Patents

Literature

209results about How to "Implement automatic selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

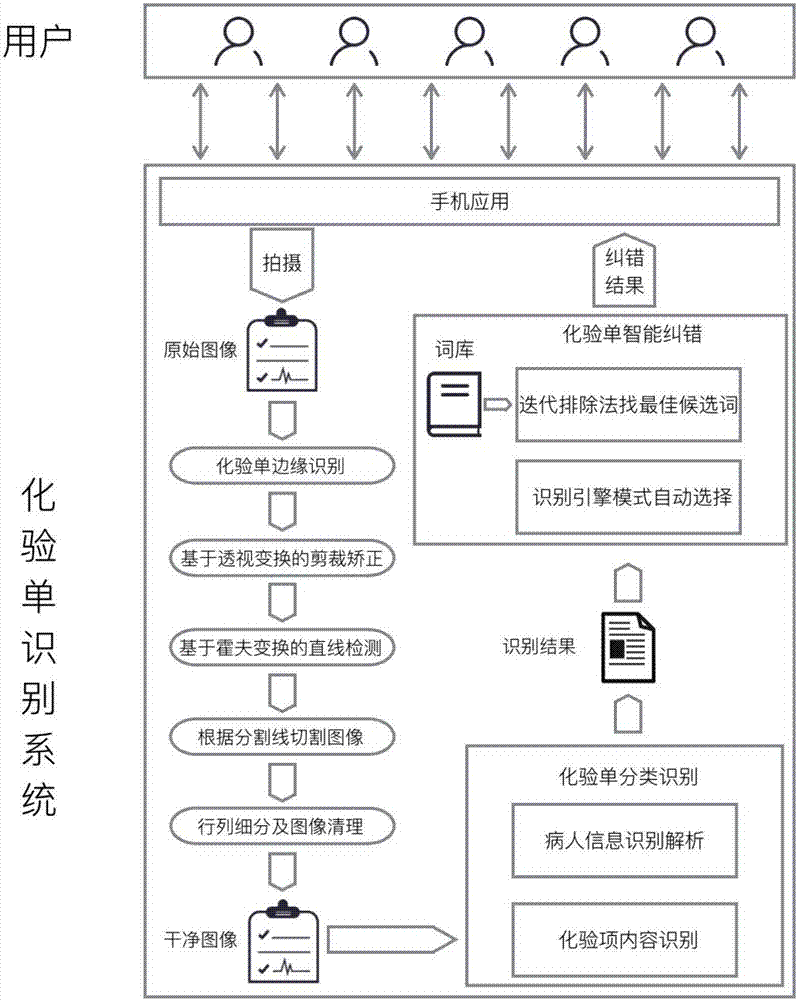

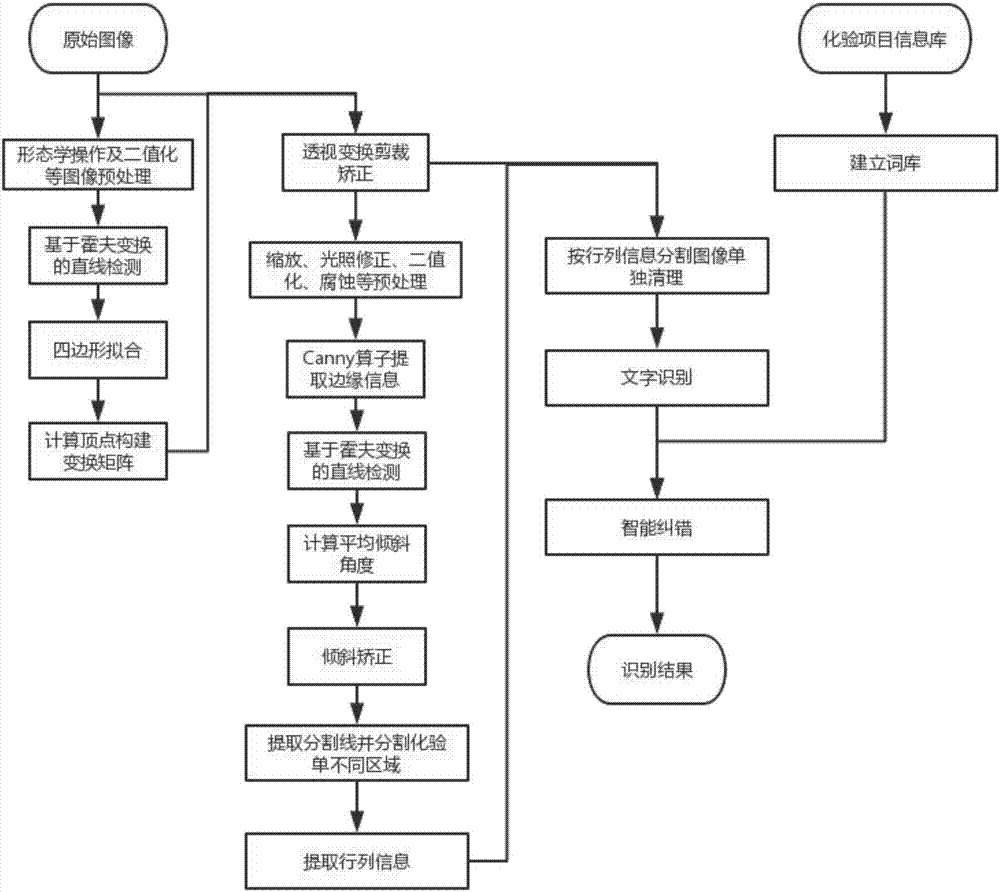

Laboratory-sheet identification method based on image processing

InactiveCN107491730AImprove reliabilityImprove accuracySpecial data processing applicationsCharacter recognitionImaging processingOpen source

The invention discloses a laboratory-sheet identification method based on image processing. According to the method, a set of algorithms which can accurately divide each area of a laboratory sheet and carry out effective cleaning are designed through investigation and analysis on a laboratory-sheet structure, how to process a laboratory-sheet photograph, which is shot by a mobile phone, step by step to finally obtain a clear image is standardized and subdivided, and a mature open-source OCR engine is used for identification; in each stage of a laboratory-sheet image processing process, the method makes thorough consideration, optimizes the performance, and improves the efficiency of image processing; and after identification, a laboratory-sheet item lexicon established by utilizing a laboratory test item information database by the method realizes automatic selection for identification engine modes and intelligent error correction for an identification result, and improves the accuracy of the laboratory-sheet identification result.

Owner:ZHEJIANG UNIV

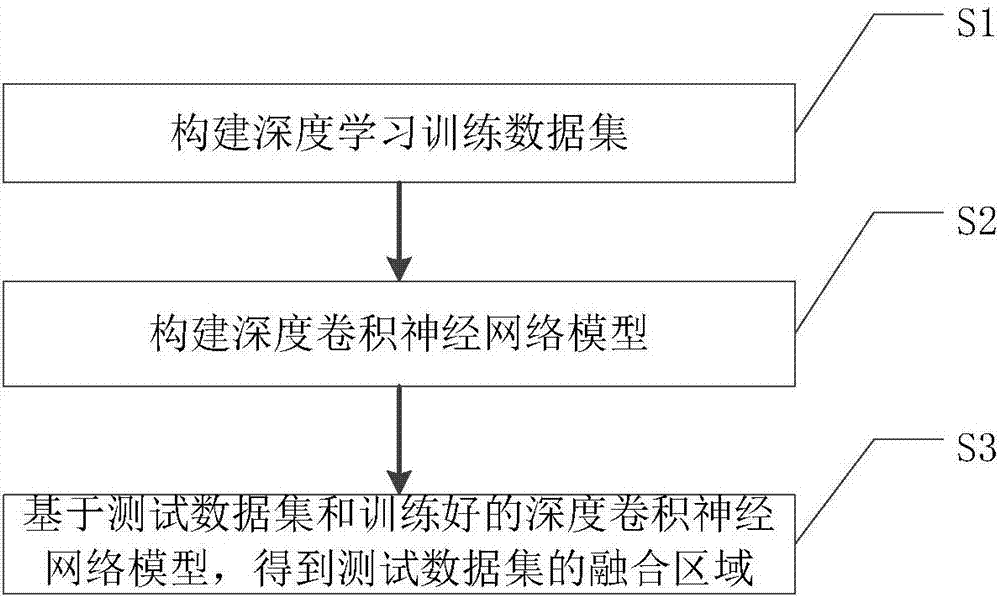

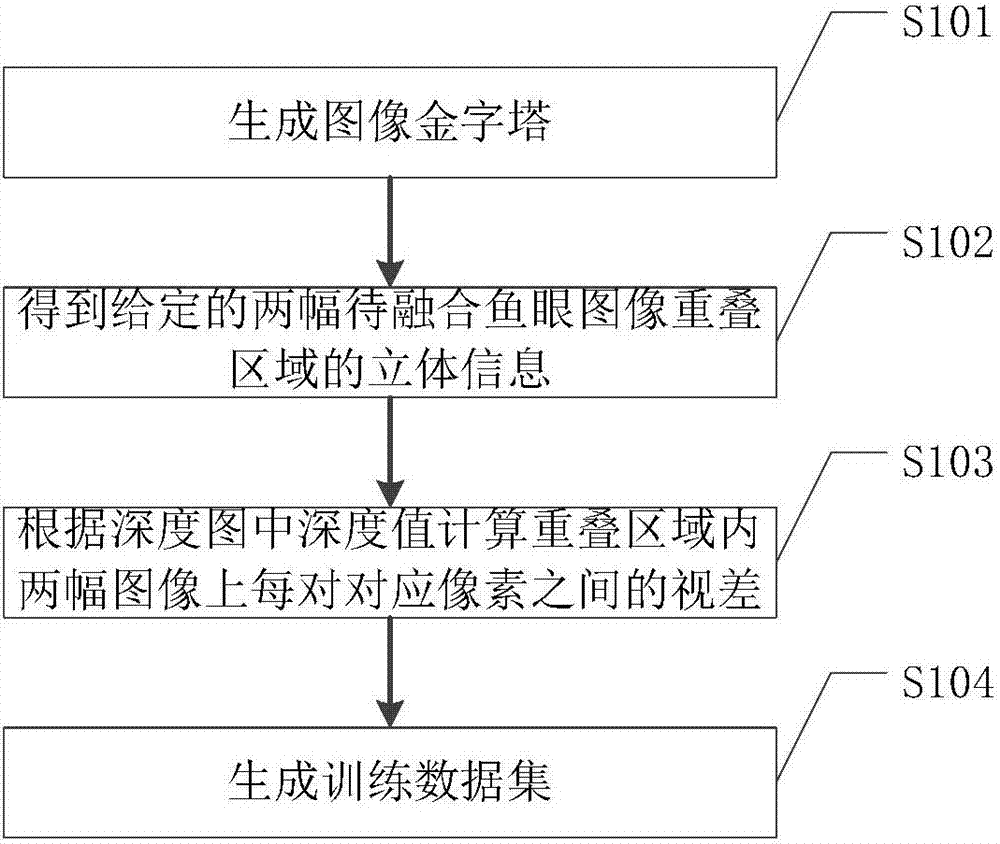

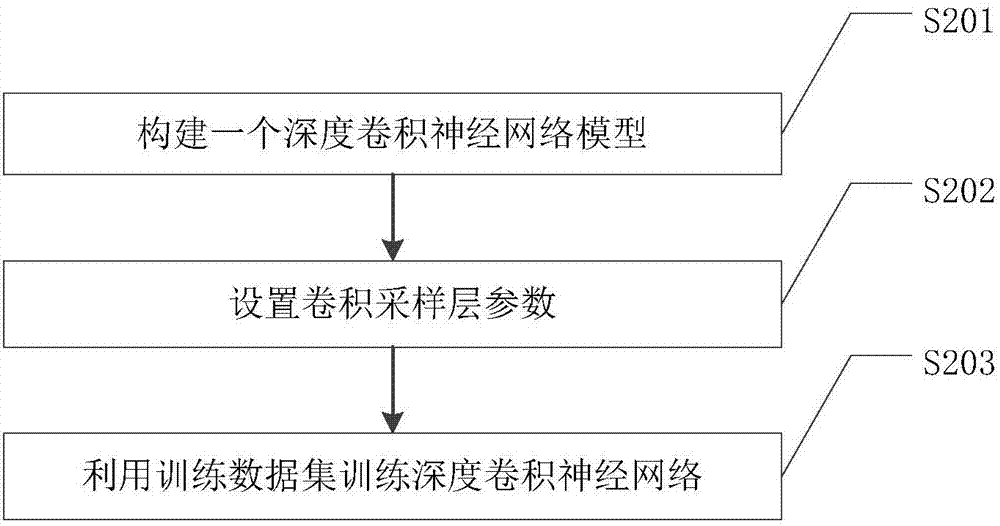

Panoramic image fusion method based on depth convolution neural network and depth information

InactiveCN106934765AReduce ghostingImplement automatic selectionImage enhancementImage analysisData setSemantic representation

The invention discloses a panoramic image fusion method based on a depth convolution neural network and depth information. The method comprises the steps of (S1) constructing a deep learning training data set, selecting overlap regions xe1 and xe2 of two fish eye images to be fused used for training and an ideal fusion area ye of a panoramic image formed after fusing the two fish eye images, and constructing a training set {xe1, xe2, ye} of the images to be fused and a panoramic image block pair, (S2) constructing a convolution neural network model, and (S3) obtaining a fusion area of a test data set based on a test data set and a trained depth convolution neural network model. According to the method, an image can be expressed more comprehensively and deeply, the image semantic representation in a plurality of abstract levels is realized, and the accuracy of image fusion is improved.

Owner:CHANGSHA PANODUX TECH CO LTD

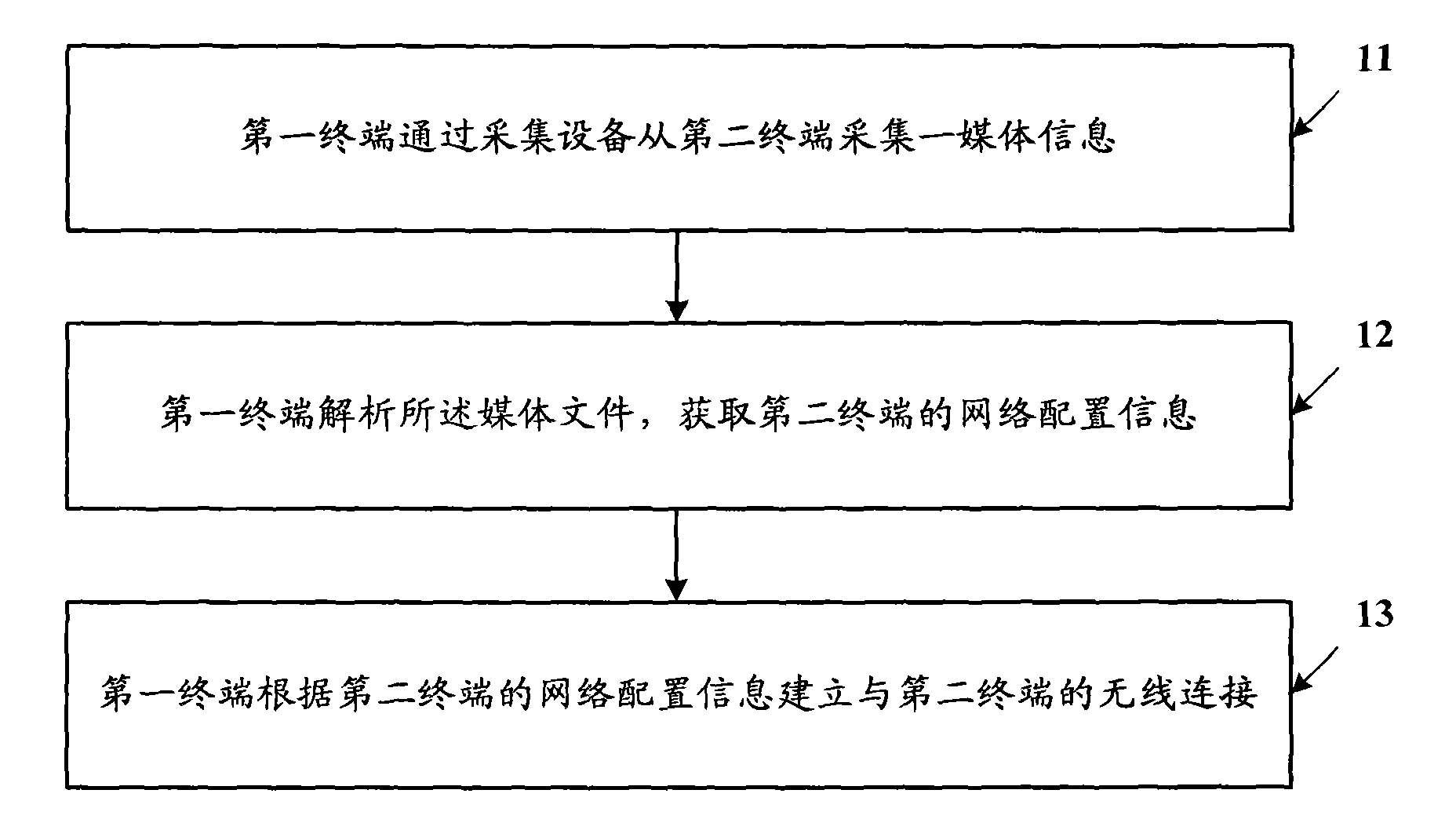

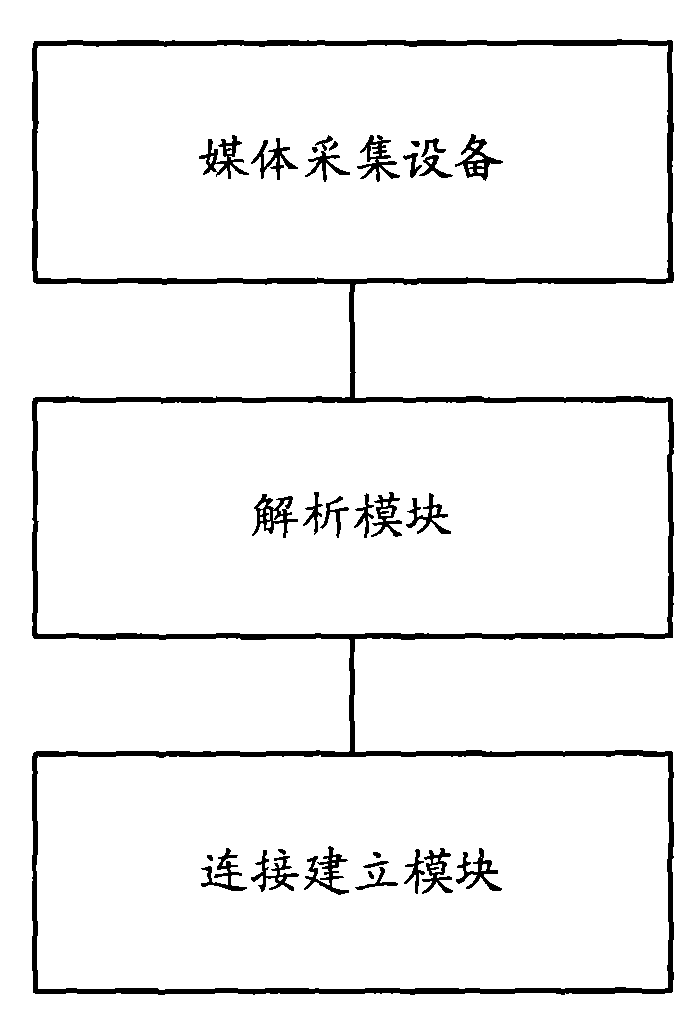

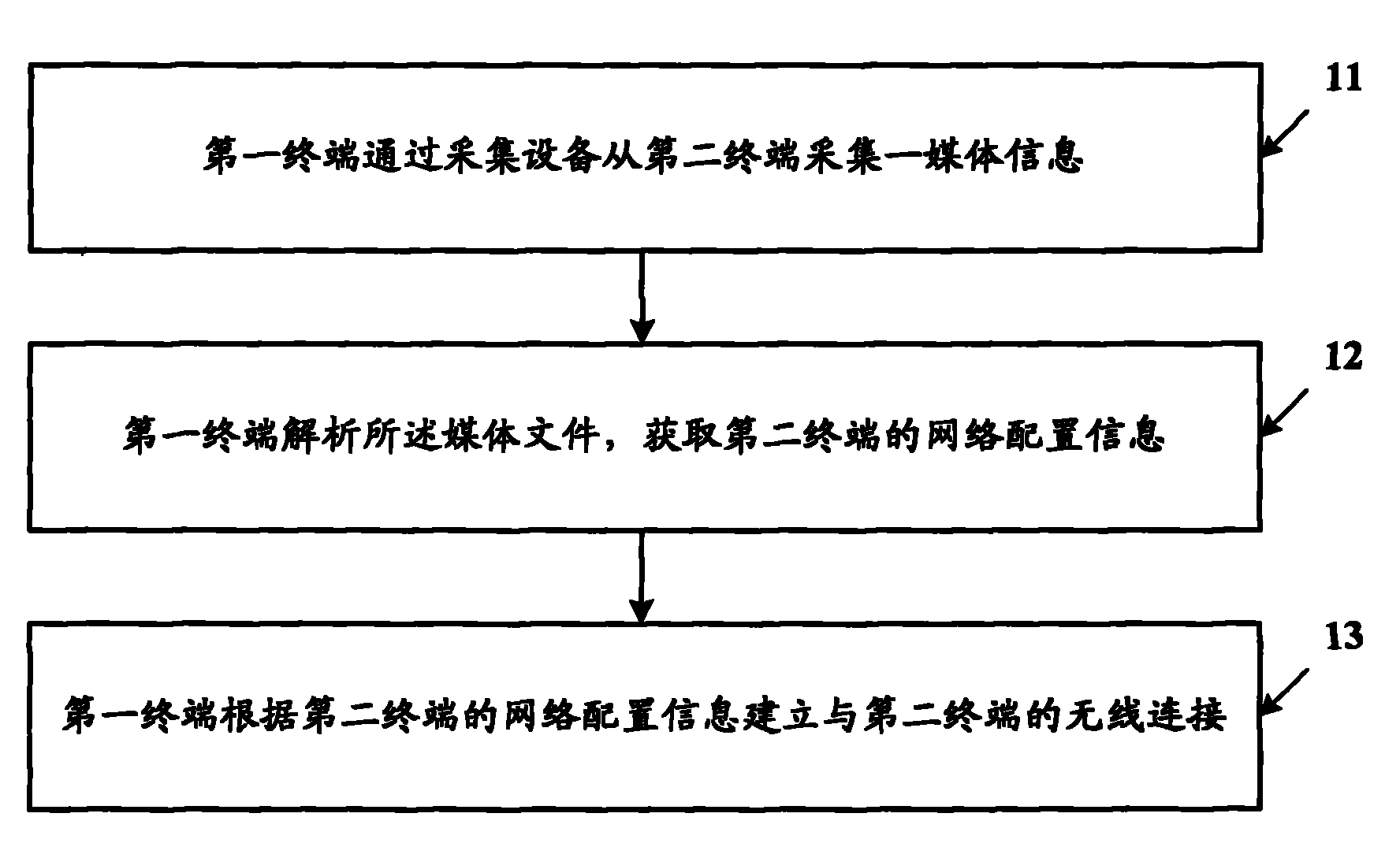

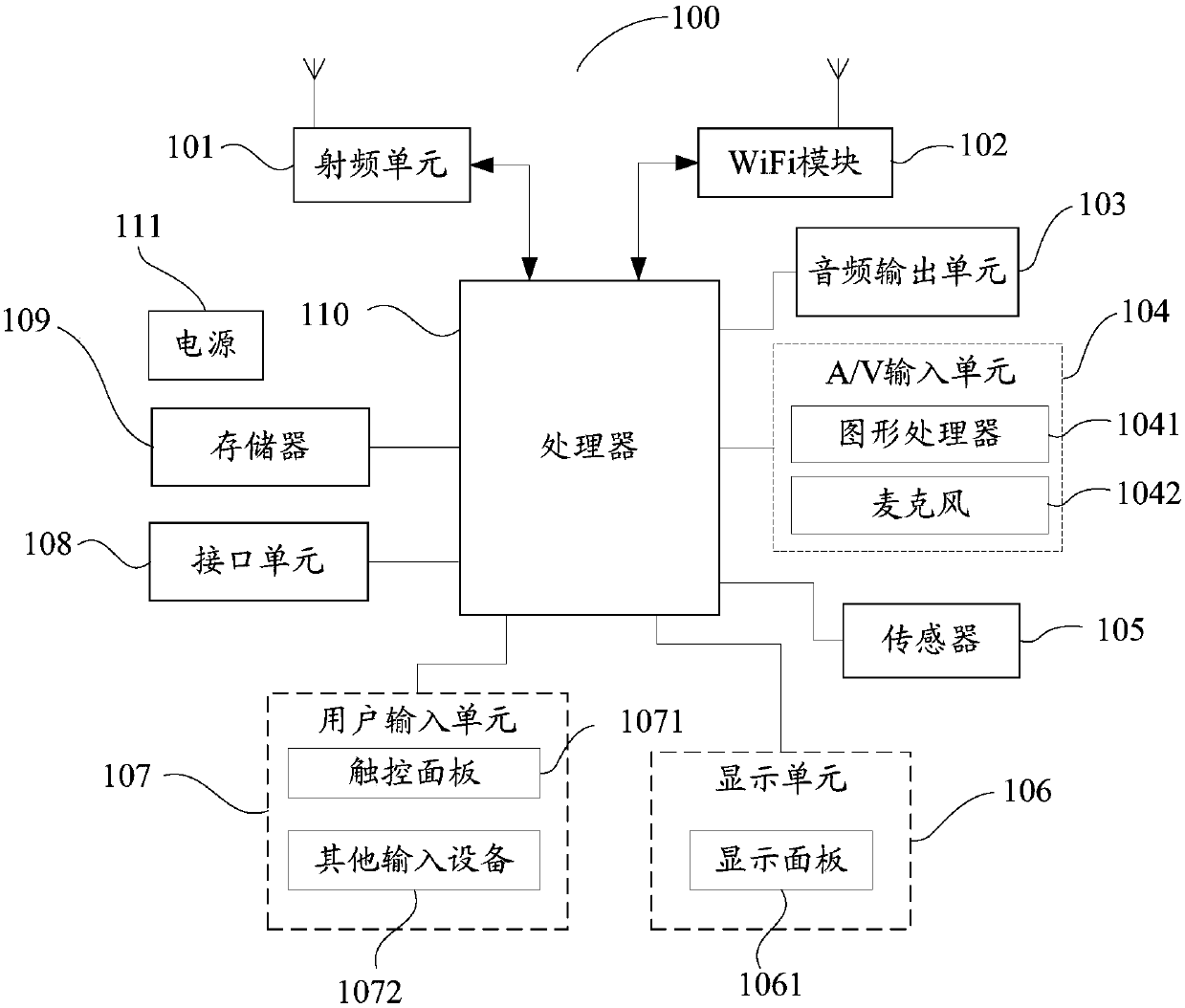

Method for establishing wireless connection and terminals

InactiveCN102056328AImplement automatic selectionAuto Select SimpleConnection managementTelecommunicationsComputer terminal

The invention provides a method for establishing a wireless connection and terminals, wherein the method is used for establishing the wireless connection between a first terminal and a second terminal, and the first terminal and the second terminal both are provided with wireless interfaces of the same type. The method comprises the following steps of: collecting first information from the second terminal by the first terminal via a collecting device, wherein the network configuration information of the second terminal is recorded in the first information; analyzing the first information by the first terminal to acquire the network configuration information of the second terminal; and establishing the wireless connection with the second terminal by the first terminal according to the network configuration information of the second terminal. By virtue of the invention, automatic selection of a device to be connected can be simply and rapidly realized on the basis of a media collecting device, the operation of manually establishing the wireless network connection by a user is avoided, and the successfully-established wireless connection can be ensured.

