Patents

Literature

697results about How to "Reduce deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

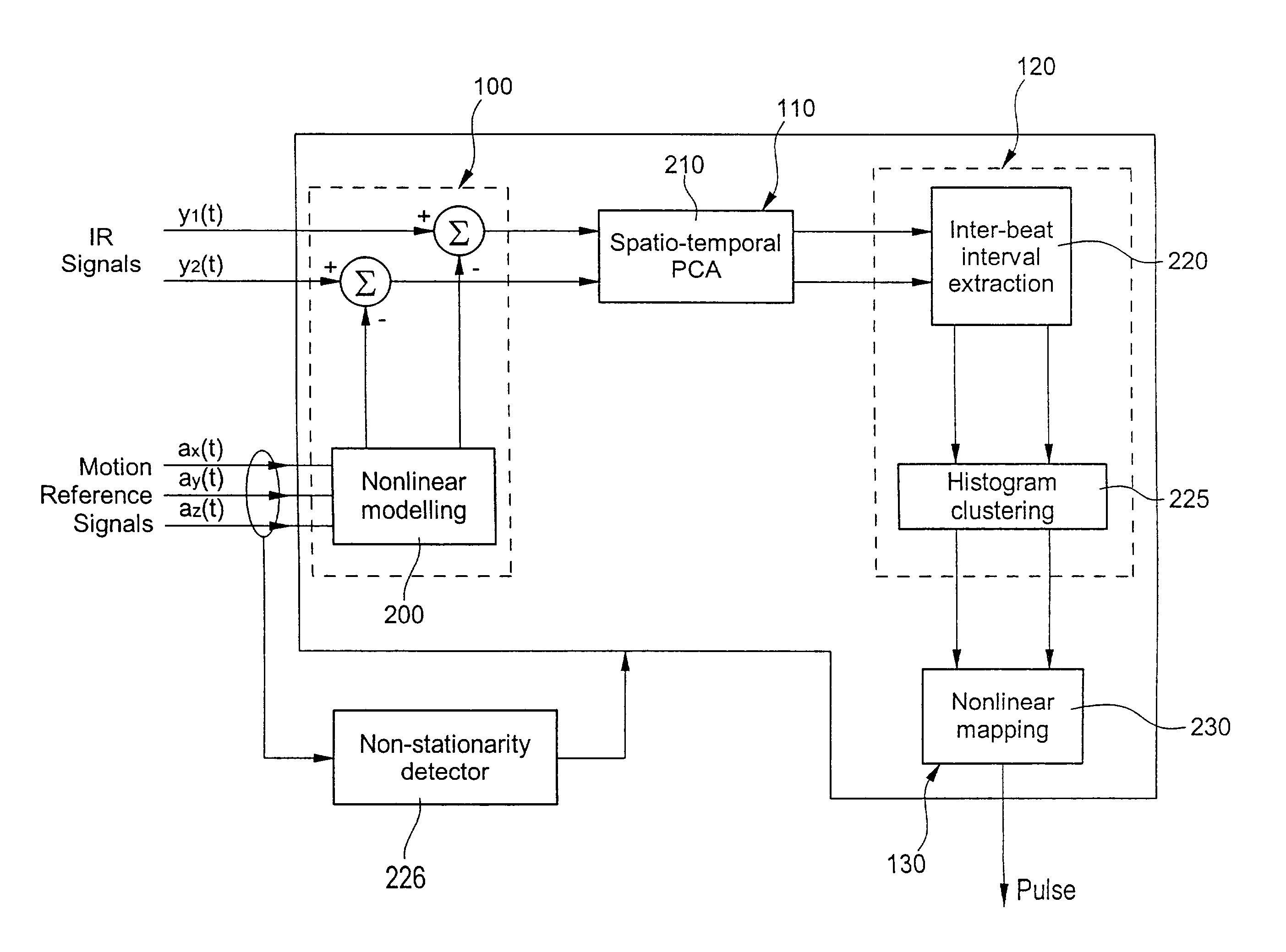

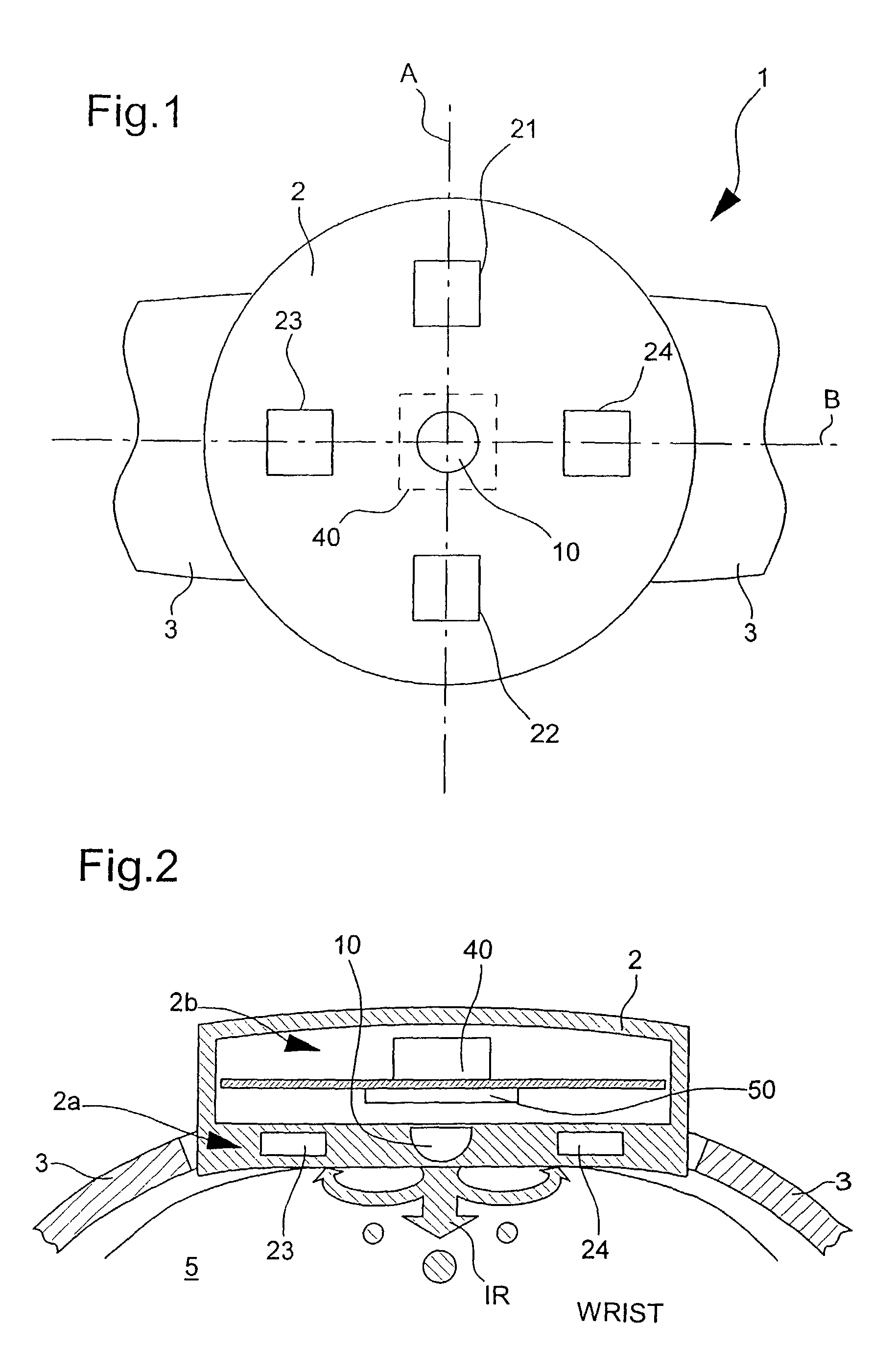

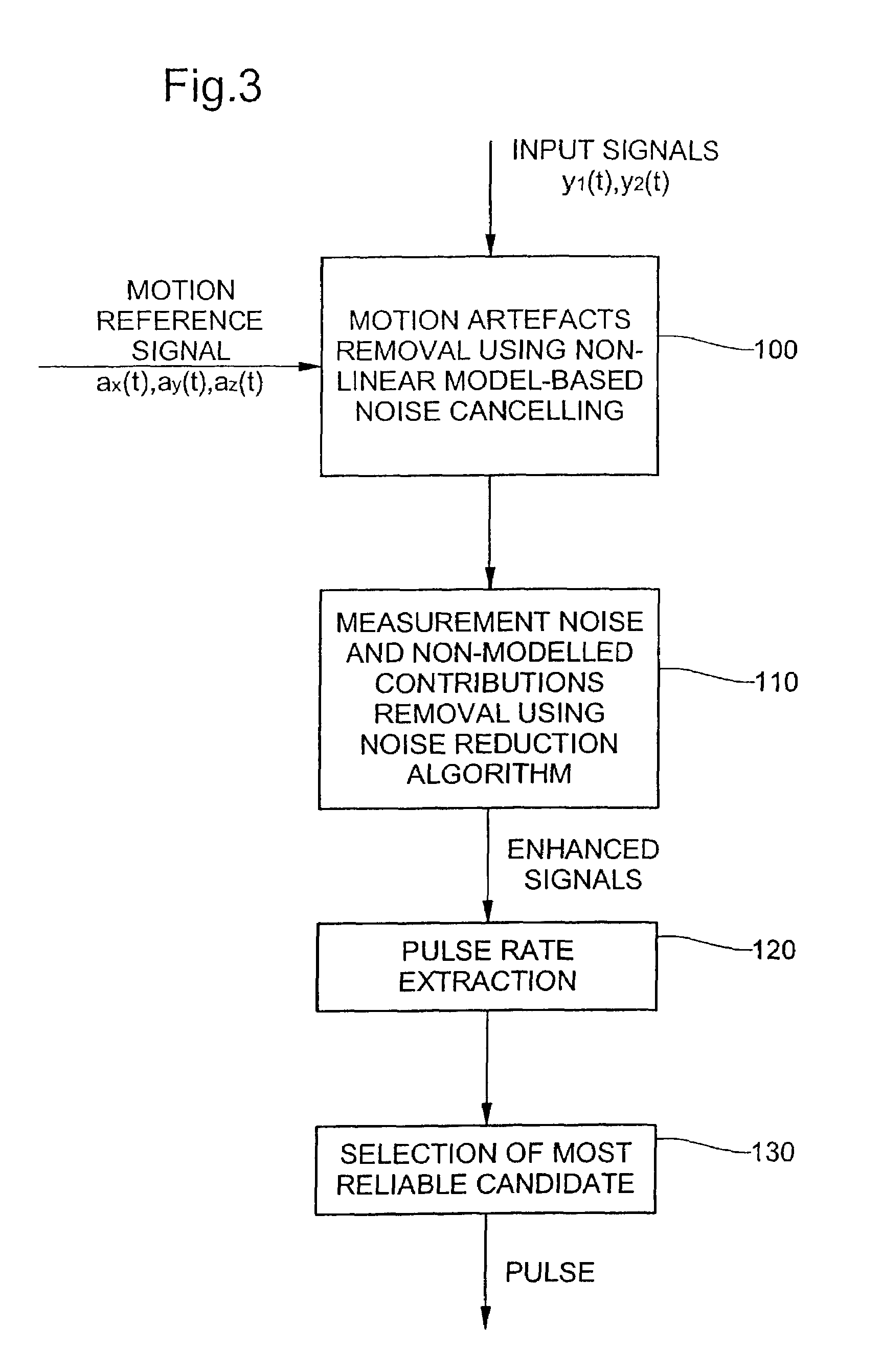

Method and device for pulse rate detection

InactiveUS7018338B2Accurately monitoring and detecting heart rateFully removedCatheterSensorsHuman bodyNoise reduction algorithm

Portable pulse rate detecting device for contact with human body tissue, including a light-emitting source for emitting radiant energy directed at through human body tissue; at least first and second light detectors for detecting intensity of radiant energy after propagation through human body tissue and for providing first and second input signals as a function of such propagation, a detecting device for providing a motion reference signal, and processing means for removing motion-related contributions from the first and second input signals and subtracting a calculated model based on the motion reference signal from each of the first and second input signals, wherein the processing means is also for removing measurement noise and residual non-modeled contributions from the first and second enhanced signals using a noise reduction algorithm.

