Torque estimation method for lean-burn natural gas engine

A technology of engine torque and natural gas, applied in engine control, machine/engine, electrical control, etc., can solve the problems of actual engine torque deviation, large deviation, vehicle control accuracy and vehicle ride comfort, etc., to achieve actual torque Precise, the effect of improving vehicle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

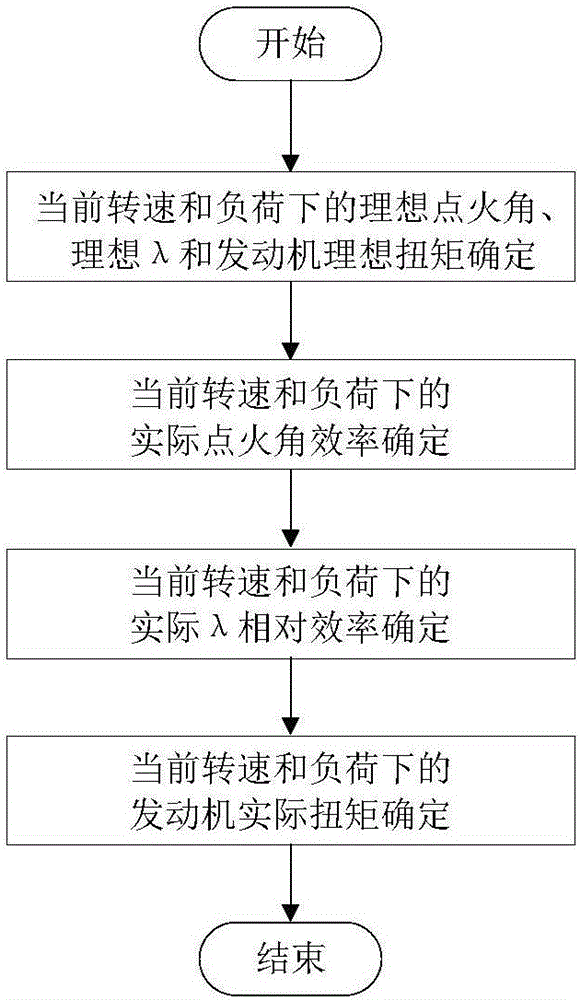

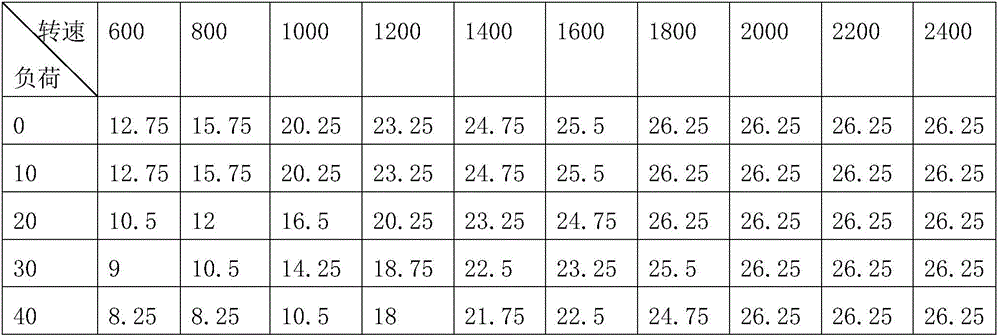

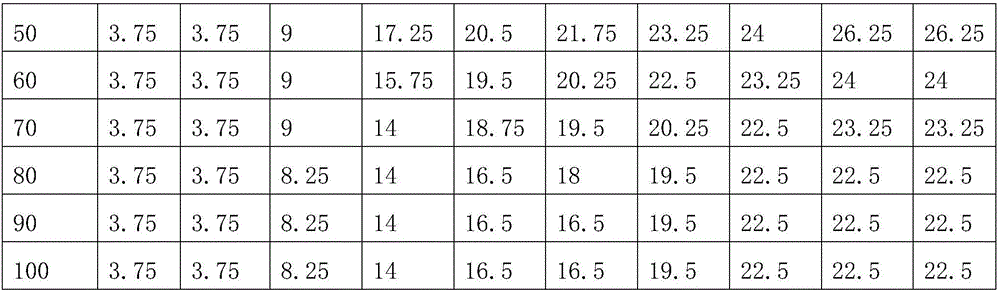

[0016] 1. Determine the ideal ignition angle, ideal lambda and engine ideal torque under the current speed and load. Carry out the bench calibration test, set the engine speed range from 600rpm to 2300rpm, and set the engine load range from 10% to 100%. Gradually adjust the engine speed at an interval of 200rpm, adjust the engine load at an interval of 10%, and conduct a point sweep test. At each speed and load point, adjust the actual ignition angle and actual λ to maximize the combustion torque output by the engine. At this time The actual ignition angle, the actual λ, and the combustion torque output by the engine are the speed, the ideal ignition angle at the load point, the ideal λ, and the ideal engine torque, and so on. Finally, the input is the speed and load, and the output is the ideal ignition angle, ideal See Table 1, Table 2 and Table 3 for the three relationship tables between λ and the ideal torque of the engine. According to these three relational tables, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com