Owner:LENOVO (BEIJING) LTD

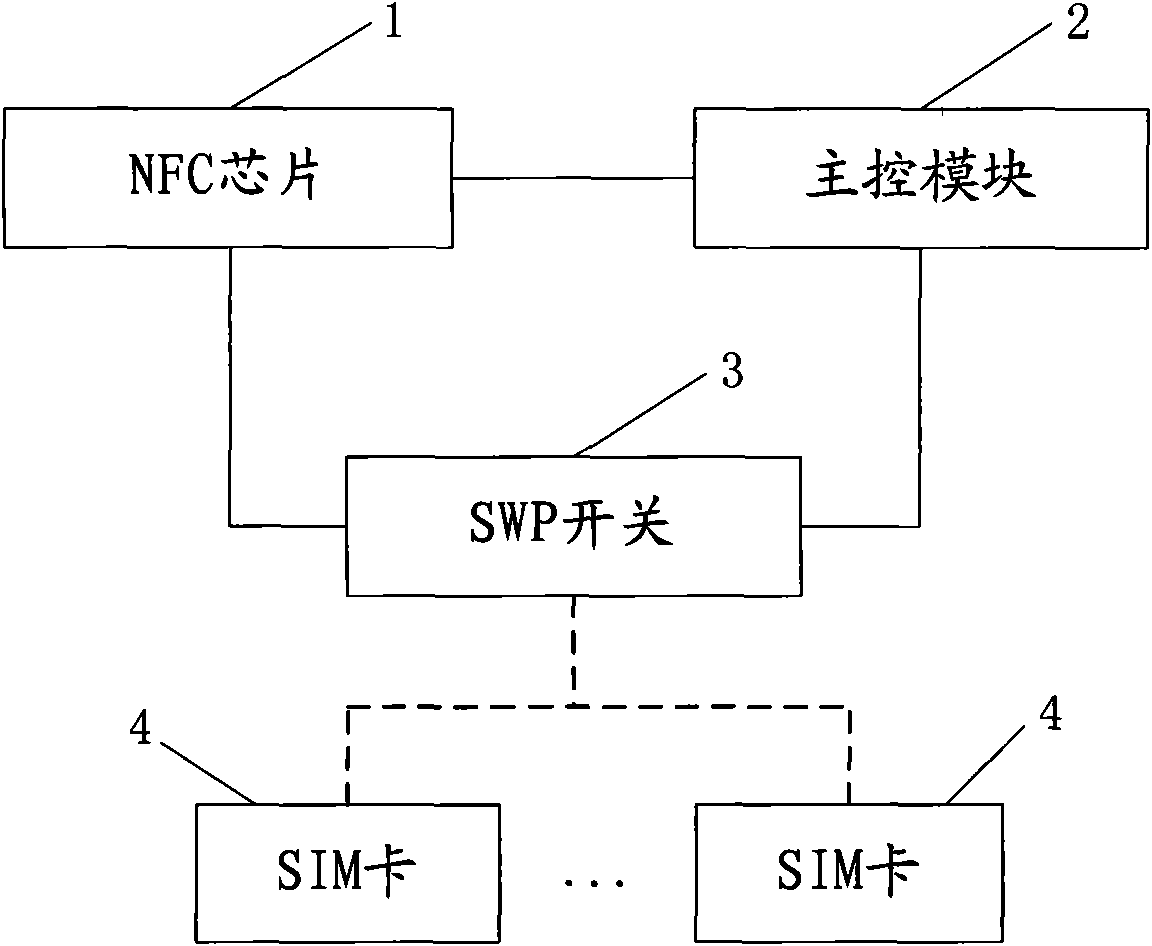

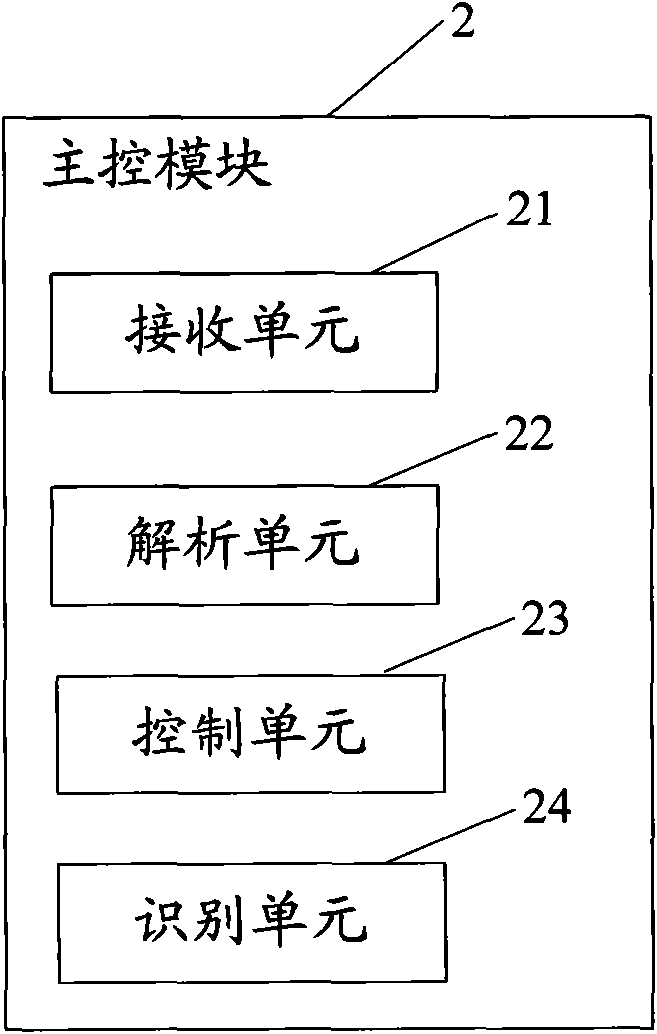

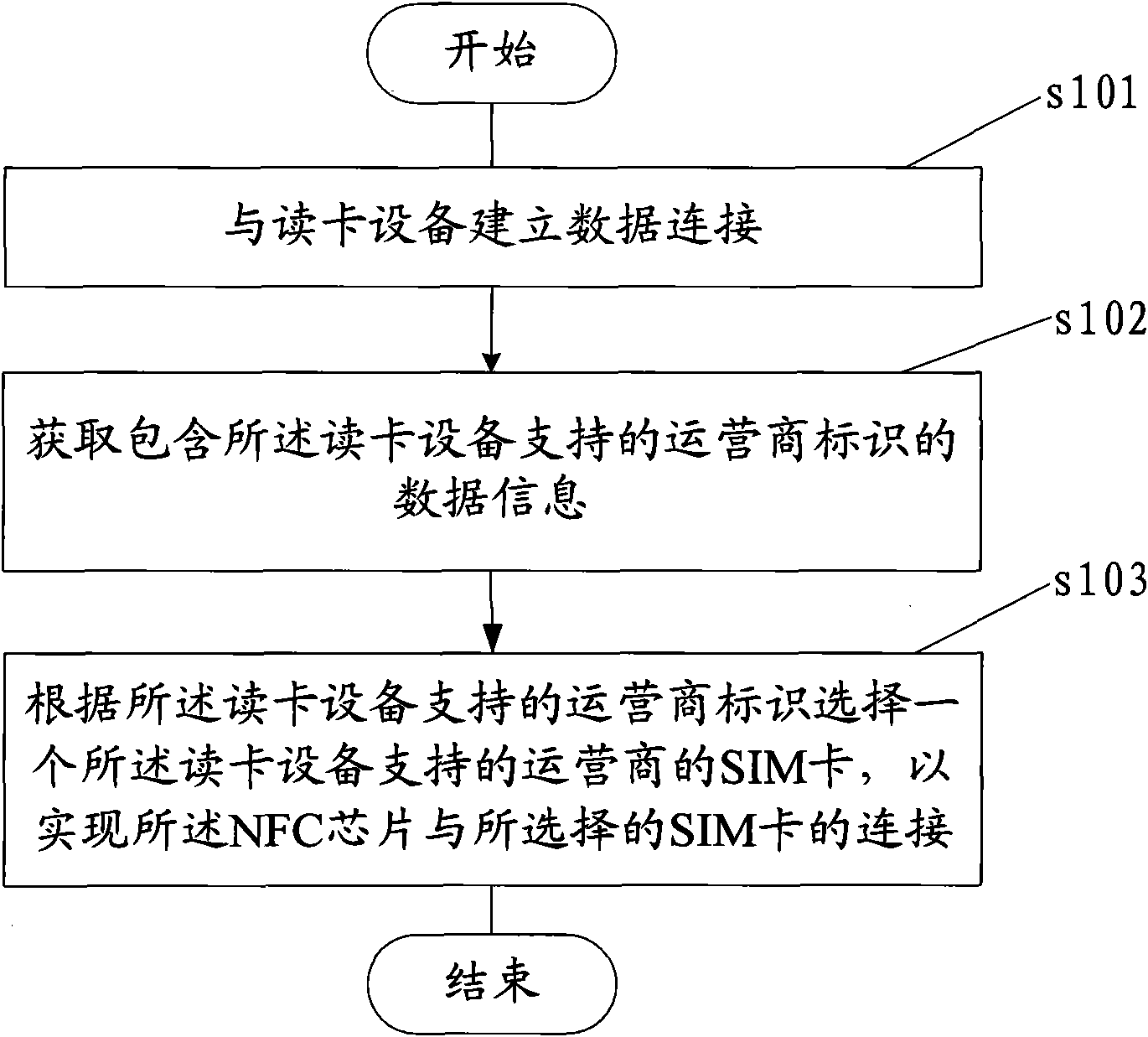

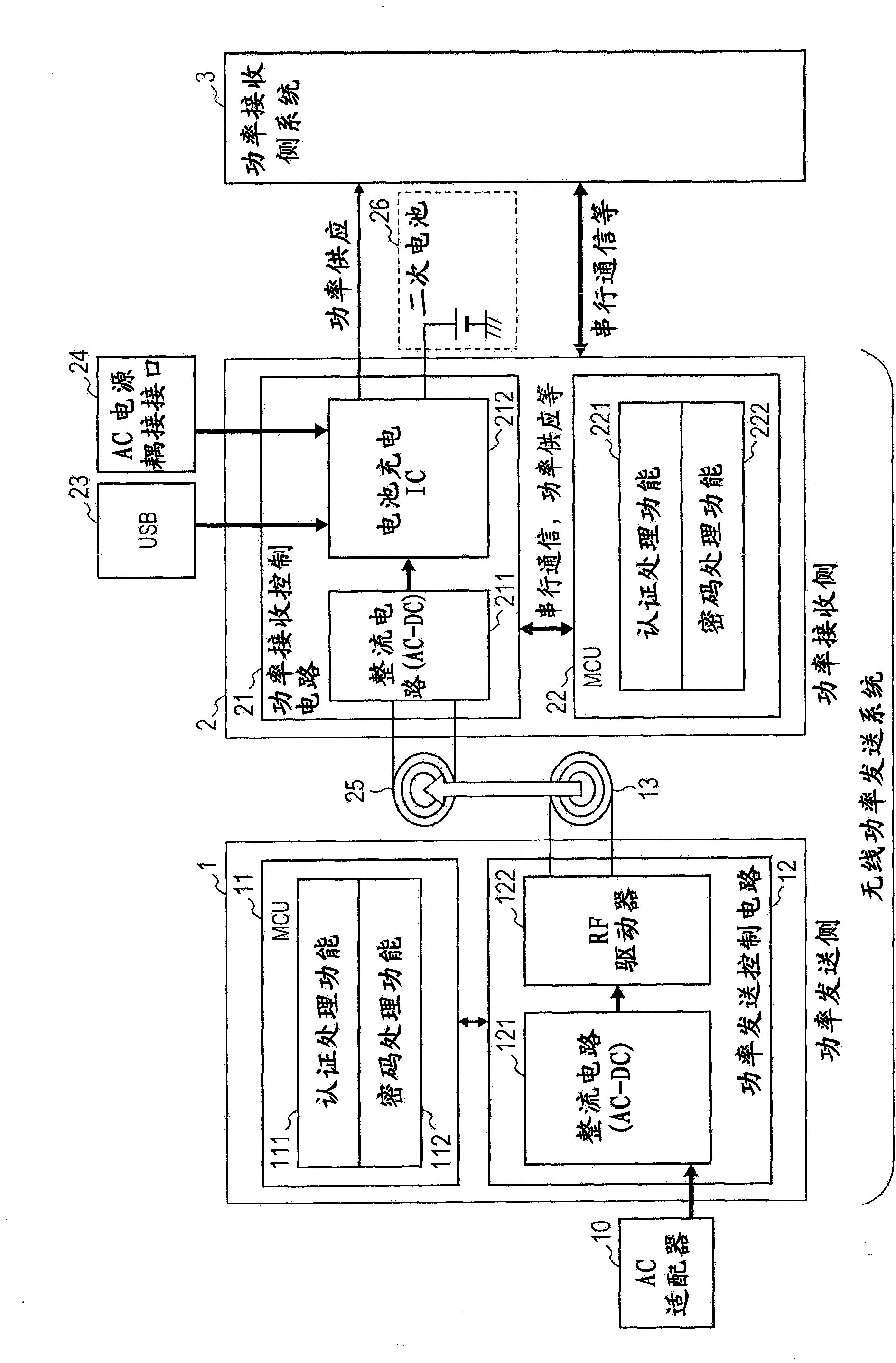

Movable terminal, NFC device supporting a plurality of SIM cards and implementation method

ActiveCN101639890AImplement automatic selectionAchieve connectionSensing record carriersWireless communicationData connectionData information

The invention discloses an NFC device supporting a plurality of SIM cards, comprising an NFC chip, an SWP switch and a main control module. The NFC chip is used for establishing data connection with an external card-reading device and acquiring data information including operator identifications supported by the card-reading device; the SWP switch is used for connecting one of a plurality of SIM cards to the NFC chip; and the main control module is used for controlling the SWP switch to select an operator SIM card supported by the card-reading device according to the operator identifications supported by the card-reading device and connecting the NFC chip with the SIM card. The invention also discloses an NFC implementation method supporting a plurality of SIM cards and a mobile terminal,decreases the cost by only using one NFC chip and automatically selects the SIM card connected with the NFC chip according to the acquired operator identifications supported by the card-reading device.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

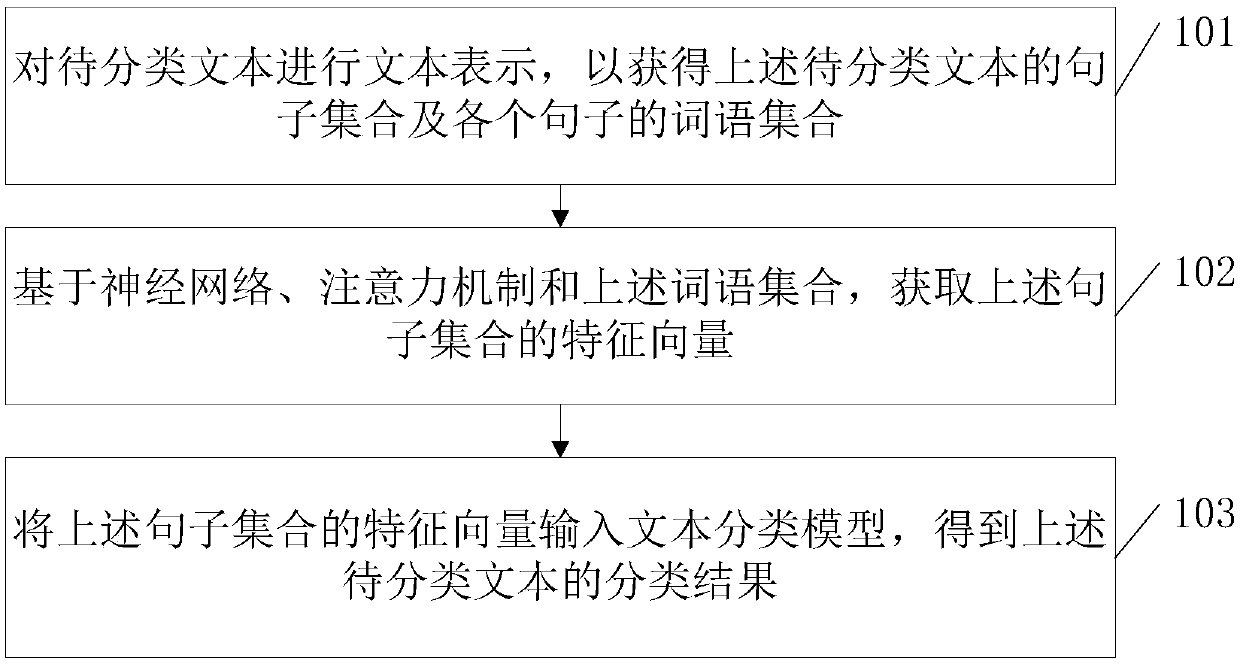

Text classification method, text classification device and computer readable storage medium

PendingCN110209806AImprove classification efficiencyImplement automatic selectionCharacter and pattern recognitionNatural language data processingFeature vectorNatural language processing

The invention provides a text classification method, a text classification device and a computer readable storage medium. The text classification method comprises the steps that text representation isconducted on a to-be-classified text to obtain a sentence set of the to-be-classified text, the sentence set is composed of word sets of all sentences in the to-be-classified text, and the word setsare composed of word vectors of words contained in corresponding sentences; based on a neural network, an attention mechanism and the word set, a feature vector of the sentence set is obtained; and the feature vectors of the sentence set is input into a text classification model to obtain a classification result of the to-be-classified text. According to the technical scheme, the text classification efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

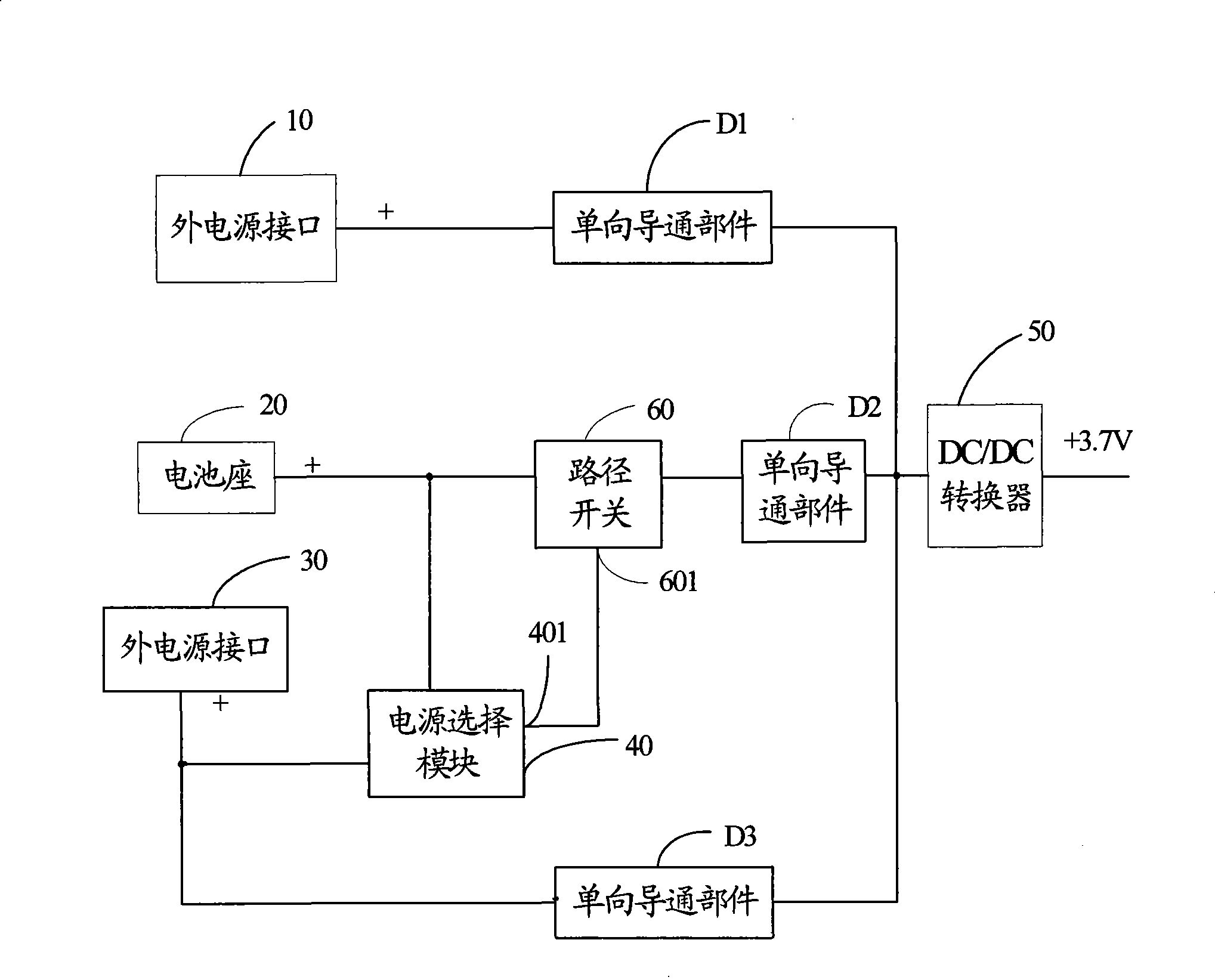

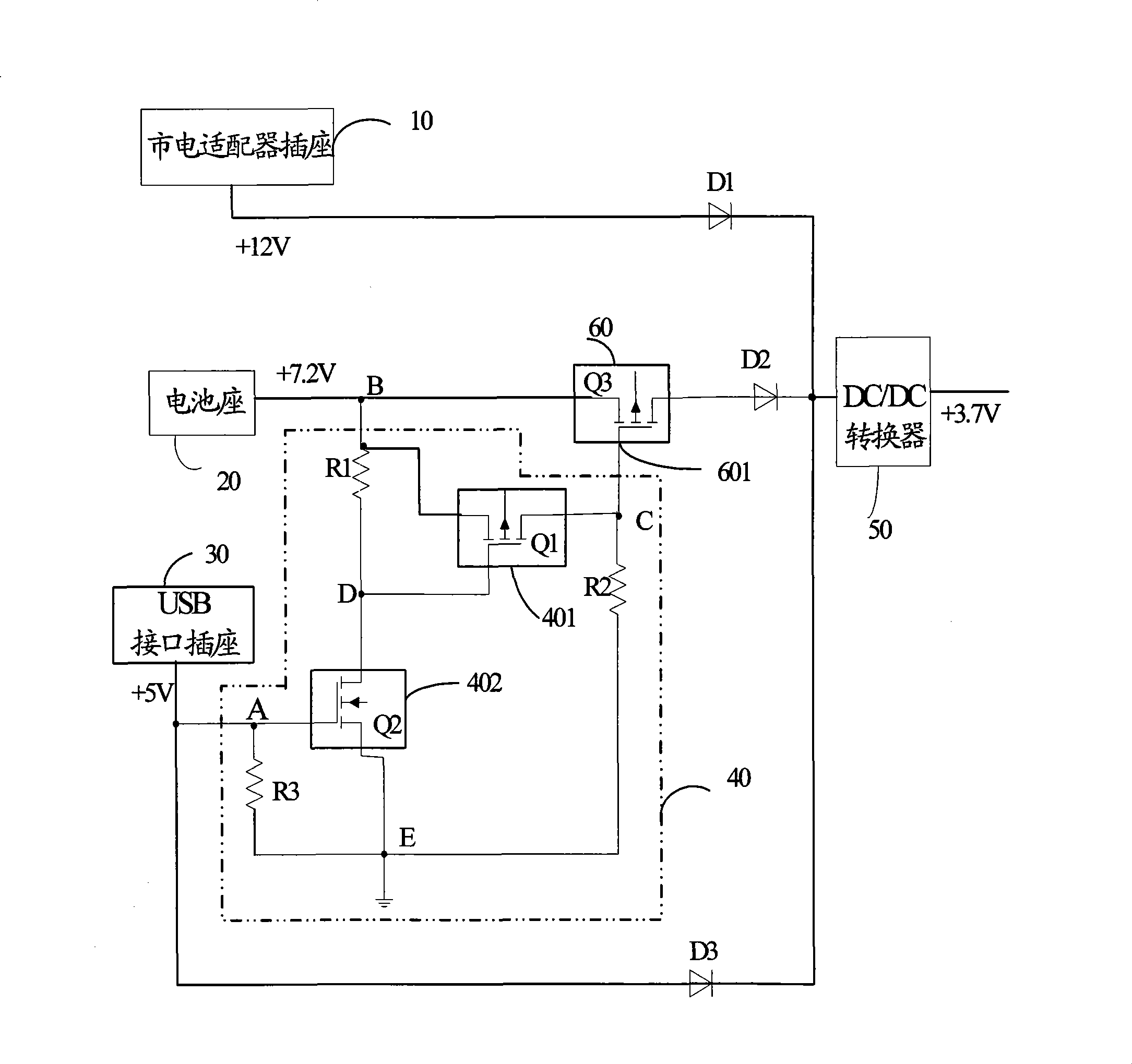

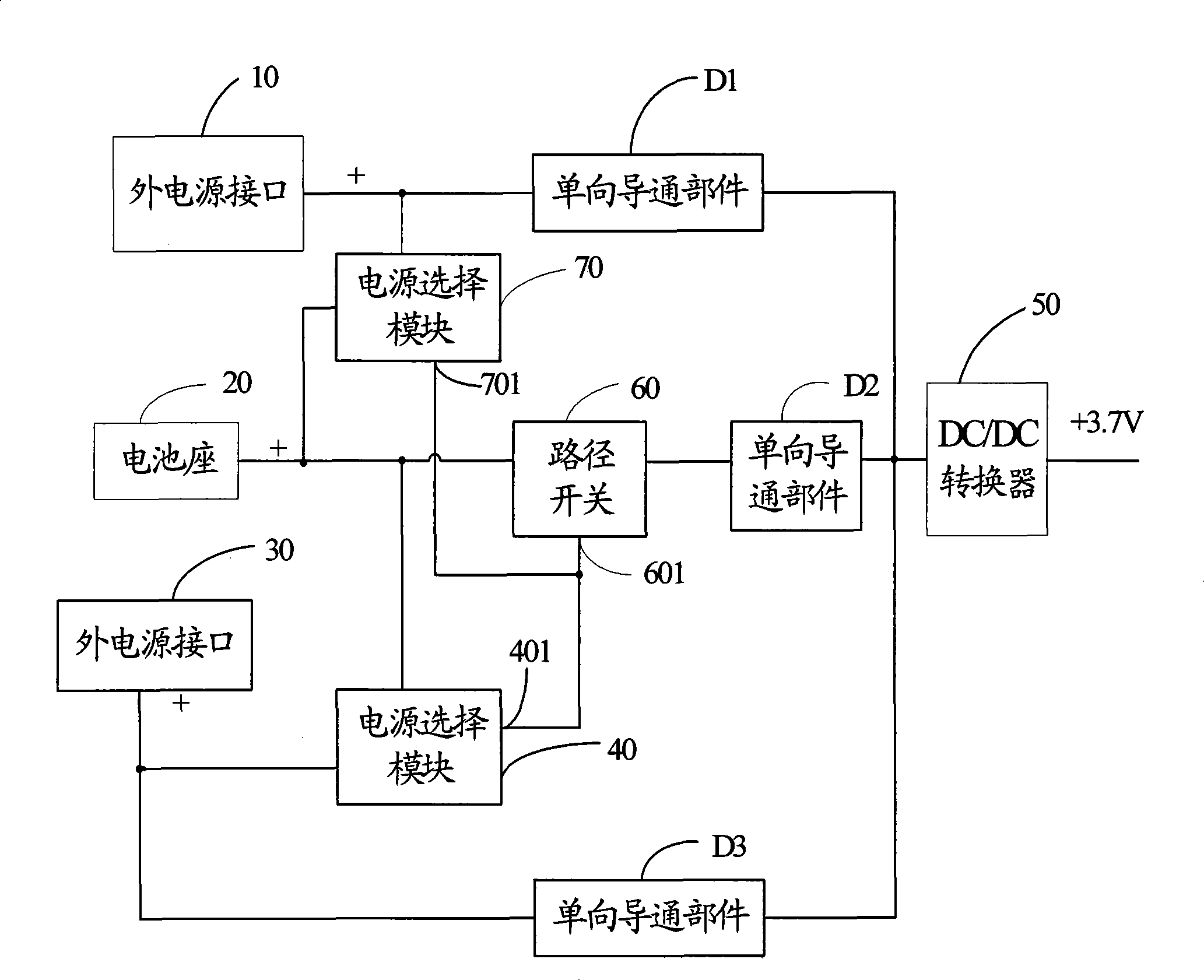

Electronic apparatus capable of automatically choosing power supply source

InactiveCN101364745AImplement automatic selectionElectric signal transmission systemsDc network circuit arrangementsLow voltageCell voltage

An electronic device capable of automatically selecting power supplies can automatically select a power supply from a plurality of power supplies to supply power to the electronic device. Three optional power supplies include one internal battery and two external power supplies, wherein the two external power supplies can be a DC power supply converted from a city power supply by an adapter and an interface power supply or other external power supplies. The battery voltage is larger than the voltage at least one of the external power supplies, and a power selection module is arranged between the interface of the external power supply having a voltage smaller than the battery voltage and the battery. Three one-way conduction components are respectively arranged in the output paths of the voltage positive electrode ends of the three power supplies, wherein a path switch is also arranged between the voltage positive electrode end of the battery and the one-way conduction components. Through the action of the one-way conduction components, the power selection module and the path switch, the three power supplies can be selected in the following sequence: the external power supply with higher voltage, the external power supply with lower voltage and the internal battery.