Owner:MENDEL BIOTECHNOLOGY INC +1

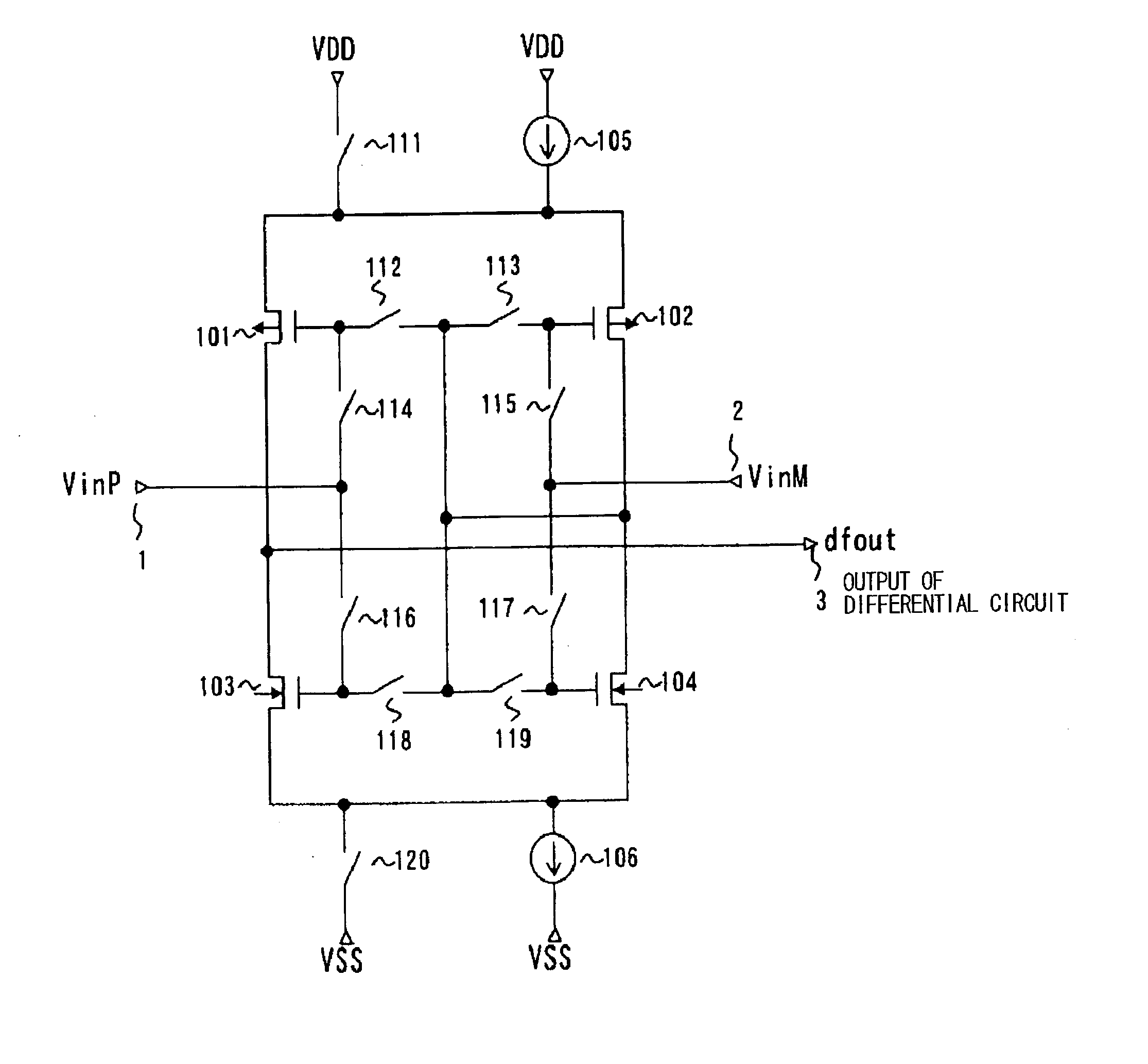

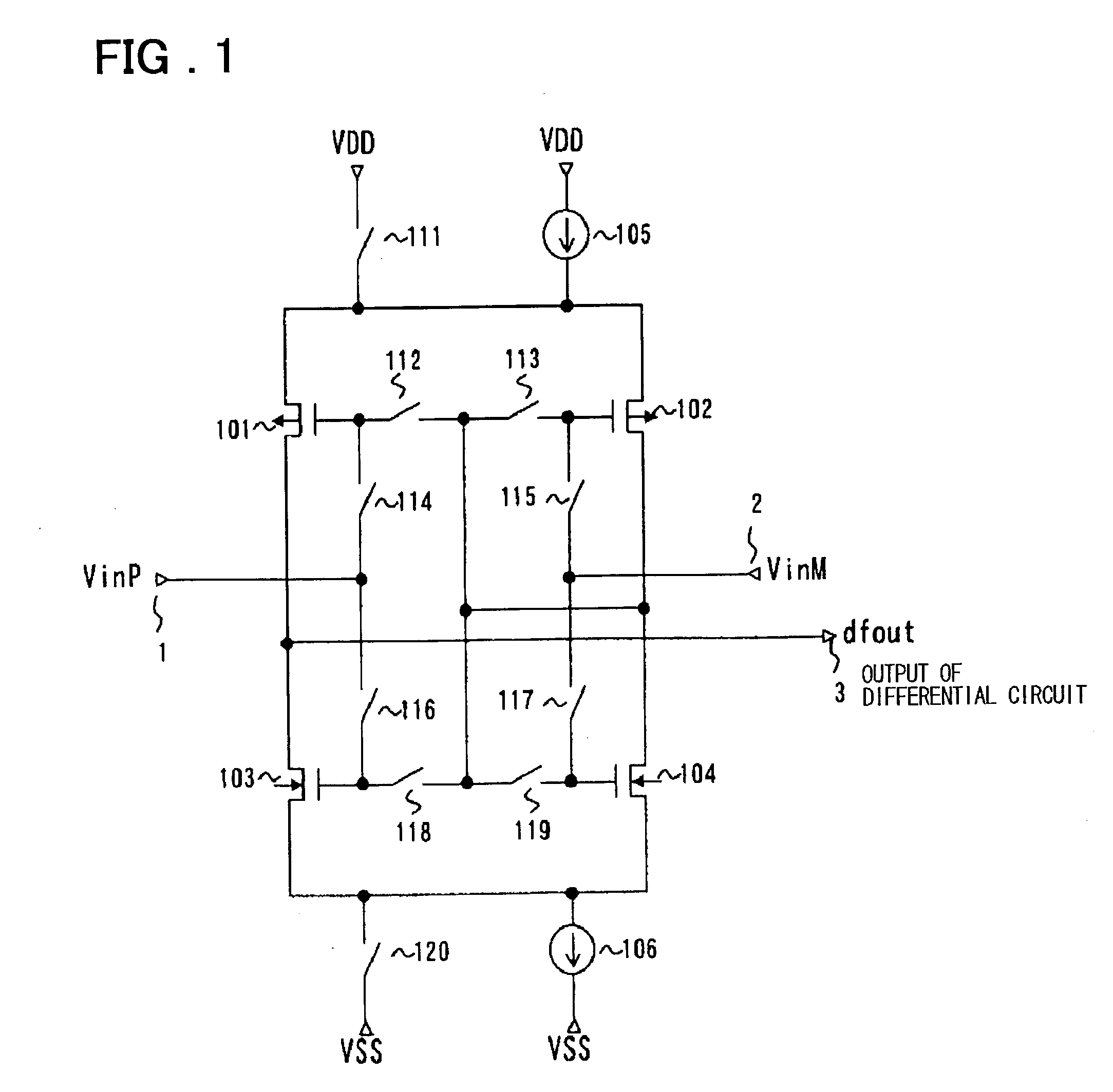

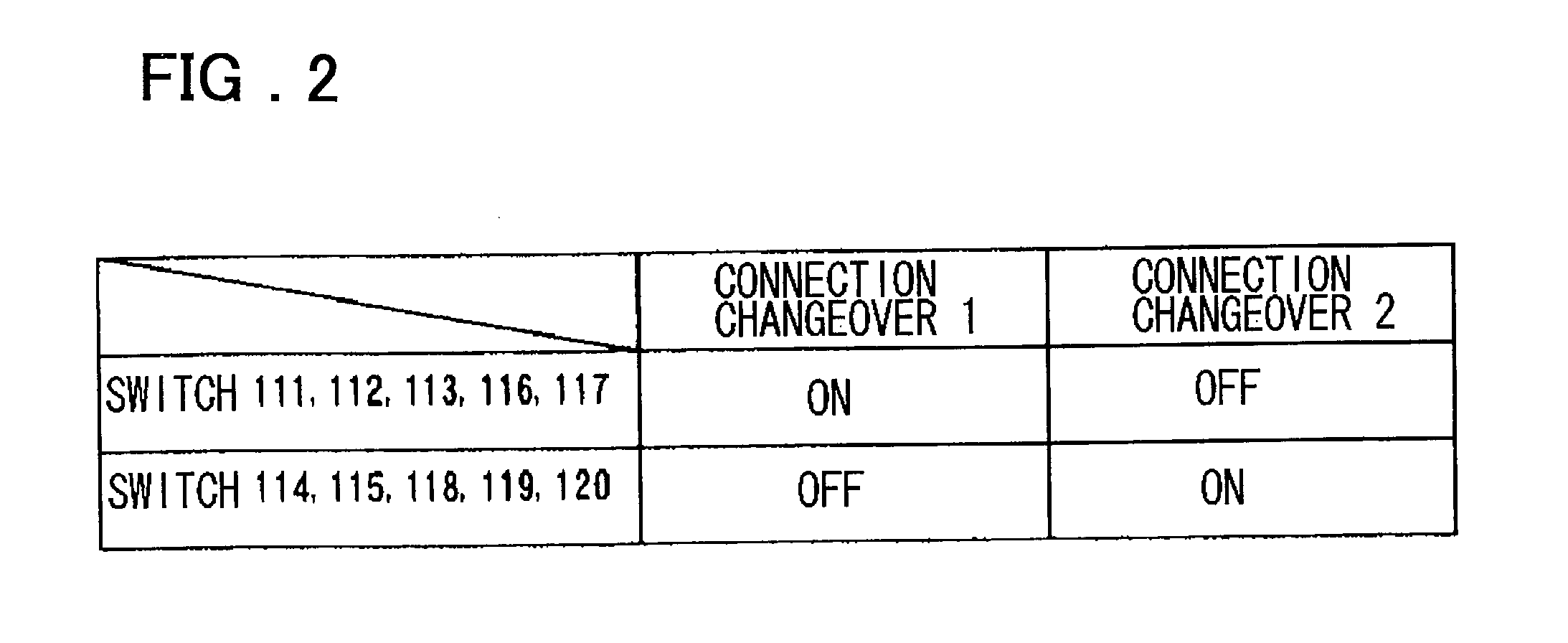

Differential circuit, amplifier circuit, driver circuit and display device using those circuits

ActiveUS20030160749A1Reduce power consumptionReducing amplitude difference deviationStatic indicating devicesGated amplifiersDriver circuitAudio power amplifier

A differential circuit and an amplifier circuit for reducing an amplitude difference deviation, performing a full-range drive, and consuming less power are disclosed. The circuit includes a first pair of p-type transistors and a second pair of n-type transistors. A first current source and a first switch are connected in parallel between the sources of the first pair of transistors, which are tied together, and a power supply VDD. A second current source and a second switch are connected in parallel between the sources of the second pair of transistors, which are tied together, and a power supply VSS. The circuit further includes connection changeover means that performs the changeover of first and second pairs between a differential pair that receives differential input voltages and a current mirror pair that is the load of the differential pair. When one of the two pairs is the differential pair, the other is the current mirror pair. In a differential amplifier circuit, there is provided an added transistor connected in parallel to a transistor, which is one transistor of a differential pair transistors, whose control terminal is a non-inverting input terminal. The added transistor has a control terminal for receiving a control voltage which is set so that, when an input voltage applied to the non-inverting input terminal is in a range in which the transistor whose control terminal is the non-inverting input terminal is turned off, the added transistor is turned on.

Owner:RENESAS ELECTRONICS CORP

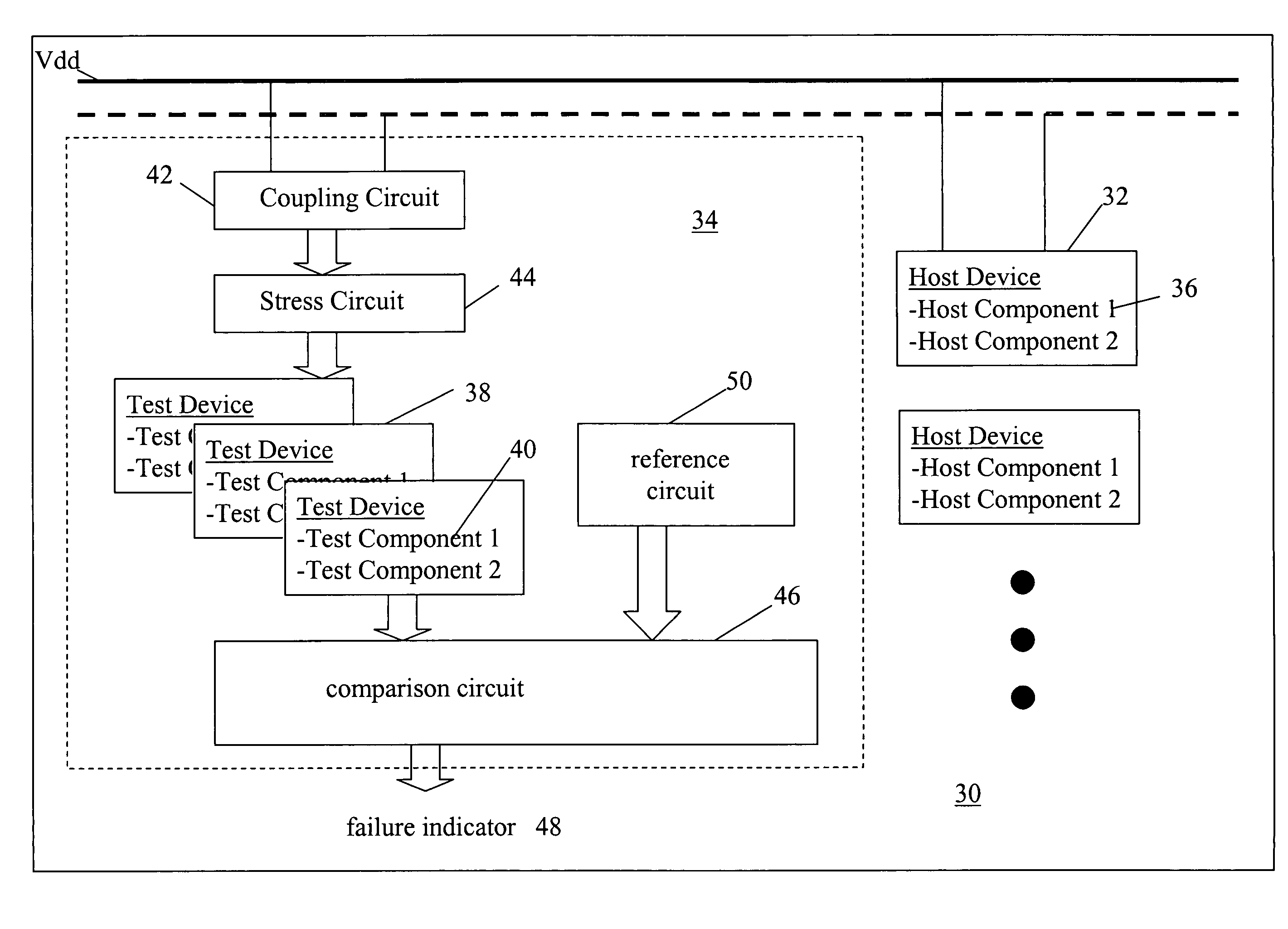

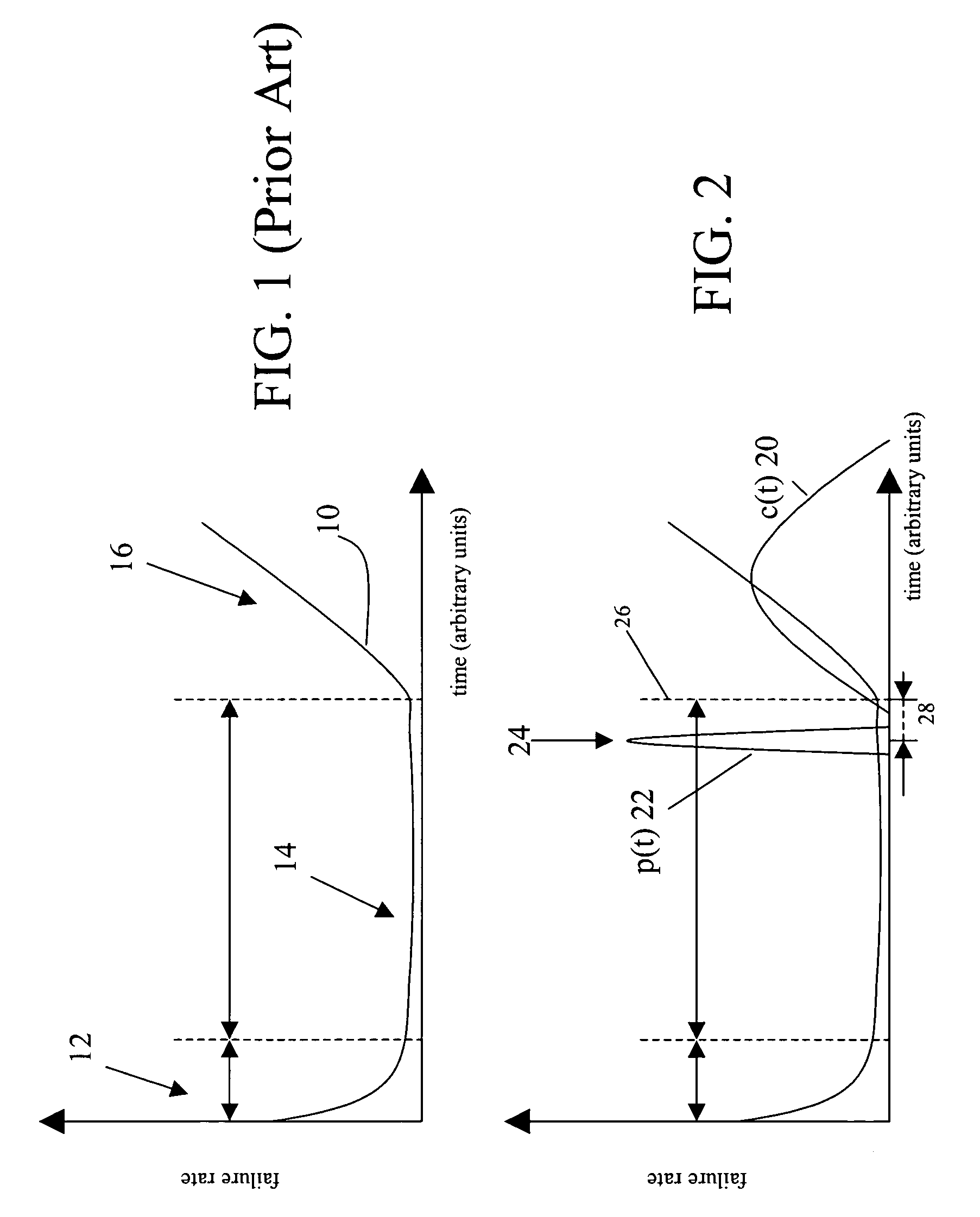

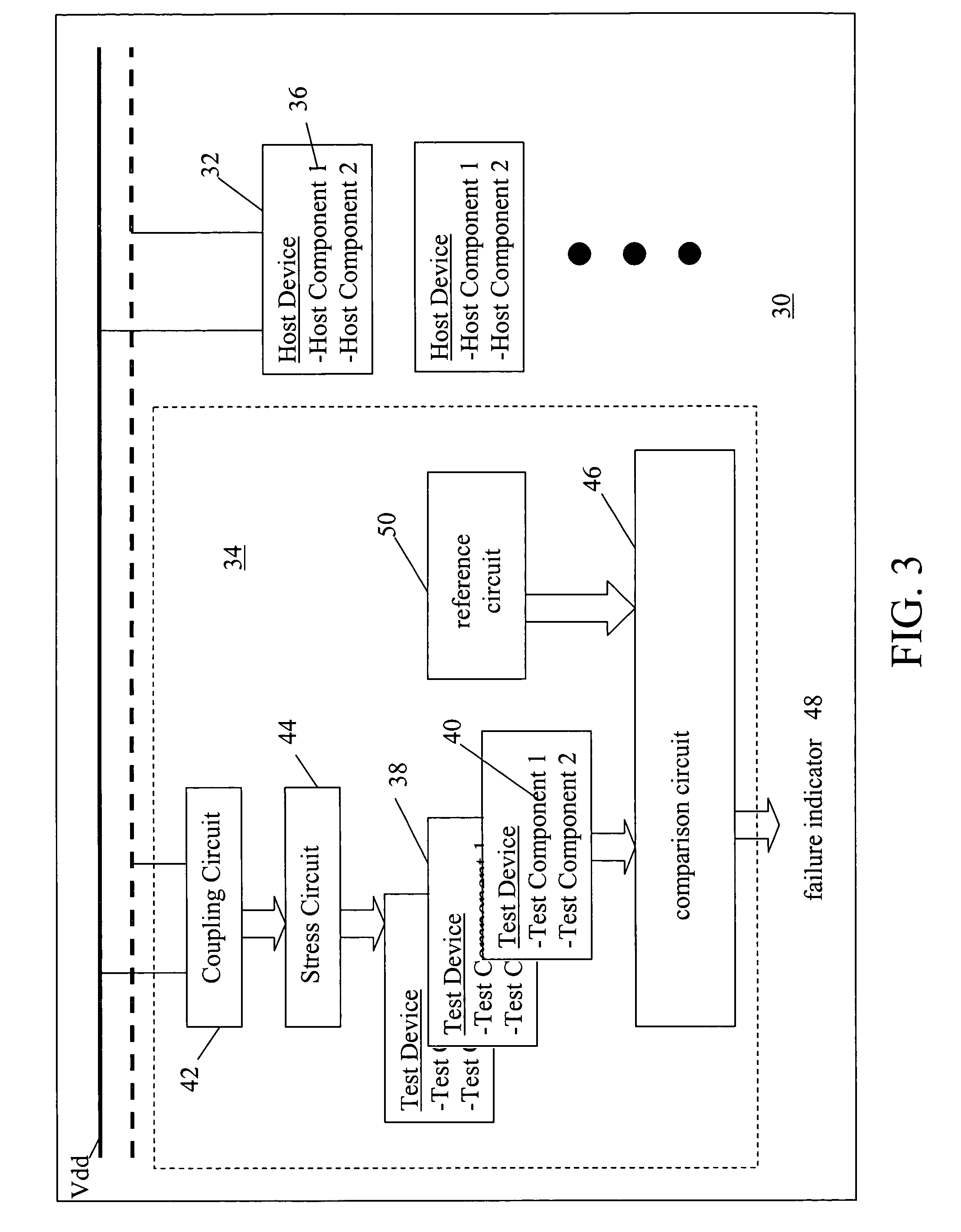

Prognostic cell for predicting failure of integrated circuits

InactiveUS7271608B1Improve deteriorationLow operating pressurePlug gaugesAlarmsRelative timesIntegrated circuit

A prognostic cell is used to predict impending failure of a useful circuit or circuits in a host IC. Increasing the stress on the prognostic cell relative to the useful circuit shifts the failure distribution of the cell along the time axis. The relative amount of time between the useful circuit failure and prognostic cell trigger point is the “prognostic distance”. The prognostic distance is controlled by designing in the excess stress applied in test device(s), by setting the threshold for triggering in the comparison circuit or by both. Prediction accuracy is enhanced by using multiple test devices to oversample the underlying failure distribution and triggering the failure indicator when a certain fraction fail.

