Numerical control machine tool fault diagnosis method

A technology for CNC machine tools and fault diagnosis, applied in the field of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

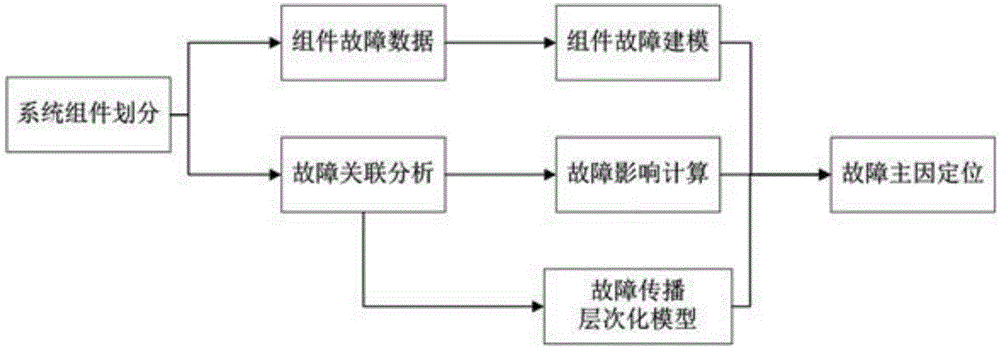

Method used

Image

Examples

Embodiment

[0121] CNC Machine Tool Fault Diagnosis

[0122] Fault analysis was performed on 106 fault data collected from a CNC machine tool site, and a total of 9 components were found to be faulty. The fault information of the 9 components of the CNC machine tool is shown in Table 1.

[0123] Table 1 System component codes and failure interval schedule

[0124]

[0125]

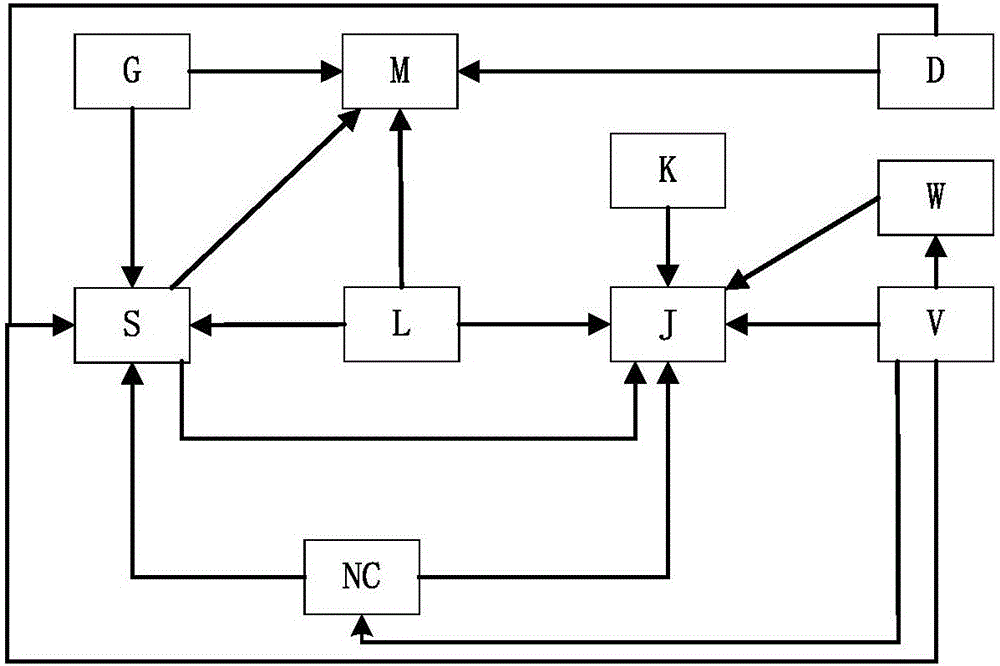

[0126] The system consists of 10 nodes to form a node set V, and the directed edge set E={e ij}(1≤i, j≤10), with the help of relevant experience in the structure and function of the system, combined with the fault diagnosis manual, the fault directed graph G(V,E) is obtained, see image 3 shown.

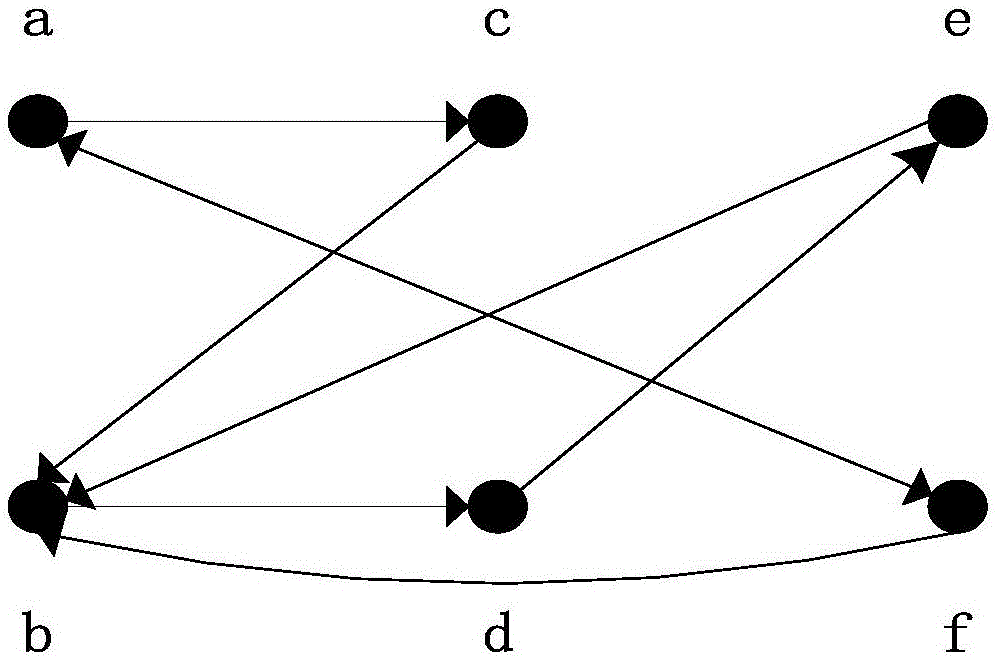

[0127] According to Table 1 and image 3 , to determine the adjacency matrix A of the direct relationship between the faults of the system components. According to the adjacency matrix A plus the identity matrix I, after the Boolean self-multiply operation, the reachable matrix M of the indirect fault relationships ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com