Owner:PENGZHI TECH SHENZHEN +1

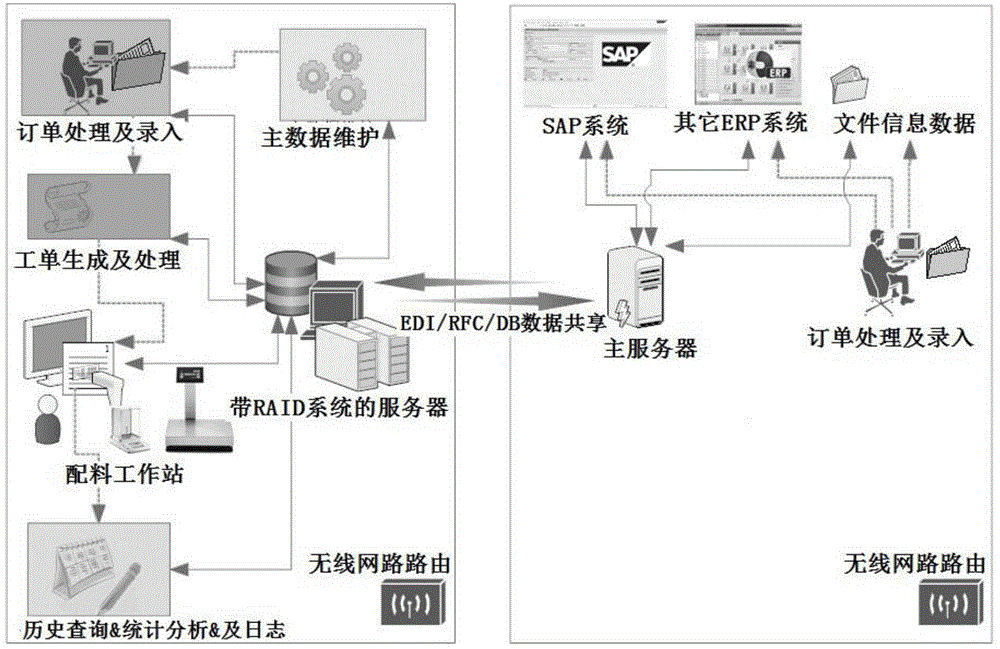

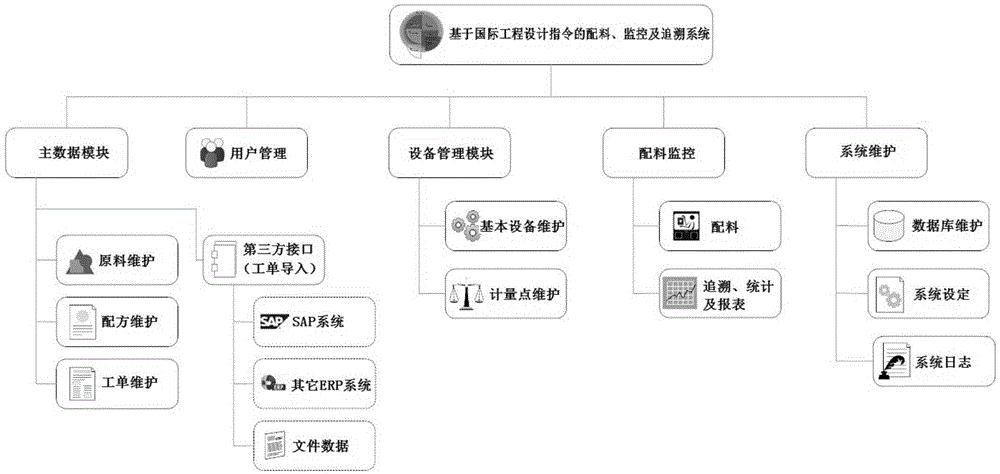

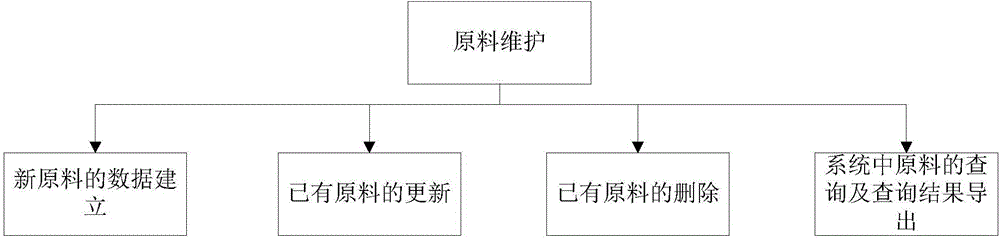

Batching monitoring and tracing method and system

ActiveCN104484730APut an end to multiple configurationsPut an end to less matchingResourcesData retrievalStatistical analysis

The invention discloses a batching monitoring and tracing method and system. The method has the following steps: data maintenance; order processing and recording; work order generation and processing; batching: providing work metering points, metering equipment initialization and automatic configuration, and automatic selection, work order taking and displaying, current raw material positioning and selection, raw material metering and automatic data recording, selecting metering point information or obtaining the metering point information through scanning bar codes, and taking work orders / batching sheets from a database; and history query, statistic analysis and log report outputting, which is used for historical metering data retrieval and displaying, and analyzing consumption amount of each raw material, consumption amount of raw materials in a preset time period and actual consumption amount of each raw material in a set work order. The batching monitoring and tracing method and system help to maintain ingredient data safely and conveniently, prevent various possible non-safety factors appearing in the raw material batching process, and realize data traceability in the whole process from system operation to the end.

Owner:SHANDONG JIANZHU UNIV

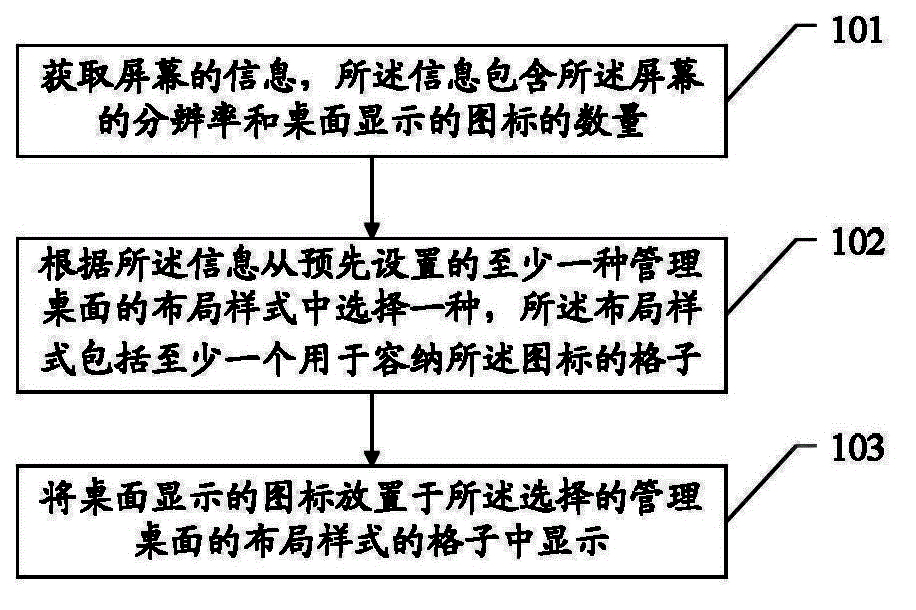

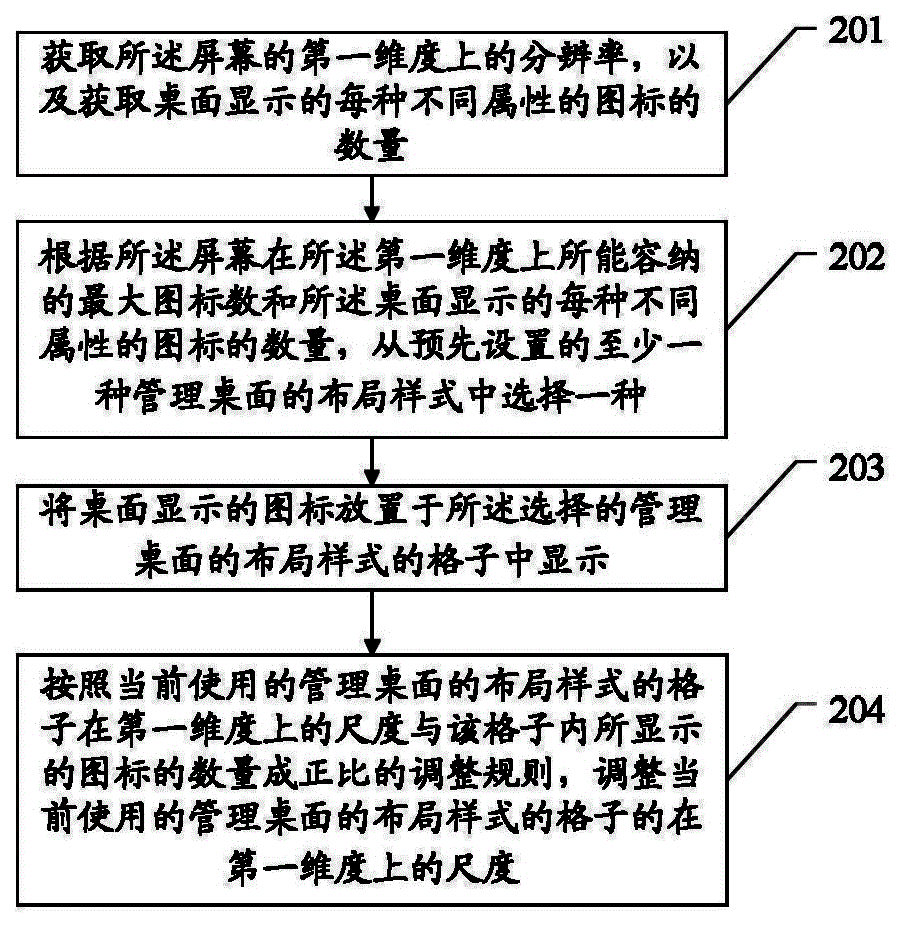

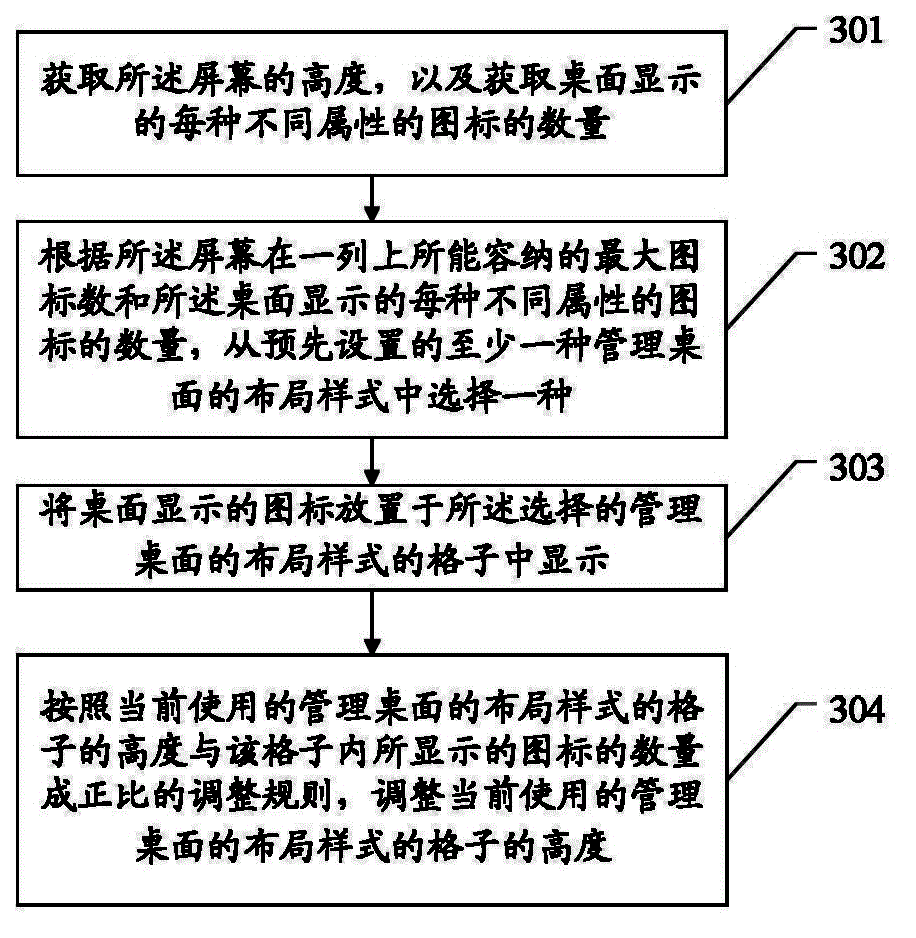

Desktop management method and terminal device

ActiveCN103941958AIntelligent managementImplement automatic selectionInput/output processes for data processingImage resolutionTerminal equipment

The embodiment of the invention discloses a desktop management method which includes the steps that information of a screen is obtained, wherein the information comprises the resolution ratio of the screen and the number of icons displayed on a desktop; according to the information, one layout style is selected from at least one preset layout styles used for managing the desktop, wherein the layout styles comprise at least one cell used for containing the icons; placing the icons displayed on the desktop in the cell of the selected layout style used for managing the desktop for display. Correspondingly, the invention further discloses a terminal device. By means of the method and the terminal device, the icons displayed on the desktop can be intelligently managed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

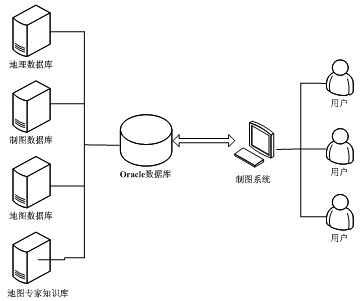

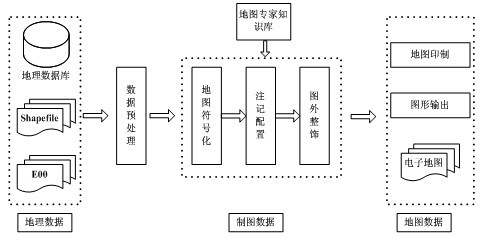

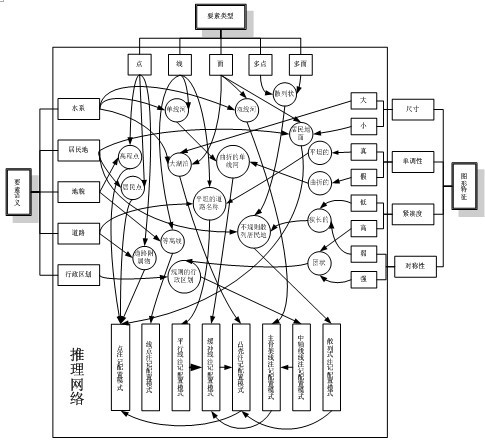

A Method for Automatic Classification and Configuration of Map Annotation Based on Visual Variables

InactiveCN102289991AImprove annotation automationQuality improvementMaps/plans/chartsGraphicsVision based

The invention relates to a visual-variable-based automatic classification and configuration method of map lettering, comprising the steps of: customizing a map lettering configuration rule base; inputting geographic data and carrying out mapping expression on the geographic data; calculating graphical symbol variable of single feature element; and matching the rules in the lettering configurationrule base, selecting a lettering configuration mode and finishing classification and configuration of the map lettering. In the visual-variable-based automatic classification and configuration method, the map lettering configuration is divided into seven basic configuration modes according to the substitutive characteristics and the configuration rule requirements of the feature elements needing to be lettered in the national basic scale topographic map, and simultaneously, the expansion and the combined use of the lettering configuration modes are supported; and the map lettering configuration model which is simple and is easy to realize is provided, so that automatic selection of the map lettering configuration modes in mapping of a computer map can be realized. In the visual-variable-based automatic classification and configuration method, the selection problem of lettering configuration modes of the example-level feature elements is solved, and the lettering automation level and the lettering quality in the national basic scale topographic map are improved.

Owner:WUHAN UNIV

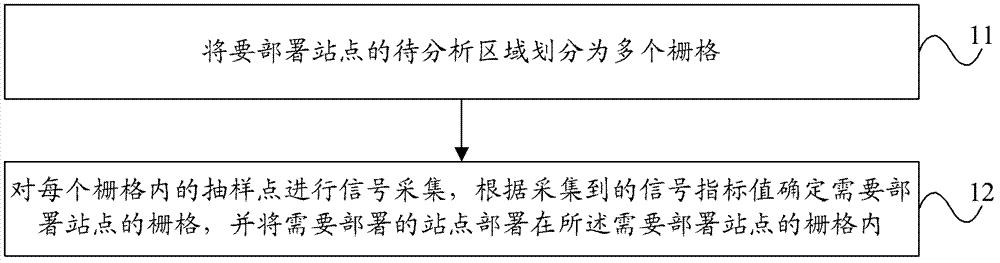

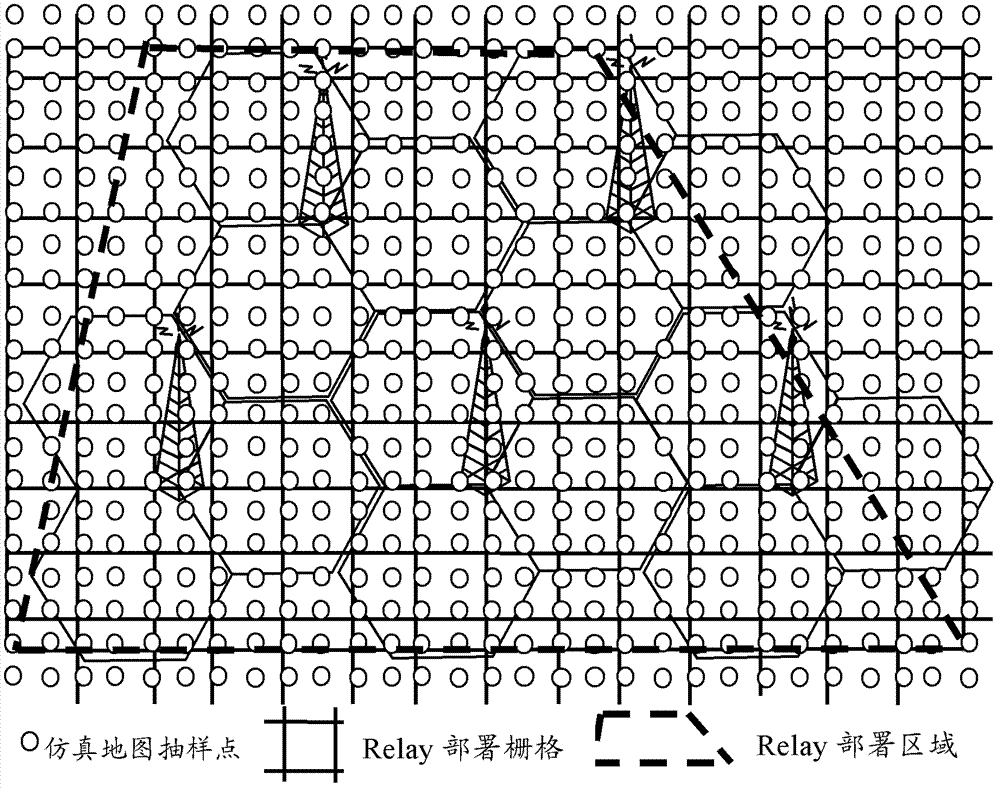

Selection method and equipment of site locations and selection method and equipment of grids

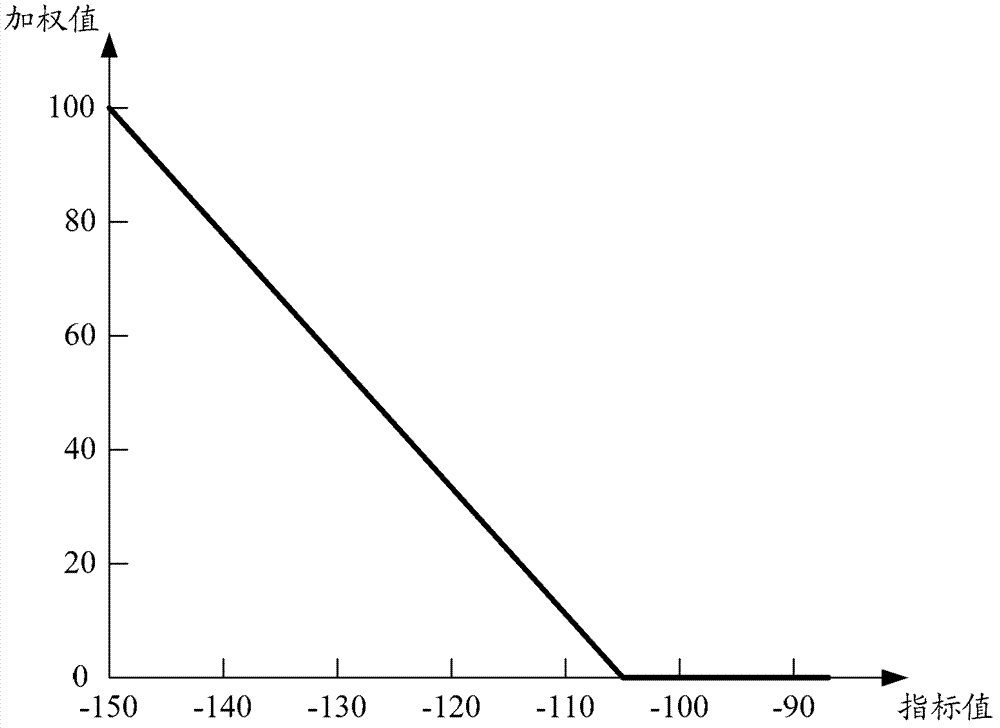

ActiveCN103118369AImplement automatic selectionAssess restrictionNetwork planningSite locationEngineering

The invention provides a selection method and equipment of site locations, and a selection method and equipment of grids. The method comprises the steps that a to-be-analyzed area in which the site locations are arranged is divided into a plurality of grids, signal sampling is carried out on sampling points in each grid, the grids which need the site locations to be arranged are confirmed according to collected signal index values, and the site locations needing to be arranged are arranged in the grids which need the site locations to be arranged. The selection method and the equipment of the site locations, and the selection method and the equipment of the grids can achieve automatic selection of the site locations.

Owner:HUAWEI TECH CO LTD

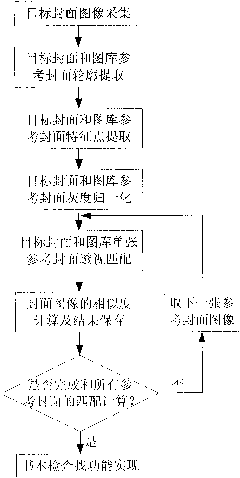

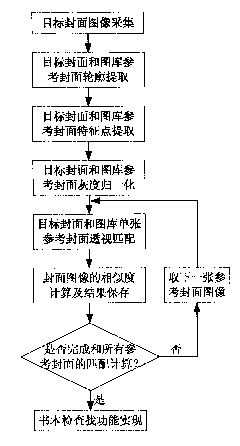

Book lookup method based on perspective transformation for video point reading machine

InactiveCN101799828AEliminate distractionsImplement the lookup functionCharacter and pattern recognitionElectrical appliancesComputer graphics (images)Perspective transformation

The invention discloses a book lookup method based on perspective transformation for a video point reading machine, which includes the following steps: 1) collecting single frame of a book cover picture at real time through a video camera and inputting the picture to a microprocessor; 2) respectively picking up the book cover edge contours of a target cover and reference cover pictures in an picture gallery; 3) respectively picking up the characteristic points of the target cover and the reference covers in the picture gallery by using the edge contours of the book covers; 4) normalizing the gray scales of the target cover and the reference covers in the picture gallery; 5) conducting perspective matching to the target cover and the reference cover pictures in the picture gallery; 6) calculating to work out the similarity between the target cover and each reference cover picture in the picture gallery; and 7) realizing the book lookup method based on perspective transformation for the video point reading machine. The book lookup method has the advantages that the book lookup method based on perspective transformation is simple and practical and realizes automatic selection of the books in the point reading machine.

Owner:NANCHANG HANGKONG UNIVERSITY

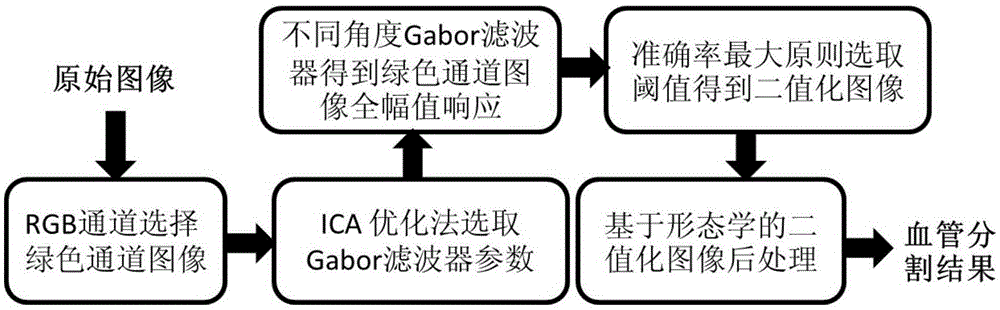

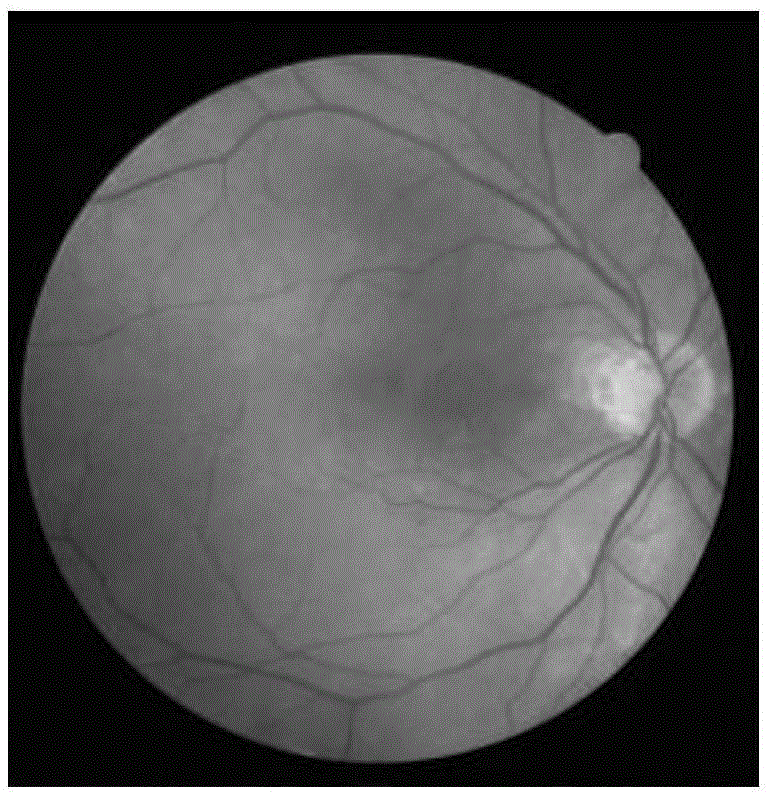

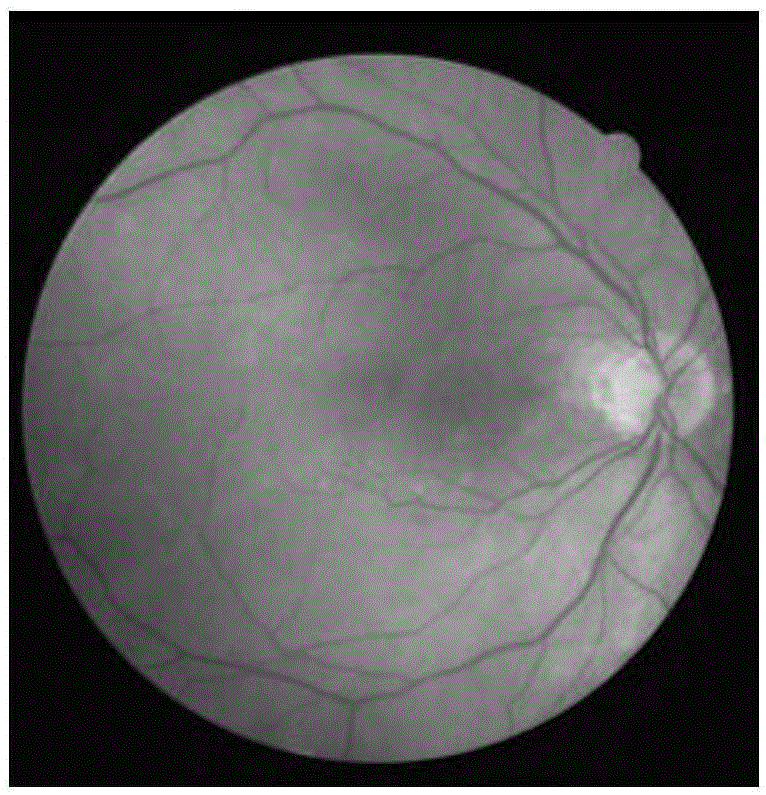

Automatic eyeground image blood vessel segmentation method based on Gabor filters

InactiveCN105261015AImplement automatic selectionImprove accuracyImage enhancementImage analysisMorphological processingAutomatic threshold

The invention relates to an automatic eyeground image blood vessel segmentation method based on Gabor filters. The method comprises steps that, as a segmentation result is guaranteed to be valid, the direction of the filter is effectively reduced, automatic selection for filter parameters and a threshold is realized, a green channel image having the optimum blood vessel contrast is firstly selected before a pre-processing stage, an eyeground image blood vessel edge is roughly extracted by utilizing 20 Gabor filters having different angles, the largest response of the filters is taken as the rough positioning position of a blood vessel, during filter parameter selection, the optimized ICA algorithm is introduced to realize automatic parameter selection, during binary threshold selection, on the basis of largest accuracy principle, automatic threshold selection is realized, and an image mask acquired through morphological processing is utilized to remove a false positive area of the segmentation edge to acquire the final blood vessel segmentation result.

