Patents

Literature

235 results about "Fault propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

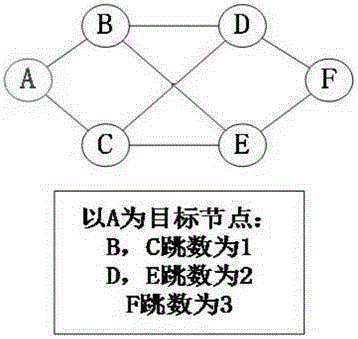

Fault propagation is a problem even within a single processor. We put code out in processes to help isolate the code. But there are often fault propagation paths that confuse other parts of the system if the process fails. These fault propagation paths can be fairly predictable (e.g.

Method for diagnosing fault by functional fault directed graph

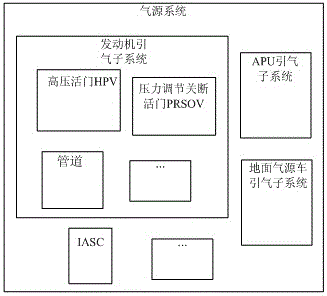

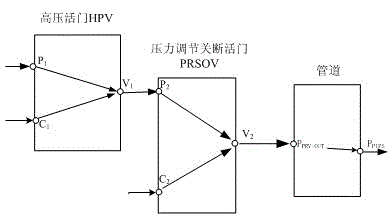

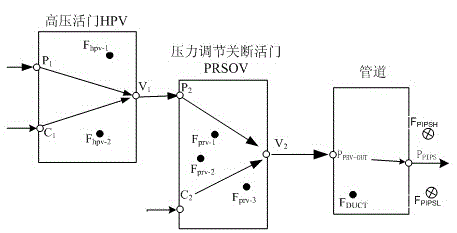

ActiveCN102945311ACompleteImprove diagnostic efficiencyStructural/machines measurementSpecial data processing applicationsAir conditioningFault model

The invention provides a method for diagnosing a fault by a functional fault directed graph, which can be applied to the field of fault diagnosis for some systems of aircrafts (such as an air source system, an anti-icing system and an air-conditioning system of an airplane gas path). The method comprises the steps of: decomposing a diagnosis object system to determine component relation and build a system structural model, confirming the corresponding input and output based on the component functions, determining the component fault model, analyzing fault propagation path and influence relation, setting test points and test information of a sensor, monitoring parameter variation that indicates the potential fault, forming an FF-SDG model, and at last, searching the potential fault source by a hierarchical policy inference method based on the FF-SDG model to perform fault diagnosis. The method can quickly and effectively find out the system fault source of the aircraft system, discover the fault cause, and make up shortage of the fault diagnosis technique based on manuals and cases when some fault cannot be predicated and the knowledge is difficult to be acquired by domain experts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

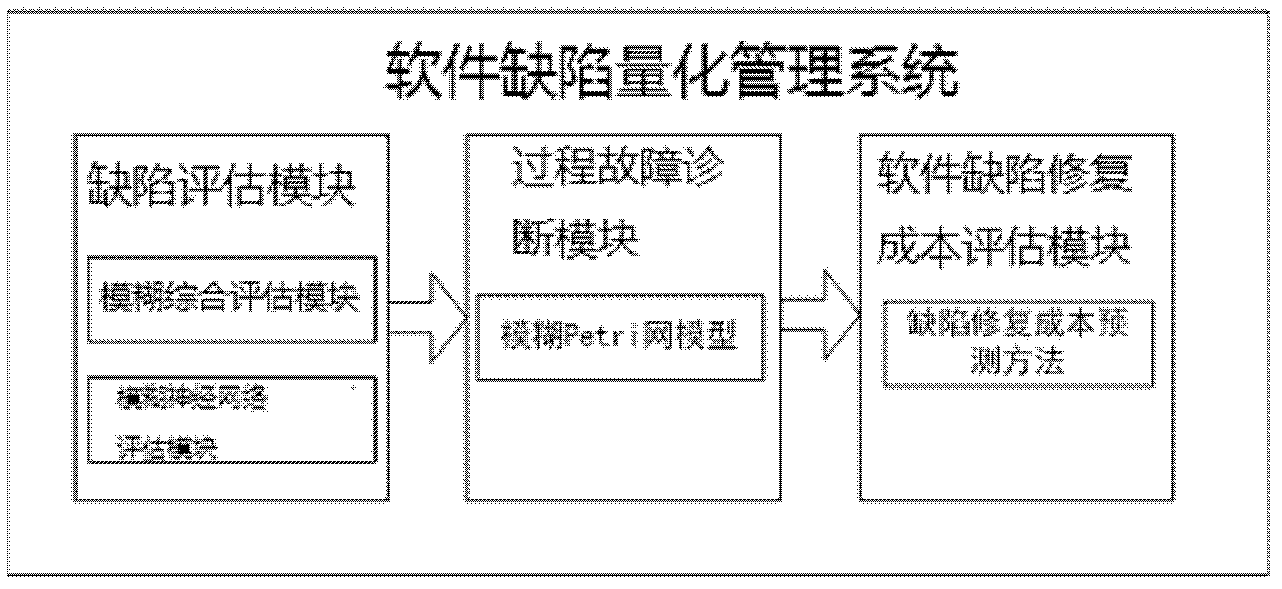

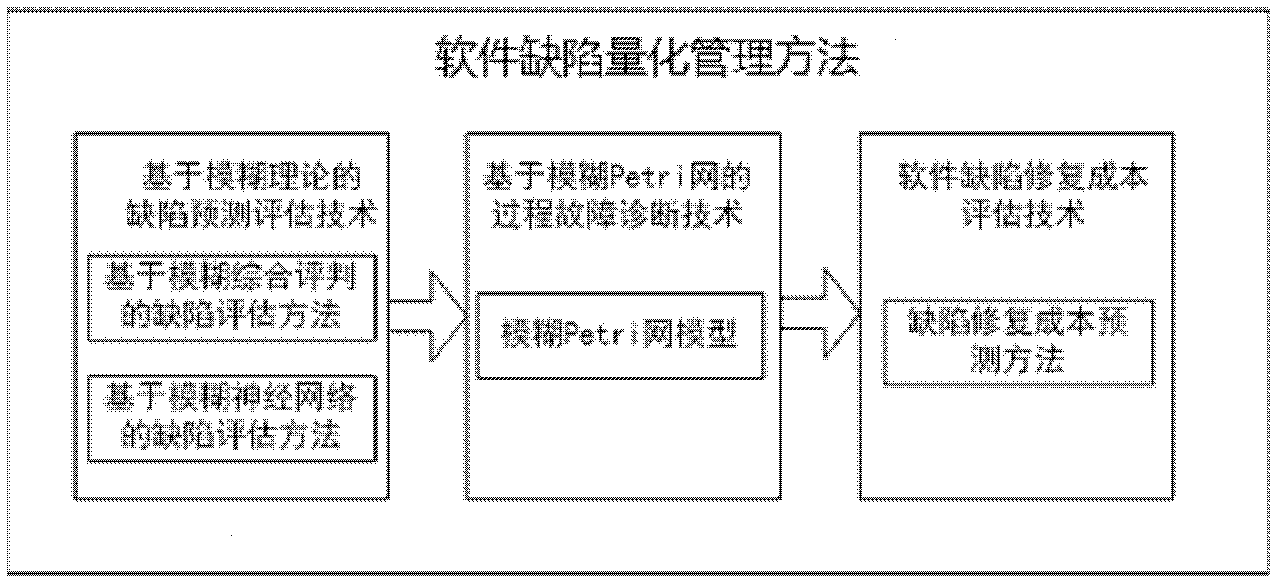

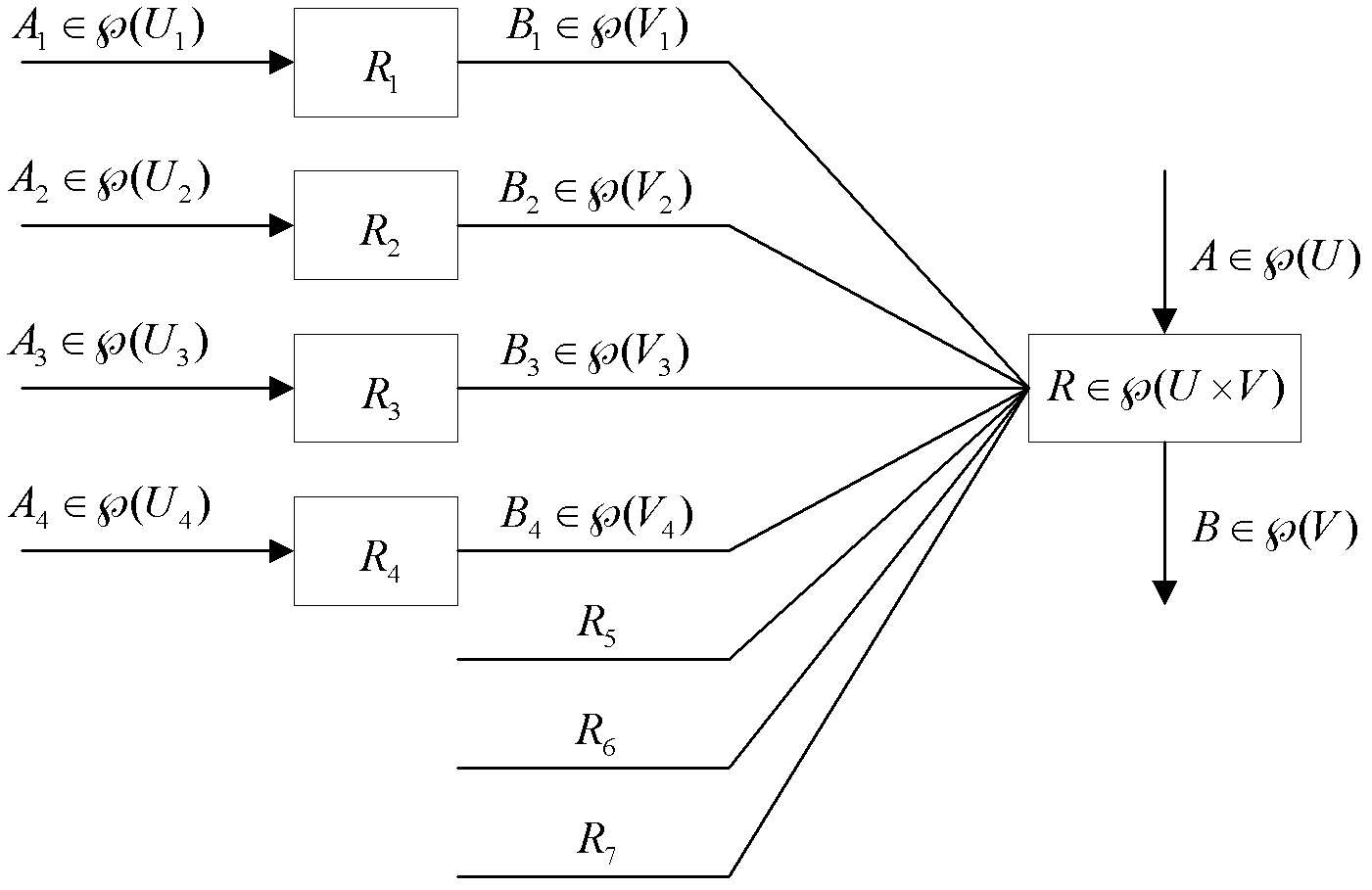

System and method for quantitative management of software defects

InactiveCN102622510ARealize intelligent evaluationImprove fault diagnosis efficiencyBiological neural network modelsSoftware testing/debuggingInference machineFault propagation

The invention discloses a system for quantitative management of software defects, which comprises a defect prediction and evaluation module, a process fault diagnosis module and a software defect mending cost estimating module. The defect prediction and evaluation module is used for evaluating and predicting the amount of software defects. The process fault diagnosis module is used for simulating the propagation process of software process faults, expressing fuzzy fault knowledge and providing a target-drive-oriented backward reasoning mechanism and software product fault diagnosis. The software defect mending cost estimating module is used for researching a defect mending cost predicting method so as to calculate mending cost and accurately estimate the defect mending cost. By the system, intelligent evaluation on software defects is realized, efficiency and accuracy in software process fault diagnosis are improved, software process is more controllable, and development process is more highly mature.

Owner:龚波

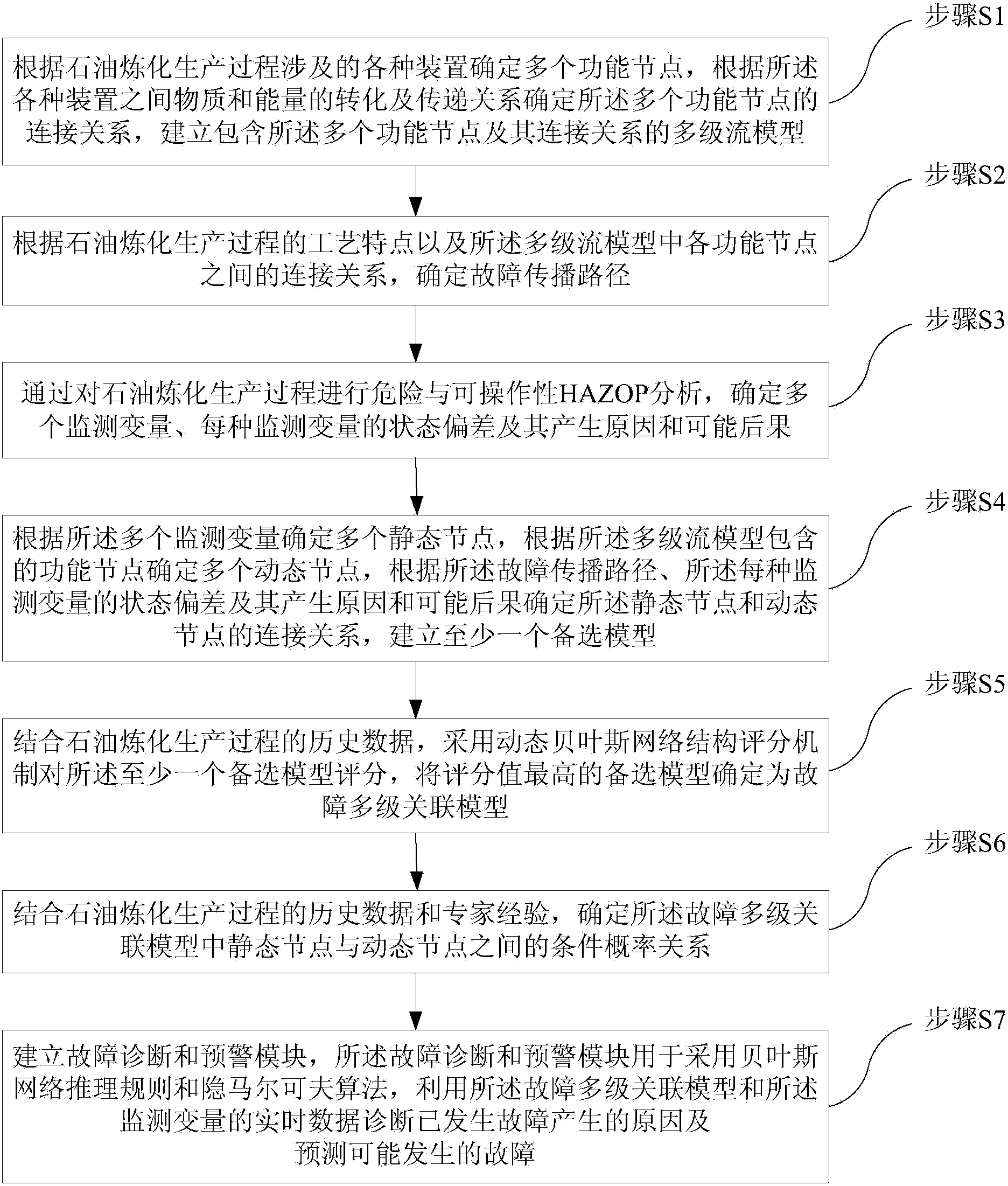

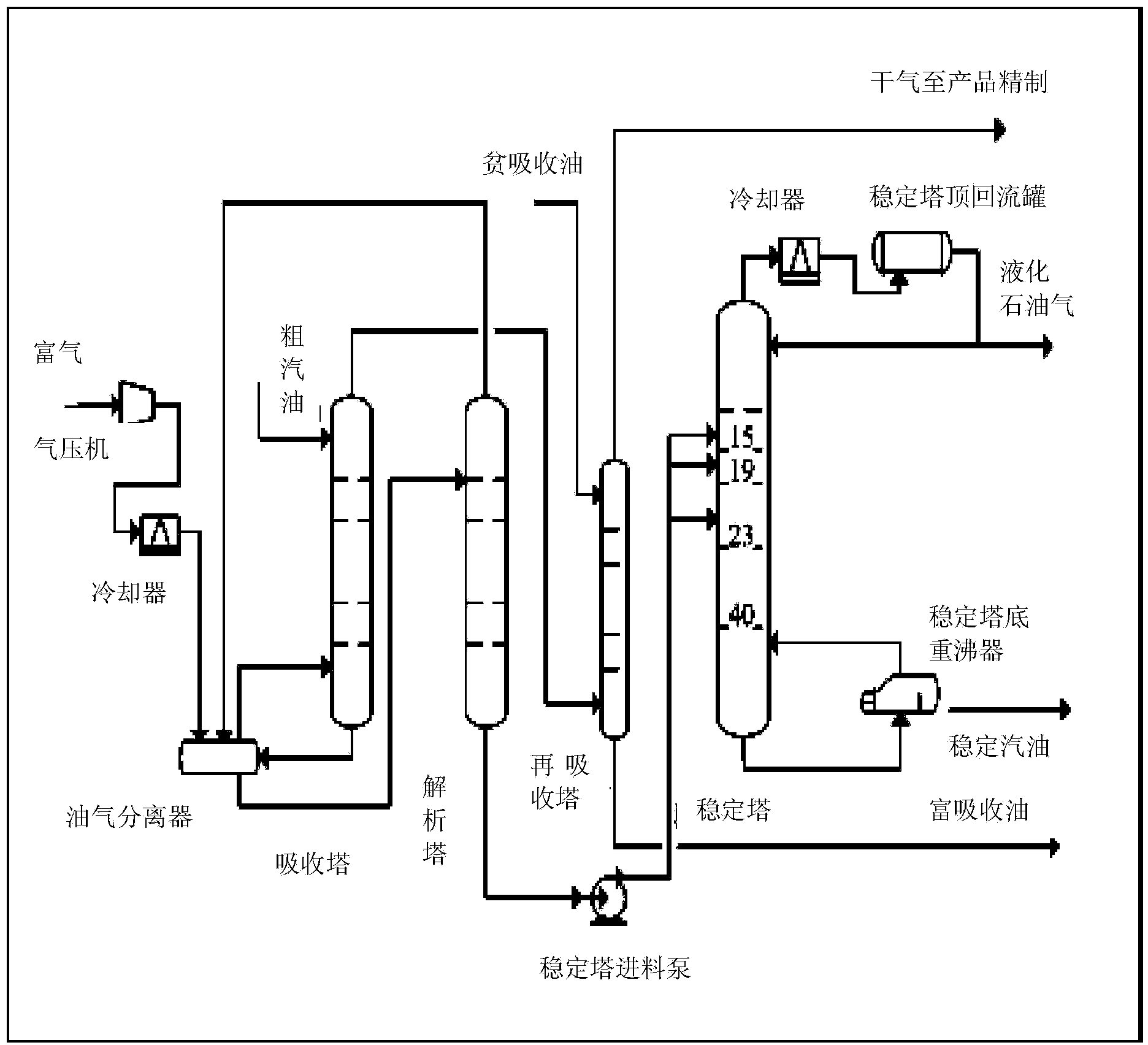

Fault diagnosis and pre-warning system in oil refining production process and establishment method thereof

ActiveCN104238545AStrong fault propagationStrong fault tracing and reasoning abilityElectric testing/monitoringOperabilityEngineering

The invention provides a fault diagnosis and pre-warning system in the oil refining production process and an establishment method of the fault diagnosis and pre-warning system. The method comprises the steps of establishing a multilevel flow model in the oil refining production process, determining a fault propagation path, conducting hazard and operability (HAZOP) analysis on the oil refining production process, determining a plurality of static nodes and a plurality of dynamic nodes, determining the connected relation of the static nodes and the dynamic nodes, establishing at least one alternative model, adopting the dynamic Bayesian network structure scoring mechanism for scoring of the alternative models, determining the alternative model with the highest score as a fault multilevel related model, determining the conditional probability relation between the static nodes and the dynamic nodes in the fault multilevel related model, and establishing a fault diagnosis and pre-warning module. The established fault multilevel related model and the fault diagnosis and pre-warning module have the higher fault propagation and fault tracing and reasoning capability, and accurate diagnosis and timely warning of faults generated in the oil refining production process can be achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

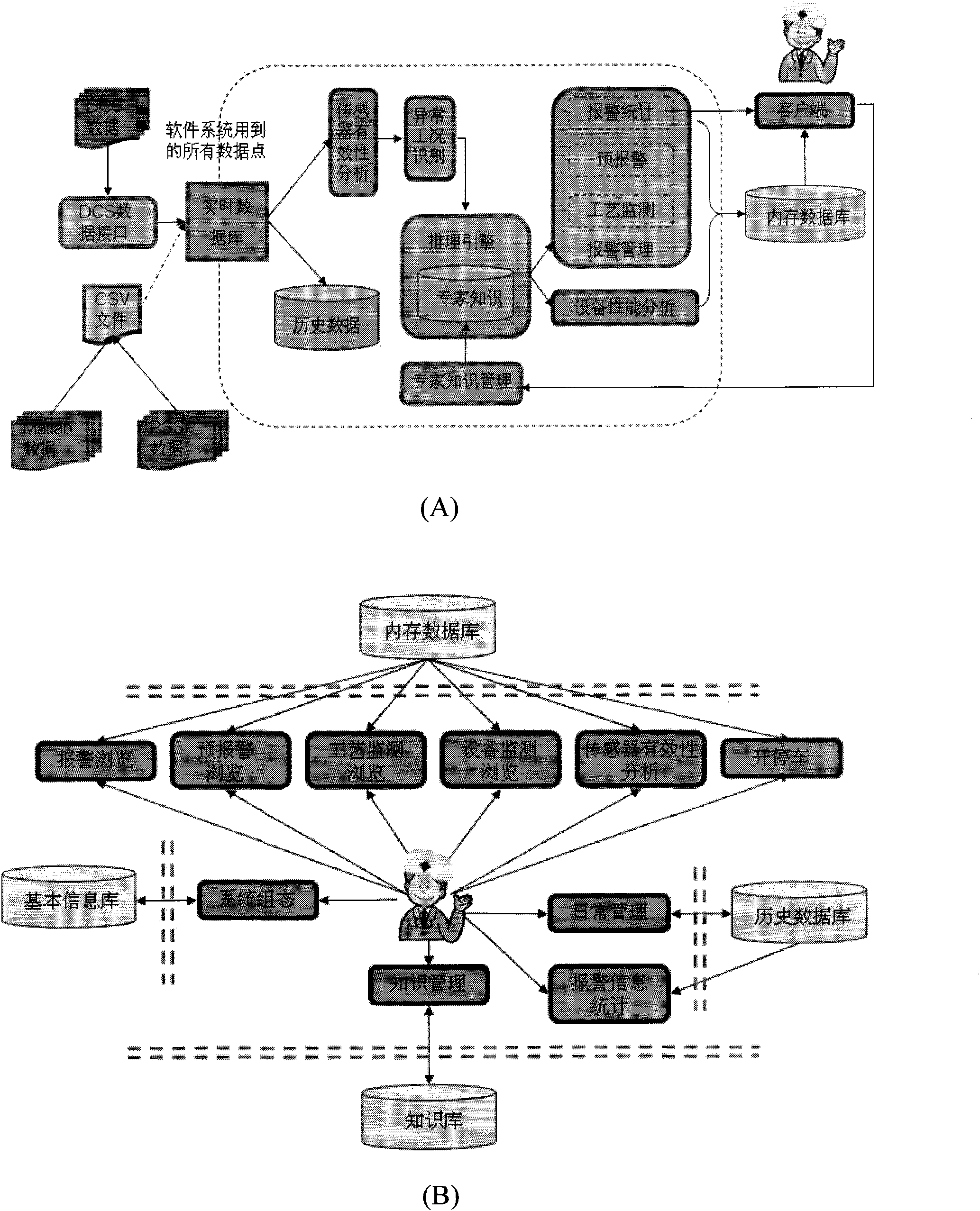

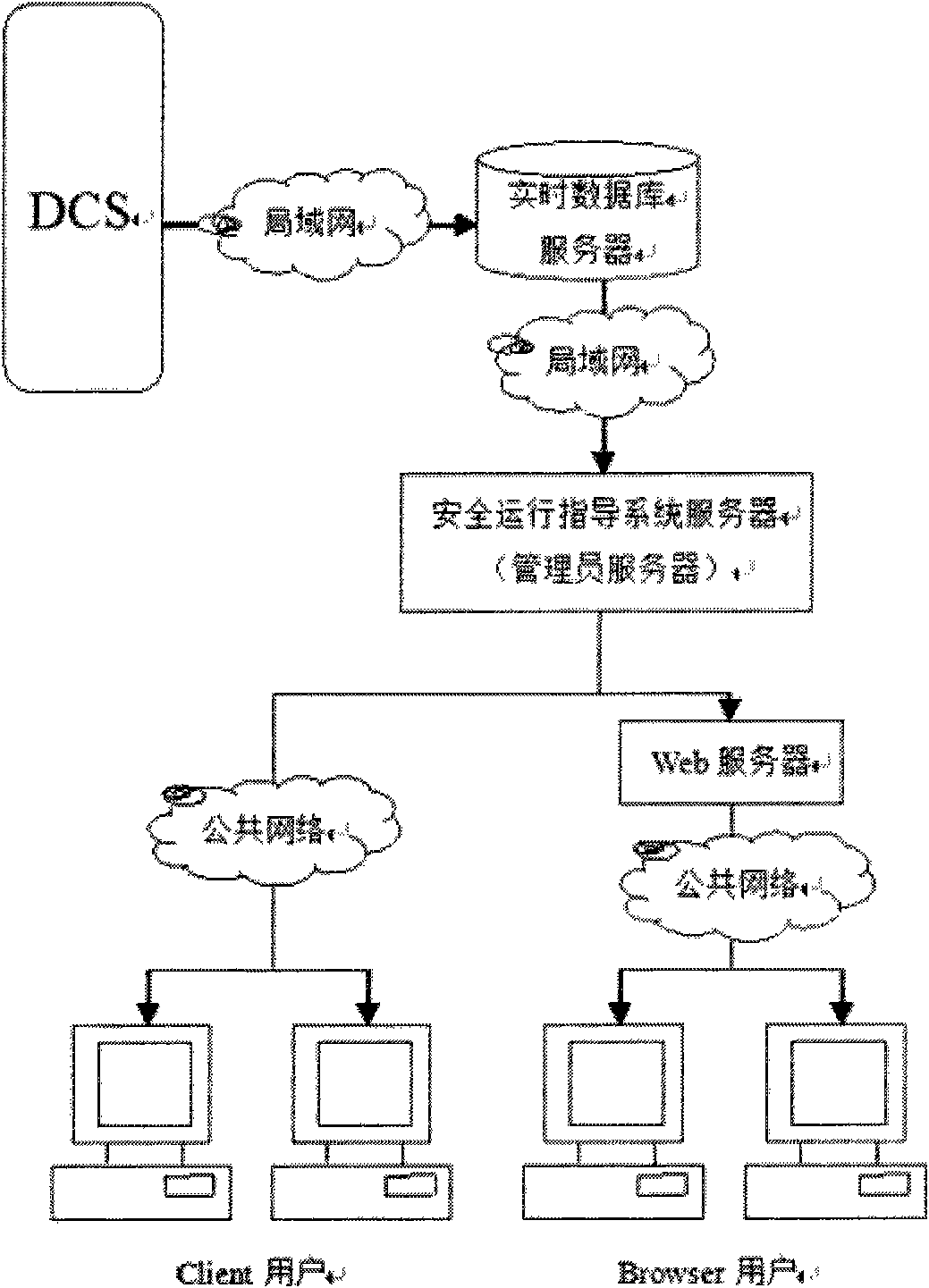

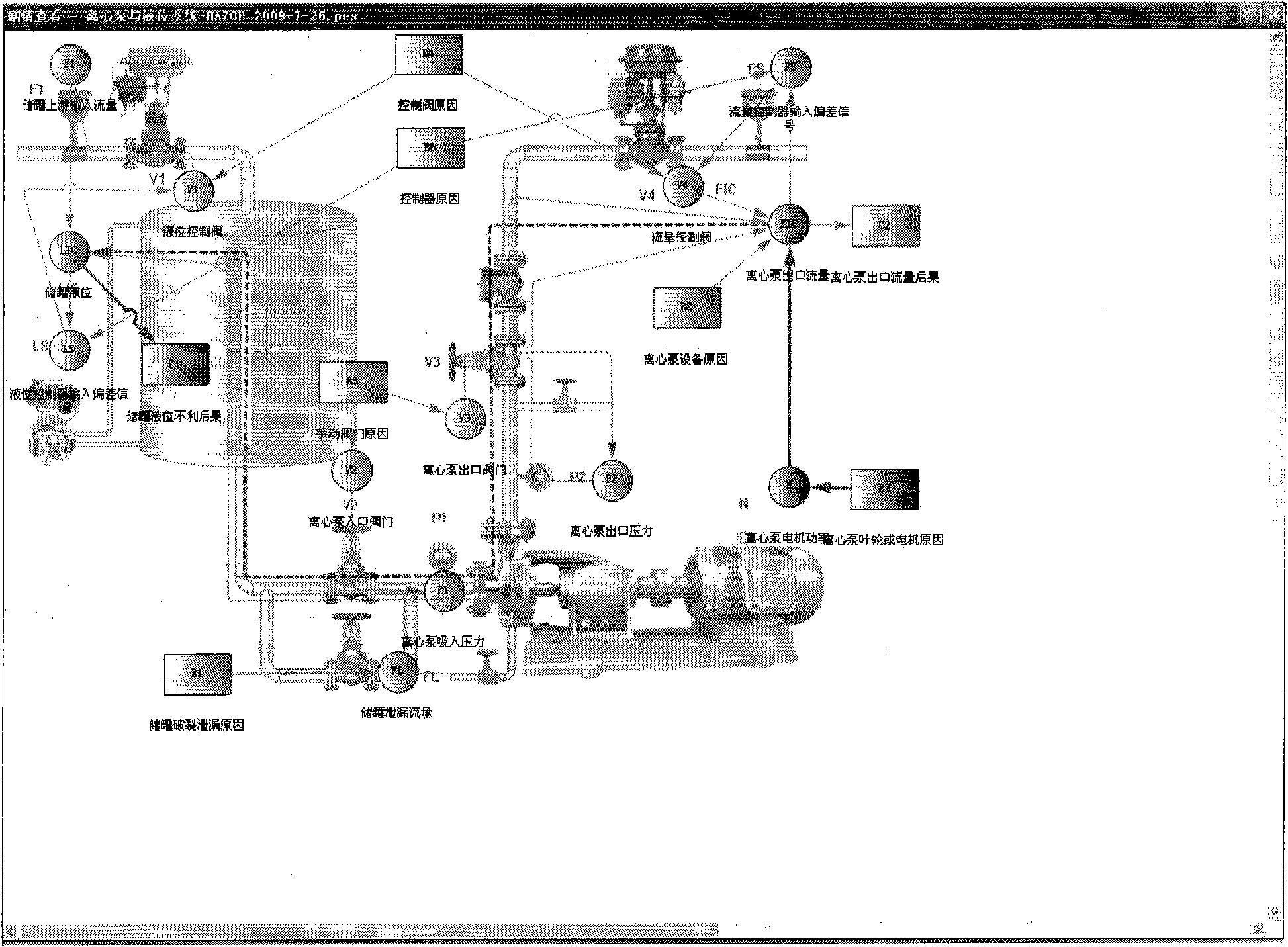

On-line real-time failure monitoring and diagnosing system device for industrial processing of residual oil

ActiveCN101989087ALong period of delayDelay full loadTotal factory controlProgramme total factory controlData acquisitionFilter effect

The invention relates to an on-line real-time failure monitoring and diagnosing system device for industrial processing of residual oil. The device has the functions of data acquisition, data filtering, sensor efficiency analysis, alarm management (process monitoring, pre-alarm and alarm counting), equipment monitoring, expert knowledge management, intelligent self-explanation of failure scenario, visualization display and the like, and can provide the daily management functions of shifting of duty, operation log, working calendar, process chart and the like. An inference engine subsystem is a core part, comprises a process monitoring engine and an equipment monitoring engine, is in charge of most inference work, and mainly comprises a signed directed graph (SDG), principal element analysis, fuzzy logic, mathematical analytical model and expert rule base. A process monitoring module uses a hybrid algorithm engine with various fused inference algorithms to obtain compatible paths of failure propagation, and removes false compatible paths by the filtering effect of expert rules to obtain the final diagnostic result.

