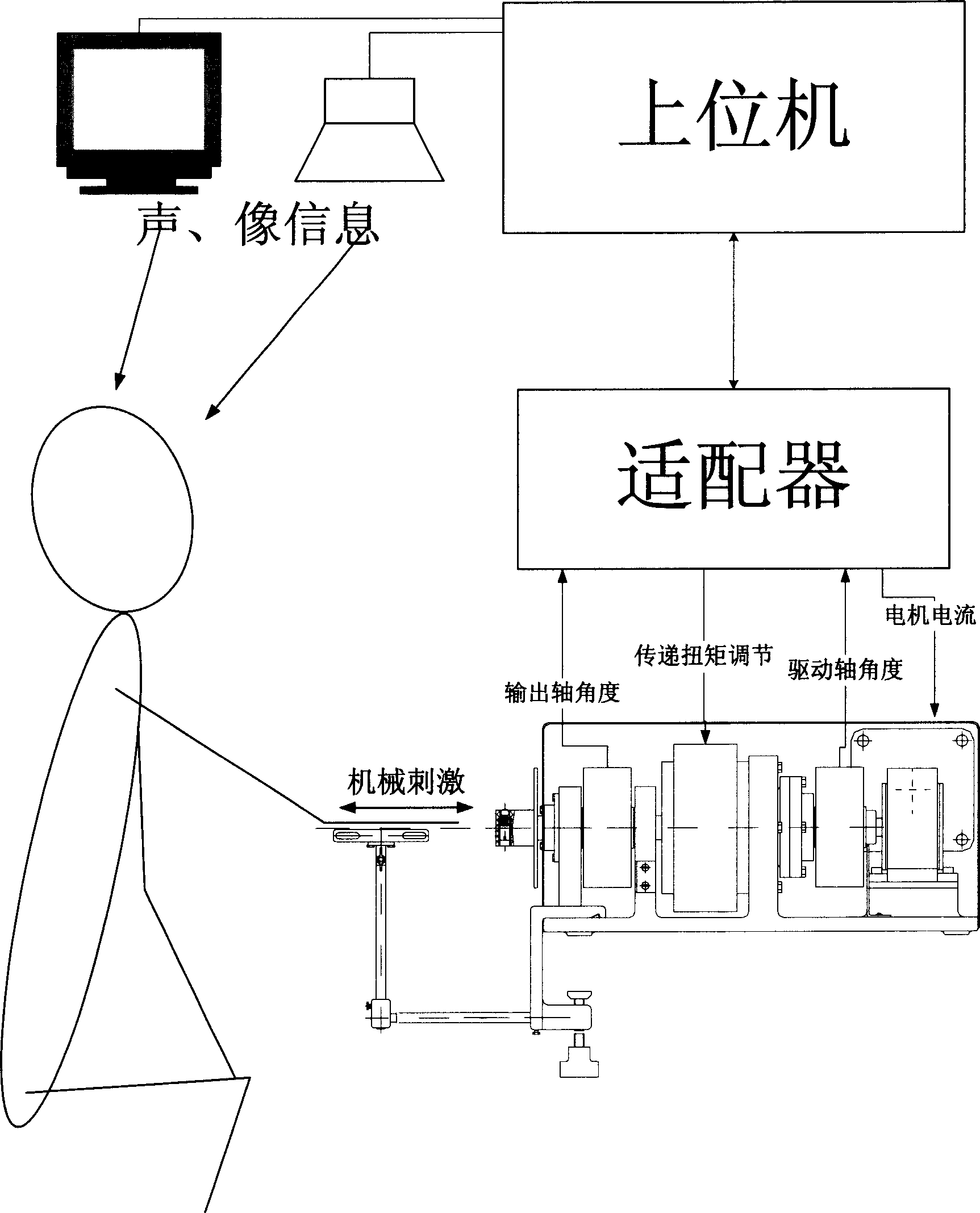

Wrist and finger joint movement rehabilitation training robot

InactiveCN1736521AExpand the scope of actionAccurate torqueGymnastic exercisingChiropractic devicesSignal onSacroiliac joint

The invention relates to a rehabilitation exercising robot of wrist and finger articulation in the medical mechanic technique domain, which is characterized by the following: the rehabilitation exercising robot realizes the automatic auxiliary; the upper machine connects angle detection part and adjustable part by adapter; the robot matches a group of robotic stick clamp apparatus and hand rest on the stick clamp for supporting wrist and palm; the adjustable part contains the speed governing activation device of outputting real-time angle signal on the base of exercising case and magnetic particle clutch whose input shaft connects the output shaft of activation device rigidly; the robot also comprises the following parts: handle output shaft in connection with magnetic particle clutch rigidly, angle detection device of handle output shaft and various usage exercising handle by the handle connection draw-in gear in connection with the handle output shaft rigidly.

Owner:TSINGHUA UNIV +1

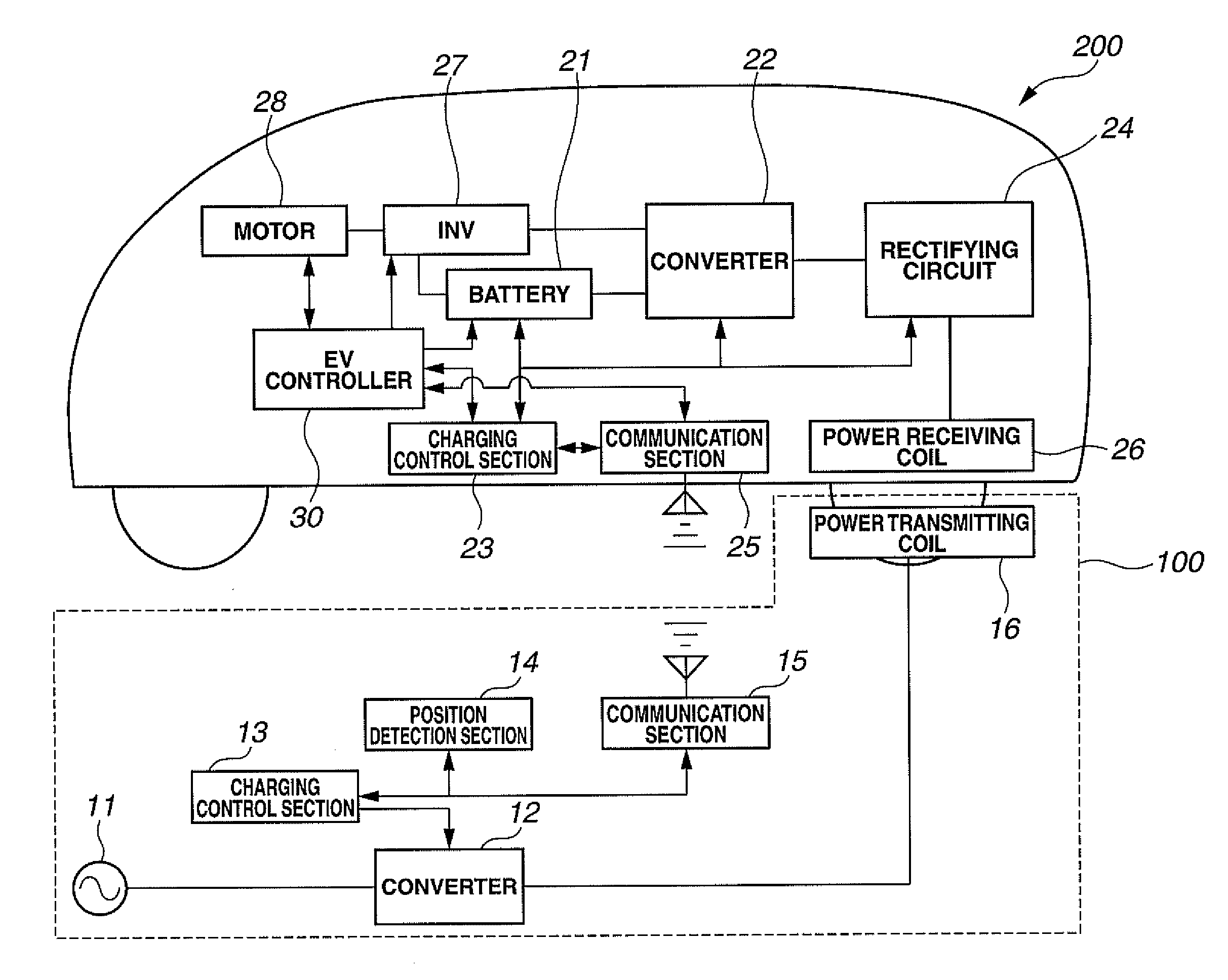

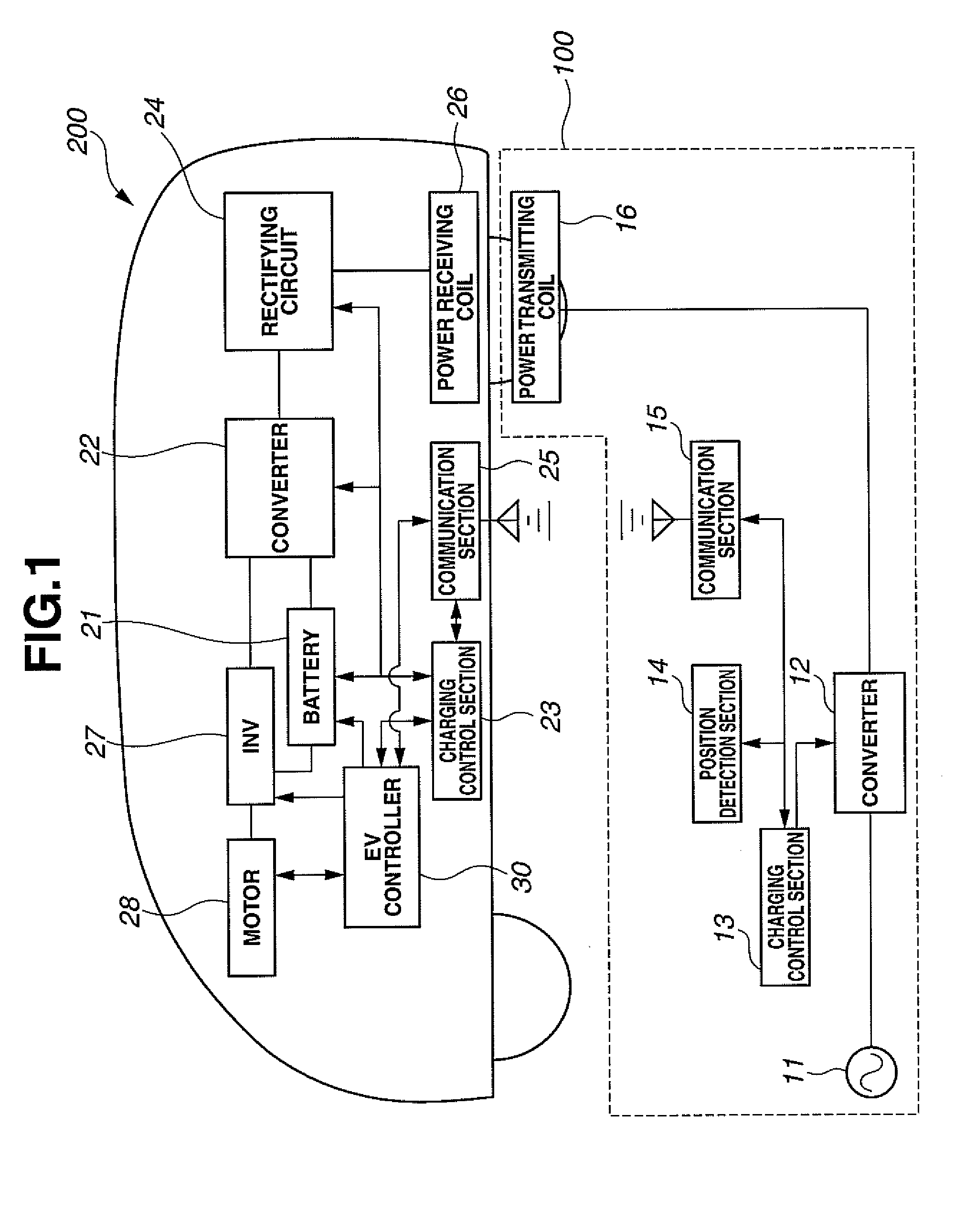

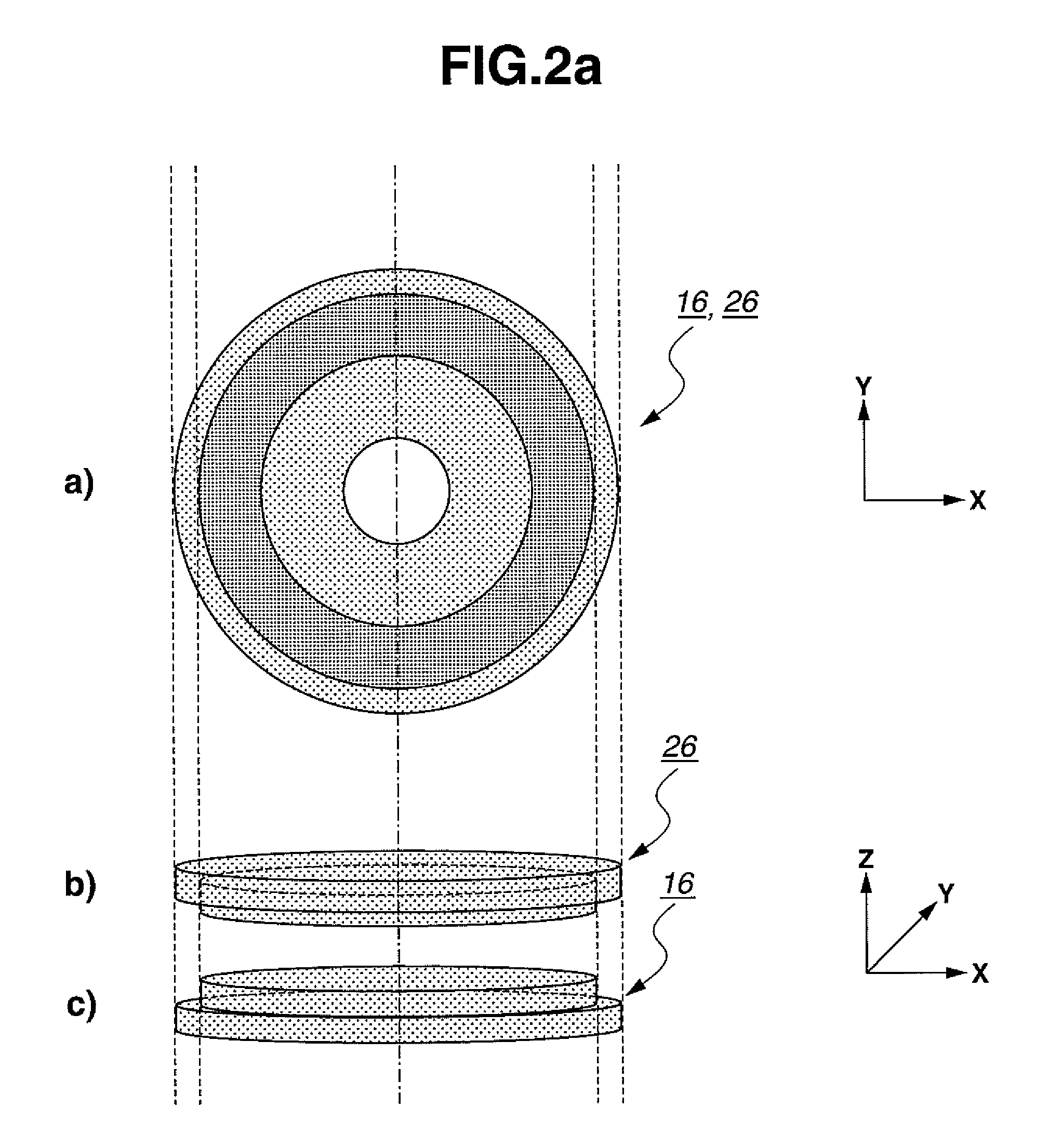

Torque control apparatus and contactless charging system

ActiveUS20140039728A1Accurate torqueHelp positioningBatteries circuit arrangementsDigital data processing detailsControl theoryControl equipment

Owner:NISSAN MOTOR CO LTD

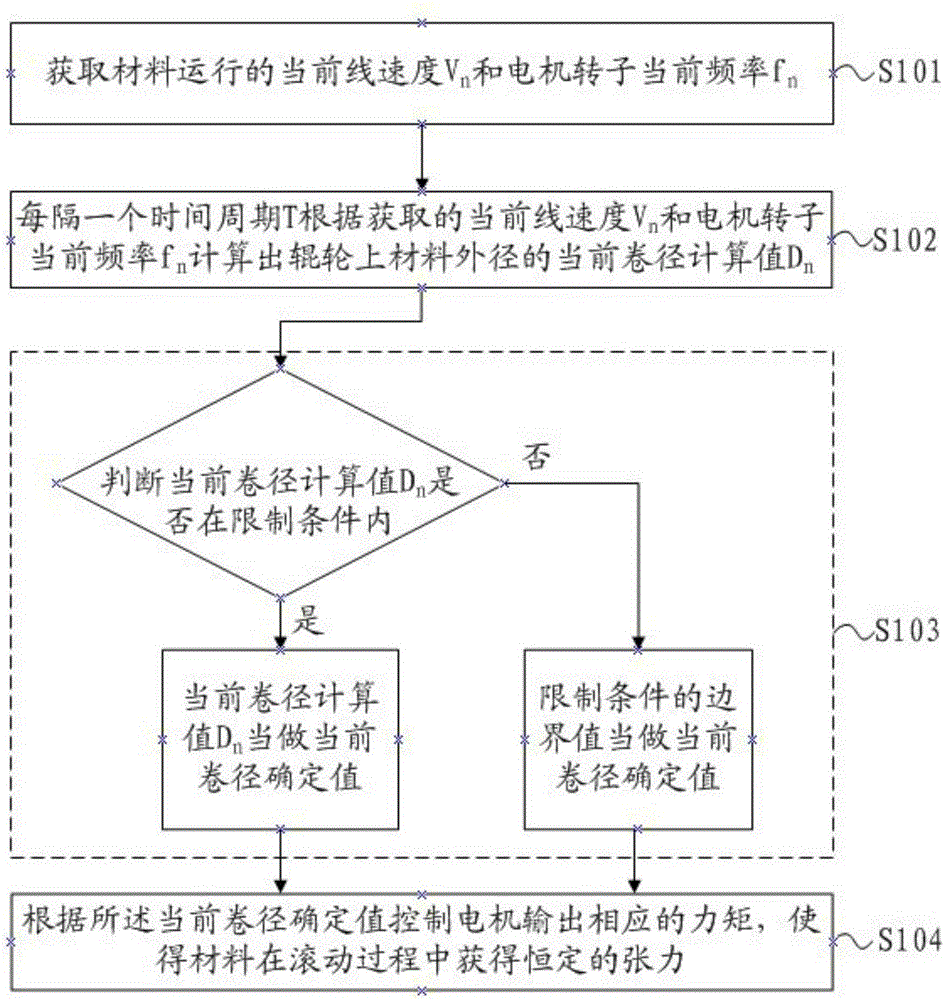

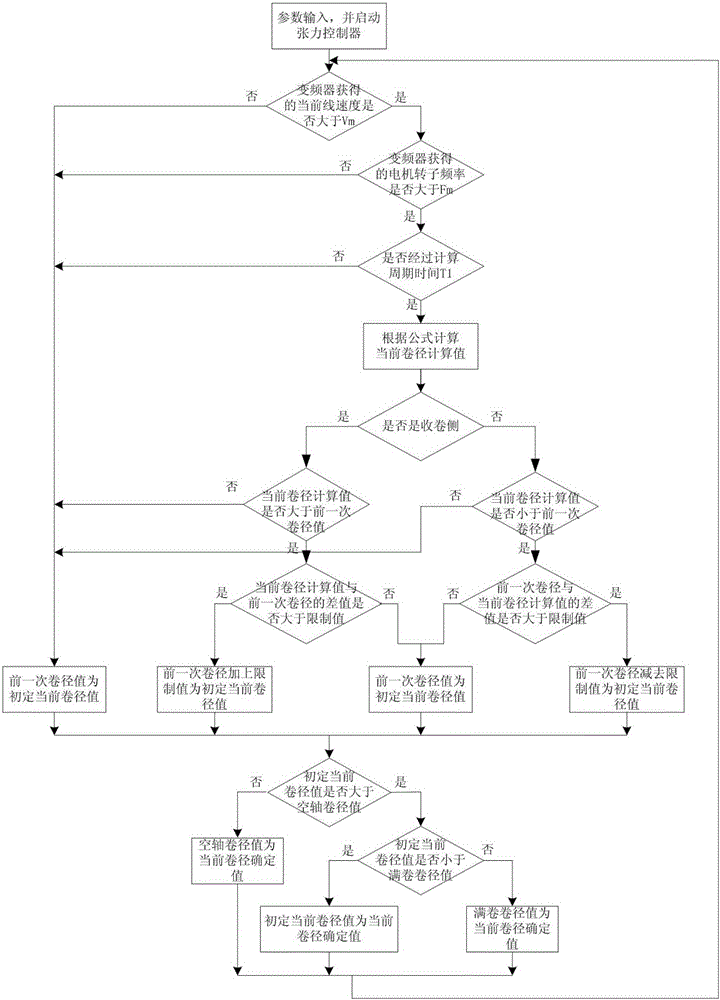

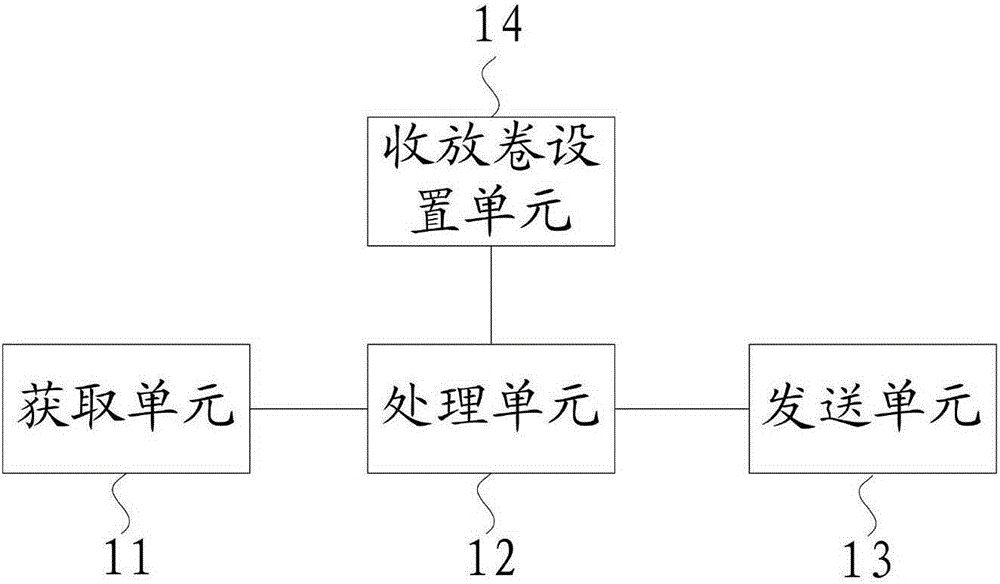

Tension control method, device and system of rolling and unrolling equipment

ActiveCN105197685AConstant tensionGood retractable effectFilament handlingFrequency changerTime cycles

The invention discloses a tension control method, device and system of rolling and unrolling equipment. The tension control method comprises the steps of obtaining the current linear velocity V<n> of operation of a material and the current frequency f<n> of a motor rotor; calculating out the current rolling diameter calculated value D<n> of the outer diameter of the material on a roller wheel every other time cycle T according to the obtained current linear velocity V<n> and the current frequency f<n> of the motor rotor; comparing the current rolling diameter calculated value D<n> with a predetermined limiting condition, and determining the current rolling diameter determined value; according to the current rolling diameter determined value, controlling a motor to output a corresponding force moment. According to the tension control method, device and system of the rolling and unrolling equipment, due to the fact that a tension controller calculates out the current rolling diameter calculated value by obtaining the material operation linear velocity, then conducts error judgment on the current rolling diameter calculated value obtained through calculation, conducts judgment by comparing the current rolling diameter calculated value with the limiting condition and finally controls a frequency converter to output the corresponding force moment according to the current rolling diameter determined value obtained through calculation and judgment, the material on the roller wheel can obtain constant tensile force all the time, the material can be rolled and unrolled more stably, and the rolling and unrolling effect is better.