Owner:RIDGETOP GROUP

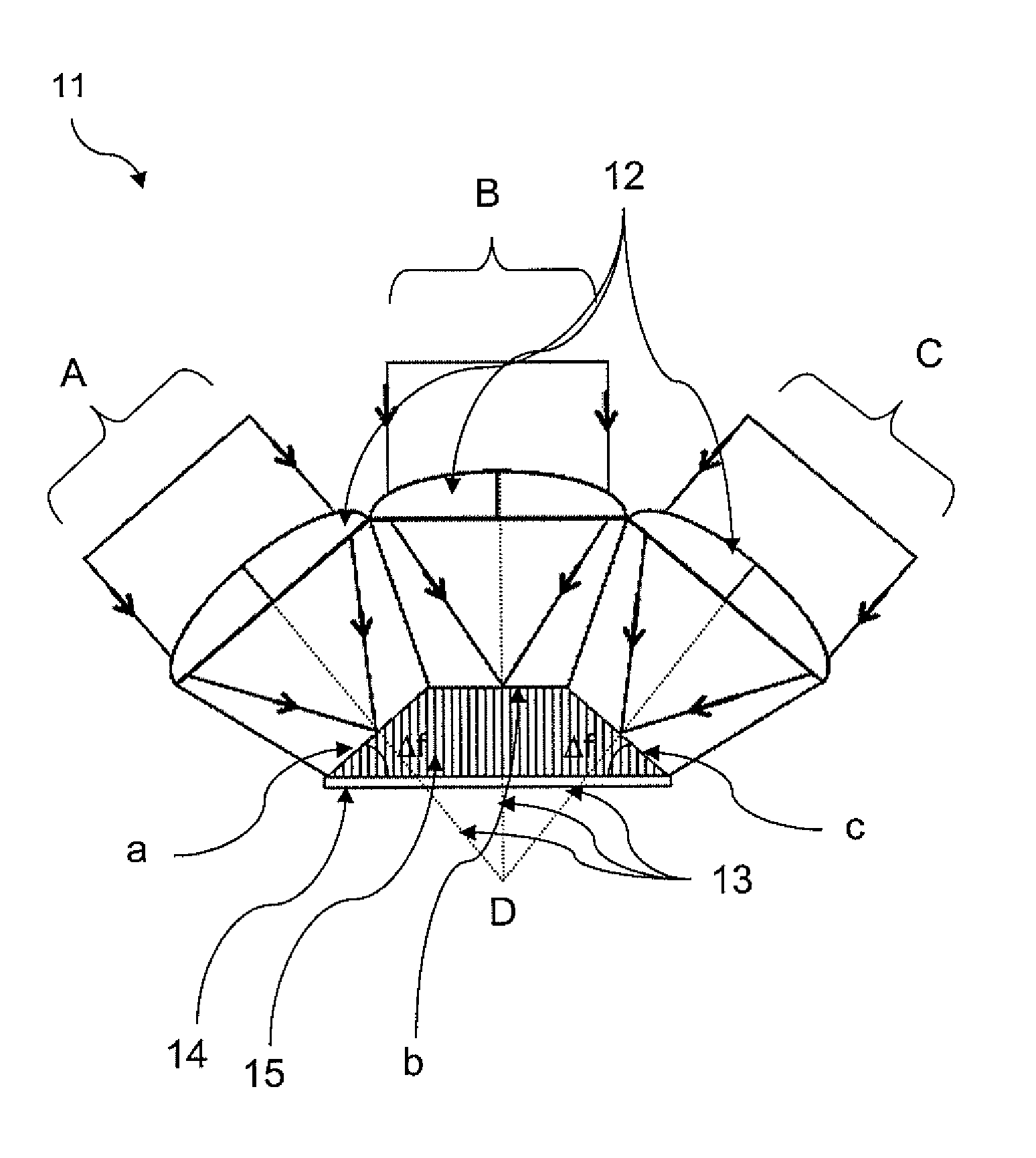

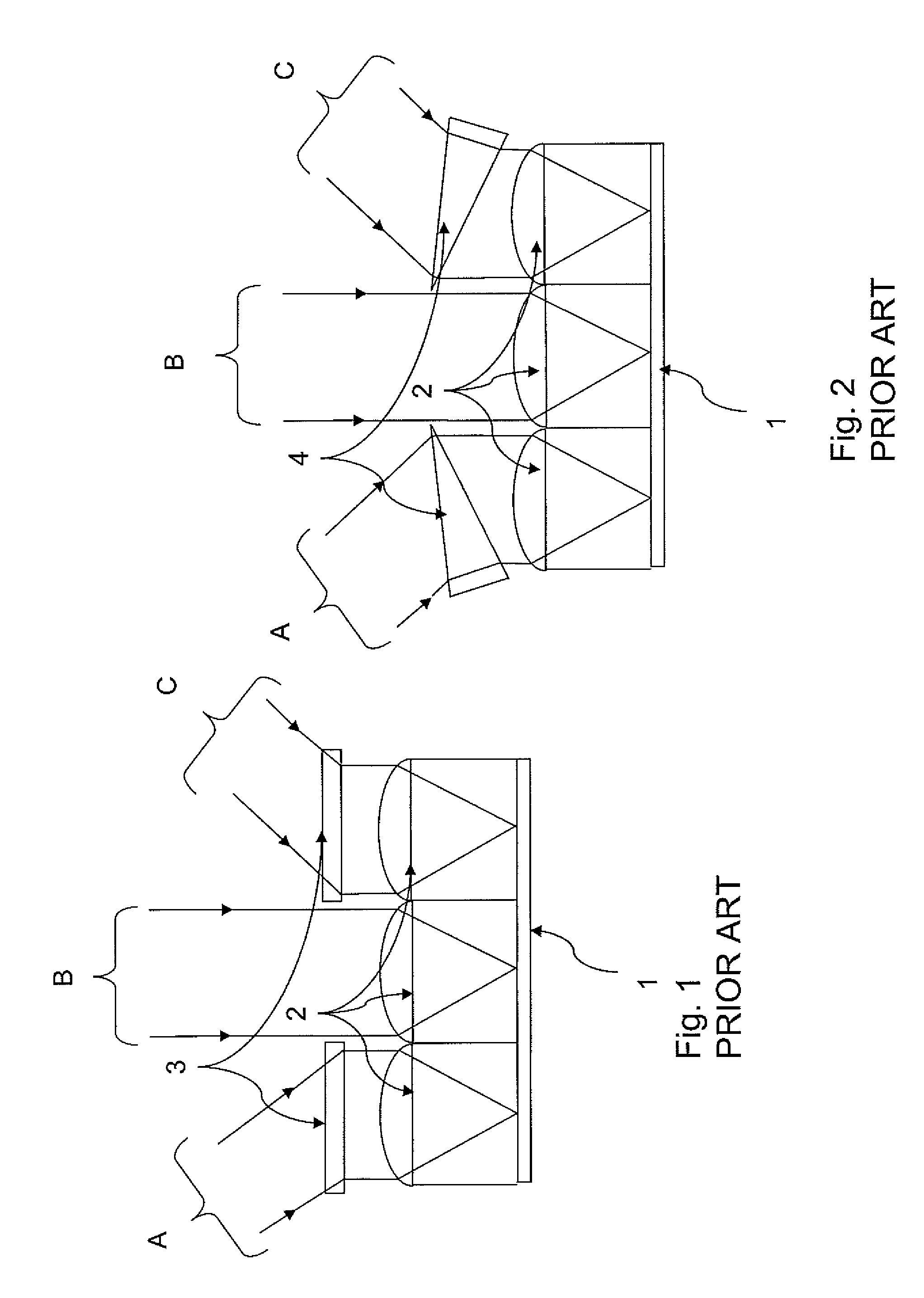

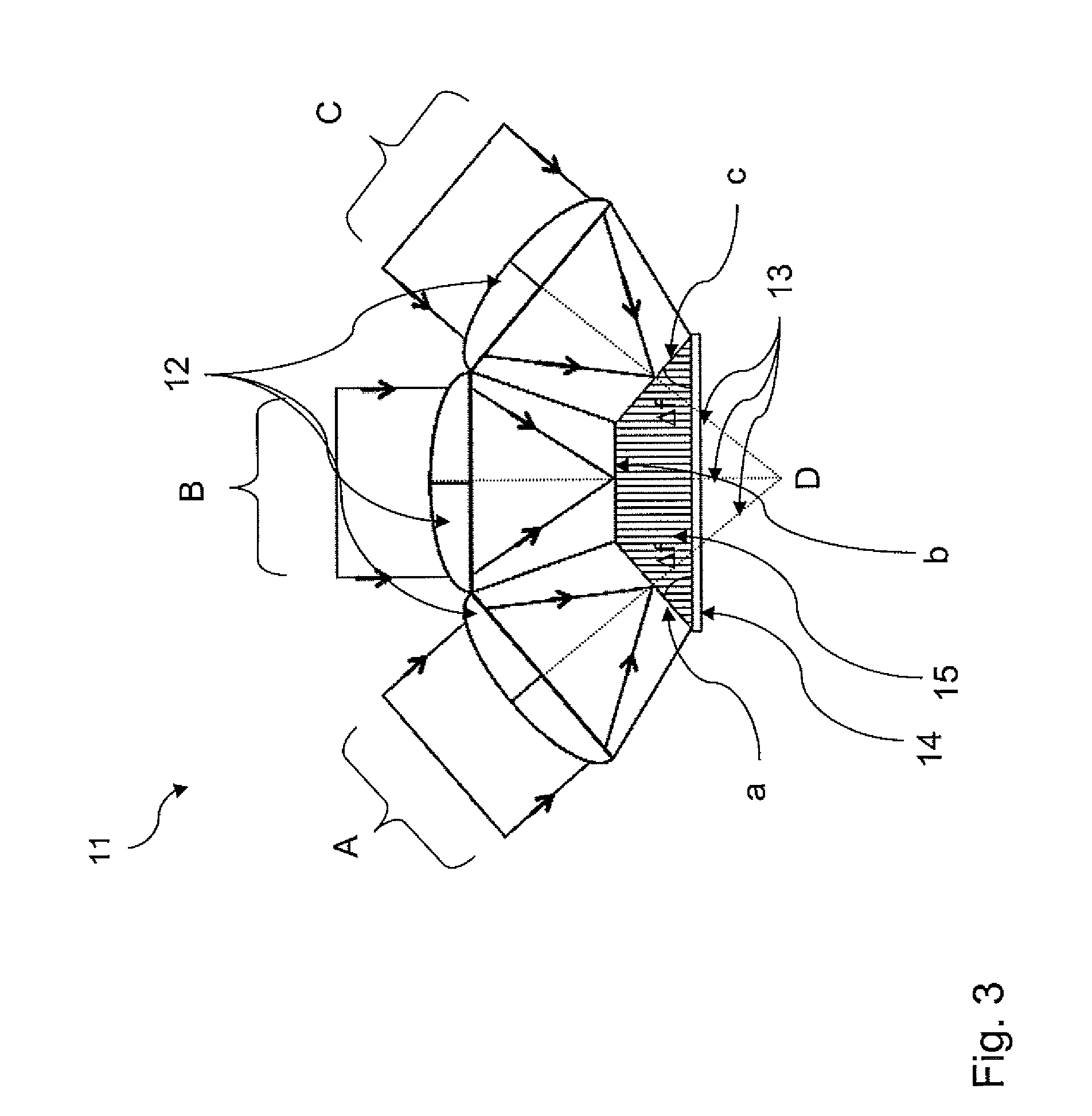

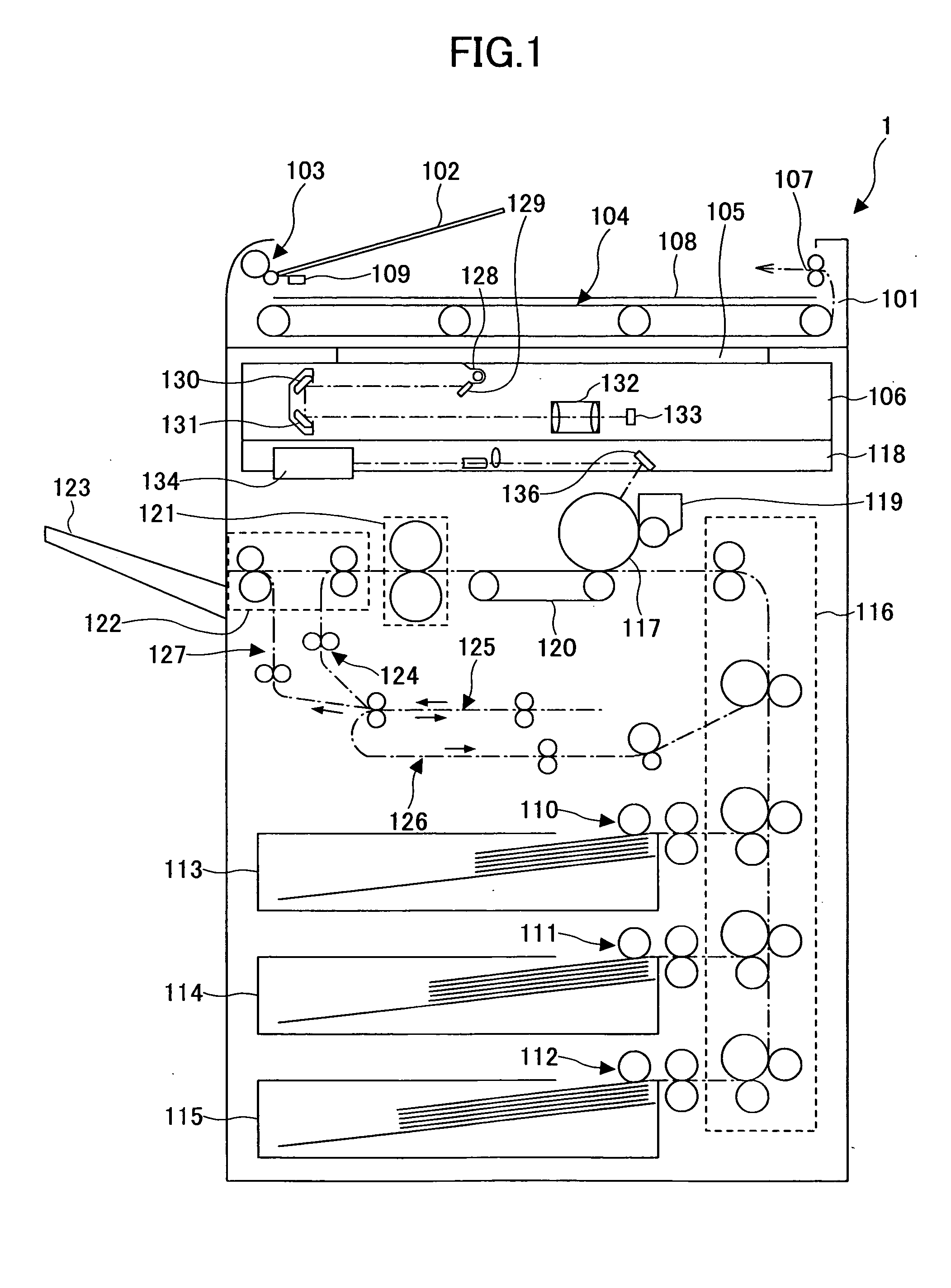

Imaging device

ActiveUS20100200736A1Facilitates guidingEasy to guideTelevision system detailsTelevision system scanning detailsEngineeringMissile

An imaging device, particularly but not exclusively for use in a targeting sensor for missile seekers. The imaging device including at least one lens; a substantially planar sensor having a plurality of pixels; a light guiding arrangement for directing light received via said lenses toward said sensor; in which said light guiding arrangement includes a plurality of light guides.

