Method for selecting roughing tool for aircraft complex component based on Voronoi Mountain variation

A tool and mutation technology, applied in the field of tool selection for rough machining of aircraft complex components based on mutated Voronoi Mountain, can solve the problems of unable to generate Voronoi Mountain and not considering the slotting situation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific implementation processes are provided, but the protection scope of the present invention is not limited to The following implementation examples.

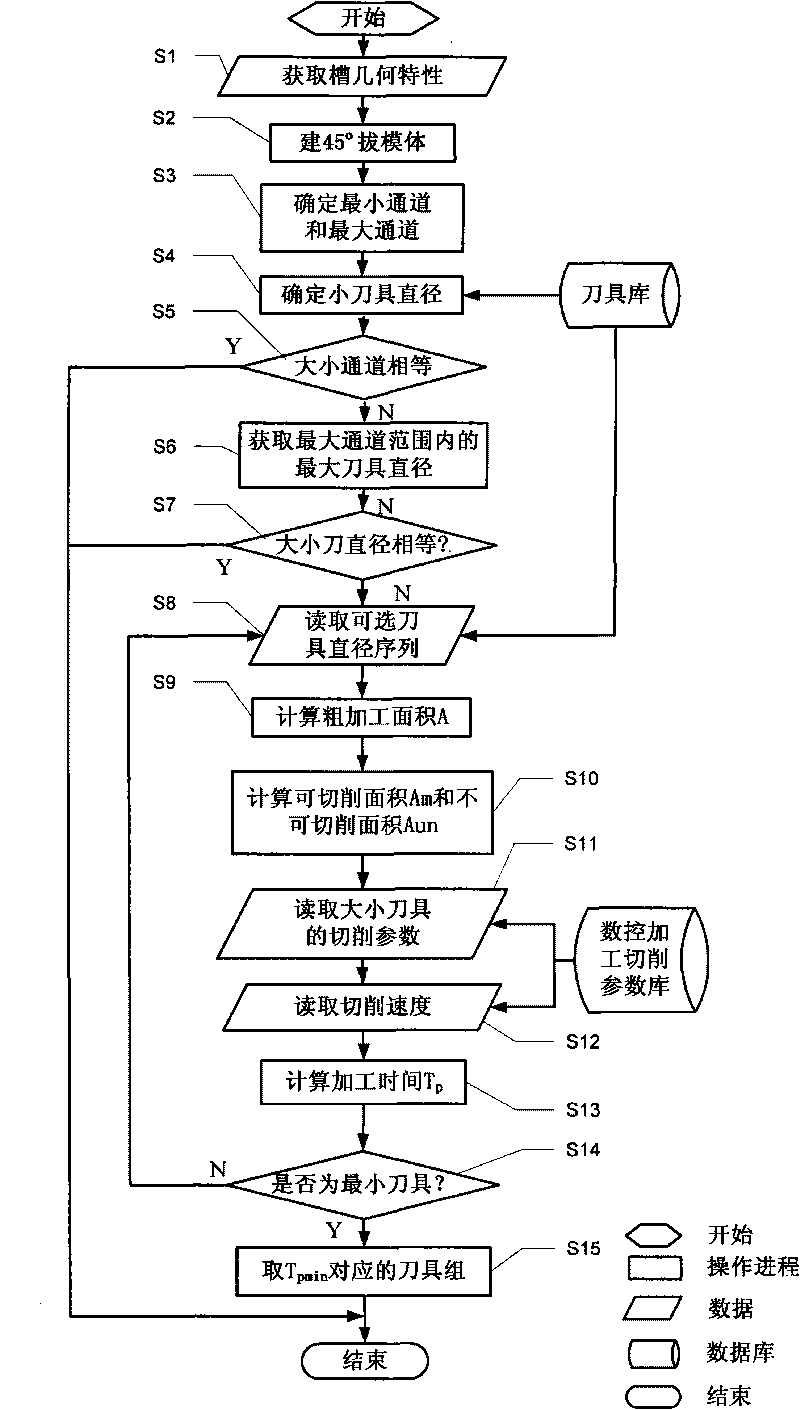

[0066] figure 1 Shown is the aircraft complex component rough machining tool selection process based on variation Voronoi Mountain that the present invention proposes, and its specific implementation steps are as follows:

[0067] Step 1) Obtain the groove geometrical characteristics (S1), including groove side wall surface, groove bottom surface, island contour and outer contour;

[0068] Step 2): Establish a 45° draft body (S2) based on the variant Voronoi Mountain, including a 45° draft body with a closed groove profile and a 45° draft body with a slotted profile: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com