Owner:SHENZHEN INVT ELECTRIC

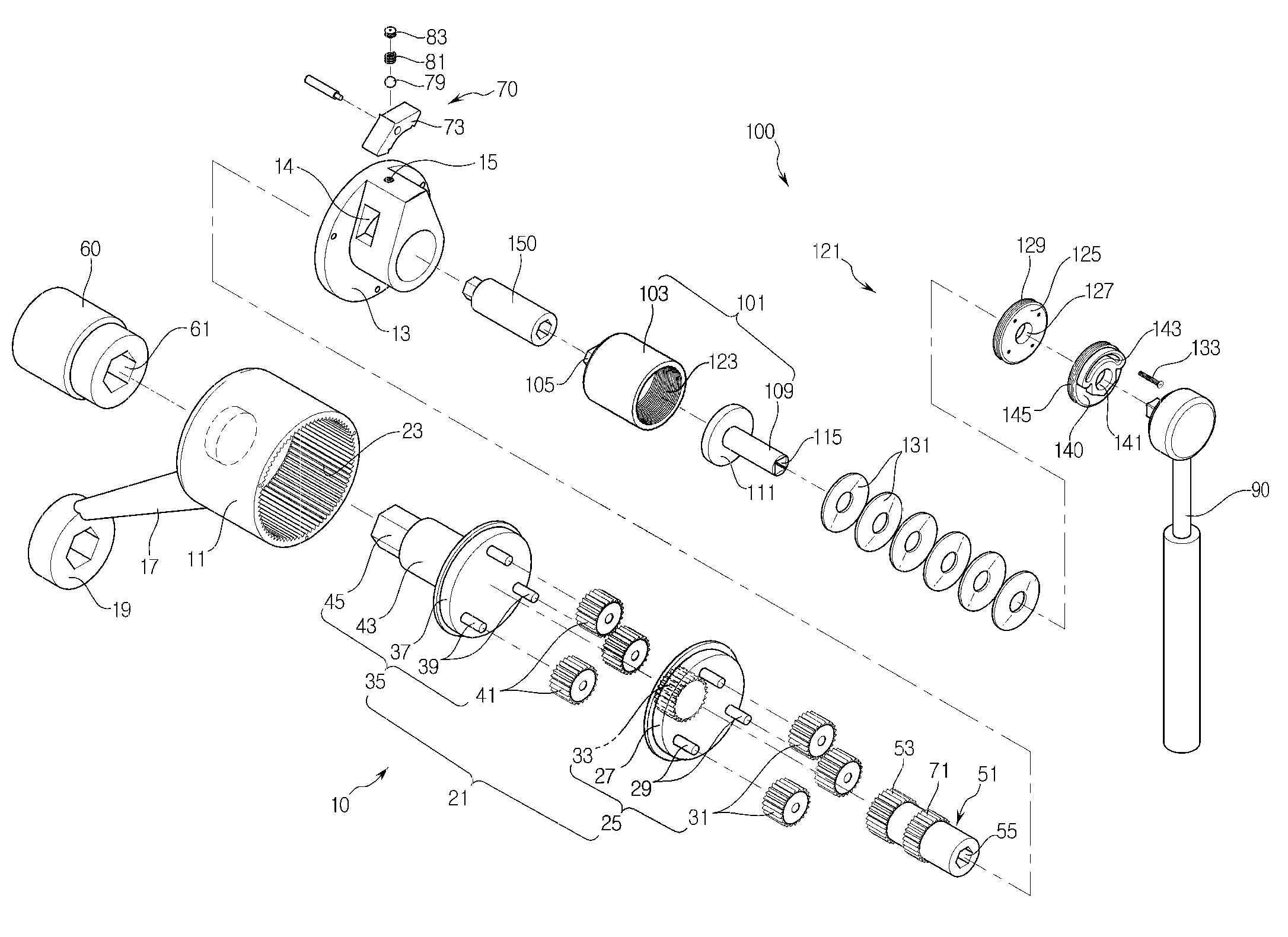

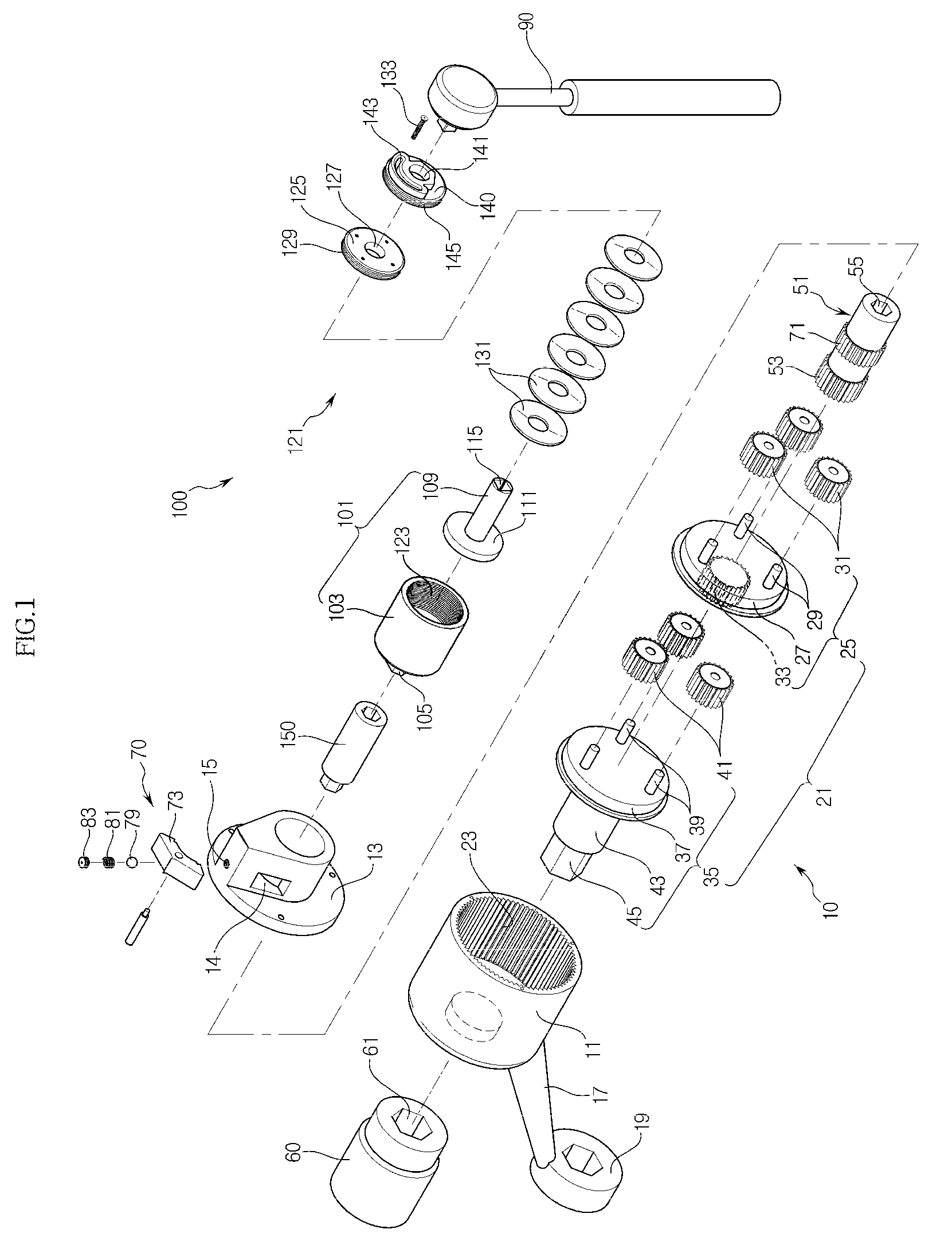

Torque control wrench for both left-hand thread and right-hand thread

InactiveUS8443699B2Accurate torqueEasy to tightenWheel mounting apparatusSpannersEngineeringControl theory

A torque control wrench for both a left-hand thread and a right-hand thread is disclosed. The torque control wrench includes a wrench unit having a transmission unit, a movable shaft engaged with the transmission unit, for rotating the transmission unit with external force, and a socket for receiving rotational force at a rotation speed changed by the transmission unit and tightening or loosening a bolt with the received rotational force, a handle for generating the rotational force with which the socket tightens or loosens the bolt, and a torque controller between the wrench unit and the handle, for controlling a torque applied from the handle to the socket, including a clutch for rotating along with rotation of the handle and thus rotating the movable shaft and, if a torque equal to or greater than a preset torque value is applied, rotating idly, and a clutch torque controller for controlling the torque applied from the handle to the clutch.

Owner:SEWON PM TECH

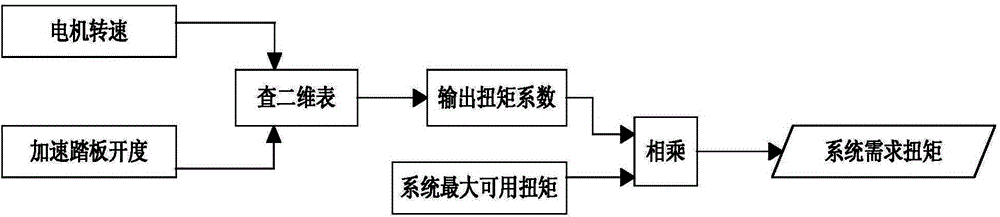

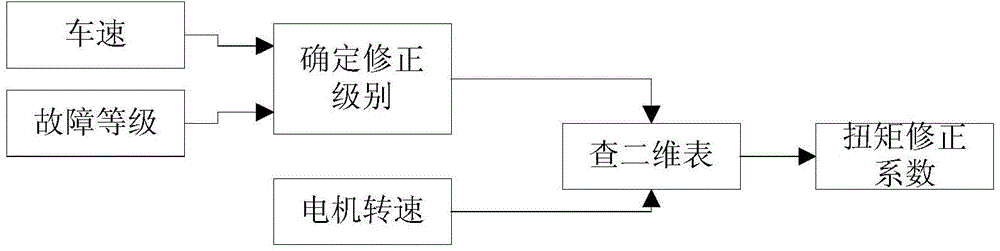

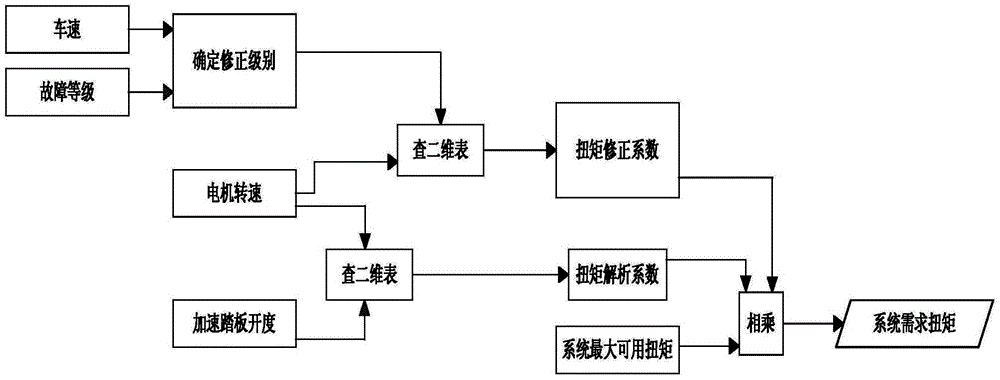

Torque correction coefficient calculation and torque analysis methods and systems for electric automobile

InactiveCN104859483AImprove Torque Control AccuracyGood dynamic responseSpeed controllerElectric energy managementMotor speedTorque analysis

The invention provides torque corrosion coefficient calculation and torque analysis methods and systems for an electric automobile. Besides consideration of motor speeds and opening degrees of an accelerator pedal, speeds of the automobile and fault levels are comprehensively considered to determine correction coefficients and correction starting points of torque, and required torque for system analysis is corrected in real time. When the speeds of the automobile and the fault levels are different and the opening degrees of the accelerator pedal are the same, different torque corrosion coefficients can be obtained, and more accurate toque analysis coefficients are obtained; with the adoption of the scheme, more accurate and more comprehensive consideration factors are provided for actual output torque of a motor, and the torque control precision of the whole automobile is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Lane keeping traveling support apparatus

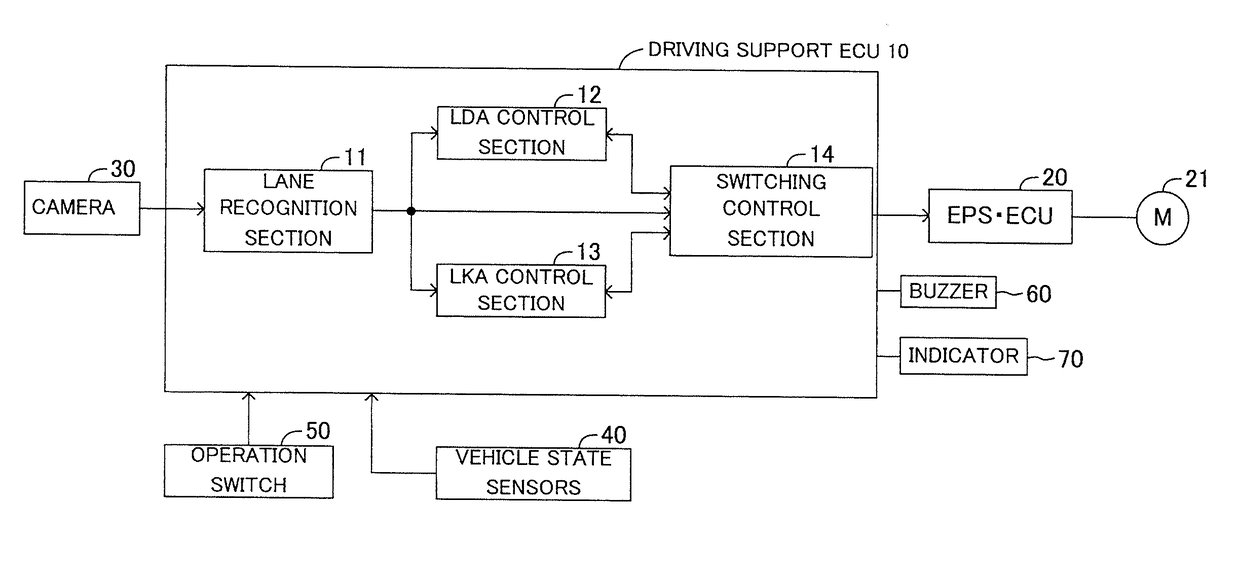

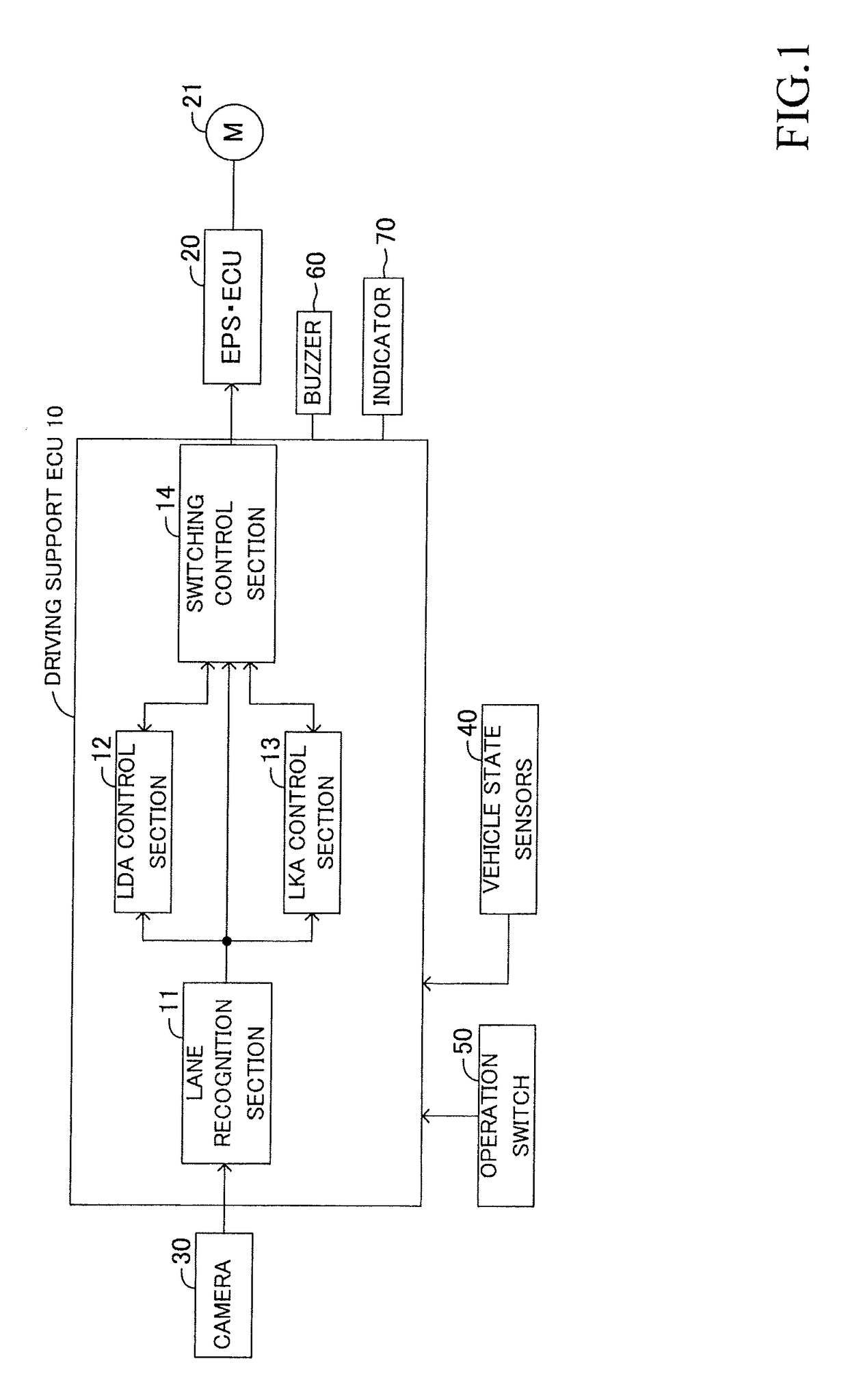

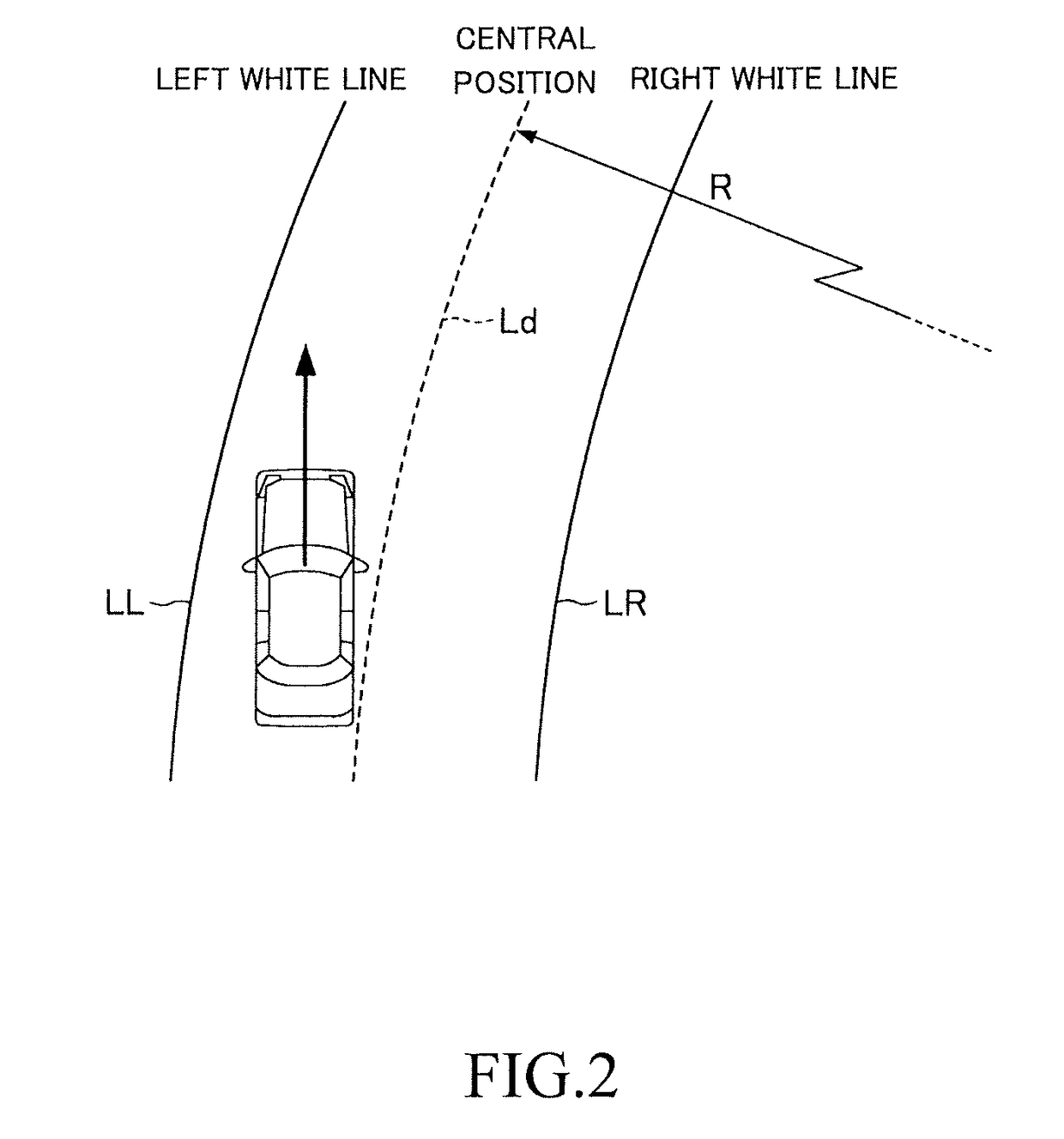

ActiveUS20180154938A1Reduce deviationPrevent deviationAutomatic steering controlPower driven steeringSteering wheelVehicle behavior

A lane keeping traveling support apparatus includes a driving support ECU. The driving support ECU is configured to inform a driver that the LDA control is being performed by causing the driver to have uncomfortable feeling by a movement of a steering wheel and a vehicle behavior when the LDA control is performed. This function is achieved by enhancing responsiveness of the LDA control.

Owner:TOYOTA JIDOSHA KK

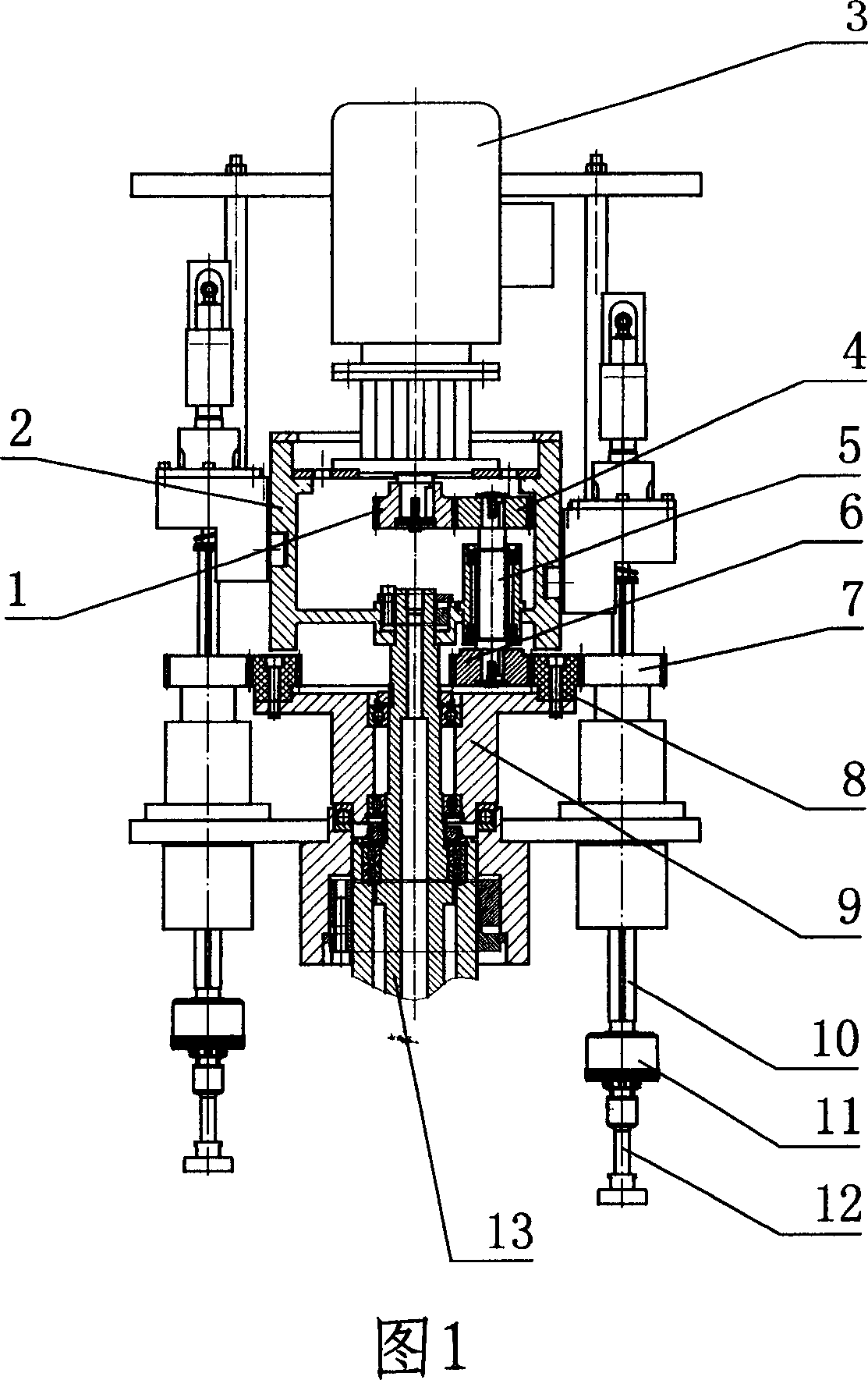

Cap rotating mechanism for continuous round disc type cap rotating machine

The unscrewing mechanism of a consecutive disk type unscrewing device driven by electric motor speed reducer for free rotation, flexible and convenient of operation and applicable of bottles of alls kinds of specifications, comprises of electric motor speed reducer, speed reducer gear, cam of the middle cylinder, upper gear, gear shaft, lower gear, gear, middle gear, middle gear base, drive shaft, friction clutch, central fixing shaft, and unscrewing head, with speed reducer gears equipped on the shaft end of the electric motor speed reducer, and upper gears, gear shaft and lower gears equipped on the middle cylinder cam. The gear shaft fastens on the middle cylinder cam through a bearing base; the middle gear tooths with gears that connect sequentially with the drive shaft, the friction clutch and an unscrewing head.

Owner:SHANGHAI LONGTENG TECH

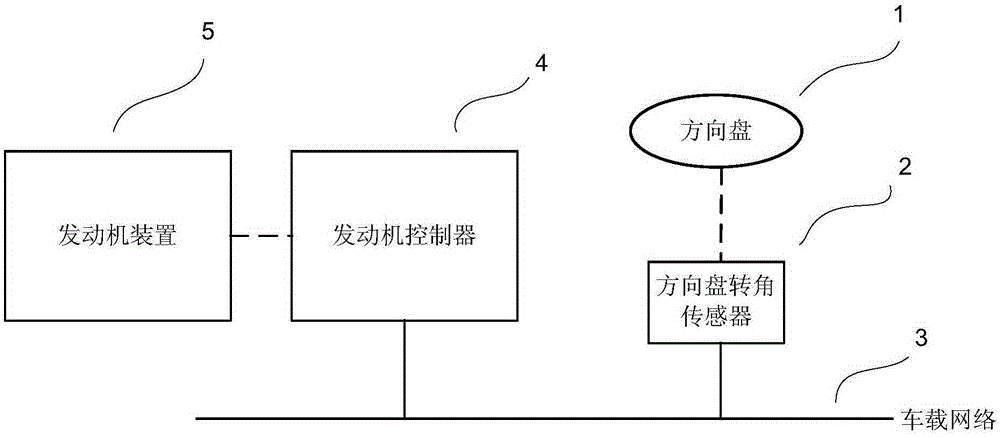

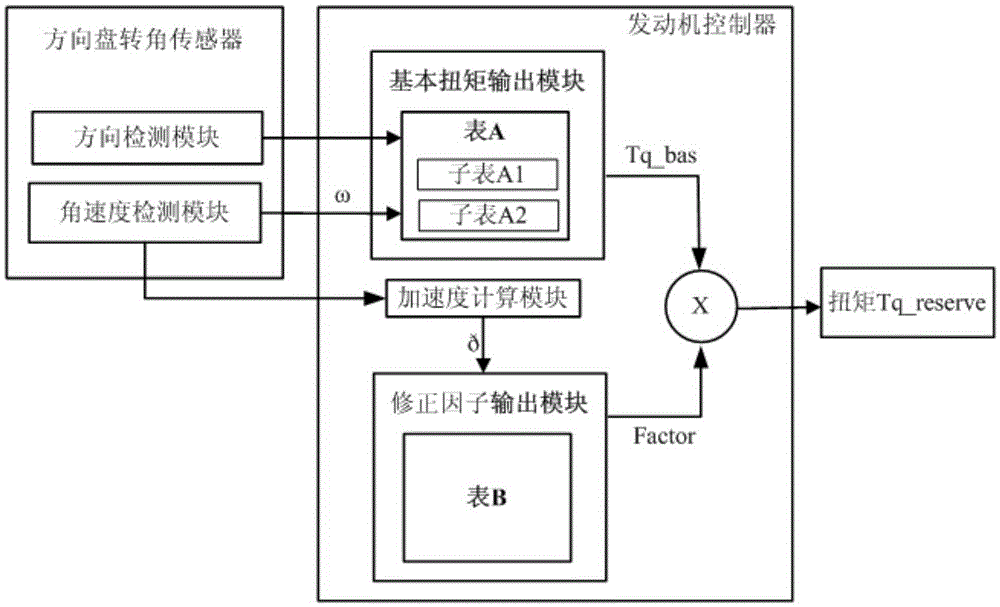

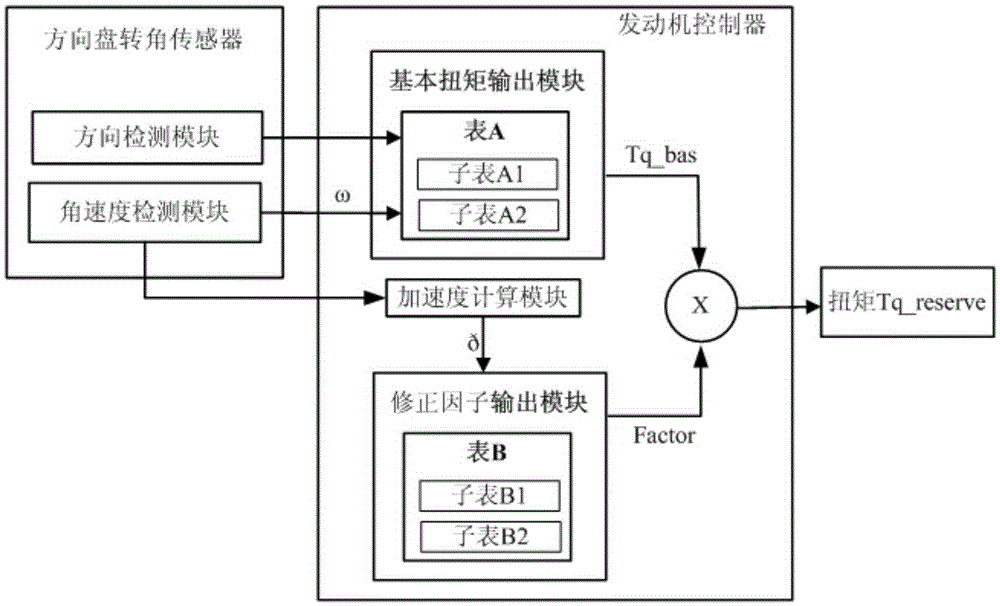

Power-assisted steering torque compensation method and system based on rotating angle information of steering wheel

The invention provides a power-assisted steering torque compensation method. The power-assisted steering torque compensation method comprises the following steps of detecting a rotating angle A and a rotating direction D of a steering wheel, and calculating out the angular speed Omega and the angular acceleration Sigma of the rotating of the steering wheel; according to the rotating direction D and the angular speed Omega, determining the basic torque compensation value Tq_bas required by an electronic hydraulic power-assisted steering system EHPS; according to the angular acceleration Sigma of the steering wheel, determining the amendment factor Factor of the basic torque compensation value Tq_bas; and according to the amendment factor Factor, amending the basic torque compensation value Tq_bas, and obtaining actual torque compensation value Tq_reserve. According to the power-assisted steering torque compensation method and system based on the rotating angle information of the steering wheel provided by the invention, accurate torque compensation value can be calculated through utilizing multi-direction and multi-type information of the steering wheel, and accurate calculation on a torque is realized at low cost, so as to reduce the consumption of automobile fuel.