Owner:BAE SYSTEMS PLC

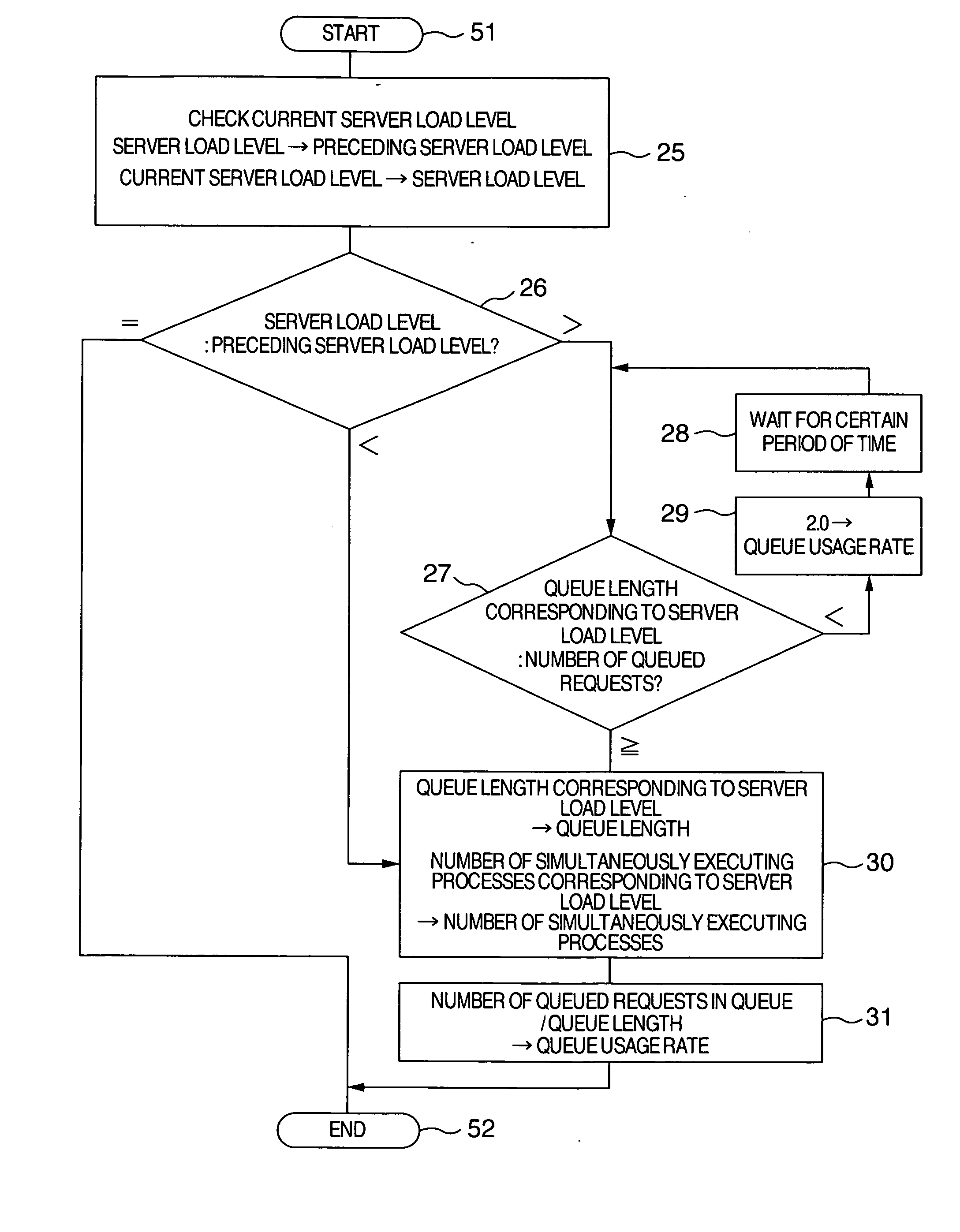

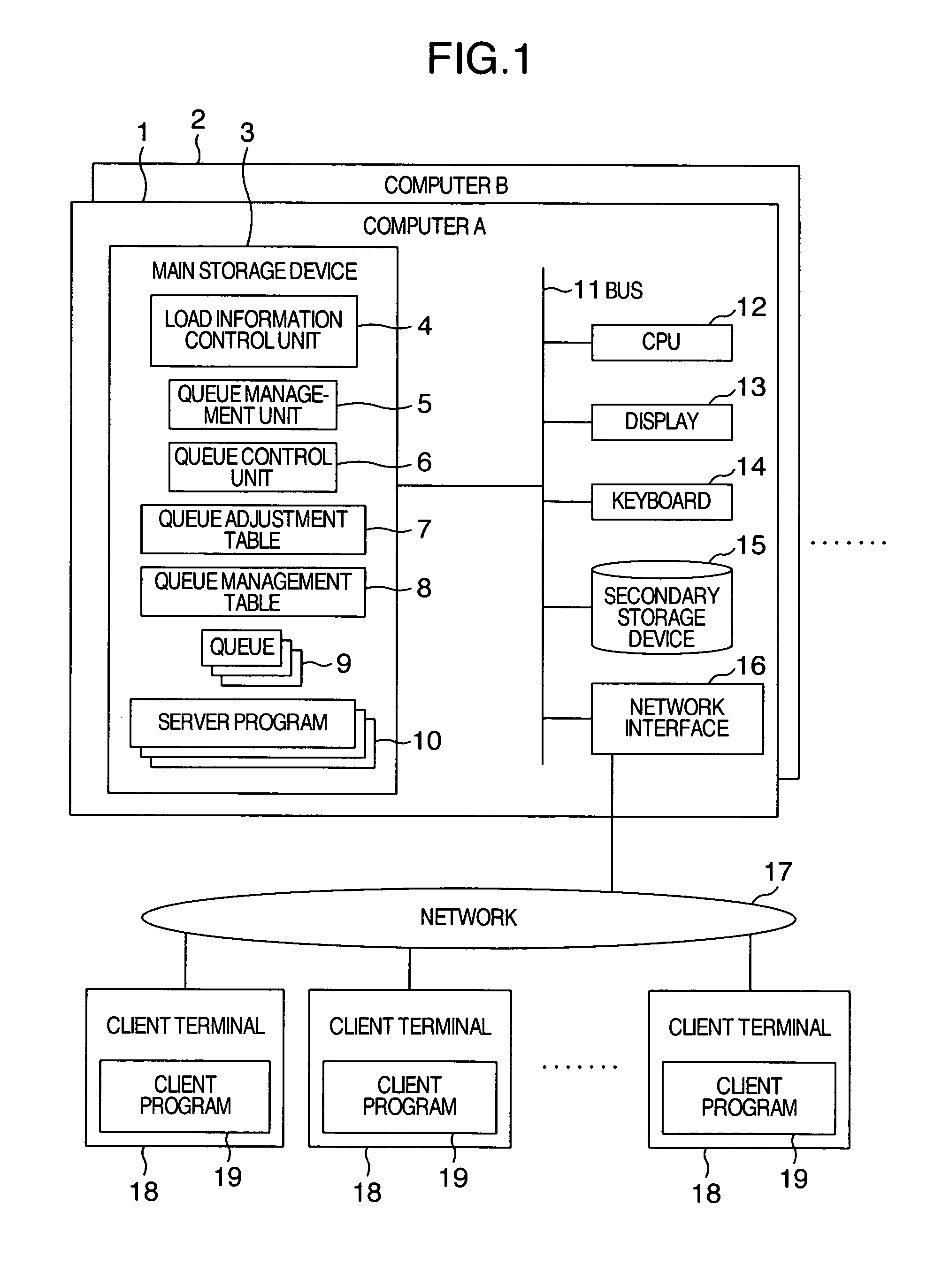

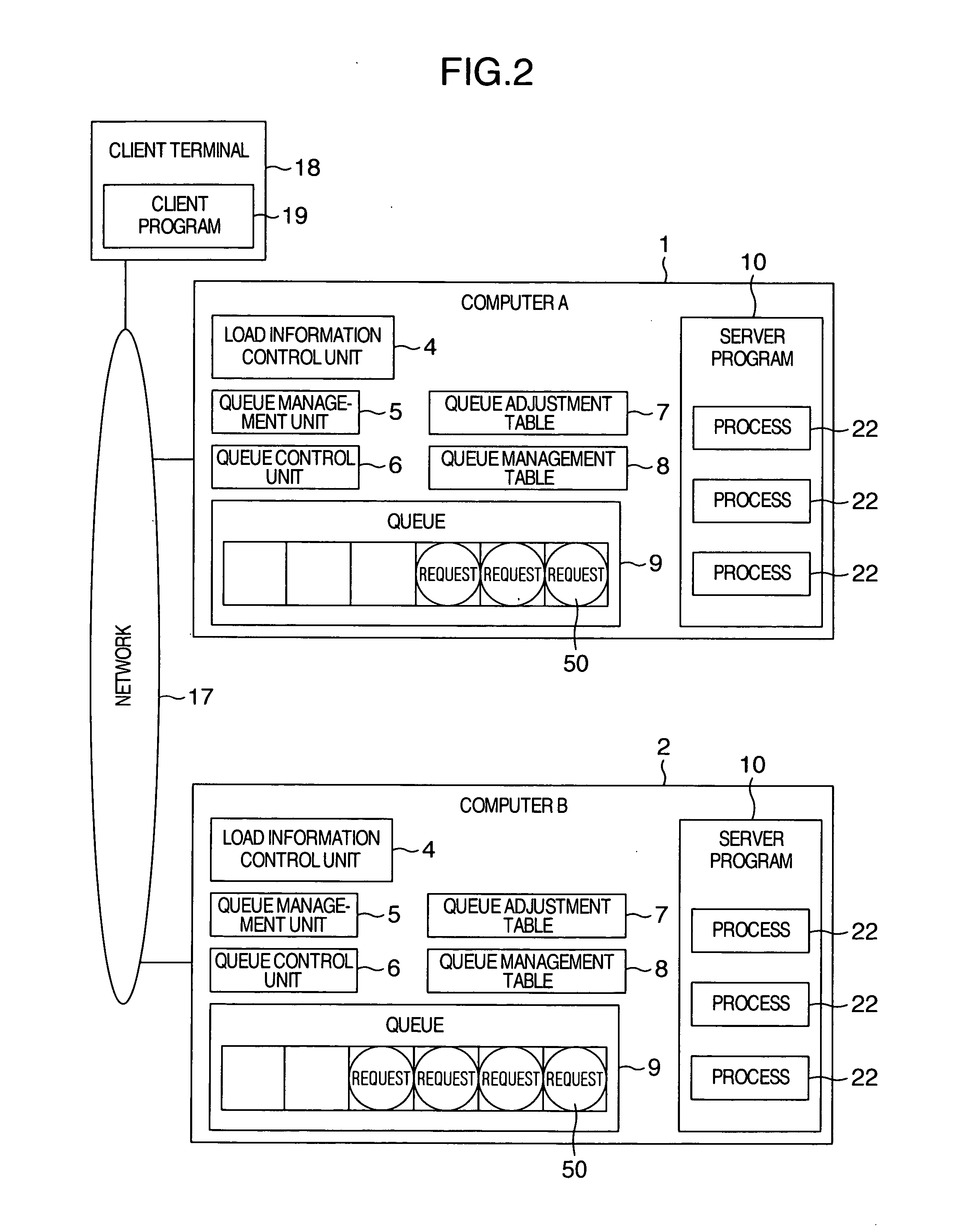

Method and system for managing load balancing in data processing system

InactiveUS20060212873A1Reduces standard deviationLow use rateDigital computer detailsMultiprogramming arrangementsData processing systemLoad Shedding

In a dynamic queue load balancing method using a plurality of computers, the load level of each computer is obtained. A queue management table including information on a queue length and the number of queued requests in each queue and a queue adjustment table including information on a queue length at each load level are referred to. The queue length in the queue management table is changed to the queue length in the queue adjustment table corresponding to the obtained load level by a storage device. A queue usage rate of queue is calculated from the queue length and the number of queued requests in the queue management table. Information on the calculated queue usage rate of queue is exchanged among the computers through a communication device. According to the exchanged information on the queue usage rate, selective assignment of a processing request among queues of the computers is performed.

Owner:HITACHI LTD

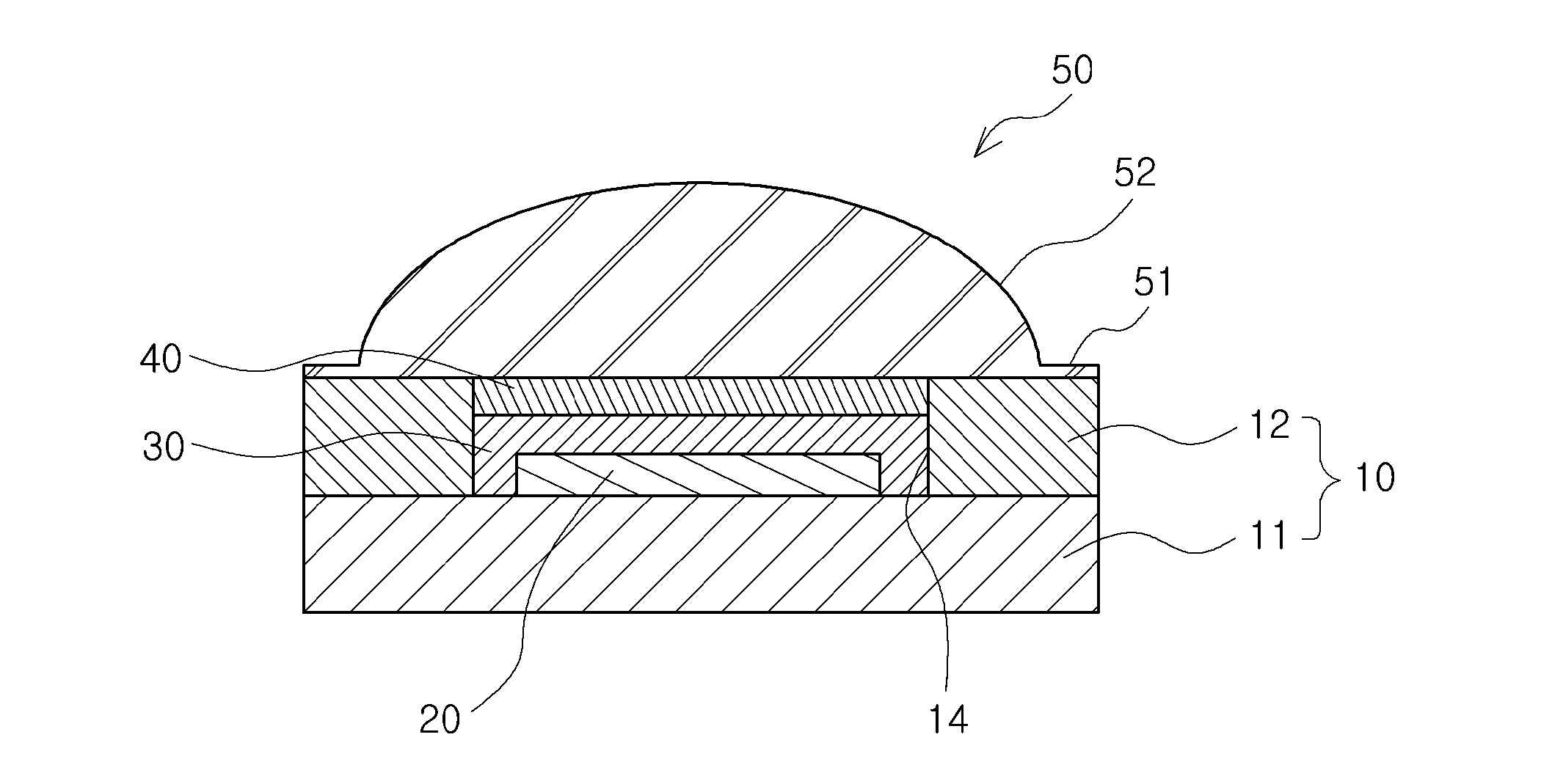

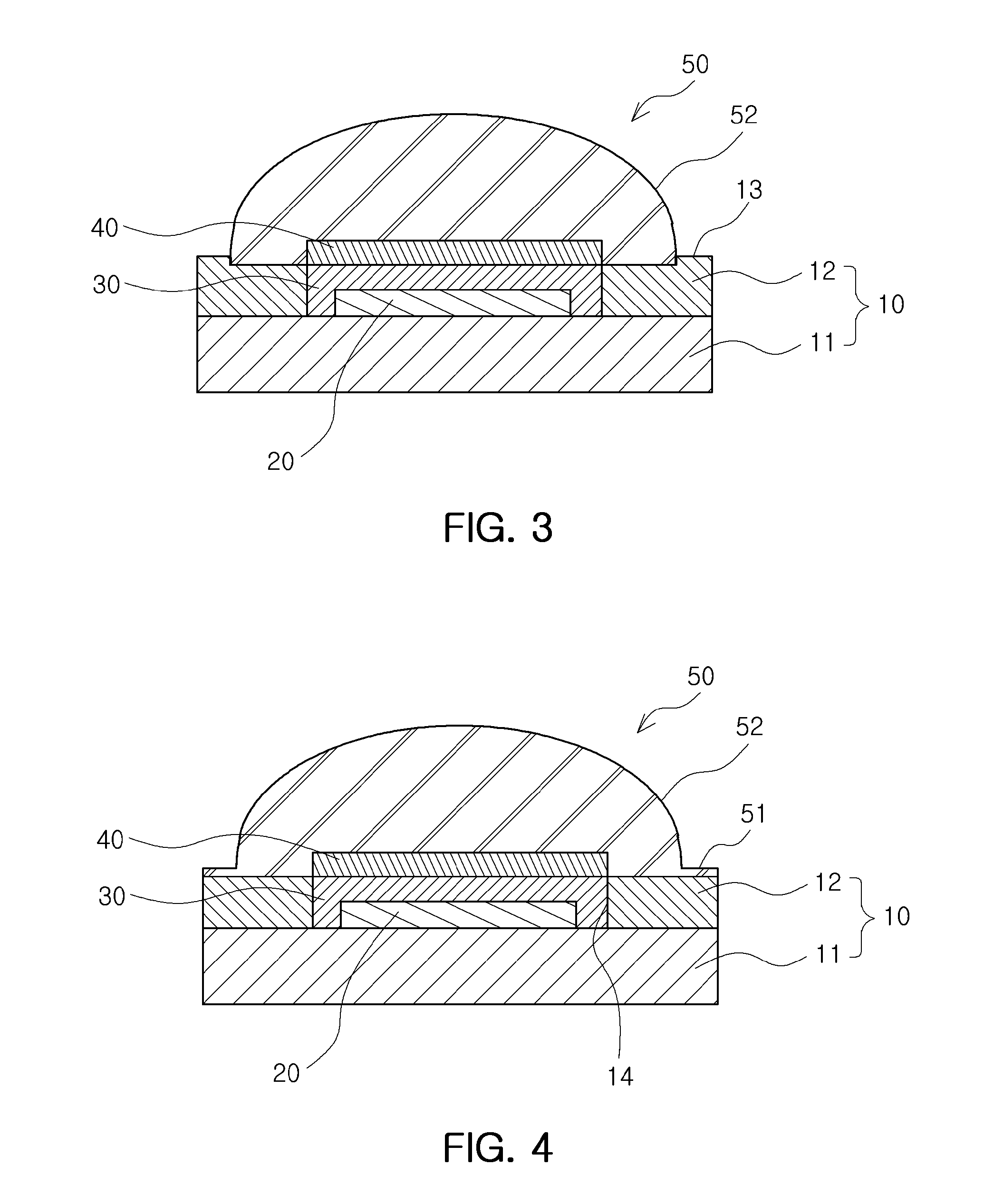

Light emitting device package and manufacturing method thereof

InactiveUS20120305970A1High color temperatureReduce deviationSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLength wave

There is provided a light emitting device package including a substrate having a cavity therein; alight emitting device mounted on a bottom surface of the cavity; a first wavelength conversion part including a first phosphor for a wavelength conversion of light emitted from the light emitting device and covering the light emitting device within the cavity; and a second wavelength conversion part including a second phosphor allowing for emission of light having a wavelength different to that of the first phosphor and formed as a sheet on the first wavelength conversion part.