Owner:BEIJING UNIV OF TECH

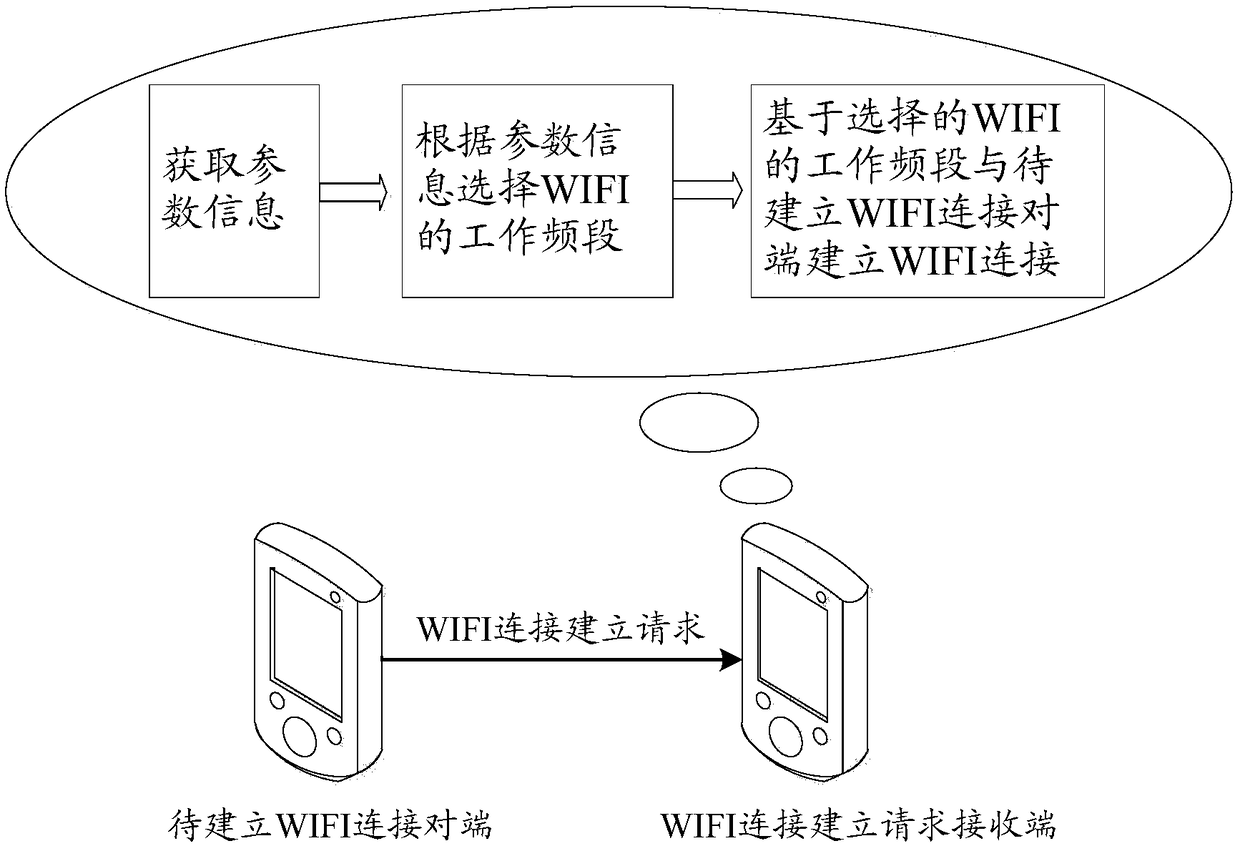

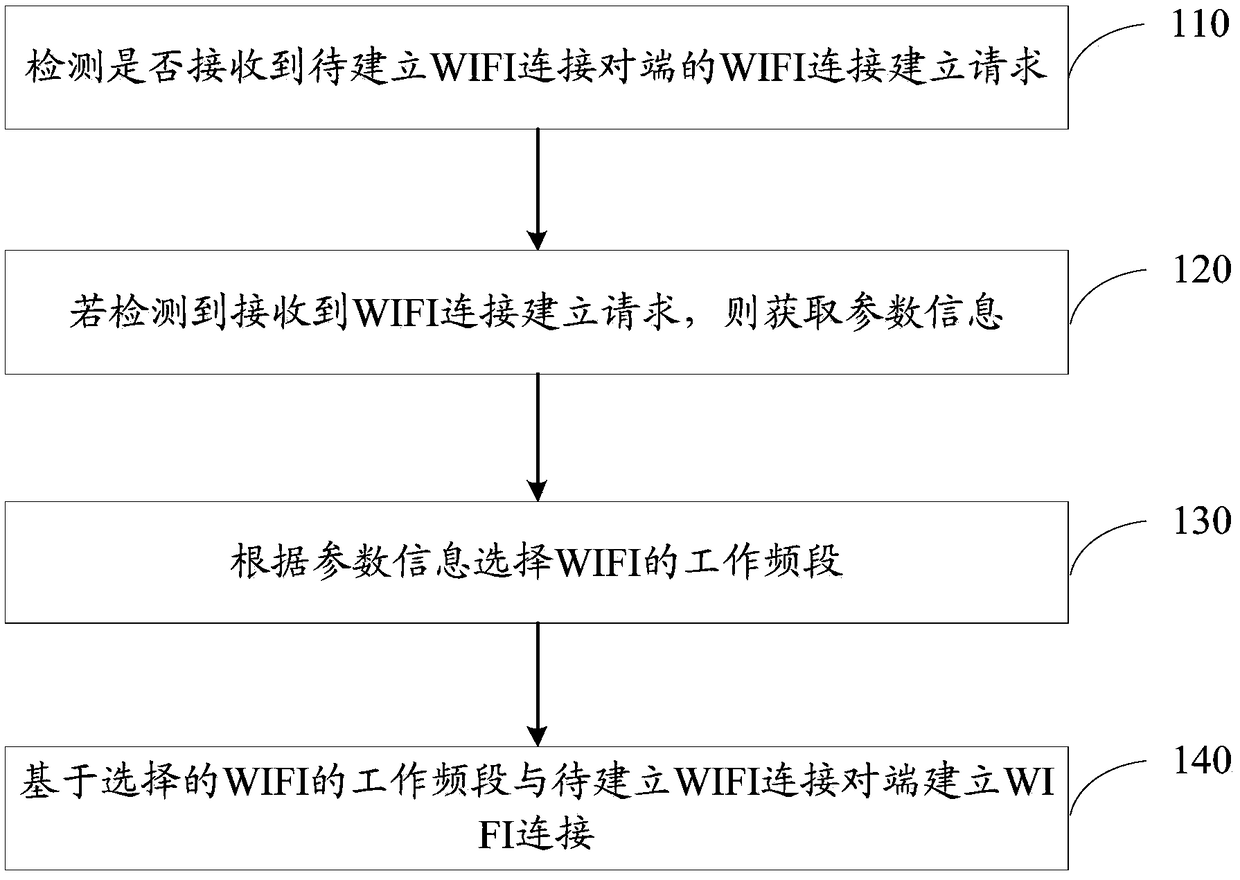

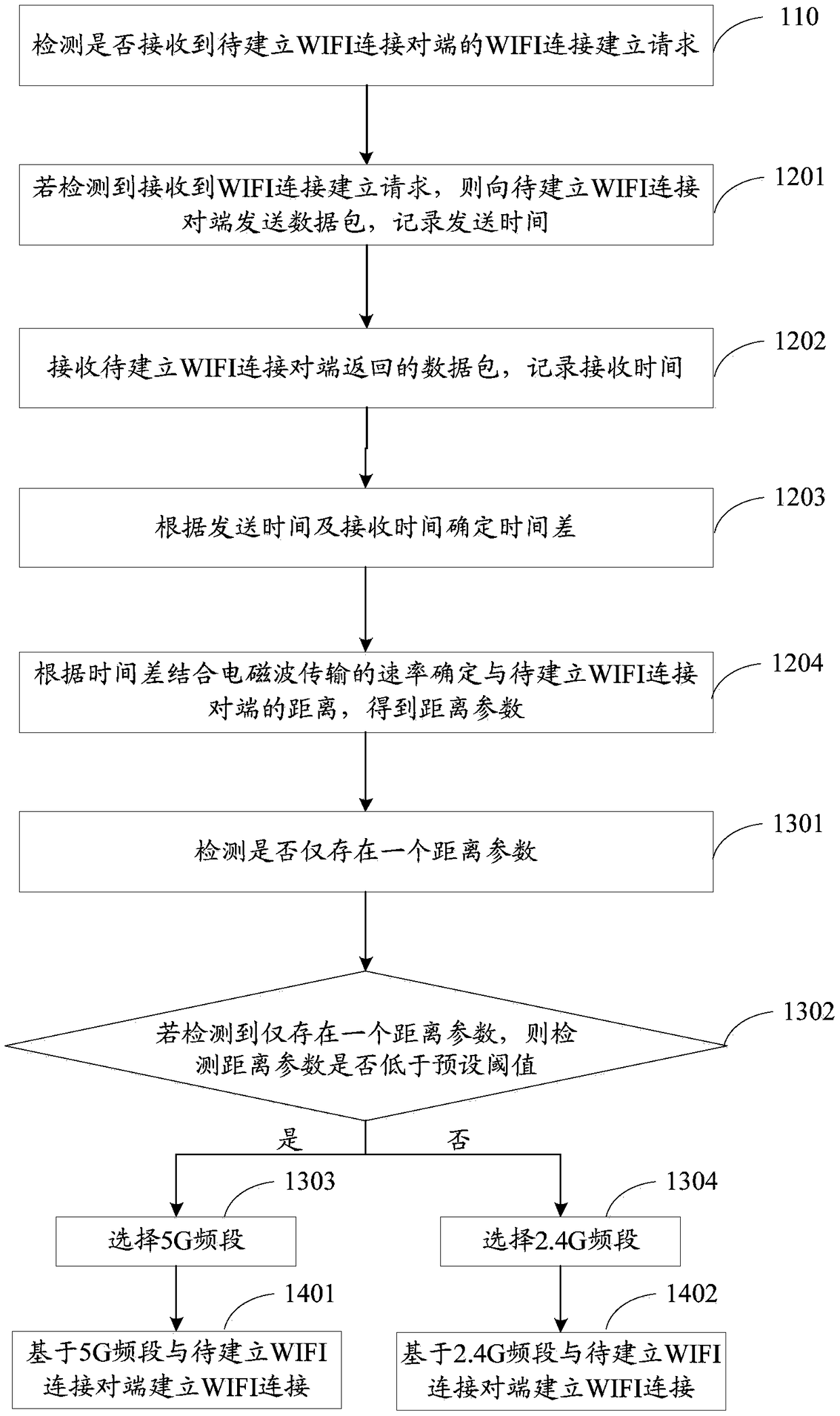

WIFI band selection method and device, memory medium and electronic equipment

ActiveCN108770068AImplement automatic selectionIncrease flexibilityConnection managementElectric equipmentEmbedded system

The invention discloses a WIFI band selection method and device, a memory medium and electronic equipment. The method comprises the steps of detecting whether a WIFI connection establishment request of an opposite end with to-be-established WIFI connection is received or not; obtaining parameter information if it is detected that the WIFI connection establishment request is received; selecting a WIFI working band according to the parameter information, wherein the WIFI working band comprises a 2.4G band and a 5G band; and establishing WIFI connection with the opposite end with the to-be-established WIFI connection, based on the selected WIFI working band. The WIFI working band can be automatically selected according to the parameter information, the WIFI band is automatically selected, andthe WIFI band selection flexibility is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

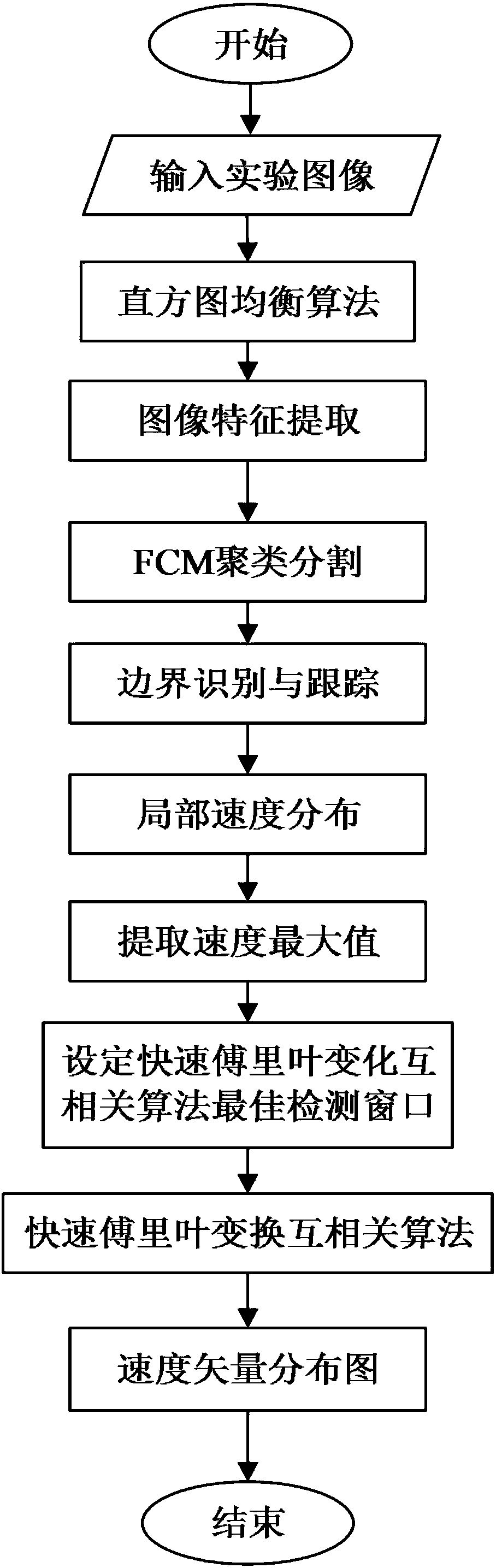

Turbulent boundary layer flow field velocity measurement method based on boundary tracing

ActiveCN107705318AImprove efficiencyLow costImage enhancementImage analysisSingle phaseHistogram equalization

The invention provides a turbulent boundary layer flow field velocity measurement method based on boundary tracing and belongs to the field of fluid computing. The method is used for acquiring velocity vector distribution of turbulent boundary layer fluid with hydrogen bubbles being tracing particles under a single-phase condition. The method comprises the steps that a hydrogen bubble image is acquired through a special experimental facility, the obtained experimental image is subjected to image input processing, processing through a histogram equalization algorithm, image feature extraction processing, FCM cluster partitioning processing, boundary recognition and tracking processing, local velocity distribution processing, velocity maximum value extraction processing, setting of an optimal detection window of a fast Fourier transformation cross-correlation algorithm, processing through the fast Fourier transformation cross-correlation algorithm, velocity vector distribution processingand other processing processes in sequence, and finally the velocity vector distribution is obtained. The method is simple, easy to implement, high in application value, high in operability and convenient to realize; and quantitative analysis is performed on a large-scale structure existing in a turbulent boundary layer, and the blank of quantitative research about a turbulent boundary layer quasi-order structure with the hydrogen bubbles being the tracing particles is filled up.

Owner:HARBIN ENG UNIV

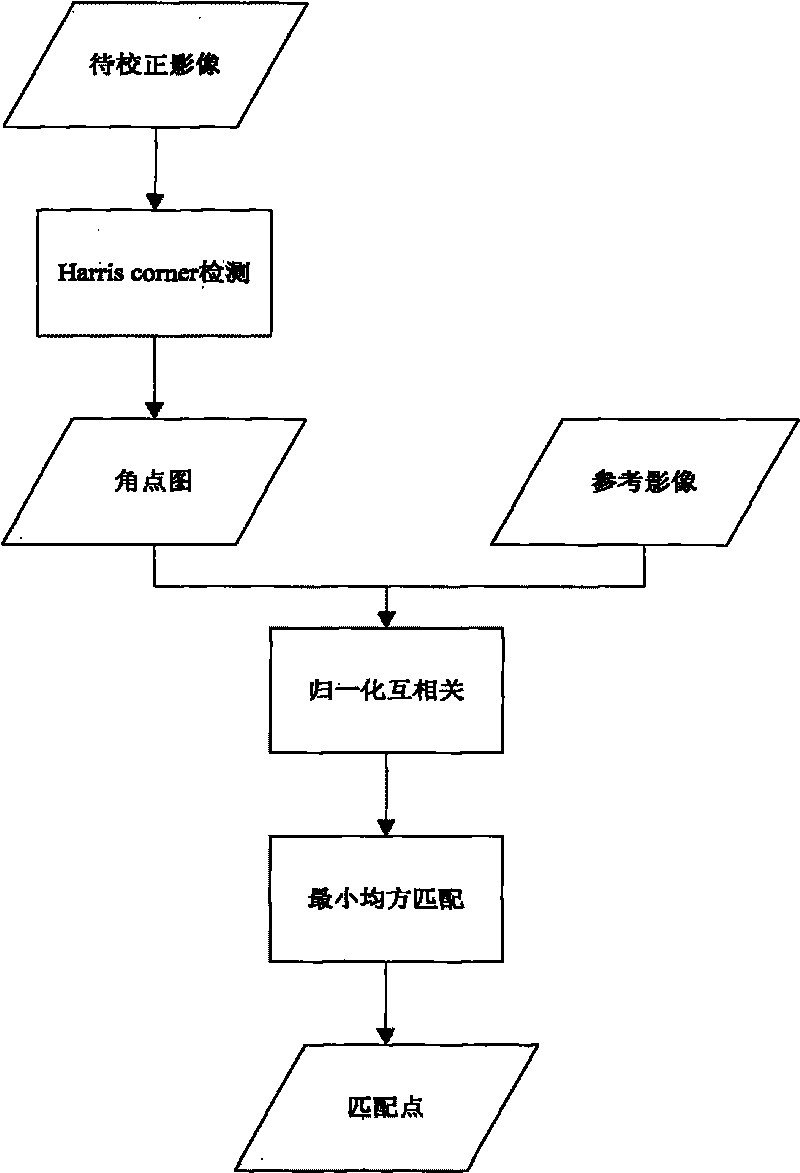

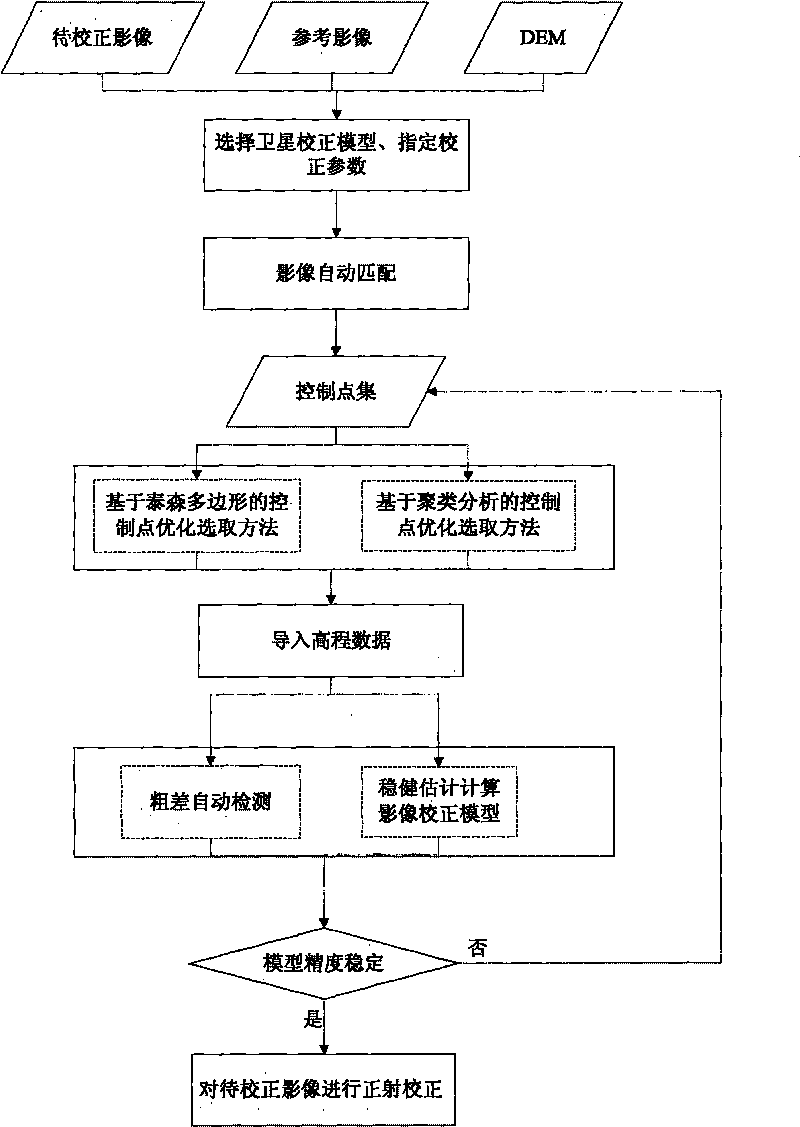

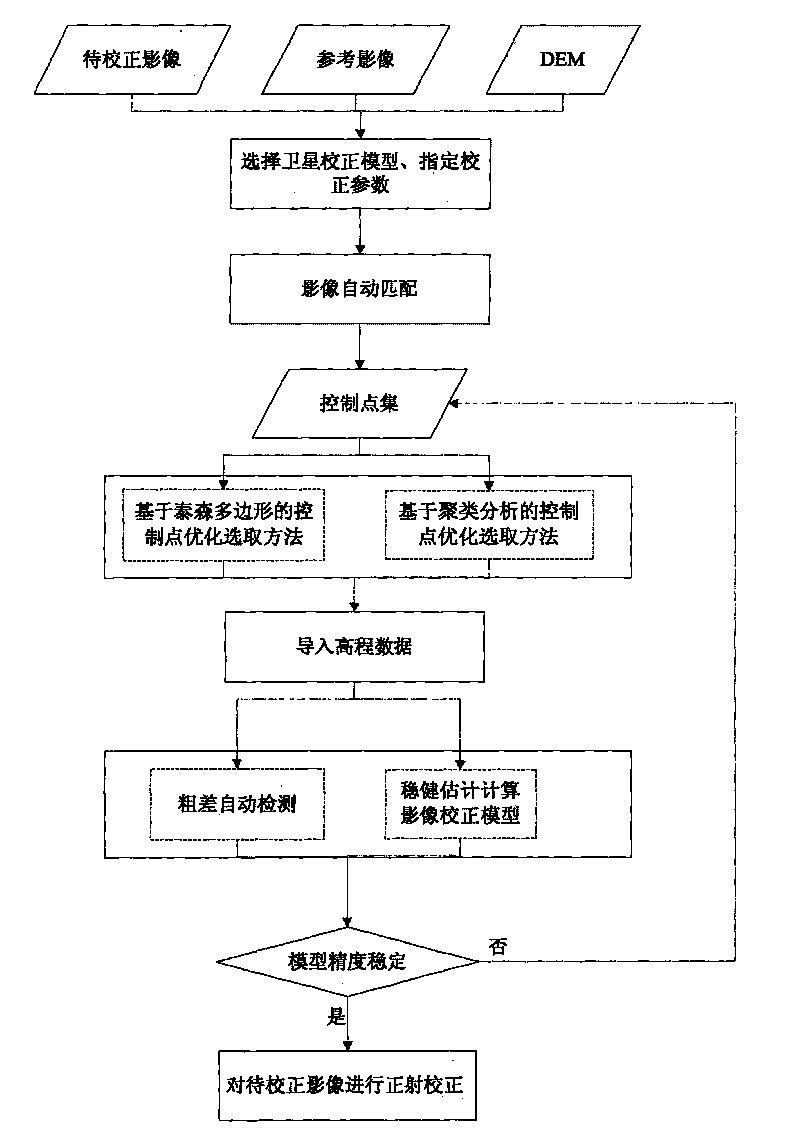

Automatic and moderate orthographic projection correction method of satellite remote sensing image

ActiveCN101750606AIncrease the level of automationImprove calibration accuracyWave based measurement systemsCorrection methodComputer science

Owner:CENT FOR EARTH OBSERVATION & DIGITAL EARTH CHINESE ACADEMY OF SCI

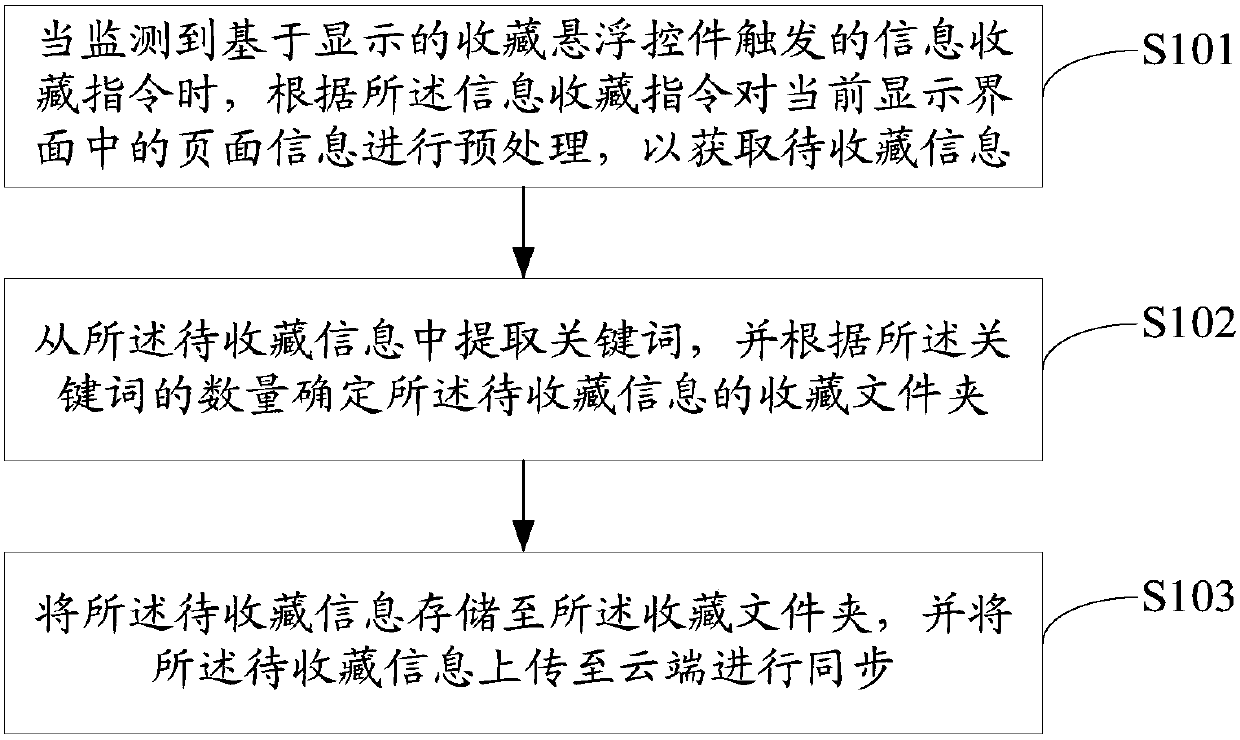

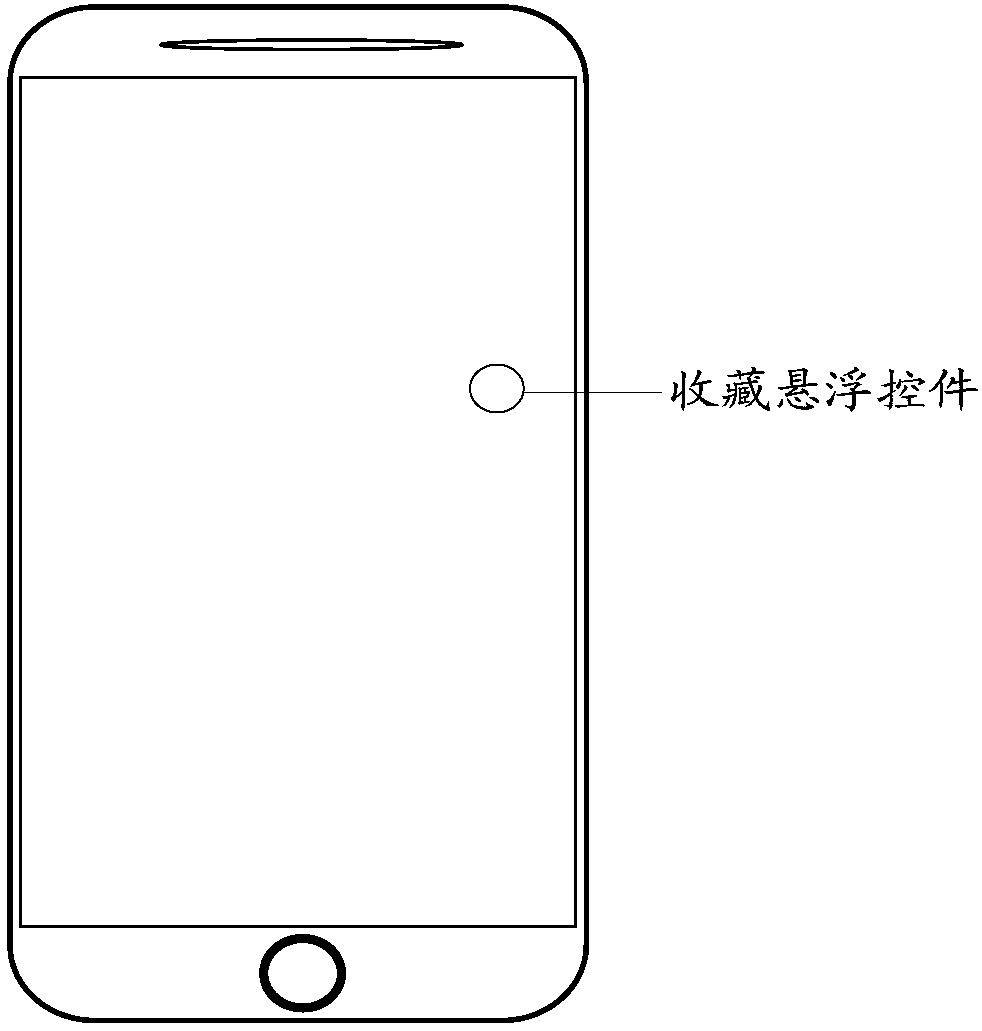

Information collection method, mobile terminal and computer readable storage medium

ActiveCN107657045ACollection realizedImplement automatic selectionSpecial data processing applicationsInput/output processes for data processingInformation storageWeb page

Owner:NUBIA TECHNOLOGY CO LTD

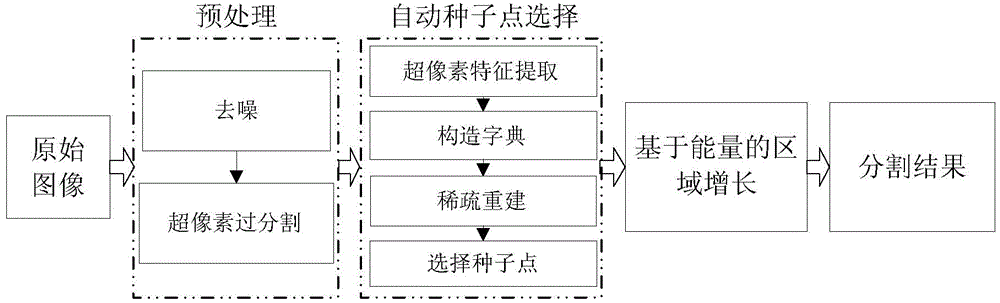

Region growth ultrasound image automation segmentation method based on energy constraint

ActiveCN104915950AThe segmentation result is accurateReduce computationUltrasonic/sonic/infrasonic diagnosticsImage enhancementSonificationFeature extraction

The invention discloses a region growth ultrasound image automation segmentation method based on energy constraint. The method comprises the following steps: (1) preprocessing is performed on an original ultrasound image, (2) automatic selection of a seed point is performed on the ultrasound image after the preprocessing, and (3) the seed point obtained in the step (2) is used to be taken as a start point of region growth, constrained growth is performed under an energy function, the growth stops when a constraint condition is reached, and then a final segmentation result is obtained. The obtained segmentation result is accurate, the segmentation process needs no artificial participation, fully automatic ultrasound image segmentation is really achieved, and subsequent processing such as focal region characteristic extraction is facilitated.

