A large-length-diameter-ratio shaft hole assembling system and method based on contact force and torque prediction and analysis

A large length-to-diameter ratio, assembly system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to complete assembly, assembly obstruction, and increase the difficulty of assembly control, so as to remove interference data and control Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

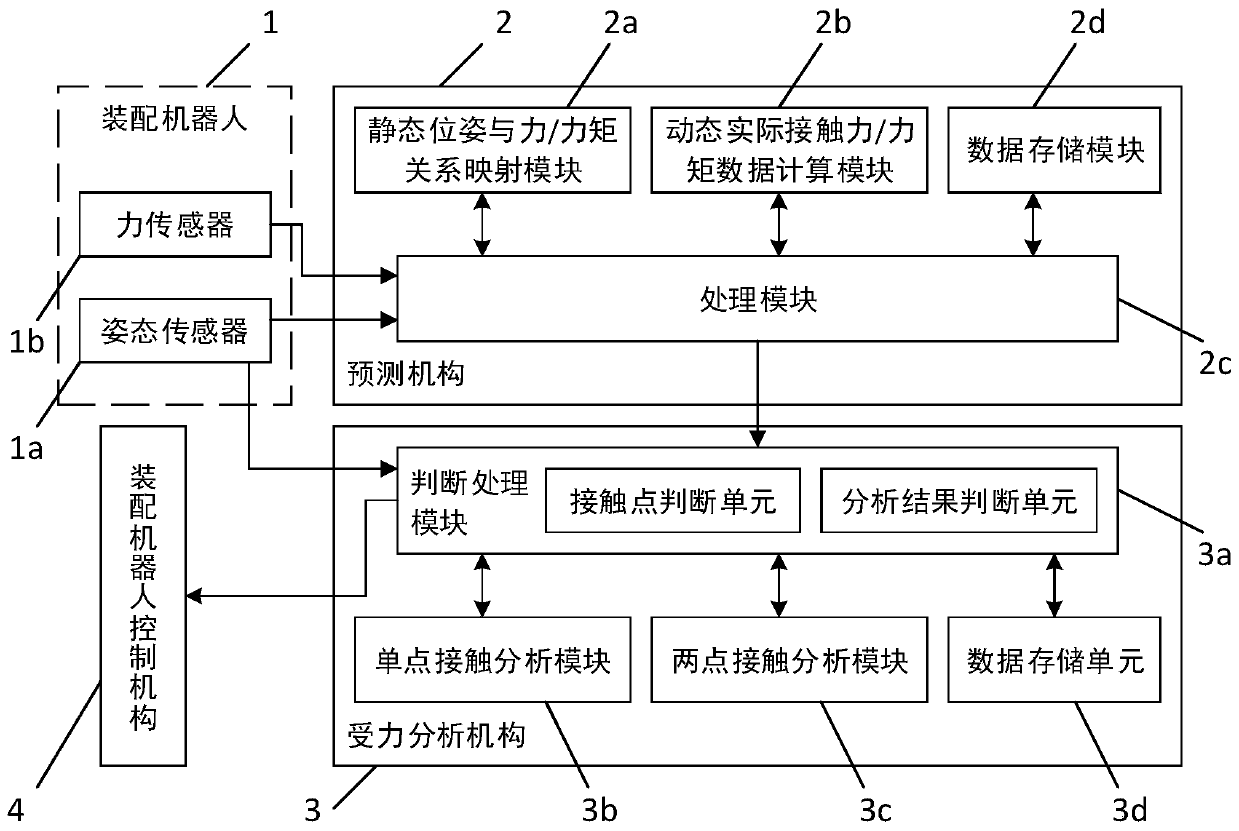

[0089] A large aspect ratio shaft hole assembly system based on contact force and moment prediction and analysis, such as figure 1 As shown, an assembly robot 1 is included, and the assembly end of the assembly robot is provided with an attitude sensor 1a and a force sensor 1b, and the attitude sensor 1a is used to detect the three-axis pose parameter I of the assembly end 1 , the force sensor 1b is used to detect the triaxial contact force data I of the assembly end 2 , Triaxial moment data I 3 ;