Owner:CHINA PETROLEUM & CHEM CORP +1

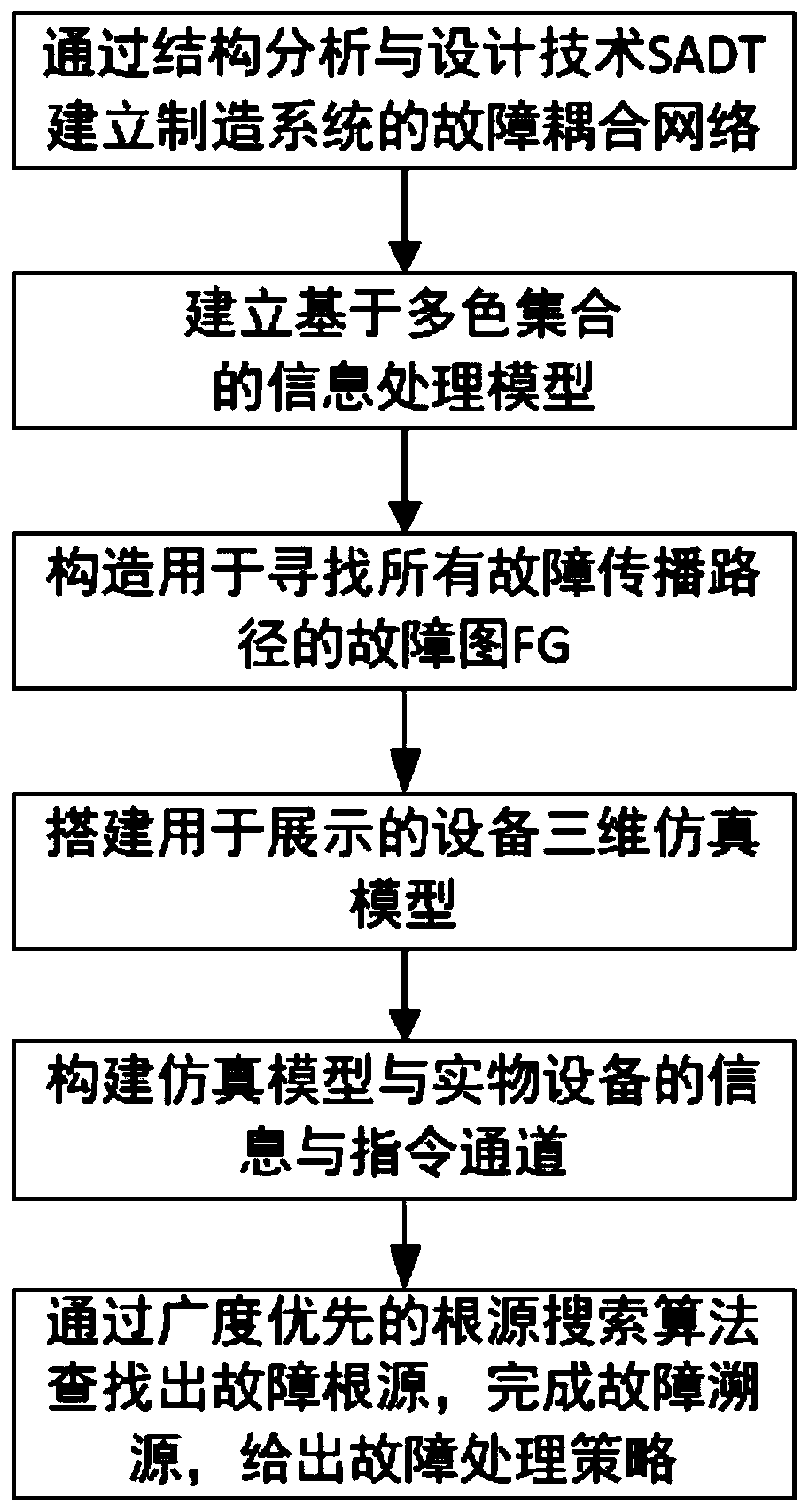

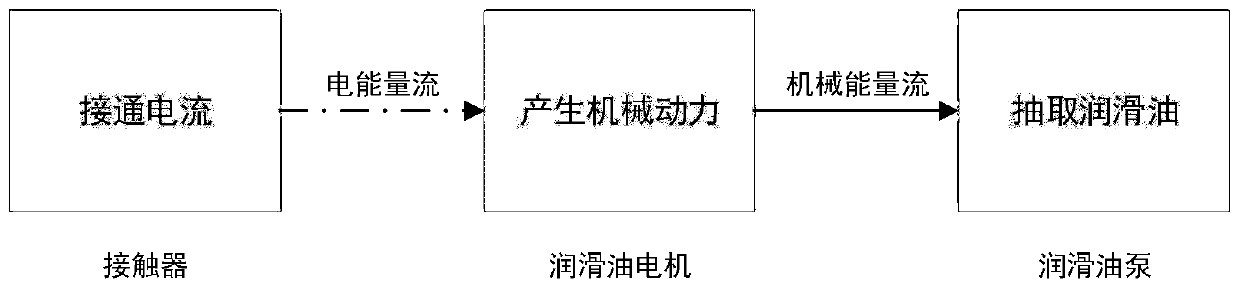

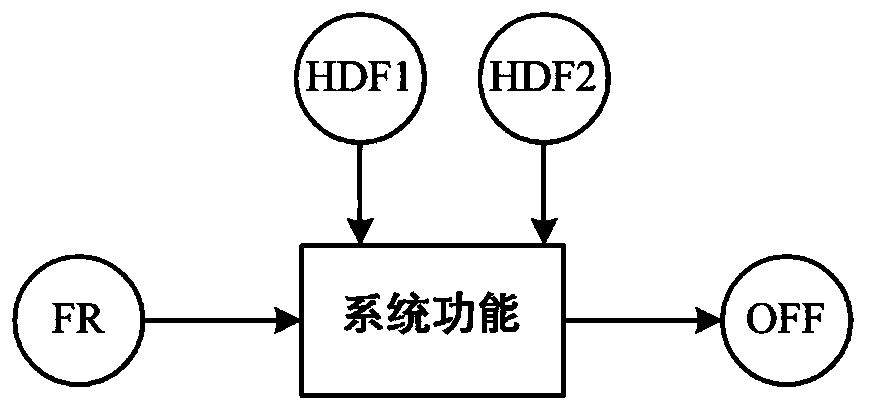

Manufacturing system fault tracing method and system based on digital twin model

ActiveCN110276147AImproves diagnosabilityDesign optimisation/simulationComplex mathematical operationsInformation processingAssistive technology

The invention discloses a manufacturing system fault tracing method and system based on a digital twin model. The manufacturing system fault tracing method comprises the following steps that A, a digital twin fault tracing mathematical model is built on a simulation platform; b, a visual simulation model of the digital twin of the manufacturing system is built on the simulation platform; c, a digital twinning model of the manufacturing system is built; and step D, all fault propagation paths in the information processing model based on the multi-color set are searched through a breadth-first root search algorithm, and a fault root is found out. The root cause of the fault can be better and faster found, the diagnosability can be improved, and technicians can be assisted in providing reliability improvement measures in a targeted mode.

Owner:GUANGDONG UNIV OF TECH

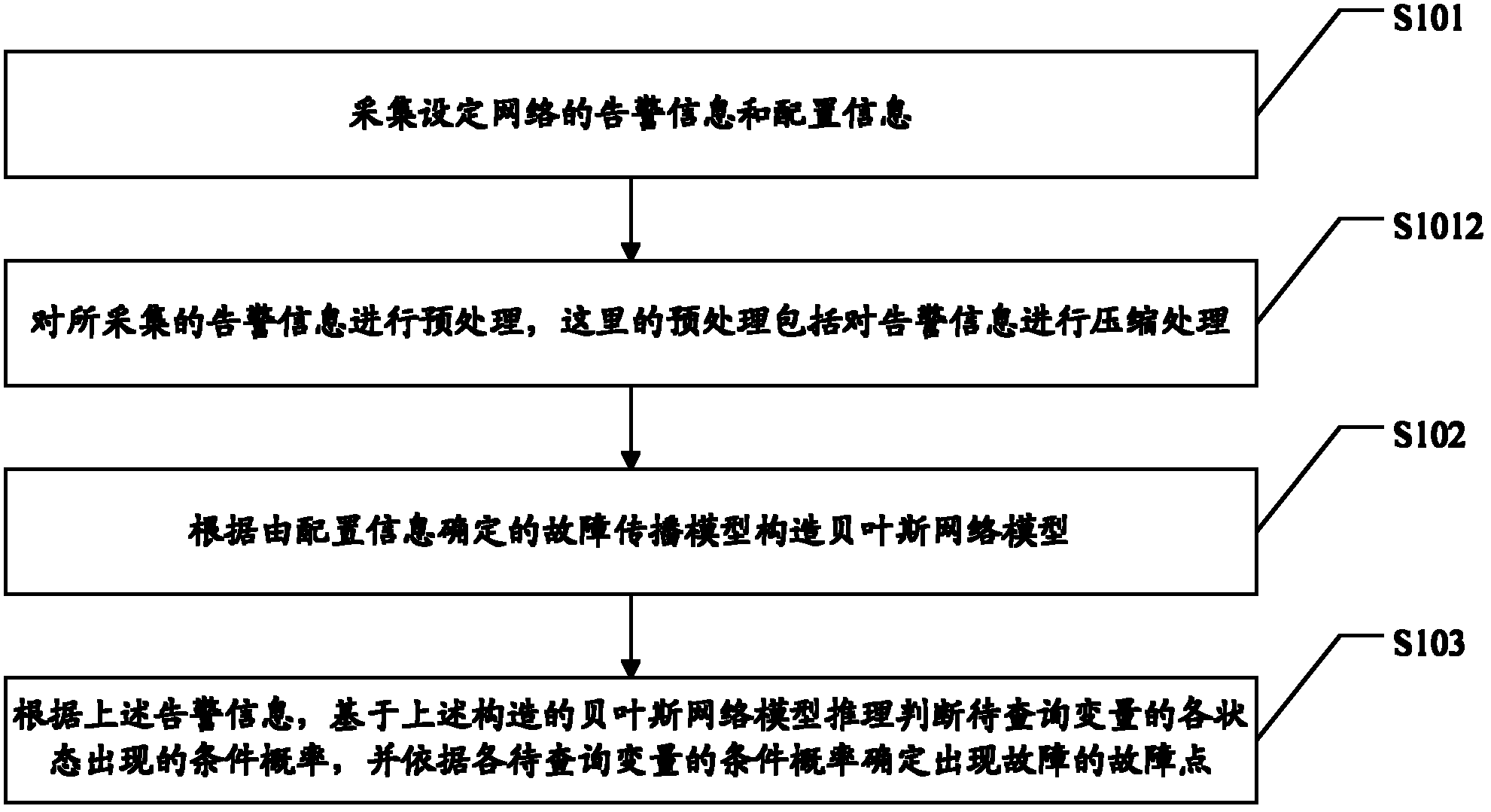

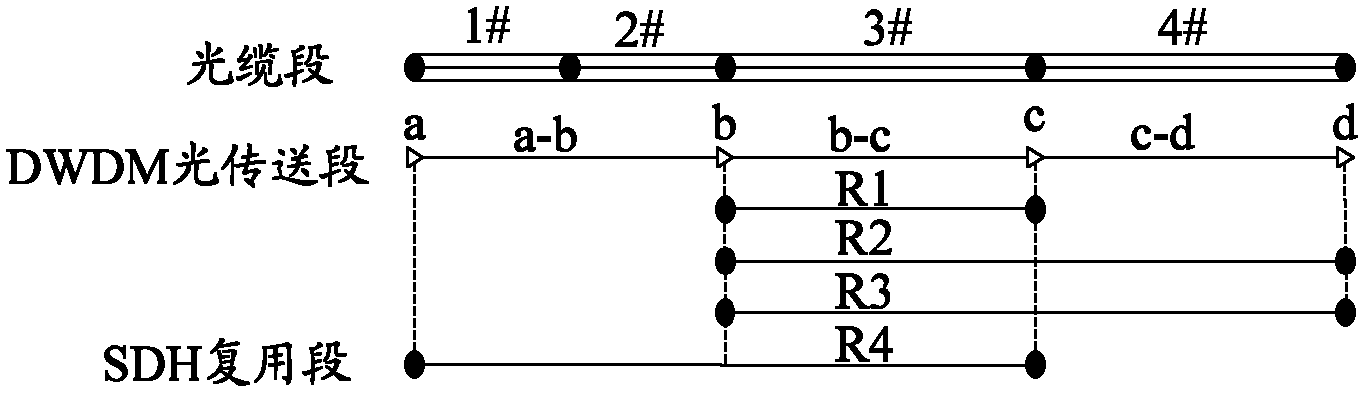

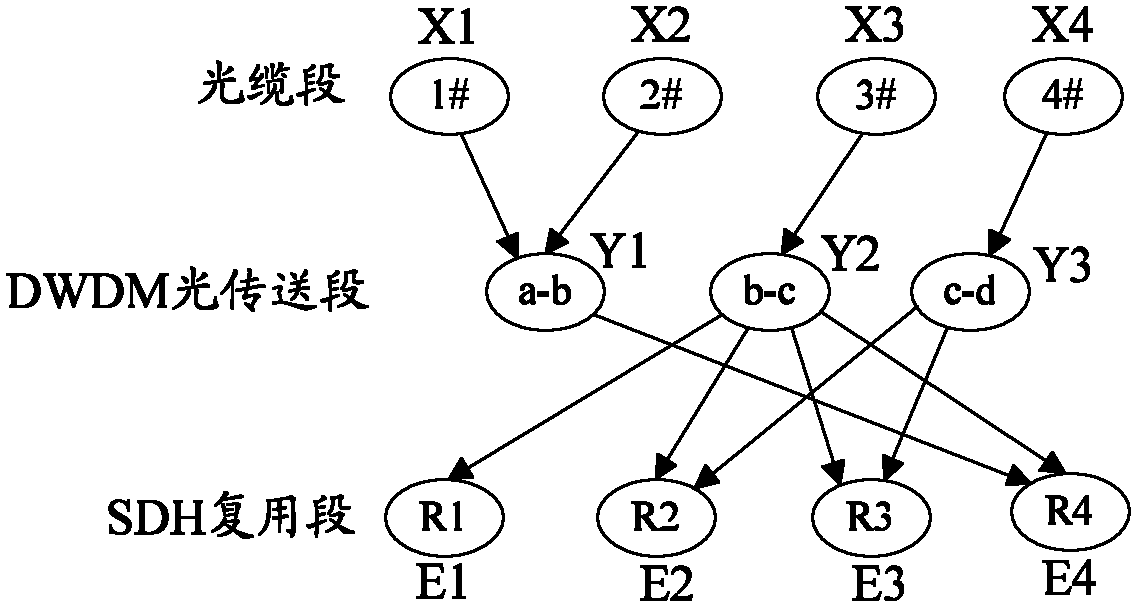

Method and device for diagnosing transmission network failure

InactiveCN102255764AInference results are accurate and reliableEasy to operateData switching networksNetwork connectionNetwork model

The invention discloses a method and device for diagnosing a transmission network failure. The method comprises the following steps of: acquiring alarm information and configuration information of a set network, wherein the configuration information comprises network element layer information and network connection layer information; configuring a Bayes network model according to a failure propagation model determined by using the configuration information: defining a group of variables of a Bayes network corresponding to each node in the failure propagation model, defining a directed edge of the Bayes network corresponding to each directed edge in the failure propagation model, and initializing the prior probability of each root node and the conditional probability of each directed edge in the Bayes network; and reasoning and judging the conditional probability of the occurrence of each status of each variable to be inquired based on the Bayes network model according to the alarm information, and determining a failure point according to the conditional probability status of each variable to be inquired. According to the scheme disclosed by the invention, the failure point can be positioned accurately; and the method and the device have high operability.

Owner:GUANGDONG POWER GRID POWER DISPATCHING CONTROL CENT

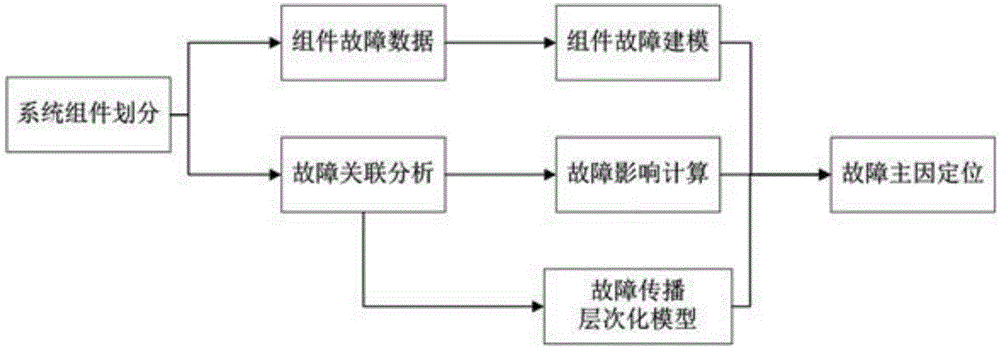

Numerical control machine tool fault diagnosis method

The invention belongs to the numerical control machine tool technology field and relates to a numerical control machine tool fault diagnosis method. The method comprises the following steps of 1, dividing a system part into n component; and establishing a corresponding relation of each component and fault time and a fault propagation relation among the components; 2, establishing a component fault propagation digraph and describing a numerical control machine tool system component fault propagation digraph; 3, calculating a numerical control machine tool system component fault influence; 4, converting the fault propagation digraph into a fault-propagation hierarchical model; 5, modeling based on a numerical control machine tool system component failure rate related to time; and 6, positioning a fault main cause and carrying out numerical control machine tool fault diagnosis. In the invention, a system component fault propagation hierarchy relation and the fault propagation influence are considered and a fault time correlation influence of the system component during component failure rate determination is also considered; component fault modeling accuracy is increased; compared to traditional system component fault incidence rate diagnosis based on a graph theory or single data driving, the method possesses real-time performance and accords with realities.

Owner:JILIN UNIV

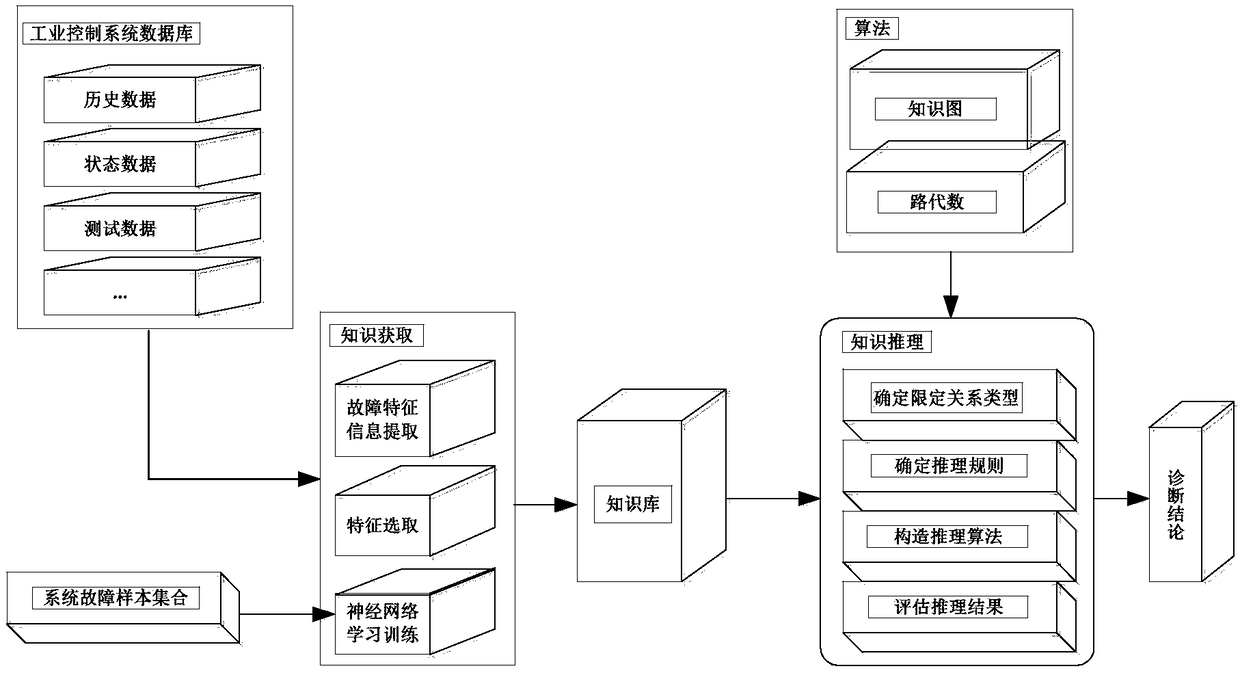

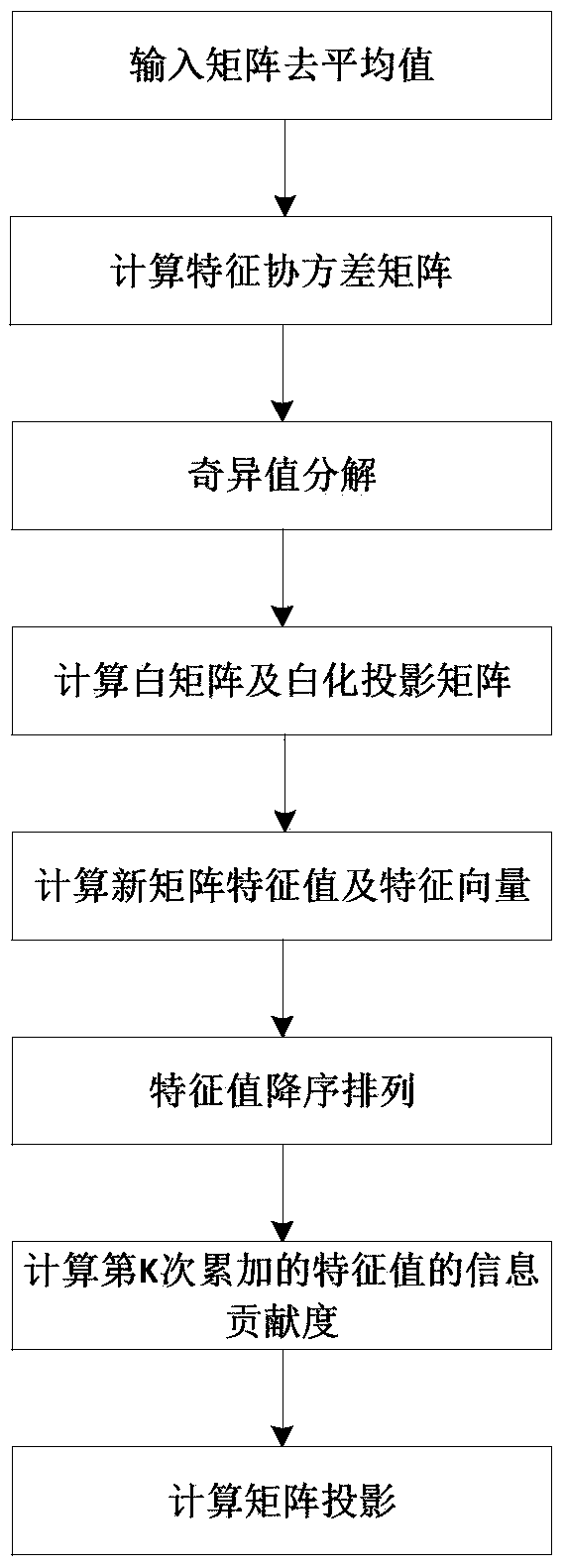

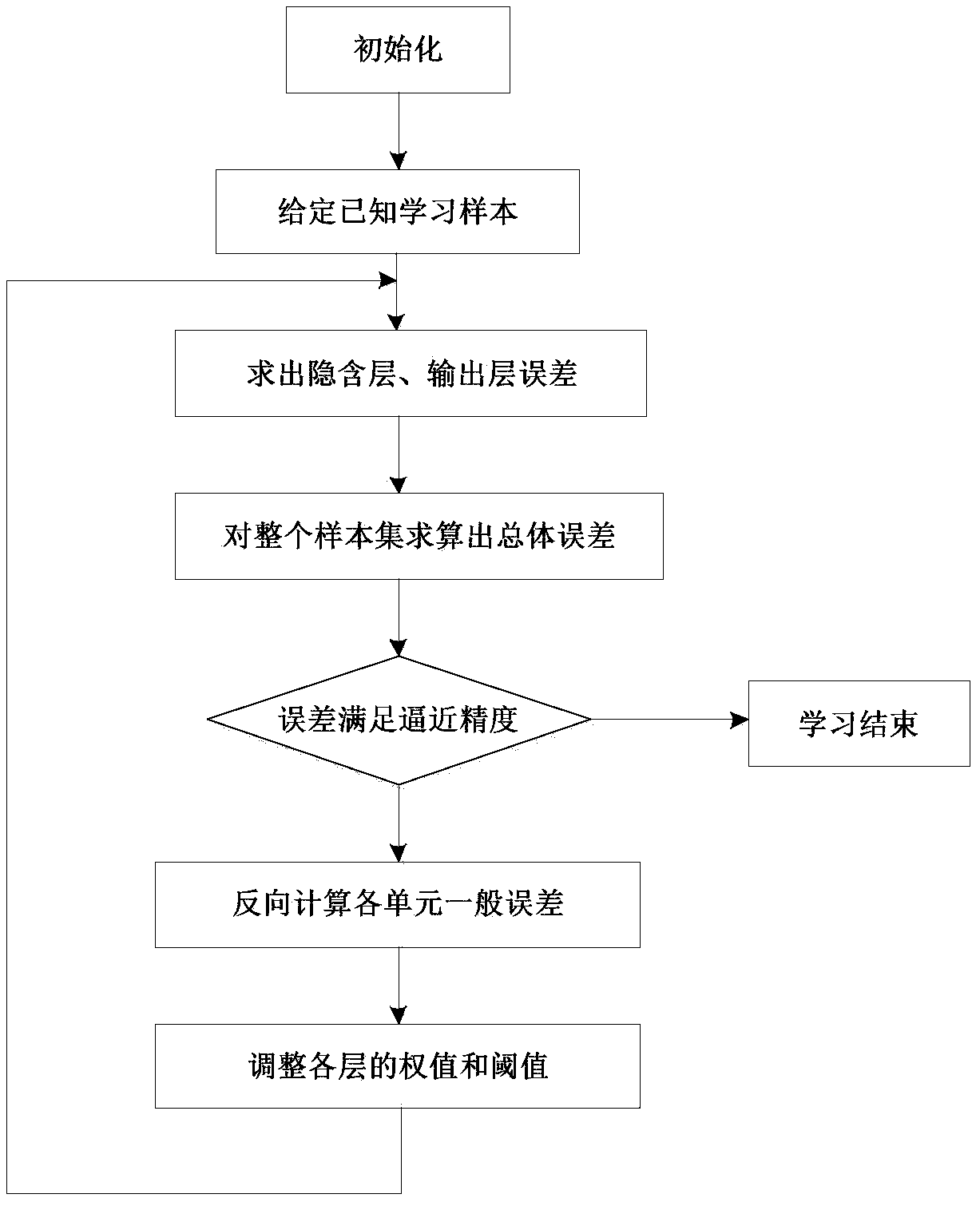

Knowledge-based fault diagnosis method

ActiveCN109491816AOvercoming the \"Combination Explosion\"Overcome \"infinite recursion\" and other problemsFault responseInference methodsMachine learningInference