Owner:VITESCO AUTOMOTIVE ELECTRONICS (CHANGCHUN) CO LTD

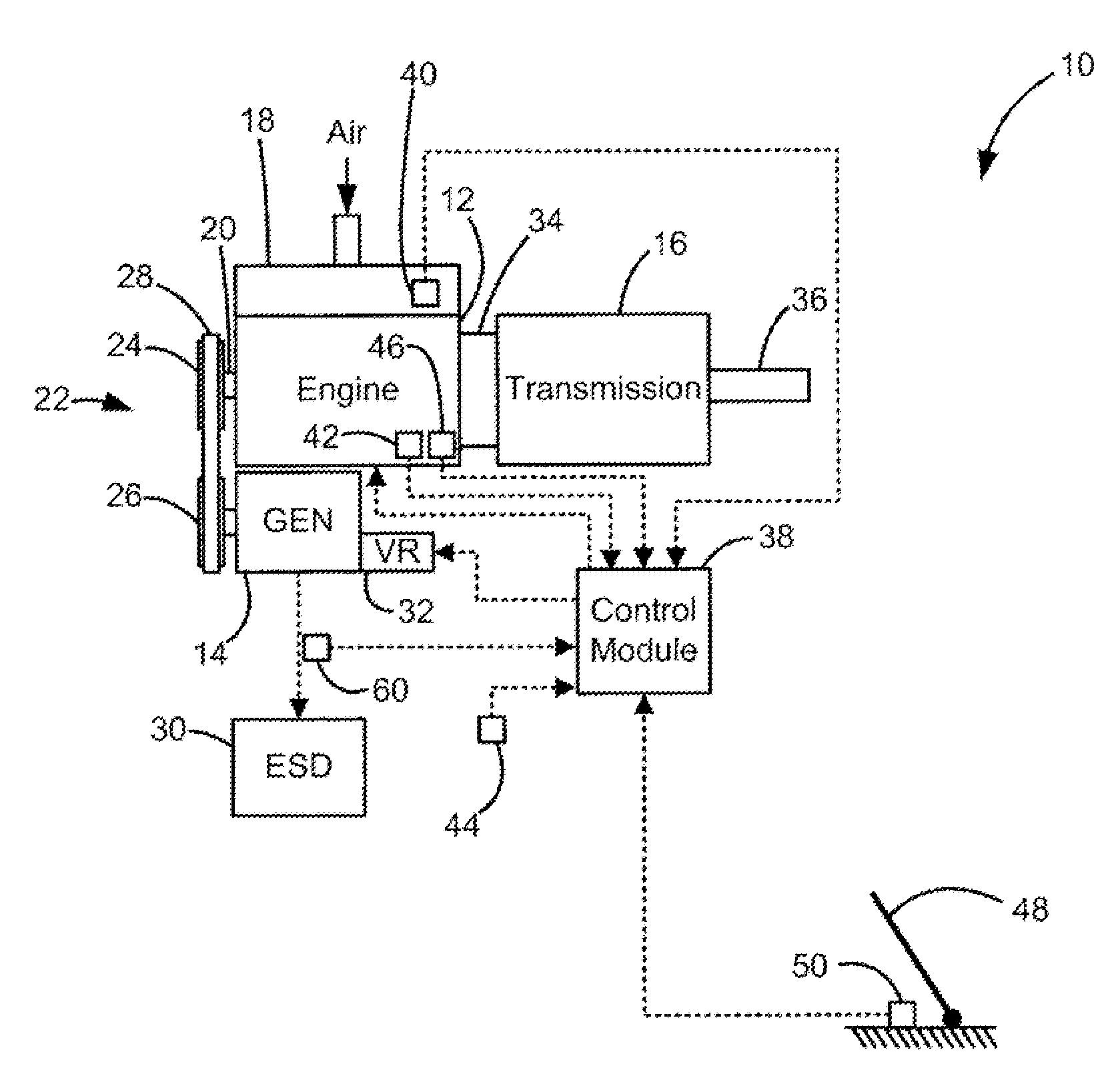

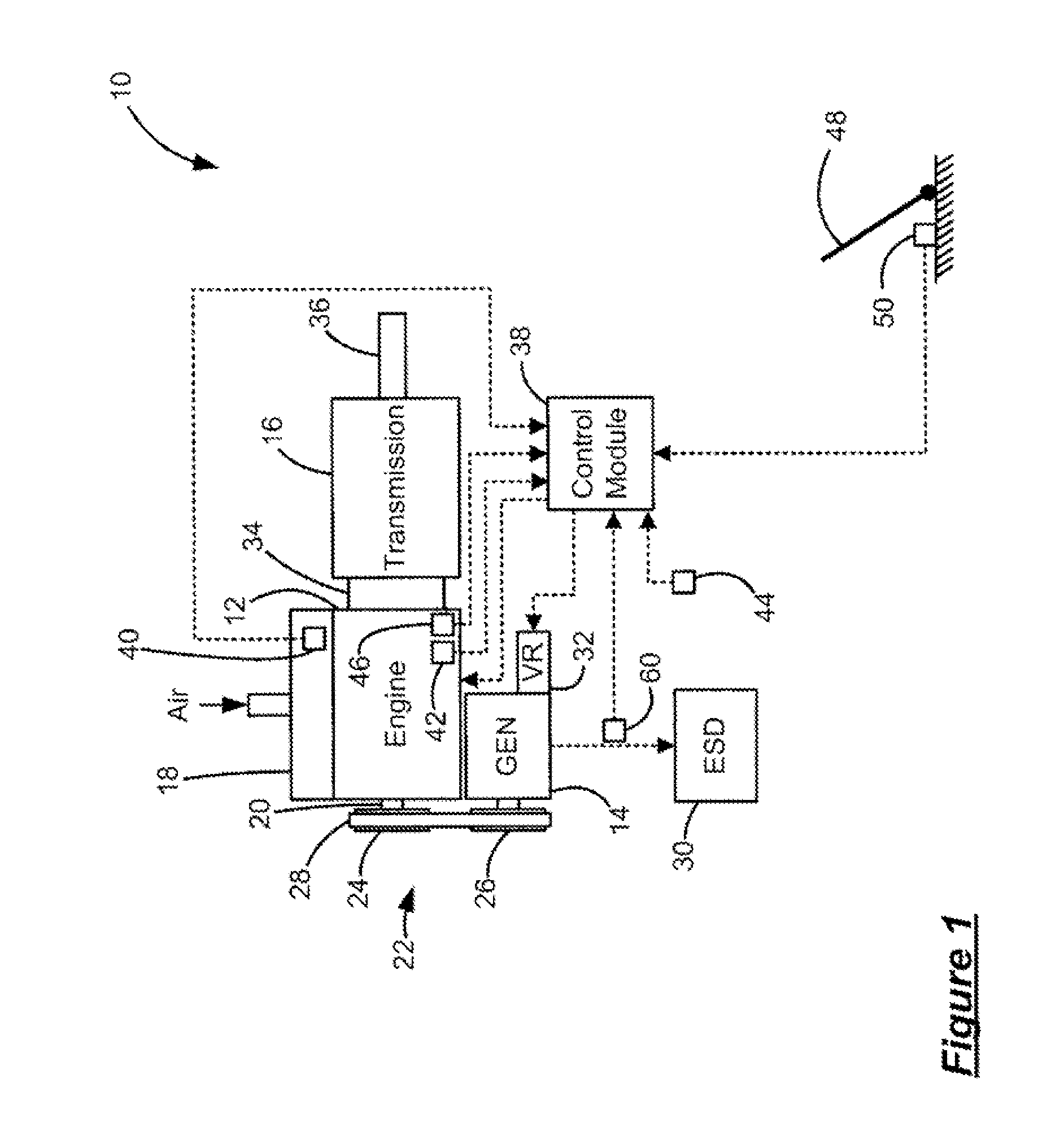

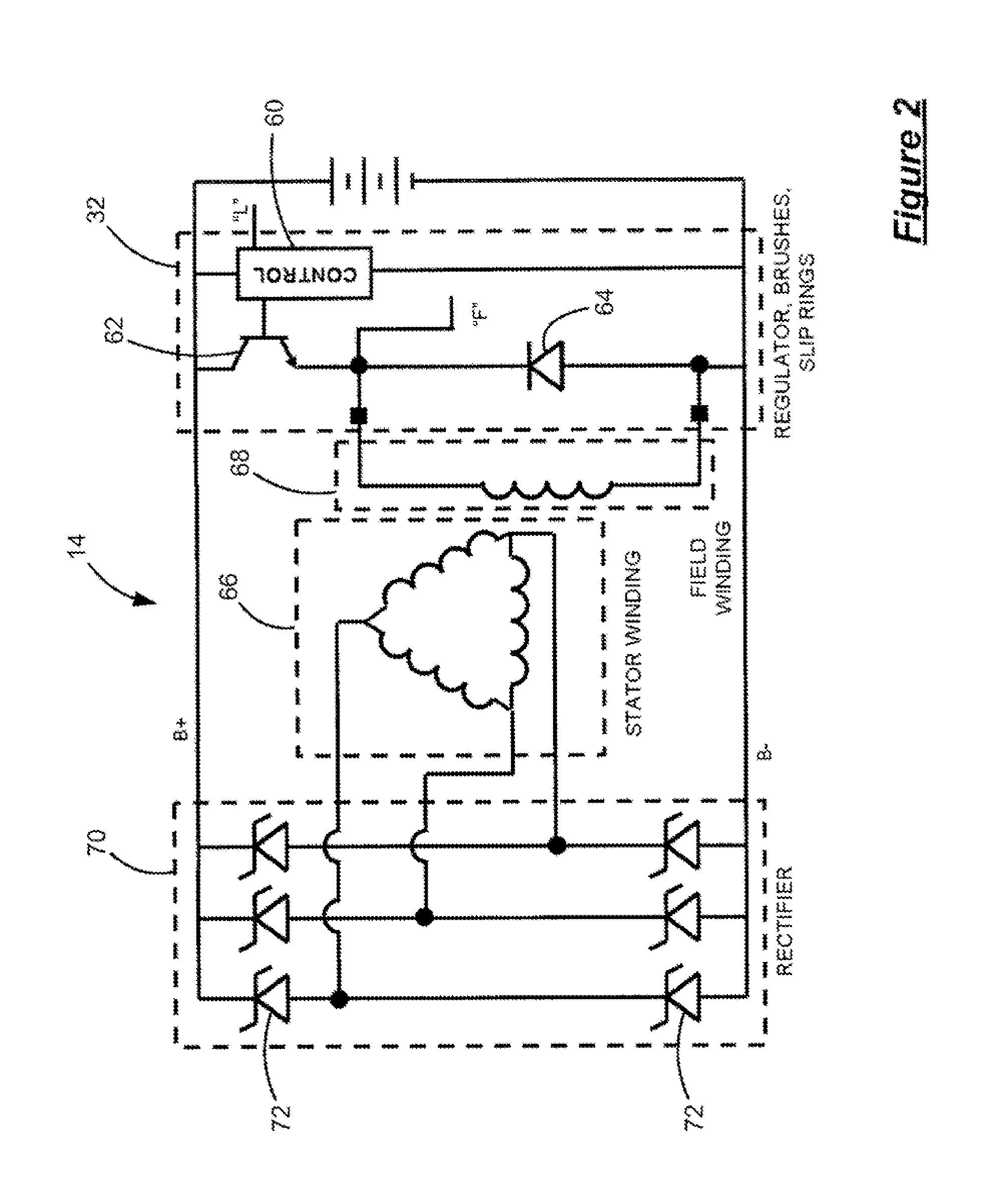

Torque estimation of engine driven generator

ActiveUS20080054646A1Accurate torqueAnalogue computers for vehiclesElectrical controlEngineeringControl system

An engine control system for an engine that drives a generator includes a temperature sensor that generates a temperature signal and a control module that determines a generator torque based on an engine speed and a generator characteristic. The control module determines a torque correction factor based on the temperature signal and determines a corrected generator torque based on the generator torque and the torque correction factor. Various embodiments of the invention utilize engine speed, system voltages field winding duty cycle engine temperature, ambient temperature and / or generator current.

Owner:GM GLOBAL TECH OPERATIONS LLC

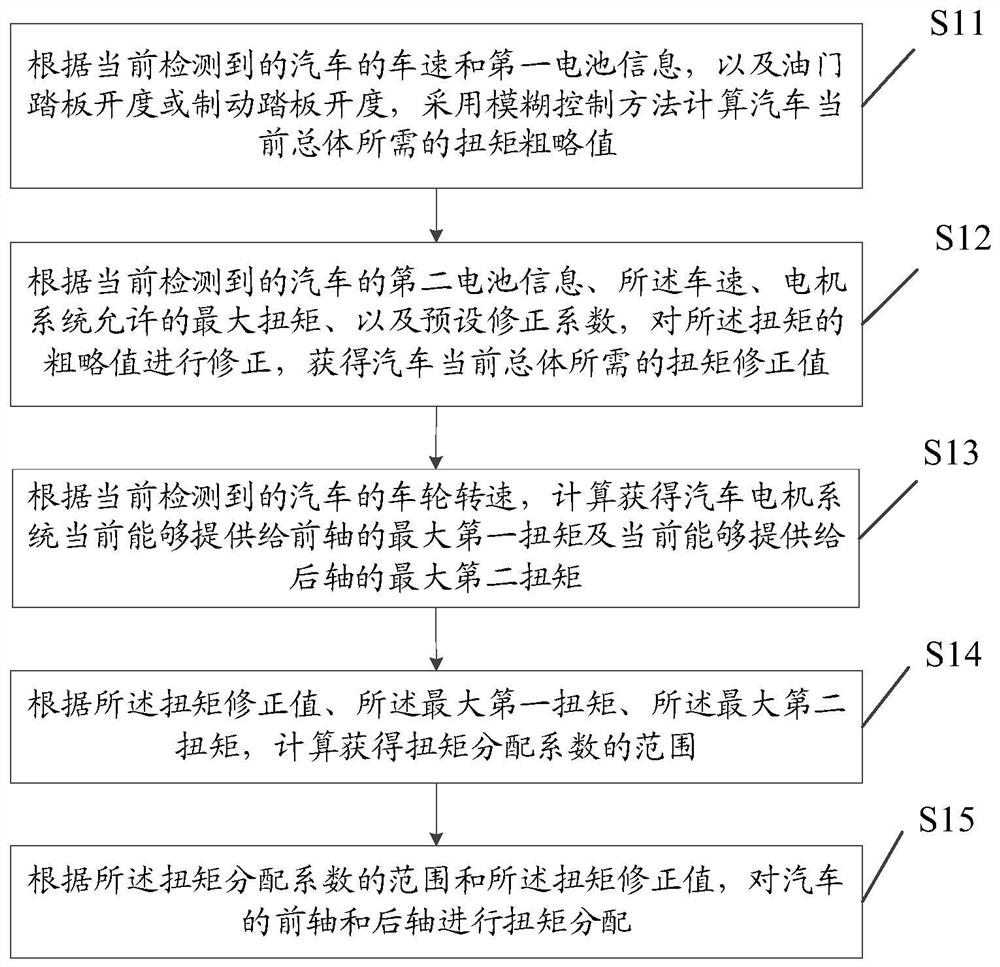

Energy consumption optimization control method, device and electric four-wheel drive vehicle

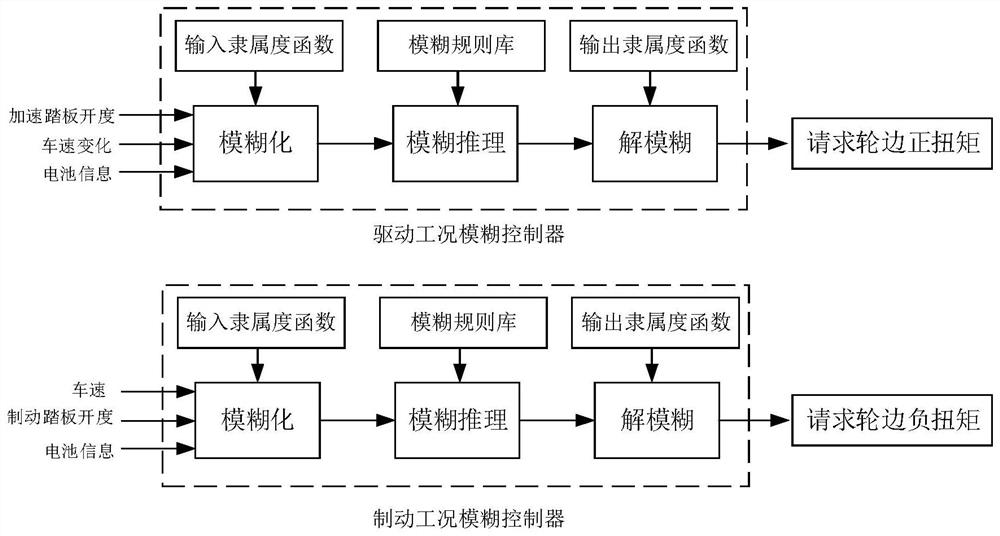

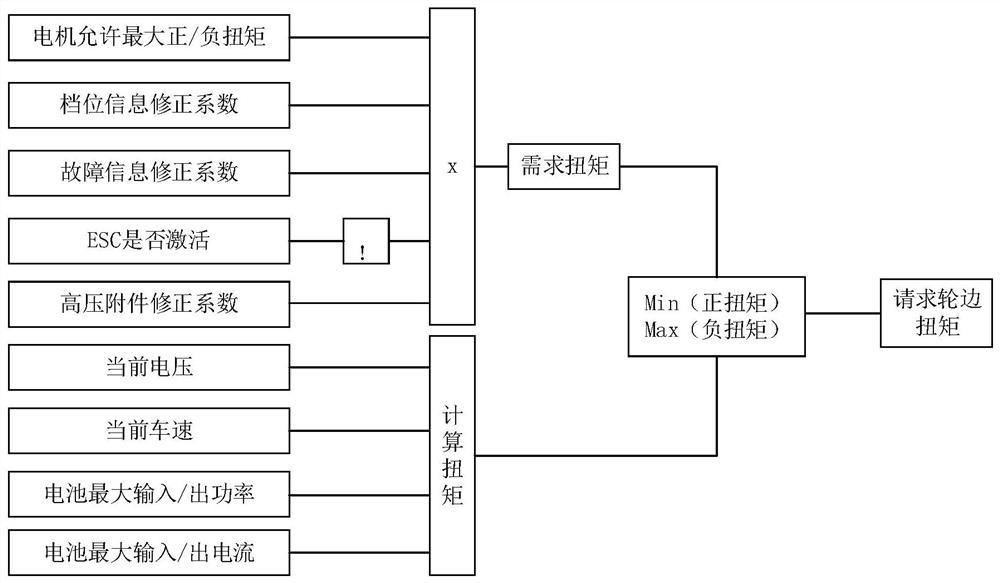

ActiveCN112163269AAccurate torqueImprove accuracyGeometric CADHybrid vehiclesElectrical batteryFuzzy control system

The invention discloses an energy consumption optimization control method, a device and an electric four-wheel drive vehicle. The method comprises the steps that according to the currently detected vehicle speed and first battery information of the vehicle and the opening degree of an accelerator pedal or a brake pedal, the energy consumption of the vehicle is optimized; a fuzzy control method isadopted to calculate a torque rough value currently needed by the automobile as a whole, and the torque rough value is corrected; according to the currently detected wheel rotating speed of the automobile, the calculation is carried out to obtain the maximum first torque which can be currently provided for the front axle and the maximum second torque which can be currently provided for the rear axle by the automobile motor system; the range of a torque distribution coefficient is calculated according to the torque correction value, the maximum first torque and the maximum second torque; and the torque distribution is carried out on the front axle and the rear axle of the automobile according to the range of the torque distribution coefficient and the torque correction value. By means of the technical scheme, optimization of automobile torque distribution is achieved according to the current working condition of the automobile, and the automobile driving range and the whole automobile economy are improved.

Owner:DONGFENG MOTOR CORP HUBEI

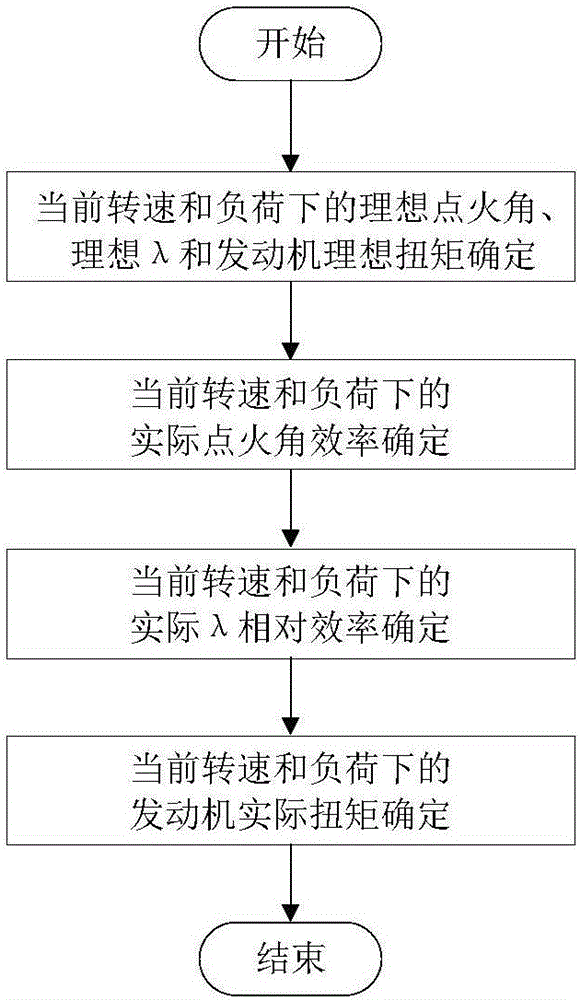

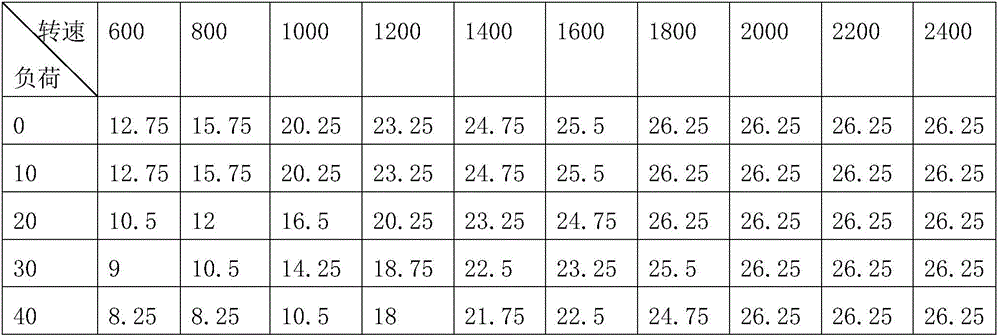

Torque estimation method for lean-burn natural gas engine

ActiveCN106438069AAccurate torqueAccurate calculation of actual torqueElectrical controlMachines/enginesAutomatic transmissionEstimation methods

The invention belongs to the field of development of automobile electronic software, and discloses a torque estimation method for a lean-burn natural gas engine. The torque estimation method includes the following steps that 1, the ideal firing angle, the ideal gamma and the ideal engine torque under the current rotating speed and load are determined; 2, the actual firing angle efficiency under the current rotating speed and load is determined; 3, the actual gamma relative efficiency under the current rotating speed and load is determined; and 4, the actual engine torque under the current rotating speed and load is determined by integrating the ideal engine torque, the actual firing angle efficiency and the actual gamma relative efficiency under the current rotating speed and load, and the actual engine torque is equal to the product of the ideal engine torque, the actual firing angle efficiency and the actual gamma relative efficiency. The actual firing angle efficiency and the actual gamma relative efficiency are introduced, the actual engine torque can be calculated more accurately, the actual engine torque transmitted by an automatic transmission controller and a vehicle control unit is more precise, and finally the vehicle performance is greatly improved.