Owner:SAMSUNG ELECTRONICS CO LTD

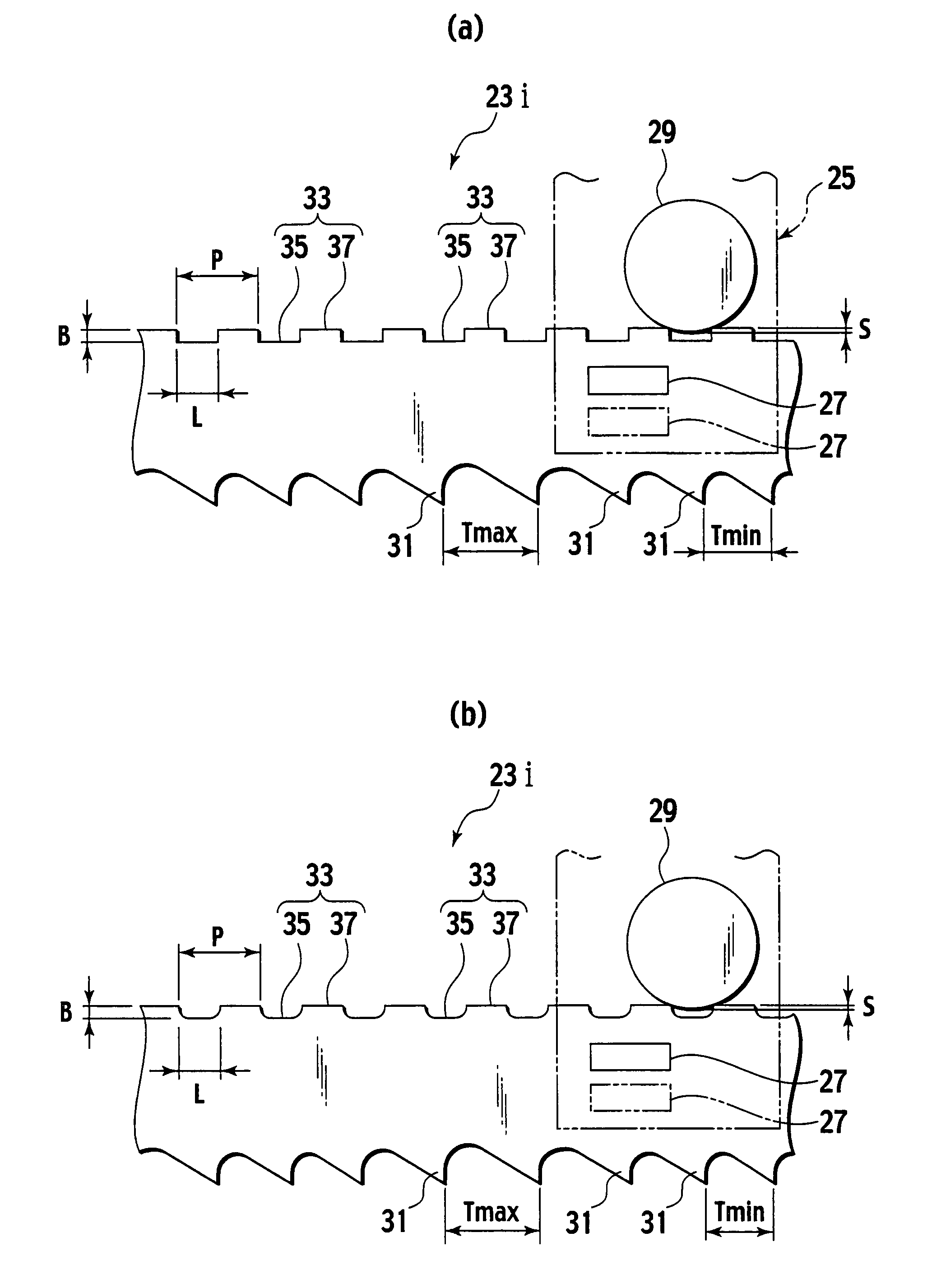

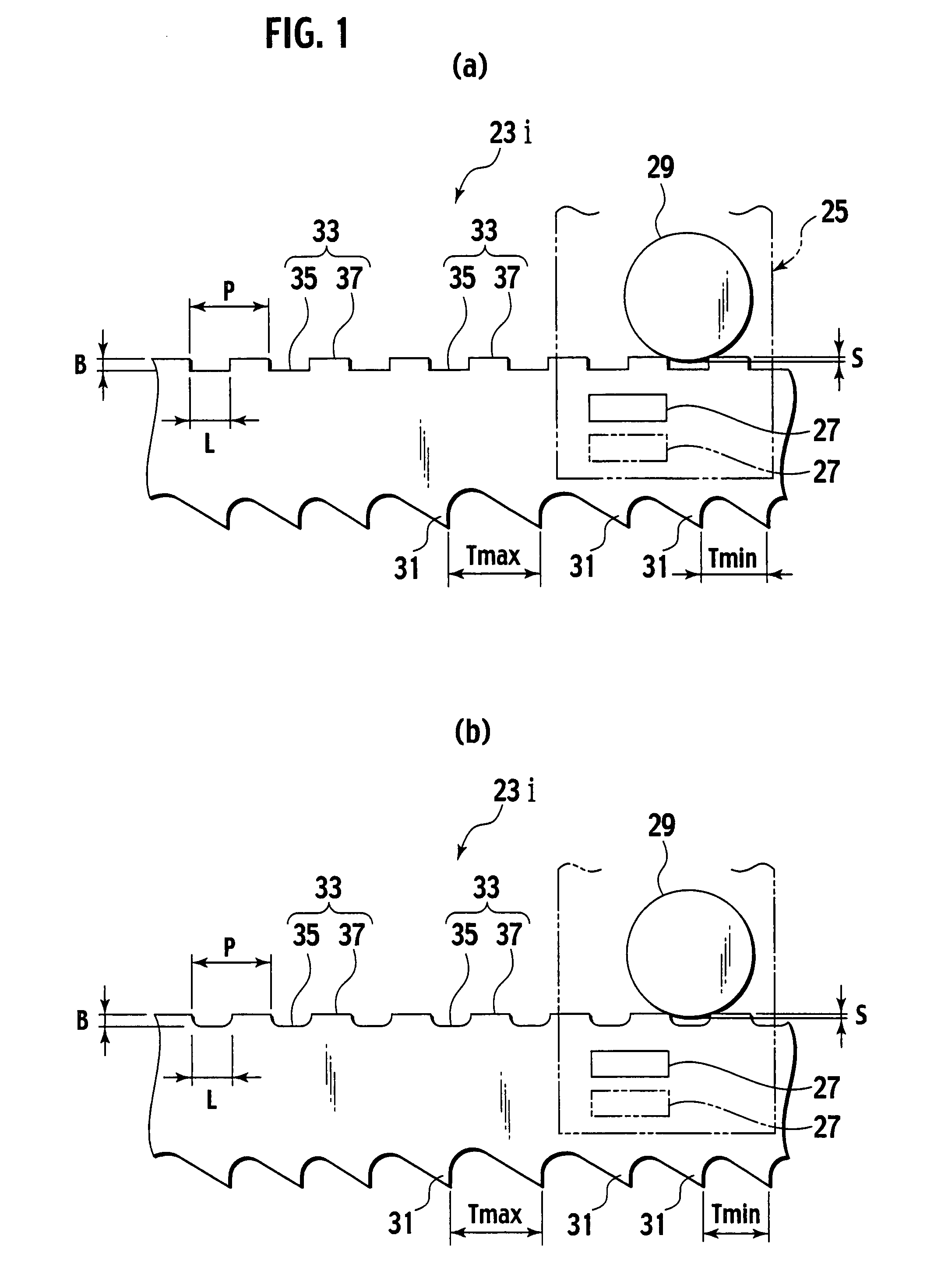

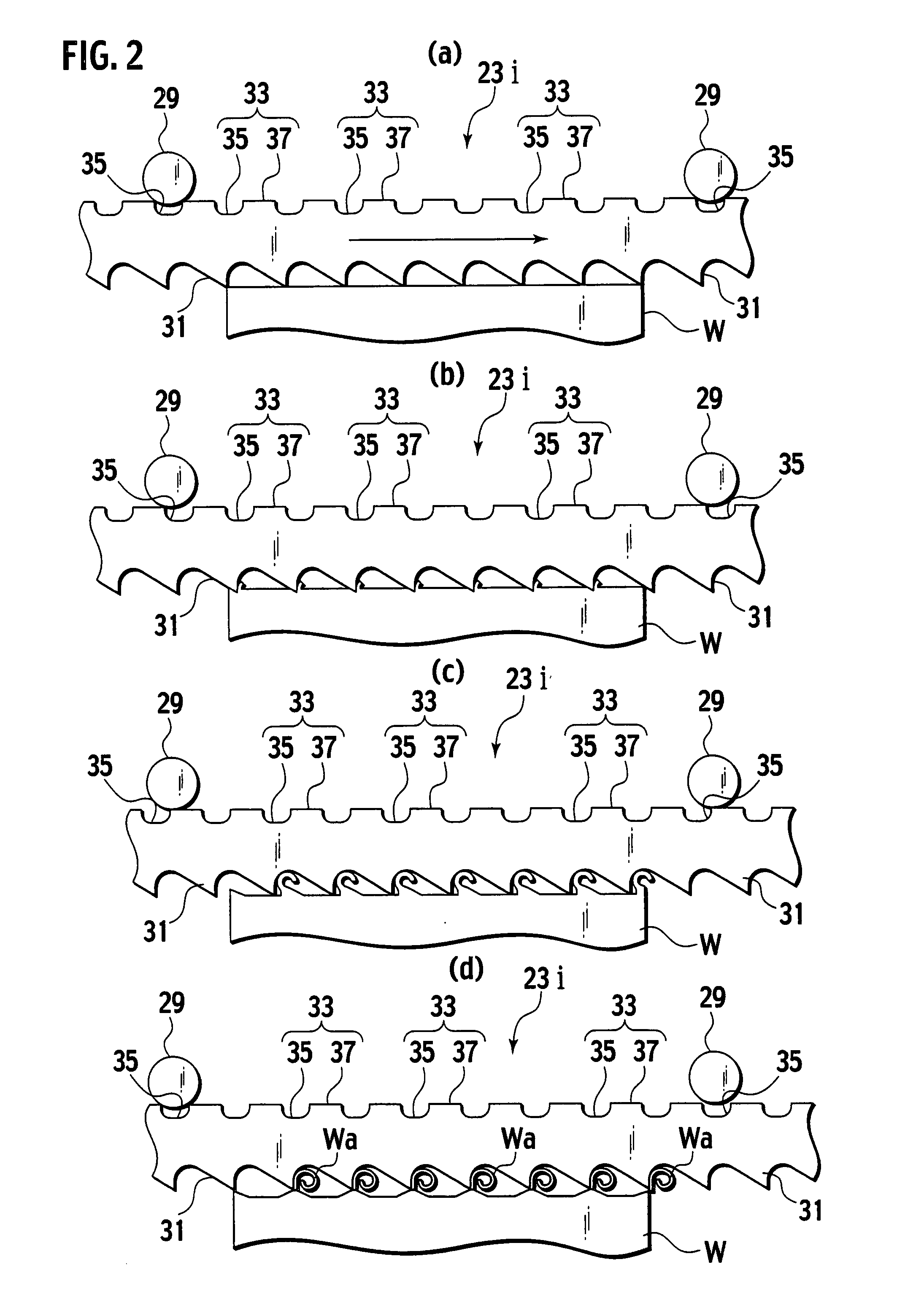

Band Saw Blade and Cutting Method

ActiveUS20080121079A1Reduce cut lengthReduce resistanceMetal sawing devicesMetal sawing toolsEngineering

Concave / convex portions are consecutively formed on a back of a band saw blade. The concave / convex portions include concave portions engageable with and disengageable from a backup guide of a band saw guide unit, and convex portions adjacent to the concave portions. A length of each of the concave / convex portions is configured to be equal to or smaller than four times a maximum pitch of a tooth top of each tooth.