The invention discloses a knowledge-based fault diagnosis method. The method comprises the following steps: establishing a typical fault case database; extracting fault feature information and selecting main data variables by adopting a signal processing technology and a main component analysis method; Learning the fault sample by using an improved neural network algorithm; the comprehensive representation of the diagnosis knowledge is realized by adopting a mode of combining a generation type rule and a framework; constructing a system fault propagation model through data analysis and the relationship among the devices in the system, and defining a system fault propagation path; and based on the obtained fault knowledge, constructing a knowledge graph, and giving an inference rule by utilizing a road algebra theory to realize fault positioning based on knowledge inference. Through an improved neural network algorithm and a knowledge reasoning theory, automatic acquisition of knowledgeand accurate positioning of faults are realized, the diagnosis precision is improved, and a basis is provided for fault diagnosis of an industrial control system.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

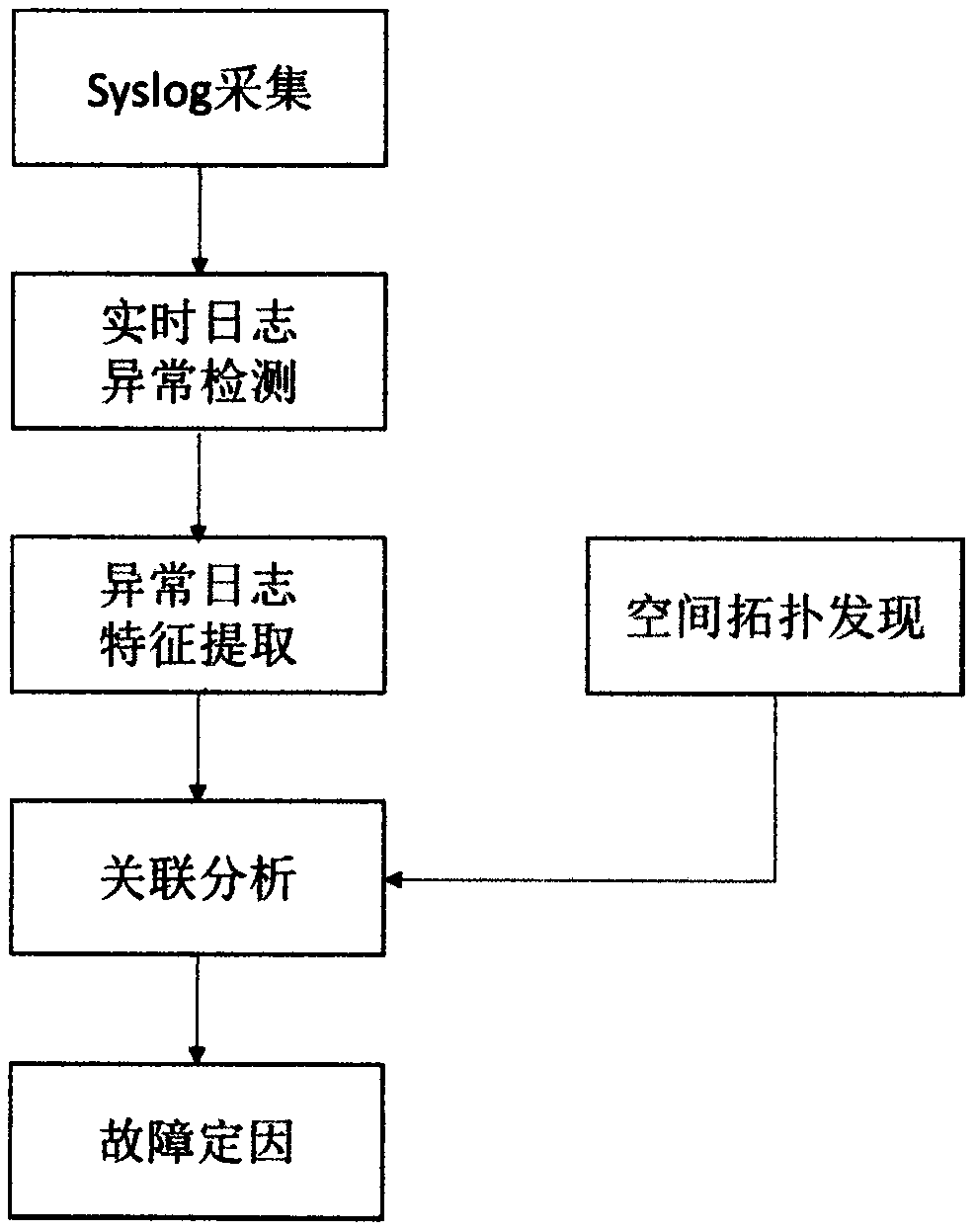

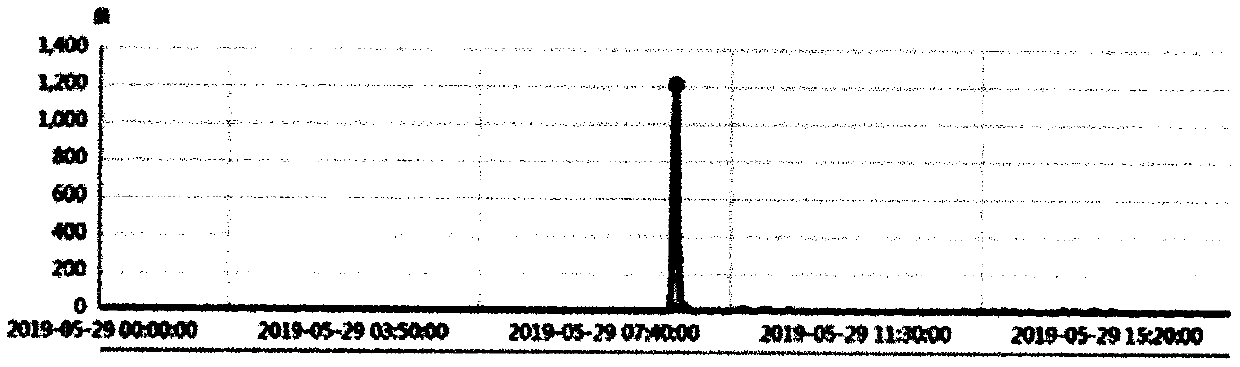

Fault cause determination method and system based on space-time analysis log

The invention discloses a fault cause determination method and system based on a space-time analysis log. The method comprises the following steps: step 1) collecting syslog logs generated by all network equipmentin a network system; 2) monitoring syslog logs generated by all equipment in the network and periodically performing feature analysis on the logs based on time space in real time; 3) performing time-based feature extraction and analysis on the running state of the network equipment, and checking hidden dangers and fault time points of the network equipment; (4) obtaining space topology information, (5) extracting related equipment logs in combination with the space topology information to construct a feature matrix of abnormal events, and (6) obtaining a fault propagation chain and root causes through an intelligent decision algorithm, and displaying detailed information of a fault influence surface and the root causes.

Owner:叶晓斌 +5

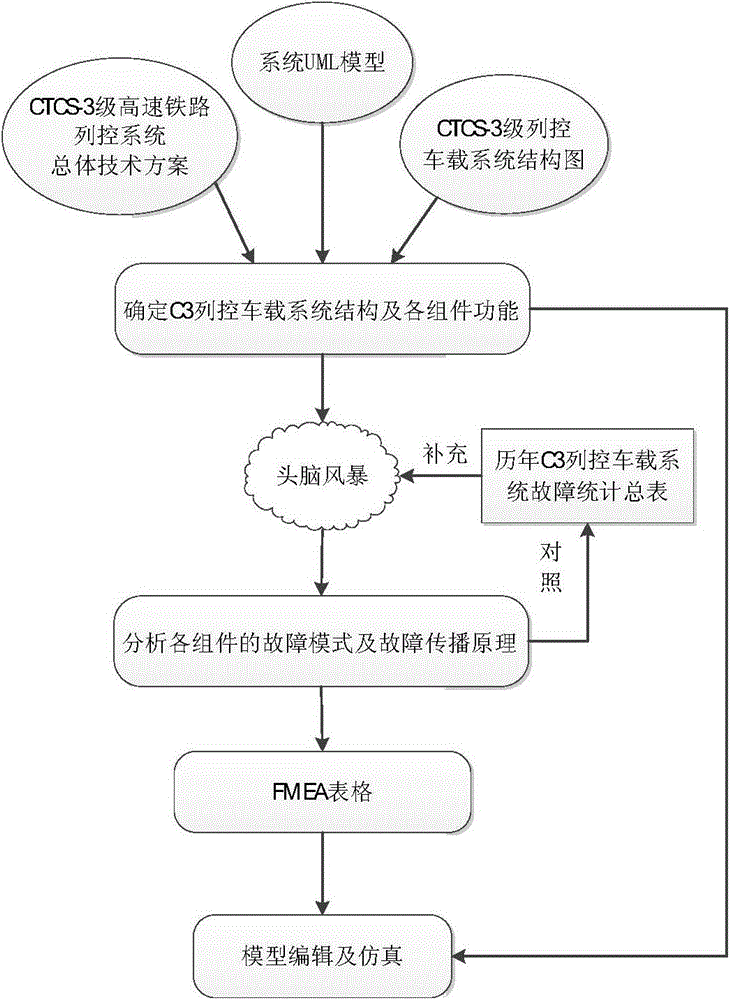

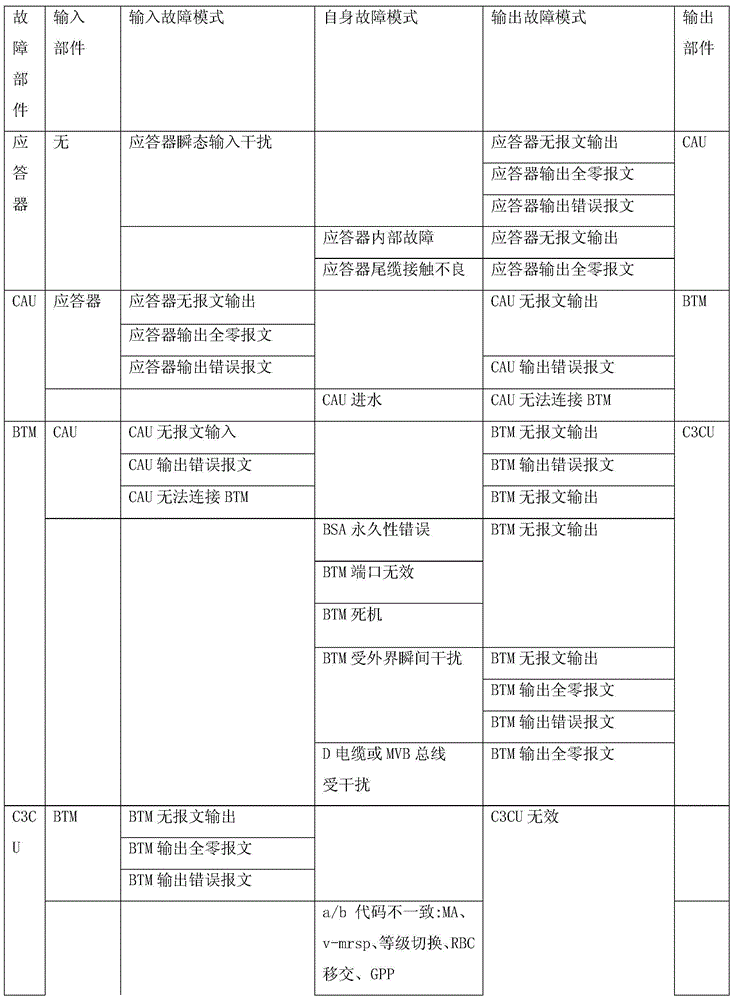

Fault logical modeling method for high speed railway train operation control vehicle-mounted system

InactiveCN103955556ASystematicAchieve conversionGeometric CADRailway traffic control systemsGraphicsSystems research

Owner:BEIJING JIAOTONG UNIV

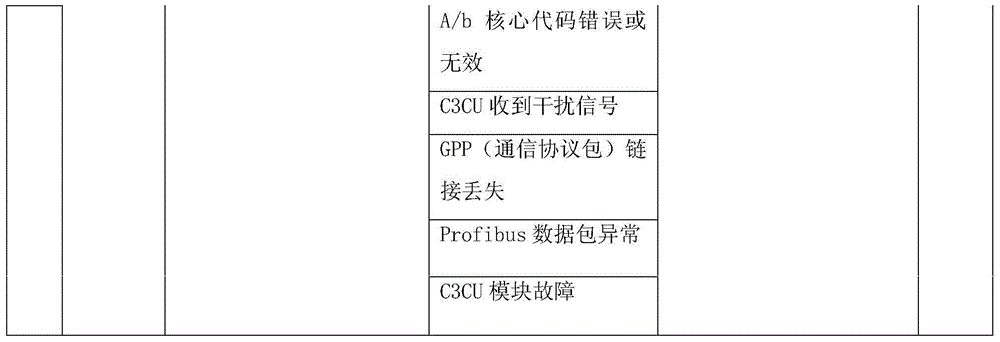

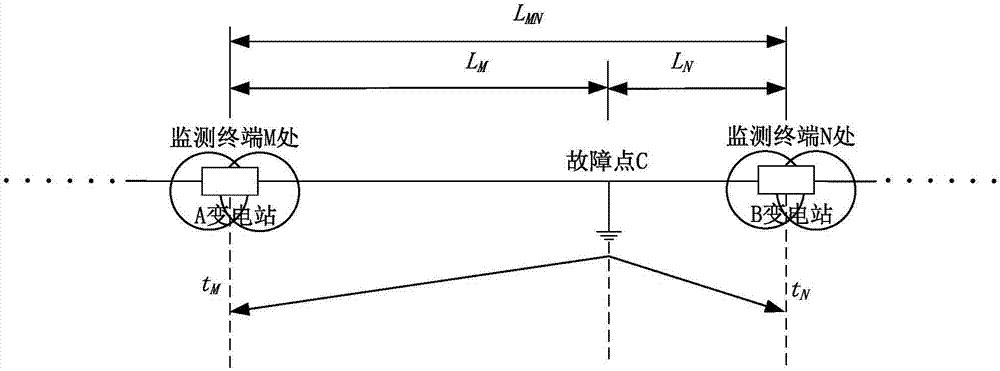

Distributed traveling wave range finding method

ActiveCN106959401AAvoid influenceShorten the monitoring distanceFault location by conductor typesHigh resistancePower flow

The invention discloses a distributed traveling wave range finding method comprising the following steps: collecting traveling wave voltage and current data of multi-measuring point according to preset distances; timing and correcting the acquisition time; determining the initial traveling wave speed according to traveling wave time and measuring point distance measured on measuring points of two ends of the fault; determining the fault position according to the initial traveling wave speed, the distance of two adjacent measuring points, the fault propagation time to the measuring point, and two end range finding. The method distributes measuring points along power transmission line poles according to certain distances, and can dynamically measure the traveling wave speed approaching to the real value, thus solving the existing power transmission traveling wave monitoring problems, and ensuring the range finding precision under various complex conditions like high resistance grounding.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

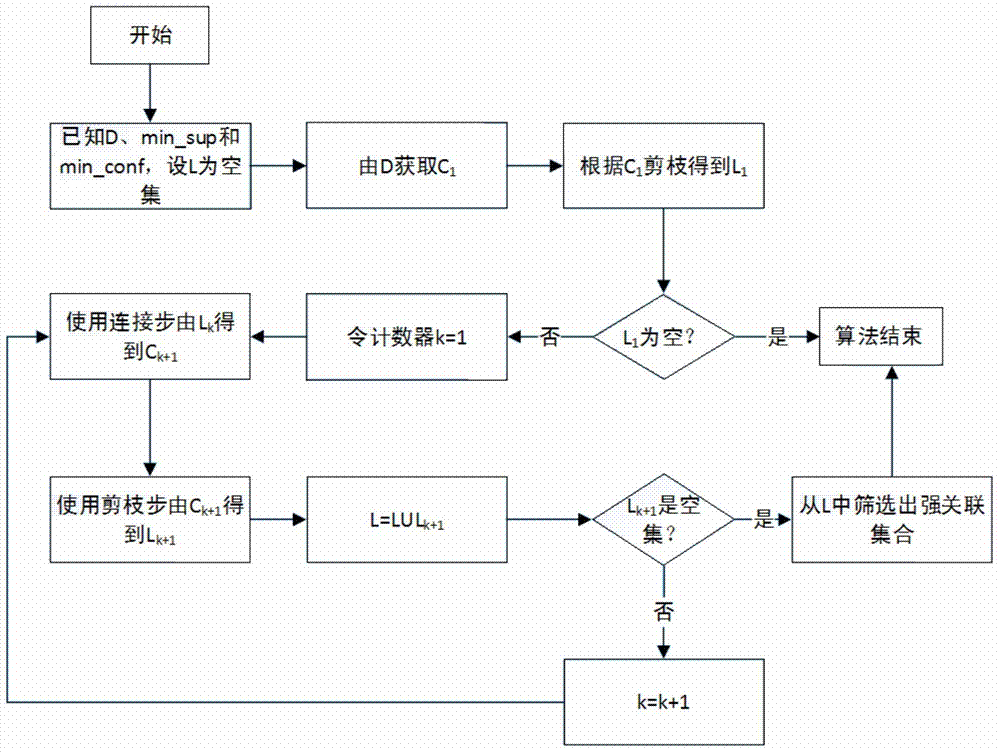

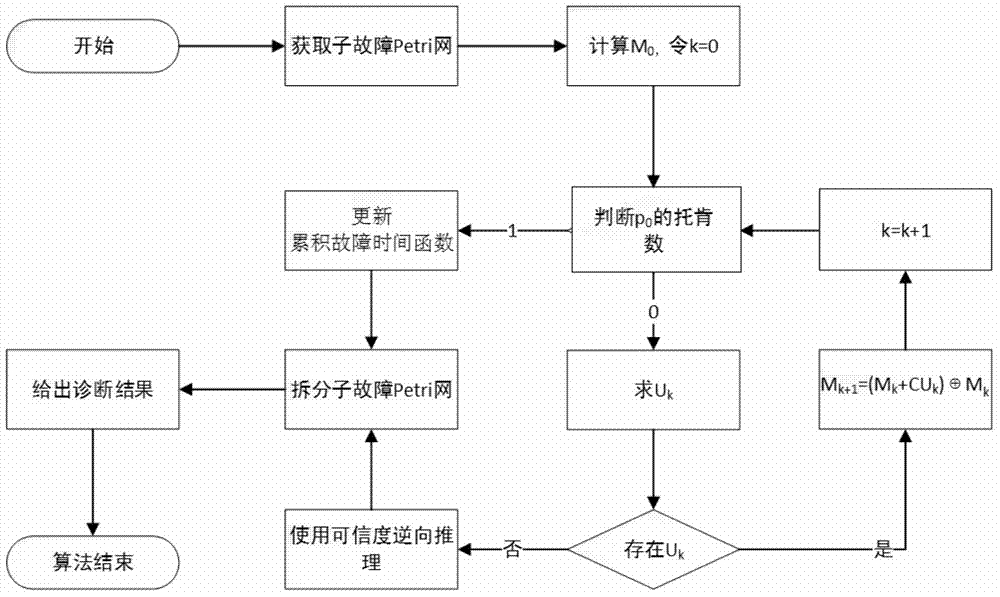

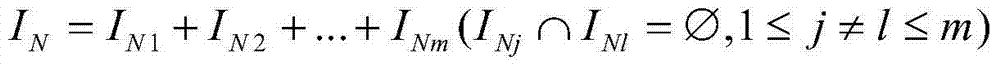

Ship electric power station fault diagnosing method based on knowledge petri network

ActiveCN104268375AChange the situation that is prone to missed judgment of the cause of failureImprove the disadvantages of lack of operabilityFault locationSpecial data processing applicationsNetwork modelRule mining

The invention discloses a ship electric power station fault diagnosing method based on a knowledge petri network. The method includes the steps that (1) fault symptom sets of units of a ship power station are obtained and screened according to a ship power station fault Petri network model; (2) by means of an improved Apriori algorithm, strong association rule mining is carried out on the fault symptom sets and the fault units; (3) by means of man-machine conversation, a user inputs fault symptom characteristic quantity and confidence, a system carries out fault symptom identification through fuzzy reasoning by means of a strong association rule to determine the fault units; (4) the fault units serve as a root database, faulty Petri subnets are extracted from the Petri network model, fault reason diagnosis is carried out by means of a forward operation and backward inference method, and according to diagnosis results, fault reasons, fault route graphs and a corresponding fault maintenance method are provided. The ship electric power station fault diagnosing method can avoid false negatives of the fault reasons, generates a fault propagation path, and improves accuracy and efficiency of ship power station fault diagnosis.

Owner:NAVAL UNIV OF ENG PLA

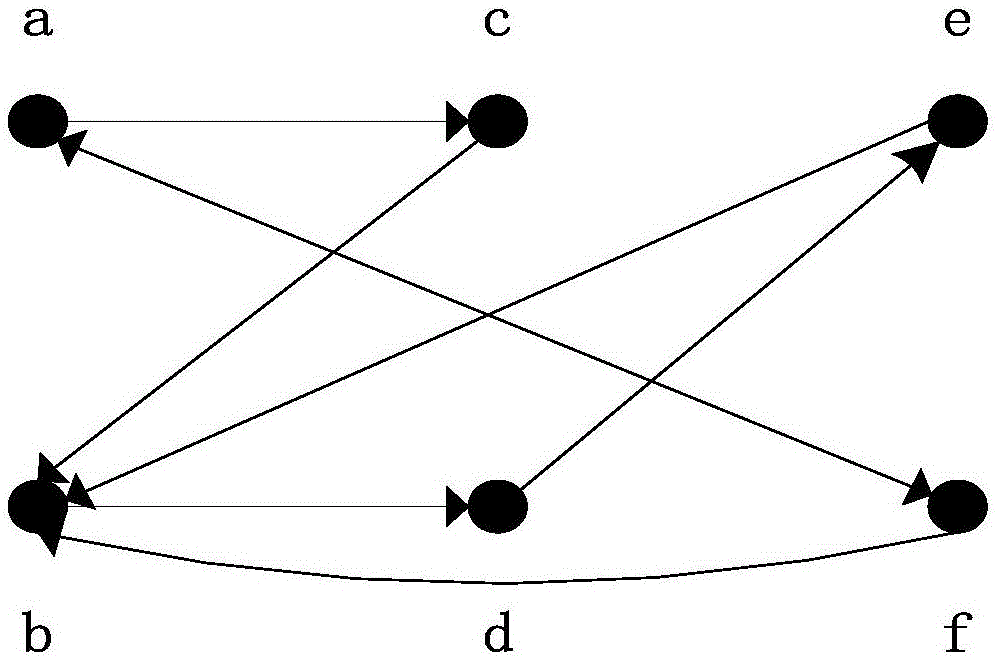

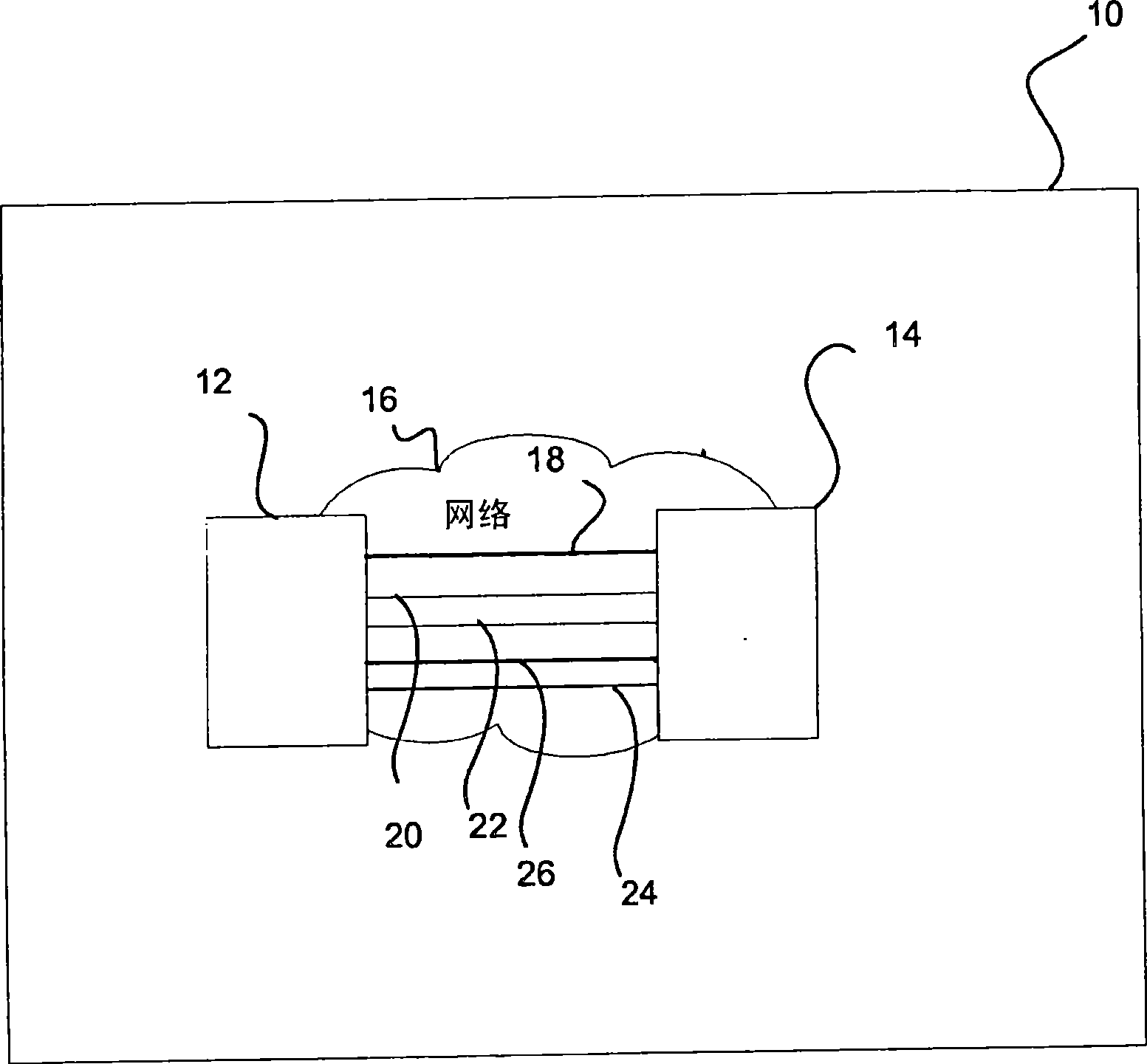

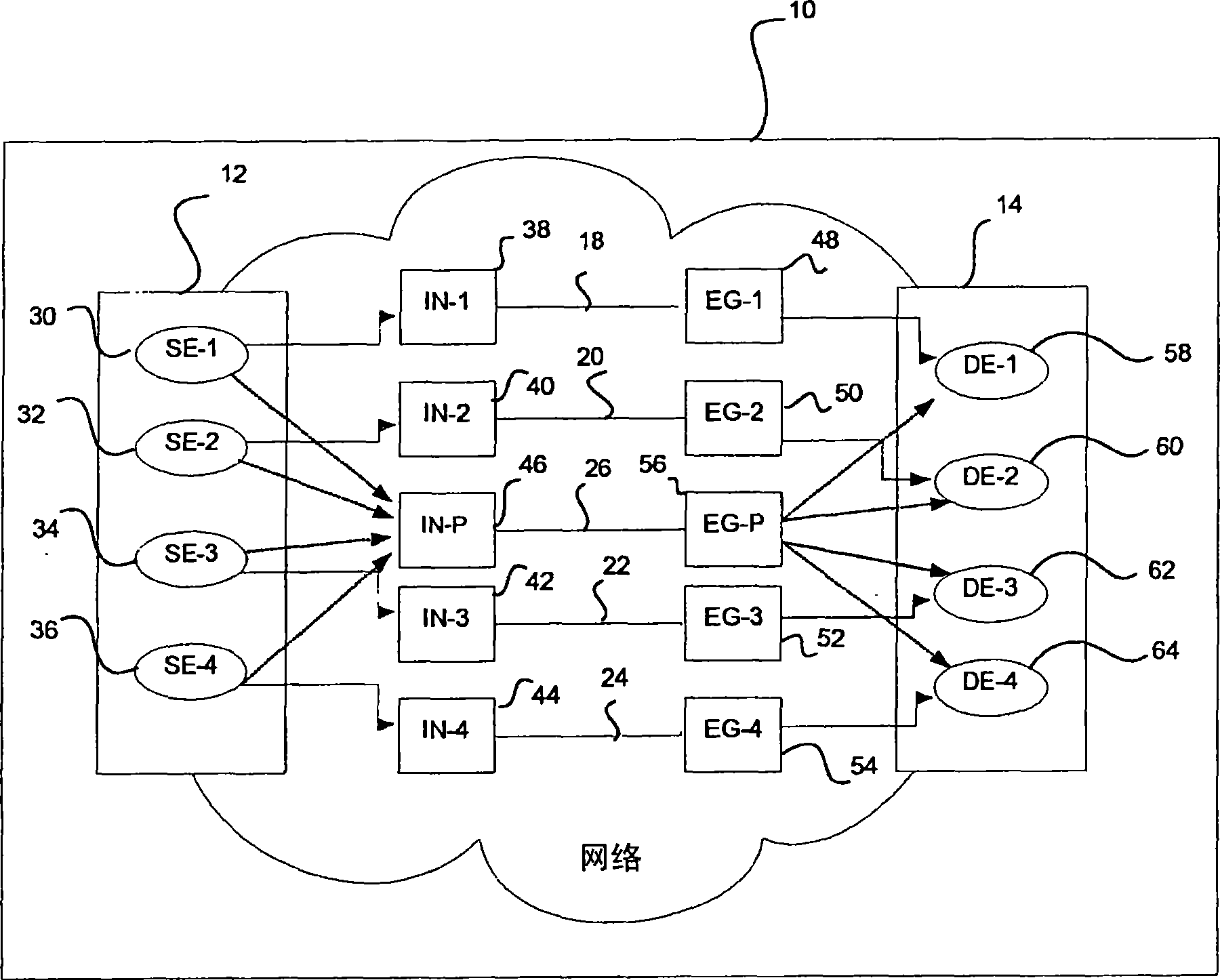

System and Method for Automated Distributed Diagnostics for Networks

InactiveUS20100192013A1Minimize the numberRelieve symptomsTesting/monitoring control systemsNon-redundant fault processingMedically unexplainedCoupling