Owner:CHINA FIRST AUTOMOBILE

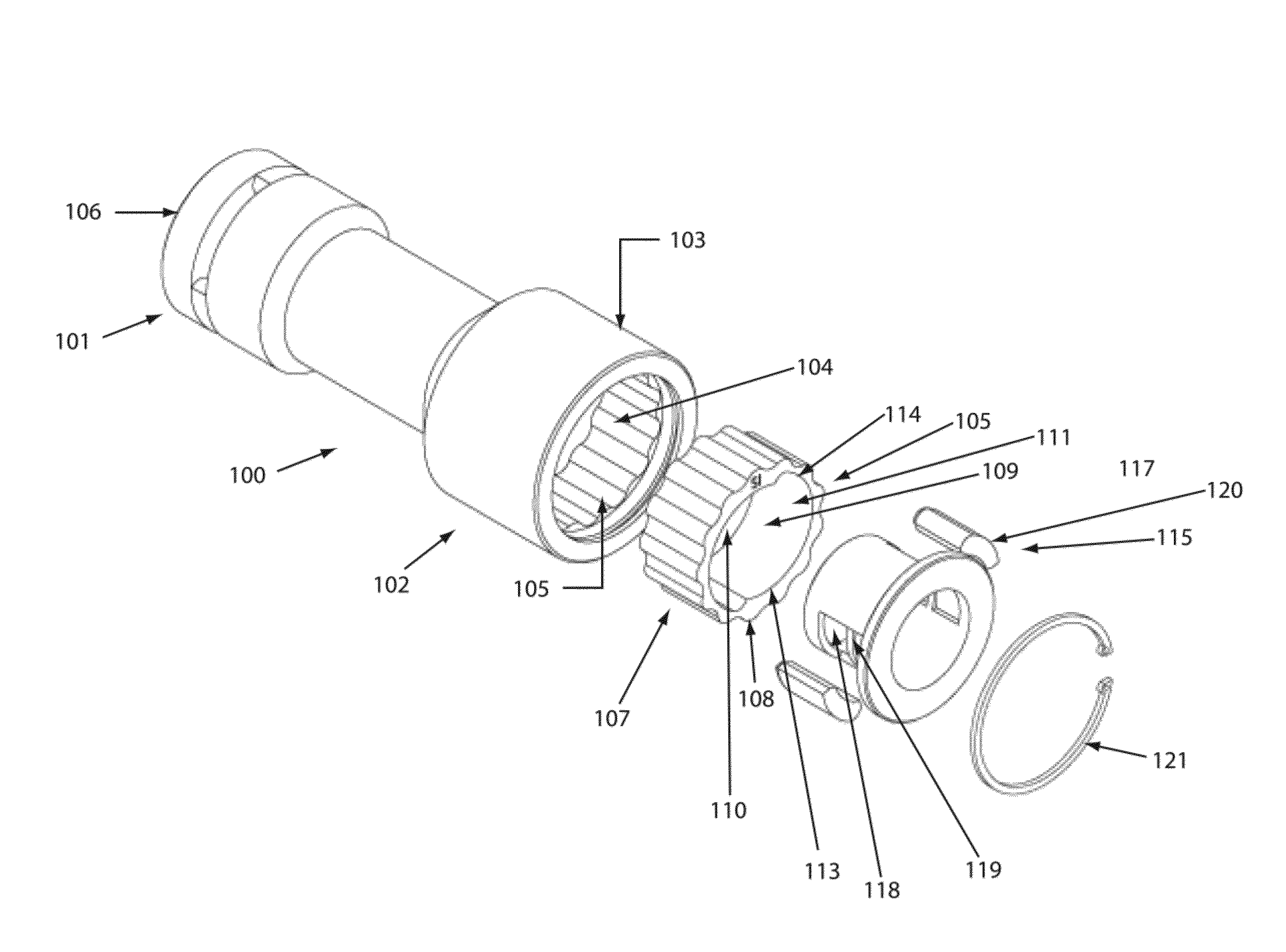

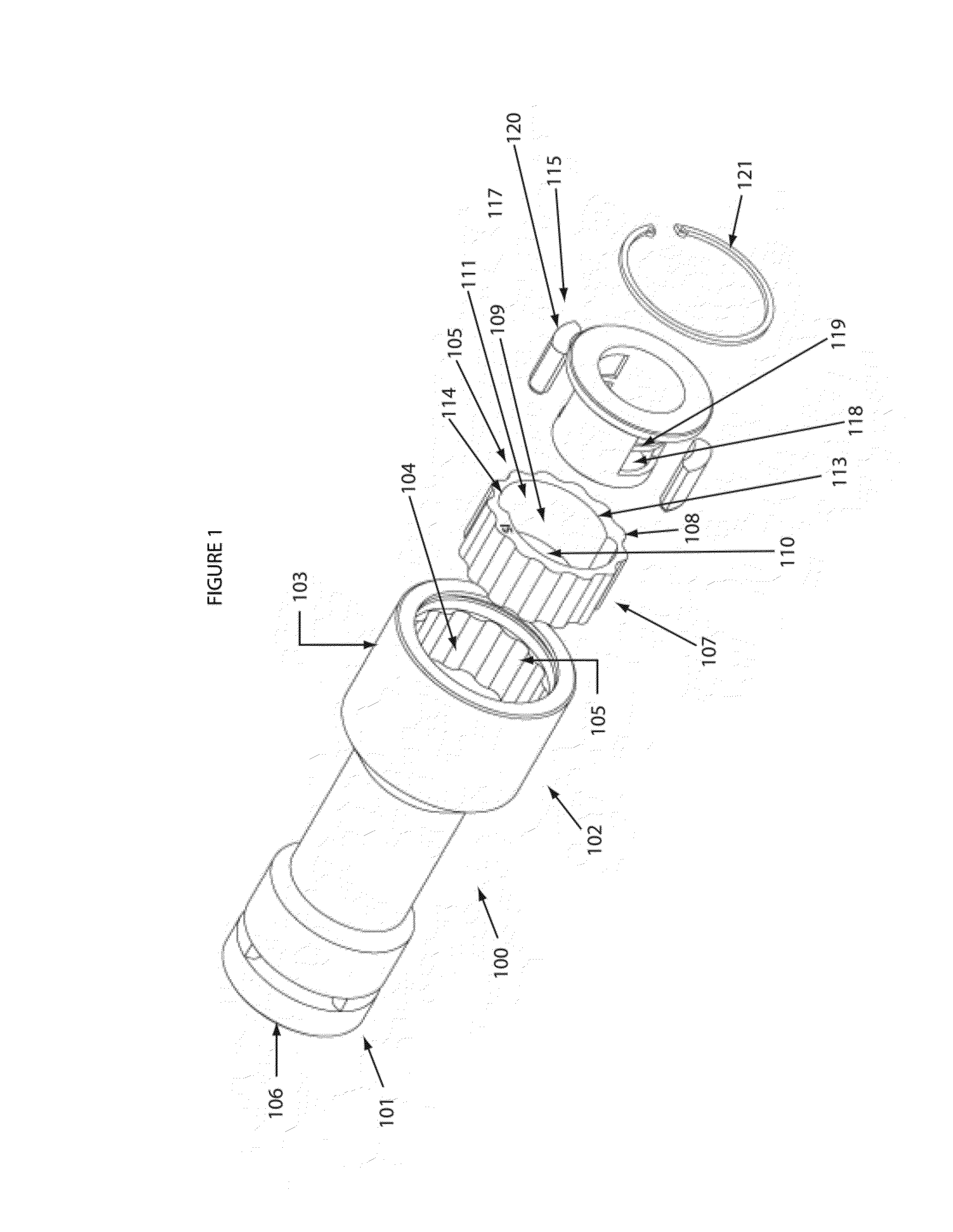

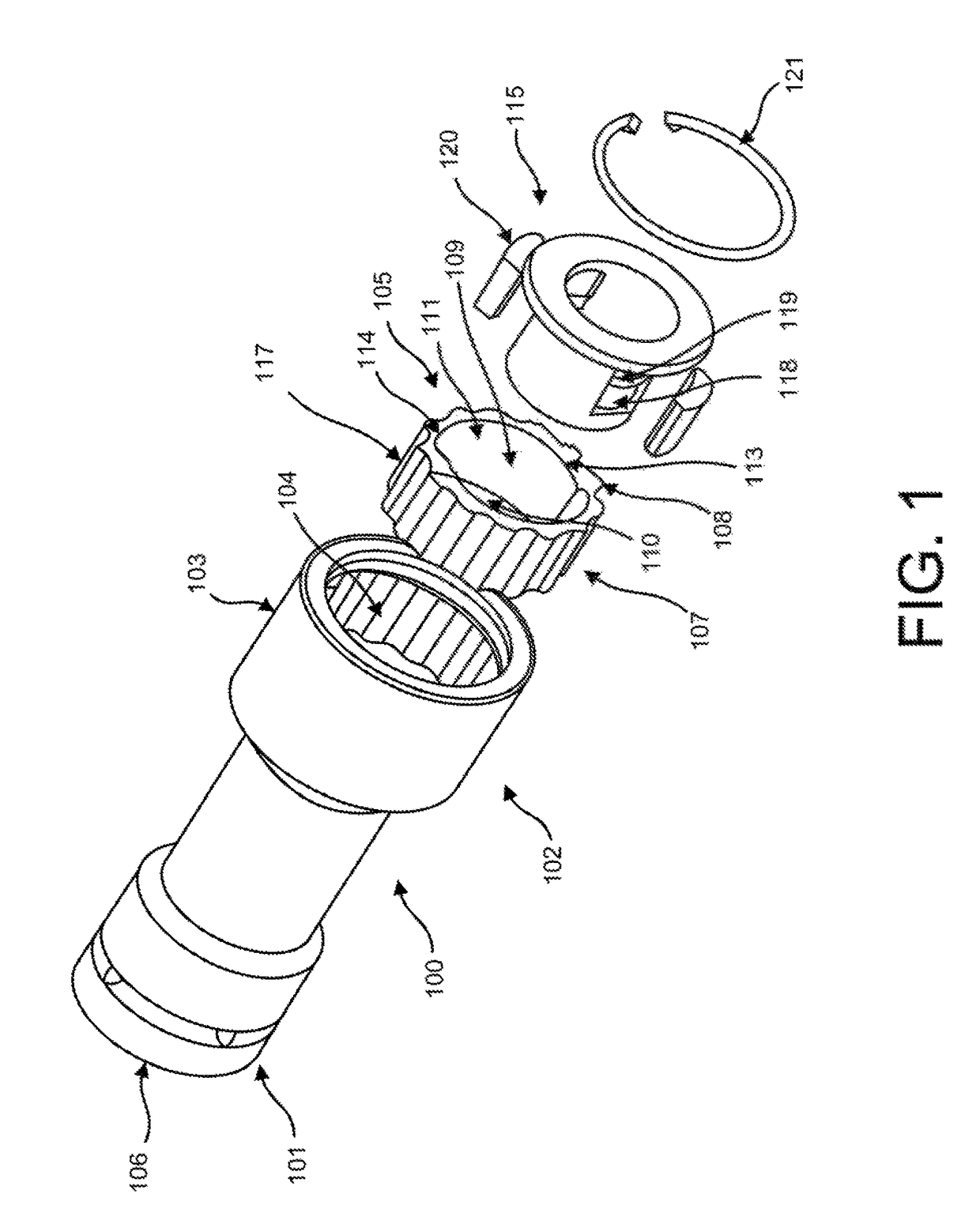

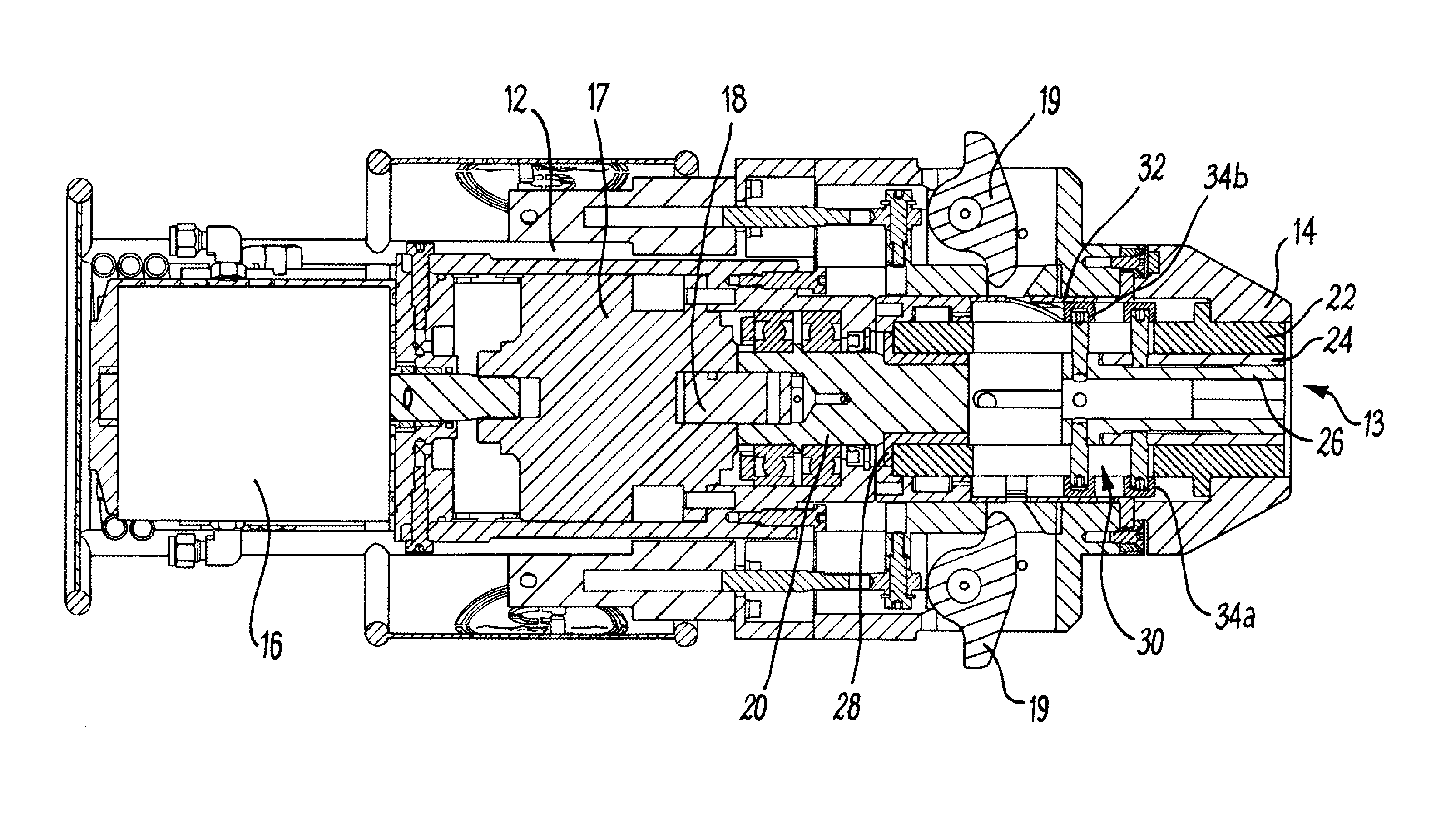

Stud Installation and Removal Tool and Method of Use

InactiveUS20160107300A1Easy to removeInventive tool is much more versatileSpannersWrenchesEngineeringCam

An inventive stud removal and installation tool and method of use is disclosed. The inventive tool incorporates a body configured to hold a cage, cam sleeve and jaws. The sleeve is capable of being oriented to accomplish either stud removal or installation. The assembly of the tool is modular such that broken elements can be replaced without the need to replace the entirety of the tool.

Owner:HENDRIX II WILLIAM R

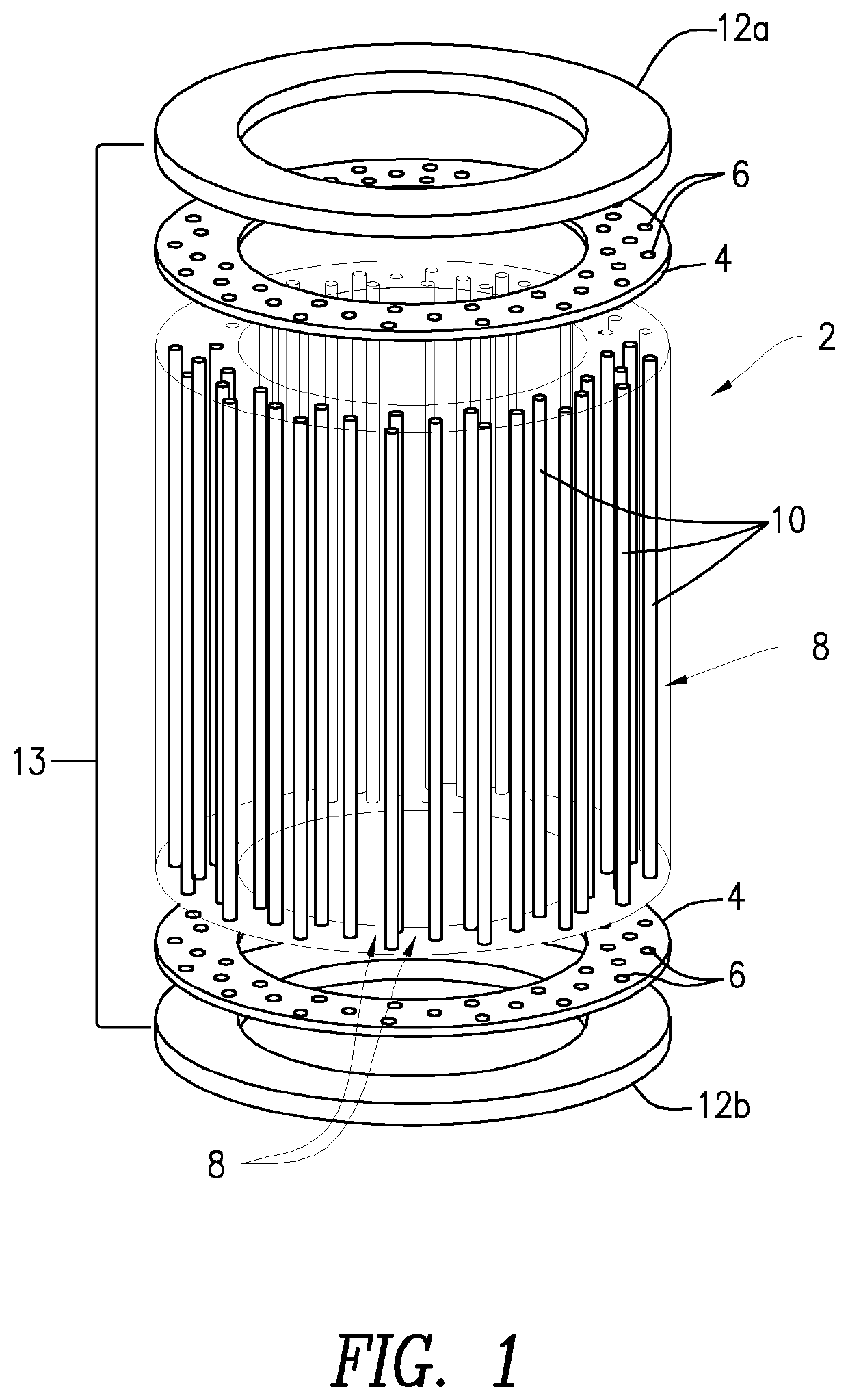

Electronically commutated axial conductor motor

ActiveUS20200295633A1Reduce labor costsAccurate torqueAssociation with control/drive circuitsPropulsion systemsElectrical conductorElectric machine

An electronic motor with a stator core having a plurality of holes for receiving a plurality of conductors, each conductor comprising a substantially linear body portion extending within the holes of the stator core, and a stator drive member adjacent each end of the stator core, the stator end member adjacent at least one end of the stator core including electronic control circuitry electrically coupled to at least some of the conductors.Also, a method of manufacturing an electronic motor by providing a stator with a plurality of holes having conductors within at least some of the plurality of holes, said conductors each having a substantially linear body portion extending through the stator core, and placing a drive member on each end of the stator core, at least one of the drive members provided with electronic circuitry, where the conductors are electrically coupled to the circuitry in the drive member.

Owner:HENDRICKS ROBERT C

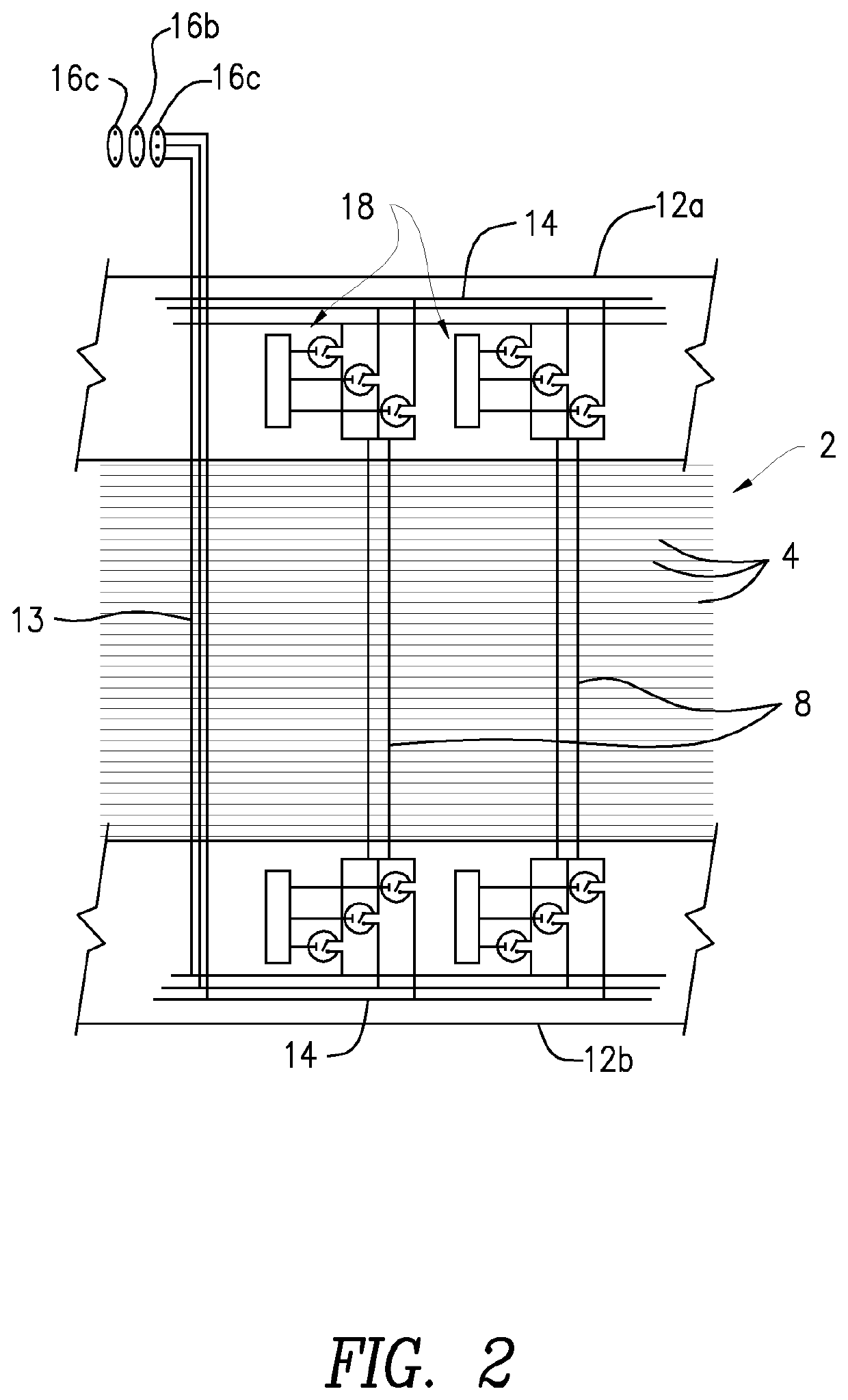

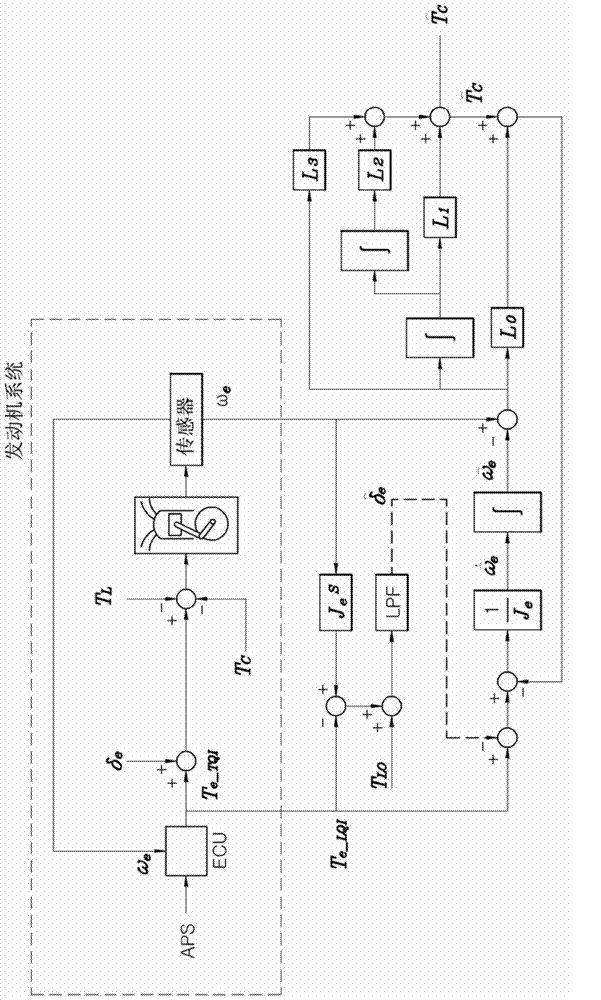

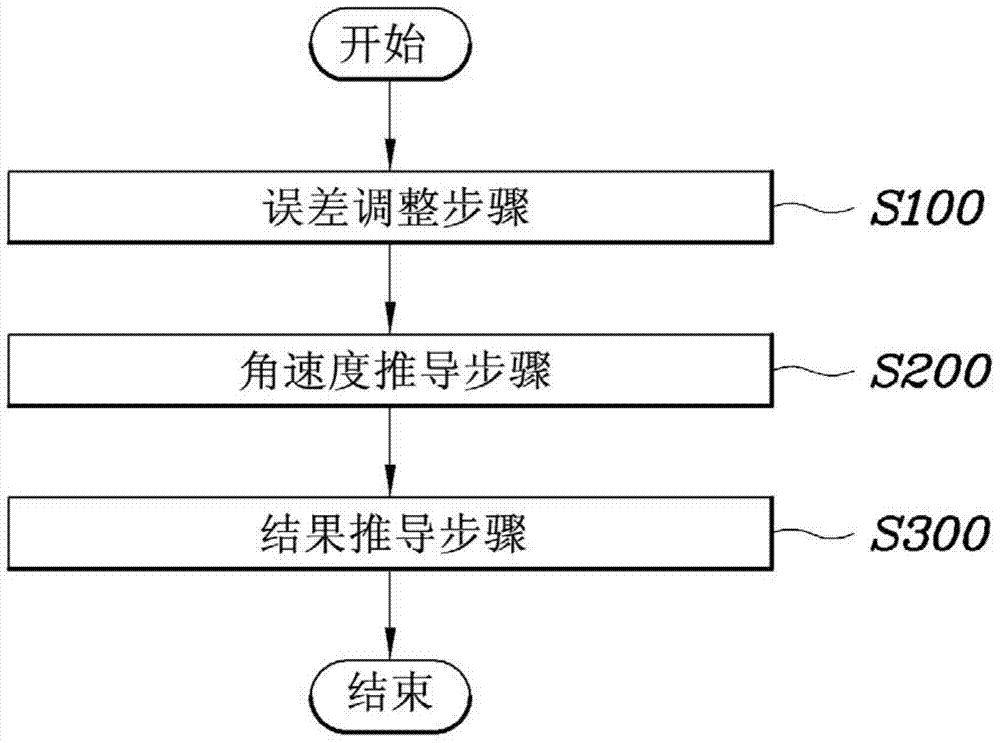

Method of estimating torque of transmission clutch

A method of estimating a torque of a transmission clutch may include adjusting an error, deducing an estimated engine angular speed and deducing an estimated clutch torque. The error may be adjusted by deducing an engine transient torque based on an engine angular speed measured using a sensor, an engine static torque deduced using a data map and a load torque depending on a driving load. The estimated engine angular speed may be deduced based on the engine static torque and the engine transient torque. The estimated clutch torque may be deduced by summing an integration value and an error compensation value. The integration value and the error compensation value may be deduced based on a difference between the estimated engine angular speed and the measured engine angular speed.