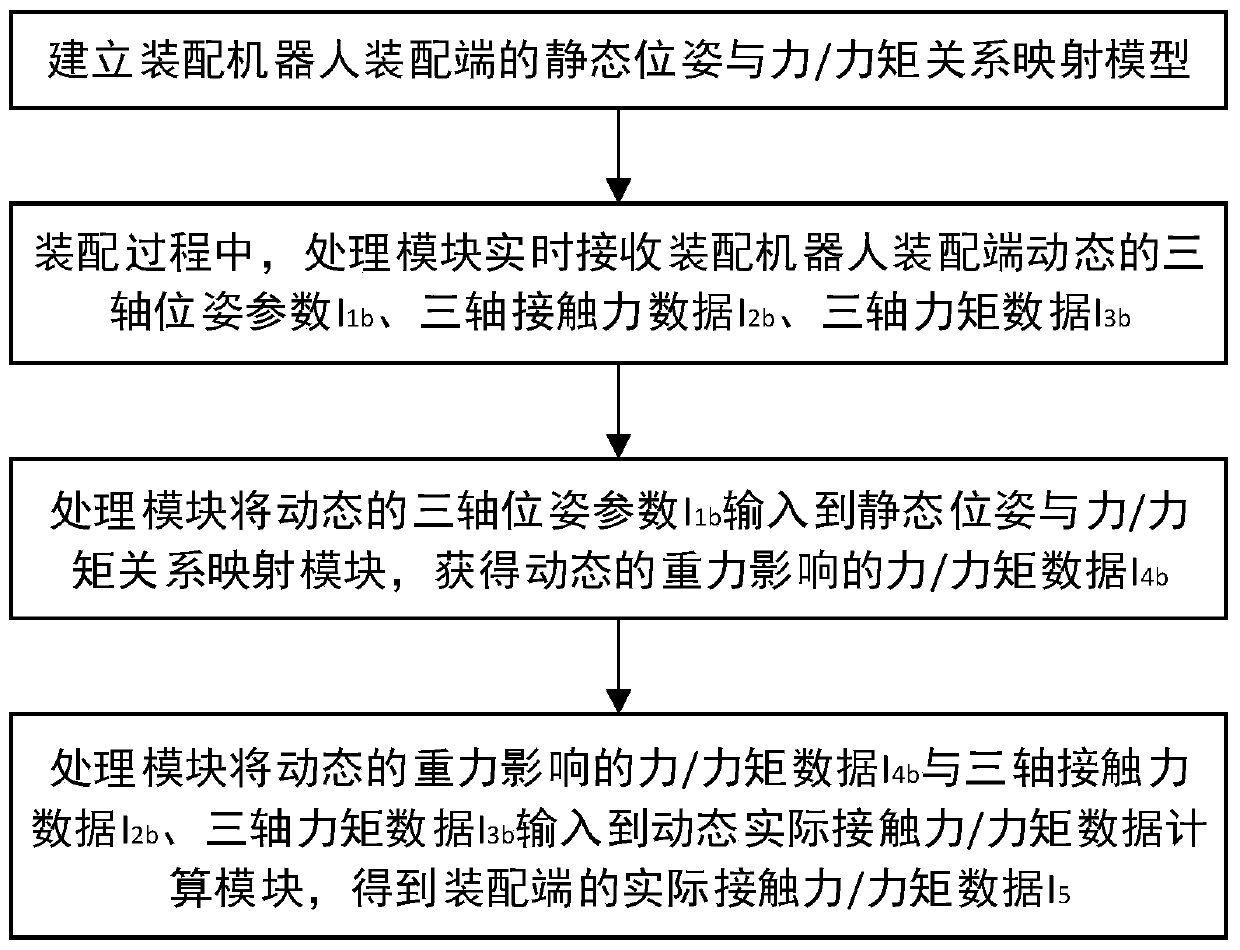

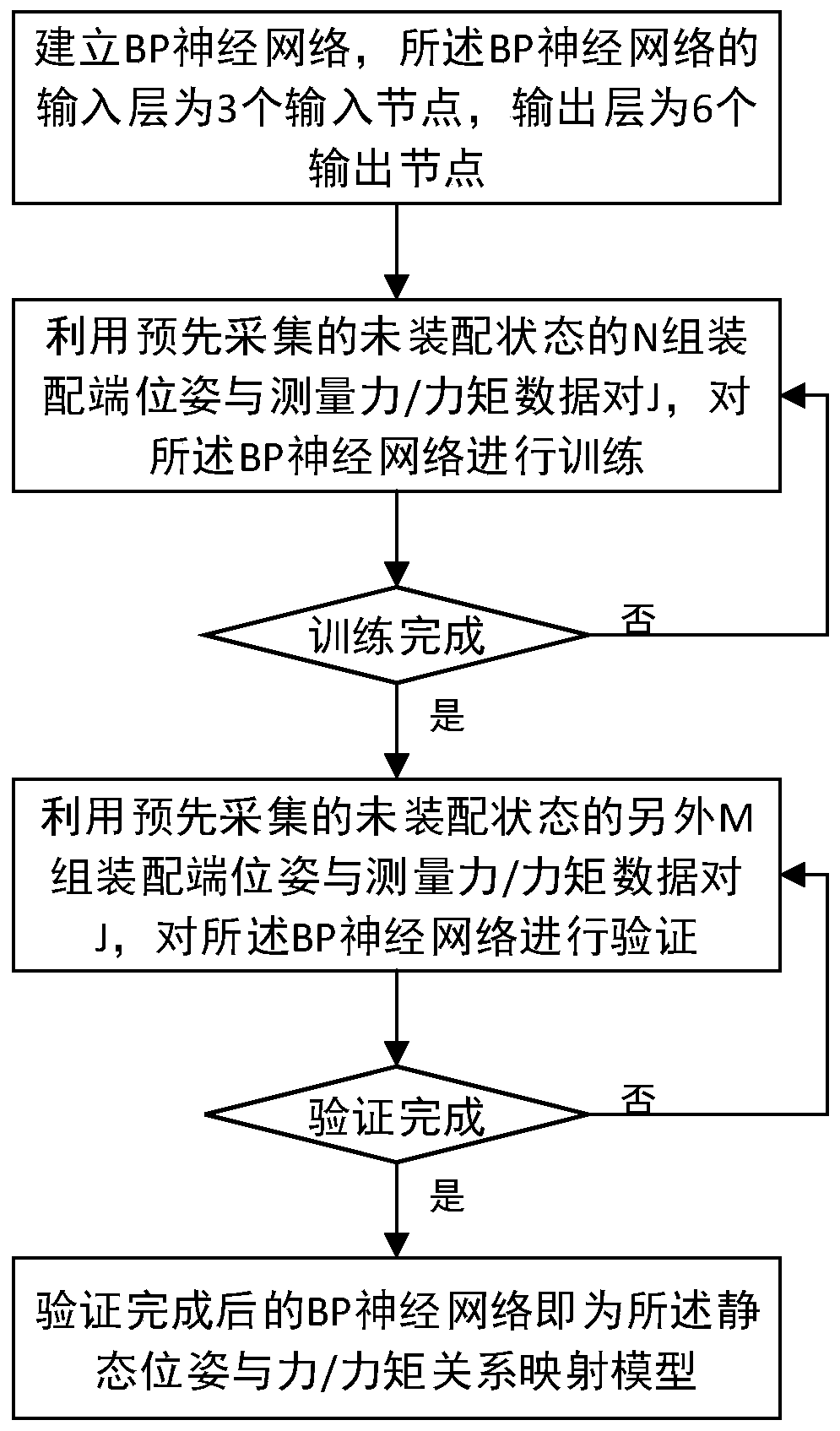

[0090] It also includes a prediction mechanism 2 and a force analysis mechanism 3, and the prediction mechanism 2 passes the three-axis pose parameter I 1 , Triaxial contact force data I 2 , Triaxial moment data I 3 Predicting Actual Contact Force / Moment Data I for Assembly Processes 5 , the force analysis mechanism 3 according to the three-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com