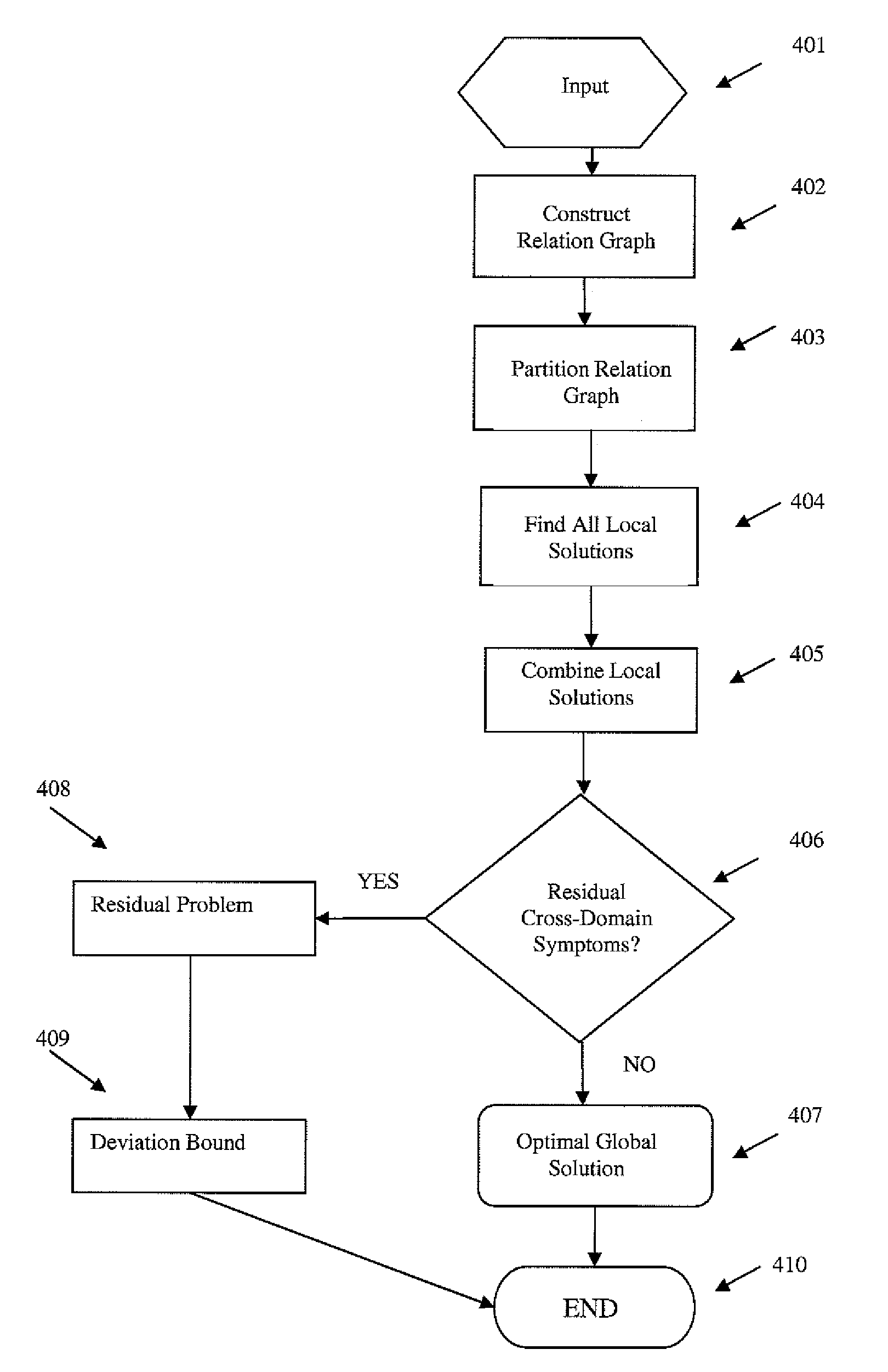

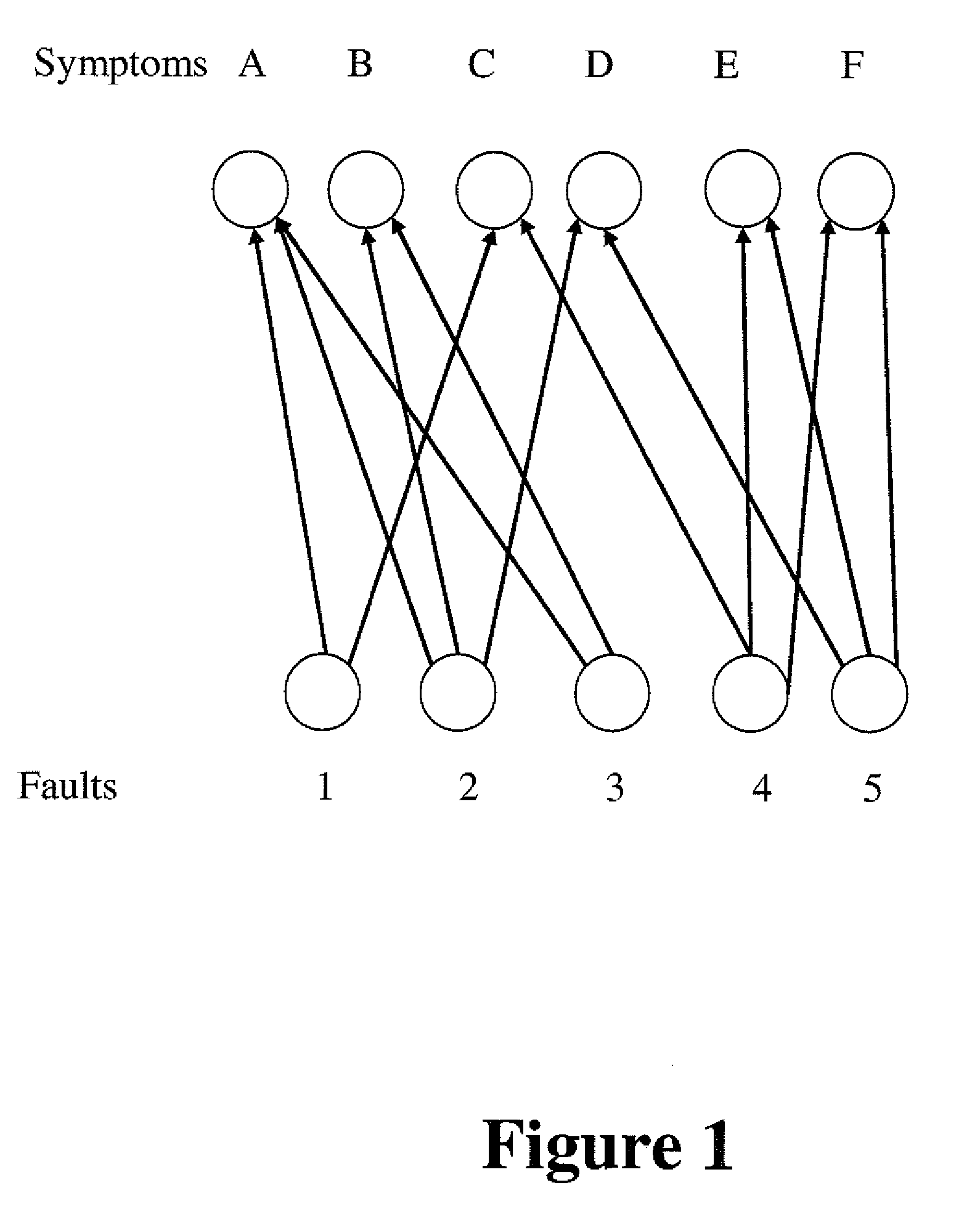

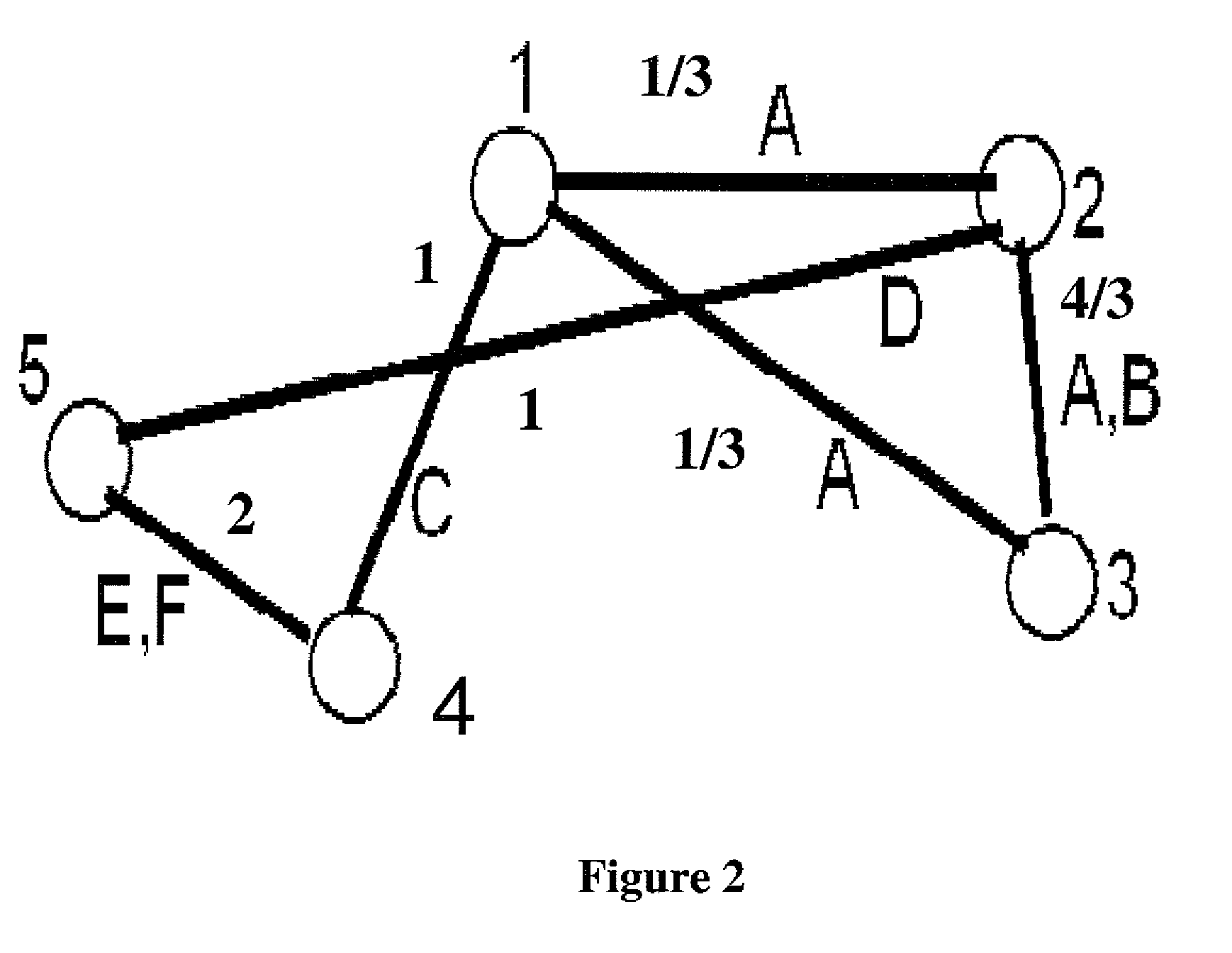

A method for distributed computations for fault-diagnosis in a system whose fault propagation model has deterministic couplings between faults and symptoms includes creating a ‘relation graph’ in which the nodes correspond to the potential faults, with two nodes connected by a ‘relational link’ if their corresponding faults have an observed symptom in common. The relation graph is then partitioned into several domains, while minimizing the number of cross-domain relational links, which correspond to cross-domain symptoms. In each domain, all the optimal local solutions to the domain's sub-problem are first determined, and then a combination is selected of the local solutions, one from each domain, that explains the maximum number of cross-domain symptoms, where the optimal solution is supplemented, if necessary, with additional faults to explain any remaining unexplained cross-domain symptoms, determining also a bound on the deviation from optimality of the global solution.

Owner:TELCORDIA TECHNOLOGIES INC

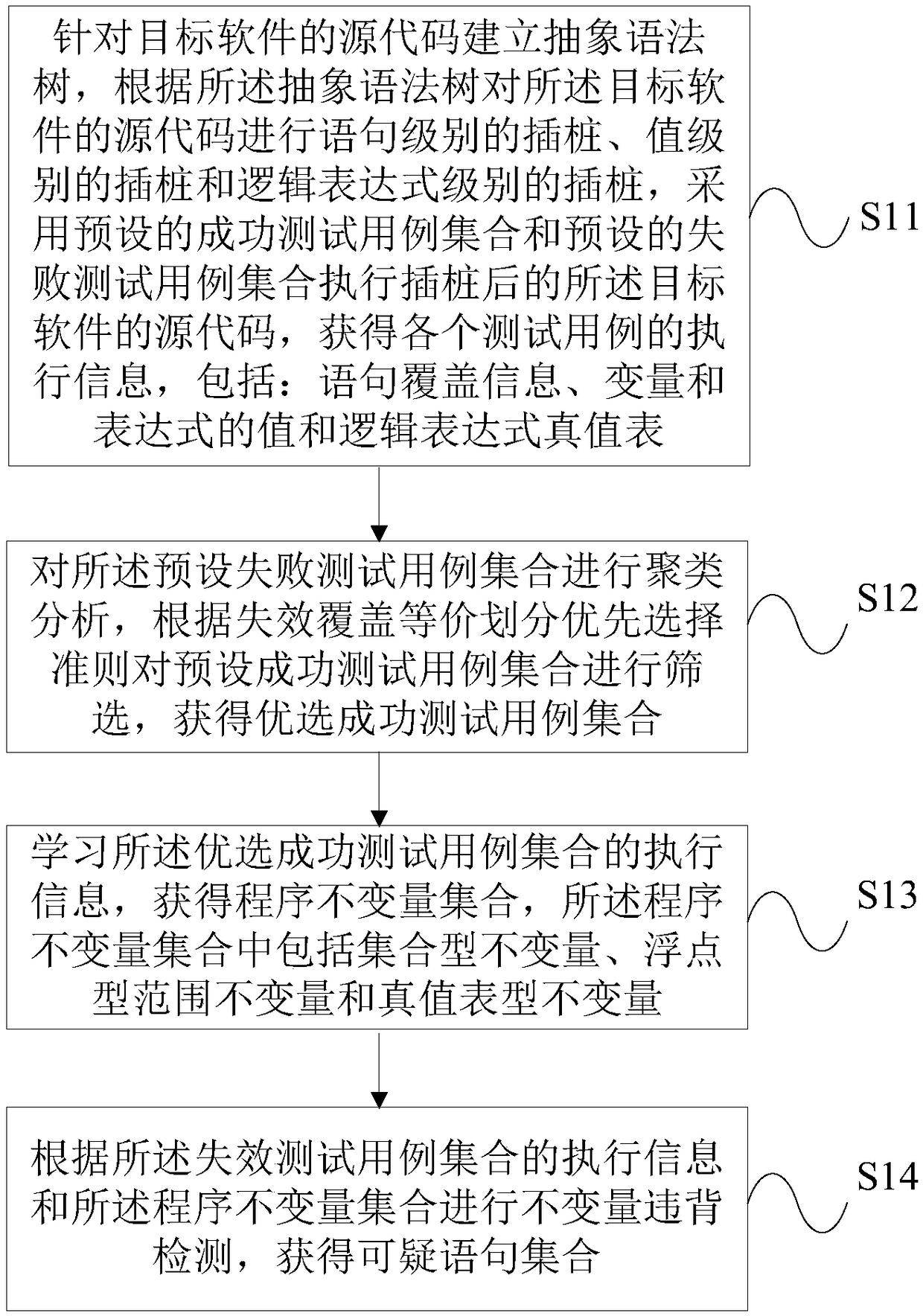

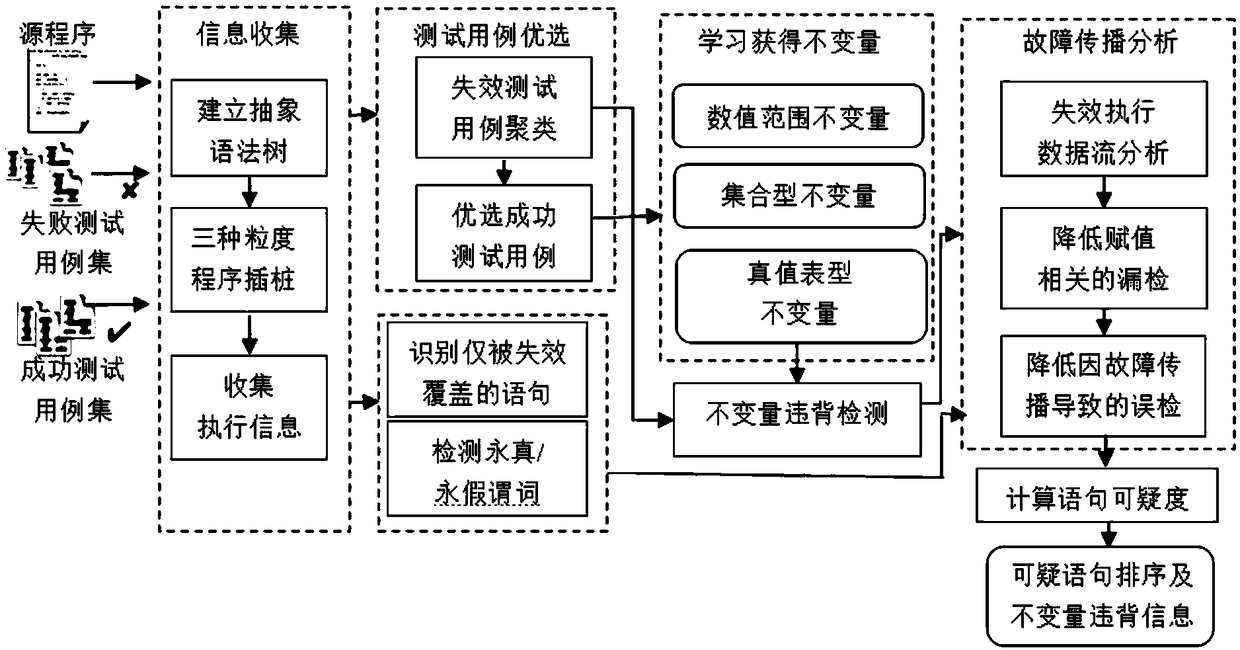

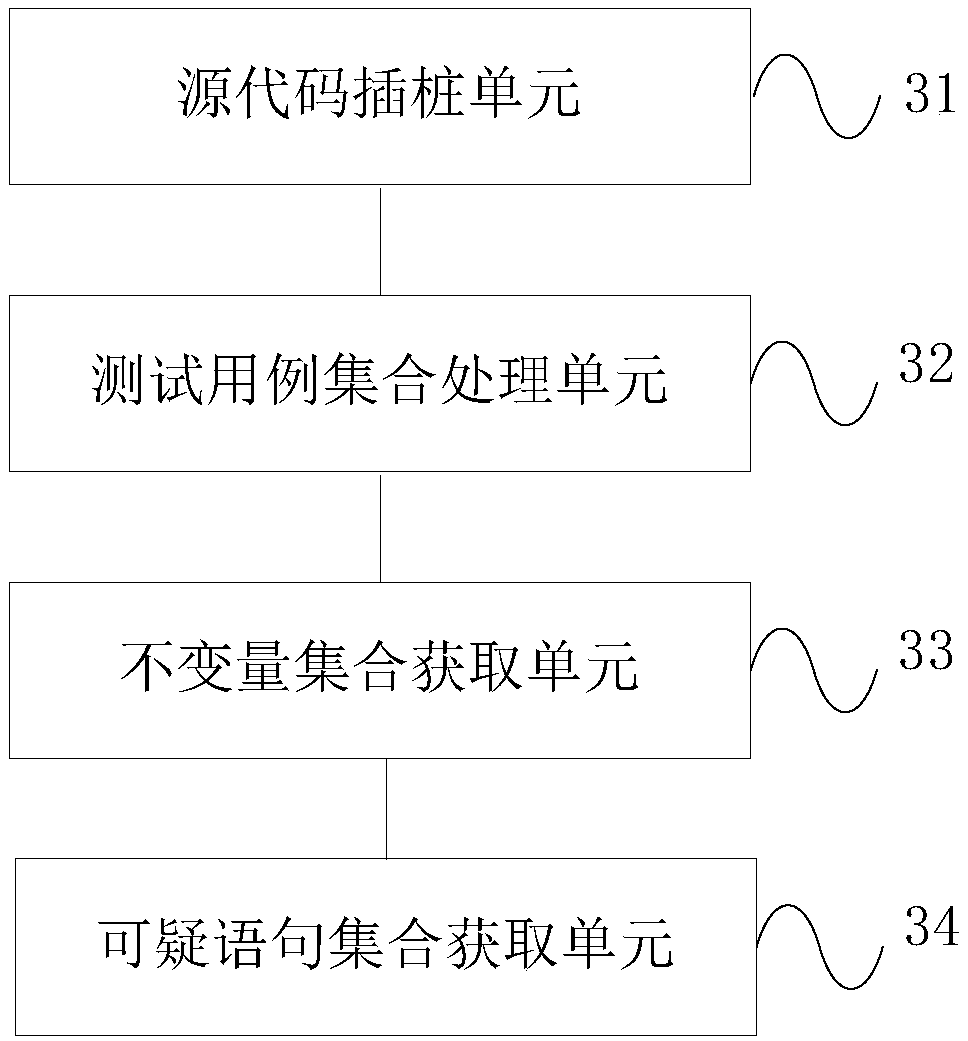

A method and apparatus for software fault location based on program invariants

ActiveCN109144882AImprove accuracyOvercome the problem of missing detection of logical expression defect locationSoftware testing/debuggingTruth valueSoftware fault

The invention discloses a software fault locating method and a device of program invariant. The method comprises the following steps that: the source code of the target software is inserted at the level of sentence, value and logical expression, and the source code after insertion is executed by a preset test case set to obtain the execution information; the source code of the target software is inserted at the level of sentence, value and logical expression; the preset failure test case set is clustered and the successful test case set is selected which is helpful to distinguish the defectivestatements for each clustering; the execution information of the preferred successful test case set is learnt, the program invariant set is obtained, including the set type, truth table type and floating point type range invariant; according to the execution information of the failed test case set and the program invariant set, the invariant violation is detected, and the suspicious statement setis obtained; dependency analysis is used to filter out invariant violation error caused by fault propagation, and invariant violation at each sentence is statistically analyzed to calculate sentencesuspicion. The invention improves the accuracy of software fault location, and overcomes the problem of missing detection of logical expression defect location.

Owner:HARBIN INST OF TECH

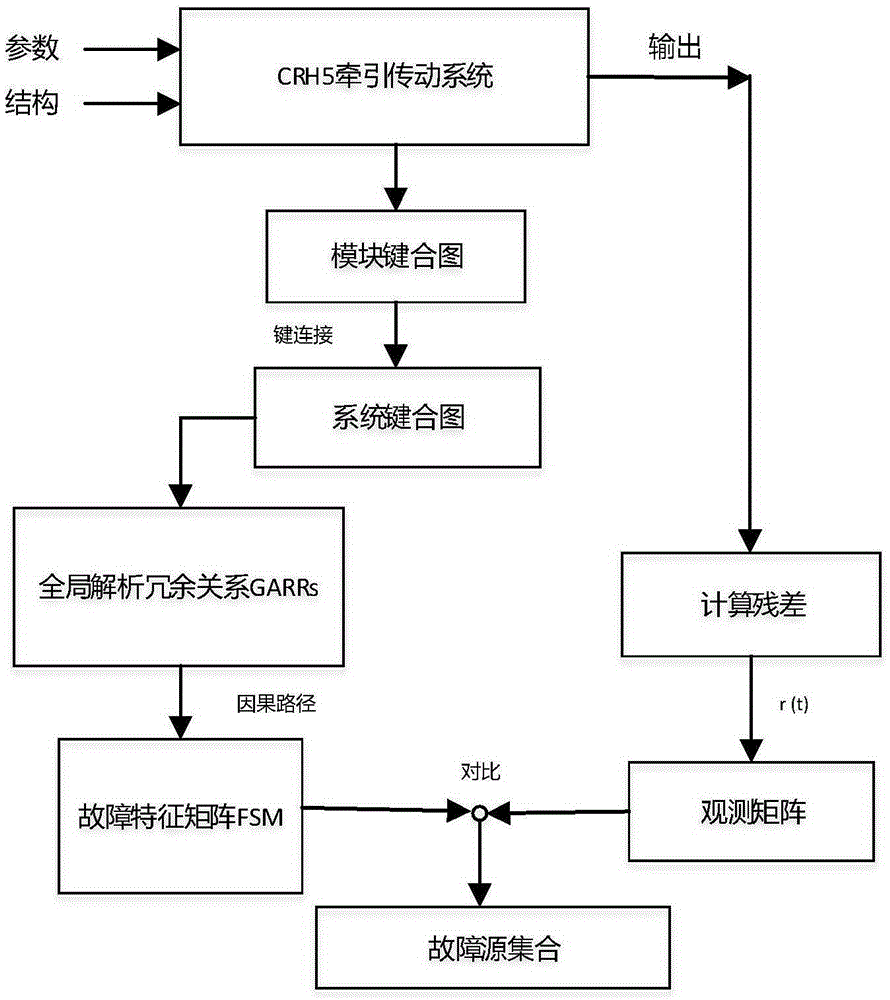

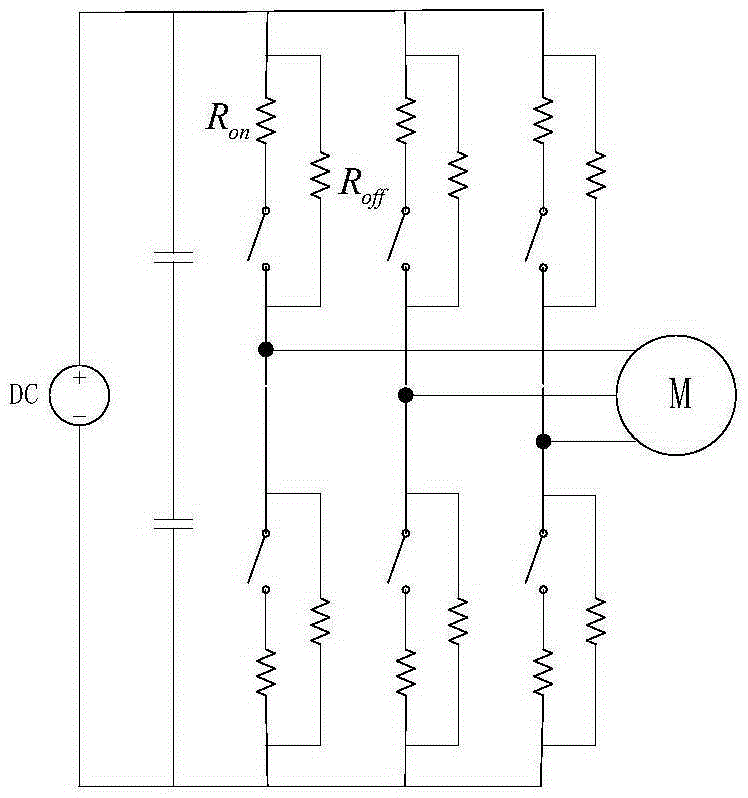

IGBT fault diagnosis method for traction drive system of CRH5 type high-speed train

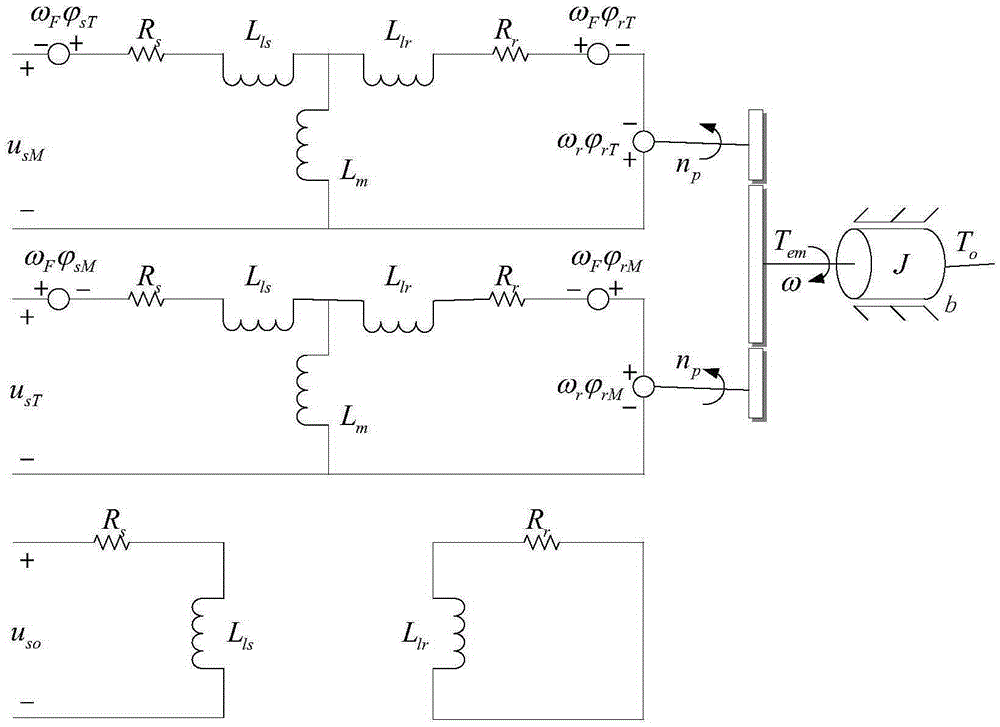

ActiveCN105301470AGuaranteed uptimeFailure is timely and effectiveIndividual semiconductor device testingGraph modelBond graph