Owner:HYUNDAI MOTOR CO LTD +1

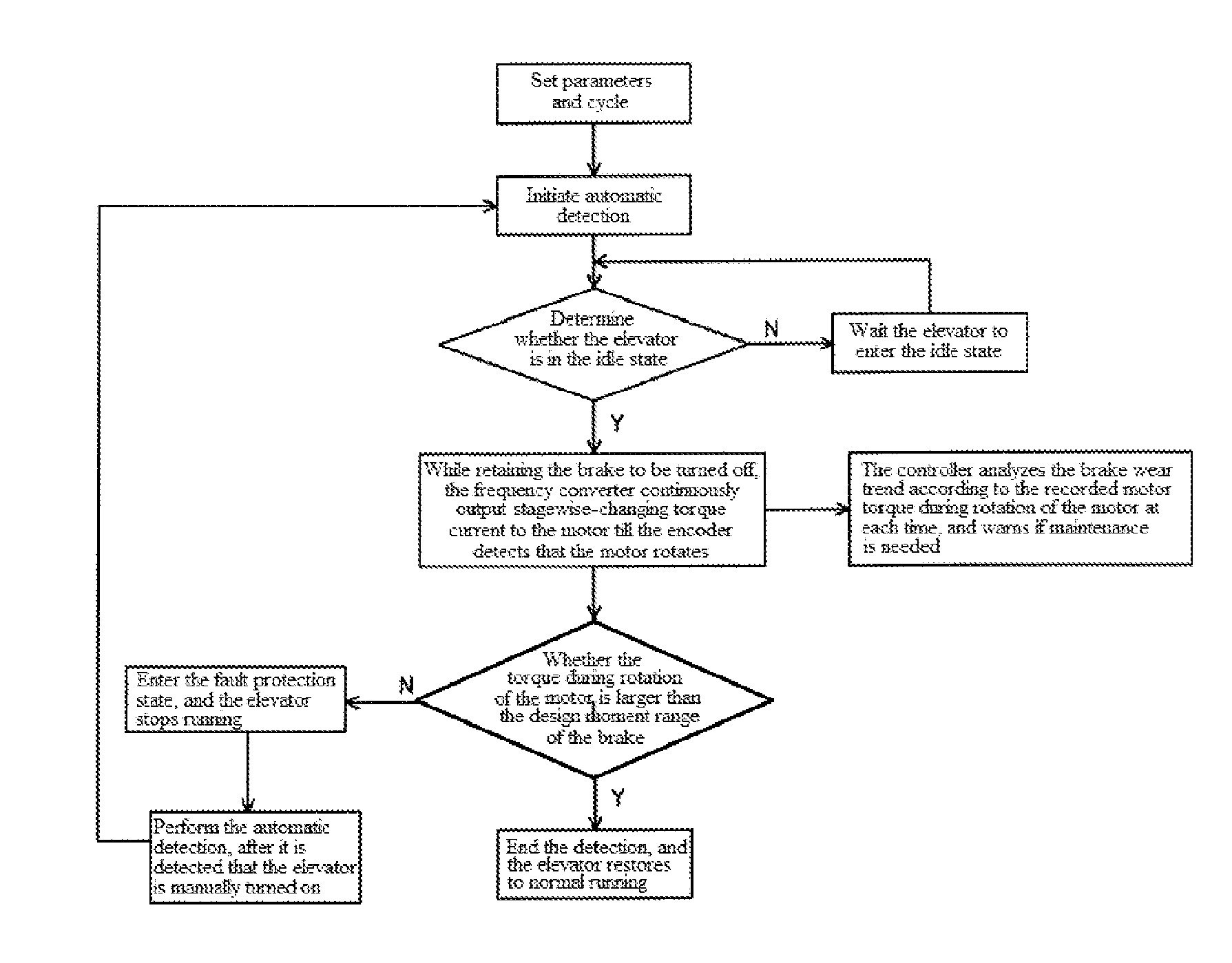

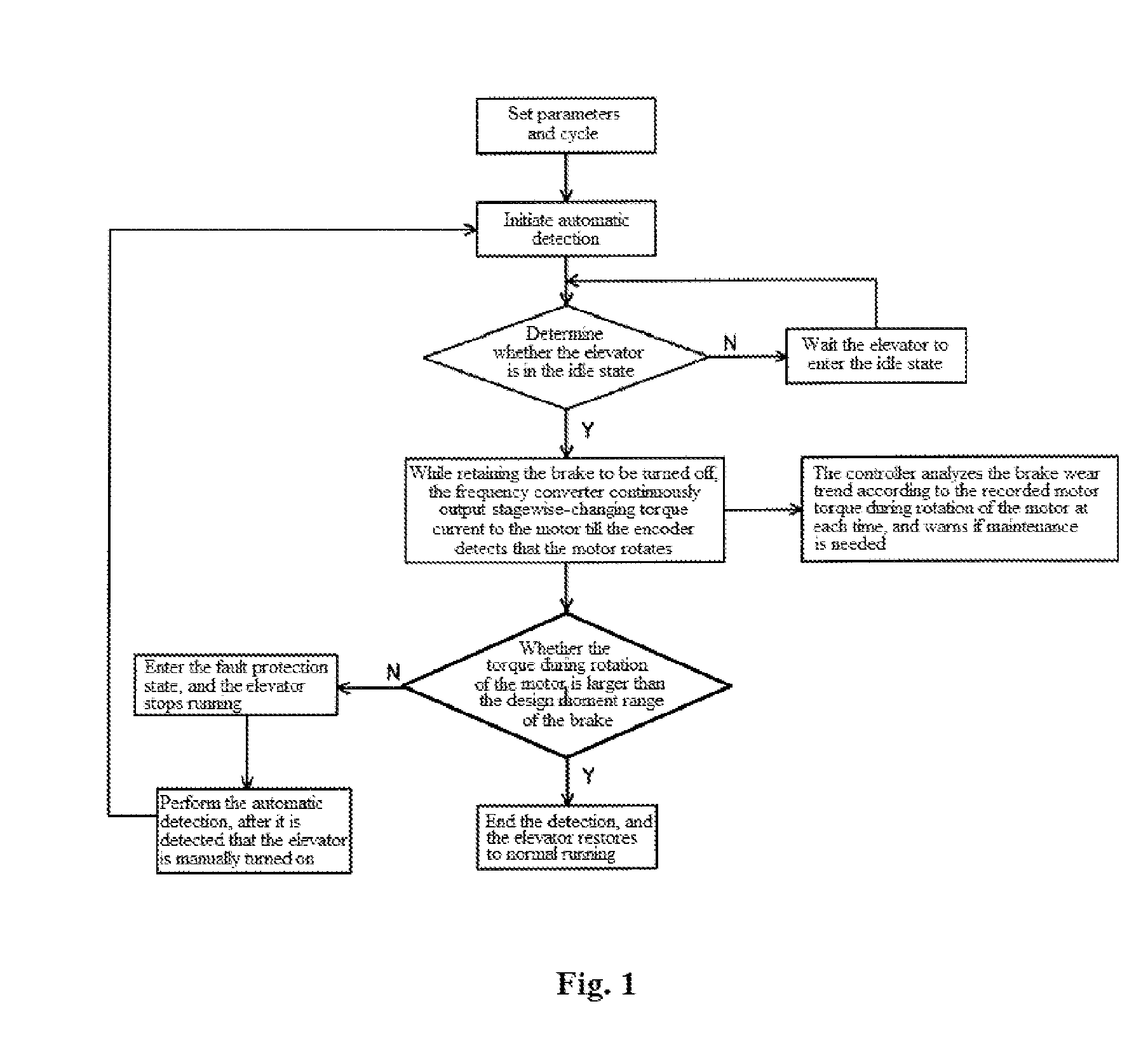

Detection method for elevator brake moment

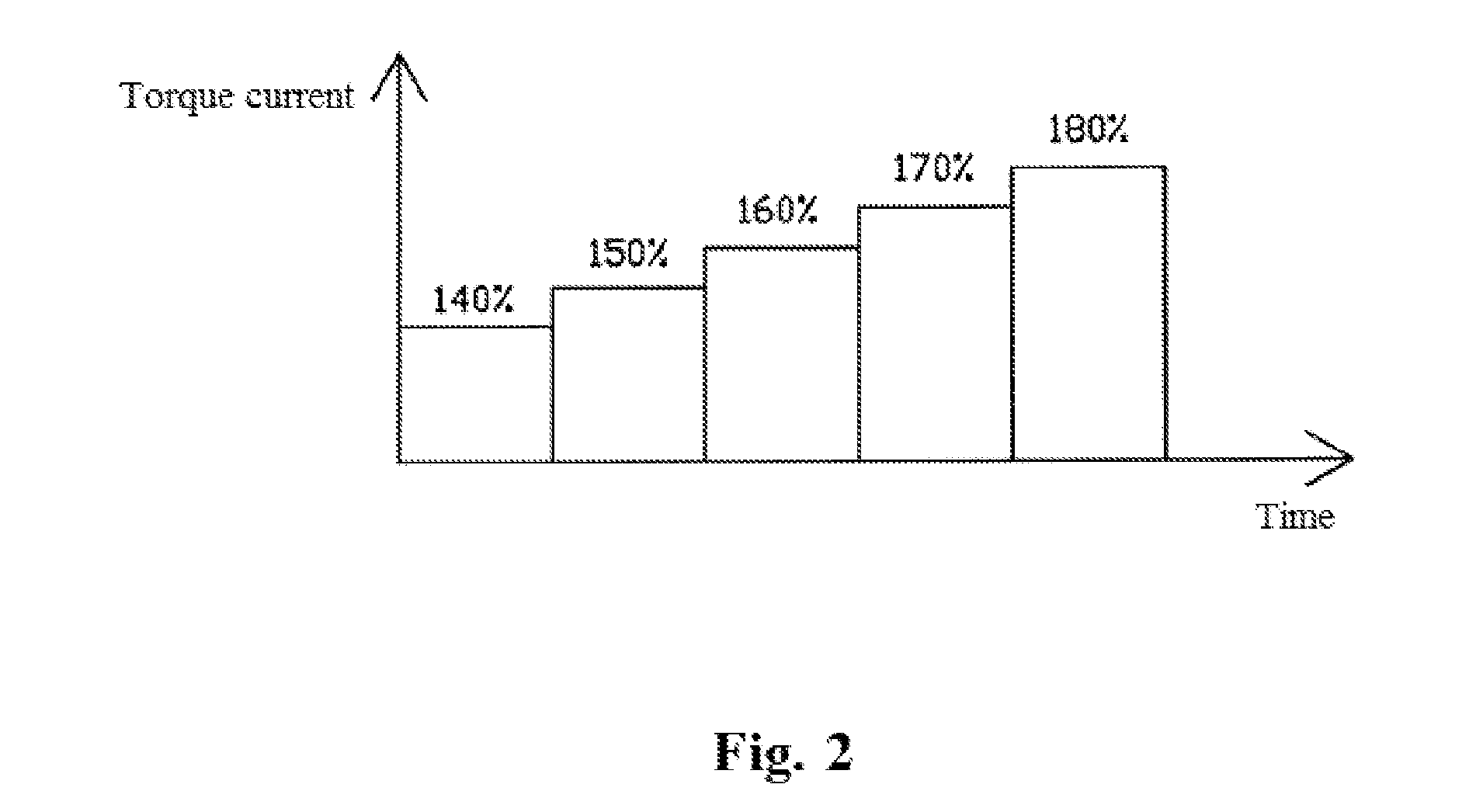

A detection method for elevator brake moment solves the problems that operation of the brake detection device in the prior art is required to be manually executed, the brake detection device is not convenient and facilitative to operate, the function is singular and the brake moment change trend and the brake wear trend cannot be reflected. In the method, by inputting stagewise torque current to the motor and determine whether the torque during rotation of a motor is within the design moment range of a brake, whether torque of the brake is enough can be determined and the brake wear trend can be analyzed according to torque recorded at each time. The method has advantages that the automatic detection is performed periodically, the functions are diversified, the detection accuracy is high, the brake moment change trend can be reflected and the brake wear trend can also be reflected.

Owner:OTIS ELEVATOR CO

Bearing nut for measuring the rotational speed of a shaft connected to a turbomachine and associated measuring device

ActiveUS20160153848A1Improve speed measurement accuracyImprove accuracyBearing assemblyResistance/reactance/impedenceRotational axisMeasurement device

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

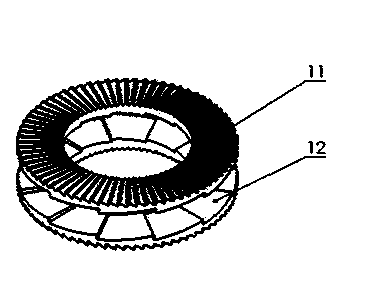

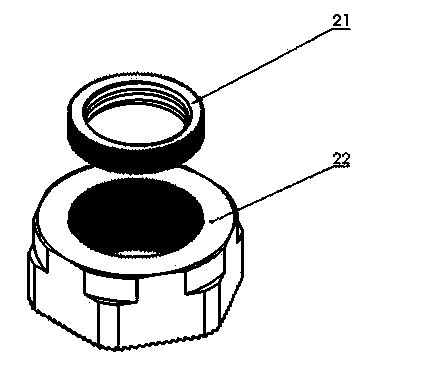

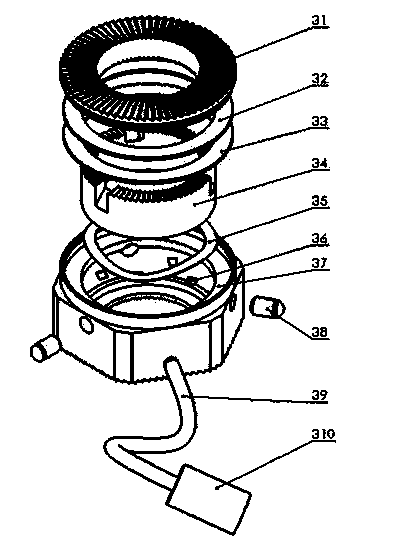

Looseness prevention tensile force measuring gasket

PendingCN108150516AReal-time display of stretching forceGuaranteed to be reusableMachine part testingWashersEngineeringHigh torque

The invention relates to the technical field of bolt accurate locking, measurement and looseness prevention, in particular to a looseness prevention tensile force measuring gasket. The looseness prevention tensile force measuring gasket comprises an upper ring, an upper gasket, a lower gasket, a check ring, a wave crest spring, a hexagonal gasket, a round head pin, a strain gauge, a data wire anda data interface, the upper end surface of the upper ring is an inverse tooth, and the lower end surface of the upper ring cooperates with the upper end surface of the upper gasket; the lower end surface of the upper gasket cooperates with the upper end surface of the lower gasket, and the lower end surface of the lower gasket cooperates with the upper end surface of the hexagonal gasket; and thelower end surface of the upper gasket and the upper end surface of the lower gasket are both grinding end surfaces. In the situation of the large-torque, high-precision and looseness prevention, the looseness prevention tensile force measuring gasket is mainly used for solving the problems that bolts cannot obtain accurate tensile force and looseness due to high-torque high-precision requirements,a lot of bolts cannot be accurately tightened and prevented from loosing. According to the looseness prevention tensile force measuring gasket, the principles of mechanical locking, looseness prevention, strain gauge force measurement and the like are applied, concentric tightness is achieved, the torque is accurate, the tensile force is accurate, accurate measurement is achieved, and the gasketis accurate and anti-loose.

Owner:SHANGHAI CHENGJIE ELECTROMECHANICAL CO LTD

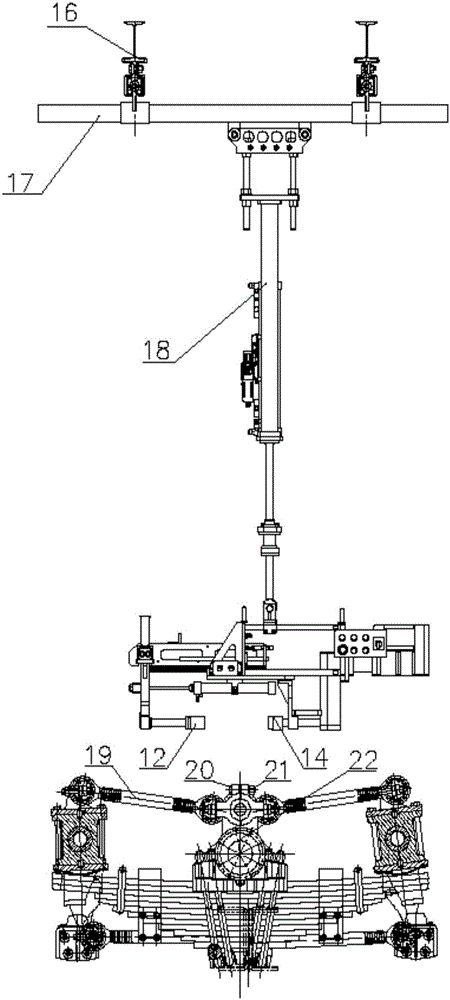

Screwing device of truck thrust rod bolt

A screwing device of a truck trust rod bolt comprises a frame body (3), a lifting base (4), a supporting rod (6), a pneumatic suspension device (18) and a longitudinal and transverse sliding rail (17); the pneumatic suspension device (18) can longitudinally and transversely move along the longitudinal and transverse sliding rail (17), the frame body (3) is provided with a screwing shaft (9), an offset gearbox (15) and a screwing sleeve (14), the frame body (3) is further provided with a telescopic support (2), a counterforce support (10) is arranged at the left end of the telescopic support (2), a handle (1) is fixedly connected to the counterforce support (10) through a bolt, a handlebar (7) in the vertical direction is arranged on the supporting rod (6), a handle button (25) is arranged on a handle (1) and is used for controlling a pneumatic suspension device (18), a counterforce rod (11) is arranged on the counterforce support (10), a counterforce sleeve (12) is arranged at the right end of the counterforce rod (11), and the counterforce sleeve (12) and the screwing sleeve (14) are arranged in an axial symmetry manner along the vertical line.

Owner:大连嘉禾自控技术有限公司

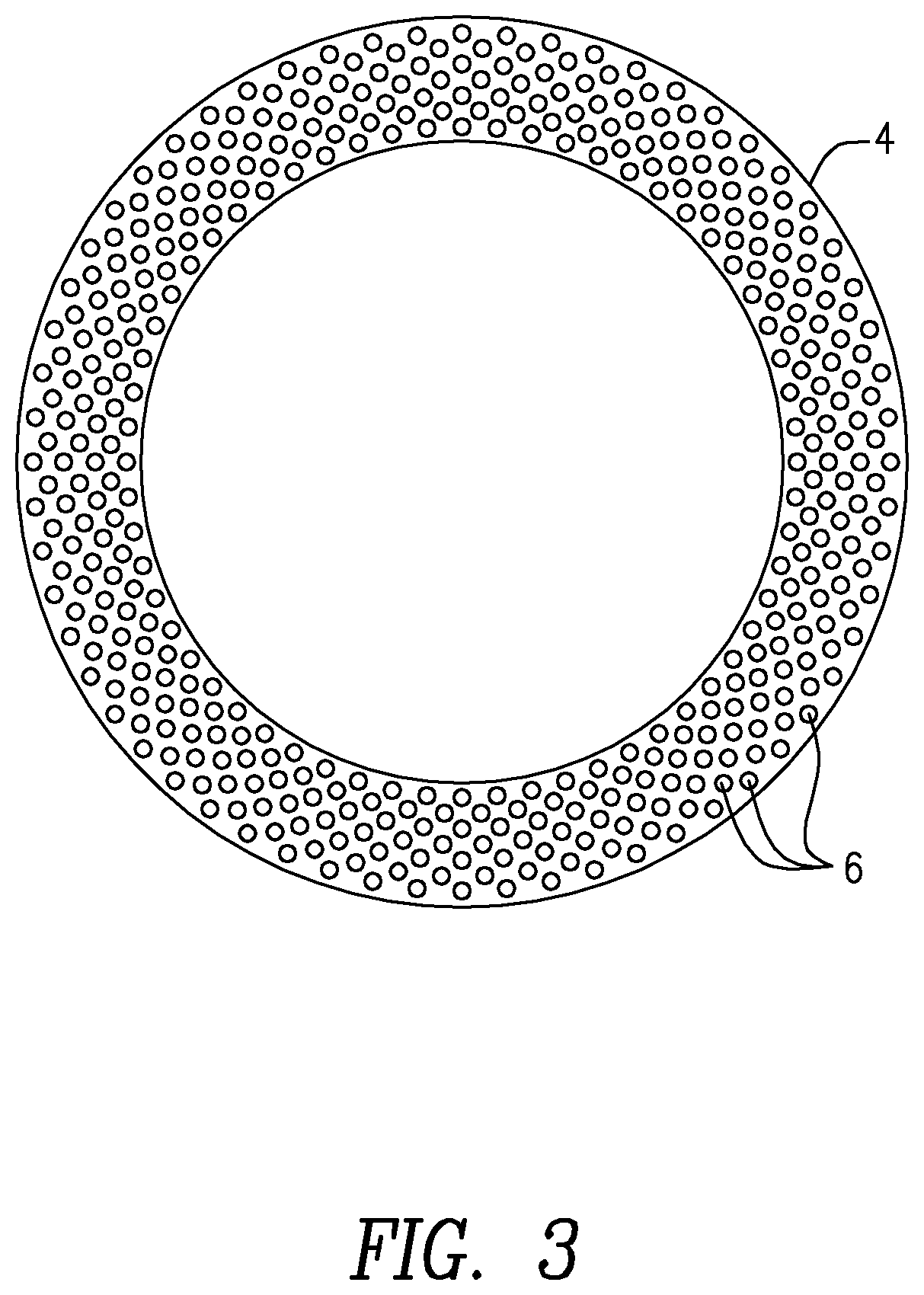

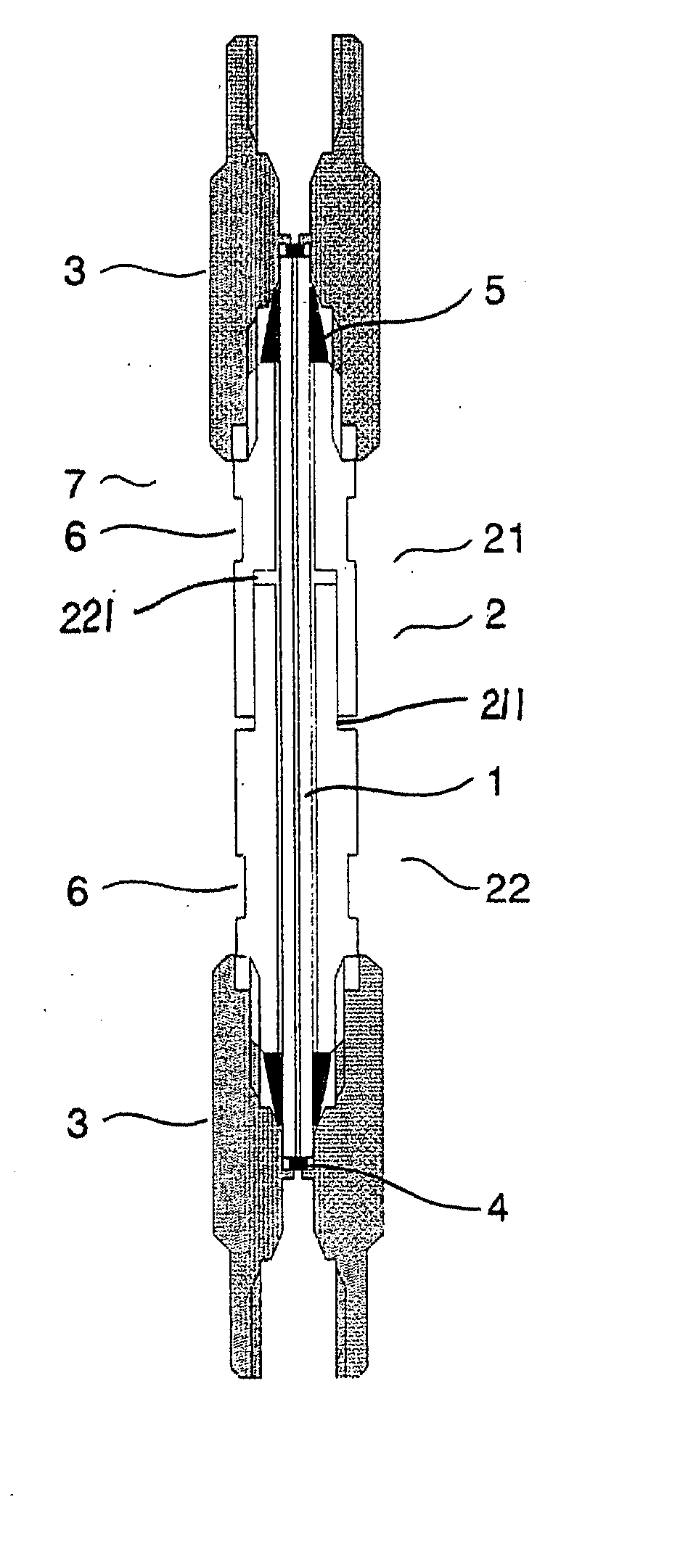

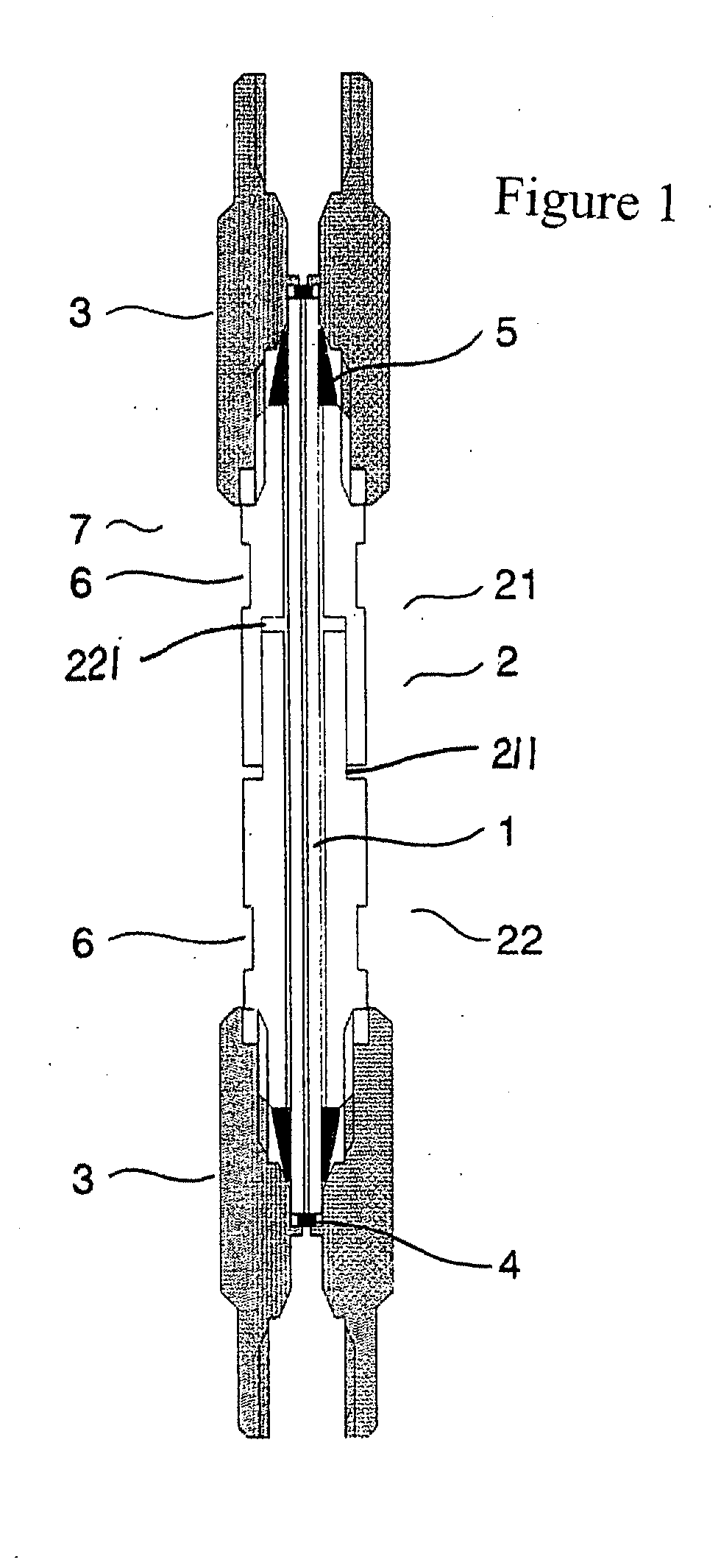

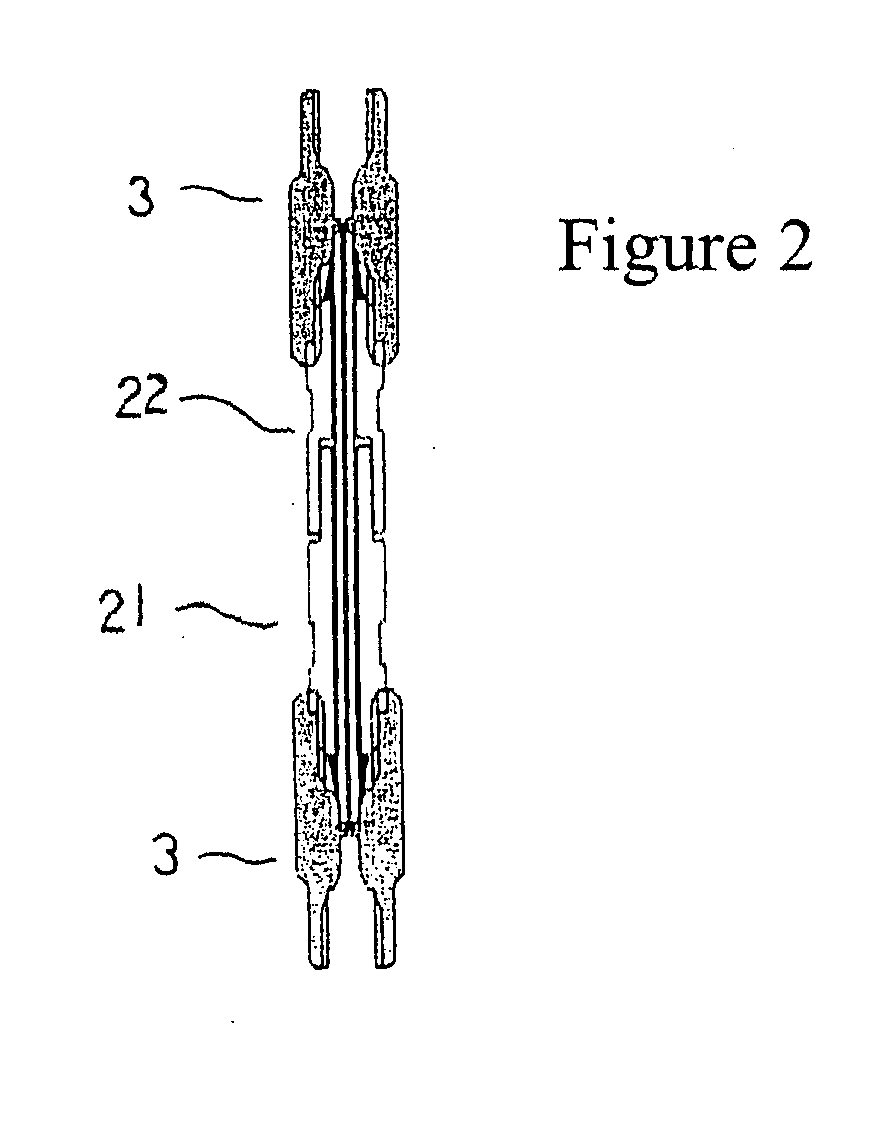

Separation column

InactiveUS20050077218A1Torque of the union nut can be preventedAccurate torqueIon-exchange process apparatusComponent separationOrganic solventDead volume

In the field of substance separation which uses the flow of a fluid, it is necessary to reduce the inside diameter of a separation column in order to meet the tendency to reduce the volume of an organic solvent used. The smaller the volume of a target sample which is caused to flow, the higher the concentration of the target sample, thereby permitting a high-sensitivity analysis. For this purpose, it is necessary to reduce the diameter of a separation column. Therefore, the manufacturing of such a separation column is difficult and besides the separation column becomes apt to fracture. Therefore, the separation column is fabricated as a double-wall tube constituted by an outer tube and an inner tube in such a manner that the outer tube is separated so as to be freely inserted and extracted. Furthermore, a union is fitted to the end of the outer tube by use of a screw thereby to prevent torsions between the outer tube and the inner tube and strains and, at the same time, to eliminate a space for a dead volume.