Owner:SOUTH CHINA UNIV OF TECH

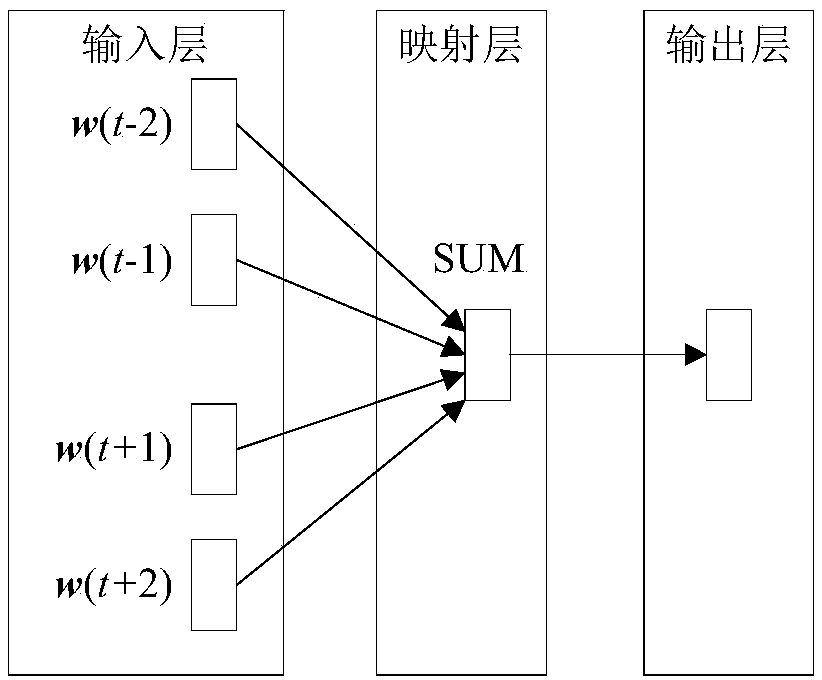

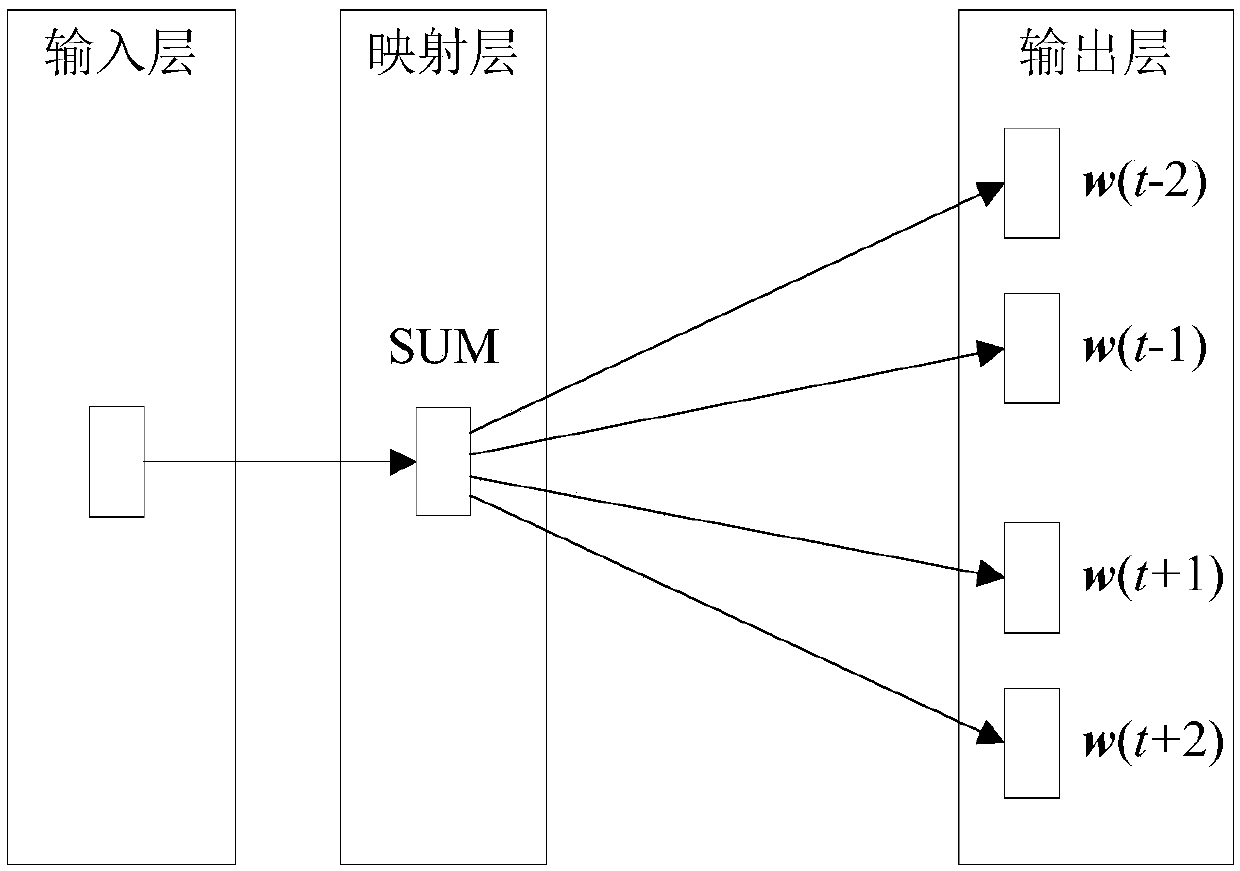

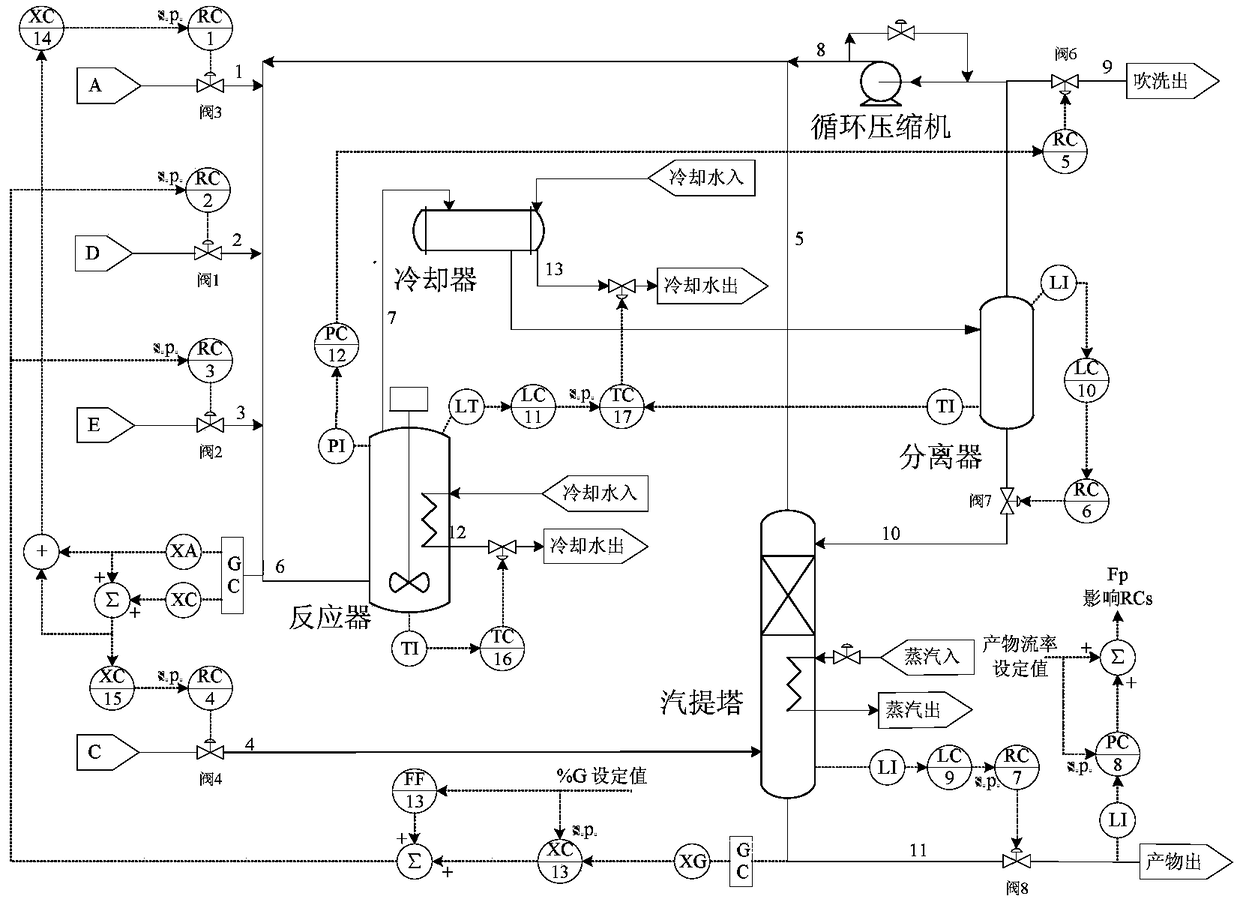

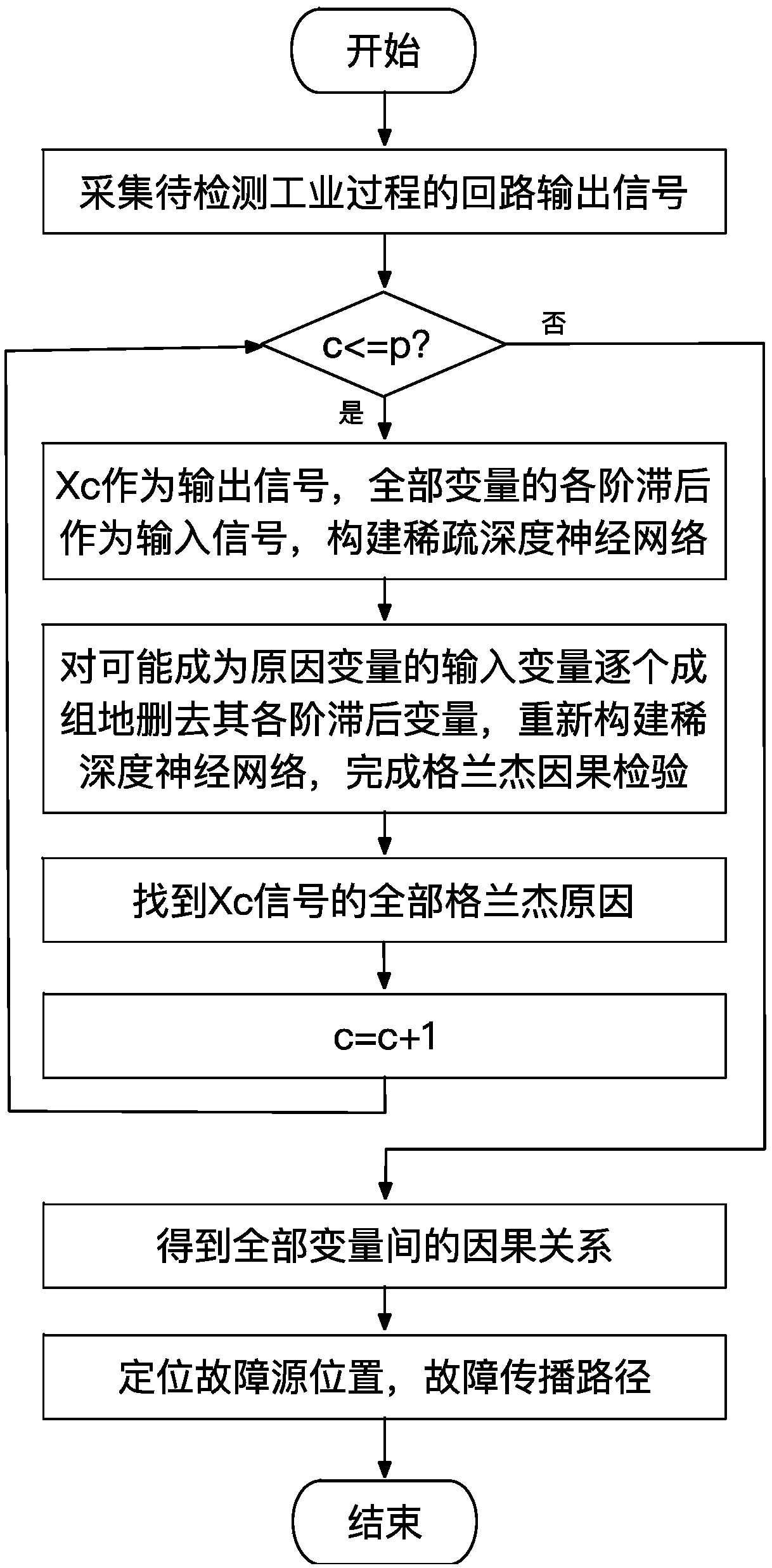

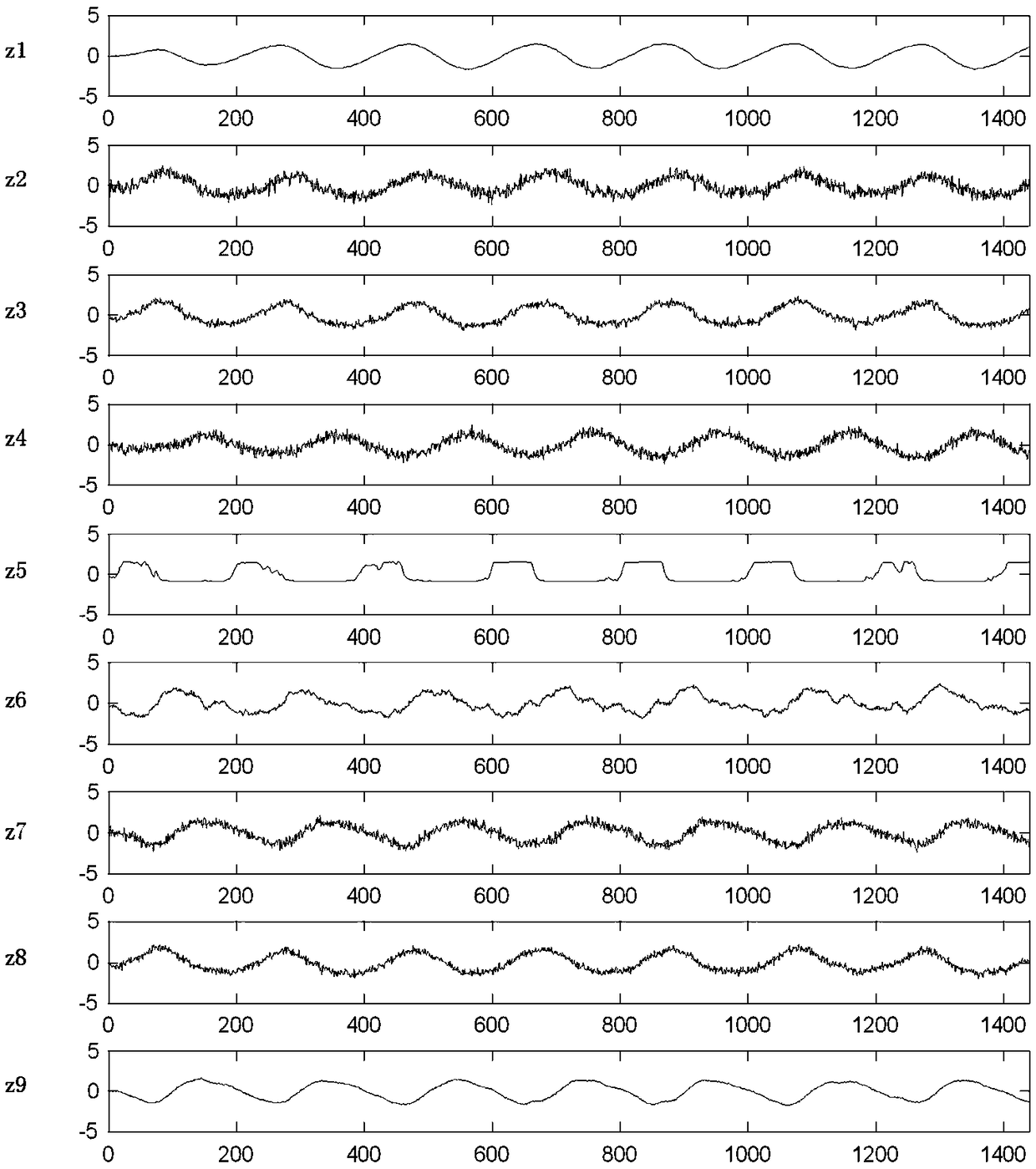

Industrial data nonlinear cause and effect analysis method based on sparse deep neural network

ActiveCN109407654AReduce the number of inspectionsImplement automatic selectionProgramme controlElectric testing/monitoringArtificial intelligenceData mining

The invention discloses an industrial data nonlinear cause and effect analysis method based on a sparse deep neural network. The method comprises the following steps of (1) collecting the process output signals of all control loops in an industrial process to be detected; (2) selecting one process output signal as an output variable and taking each order lag of all variables as an input variable to construct the sparse deep neural network; (3) through successively deleting the input variables, completing Granger causality testing one by one, and acquiring all the Granger causes of the output signal of the process; (4) repeating the steps (2) and (3), and acquiring a causal relationship among the output signals of all the process; and (5) integrating the causal relationship among the outputsignals of all the process, and positioning a fault source location and fault propagation path. In the invention, nonlinear causal analysis can be performed on the control loop signal of the industrial process, and fault source positioning and fault propagation path analysis are completed.

Owner:ZHONGDIAN HUACHUANG ELECTRIC POWER TECH RES

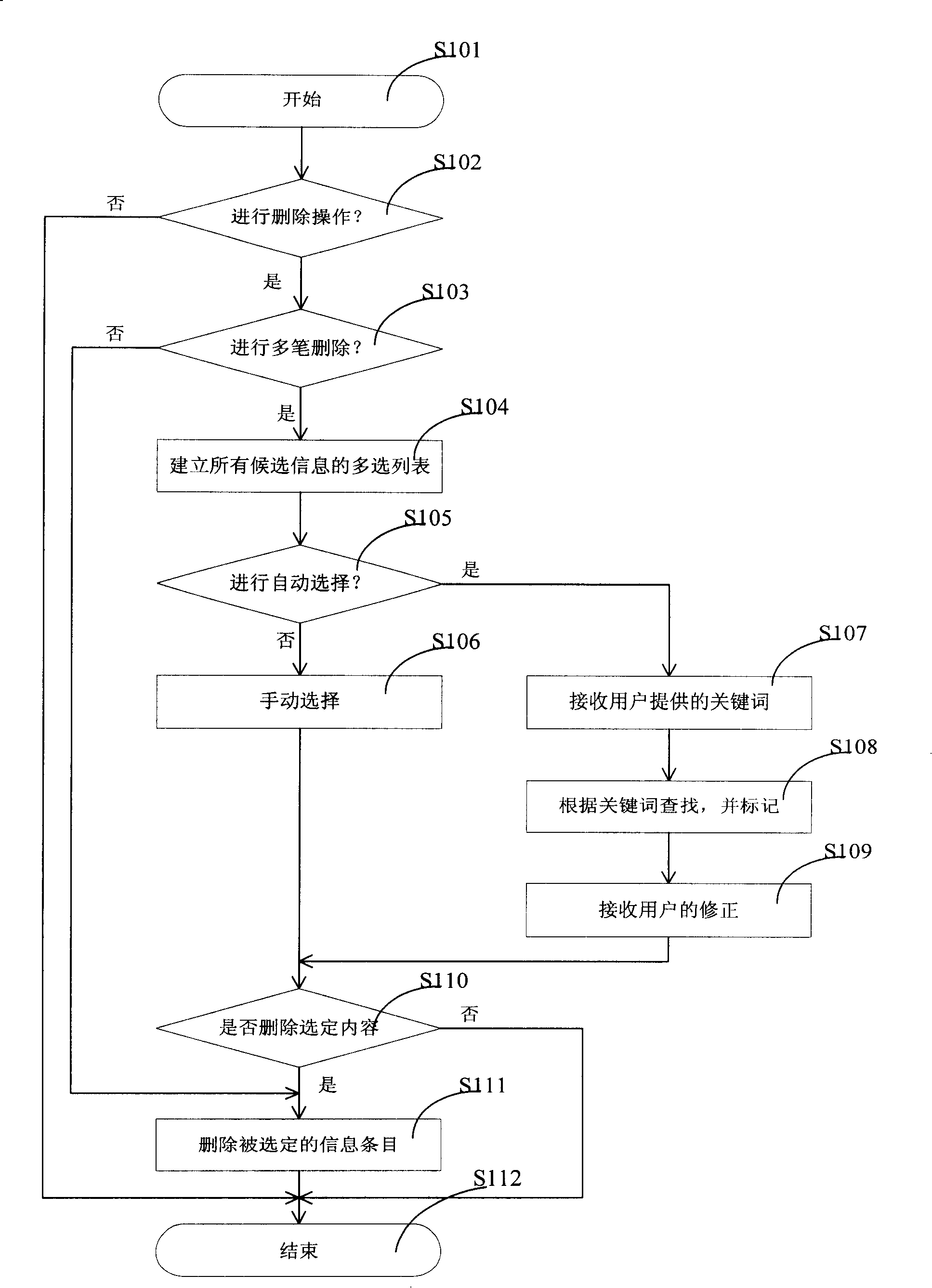

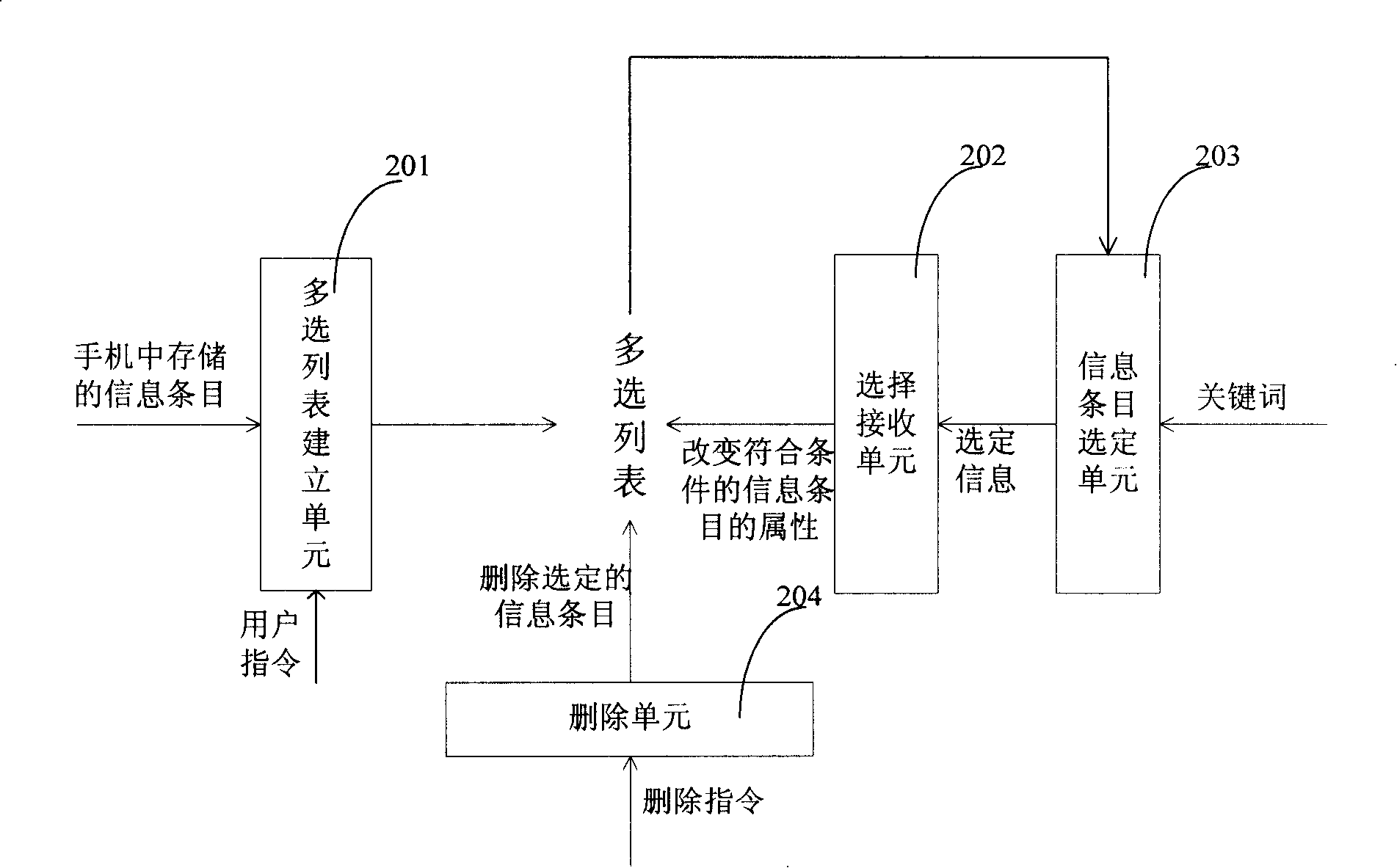

Method and device for clearing mobile telephone data entries

InactiveCN101212736AImplement automatic selectionQuick clean upSubstation equipmentRadio/inductive link selection arrangementsMobile phoneWorld Wide Web

The invention discloses a method for clearing message items of a cell phone, which comprises the following steps: a multi-selection list of all candidate message items is established; a selection or a plurality of selections among the candidate message items in the multi-selection list are received; and all selected message items are deleted according to a deleting instruction. Meanwhile, the invention provides a device for clearing the message items of the cell phone, which comprises a multi-selection list establishing unit that reads the appointed message items stored in the cell phone according to a user instruction, thus forming a multi-selection list that contains all candidate message items; a selecting and receiving unit that receives selected messages of the candidate message items in the multi-selection list and marks the corresponding candidate message items according to the selected messages; a deleting unit that is used for receiving deleting instructions of a user and deleting the selected message items recorded in the multi-selection list according to the deleting instruction. The user can select a plurality of the message items at one time and then wholly delete a plurality of the selected message items by using the method and the device.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