The invention discloses an IGBT fault diagnosis method for a traction drive system of a CRH5 type high-speed train, and the method comprises the steps: modeling a traction part bonding graph: respectively building a traction inverter model, a traction motor model, and a gearbox bonding graph model; carrying out system modeling: building a traction drive system model of a high-speed train, and simulating the operation states when the system is normal and an IGBT fault happens; building a global analysis redundancy relation: building a simplified system global analysis redundancy relation, obtaining a fault characteristic matrix, and analyzing a system fault propagation approach; carrying out fault diagnosis: enabling system output to be substituted into the global analysis redundancy relation, forming a residual error set and a consistency vector, comparing the residual error set and the consistency vector with the fault characteristic matrix, and detecting the health state of the system, and positioning an IGBT fault source. The method diagnoses the IGBT fault of the traction drive system of the high-speed train through employing a bonding graph method, builds the motor model through multiple bonding graphs, carries out the unified modeling of an electromechanical system, achieves the positioning of an IGBT element with a fault, and provides a solution for the modeling of the traction drive system of the CRH5 high-speed train and the diagnosis of the IGBT fault.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

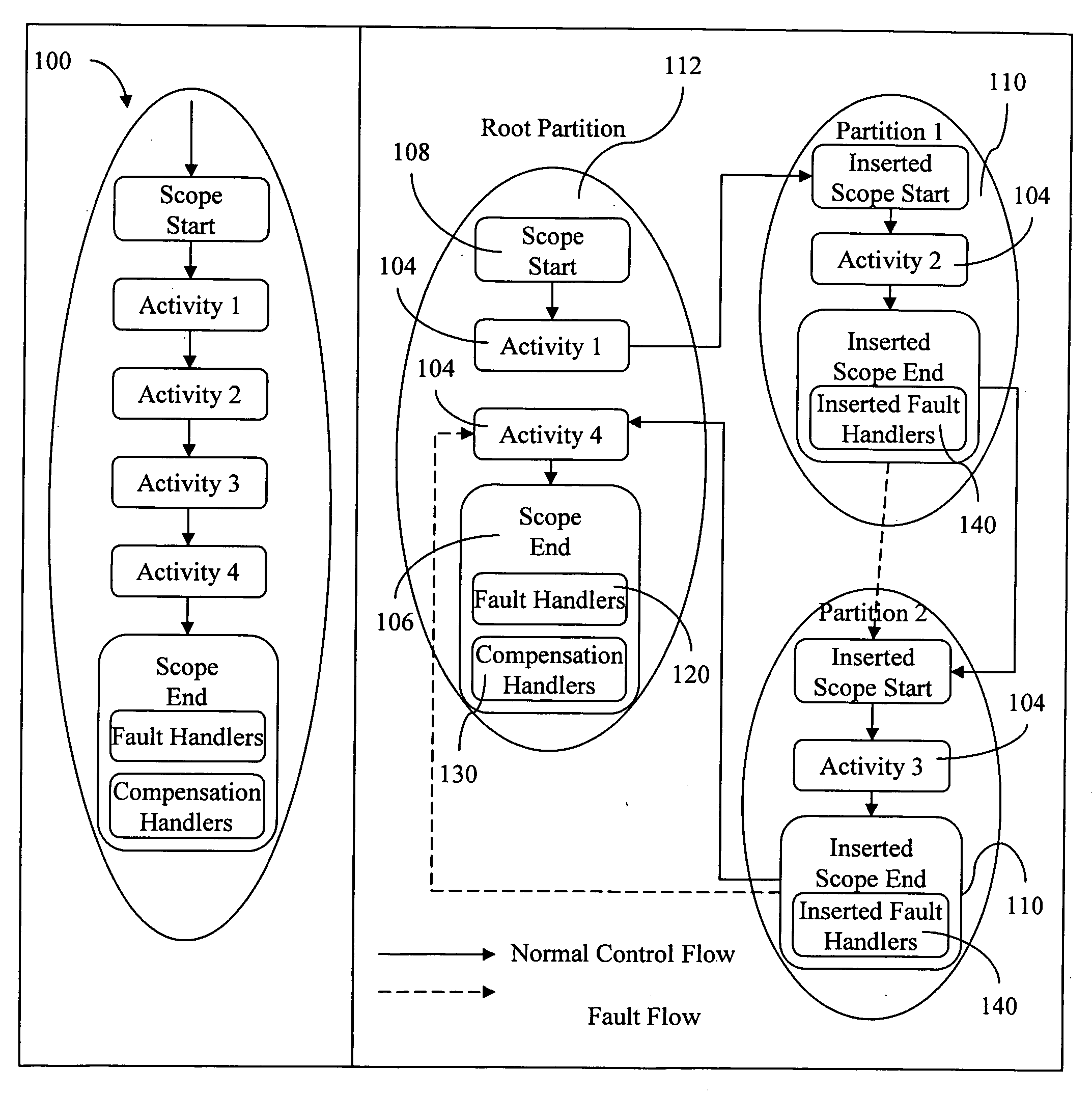

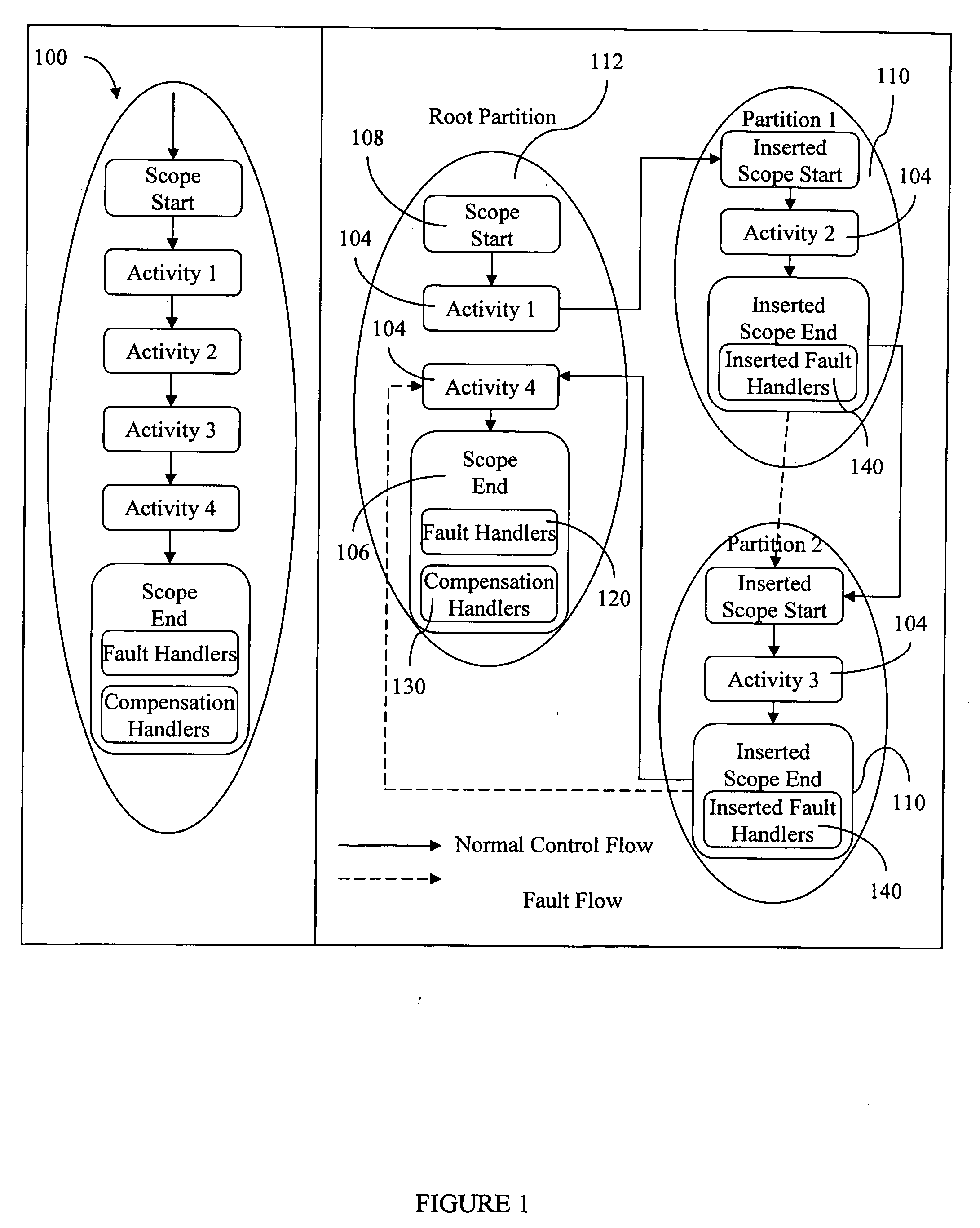

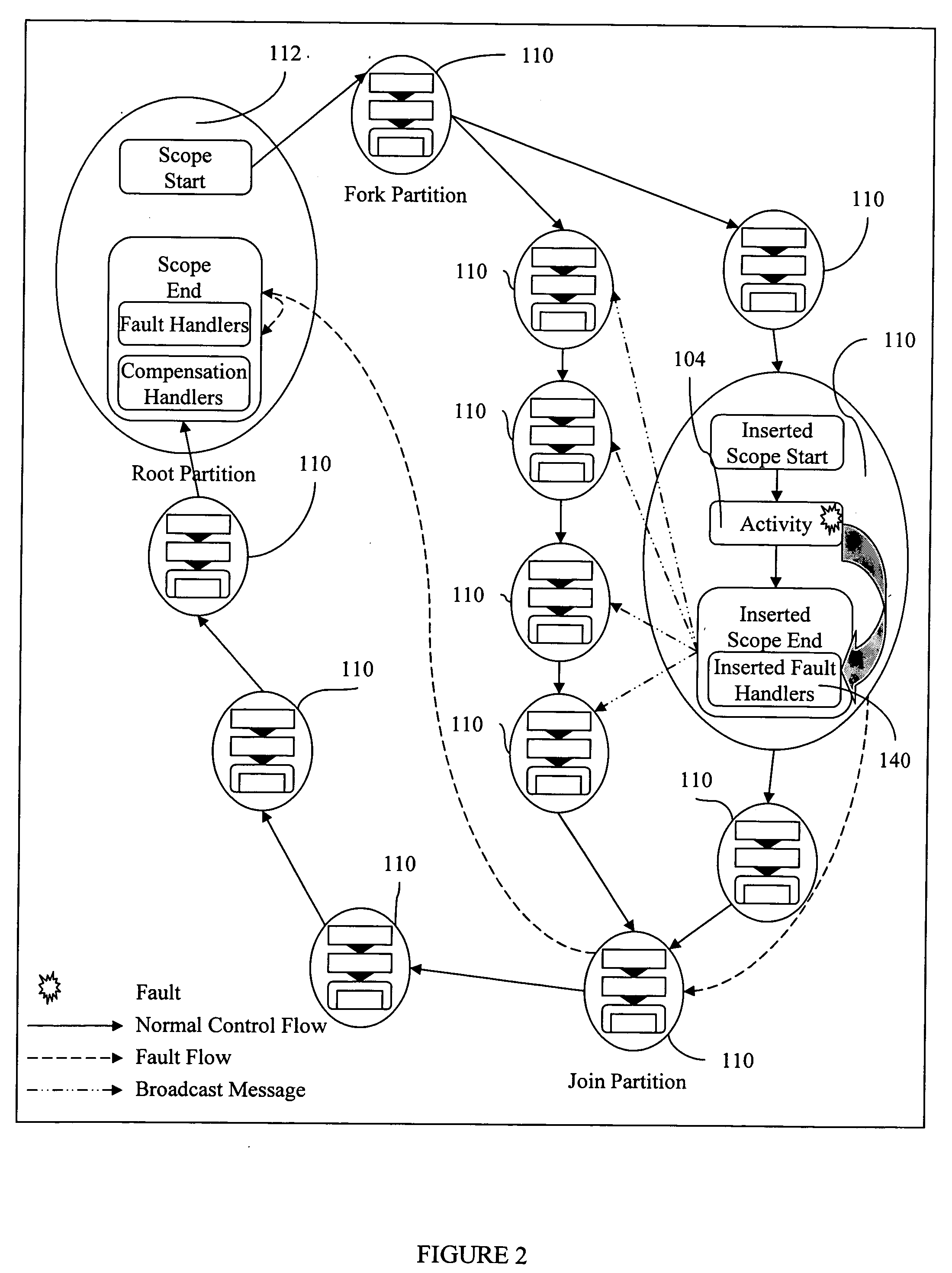

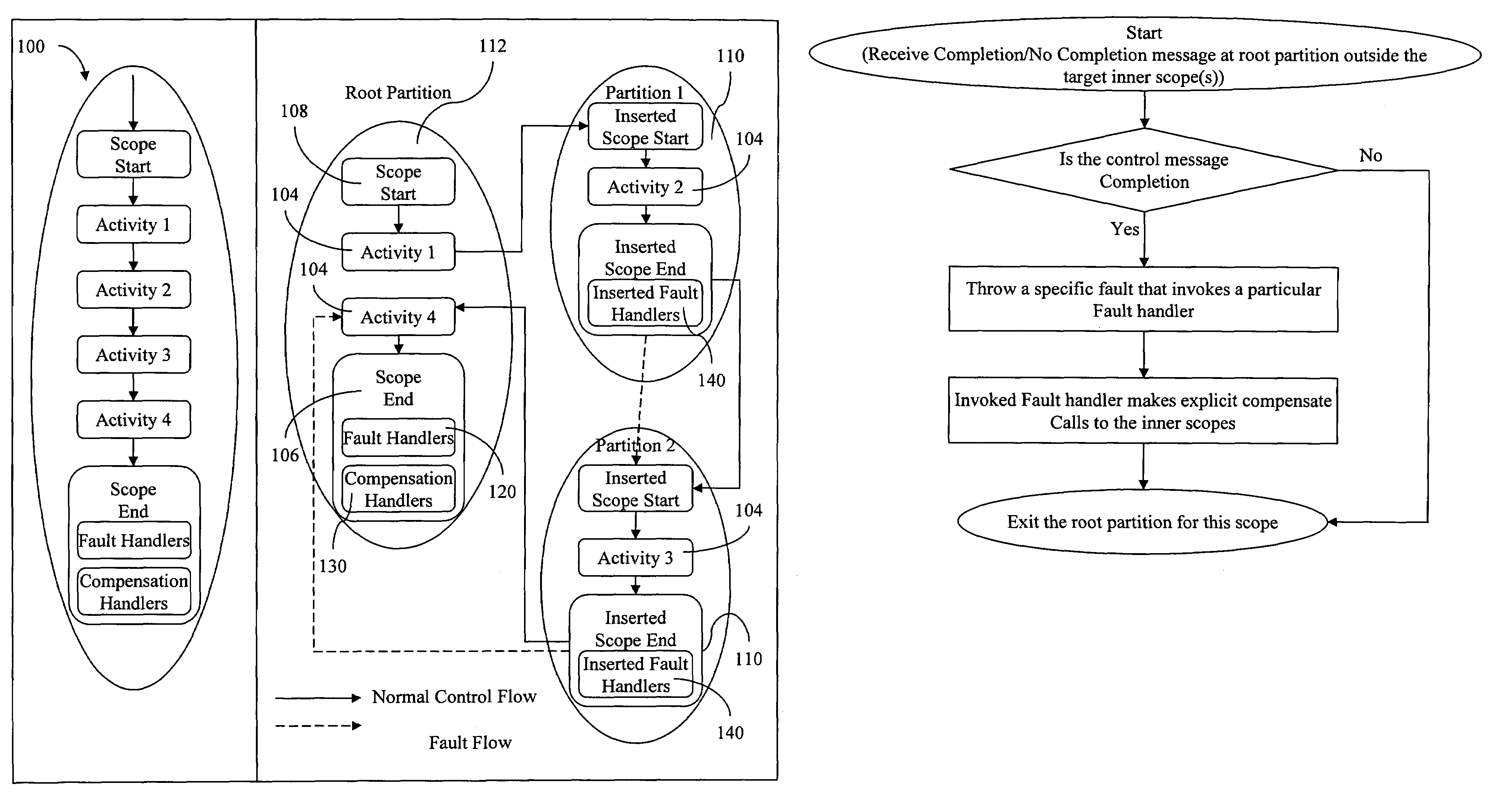

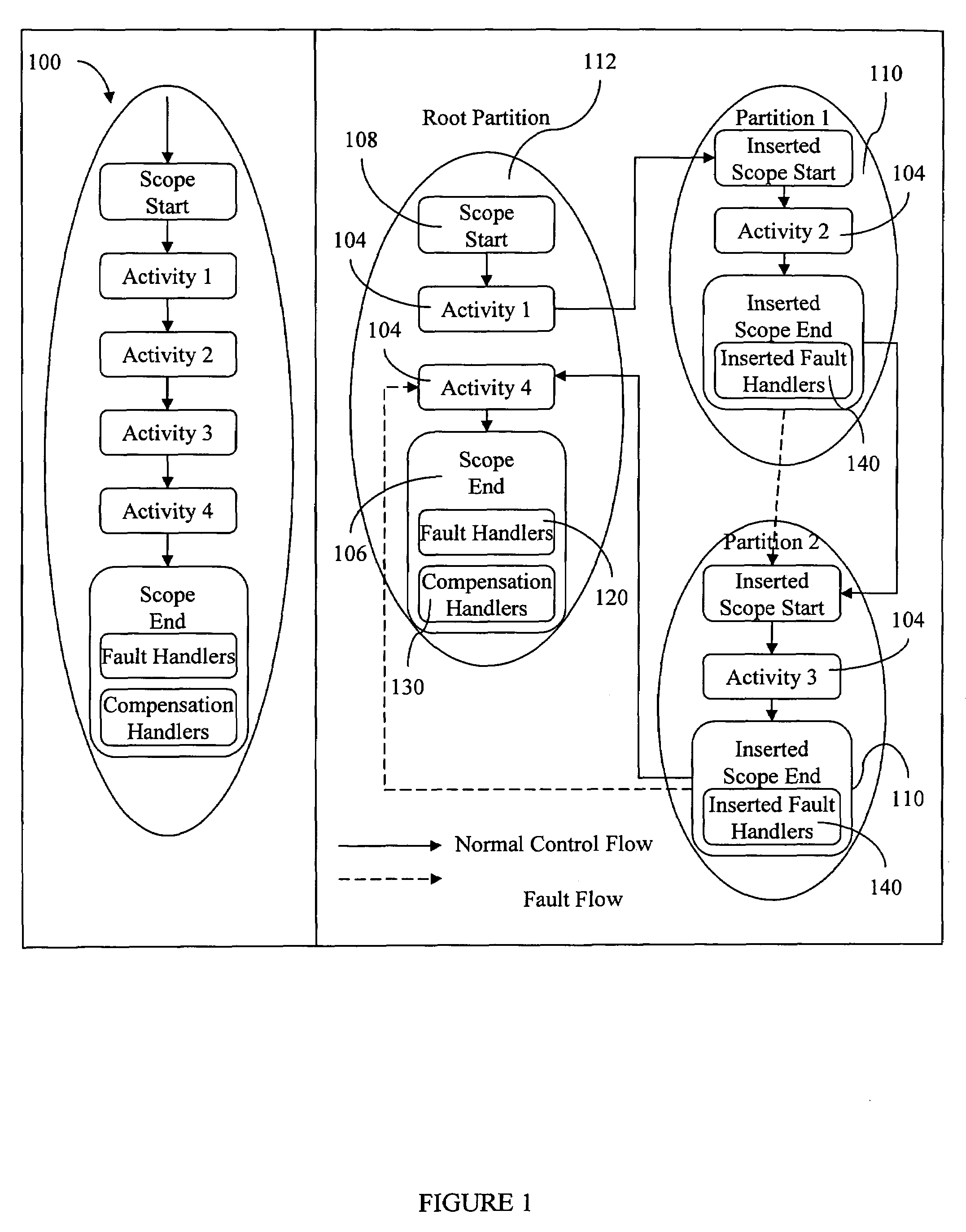

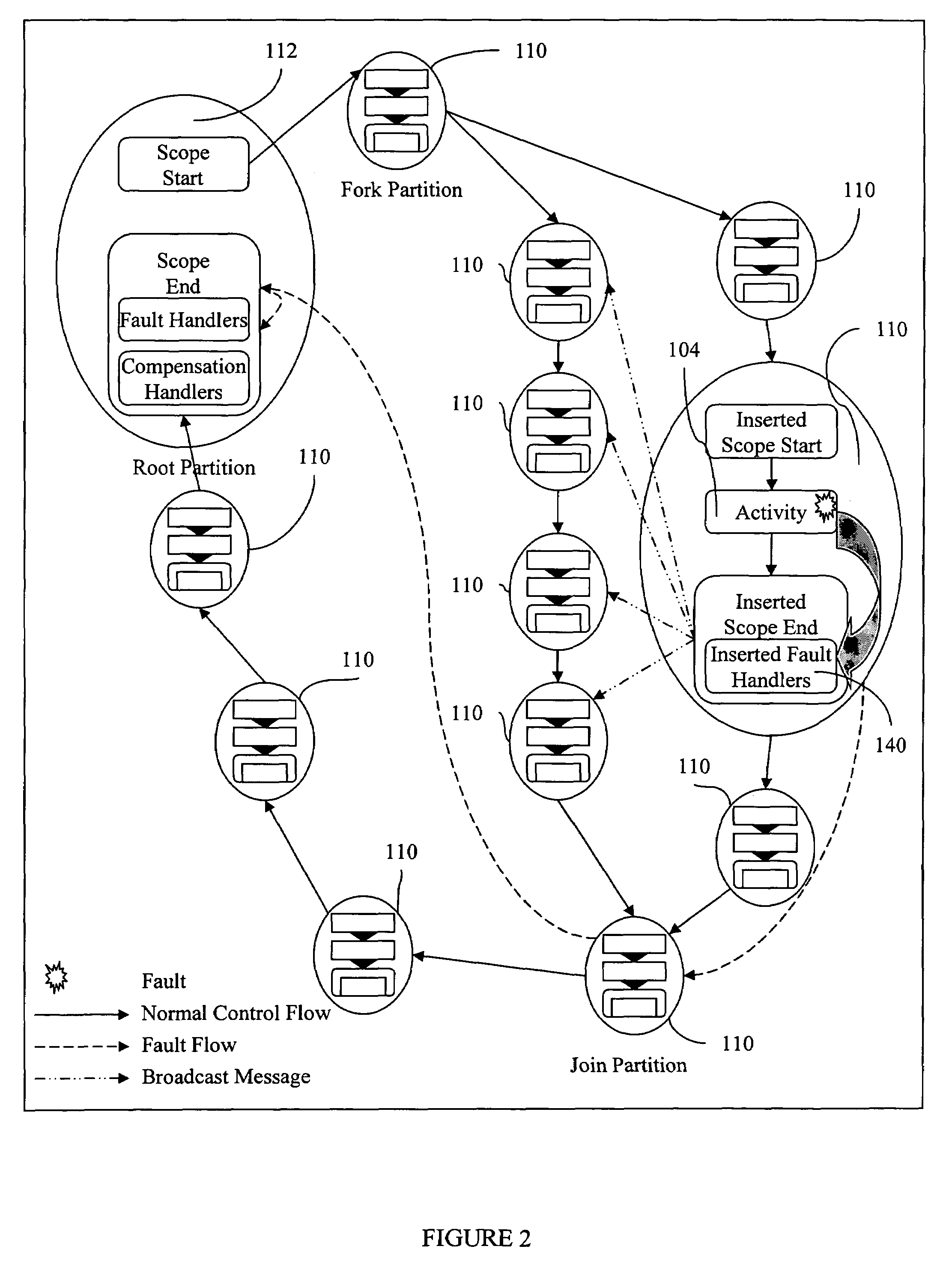

Method for fault handling in a co-operative workflow environment

InactiveUS20070101179A1Different life-timeAvoid resourcesNon-redundant fault processingControl flowSemantics

Embodiments herein provide a fault-handling scheme based on forward recovery for cooperative workflow environments. The fault handling scheme relies on the correct placement of transaction scopes and their associated fault and compensation handlers for maintaining correct application semantics, a fault propagation scheme for forwarding faults to a workflow component that has the corresponding fault handler, and a distributed mechanism for collecting data of completed workflow components to facilitate recovering from faults. The fault handling scheme makes use of control flow messages to facilitate compensation of nested transaction scopes (residing in different components). The workflow components are also modified with additional code for aiding with fault propagation and fault recovery.

Owner:IBM CORP

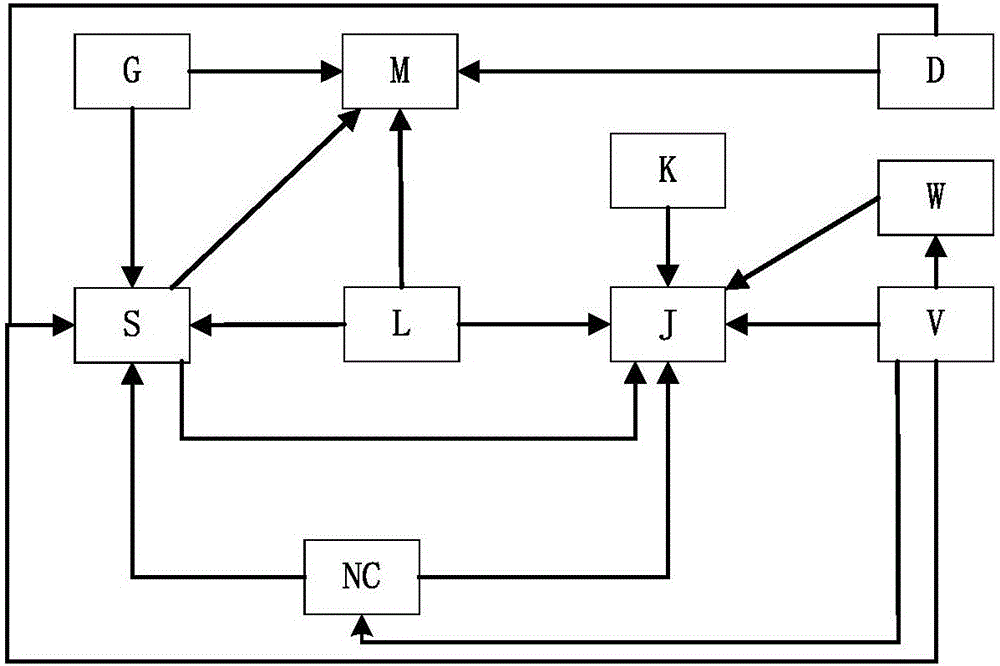

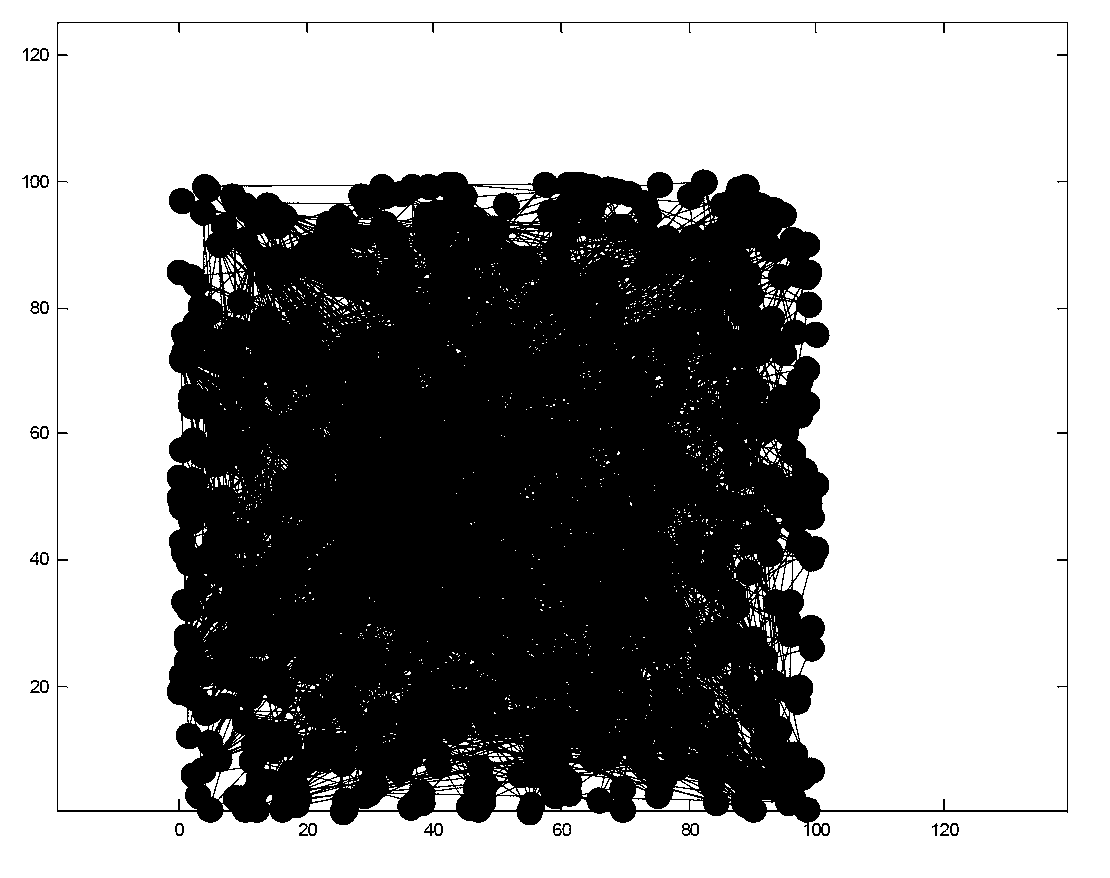

Method for modeling or fault propagation of complex wireless network control system

InactiveCN103298009ASimple structureWireless communicationWireless networked control systemNetwork control