Owner:GL SCI

Stud installation and removal tool and method of use

InactiveUS9616554B2Easy to removeInventive toot is much more versatileSpannersWrenchesEngineeringCam

An inventive stud removal and installation tool and method of use is disclosed. The inventive tool incorporates a body configured to hold a cage, cam sleeve and jaws. The cam sleeve is capable of being oriented to accomplish either stud removal or installation. The assembly of the tool is modular such that broken elements can be replaced without the need to replace the entirety of the tool.

Owner:HENDRIX II WILLIAM R

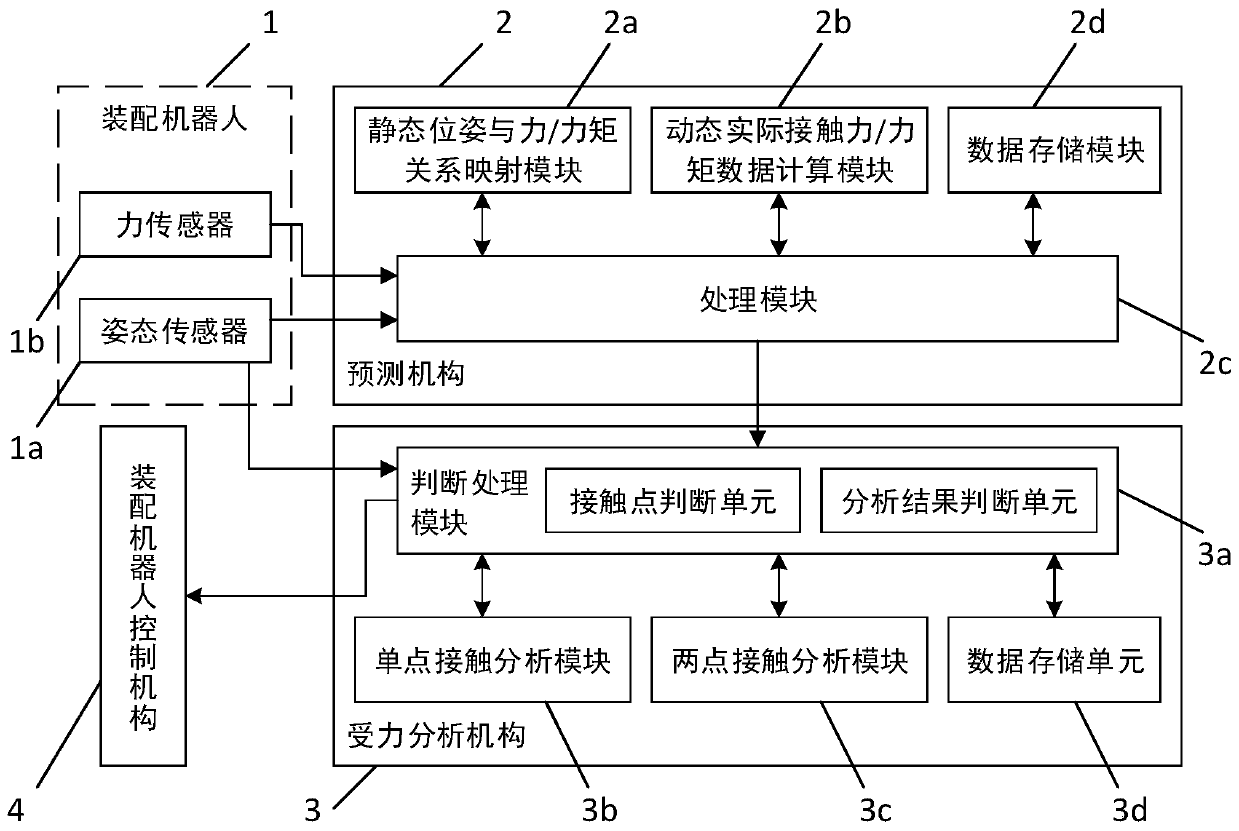

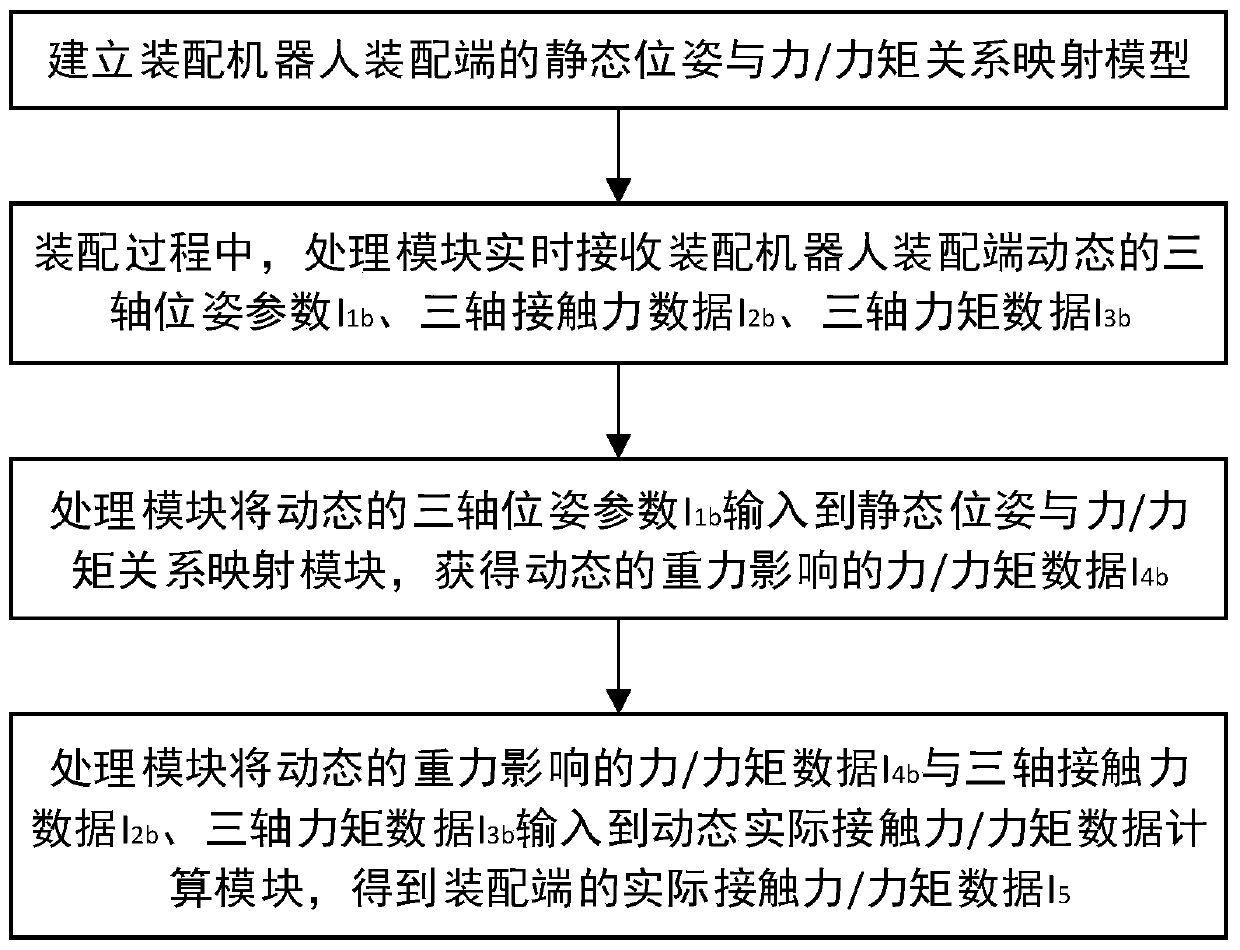

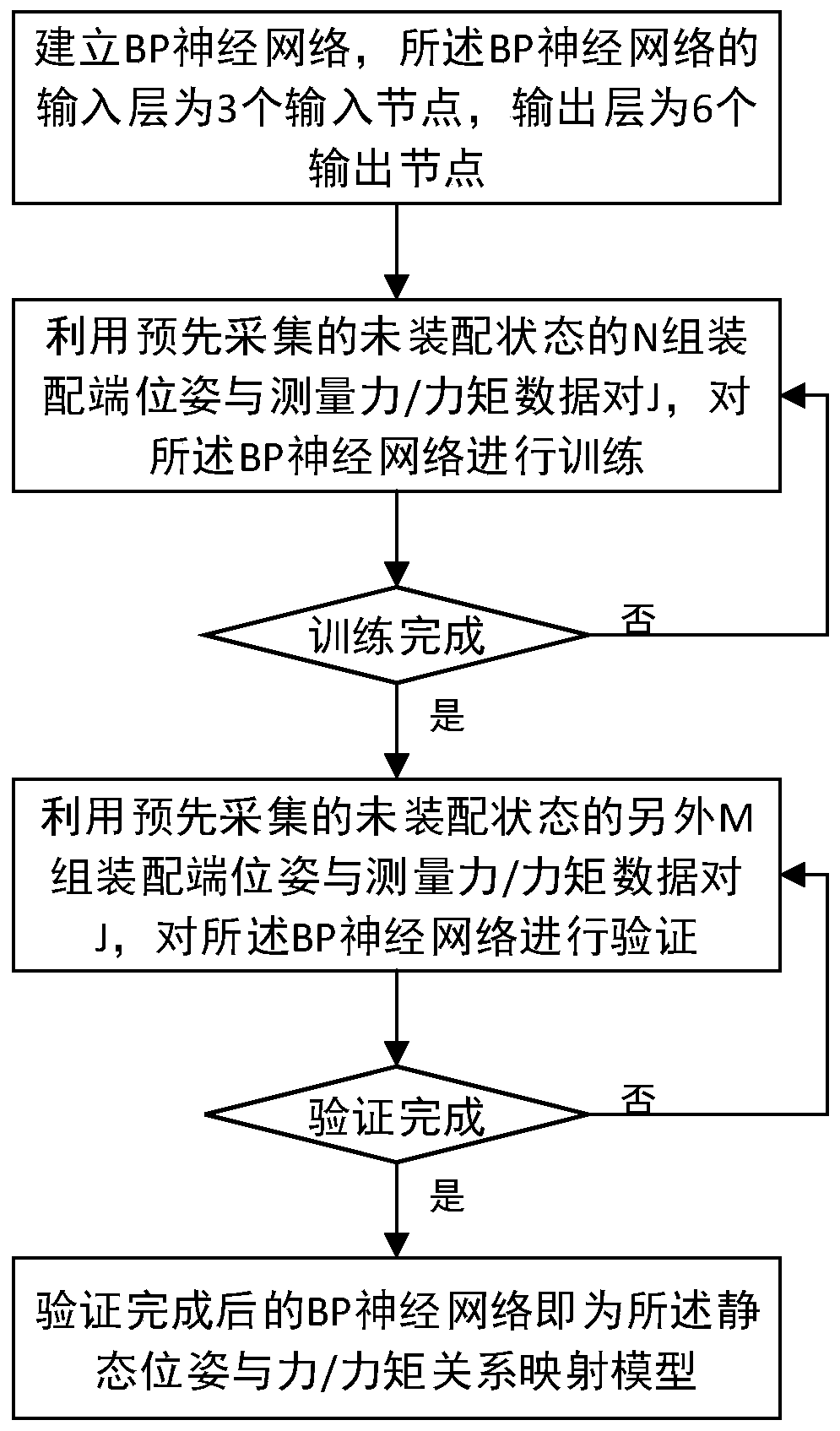

A large-length-diameter-ratio shaft hole assembling system and method based on contact force and torque prediction and analysis

ActiveCN109740270ARemove noise dataHigh control precisionMetal working apparatusManipulatorStress conditionsMathematical model

The invention discloses a large-length-diameter-ratio shaft hole assembling system and method based on contact force and torque prediction and analysis. Firstly, a prediction mechanism predicts actualcontact force / torque data I5 in the assembling process through a triaxial pose parameter I1, triaxial contact force data I2 and triaxial torque data I3; and the stress analysis mechanism analyzes thestress conditions of the large-length-diameter-ratio inserting shaft and the assembling hole in the assembling process according to the triaxial pose parameter I1 and the actual contact force / torquedata I5 to obtain an adjusting and analyzing result of the assembling pose. Beneficial effects are as follows: the feed additive is Accurate mathematical model establishment, the parameters are solvedthrough the collected data; data pairs under different conditions are collected to train a neural network model and establish a mapping relationship with the neural network model, accurate predictionof force and torque is realized, and after prediction, whether deviation exists in assembly is accurately analyzed according to the stress condition of a shaft with a large length-diameter ratio in the assembly process, so that analysis support is provided for accurate control of assembly actions.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

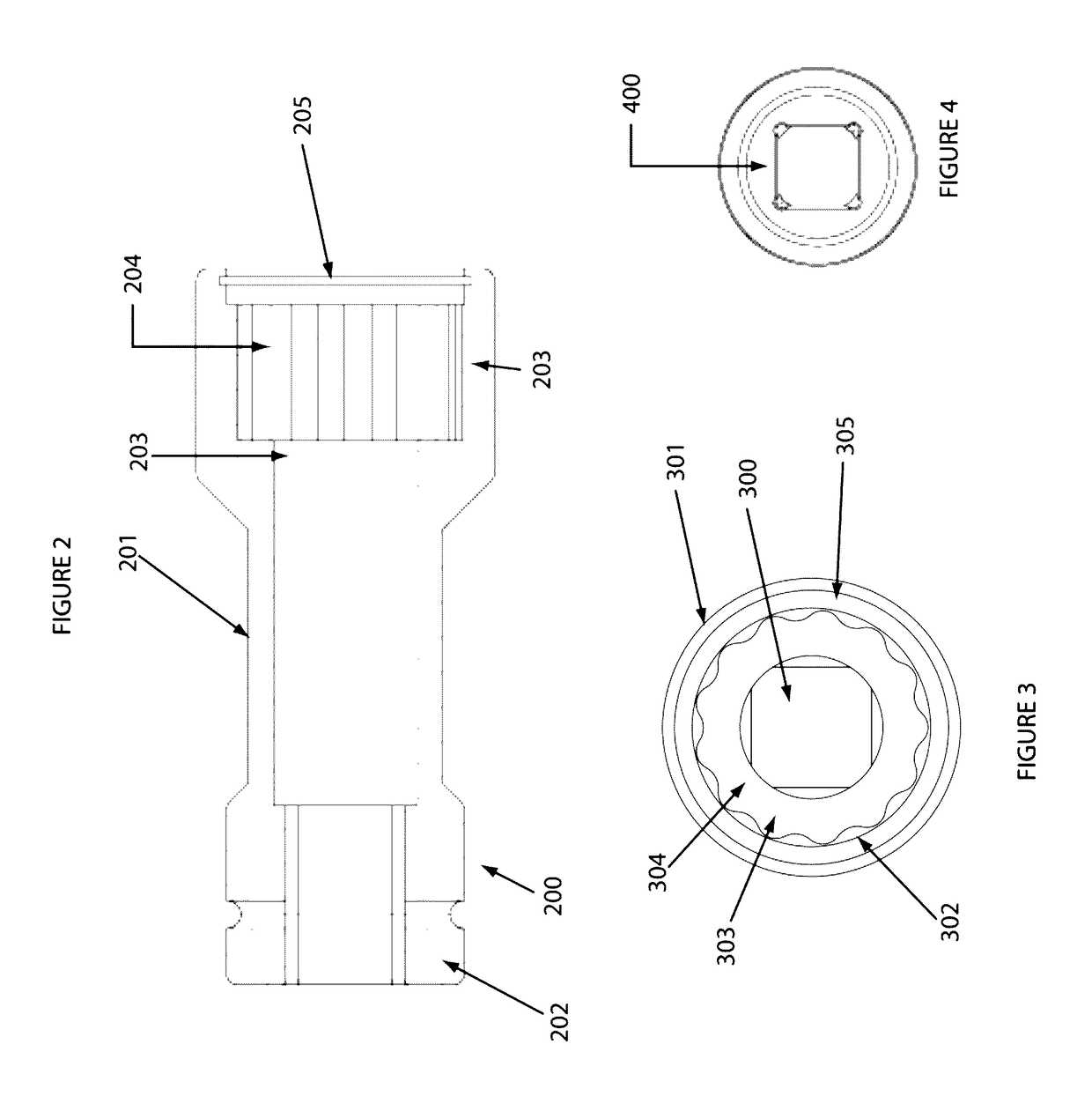

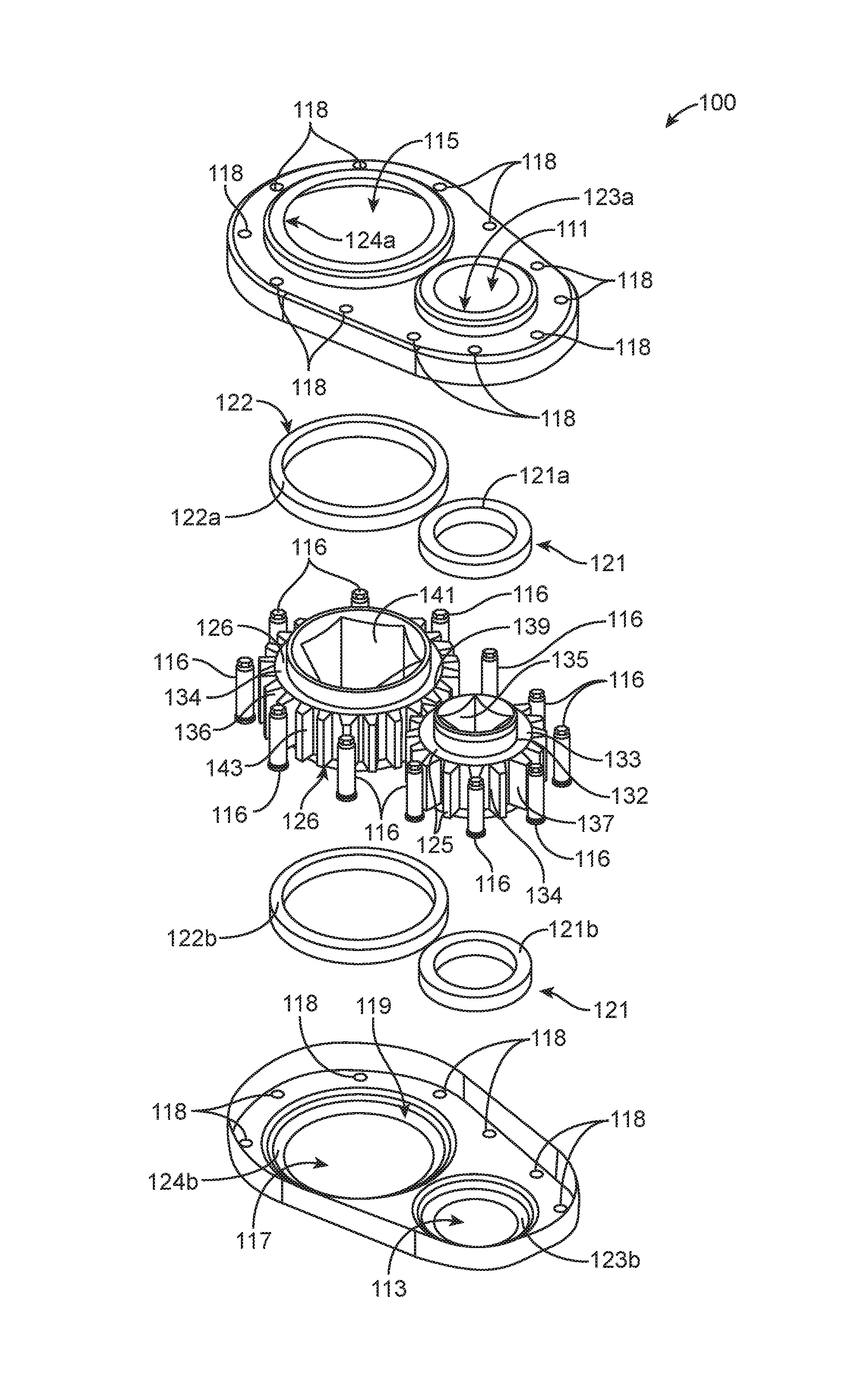

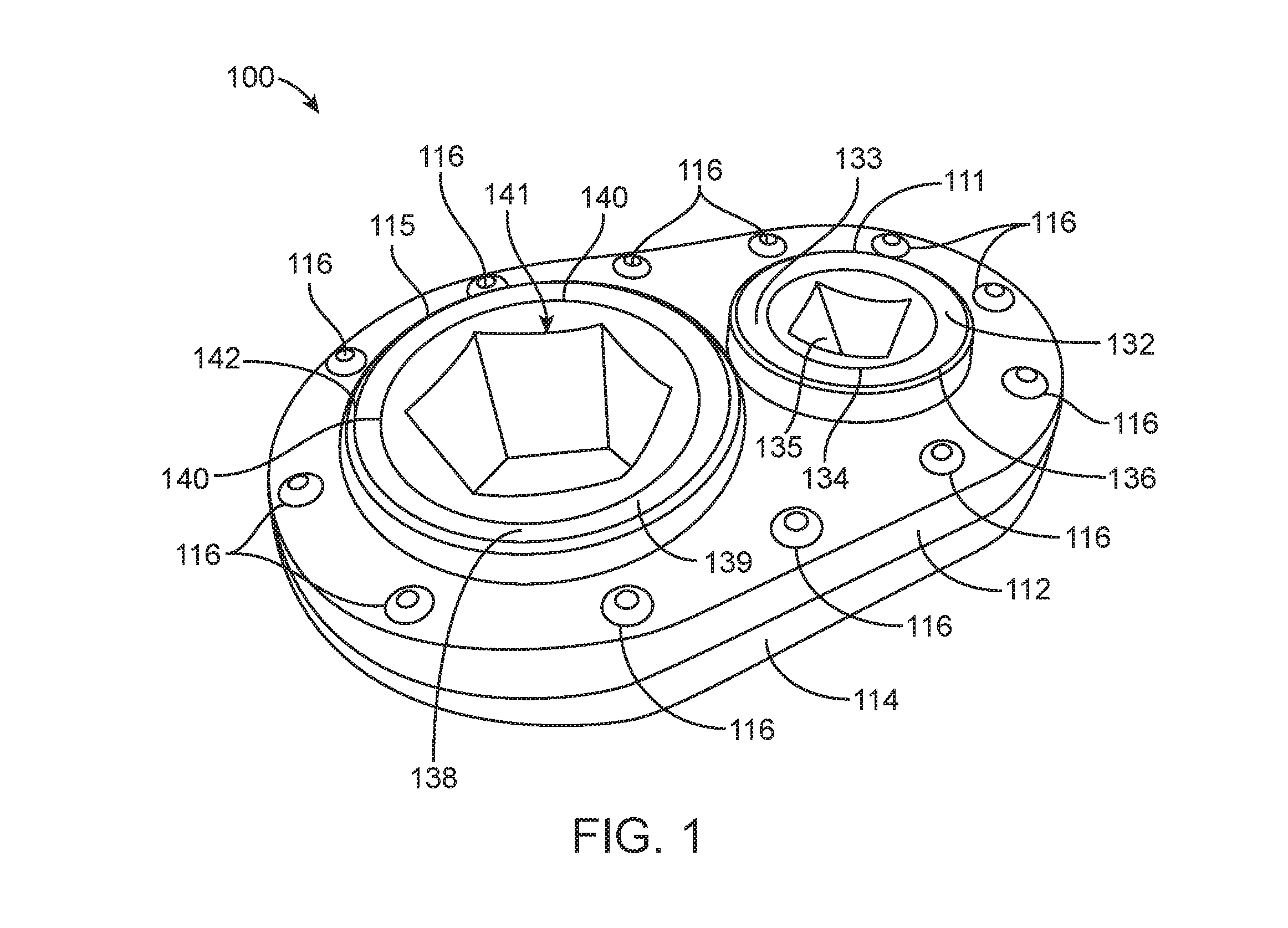

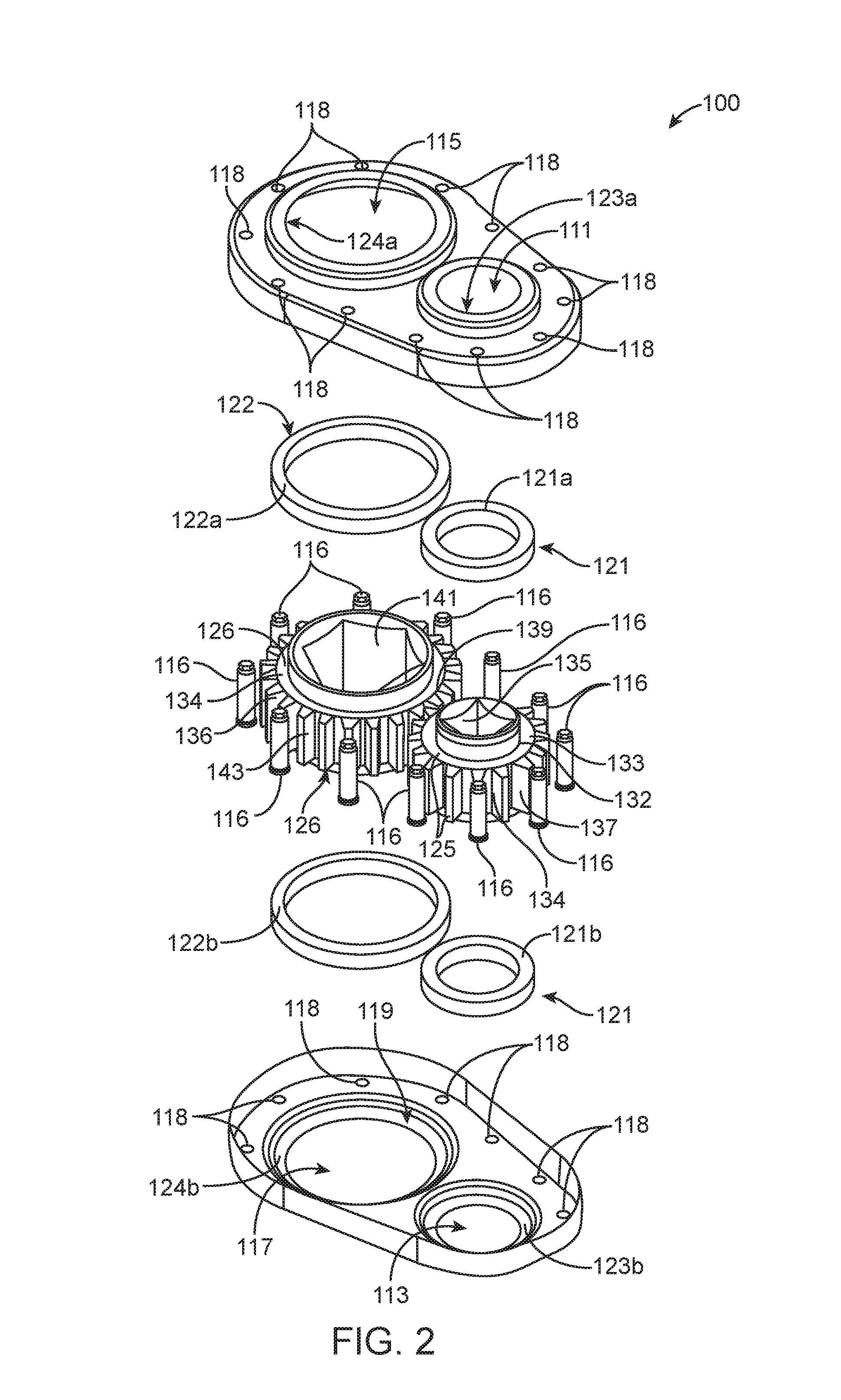

Offset torque drive apparatus and system

ActiveUS20170036326A1Efficiently and effectively torqueEfficient and effectiveGearboxesToothed gearingsSocket AdapterDrive shaft