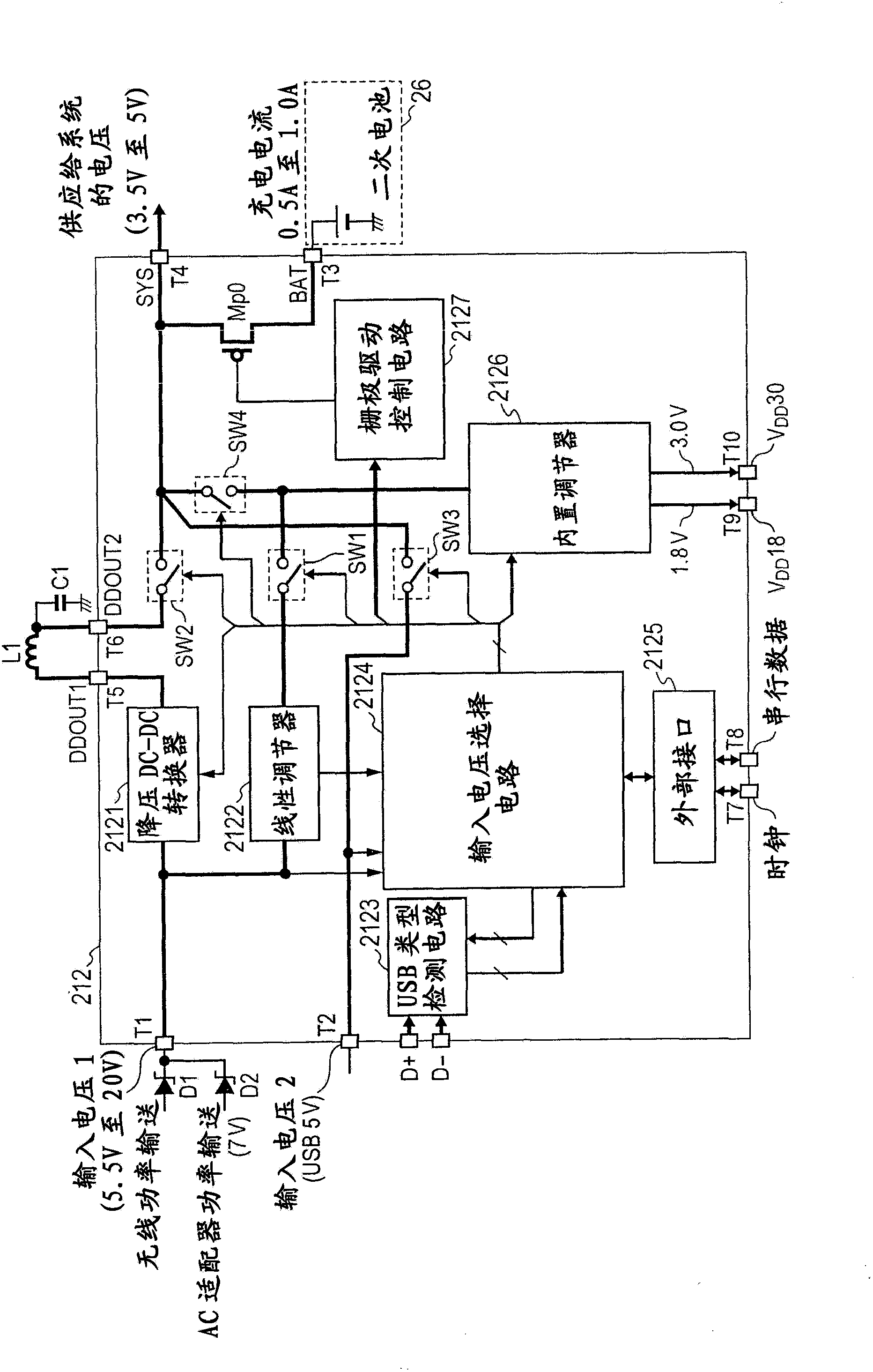

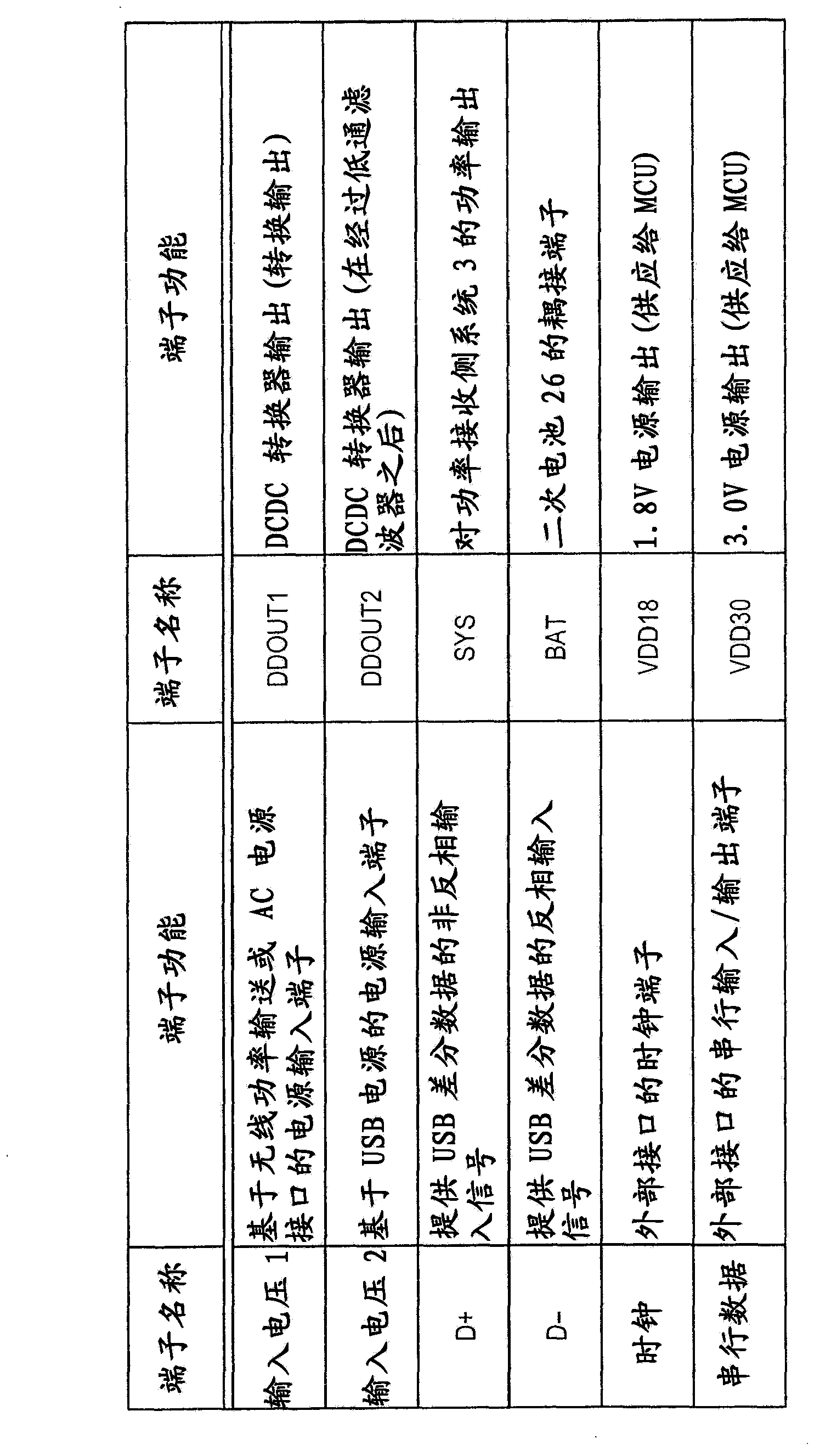

Semiconductor integrated circuit and operating method thereof

InactiveCN103457348AImplement automatic selectionBatteries circuit arrangementsSolid-state devicesPower-on resetPower switching

A semiconductor integrated circuit and its operating method are provided. The present circuit has first and second supply terminals capable of supplying first and second power supply voltages respectively, an input voltage selection circuit coupled to the first and second supply terminals, and first and second power supply switches. The input voltage selection circuit includes a power-on reset circuit, an input voltage detection circuit and a control circuit. When the supply of the first or second power supply voltage to one of both supply terminals is detected upon completion of a power on reset operation, one of both power supply switches and the other thereof are controlled to on and off respectively. When the supply of both power supply voltages to both supply terminals is detected, the one thereof and the other thereof are respectively controlled to on and off according to the preset order of precedence.

Owner:RENESAS ELECTRONICS CORP

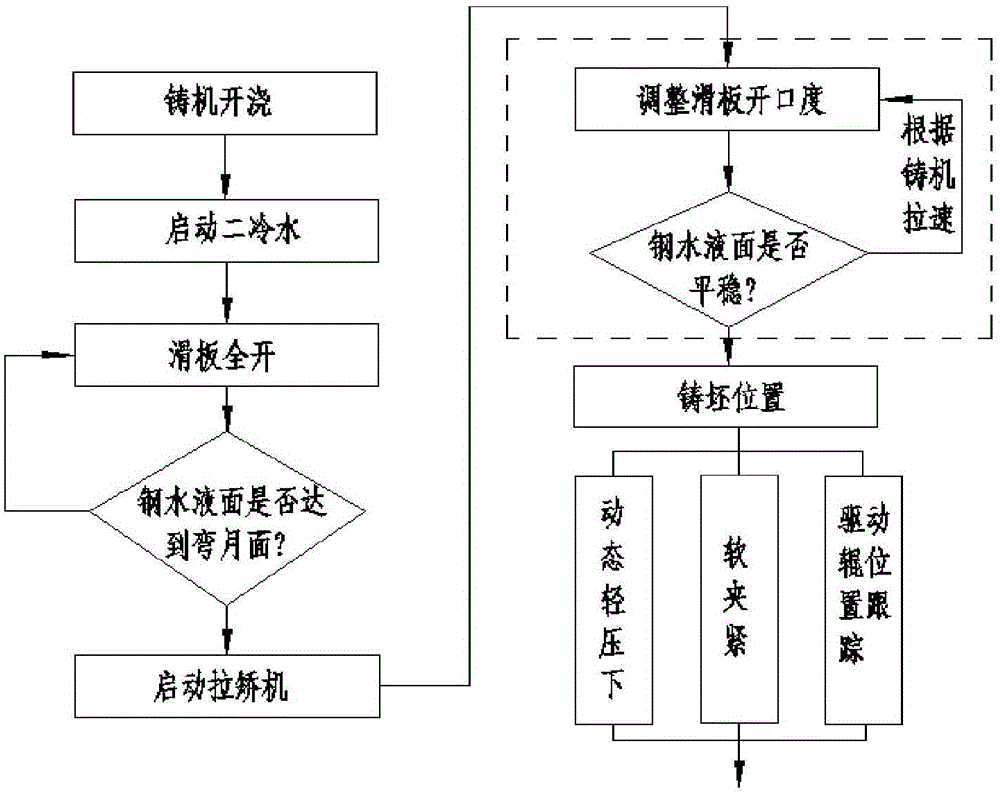

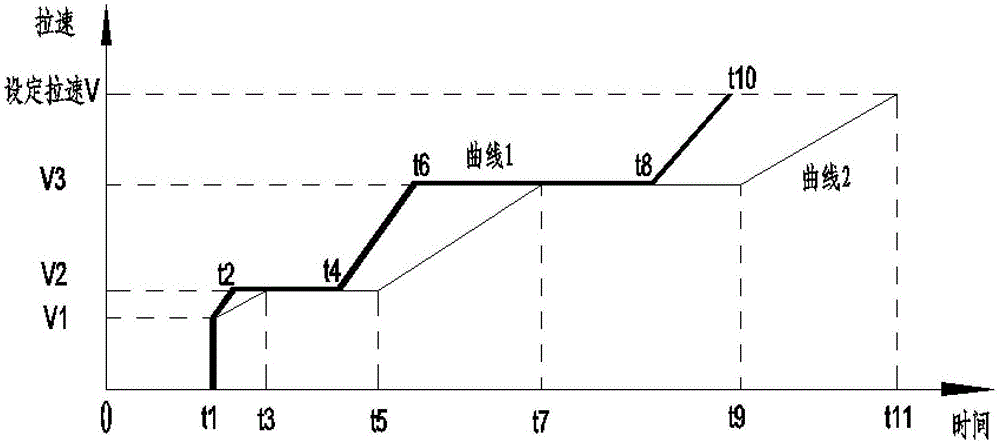

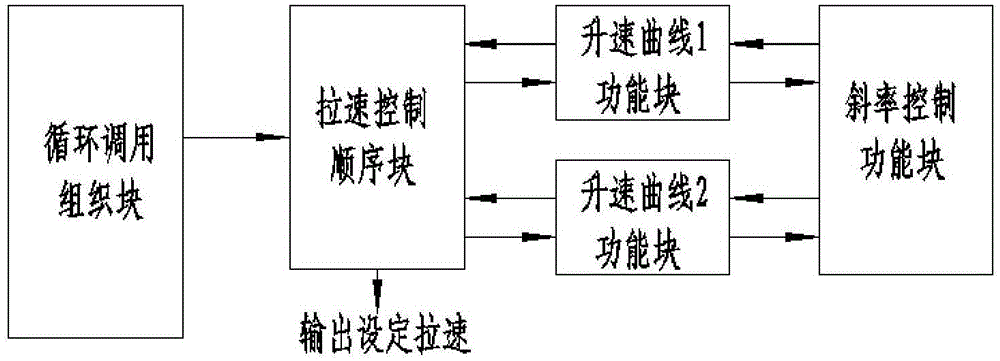

Full-automatic casting method for continuous casting machine

The invention discloses a full-automatic casting method for a continuous casting machine. According to the method, firstly system secondary cooling water is started, a system makes a medium ladle sliding plate fully opened through a liquid control valve so that molten steel can rapidly flow into a crystallizer from the medium ladle, when the molten steel reaches a crescent face, a withdrawal and strengthening machine is automatically started, and meanwhile different withdrawal and strengthening machine raising speeds are selected according to different steel grades, different casting blank fracture surfaces and different molten steel temperatures; and when the molten steel flows out of the crystallizer and after the molten steel forms a blank shell on the surface of the crystallizer, the casting blank position is calculated according to the casting machine pulling speed, a driving roller position tracking system is used for performing lifting control on a driving roller, and the system guarantees the quality in the casting blank casting process through soft clamping, dynamic light pressure and the like. According to the method, by means of match and linkage of continuous casting complete process parameters, full-automatic casting for continuous casting is achieved, and the problems that the manual casting fault rate is high, and the casting blank quality is not stable are solved; and in the control system, the molten steel liquid face can be stably controlled through real-time contrast adjustment of the casting machine pulling speed and the opening degree of the sliding plate

Owner:武汉钢铁有限公司

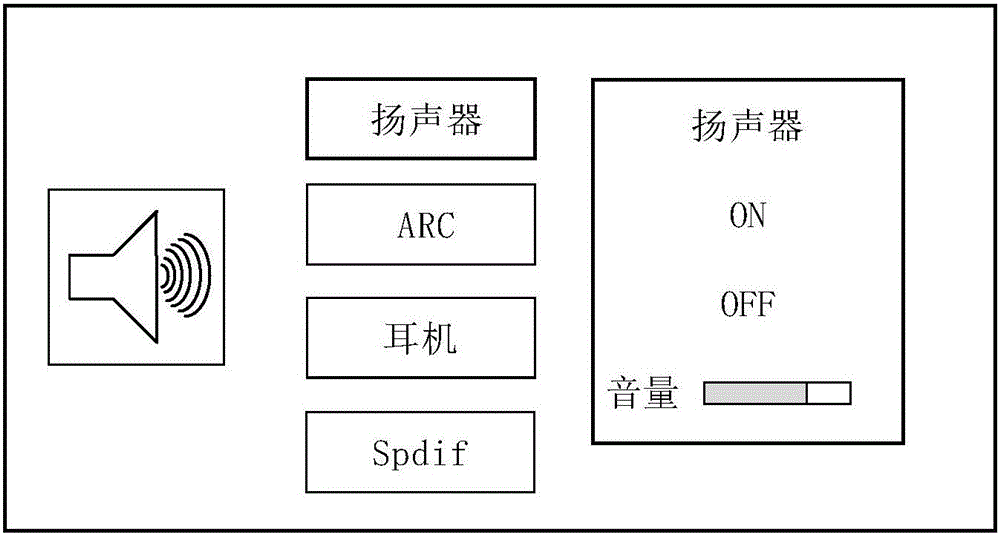

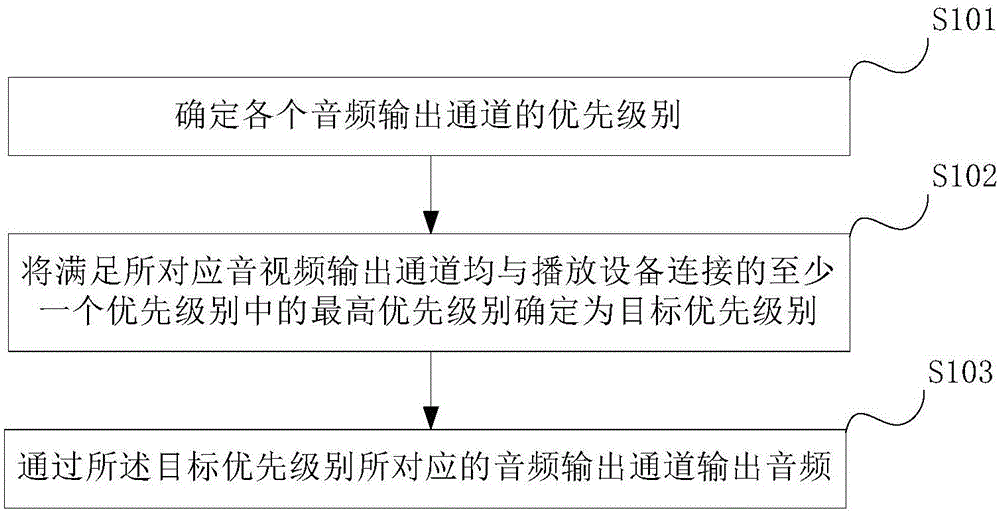

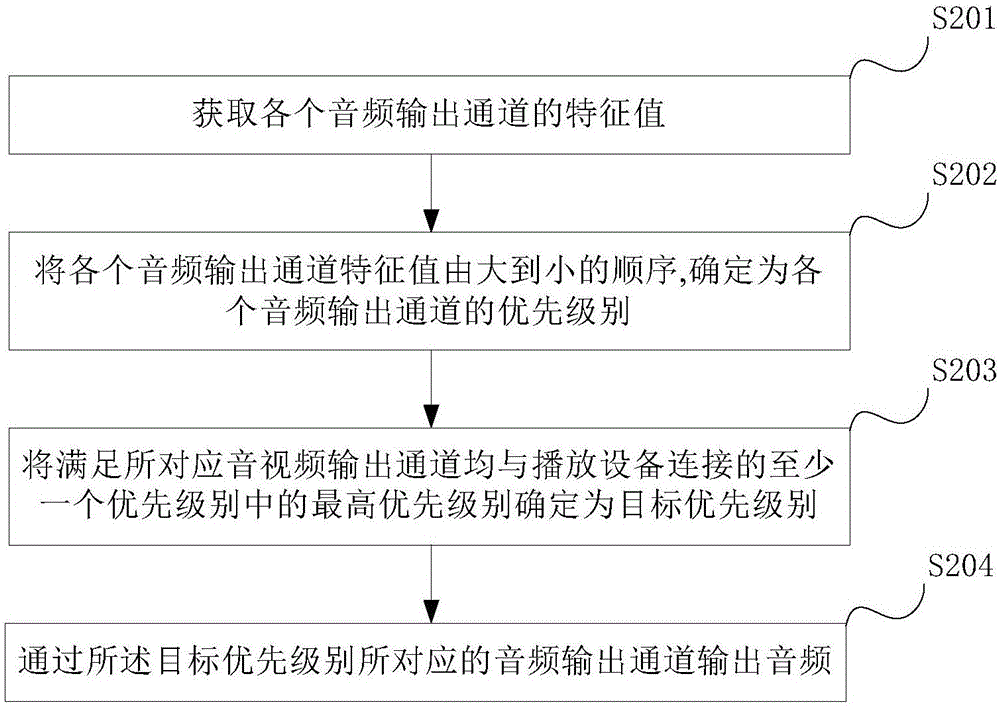

Method and device for selecting audio output channel and terminal equipment

InactiveCN106713978AImplement automatic selectionEasy to operateTelevision system detailsColor television detailsInteraction interfaceTerminal equipment

The invention provides a method and device for selecting an audio output channel and terminal equipment. According to the invention, by a set of algorithm, a target priority level is automatically determined, and by an audio output channel corresponding to the target priority level, an audio is output, so that automatic selection of a plurality of audio output channels is implemented. Various human-computer interaction interfaces and channel control algorithms do not need to be designed, and thus, a computation burden and operation time of a television terminal program can be reduced. Moreover, when a new audio output channel is added according to actual demands, only a priority level and a connection state of the newly added audio output channel need to be determined, thereby benefiting for improving flexibility in program design. According to the method, in a mode of setting various priority levels, various combination modes of the audio output channels can be provided; when the priority level and the connection state of each audio output channel are changed, the target priority level can be changed accordingly. According to the method for dynamically selecting the audio output channel, operability and flexibility of selecting the audio output channels can be improved.

Owner:HISENSE VISUAL TECH CO LTD

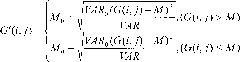

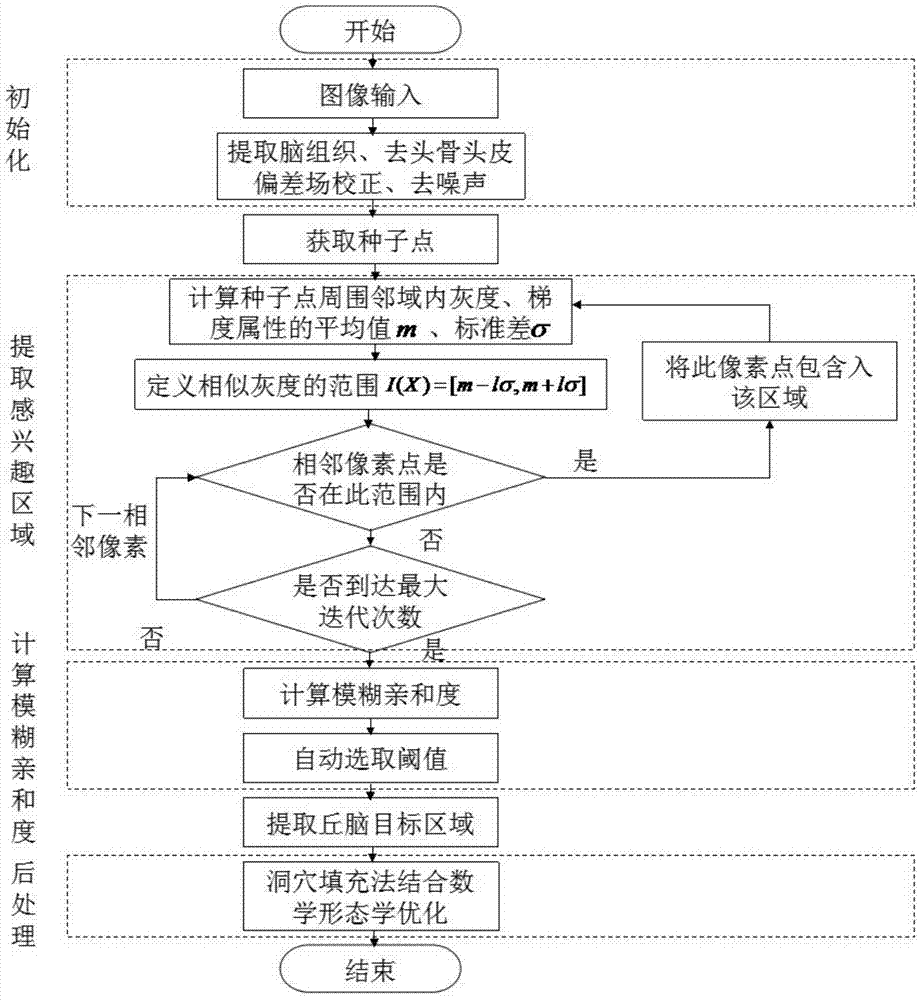

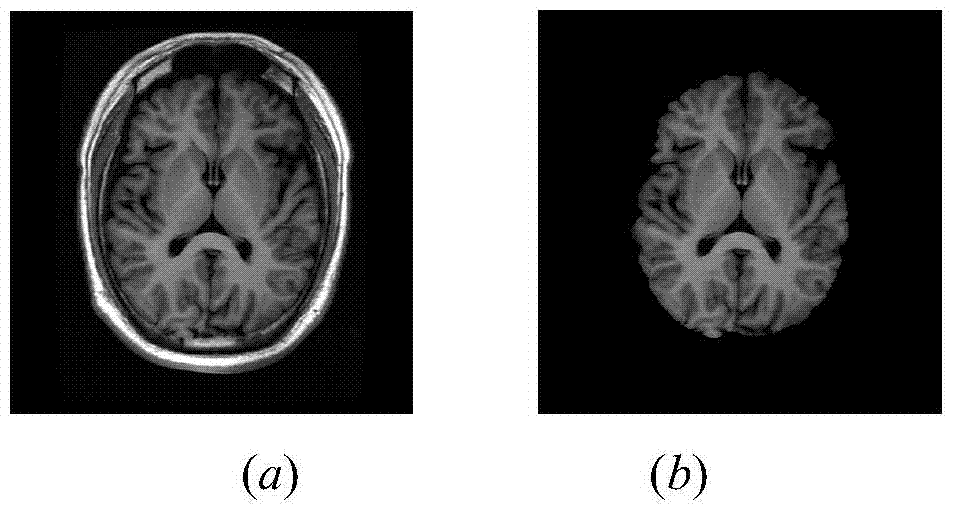

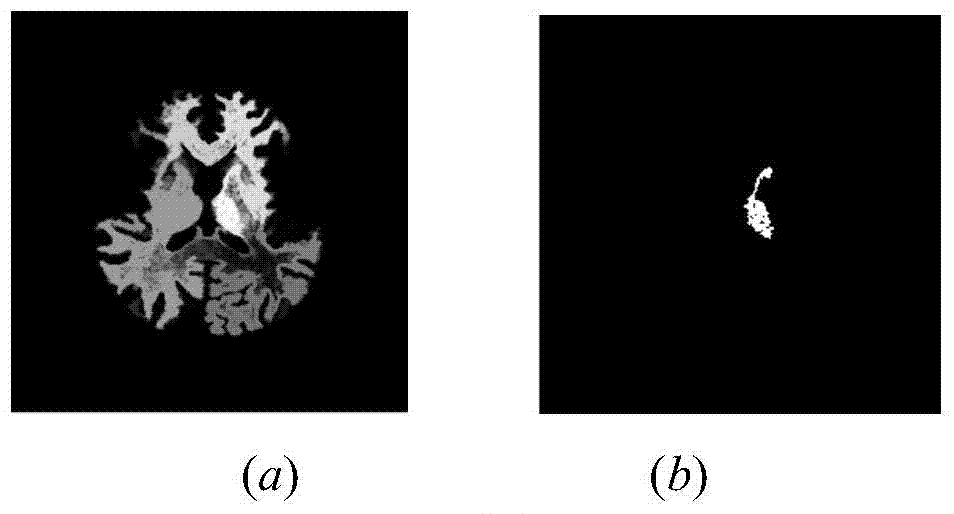

Fuzzy-connectedness-algorithm-based segmentation method of thalamus and substructures of thalamus

InactiveCN103942780AEasy to operate manuallyReduce manual interventionImage analysisPattern recognitionThalamus

The invention relates to a-fuzzy-connectedness-algorithm-based segmentation method of the thalamus and substructures of the thalamus. The method comprises the steps of inputting an original image, pre-processing the original image, automatically extracting an interesting area where a nucleus is located, estimating a mean value and a standard deviation in the area, calculating the fuzzy affinity to a seed point of the periphery region of the seed point, and conducting post-processing. According to the fuzzy-connectedness-algorithm-based segmentation method, the interesting area is automatically selected by adopting the confidence connectedness; when the fuzzy connectedness is calculated, gradient features are added on the basis that only gray features are used in the prior art, and the edge of the image can be expressed better. Experiment results show that the fuzzy-connectedness-algorithm-based segmentation method effectively reduces the frequency of segmentation-free phenomenon of a traditional fuzzy connectedness algorithm; weight coefficients between the gray features and the gradient features are obtained through self-adaption calculation, and accuracy of segmentation results is increased. According to the fuzzy-connectedness-algorithm-based segmentation method, automatic selection of fuzzy connectedness segmentation threshold values is achieved, the threshold values change along with changes of the seed point, and the degree of automation in a segmentation process is increased.