Owner:NANJING UNIV OF SCI & TECH

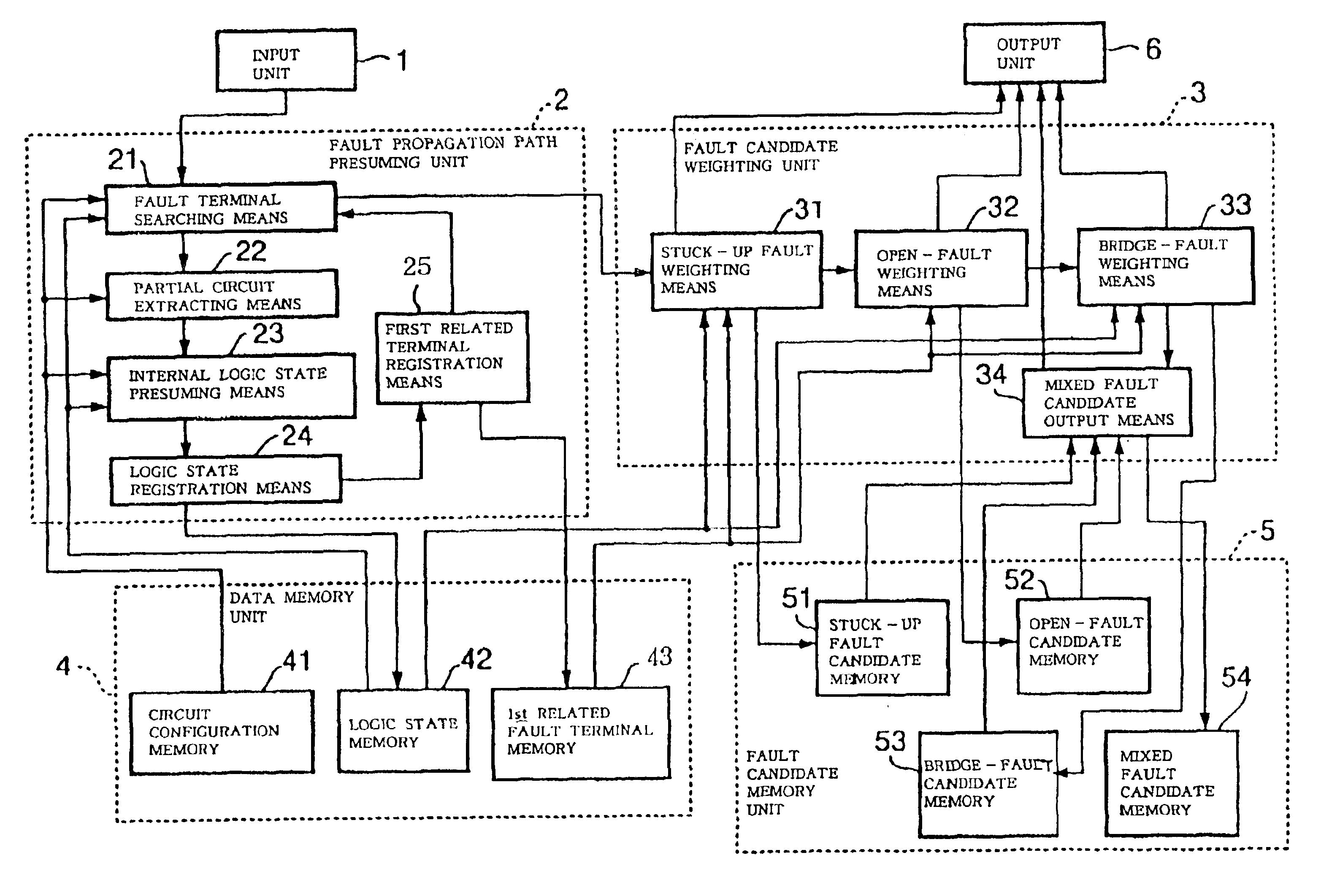

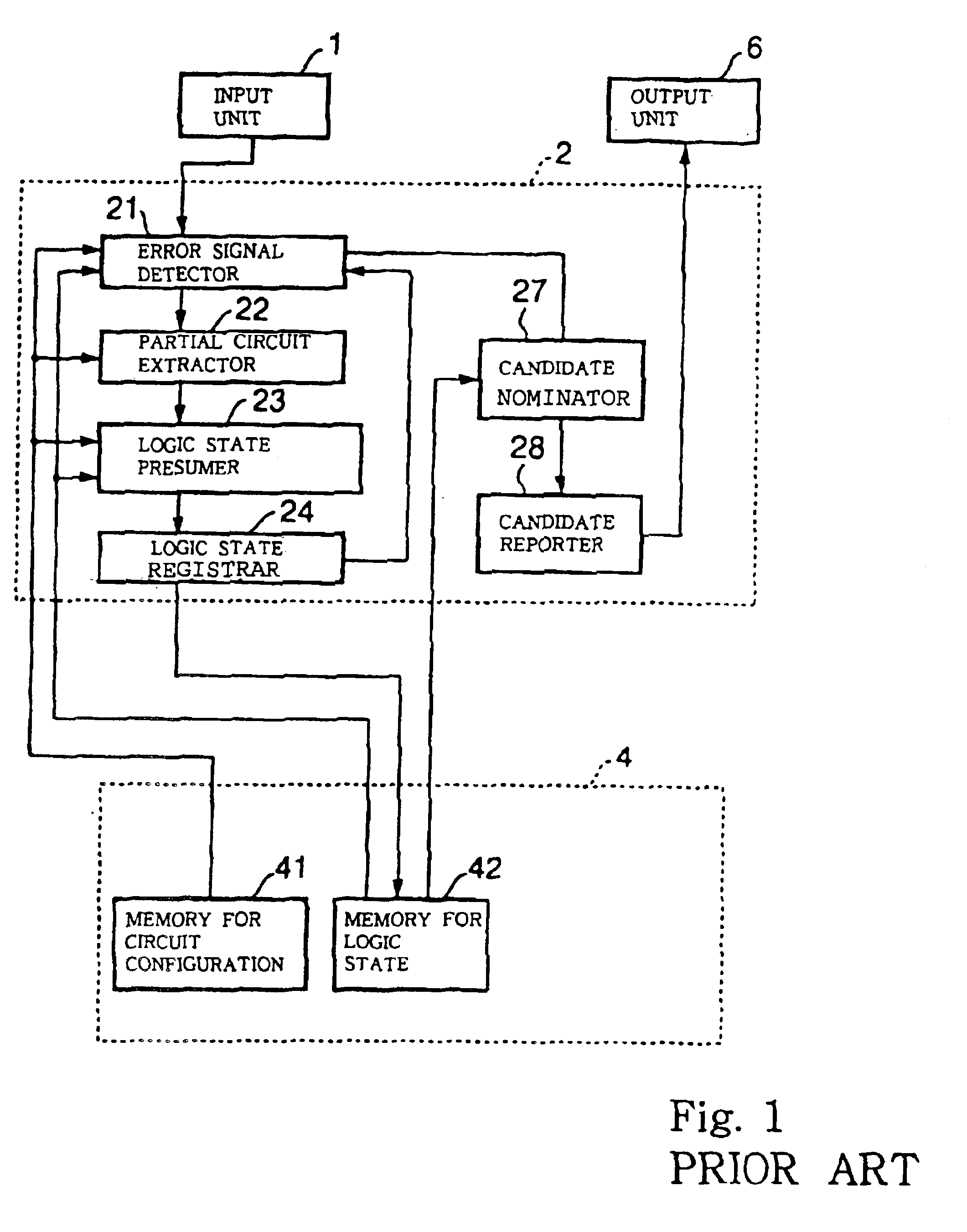

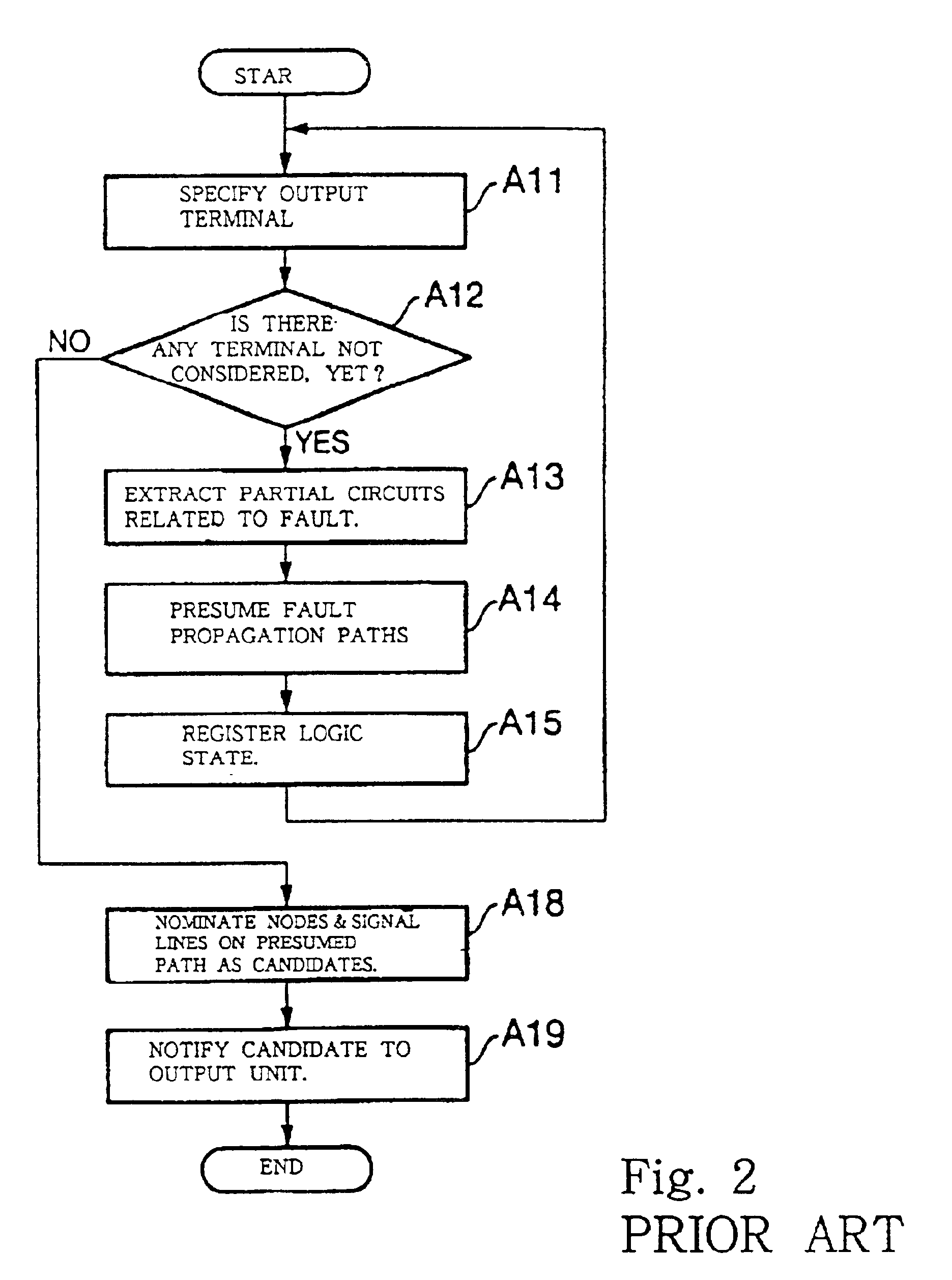

Fault analyzing system, method for pursuing fault origin and information storage medium for storing computer program representative of the method

InactiveUS6915494B2Long maintenance periodDigital circuit testingLogical operation testingComputer terminalFailure analysis

A fault analyzing system presumes fault propagation paths for specifying nodes related to fault terminals once on plural time planes, and merges pieces of related fault terminal information representative of the fault terminals related to the nodes on different time planes in different manners so that plural list of plural kinds of fault are drawn up without repeating the time-consuming presumption.

Owner:RENESAS ELECTRONICS CORP

Faults propagation and protection for connection oriented data paths in packet networks

Owner:HUAWEI TECH CO LTD

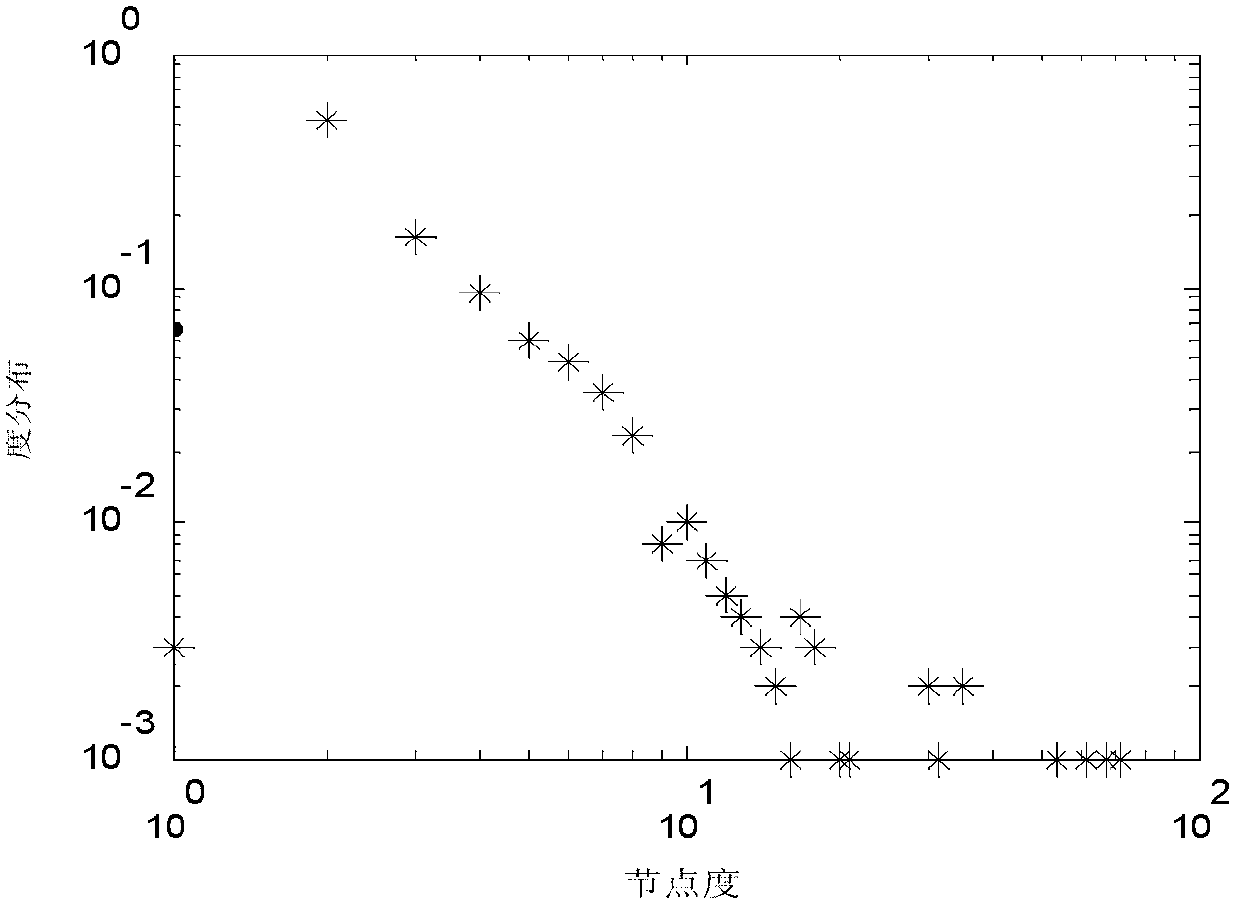

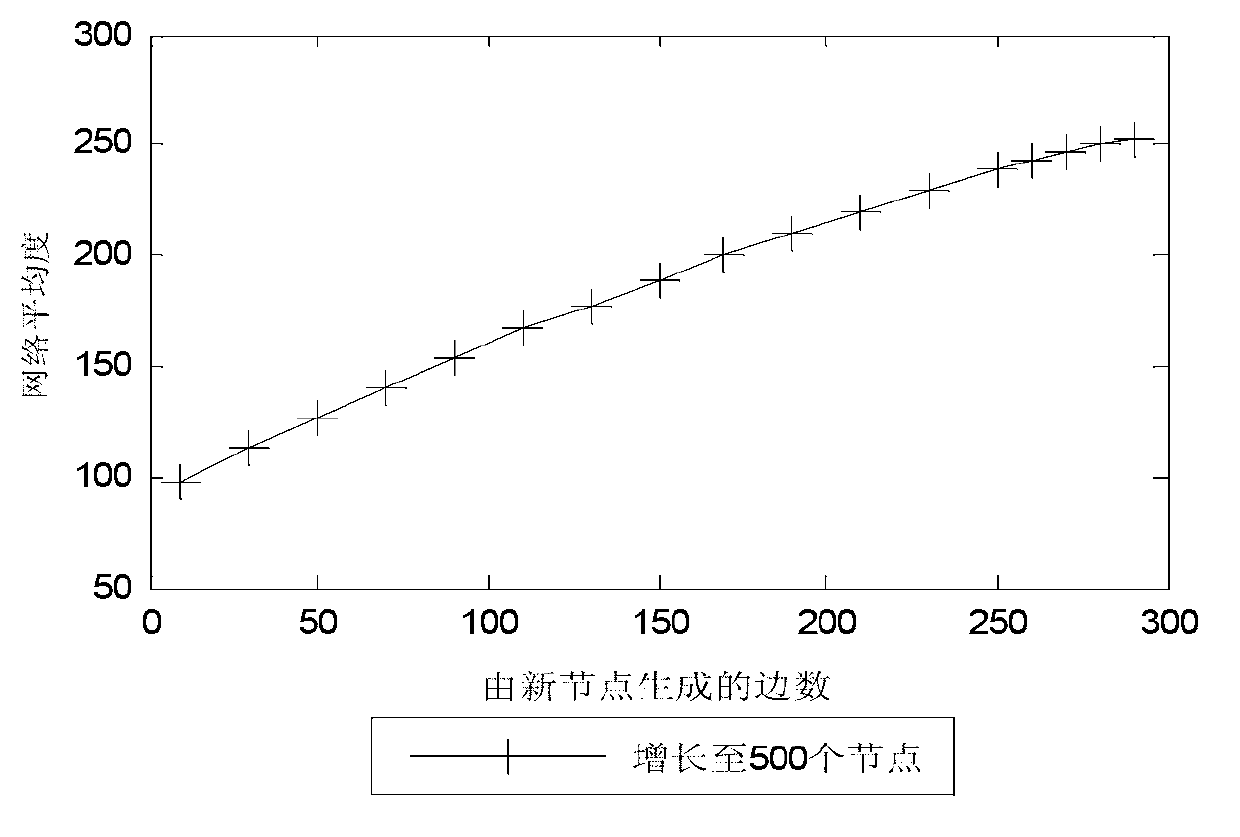

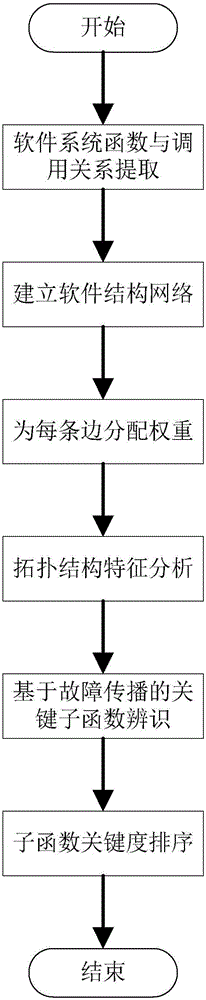

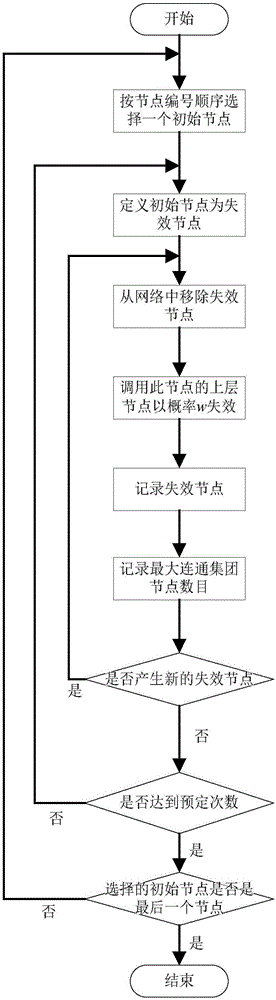

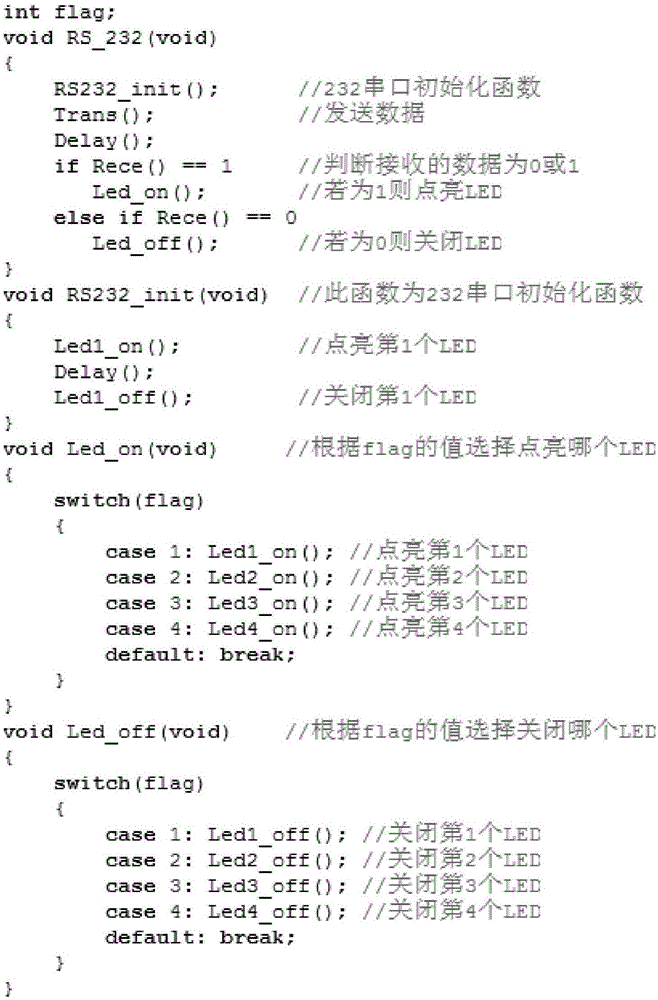

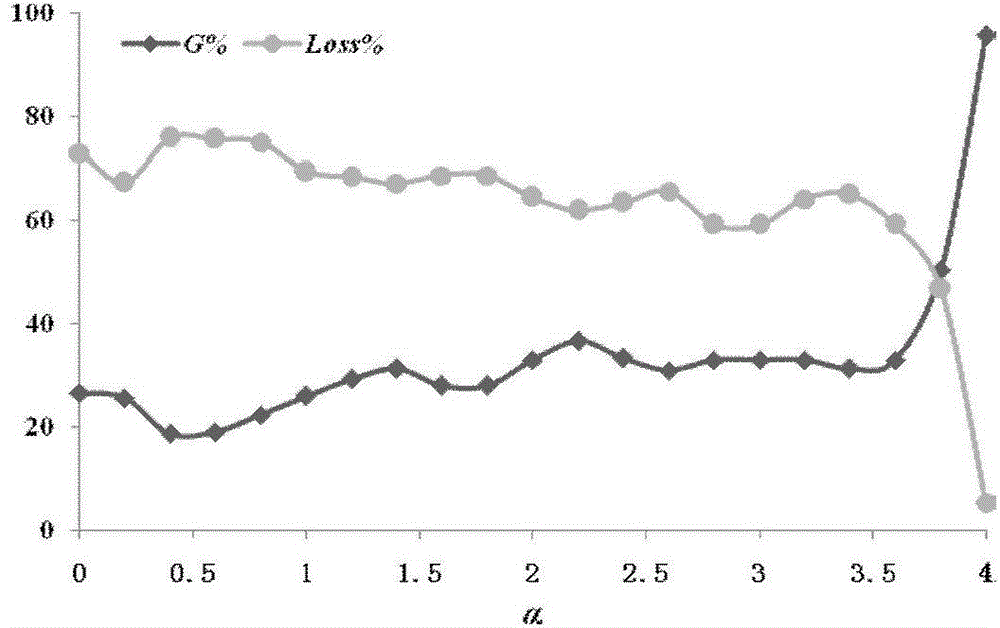

Software key function identification method based on complex network fault propagation

InactiveCN105045574ACompliant with the actual software systemGuaranteed uptimeSpecific program execution arrangementsCascading failureNODAL

The invention discloses a software key function identification method based on complex network fault propagation. The software key function identification method comprises the following steps: 1) according to a source code, carrying out subfunction and calling relation extraction on a program, and carrying out abstraction to obtain a network chart of a software structure; 2) according to a probability of calling and executing each subfunction, endowing each side with a certain weight w, wherein the weight is a failure probability of inter-function cascading faults; 3) analyzing the topological structure characteristics of software, and calculating an in-degree value and an out-degree value of each node, wherein the in-degree value of the node is a frequency that the function is called by other functions, and the out-degree value of the node is the frequency that the function calls other functions; 4) carrying out a cascading failure simulation experiment on each node of a software network, and calculating the node numbers G, i.e., the criticality, of a maximum connected subgraph of the software network after each node is subjected to stable failure; and 5) sorting the G in an increasing sequence to obtain the criticality of each function. The software key function identification method is simple and reliable. Compared with a traditional method, the software key function identification method can precisely identify a software key function.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

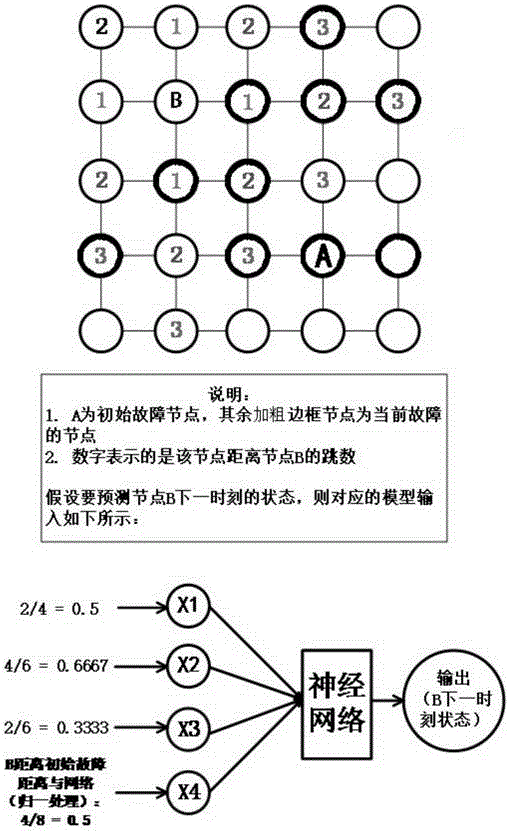

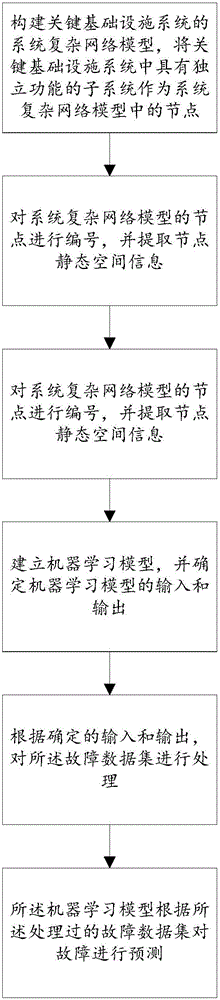

Method for predicting key infrastructure fault propagation

The invention provides a method for predicting key infrastructure fault propagation. The method comprises steps that a system complex network model of a key infrastructure system is constructed; nodes of the system complex network model are numbered; the historical fault data of cascade failure of the key infrastructure system is searched, the historical fault data of the key infrastructure system is cut according to time intervals, and a fault data set of the key infrastructure system is constructed; a machine learning model is established, and input and output of the machine learning model are determined; the fault data set is processed; faults are predicted through the machine learning model. Through the method, when cascade failure of the network occurs, a state of the network at the next moment is predicted through utilizing the state information of a node itself, the state information of a next node adjacent to the node and space attributes of the node, and the useful information is provided for system microscopic dynamic evolution control.