Owner:AMADA CO LTD

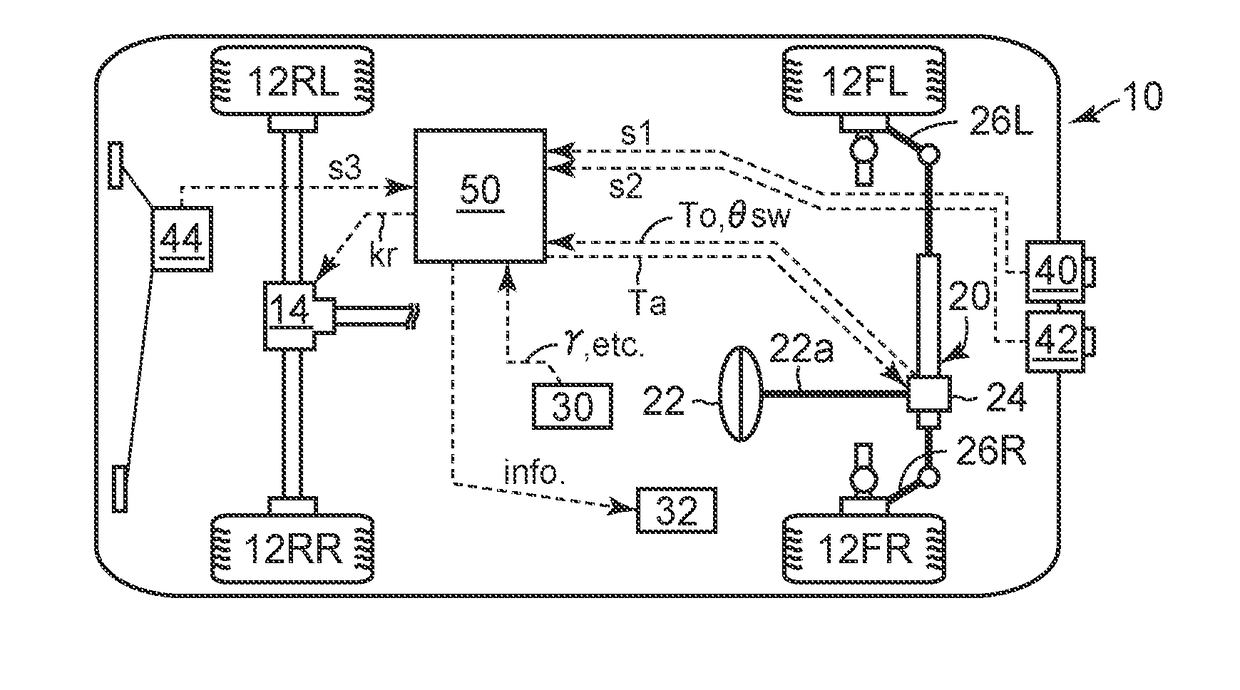

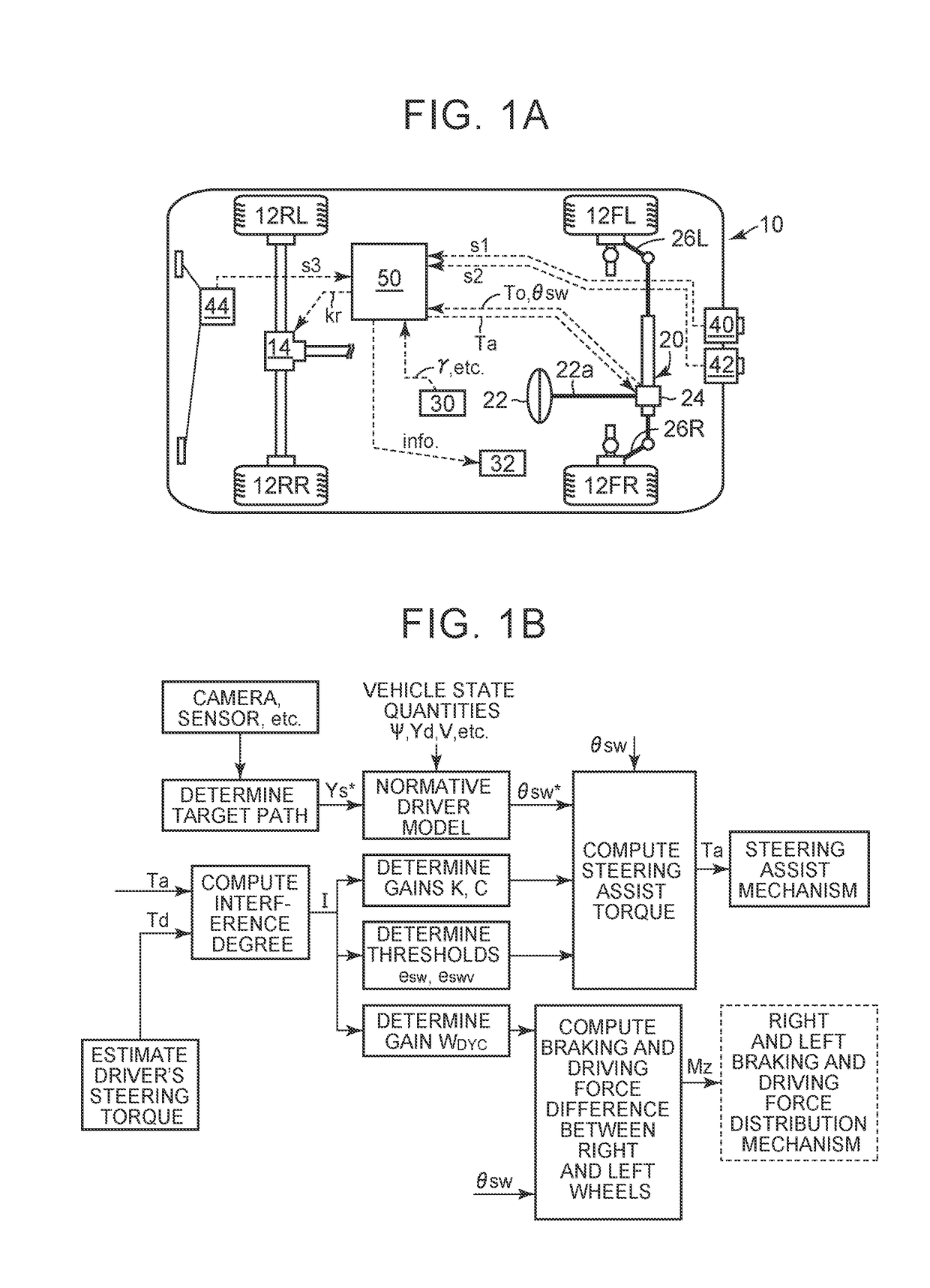

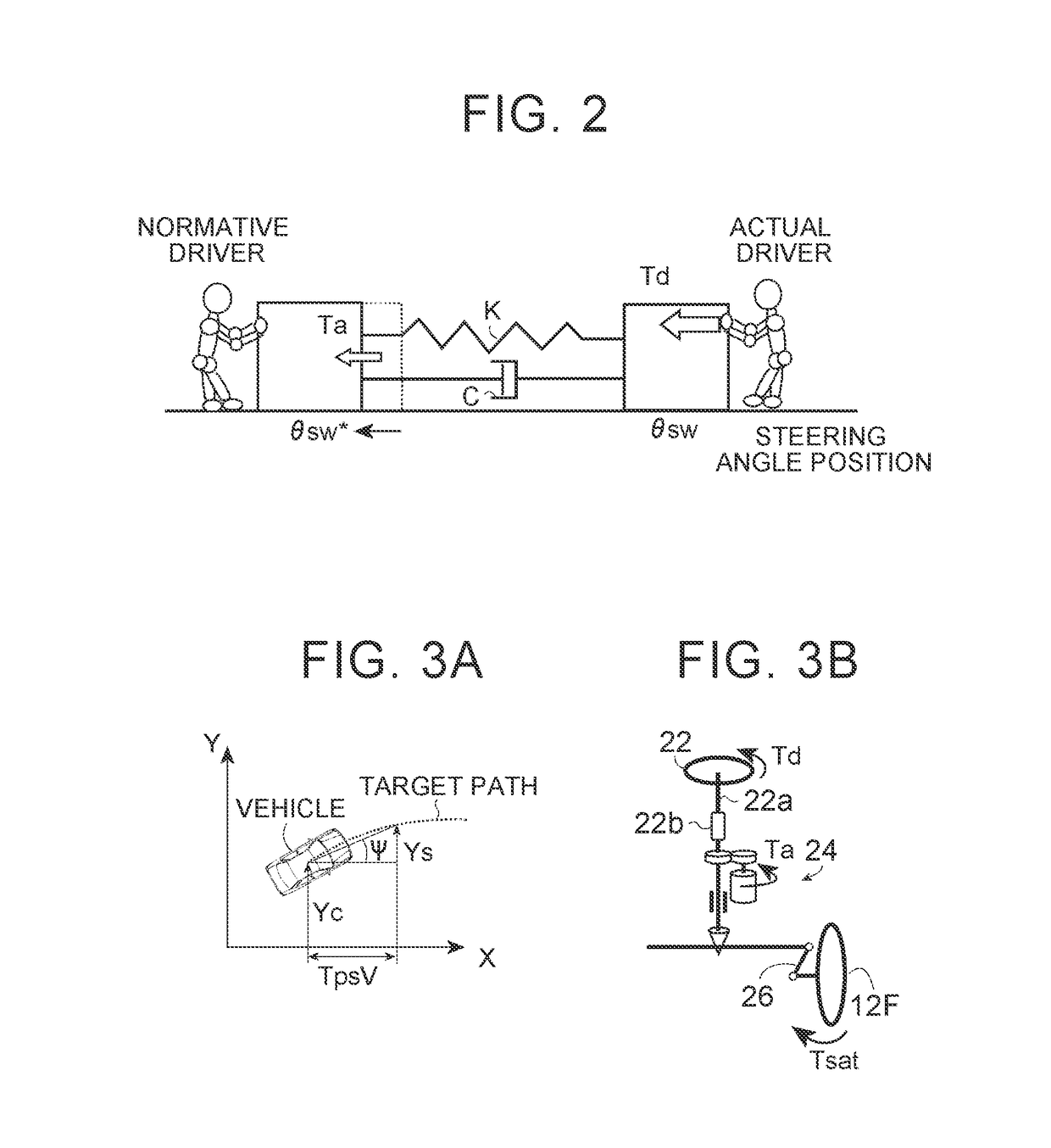

Driving assistance control apparatus for vehicle

ActiveUS20170088174A1Reduce steering angle deviationSolve the large energy consumptionBrake system interactionsSteering linkagesSteering angleEngineering

An apparatus includes a steering assist torque determination unit and a steering assist torque control unit. The steering assist torque determination unit determines a steering assist torque including a first component that is determined on the basis of a deviation between an actual steering angle and a target steering angle for achieving a target path determined irrespective of driver's steering. The steering assist torque control unit controls a steering assist mechanism such that the steering assist torque is applied. The ratio of the magnitude of the first component of the steering assist torque to the deviation between the target steering angle and the actual steering angle is determined on the basis of the magnitude of the deviation between the steering assist torque and the driver's steering torque in a past predetermined period.

Owner:TOYOTA JIDOSHA KK

Hybrid securities having protection against event risk using uncorrelated last-to-default baskets

InactiveUS20050044029A1Reduce probabilityObtained inexpensivelyFinanceOffice automationData miningEvent risk

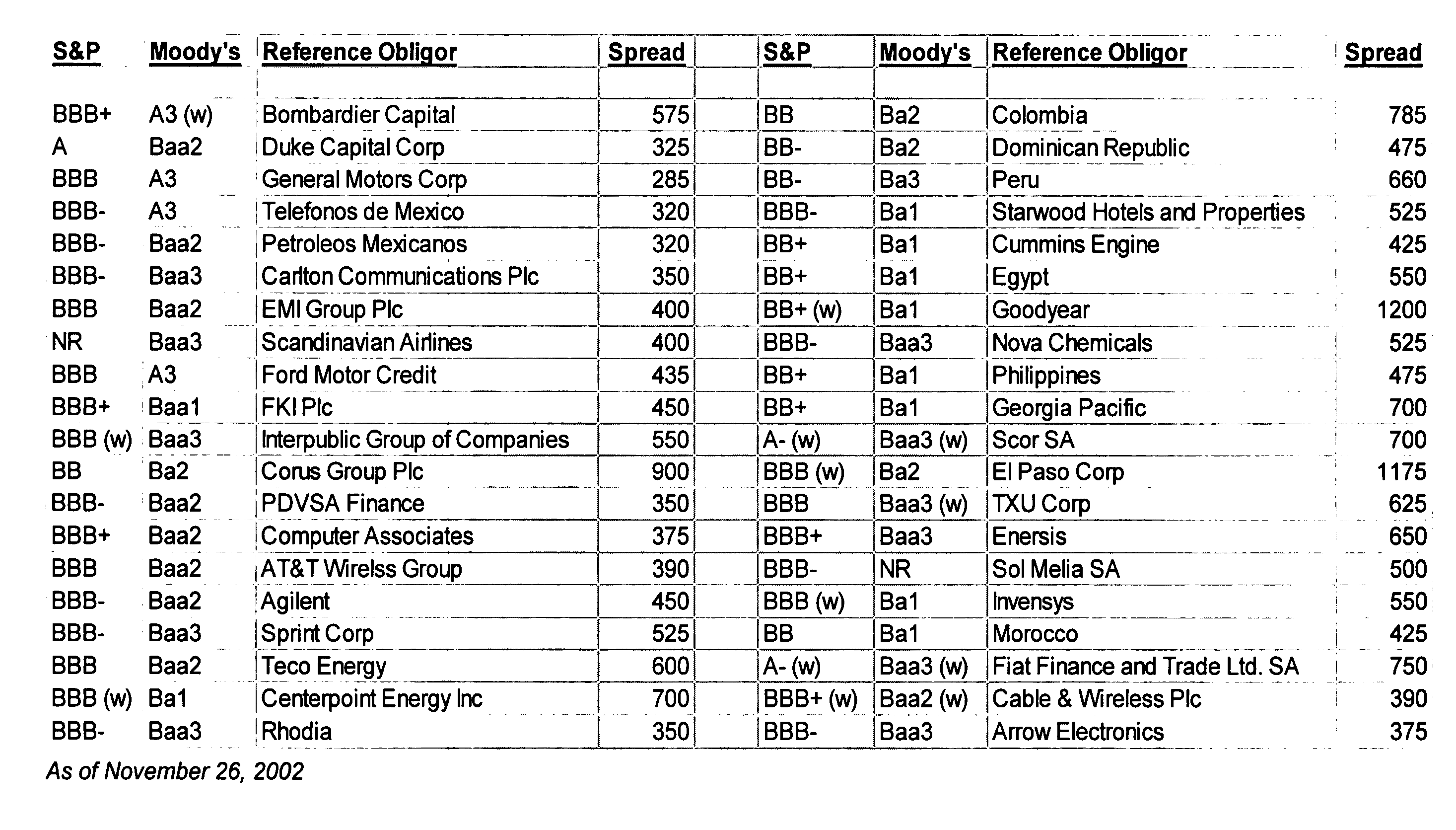

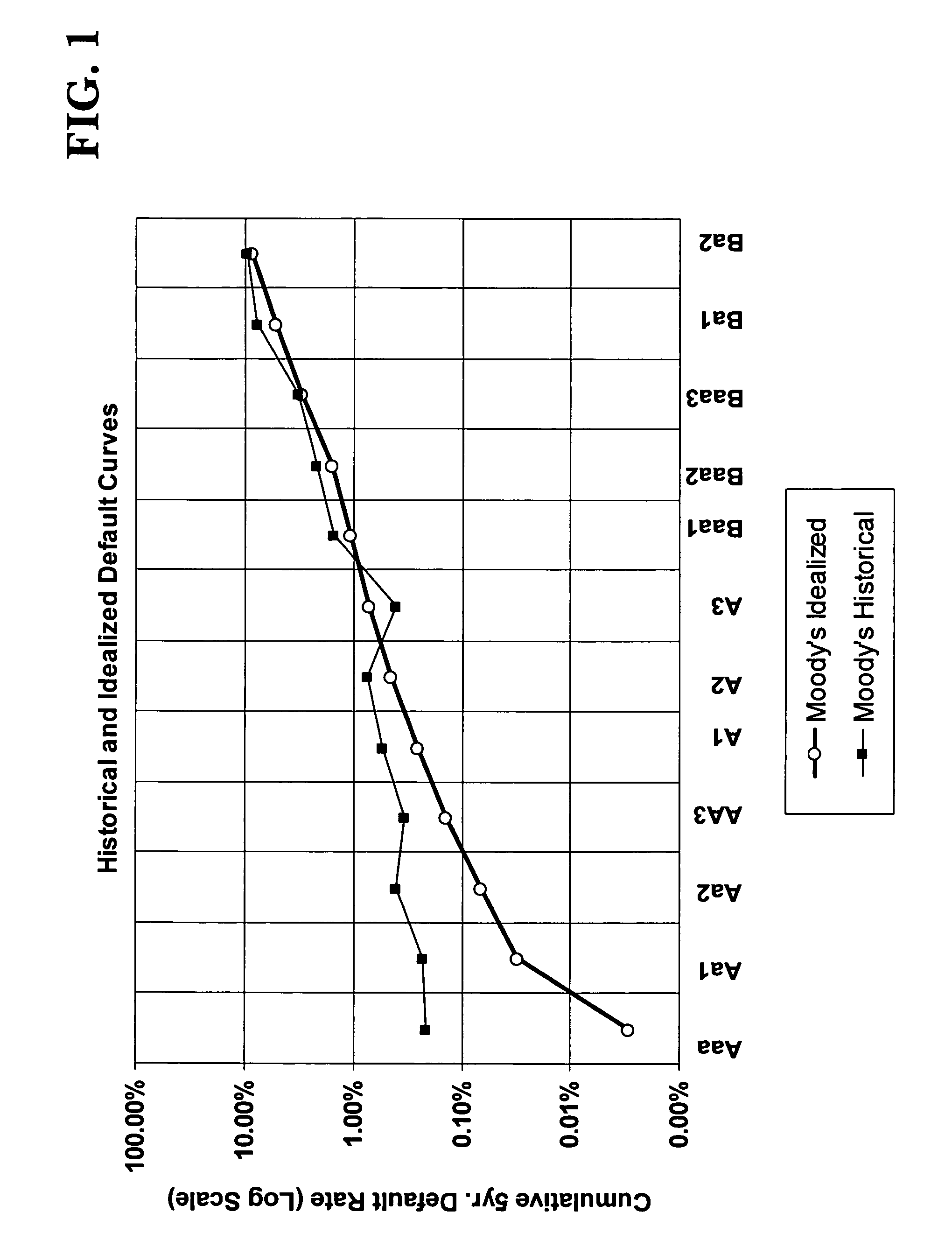

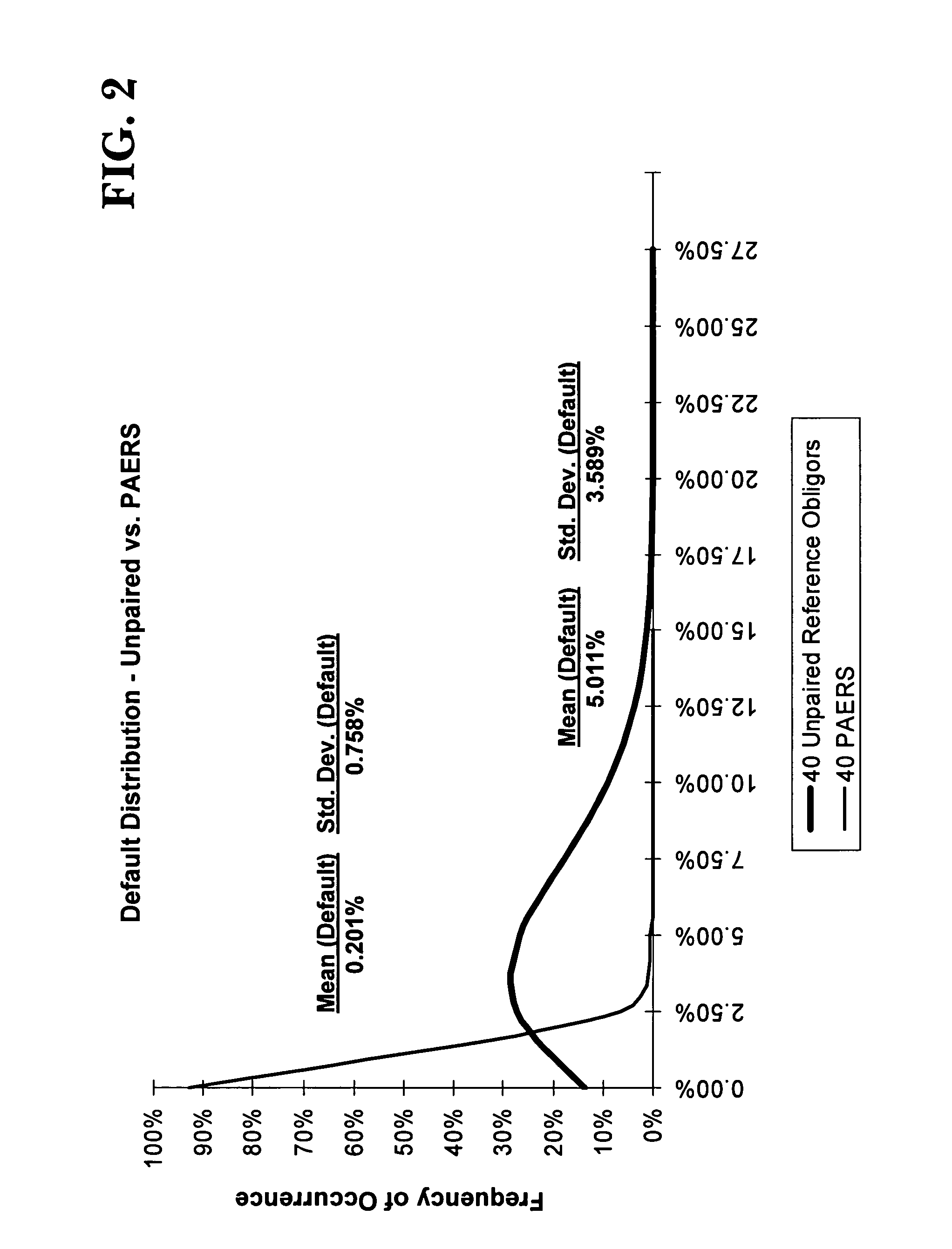

Hybrid securities defined as last-to-default credit default swaps over multiple name baskets and having protection against event risk. In the preferred embodiment, the hybrid security is defined as a second-to-default credit default swap over a two-name basket, wherein the underlying reference obligors in the basket are uncorrelated or substantially uncorrelated. A portfolio of second-to-default swaps over two-name baskets is provided, wherein the portfolio is defined in a manner that further reduces default risk through enhanced diversification achieved by recombining underlying reference obligors in different second-to-default baskets. A structured investment in a portfolio of underlying second-to-default swaps over two-name baskets is provided using a collateralized debt obligation (CDO) structure.