The present invention is an improved offset torque drive assembly and system capable having application of accurately torqueing a fastener in an opening offset from a channel or other fasteners in inaccessible locations. The offset torque drive assembly and system comprises a housing formed in upper and lower enclosure portions that encompasses an input gear and an output gear there-between. The input gear has a tool adapter portion configured to receive the drive shaft of the drive means so as to rotate the input gear. The output gear has a socket fastener aperture configured to receive and move the fastener by application of torque forces upon the input gear operably connected to the output gear. The output gear may be provide with a socket adapter portion configured as a cupped-socket portion to efficiently and effectively torque a fastener along lengths of an elongated threaded rod. The offset torque drive system includes the offset torque drive assembly with a spline drive and a spline insert. The spline insert is configured with a socket fastener aperture that may be formed in numerous designs and sold as a kit in order to provide the user with multiple options of socket shape to cooperate with the fastener, for example, square, Philips-head, hexagon, star, and other fastener shapes. Consequently, the offset torque drive system has an output gear with splines to receive a spline insert functioning to provide the user with the ability to connect to numerous variations of fastener heads and shapes allowing the offset torque drive to accurately torque to a fastener in an opening offset from a channel, fasteners in inaccessible locations, and a fastener in difficult confined areas as well as to easily change to a cupped-bottom fastener aperture configured to efficiently and effectively torque a fastener along lengths of an elongated threaded rod.

Owner:ANGELLO JOSEPH G

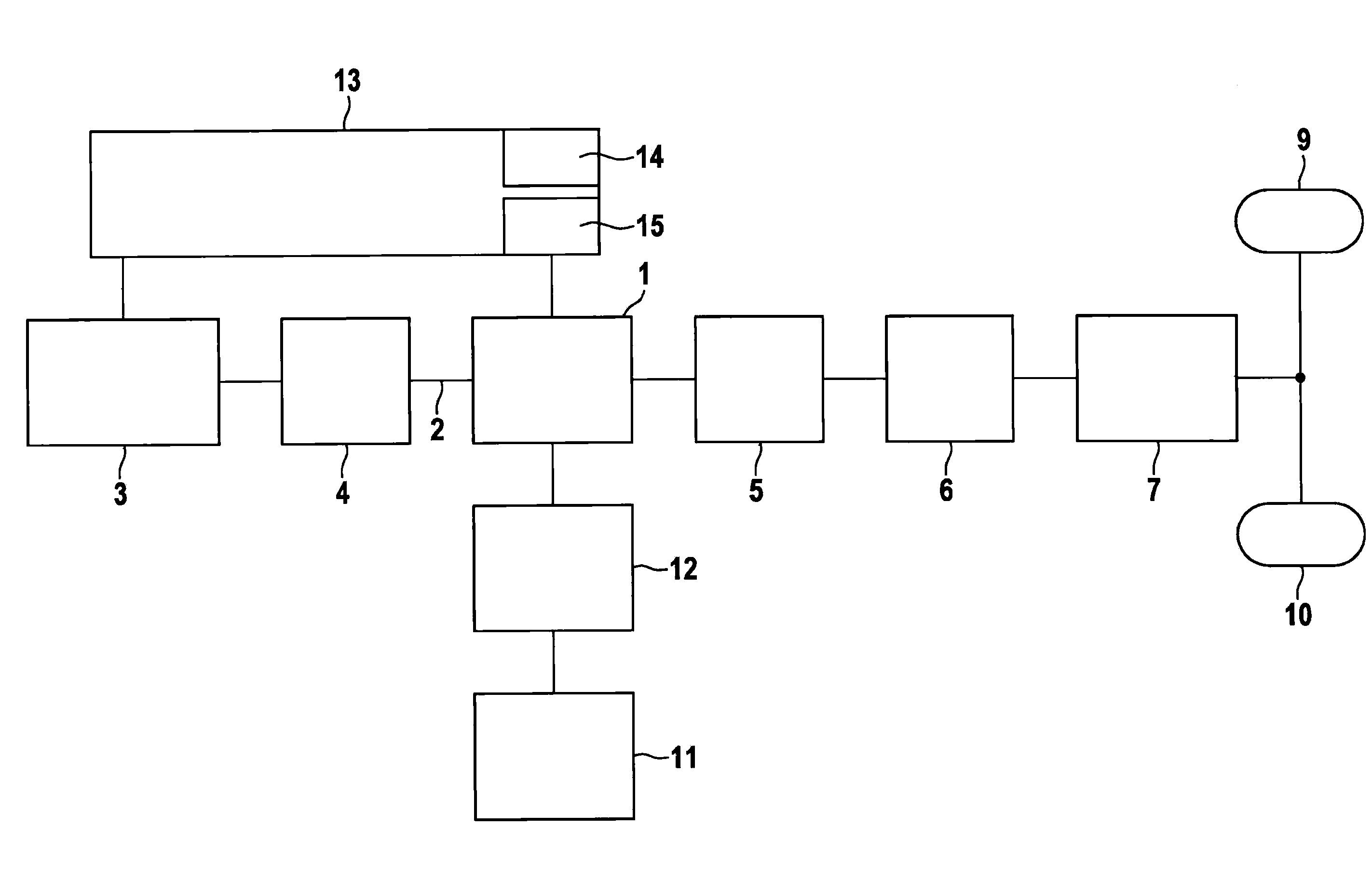

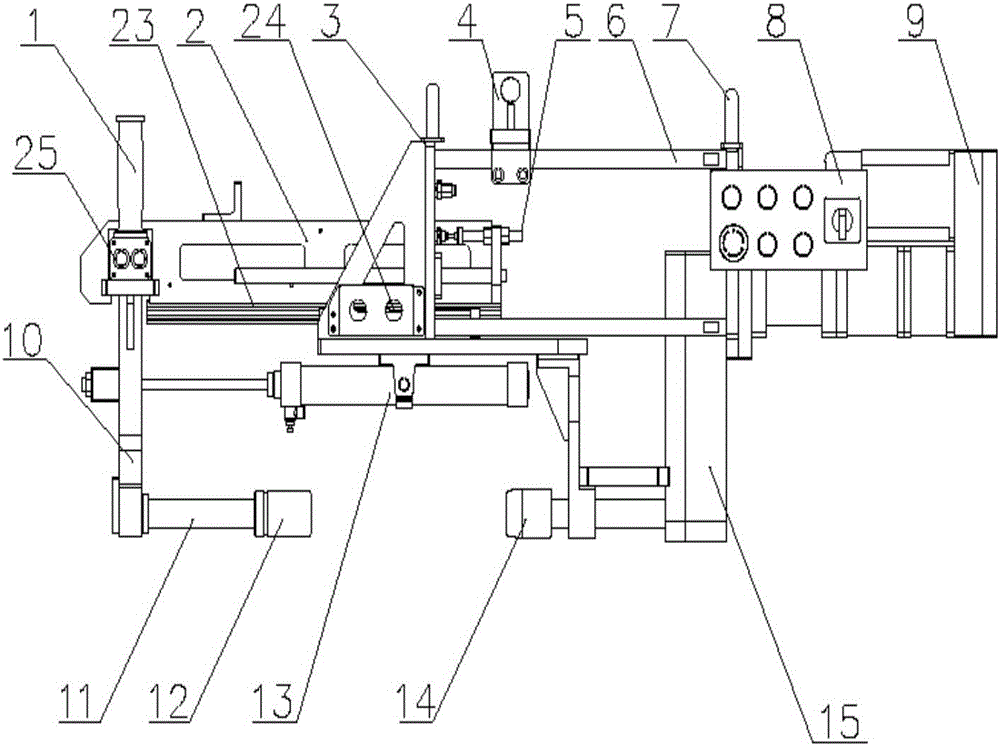

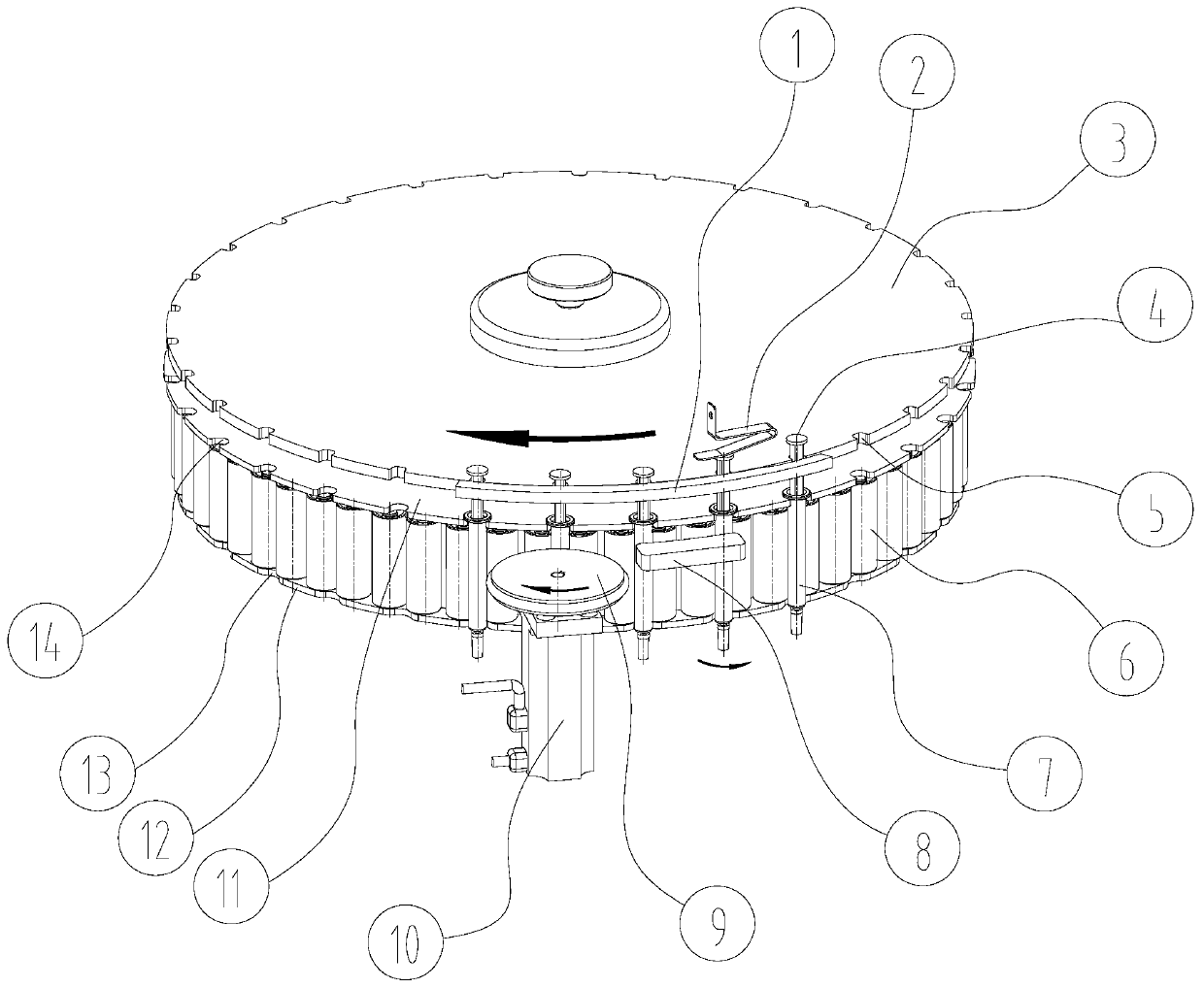

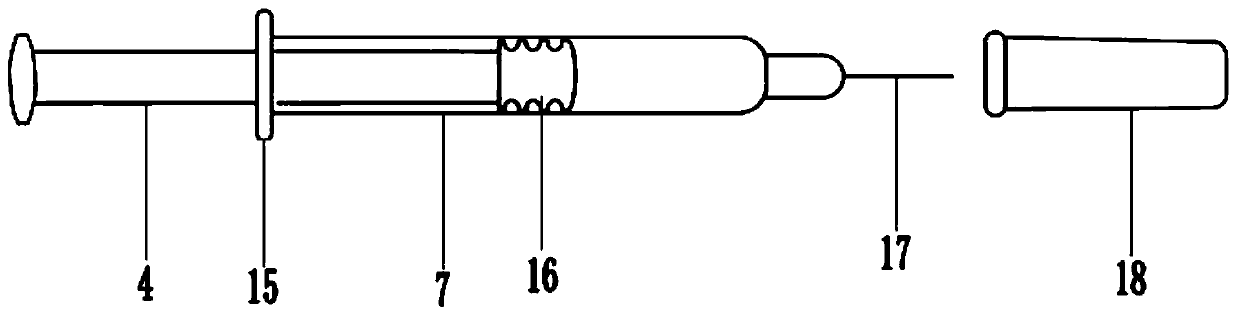

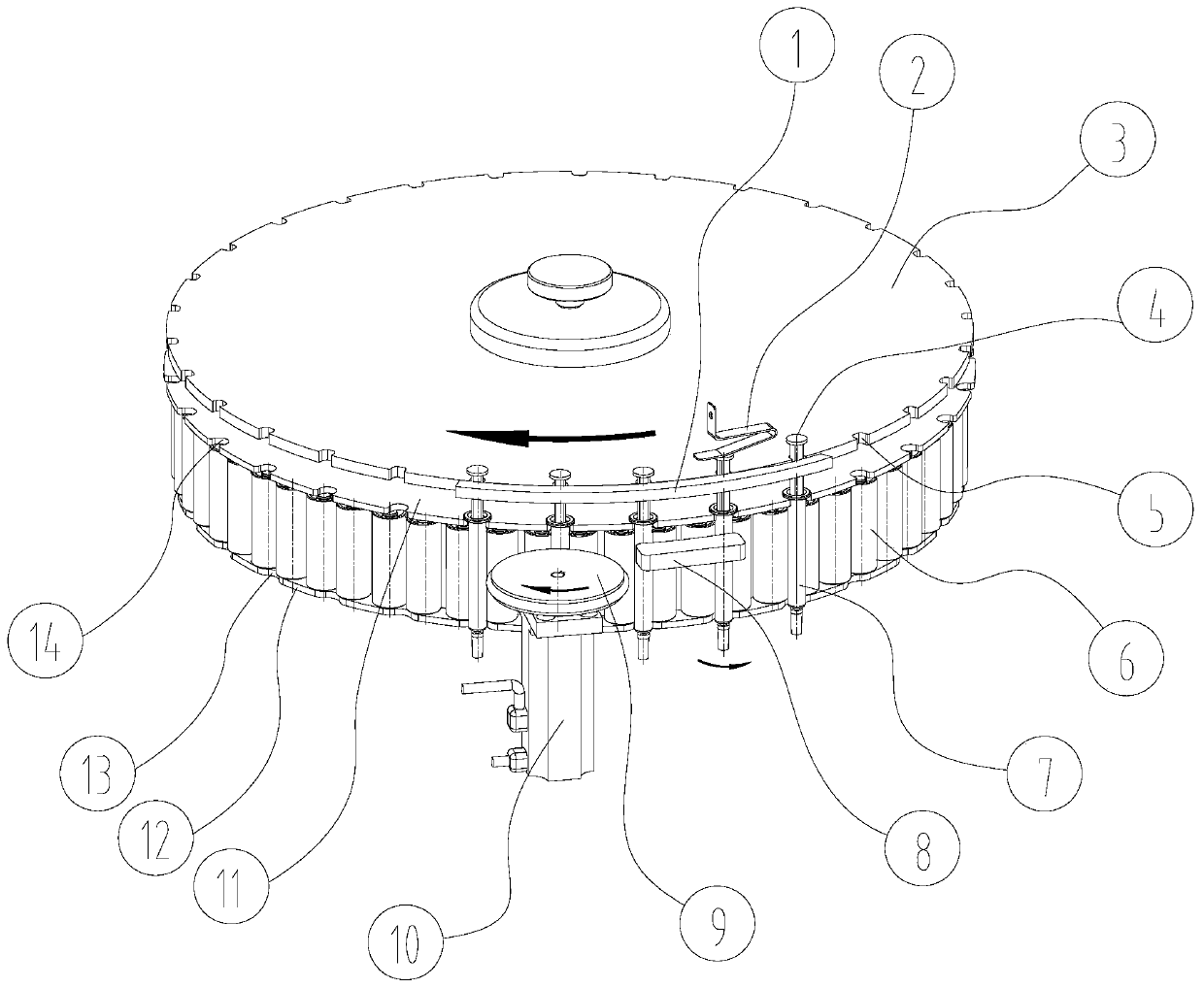

Pre-filled needle tube push rod precision assembly machine and assembly method thereof

ActiveCN106584081BEasy to controlAccurate torqueInfusion syringesMedical devicesEngineeringAssembly machine

The invention discloses a pre-filled needle tube push rod precision assembly machine and an assembly method thereof, comprising a turntable, the turntable includes an upper circular plate and a middle circular plate arranged coaxially from top to bottom, and a plurality of There is a U-shaped needle tube opening with an outward opening, a push rod bayonet on the upper circular plate, and a pair of rollers corresponding to the inner side of the U-shaped needle tube placement port; the axes of the rollers are parallel to the rotation axis of the turntable; Pre-twisted friction block, the inner side of the pre-twisted friction block is provided with an arc notch coaxial with the turntable, the rear side of the pre-twisted friction block is provided with a fine-twisted roller, and the fine-twisted roller is provided with a fine-twisted roller connected to the fine-twisted roller. Wheel drive mechanism. The present invention adopts the pre-twisted friction block and the push rod to be pre-tightened firstly, and then tightened tightly through the fine-twisted wheel, so that the push rod and the elastic rubber plug are connected in place, preventing the leakage of the injection during use. The assembly quality and production capacity of the push rod are improved, and the cost of the push rod assembly is reduced.

Owner:COLAMARK GUANGZHOU LABELING EQUIP

Open-type hydraulic torque wrench

The invention discloses an open-type hydraulic torque wrench which comprises a wrench body, a wrench head, a wedge block assembly and a hydraulic cylinder assembly, wherein the wrench body is provided with an open round hole and an axle bed, the wrench head is provided with a hinged shaft, a rounded boss, sliding chutes and a hinge pin, the hydraulic cylinder assembly is hinged with the wrench body, the boss of the wrench head is arranged in the open round hole of the wrench body, the hinged shaft of the wrench head is hinged with a piston rod of an oil cylinder, and the wedge block assembly is arranged in the sliding chutes on both sides of the wrench head. According to the invention, the design of the wedge block assembly is adopted, the wrench head is clamped on the outer side of a nut, and a torque is transmitted in a continuous swinging mode along the radial direction of the nut, therefore, the open-type hydraulic torque wrench has the advantages of simple structure, convenience for use, and accurate torque setting.