Owner:BEIHANG UNIV

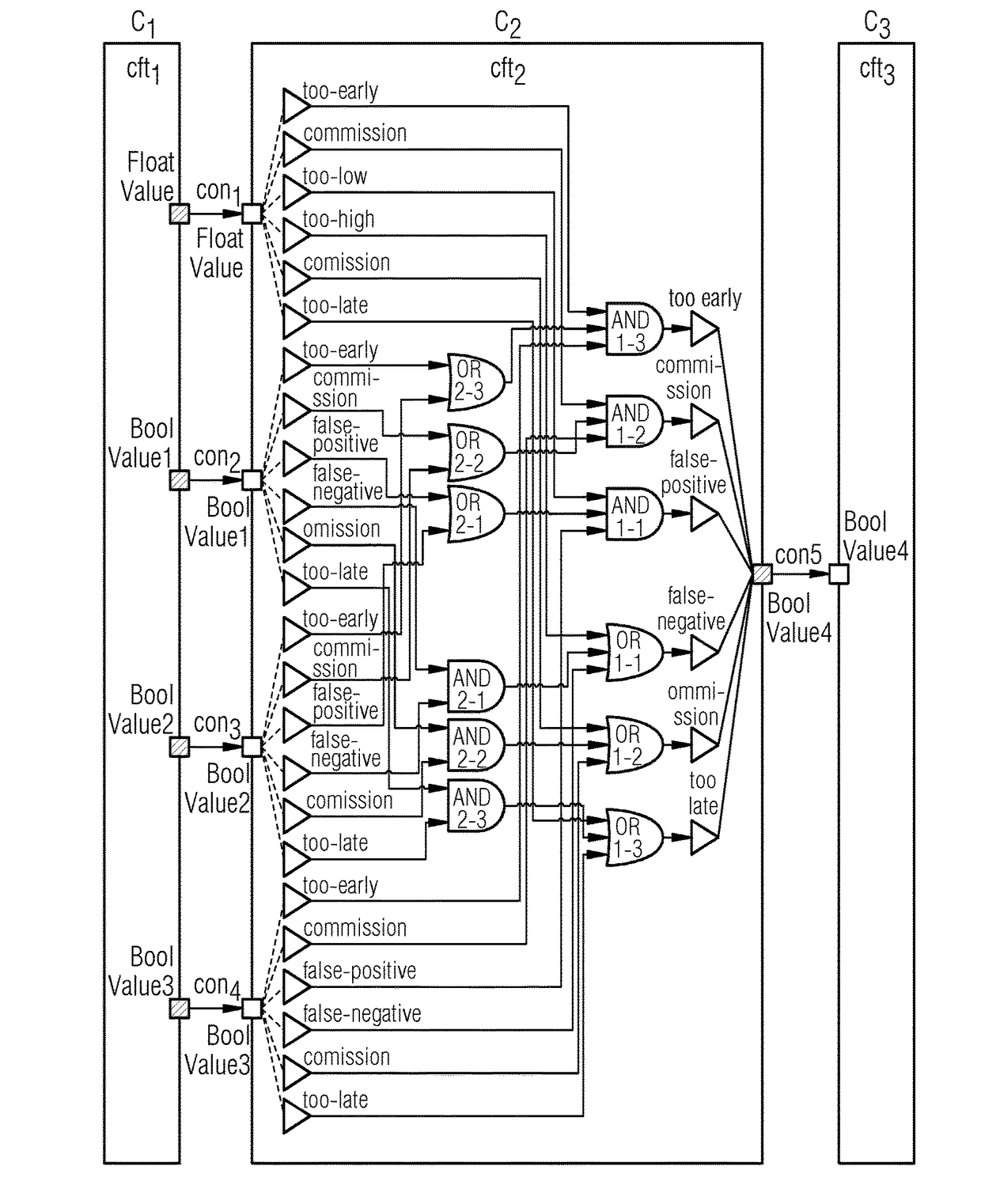

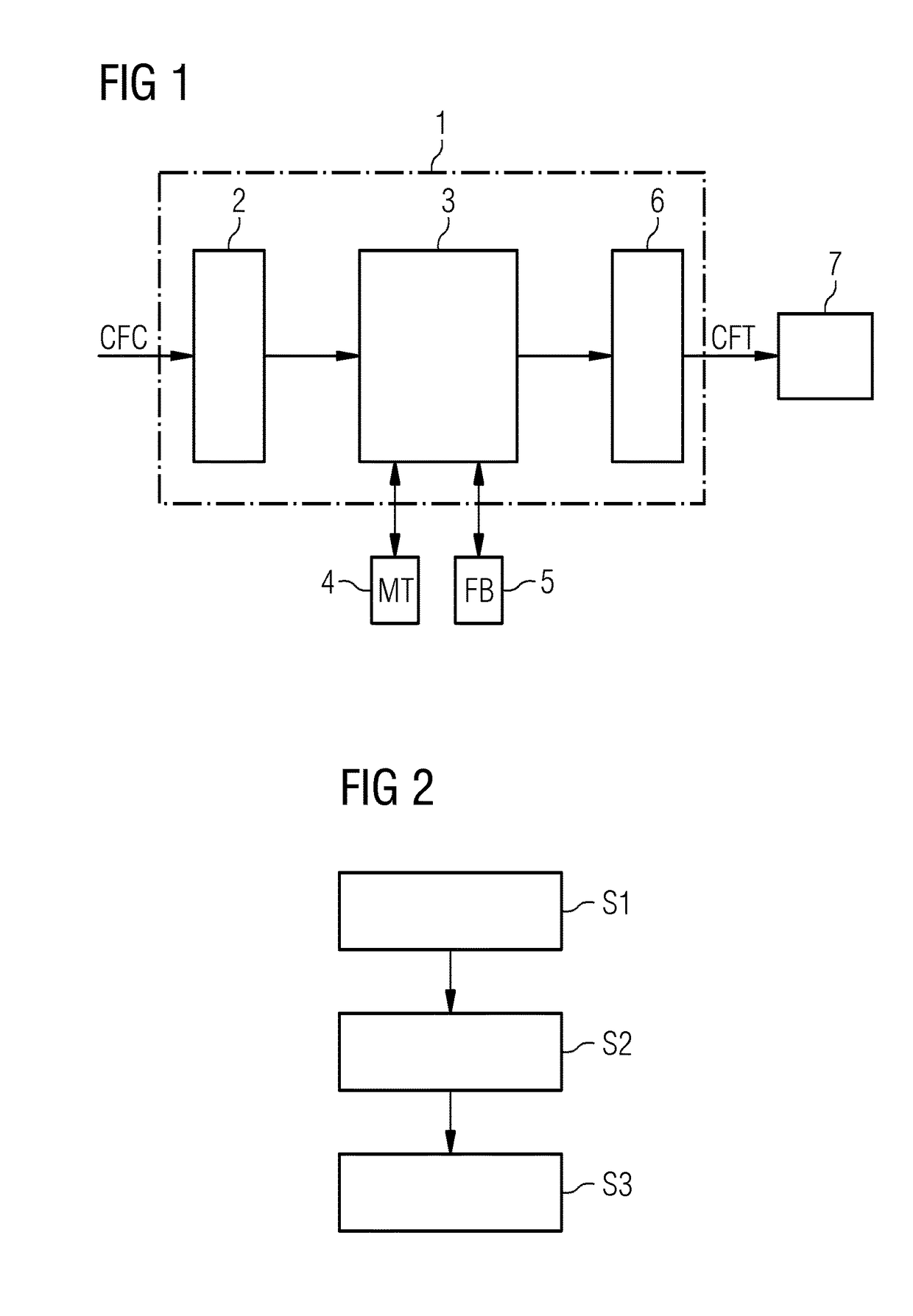

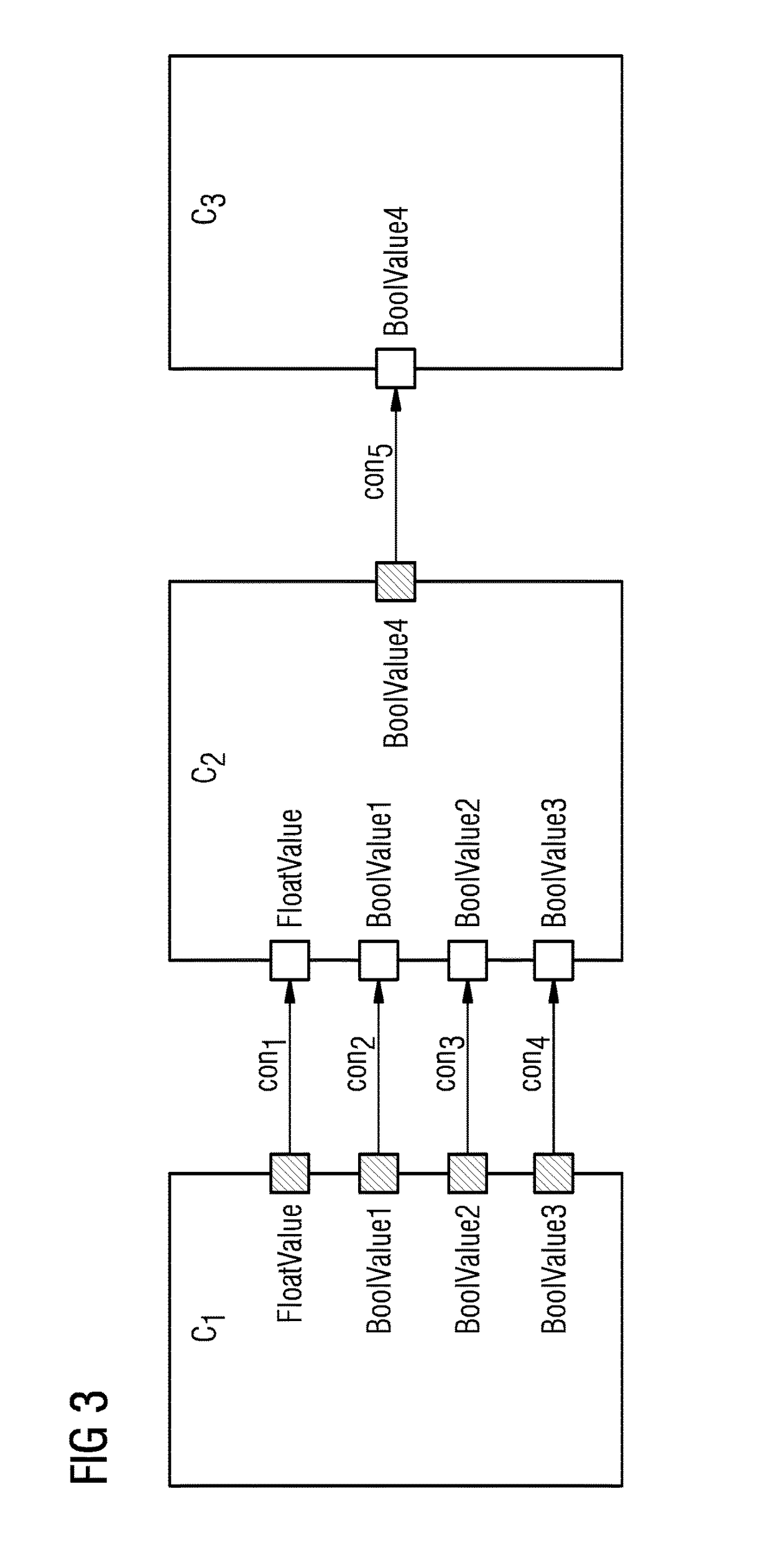

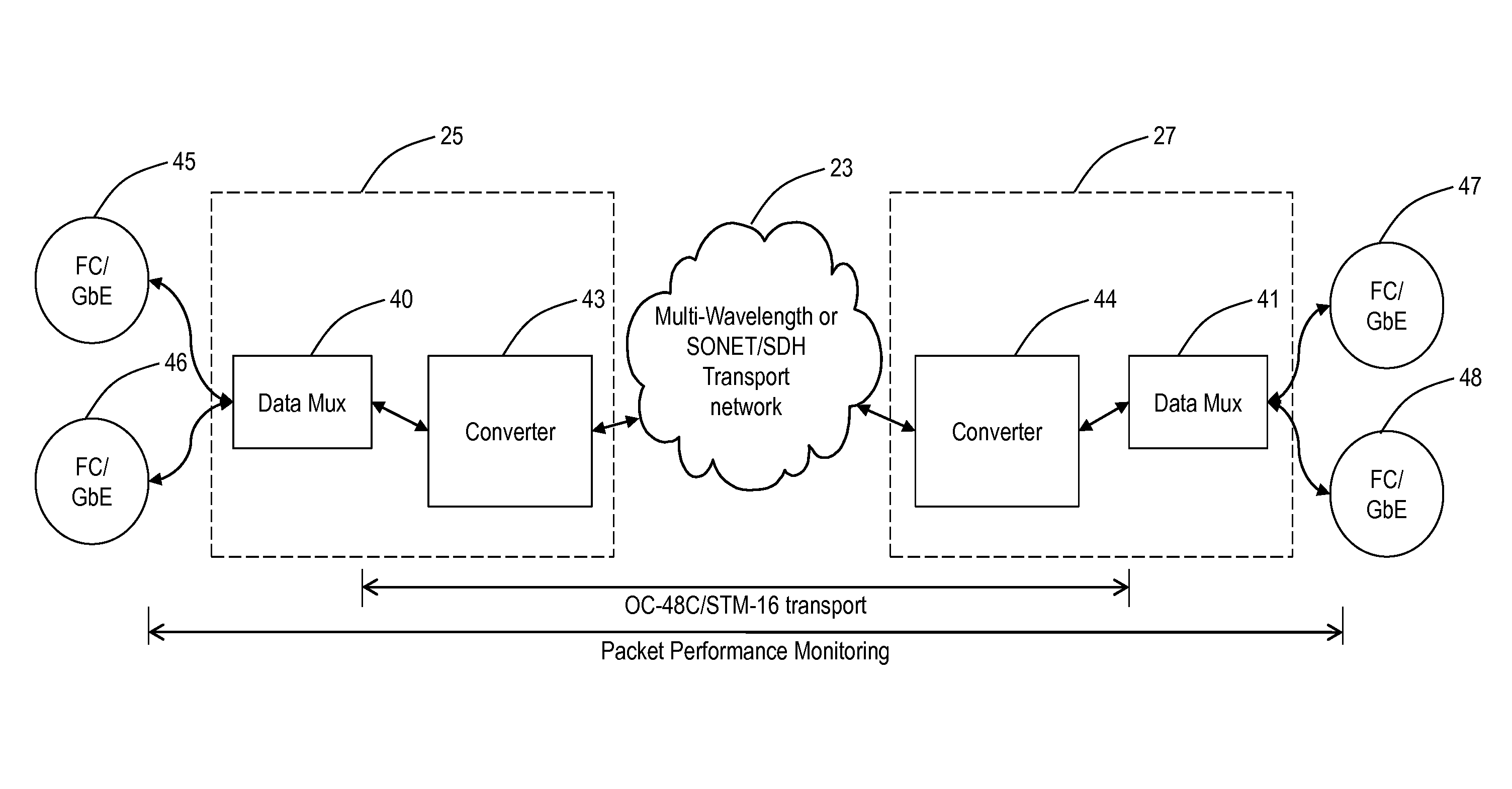

Method and apparatus for automatically generating a component fault tree of a safety-critical system

ActiveUS20170185470A1Fault responseReliability/availability analysisComputer scienceFault propagation

An apparatus includes an input that receives a continuous function chart for each component of the investigated safety-critical system. A processor generates a corresponding component fault tree element. Inports and outports of the component fault tree element are generated and interconnected based on unique names of the inputs and outputs of the corresponding continuous function chart of the respective system component. Input failure modes and output failure modes are generated based on generic mapping between connector types of the continuous function chart and failure types of failure modes of the component fault tree element. The input failure modes of a component fault tree element are connected to output failure modes of the component fault tree element via internal failure propagation paths based on interconnected function blocks of the continuous function chart of the respective system component. An output outputs the generated component fault tree of the safety-critical system.

Owner:SIEMENS AG

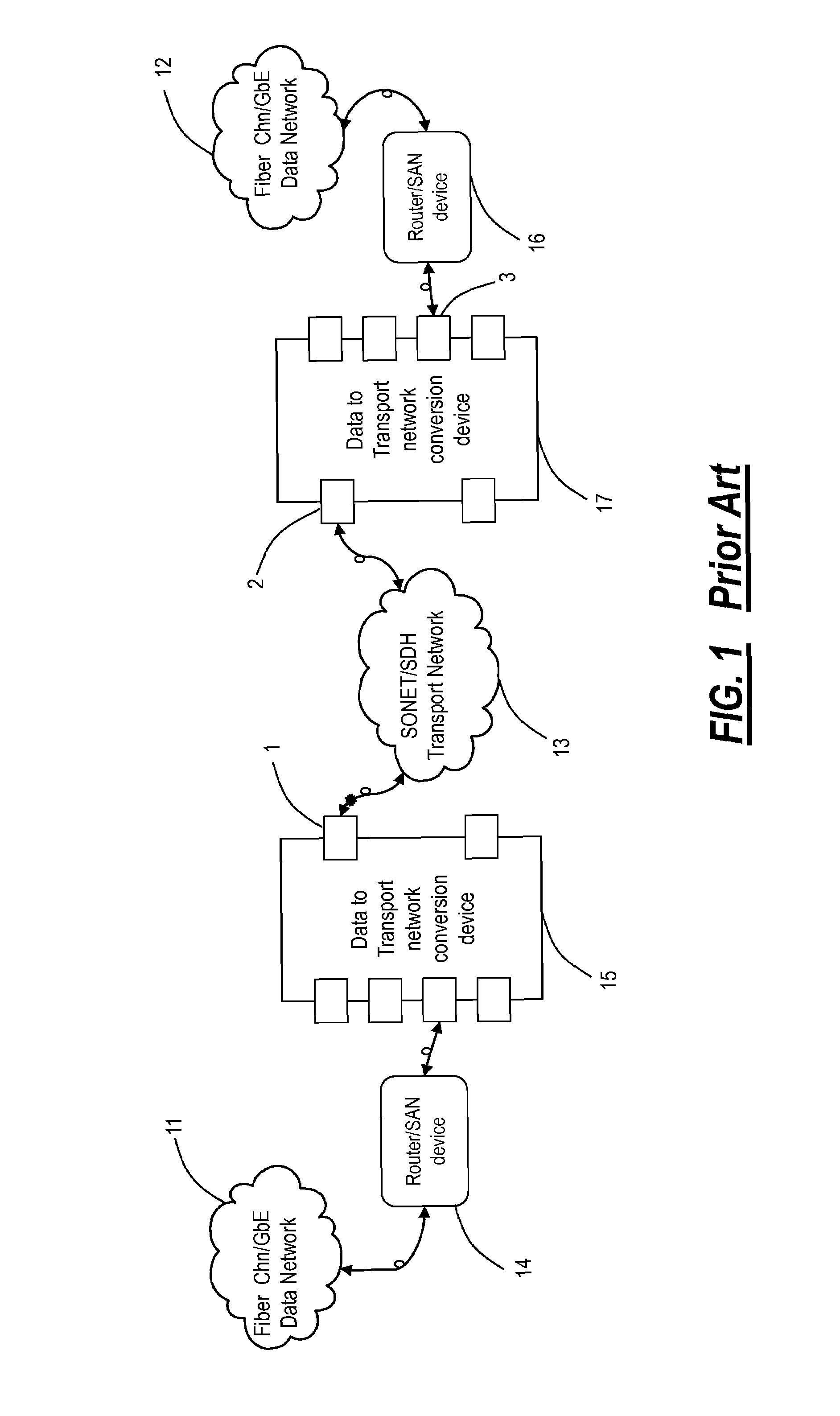

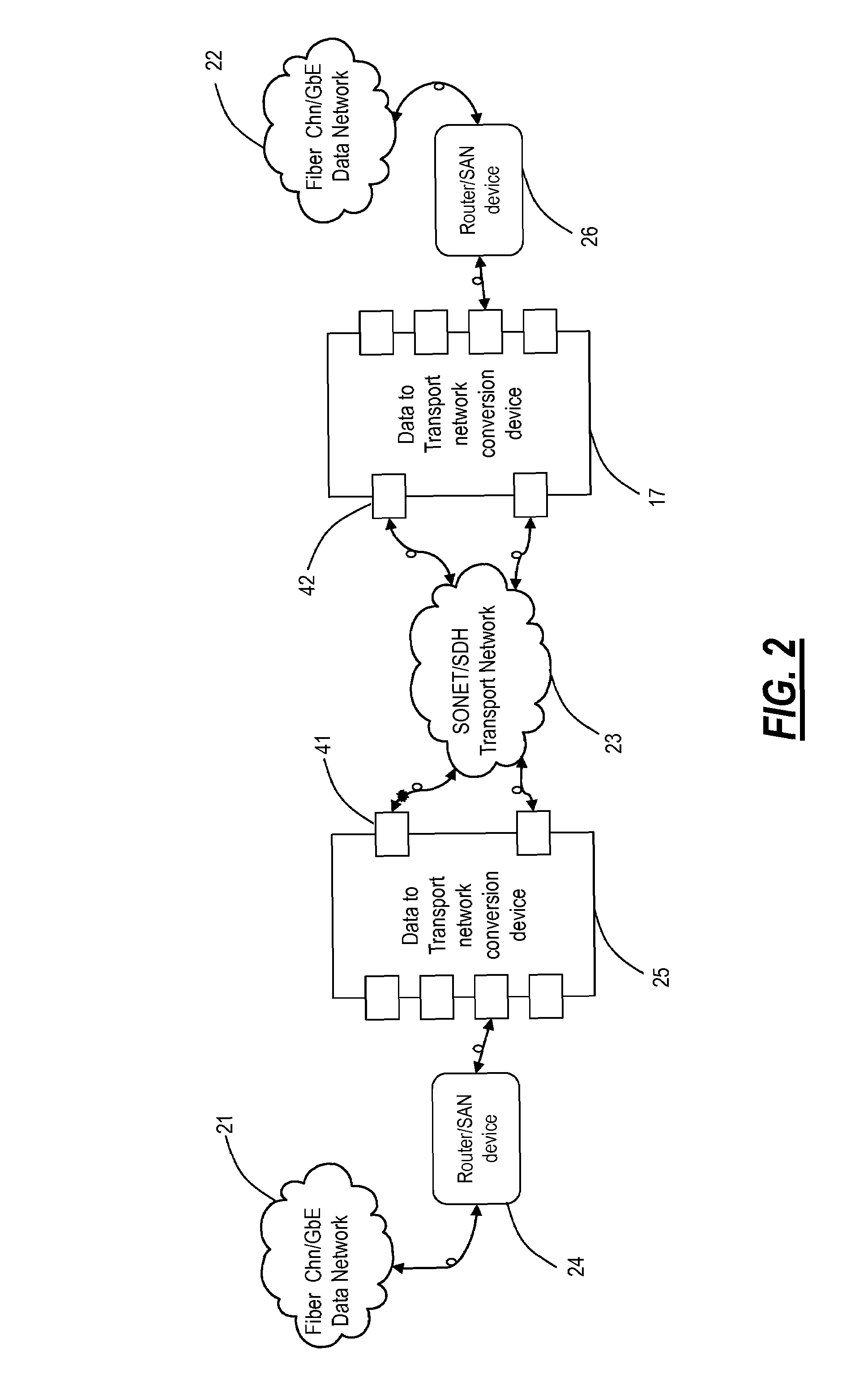

Protected SONET/SDH networks having delayed fault propagation

A method and apparatus are disclosed for protecting a network having data networks, such as Fibre Channel, Ethernet, GbE and ESCON networks, and SONET / SDH transport networks. The method and apparatus protect the network from signaling or propagating alarms for temporary faults in the transport network. When a fault is detected, a timer counts up to a fault propagation delay period and a protection switch is initiated. A signal is also sent to the data network in place of the interrupted traffic in order to maintain the link. Before the timer reaches the fault propagation delay period, if the protection switch is successful, traffic is resumed over the restored path. If the timer reaches the fault propagation delay period and the protection switch is not successful, a data network fault propagation signal is sent to the data network. The removal of the fault condition is monitored, and normal traffic is allowed to flow to the data network when the fault condition is removed.

Owner:CIENA

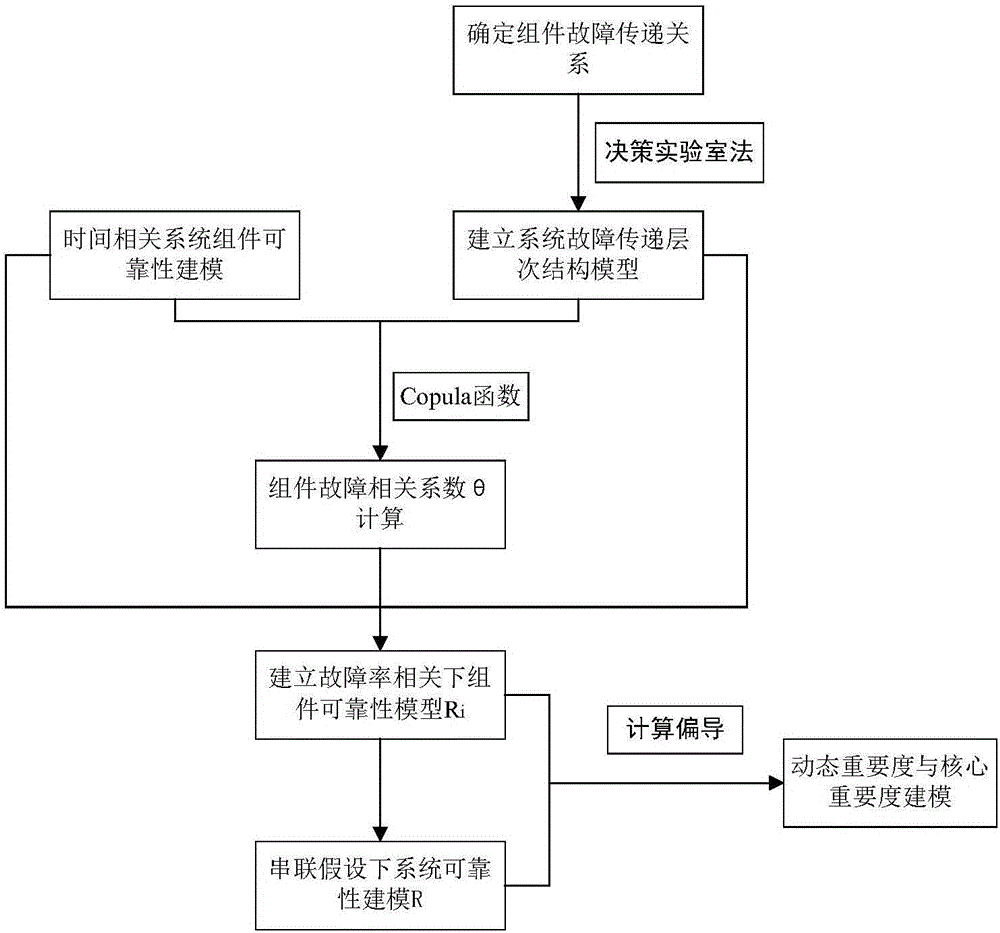

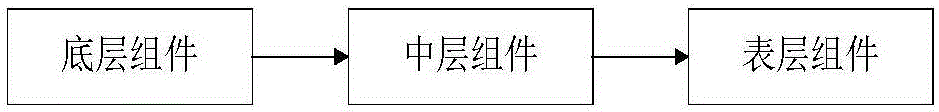

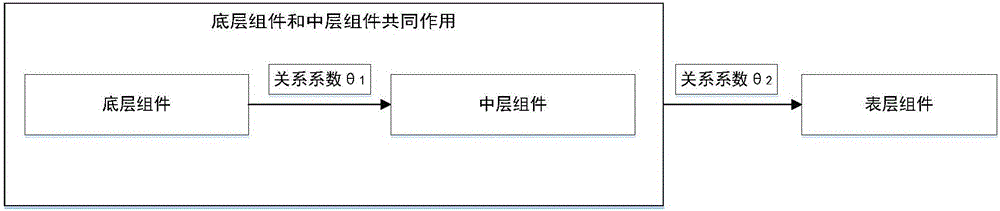

Numerically-controlled machine tool component importance analysis method

InactiveCN106597992AImprove Failure Rate Modeling AccuracyReasonable failure rate modelingProgramme controlComputer controlNumerical controlCorrelation coefficient

The invention belongs to the field of a numerically-controlled machine tool and relates to a numerically-controlled machine tool component importance analysis method. The method comprises the following steps: 1) establishing correspondence relation between components and fault time and between-component fault transfer relation; 2) carrying out analysis and establishing component transfer relation, and describing the numerically-controlled machine tool system component fault transfer relation through a matrix; 3) converting the fault transfer relation into a fault transfer hierarchy structure model, and determining the level of each system component in the fault transfer model; 4) carrying out numerically-controlled machine tool system component fault rate modeling based on time correlation; 5) calculating numerically-controlled machine tool system component fault correlation coefficient; 6) carrying out numerically-controlled machine tool system component fault rate modeling under fault rate correlation; and 7) establishing a numerically-controlled machine tool component reliability dynamic importance model and a core importance model, and carrying out component importance analysis. The method is more reasonable and practical compared with a conventional system component fault rate modeling method, which fails to give consideration to fault time correlation or fault propagation direction.