Owner:BABCOCK & BROWN

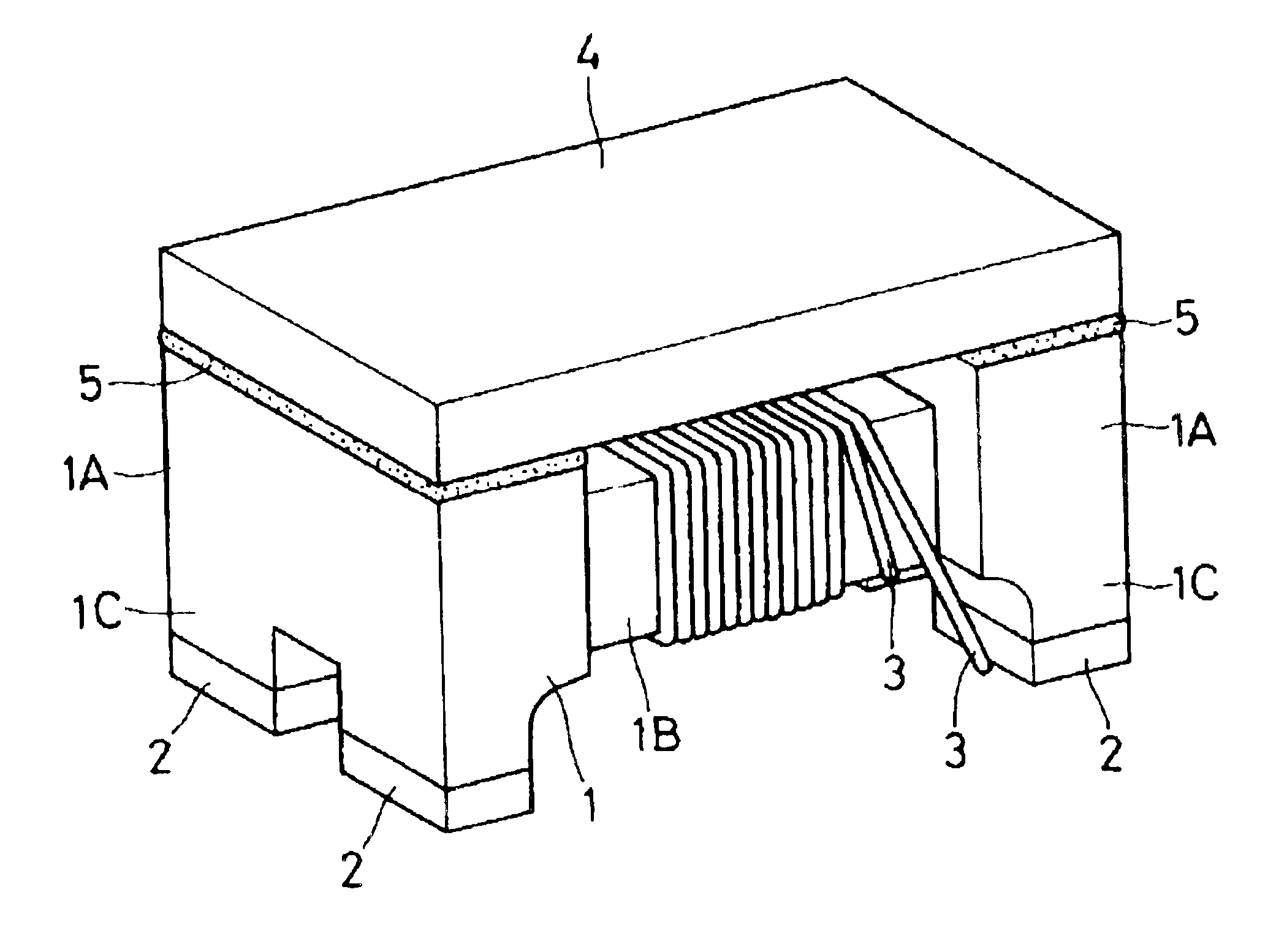

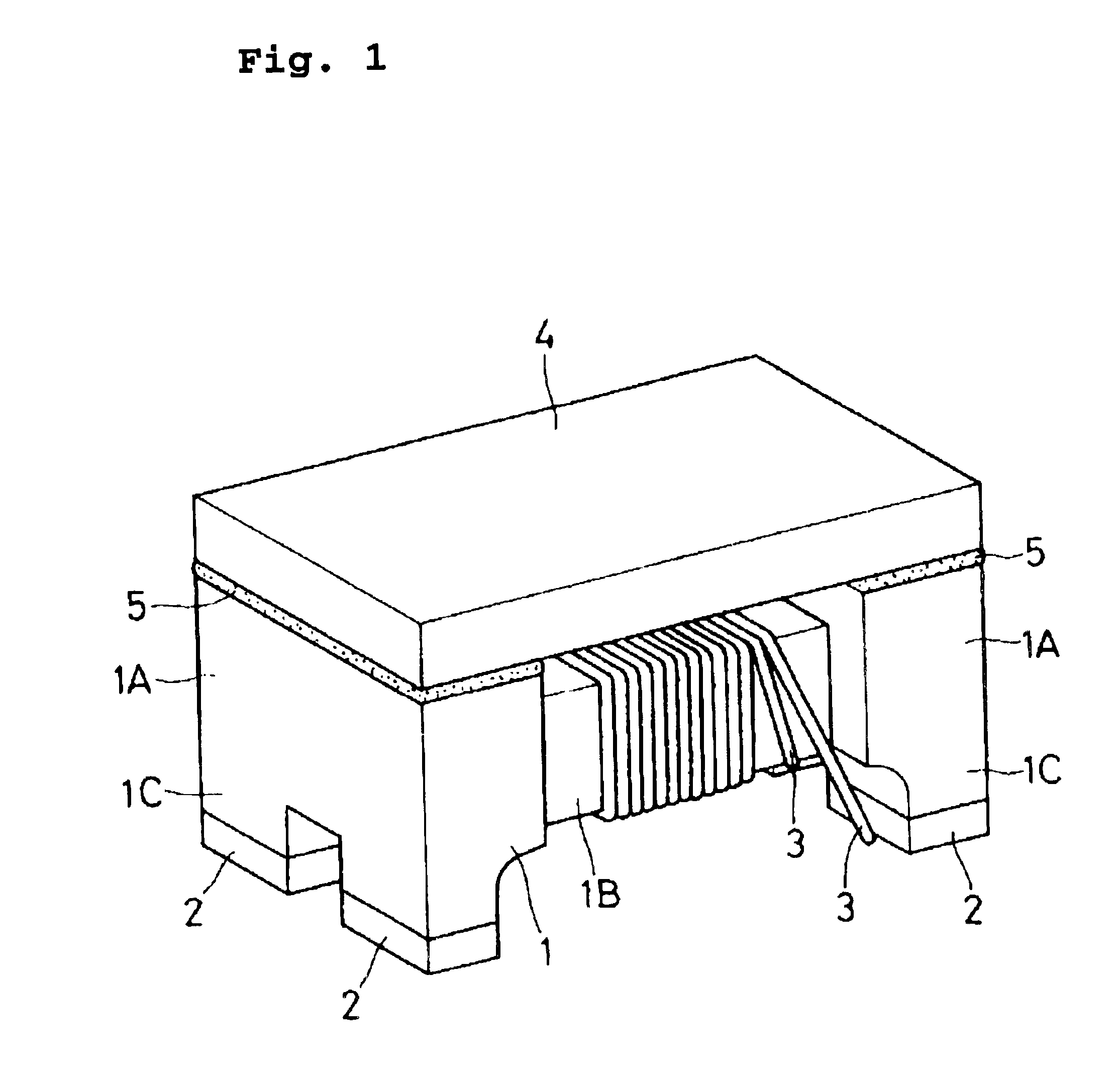

Common-mode choke coil

InactiveUS6965289B2Avoid large deviationReduce penetrationImpedence networksTransformers/inductances casingsAdhesiveEngineering

A common-mode choke coil includes a core having flanges disposed at both ends and a winding section arranged between the flanges. Electrodes are disposed in the flanges, while two pieces of wire are wound around the winding section and ends of the pieces of wire are connected to the electrodes. A ferrite plate with a relative magnetic permeability that is smaller than that of the core is attached on the upper surface of the flanges with an adhesive so as to cover the wire.

Owner:MURATA MFG CO LTD

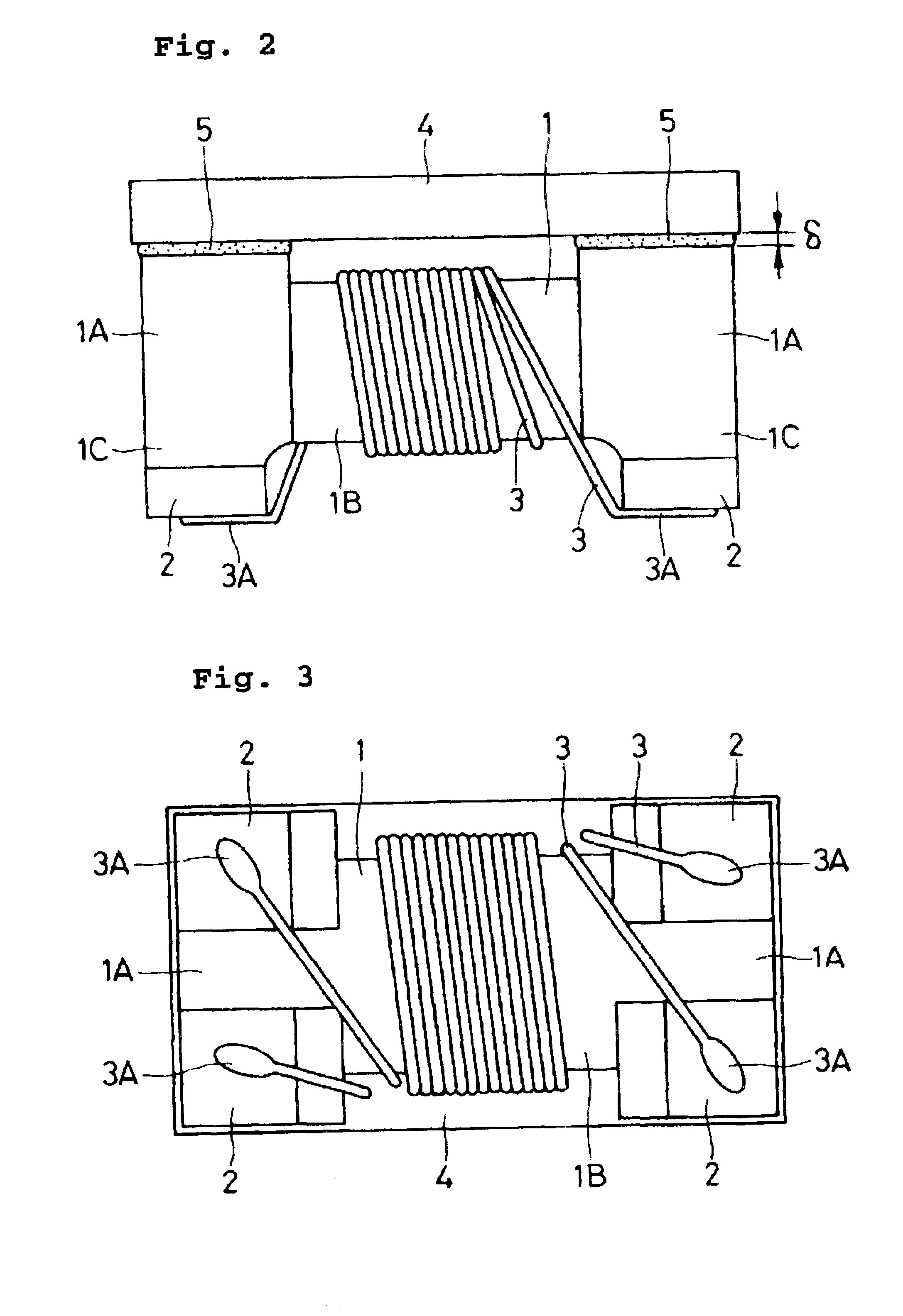

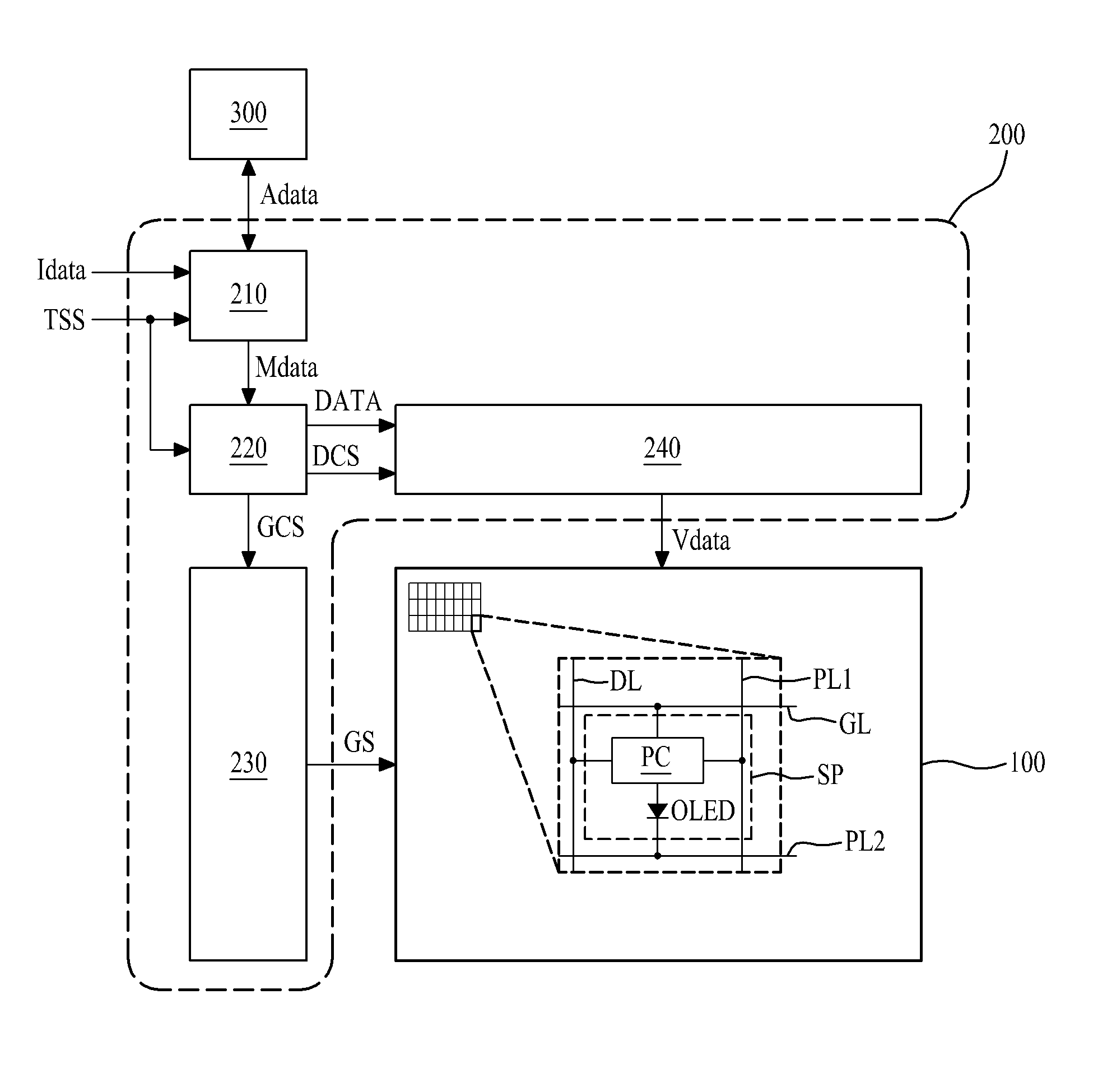

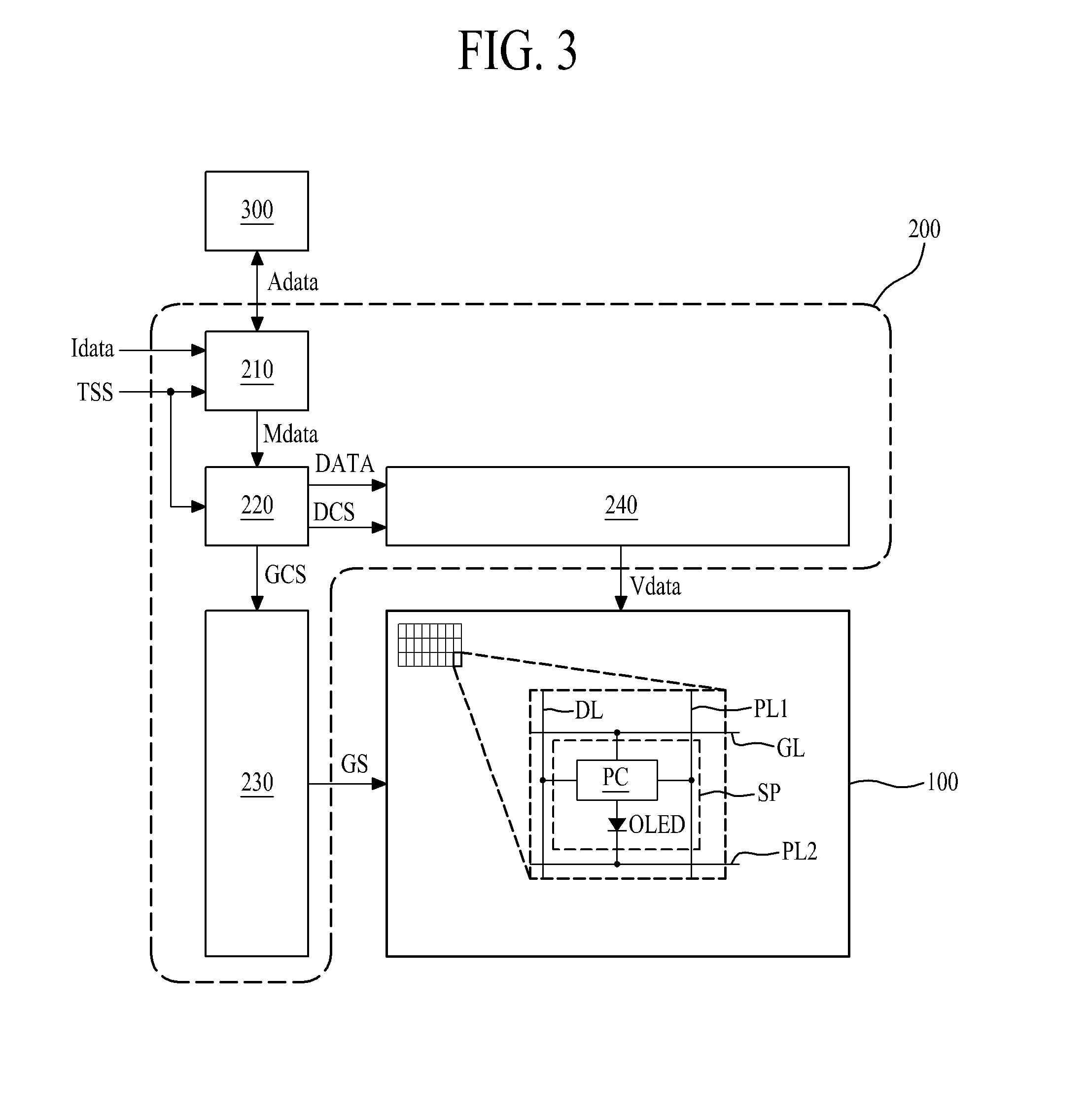

Organic light emitting display device and method for driving thereof

ActiveUS20140168039A1Reduce deviationLuminance lowering luminanceStatic indicating devicesData displayComputer hardware

An organic light emitting display device includes a display panel having a plurality of sub-pixels; a memory configured to accumulate and store data displayed by each sub-pixel; and a panel driver configured to: calculate a degradation compensation gain value for increasing or decreasing a luminance of each sub-pixel based on accumulated data of each sub-pixel stored in the memory, generate modulated data of each sub-pixel by modulating input data to each sub-pixel according to the calculated degradation compensation gain value, convert the modulated data into a data voltage, and accumulate the modulated data from the accumulated data of the corresponding sub-pixel and then store the data in the memory.