Owner:BEIJING UNIV OF TECH

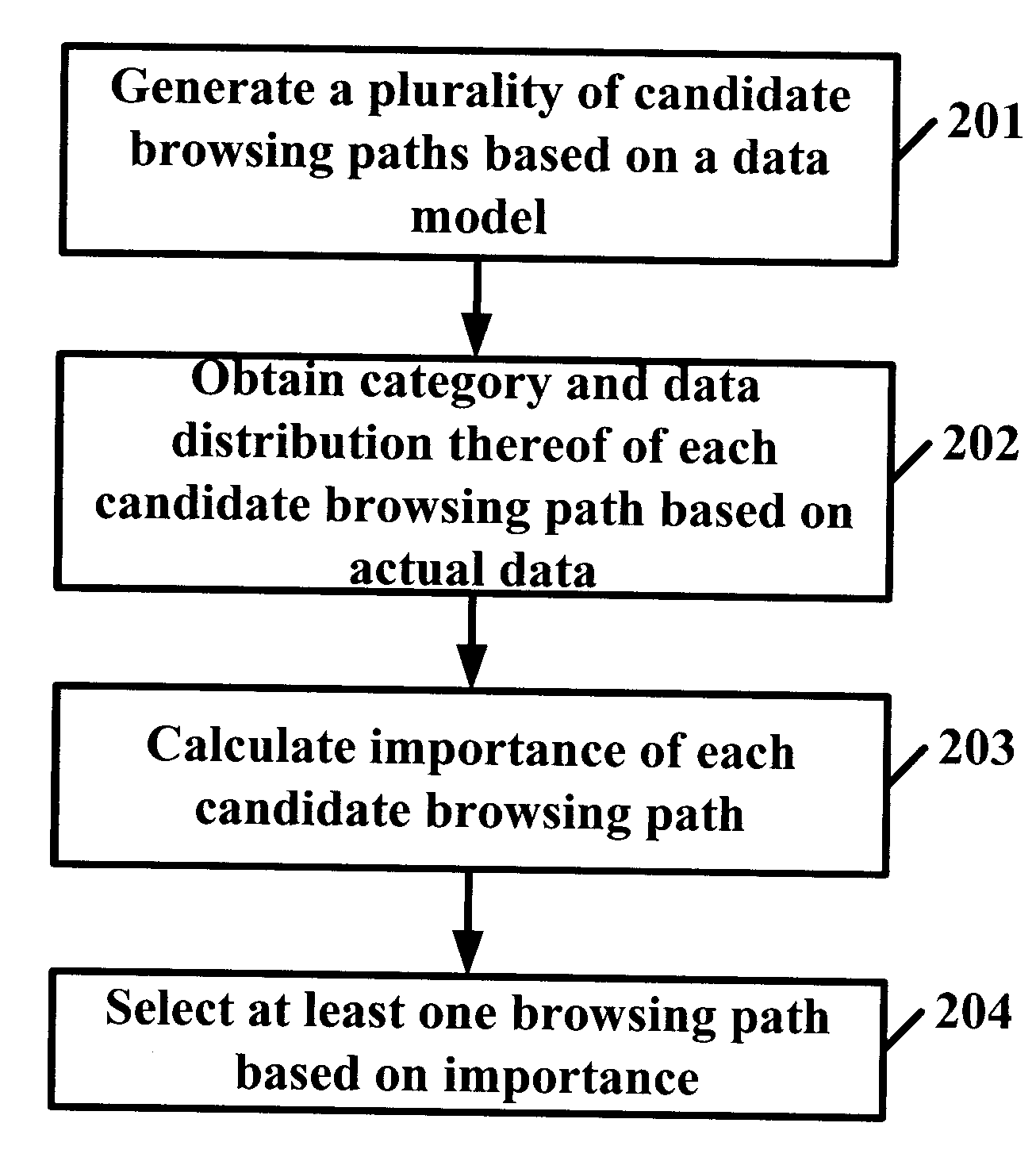

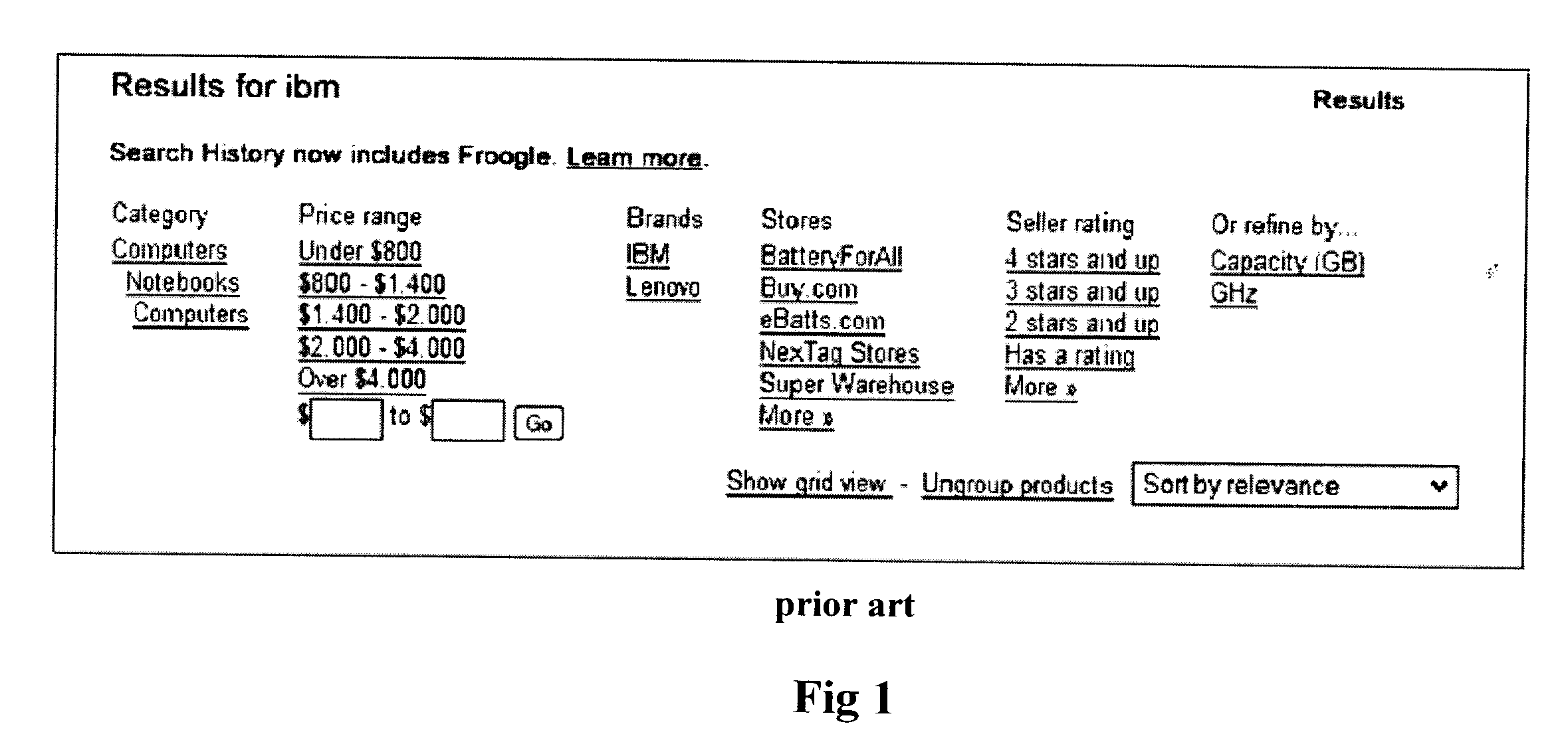

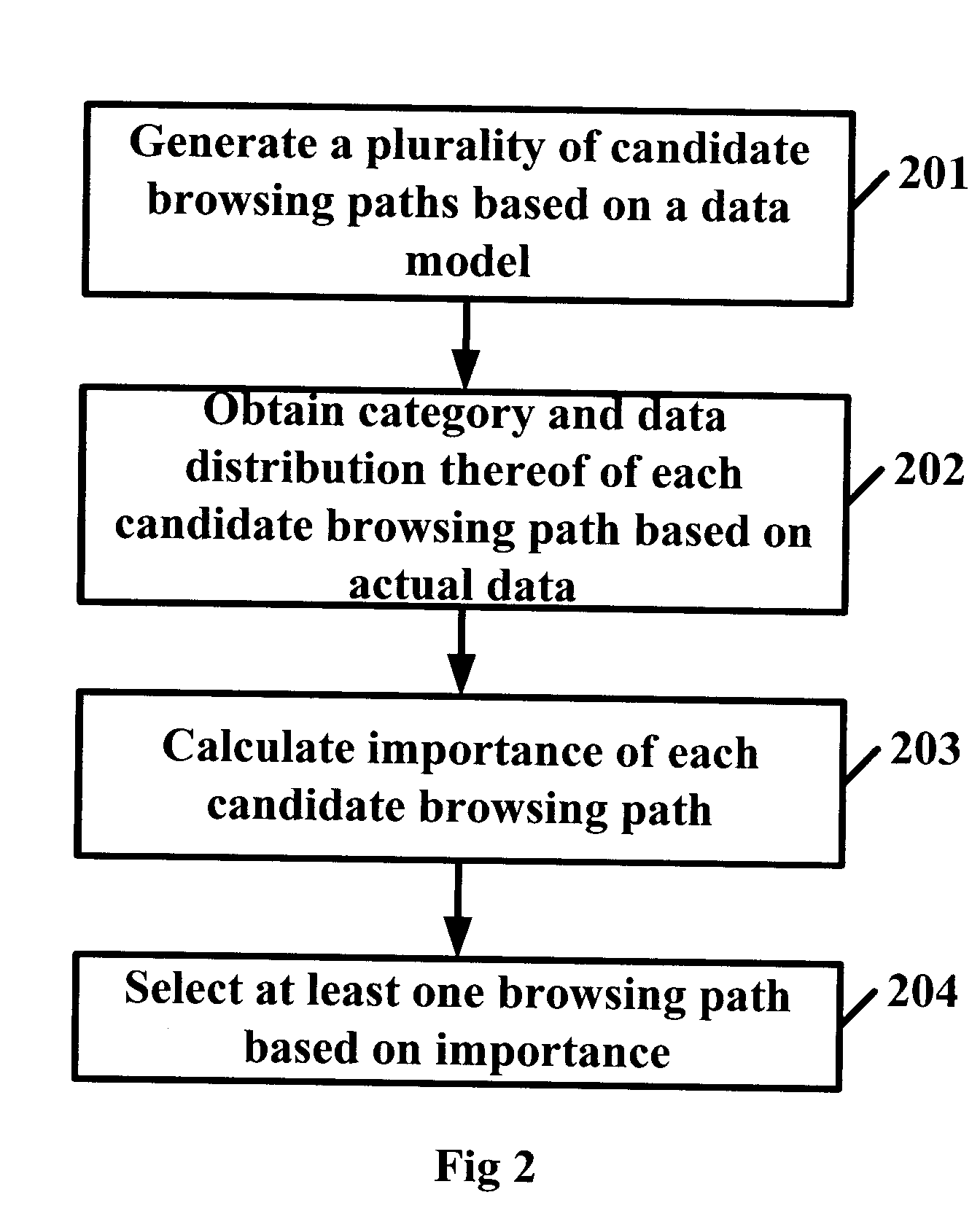

Apparatus of generating browsing paths for data and method for browsing data

InactiveUS20080027932A1Implement automatic selectionData processing applicationsWeb data navigationComputer programData structure

The present invention provides a method and apparatus of generating browsing paths for data, a method for browsing data and a computer program product. According to one aspect of the invention, there is provided a method of generating browsing paths for data. Firstly, a plurality of candidate browsing paths based on a data model describing the data structure is generated; next for each of the plurality of candidate browsing paths, importance of the browsing path based on a portion of data corresponding to the browsing path in the data is calculated; and at least one of the plurality of candidate browsing paths based on the importance is selected.

Owner:IBM CORP

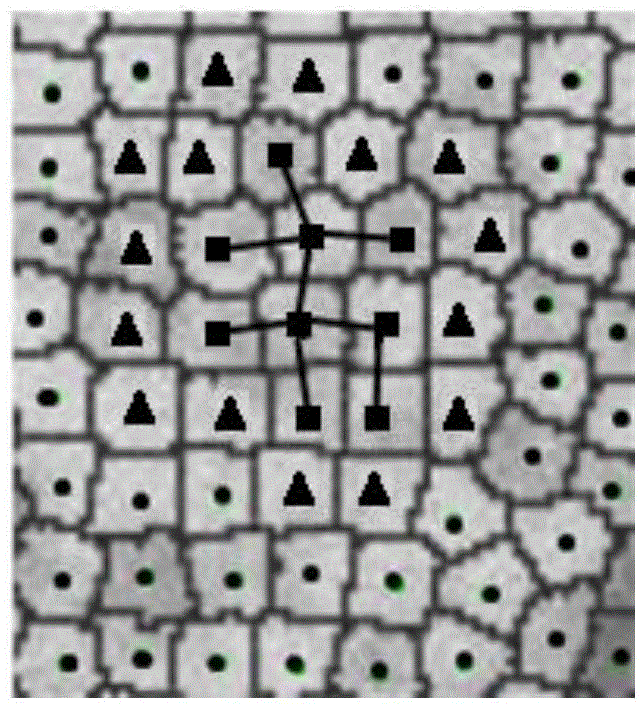

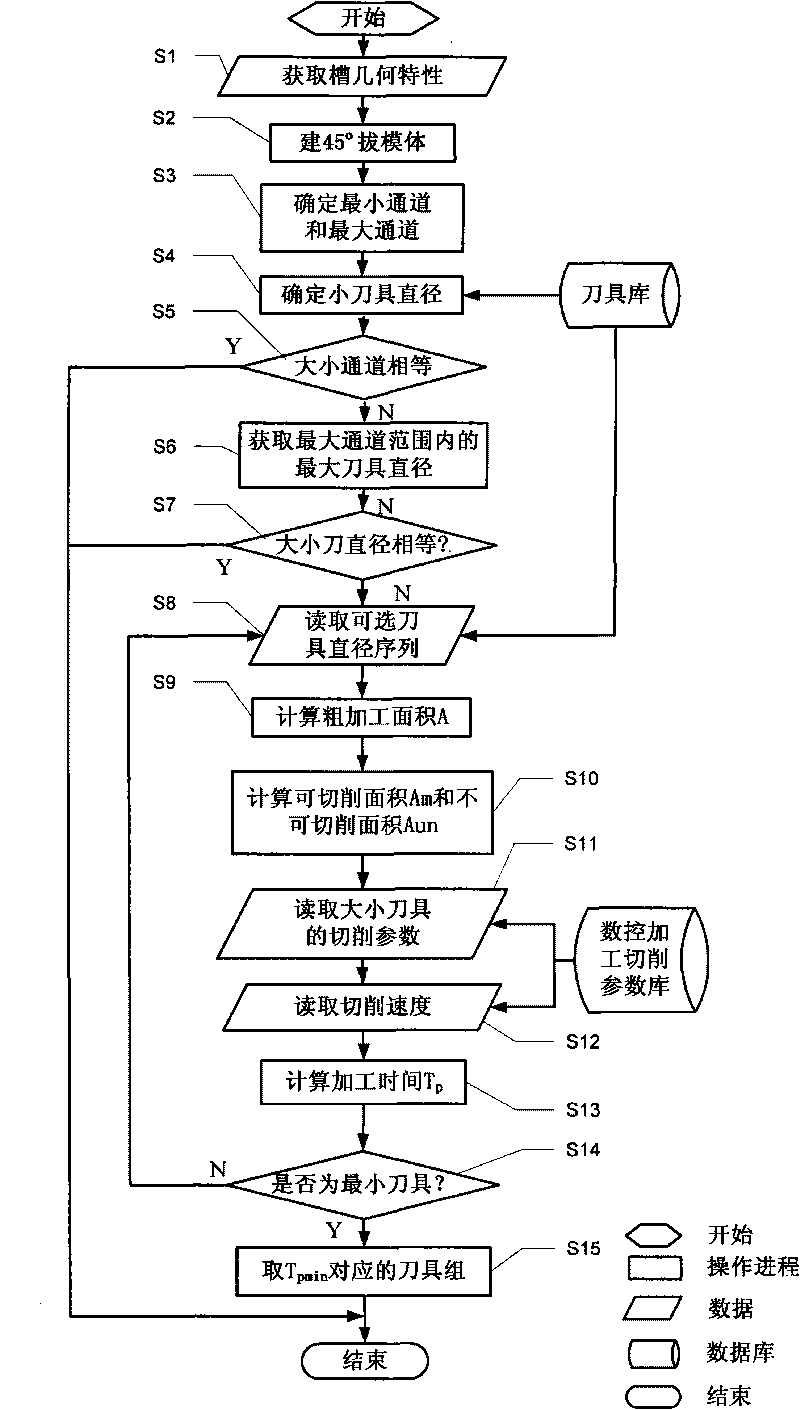

Method for selecting roughing tool for aircraft complex component based on Voronoi Mountain variation

InactiveCN101763048ASolve the optimal control problemReduce workloadProgramme control in sequence/logic controllersNumerical controlEngineering

The invention discloses a method for selecting a roughing tool for an aircraft complex component based on a Voronoi Mountain variation and provides a method for selecting a roughing tool for an aircraft complex component automatically based on a Voronoi Mountain principle. The method adopts a drawing mode of 45 degrees to construct a variation of a Voronoi Mountain drawing body, thus realizing maximum calculation of an enclosed slot and a slot and minimum channel calculation, thus obtaining the diameter of a knife suitable for slot roughing, and tool quantity is judged automatically and the diameter of a selected large tool is calculated by judging a region which can be processed according to the principle that the whole processing time of a single slot Tp is the shortest, thus completing the selection process of the roughing tool. The method solves the tool optimization problem in numerical control automatic programming effectively, reduces the workload of interactive programming of users obviously and increases numerical control programming efficiency and processing efficiency obviously.

Owner:SHENYANG AIRCRAFT CORP +1

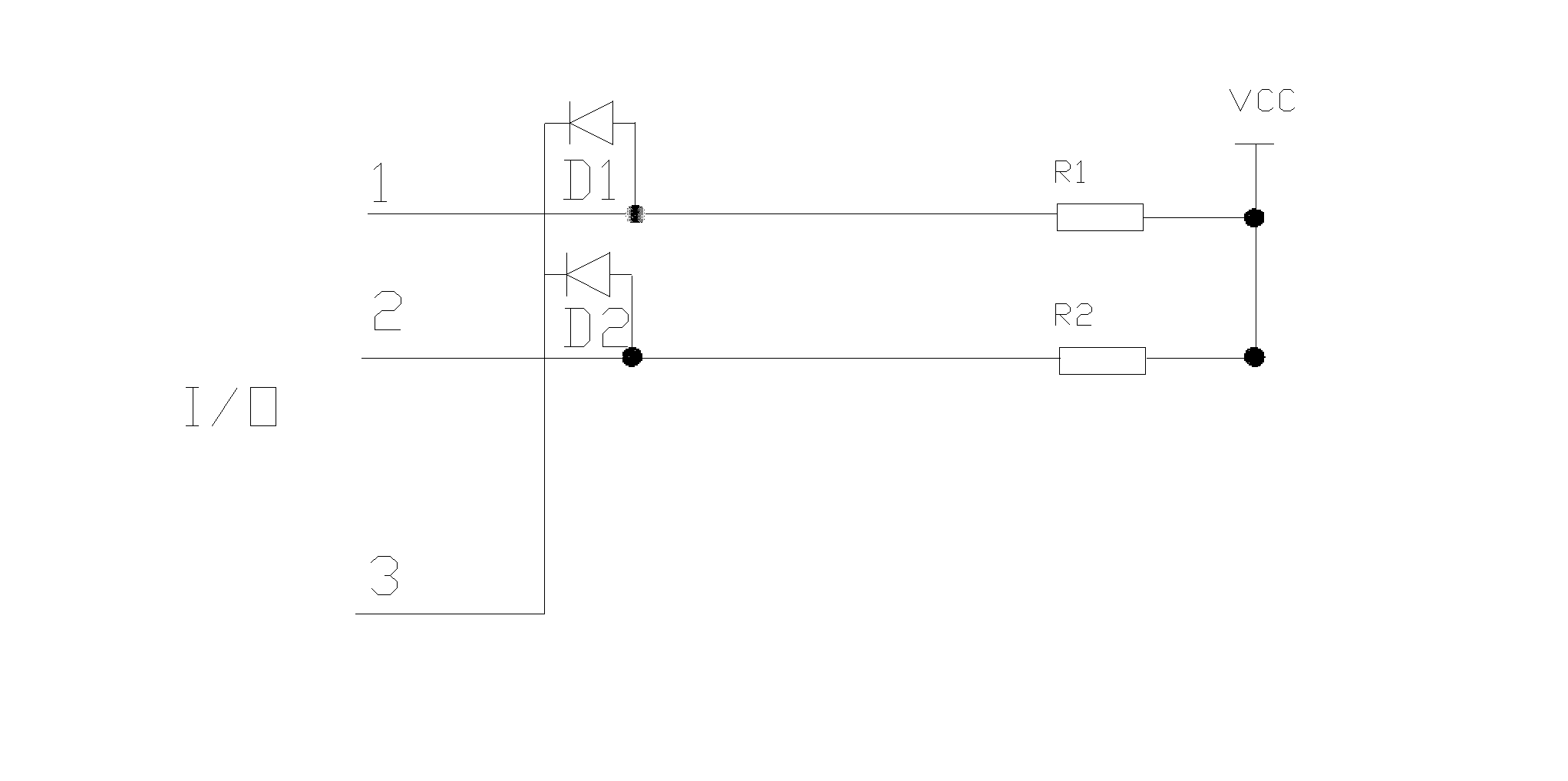

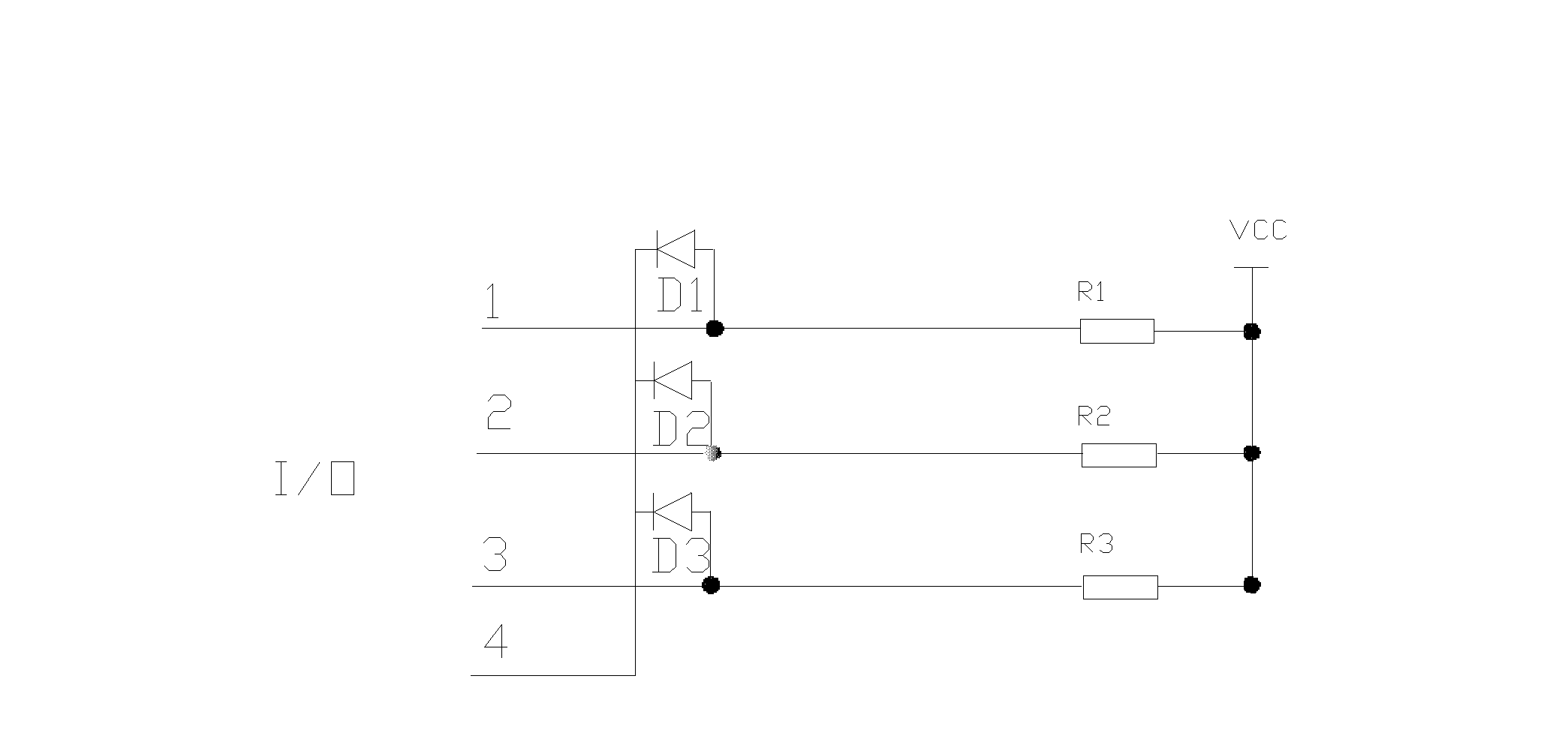

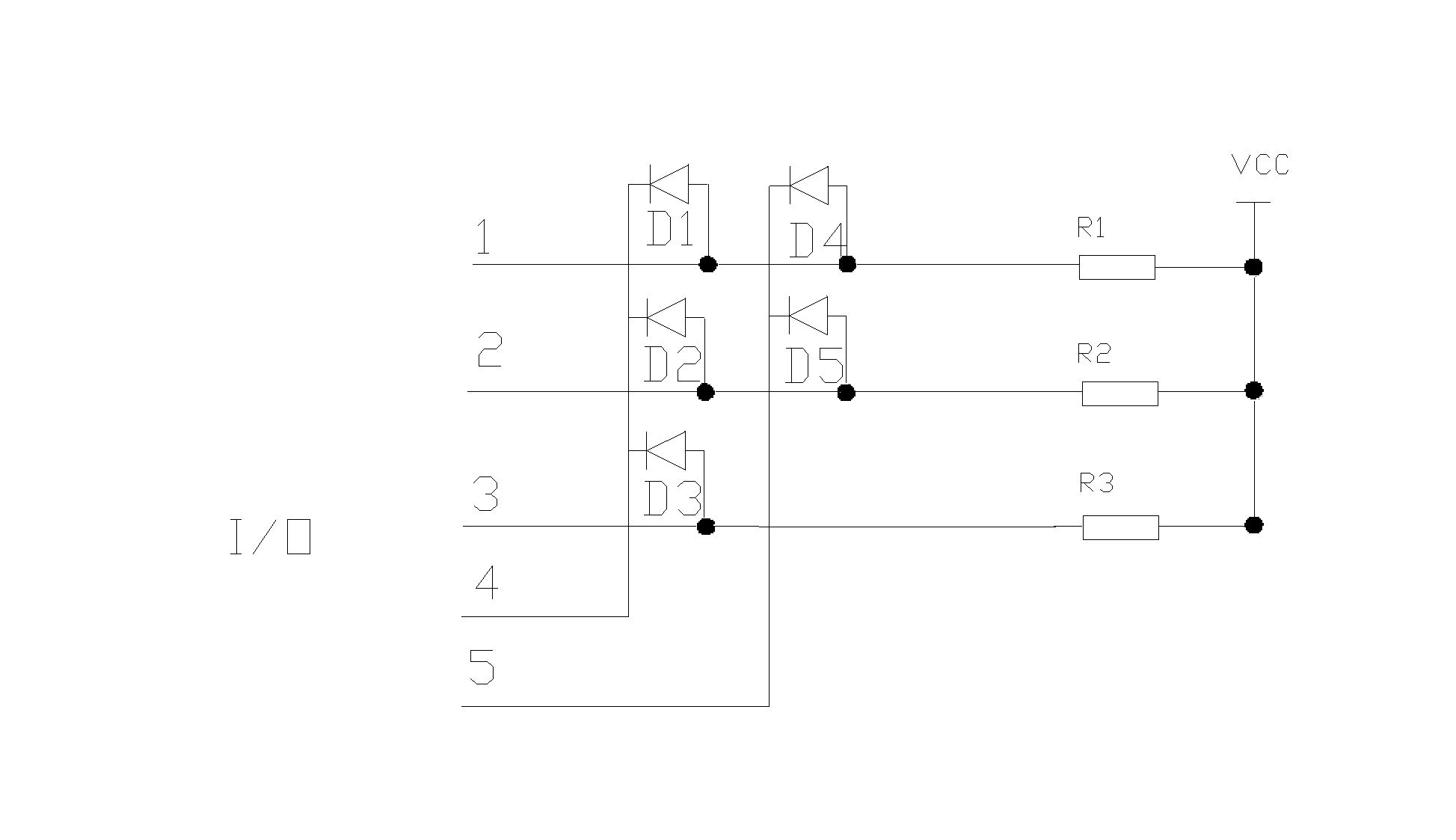

Air-condition controller compatible with various machine types

ActiveCN102589090ASave resourcesHigh precisionSpace heating and ventilation safety systemsLighting and heating apparatusComputer compatibilityEngineering

The invention discloses an air-condition controller compatible with various machine types, which comprises a level input circuit and a level output circuit, wherein the level input circuit comprises more than two branch level input circuits which are respectively provided with a resistor, and the more than two branch level input circuits are connected in parallel to be connected with a Vcc (Voltage To Current Converter); the level output circuit comprises more than one branch level output circuit; and each branch level output circuit is connected with at least one branch level input circuit through a diode. Compared with the prior art, the air-condition controller compatible with various machine types can realize that the same one electronic control is compatible with all machine types and functions, the integration level and the compatibility of an air-conditioning system are enhanced, a power supply is not influenced, and the working stability of the air-conditioning system can be improved.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Implementation method for achieving self-adaption of baud rate

InactiveCN103514127AImplement automatic selectionImprove versatilityElectric digital data processingNetwork packetComputer science

The invention belongs to the technical field of serial communication, and particularly relates to an implementation method for achieving self-adaption of the baud rate. The method includes the following steps of setting the format of a serial communication data package, detecting the baud rate and automatically adjusting the baud rate. The method solves the technical problem that an existing technology can meet different design requirements for the baud rate unless external equipment is provided and cannot achieve self-adaption of the baud rate. The method has the advantages that when the method is utilized to carry out serial communication with other subsystems, labor hardware jumper arrangement or program selection is needless, and plug and play performance is achieved; the baud rate used at present can be automatically analyzed according to the serial communication data package, the baud rate of a system is automatically adjusted to be baud rate used at present, and thus the system is universally used for different baud rate systems.