Owner:JILIN UNIV

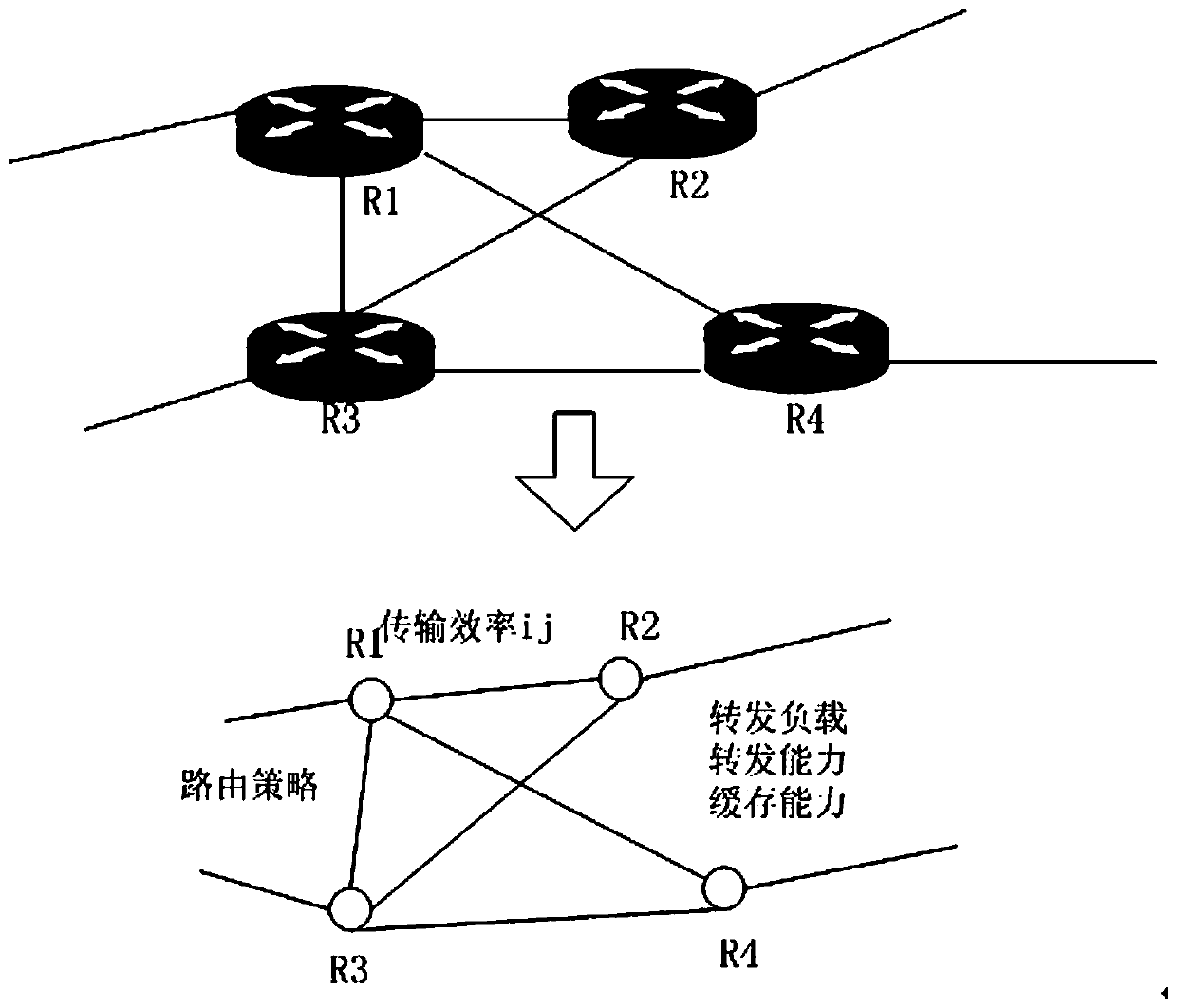

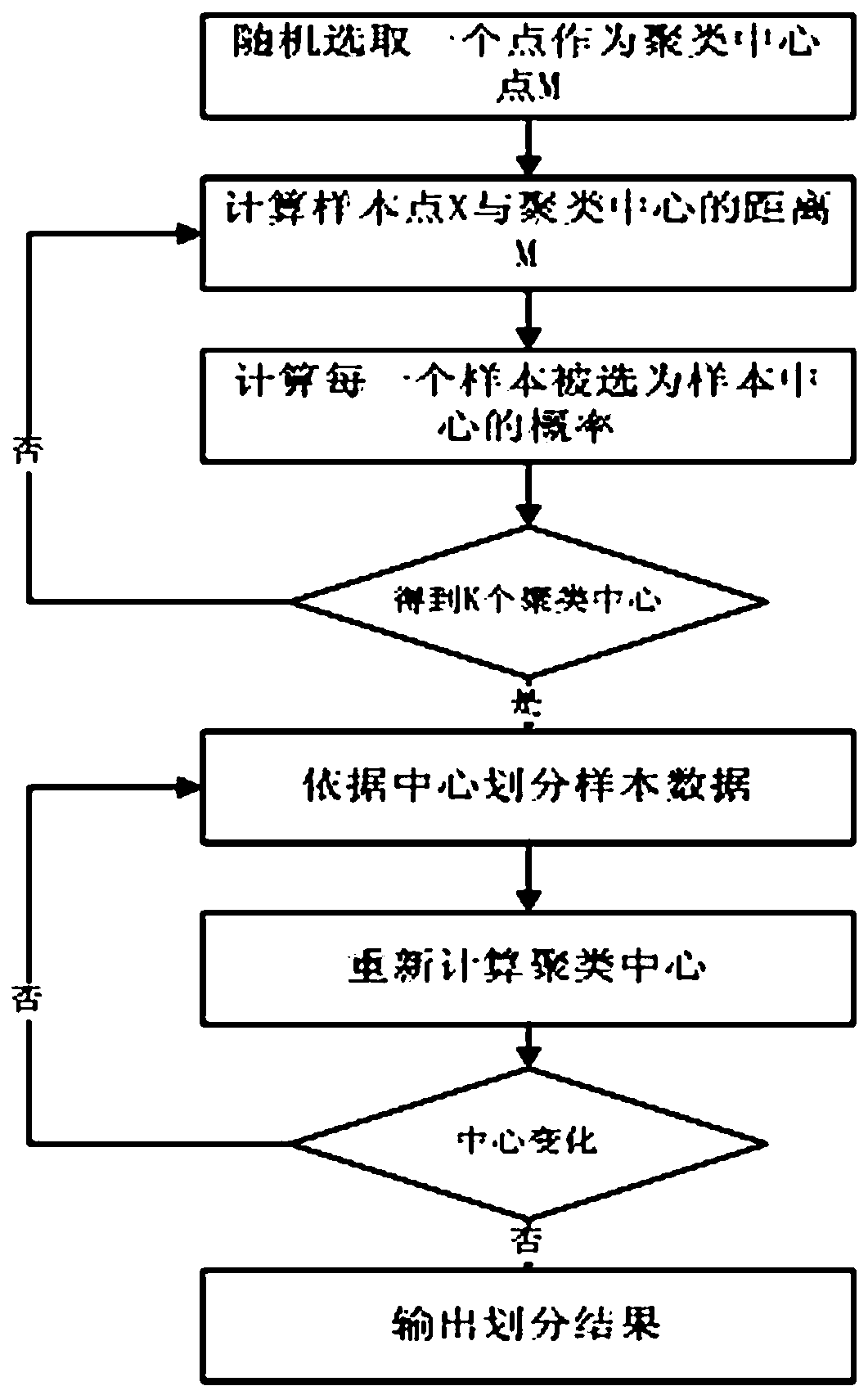

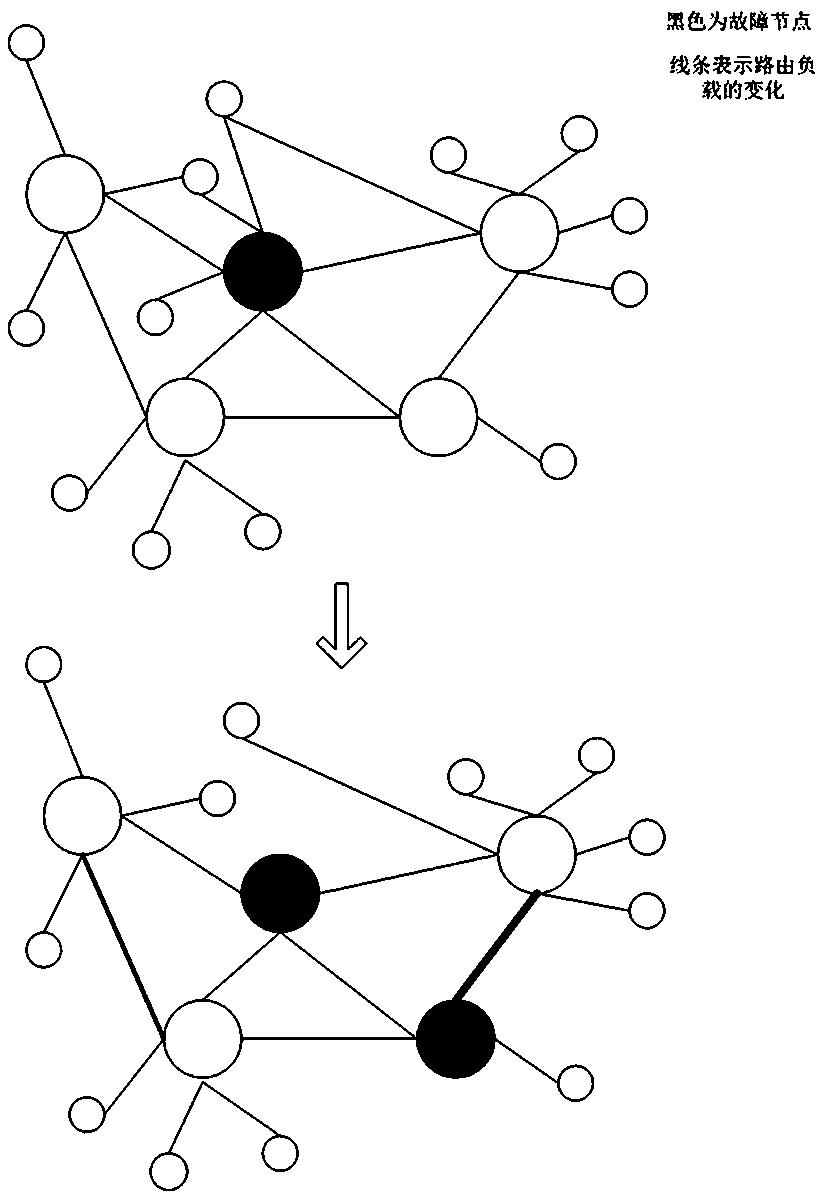

Communication network robustness assessment method based on complex network and in combination with big data

The invention provides a communication network robustness assessment method based on a complex network and in combination with big data. A communication network is abstracted into the complex networkthrough building a communication network model; a data mining algorithm is used for processing fault data; simulation modeling is performed on the model, analysis data is loaded into a simulation platform, a forwarding capacity, a caching capacity and a forwarding load are set and adjusted, and a routing strategy is changed, and thus a truer, more reliable and more accurate simulation assessment result is acquired. The network model of a real world complex system is built based on a complex network technology, system performance such as robustness, security and reliability are assessed and anoptimization scheme is provided by using a random simulation technology and operation and maintenance big data of the system; a cascade spreading and diffusion problem after a fault occurs in the communication network is found, weak links, including fault equipment and a fault spreading path, affecting the security and reliability of the whole network are found, and the optimization scheme is further provided based on a network topological structure.

Owner:ZHONGBEI UNIV

Small world power grid cascading failure restraining method

ActiveCN103151774AReduce short-distance accessAvoid accumulationAc network circuit arrangementsCascading failureShortest distance

The invention relates to a small world power grid cascading failure restraining method. The method comprises the steps that according to a network state before failure and specific information of a primary failure, a corresponding cascading failure restraining method is formulated, a connecting structure of a failure potential infection area is changed through the facts that a small amount of nodes with low transmission loads are cut off and short-distance accesses between a high cluster failure transmission subnet and power-load node pairs are reduced, and therefore failures are prevented from accumulating.

Owner:WUHAN UNIV

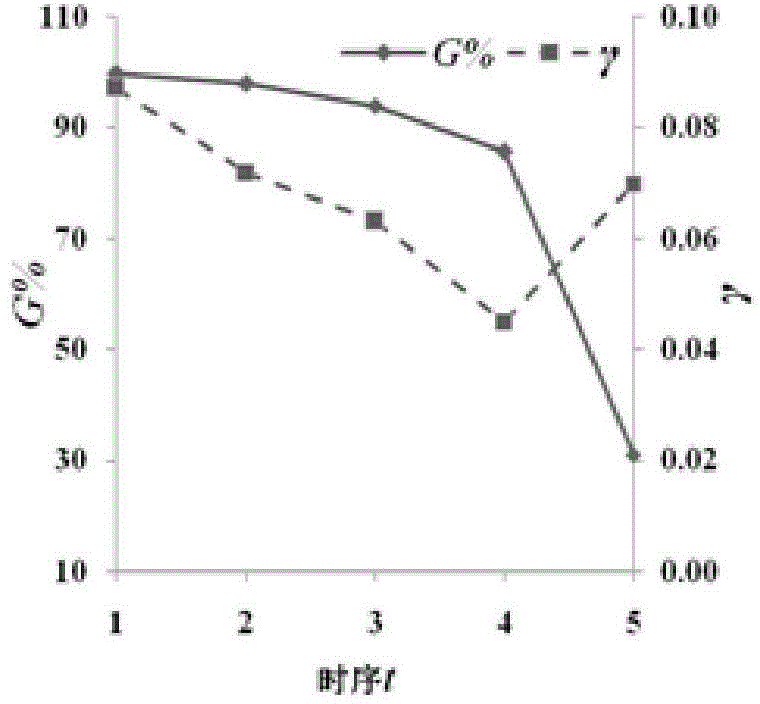

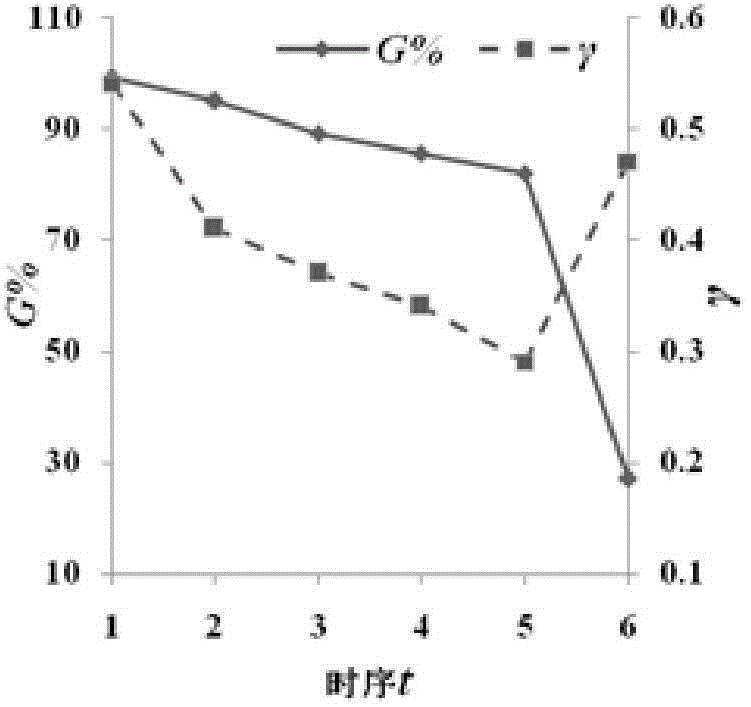

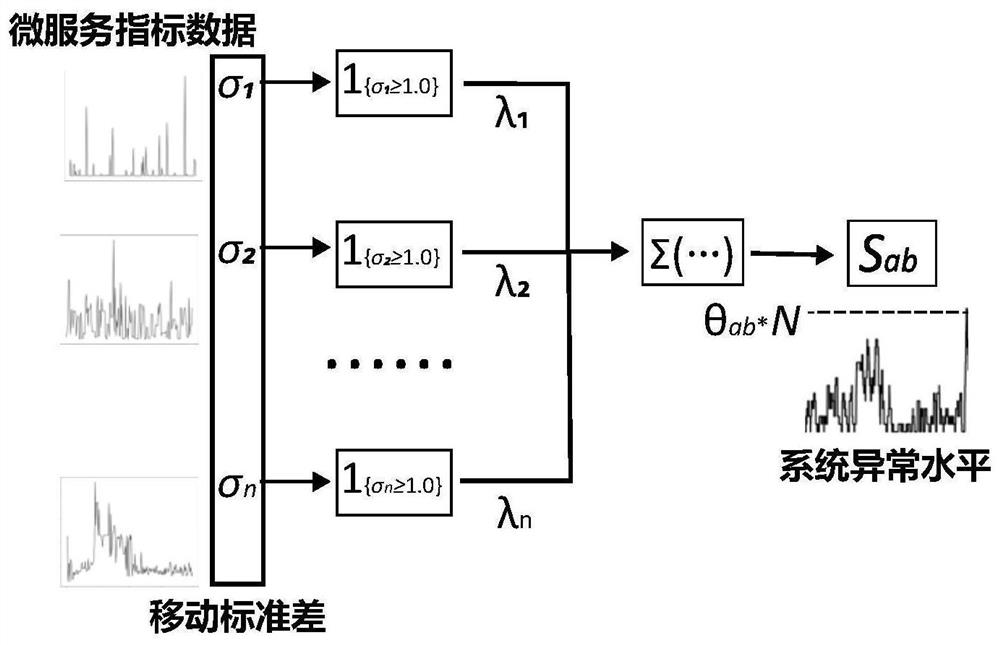

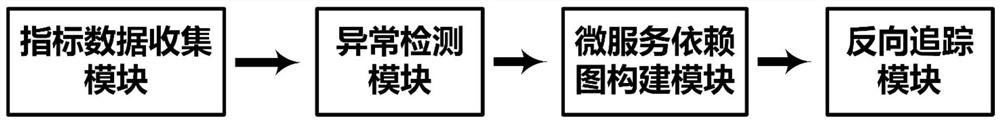

Fault root cause positioning method and system for micro-service architecture information system

ActiveCN112698975AImprove accuracyImprove interpretabilityFault responseComplex mathematical operationsDeployment timeCorrelation analysis

The invention discloses a fault root cause positioning method and system for a micro-service architecture information system. The system comprises an index data collection module, an anomaly detection module, a micro-service dependence graph construction module and a reverse tracking module. A root cause positioning algorithm based on a fault propagation chain model is designed by establishing a dynamic correlation analysis method between micro-services, the propagation process of related faults is identified while the fault root cause service is positioned, the interpretability of fault positioning and diagnosis is improved, and the method can be applied to a micro-service architecture information system and is high in practicability. The accuracy of dynamic association modeling in the micro-service architecture information system is improved, the use convenience of a fault diagnosis tool of the micro-service architecture information system is improved through a micro-service performance index data driving method, and the deployment time and energy are saved.

Owner:PEKING UNIV

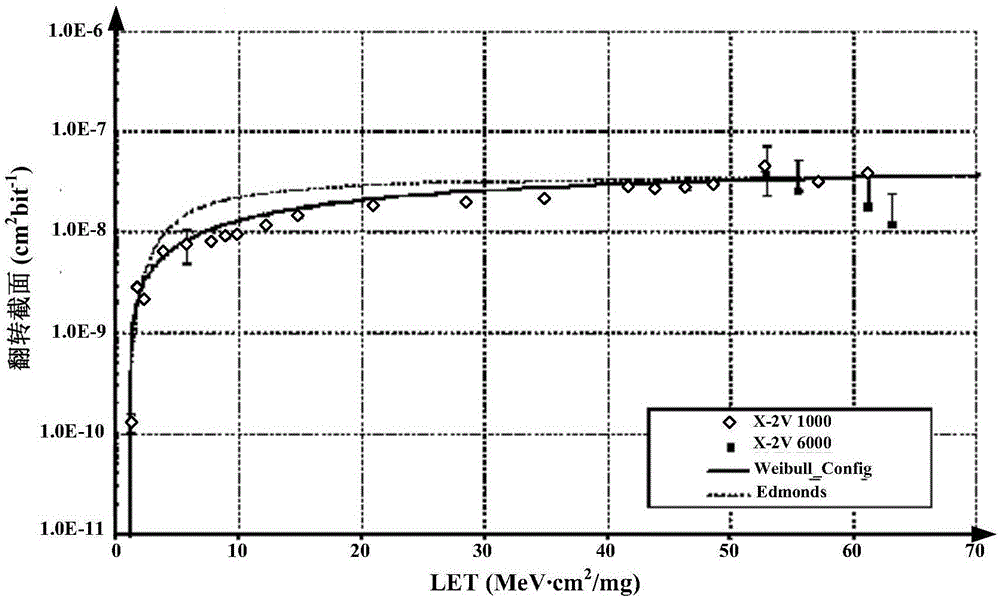

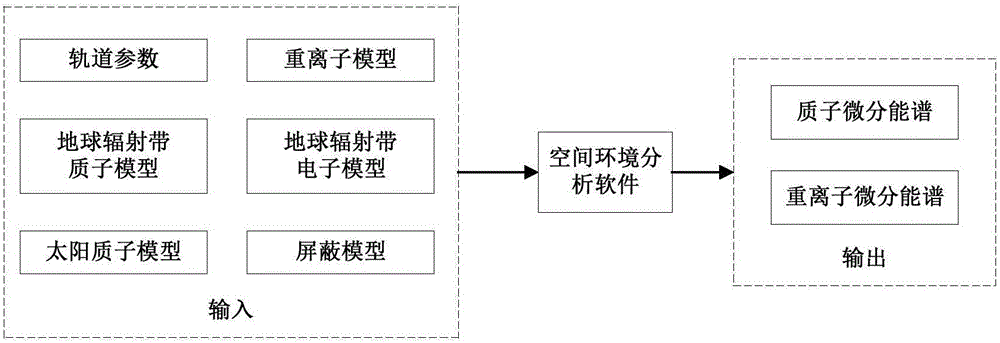

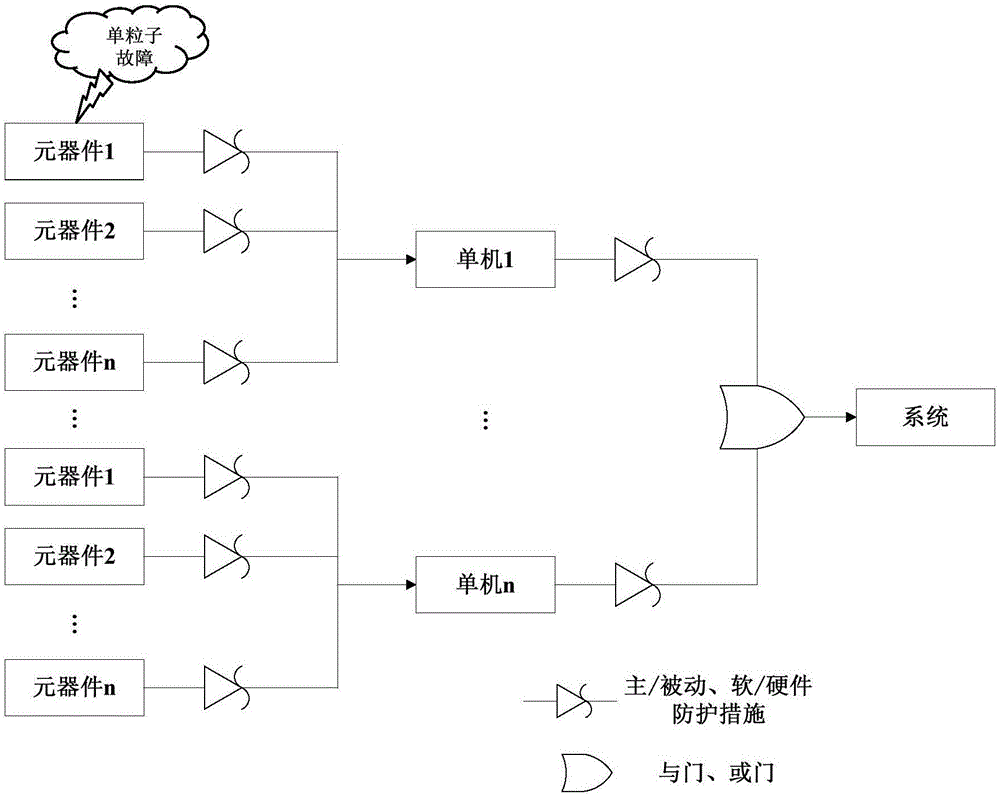

Spacecraft system-level single event upset effect analysis method based on fault propagation

InactiveCN105117576AMeet design requirementsSignificant practical significanceSpecial data processing applicationsSimulationSpacecraft design

The present invention provides a spacecraft system-level single event upset effect analysis method based on fault propagation. The method comprises spatial radiation environmental effect estimation, system single event fault propagation modeling and device-level, single-machine-level and system-level oriented single event upset fault rate calculation. The method solves the systematic and quantitative problems of estimating the effect of a single event effect on a sensitive system during existing spacecraft design and can provide a necessary reference for selection of spacecraft components and optimization of an anti-radiation design scheme of a single machine and a system.

Owner:SHANGHAI SATELLITE ENG INST

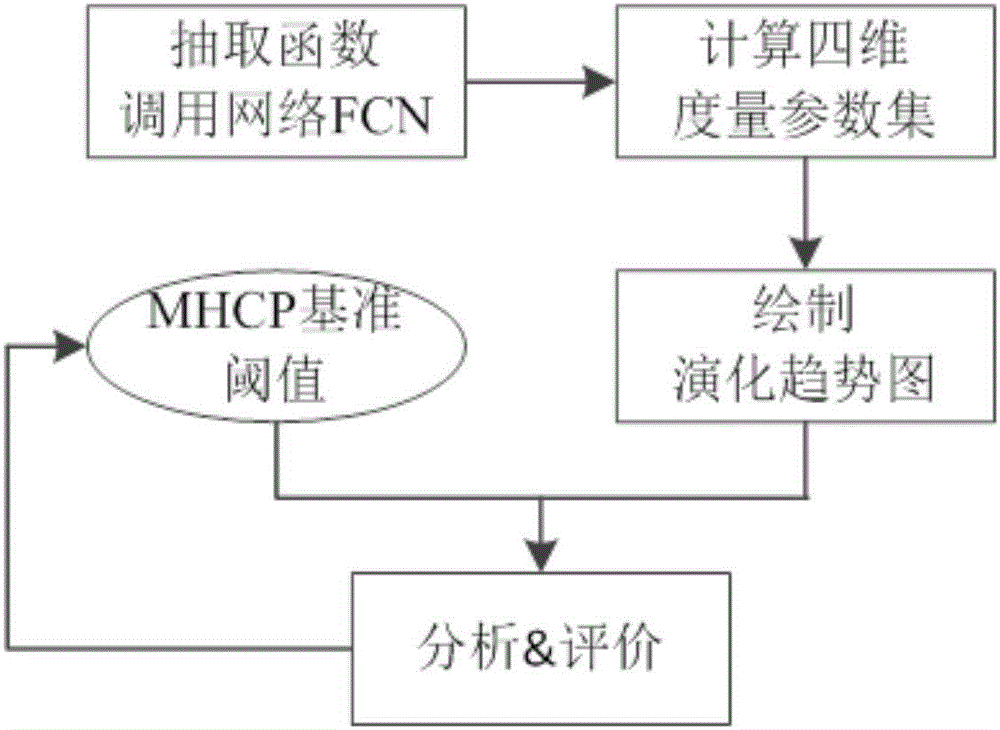

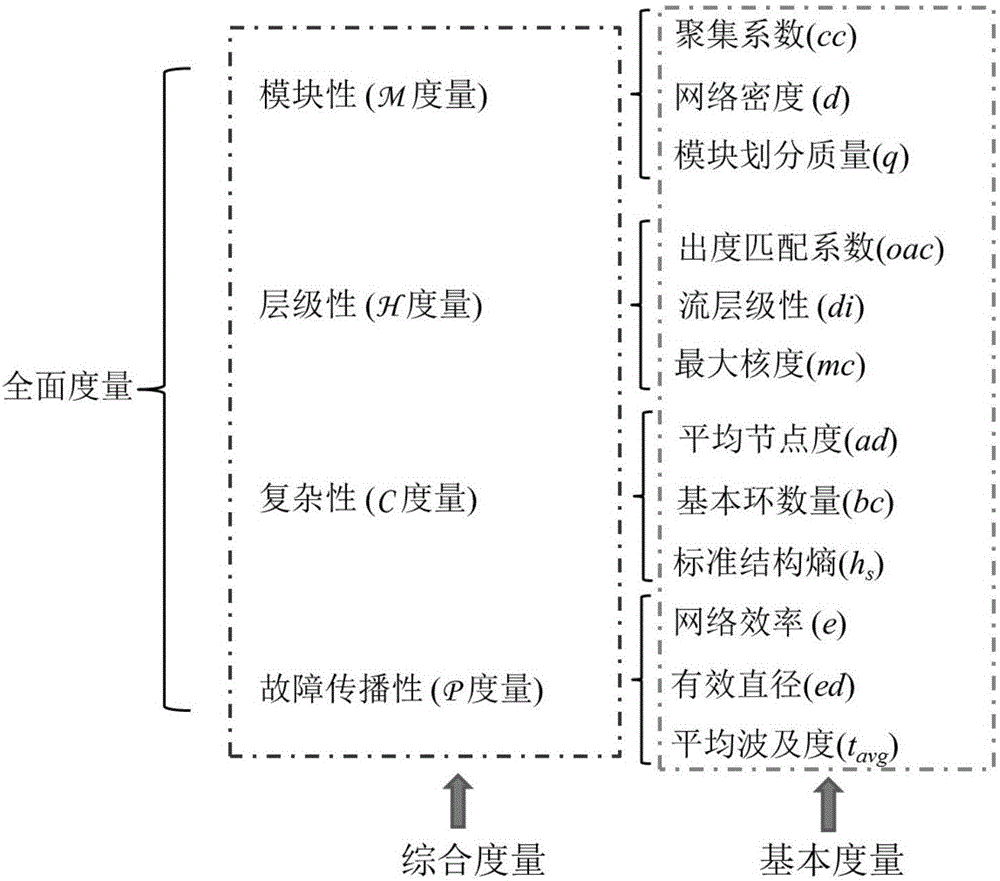

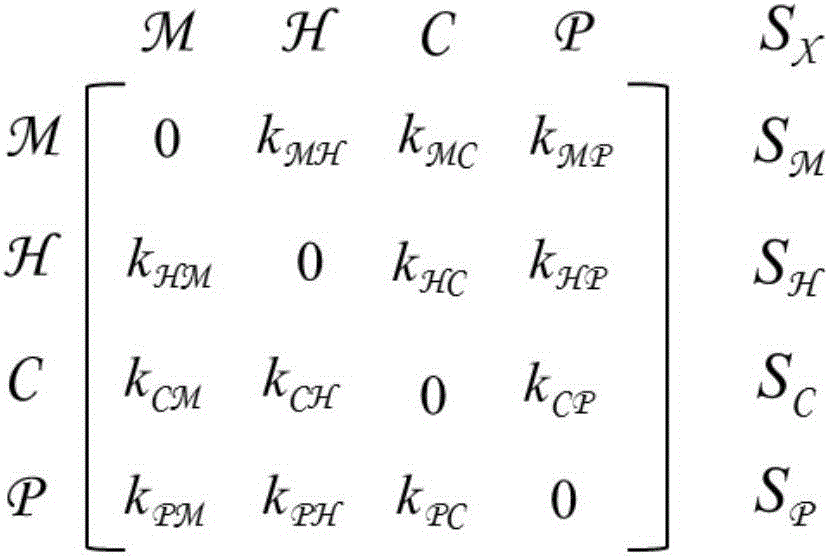

Software complex network-based four-dimensional software evolution measurement analysis method

ActiveCN106406870AEnsure objectivityGuaranteed validitySoftware maintainance/managementSpecific program execution arrangementsSoftware development processQuality level

The invention discloses a software complex network-based four-dimensional software evolution measurement analysis method, and belongs to the field of software engineering. The method comprises the steps of performing function call network extraction on a code of each version of target software; performing measurement monitoring on four dimensions of modularity, structure hierarchy, complexity and fault propagation of software in a version evolution process, wherein three basic measurement indexes are set for each dimension; performing statistics on dimension measurement results, and drawing fluctuation trend graphs of version evolution; evaluating the version of the target software in combination with a four-dimensional measurement reference threshold of a target software type; and putting the software with relatively good evaluation results into a software reference library, and performing reference threshold optimization. According to the method, comprehensive monitoring of overall structure quality level of a software product is realized; problems existent in software development can be corrected in time; and the target software of the same type is analyzed and evaluated under unified reference threshold standards, so that the objectivity and validity of the results are ensured.

Owner:BEIHANG UNIV

Method for fault handling in a co-operative workflow environment

The invention provides a method for fault handling in a co-operative workflow environment that employs a placement strategy for transaction scope and associated fault handlers and compensation handlers across different workfiow components. The method employs a fault propagation scheme for forwarding a fault occurring in any of the workflow components to a fault handler. The method employs a distributed data collection mechanism to facilitate recovery from a fault occurring in any the workfiow components. The method employs a fault recovery mechanism using compensation. The transaction scope defines a transaction boundary and provides a fault handling and a fault recovery context for a set of activities and the transaction scope may be nested inside another transaction scope resulting in outer and inner scopes.

Owner:INT BUSINESS MASCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com