Owner:杜德机械科技(上海)有限公司

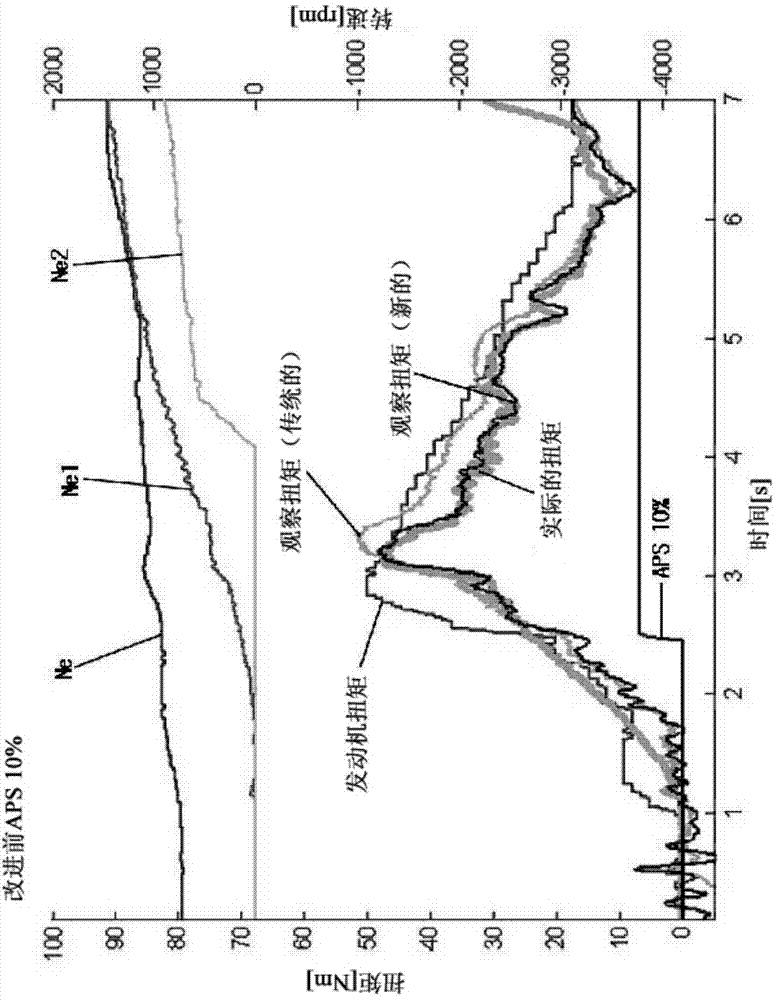

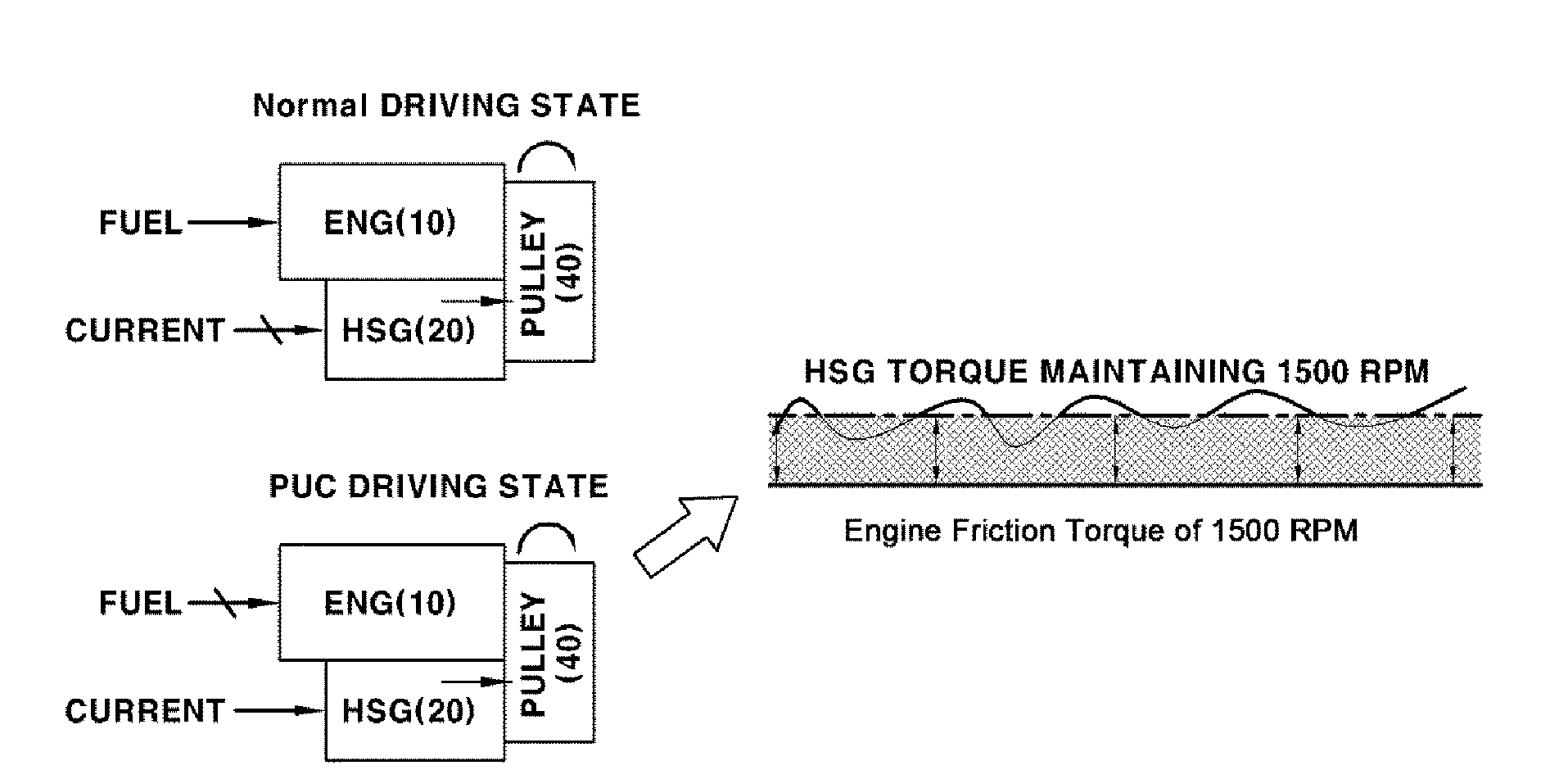

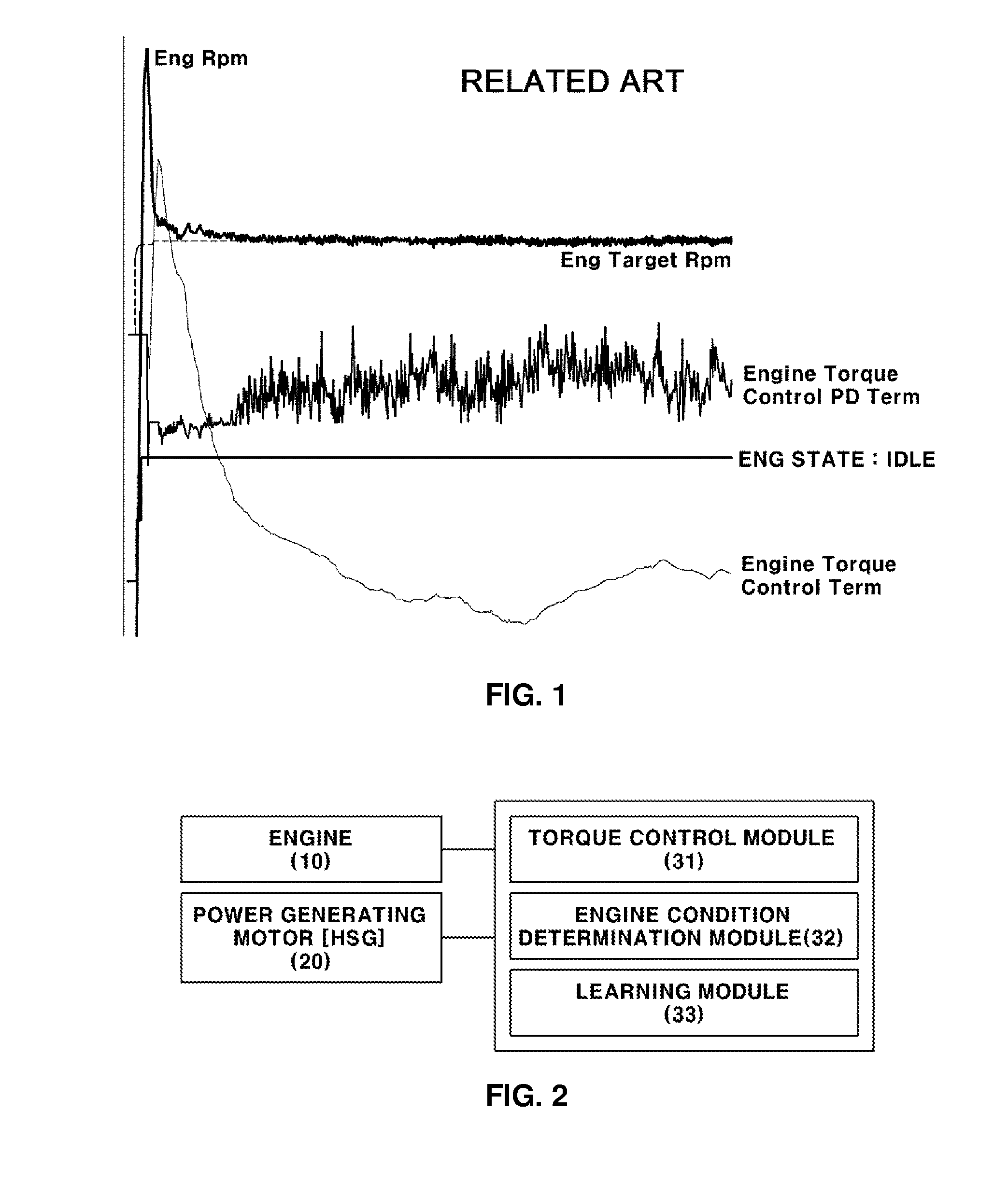

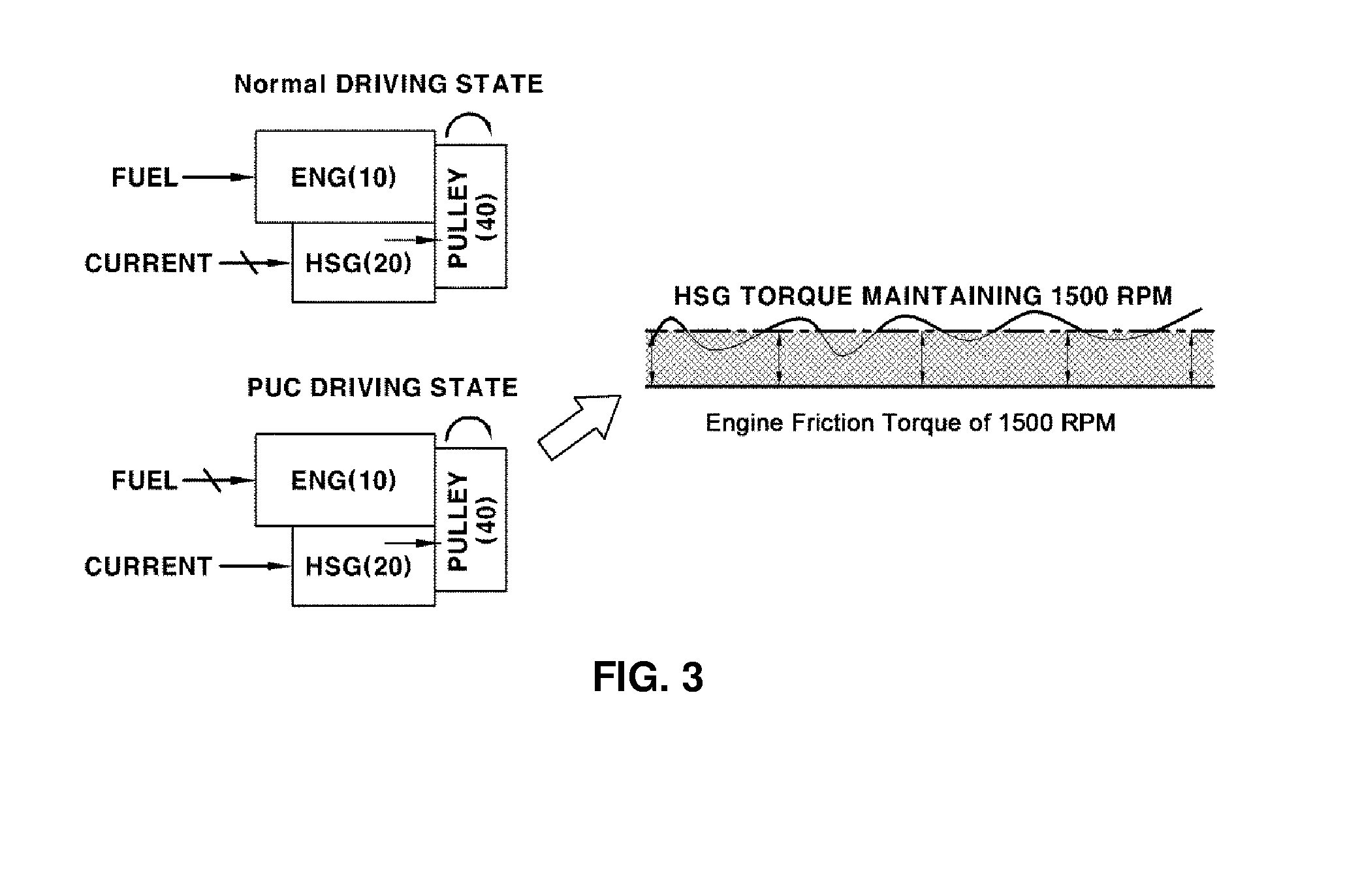

Apparatus and method for learning engine friction torque of hybrid vehicle

ActiveUS20160297421A1Accurate torqueAccurate engine frictionHybrid vehiclesGas pressure propulsion mountingFriction torqueIdle speed

The present disclosure provides a technology of determining an engine friction torque even when idling of an engine is not performed, by providing a certain engine Revolutions per Minute (RPM) in stop state of the engine using Hybrid Starter & Generator (HSG) connected to an engine pulley. The present disclosure provides a technology of determining an accurate engine friction torque using a torque provided from the outside of an engine instead of a torque generated the engine itself.

Owner:HYUNDAI MOTOR CO LTD +1

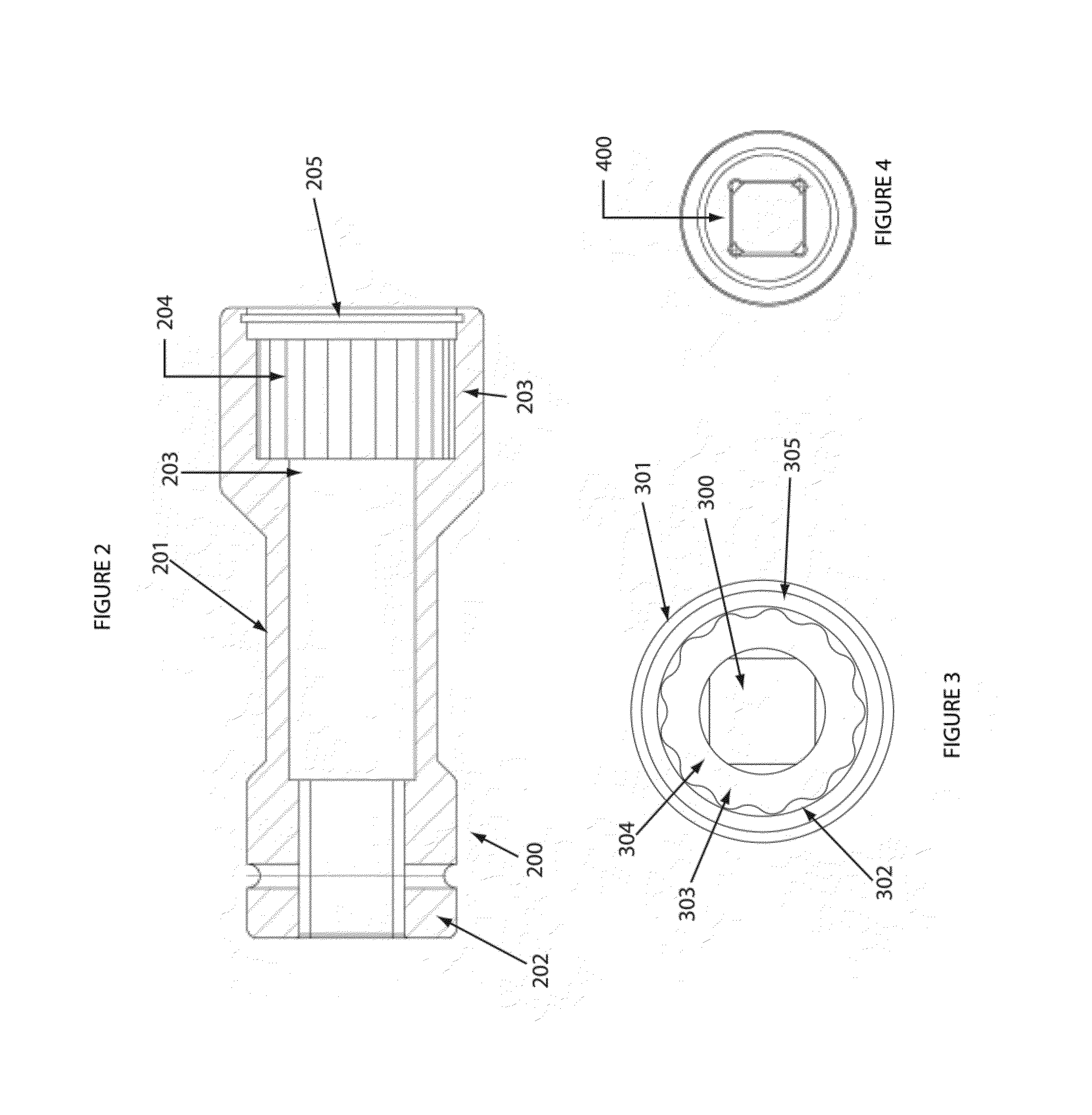

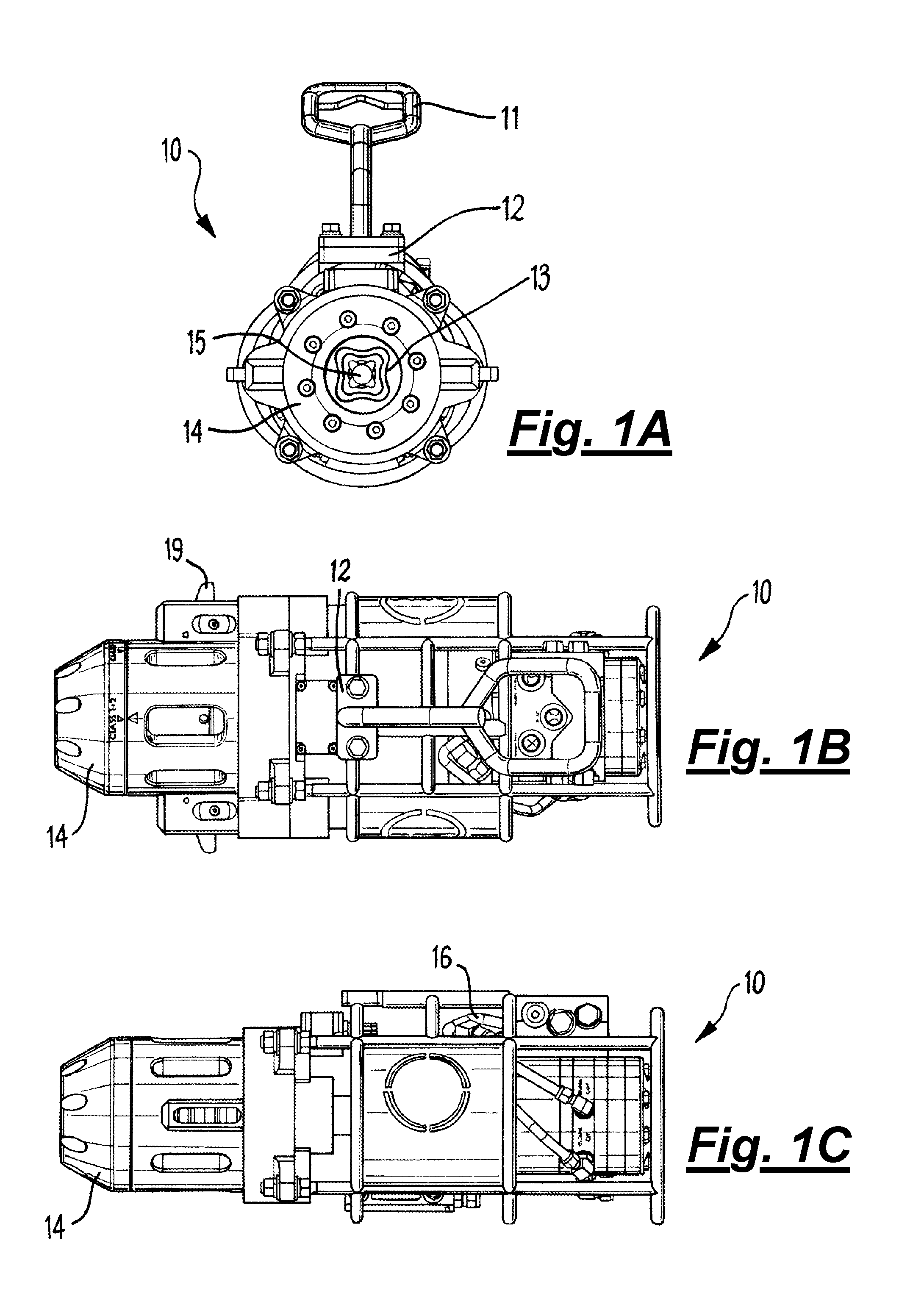

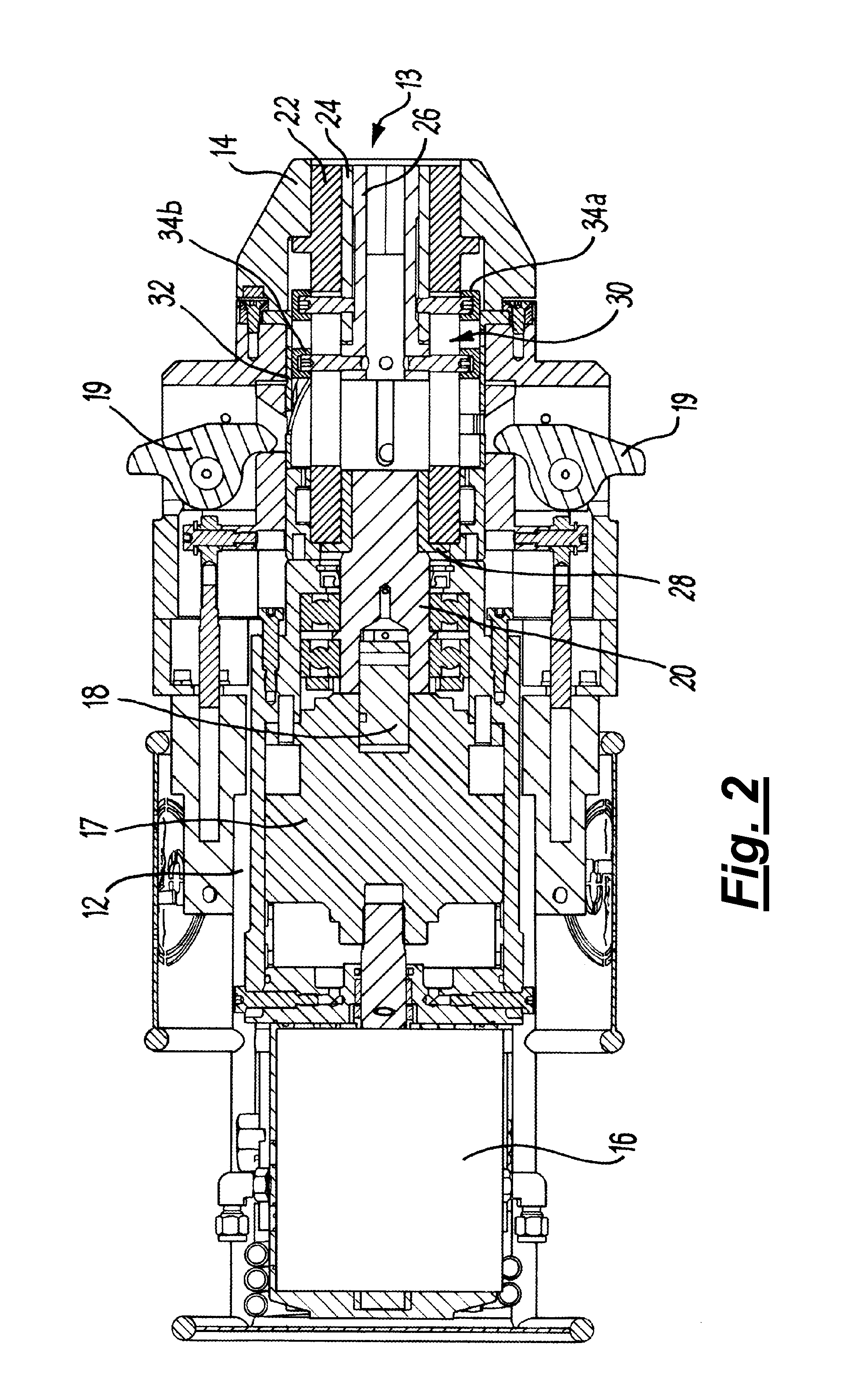

Torque tool, socket selection mechanism, and methods of use

ActiveUS20160346883A1Robust and reliable and compact torqueChange sizeSpannersWrenchesTorque transmissionCam

The invention provides a subsea torque tool (10) for a subsea vehicle system (such as an ROV), a drive head selection mechanism (30), and a method of use. The tool comprises a tool housing and a plurality of torque drive heads (22, 24, 26). The drive mechanism (17, 18, 20, 28) is operable to rotate the plurality of torque drive heads, and the drive head selection mechanism is used to select a drive head to impart a torque to a subsea device. The drive head selection mechanism comprises a rotary actuator (14, 32), and rotation of the rotary actuator effects axial movement of at least one of the plurality of drive heads between an operative position and an inoperative position. In another aspect, the drive head selection mechanism comprises an actuator operable from the exterior of the torque tool. In a preferred embodiment, the drive heads are sockets (22, 24, 26), and the selection mechanism comprises a rotary actuator and a cam mechanism. The at least one socket may be permitted to rotate with respect to the cam mechanism when a driving torque is applied to the torque sockets.

Owner:FORUM ENERGY TECH UK

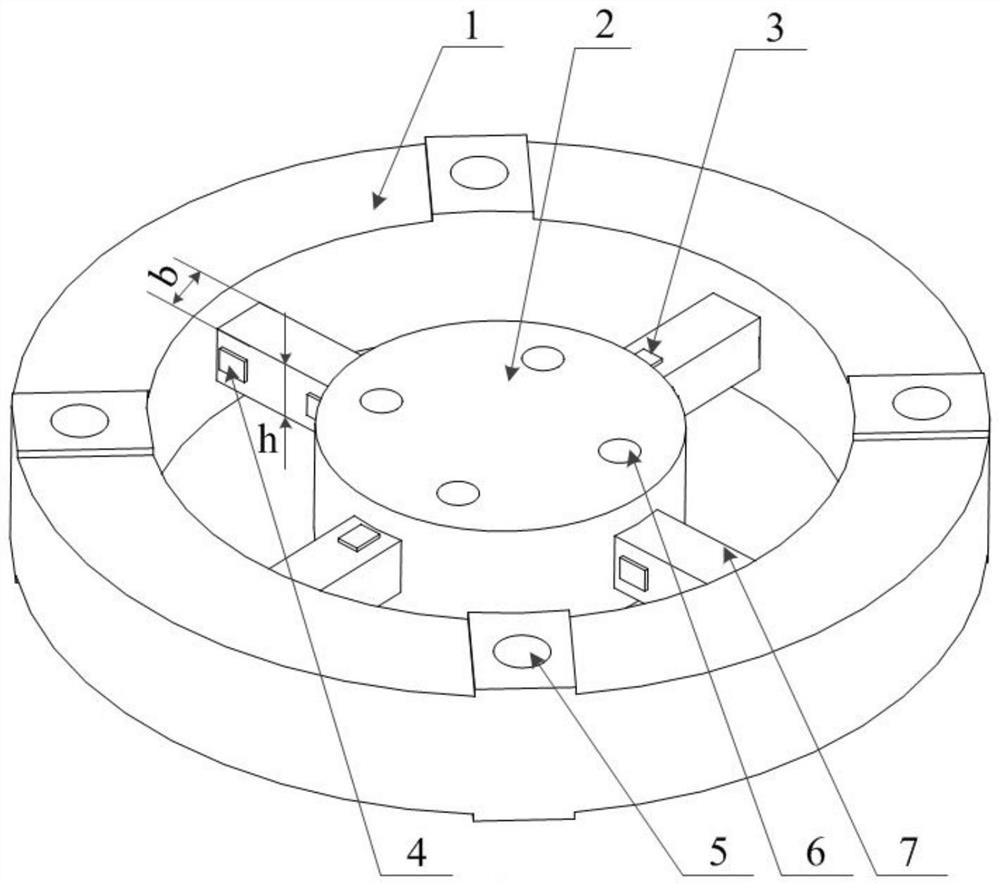

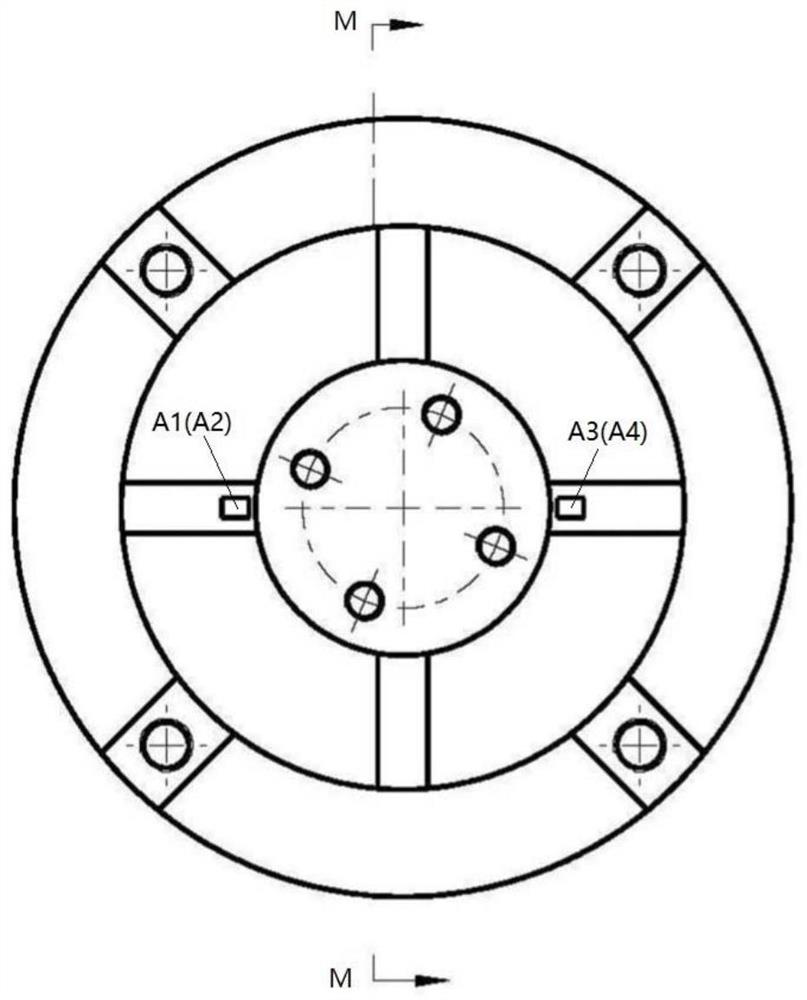

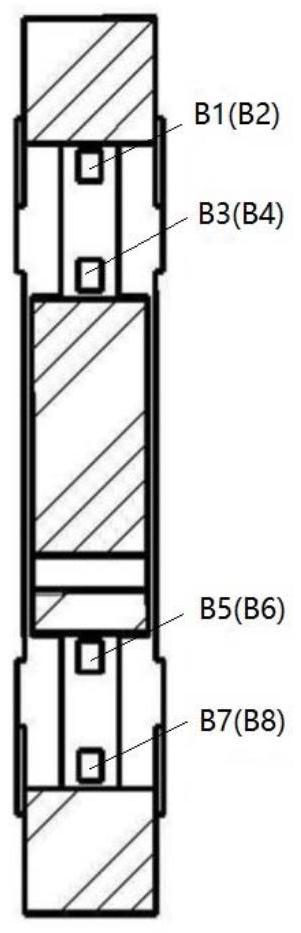

Rib type micro-axial force annular two-component strain balance

InactiveCN111649907AImprove accuracyAccurate measurementAerodynamic testingWork measurementPull forceClassical mechanics

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com