Owner:THE 3RD ACAD 8358TH RES INST OF CASC

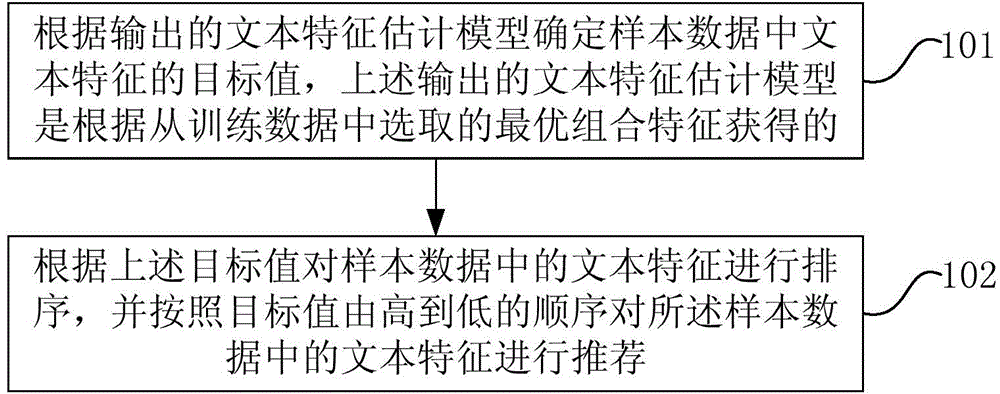

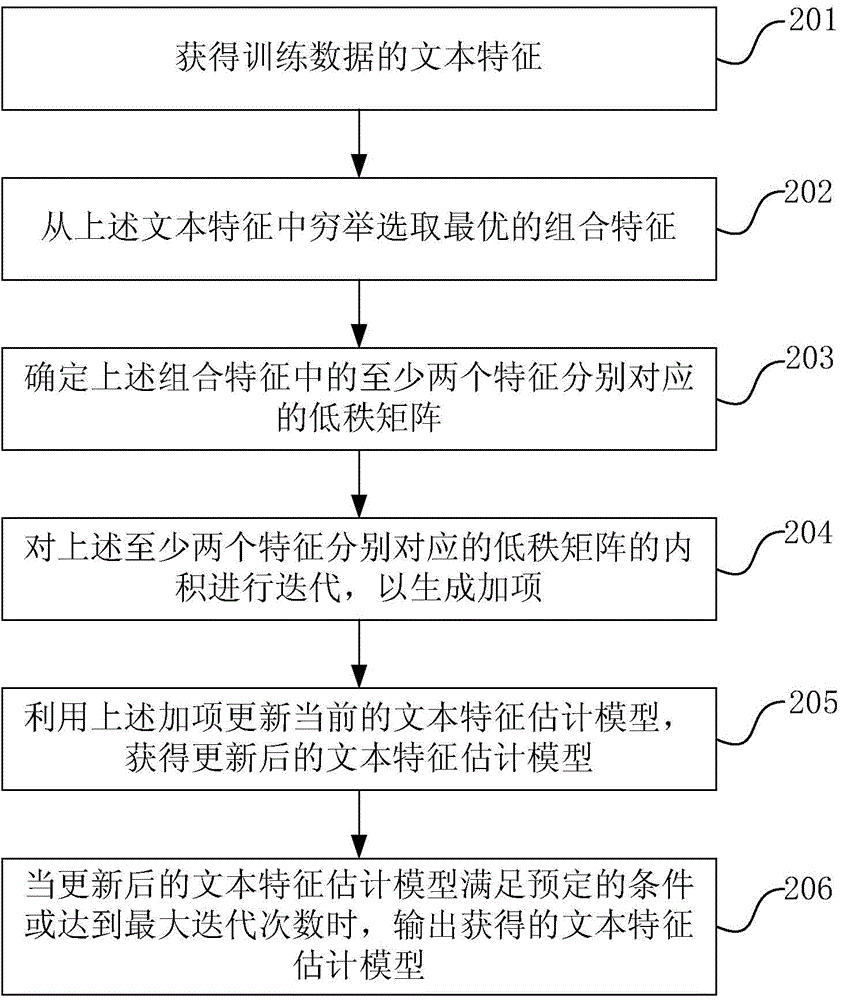

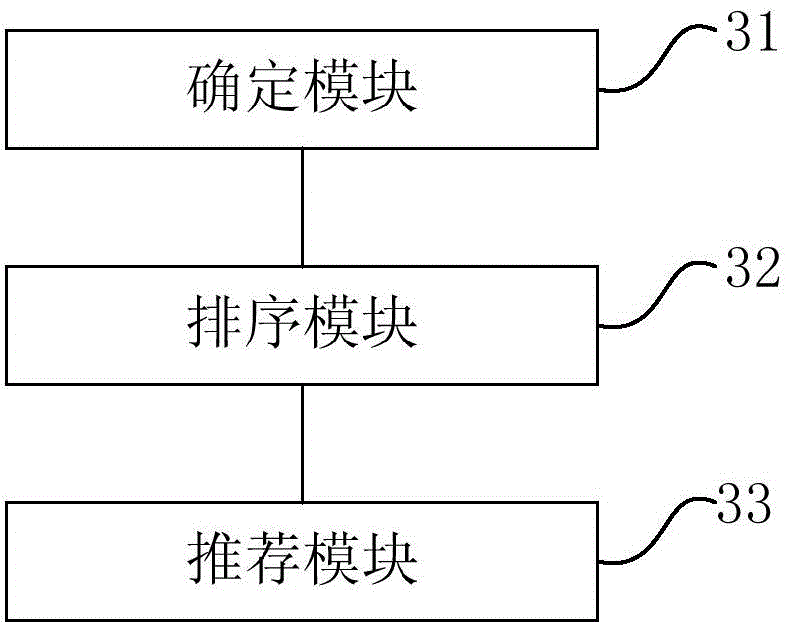

Characteristic recommendation method and device

ActiveCN104615790AImprove effectivenessImplement automatic selectionSpecial data processing applicationsData miningFeature selection

The invention discloses a characteristic recommendation method and a characteristic recommendation device. The characteristic recommendation method comprises the following steps: according to an output textual characteristic estimation model, determining target values of textual characteristics in sample data, wherein the output textual characteristic estimation model is obtained according to the optimal combined characteristics selected from training data; according to the target values, sorting the textual characteristics in the sample data and according to a sequence of the target value from high to low, carrying out recommendation on the textual characteristics in the sample data. The characteristic recommendation method and the characteristic recommendation device can realize automatic selection of the effective combined characteristics, are time-saving and labor-saving, effectively solve the difficult problems of time waste and labor waste in the existing manual characteristic selecting process and can improve effectiveness of a recommendation system.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

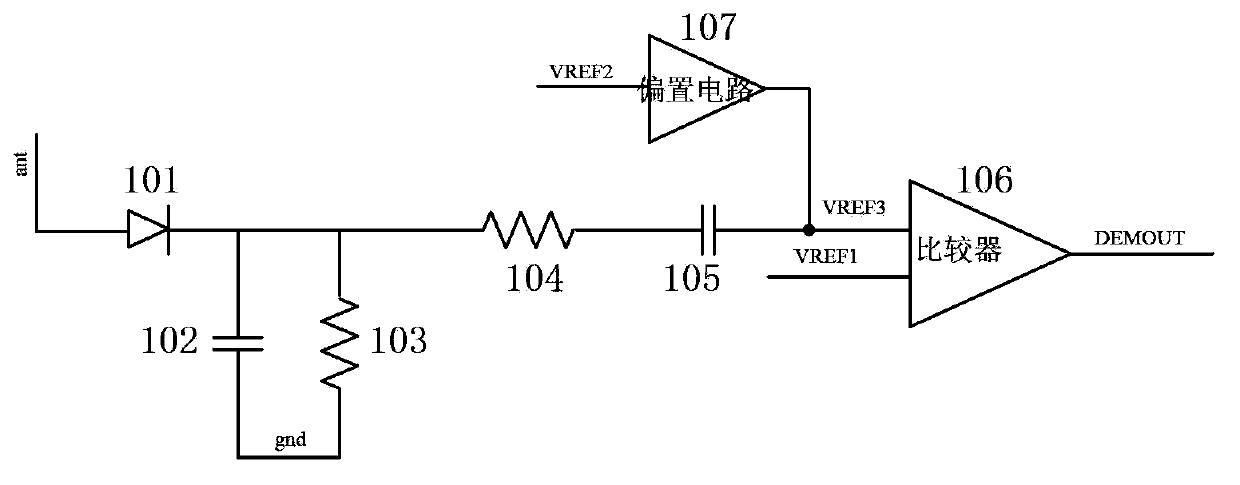

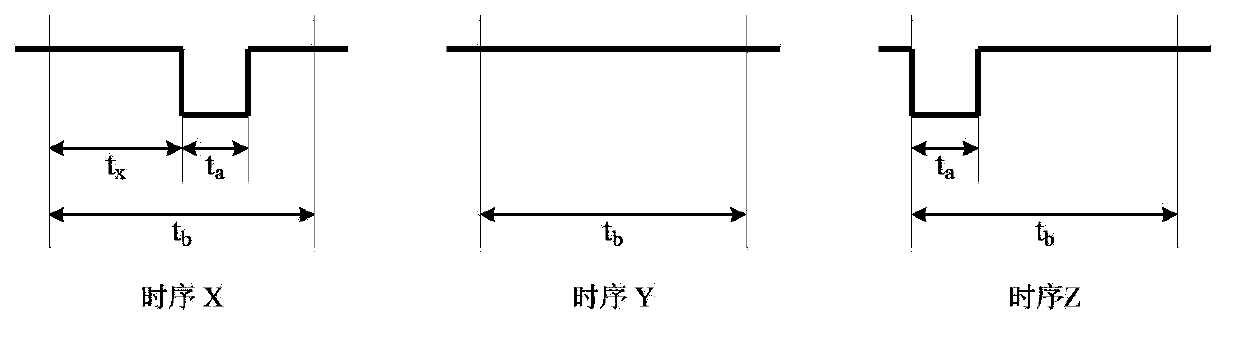

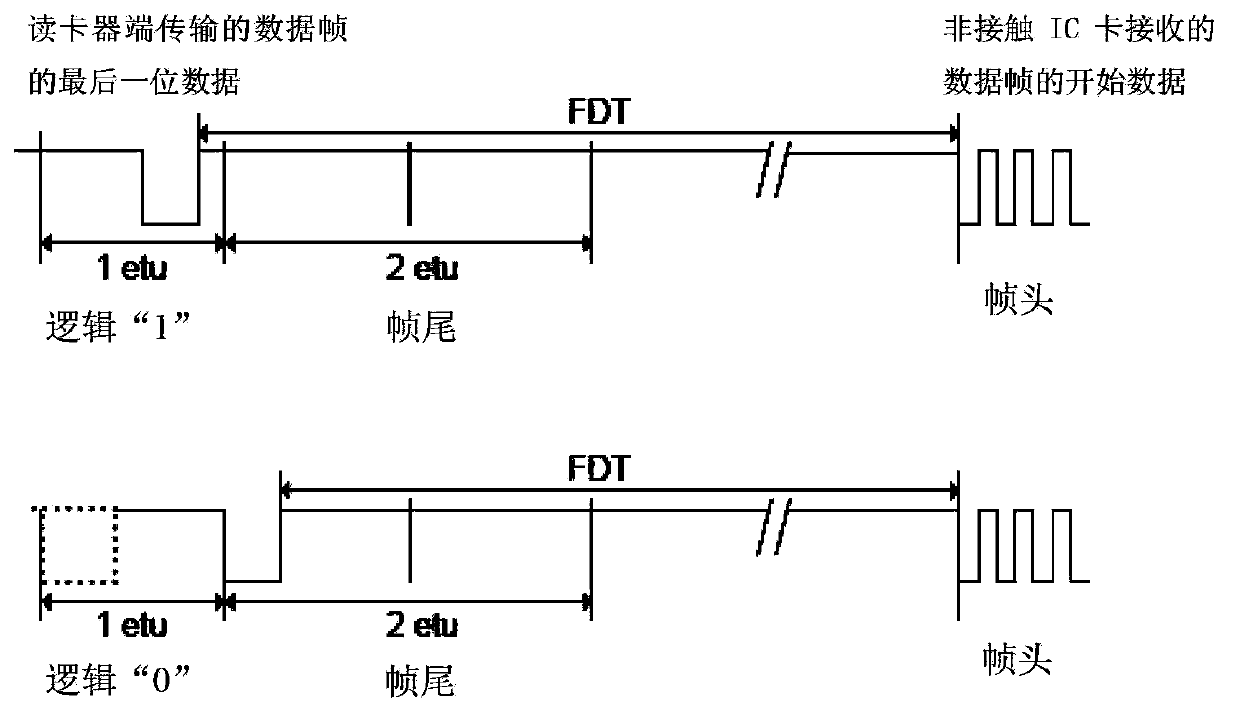

Demodulation circuit of non-contact IC card

ActiveCN103870868AImprove driving abilityDrive ability recoveryRecord carriers used with machinesVoltage referenceComparator

The invention discloses a demodulation circuit of a non-contact IC card. The demodulation circuit comprises a comparator, a bias circuit and an either-or switching circuit. The either-or switching circuit provides two reference signals of different amplitudes for the bias circuit. A driving control end of the bias circuit is connected with an output end of the comparator. The demodulation circuit outputs a demodulation signal to automatically select reference voltages input by the bias circuit and the driving capability of the bias circuit. Direct-current bias voltage at the input end of the comparator can be reduced and the driving capability can be increased upon the arrival a pause signal so that voltage at the input end of the comparator can be recovered quickly at the end of the pause signal to meet the requirement of FDT.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

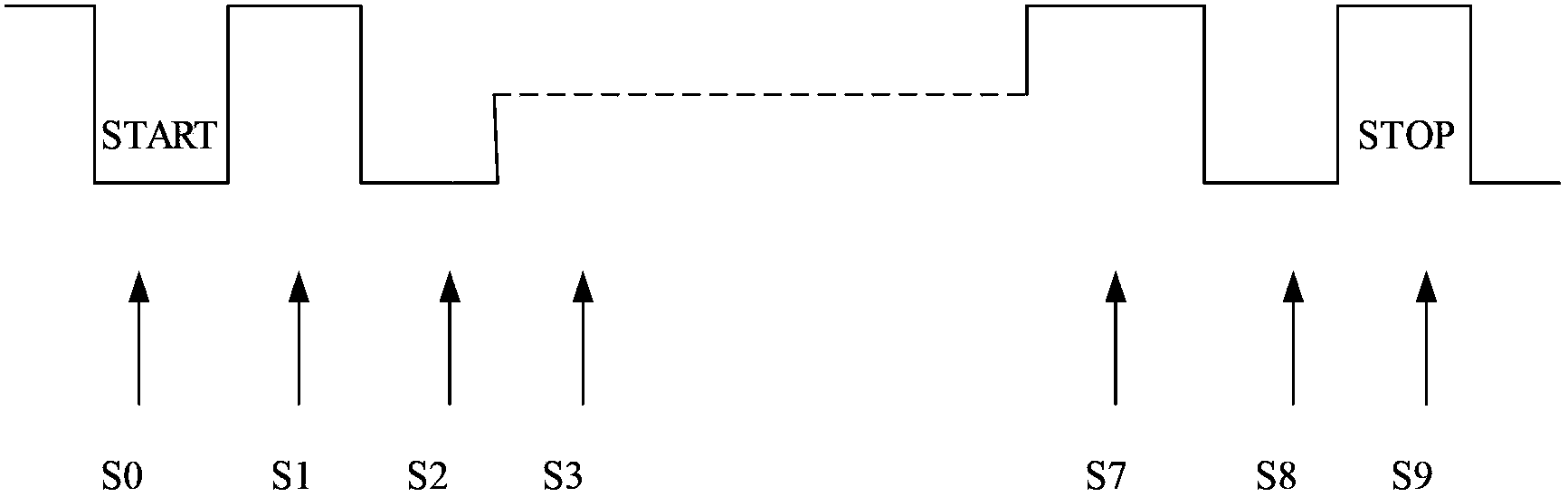

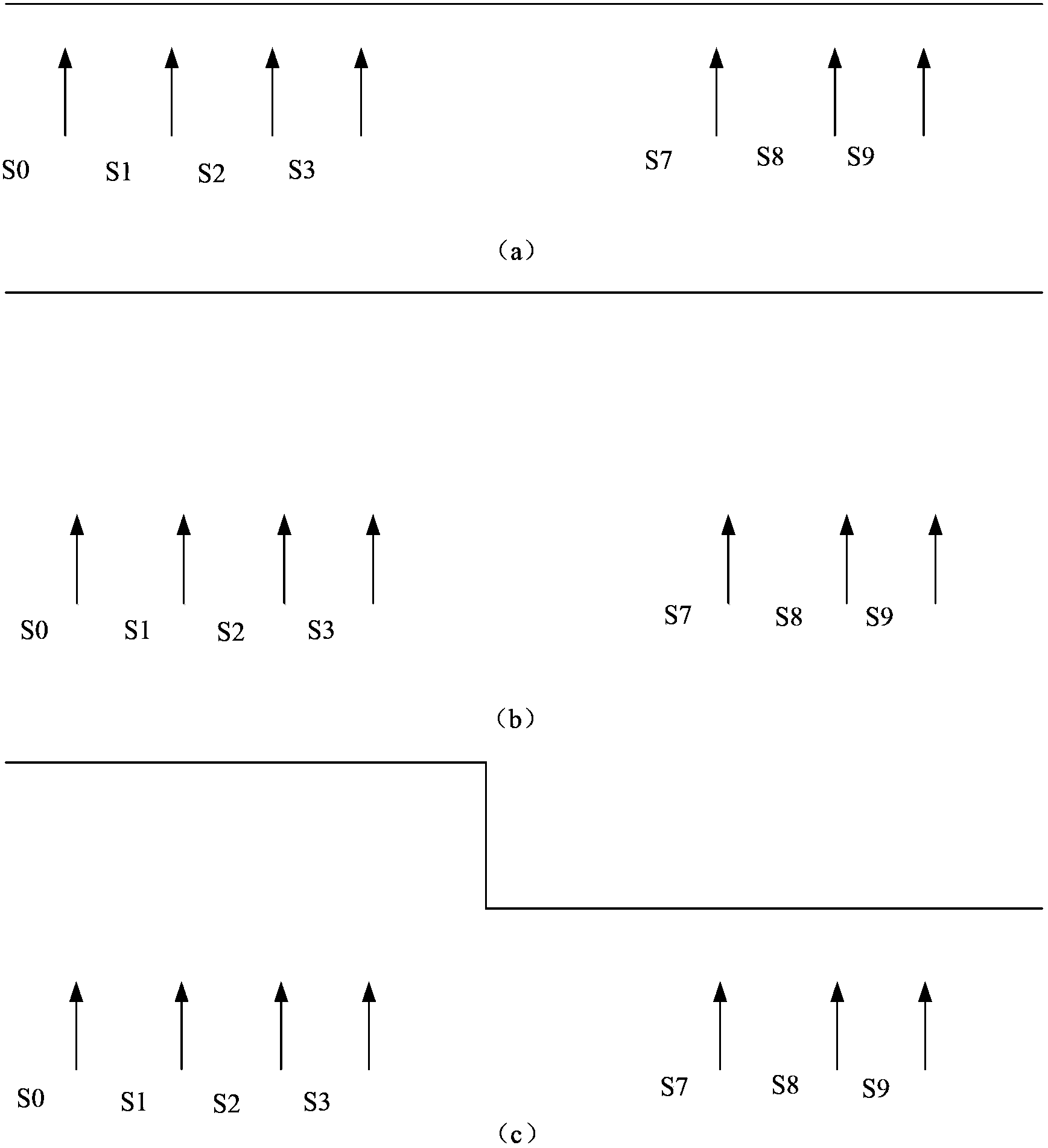

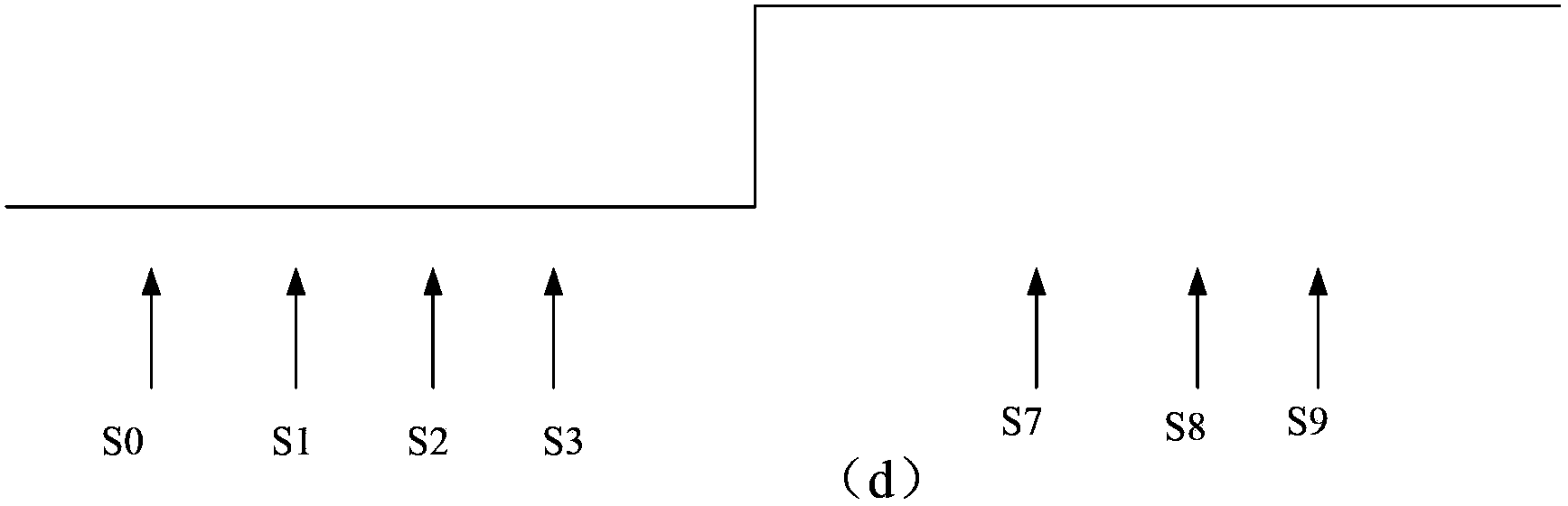

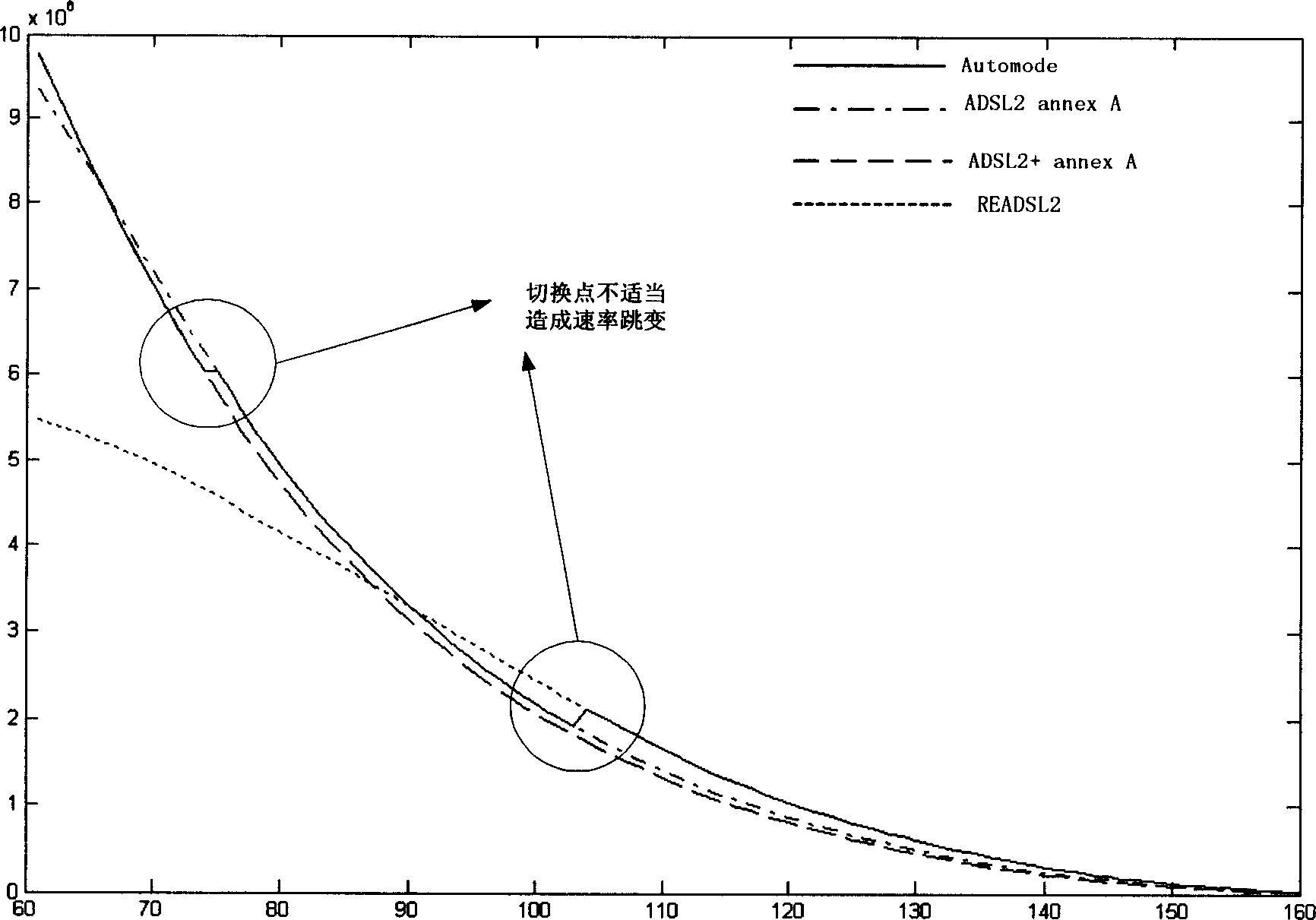

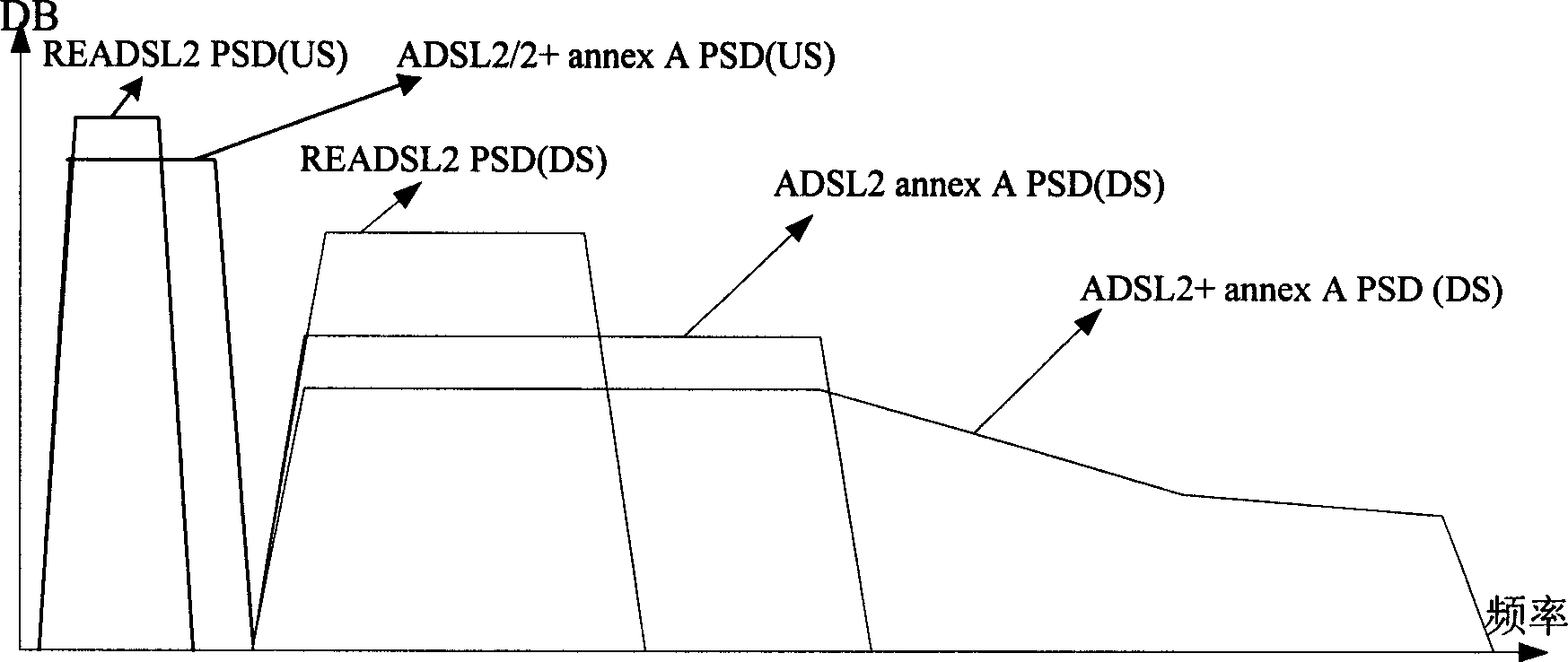

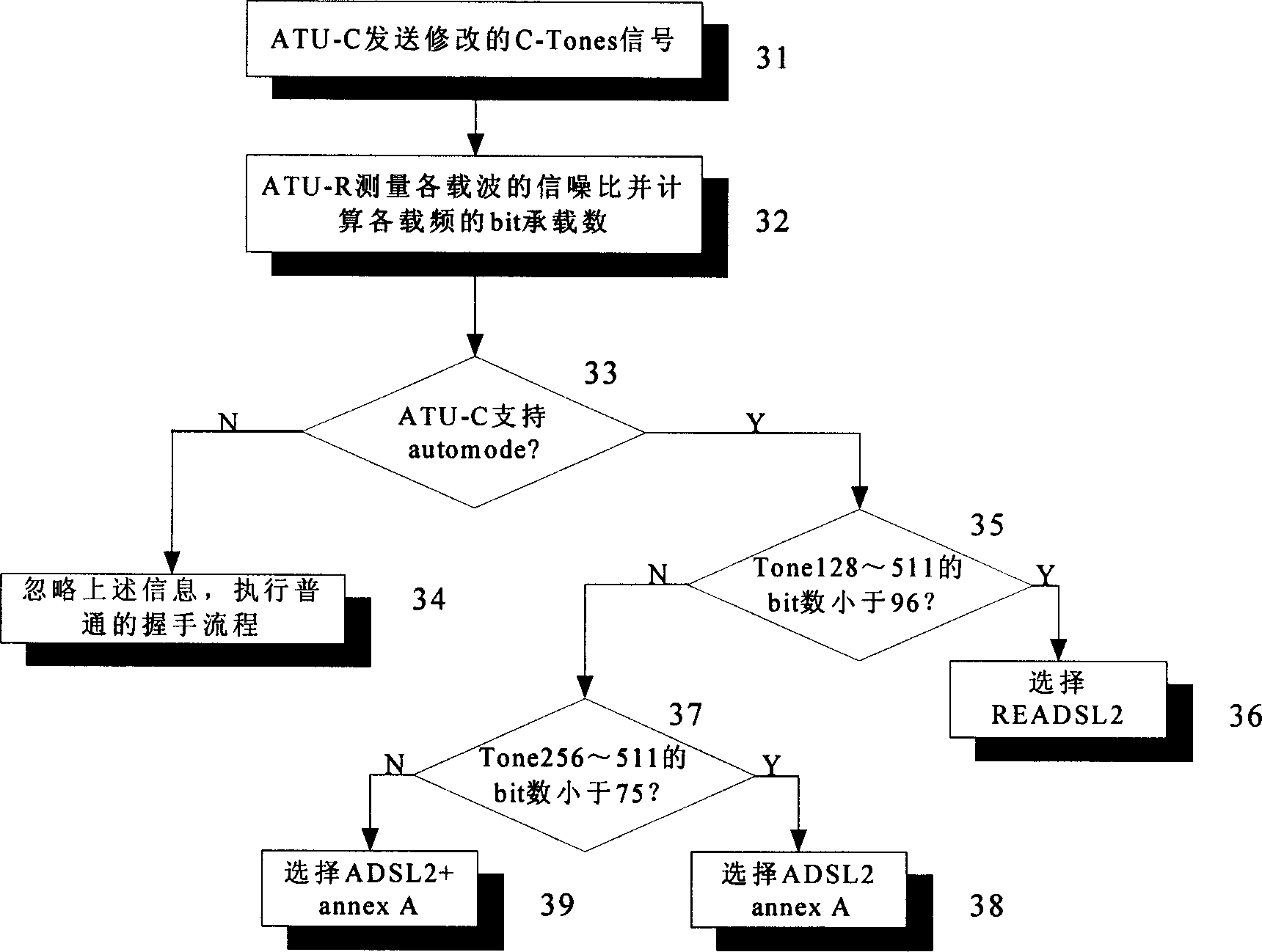

Method and apparatus for automatically selecting operation mode in XDSL network

InactiveCN1863259AImplement automatic selectionShorten the timeTelephonic communicationPayload allocationCarrier signalOperation mode

The invention relates to a method and system for automatically selecting operating modes in XDSL network, mainly comprising: firstly, branch unit transmits a group of multimode subcarrier signals to user-end unit; then, according to the subcarrier signals received by the user-end unit, calculating bit number each subcarrier can carry, and according to the bit number, determining bit number each mode can carry; and finally, according to the bit number each mode can carry, determining a mode to be selected. And the invention can implement automatic selection of operating modes according to actual line conditions and can select the best operating mode by training only once. Therefore, the invention does not increase handshaking time and complexity and can improve mode selecting accuracy.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com