Owner:LG DISPLAY CO LTD

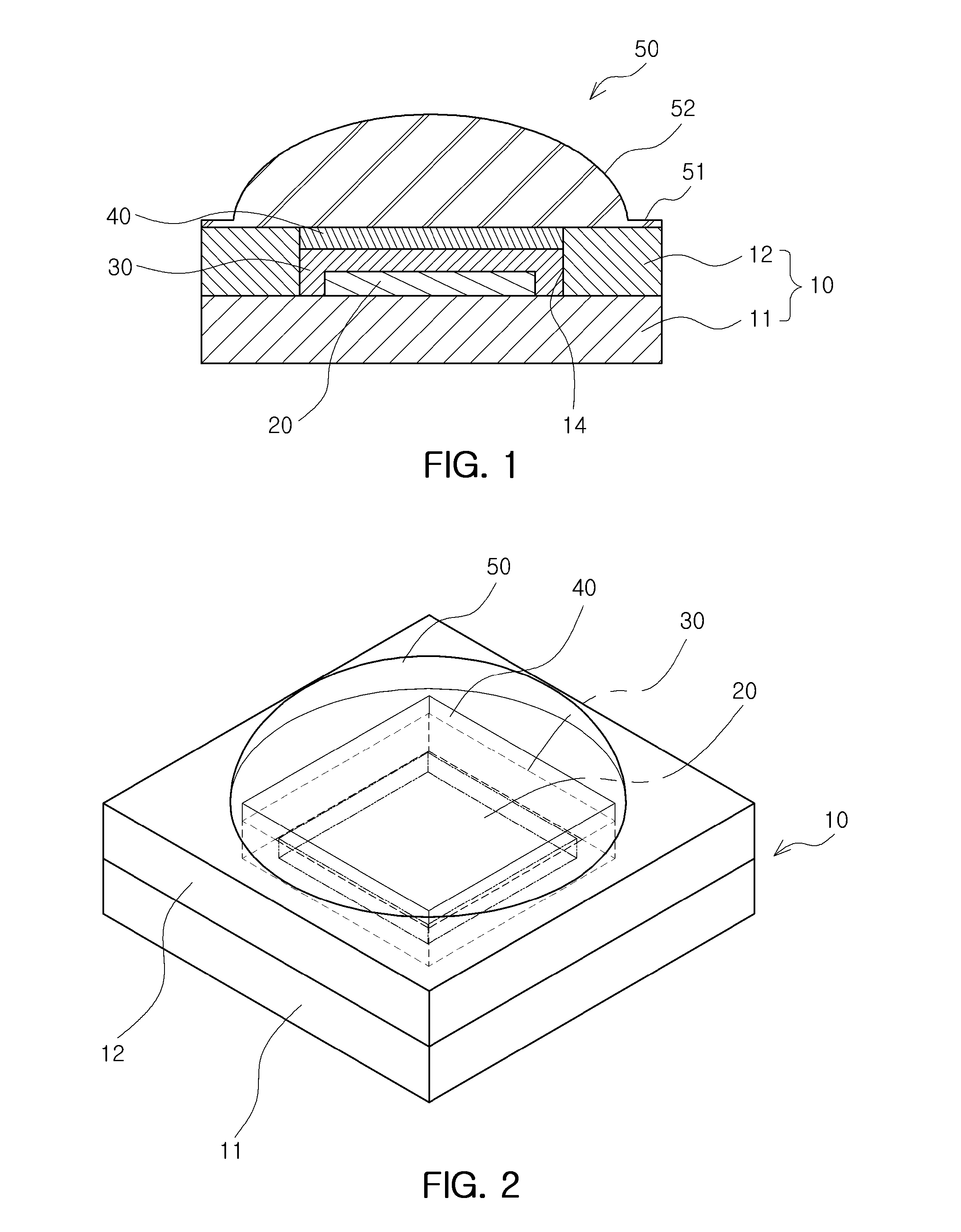

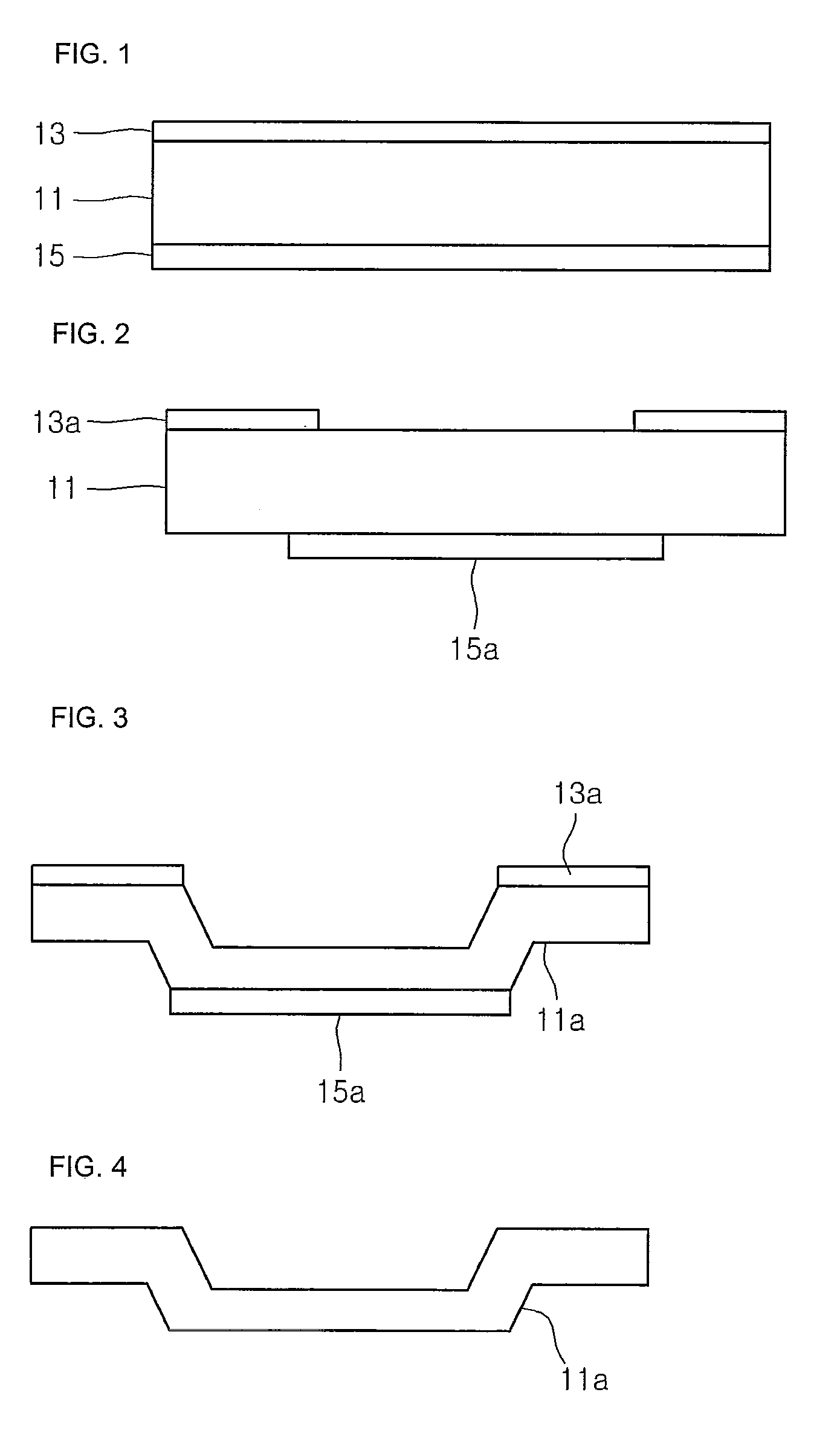

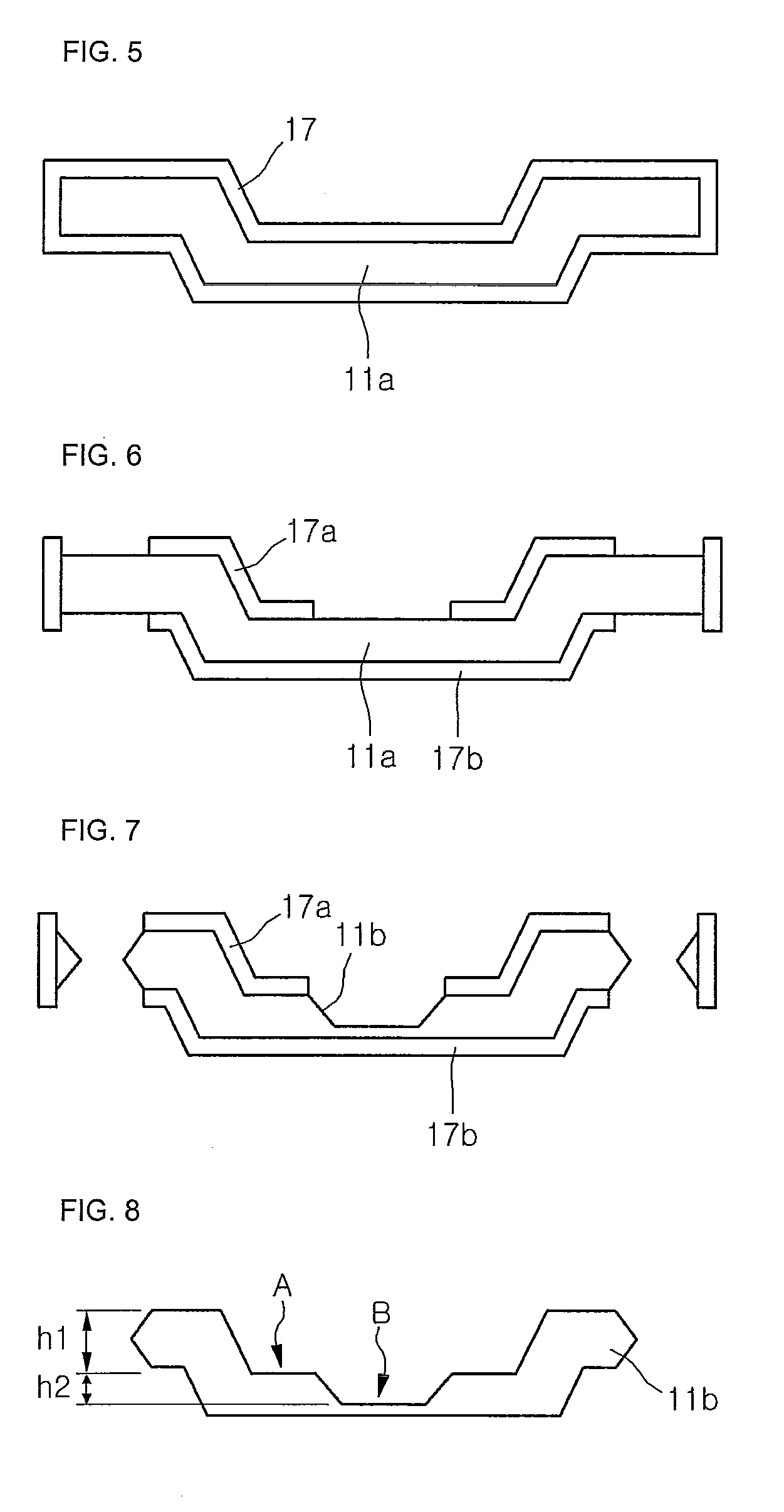

Light emitting device package

ActiveUS20090289272A1Improve lighting efficiencyReduce deviationSolid-state devicesSemiconductor devicesLight emitting deviceSemiconductor

Disclosed is a light emitting device package. The light emitting device package includes a semiconductor substrate comprising a first surface at a first depth from an upper surface of the semiconductor substrate and a second surface at a second depth from the first surface; and a light emitting part on the second surface of the semiconductor substrate.

Owner:SUZHOU LEKIN SEMICON CO LTD

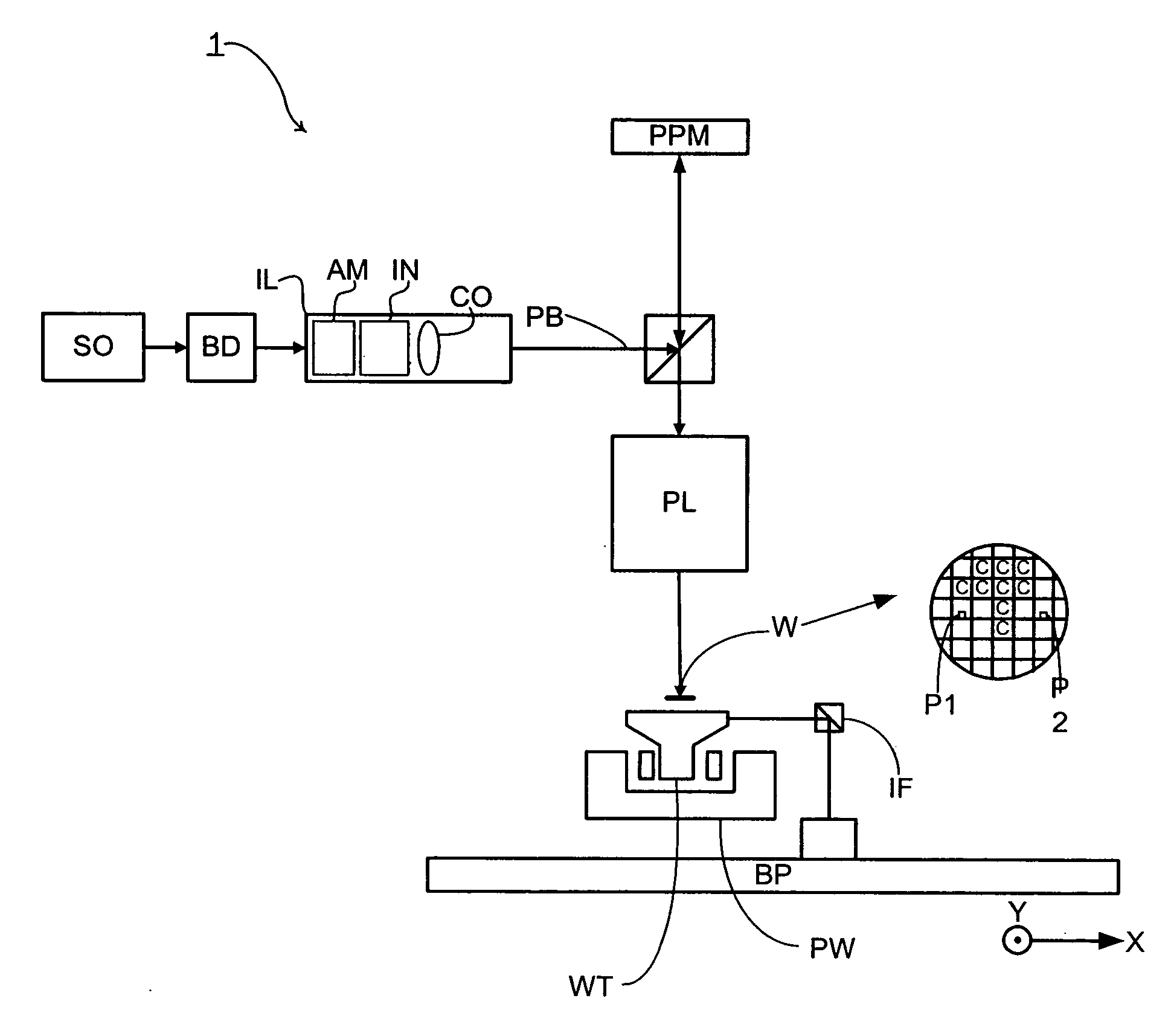

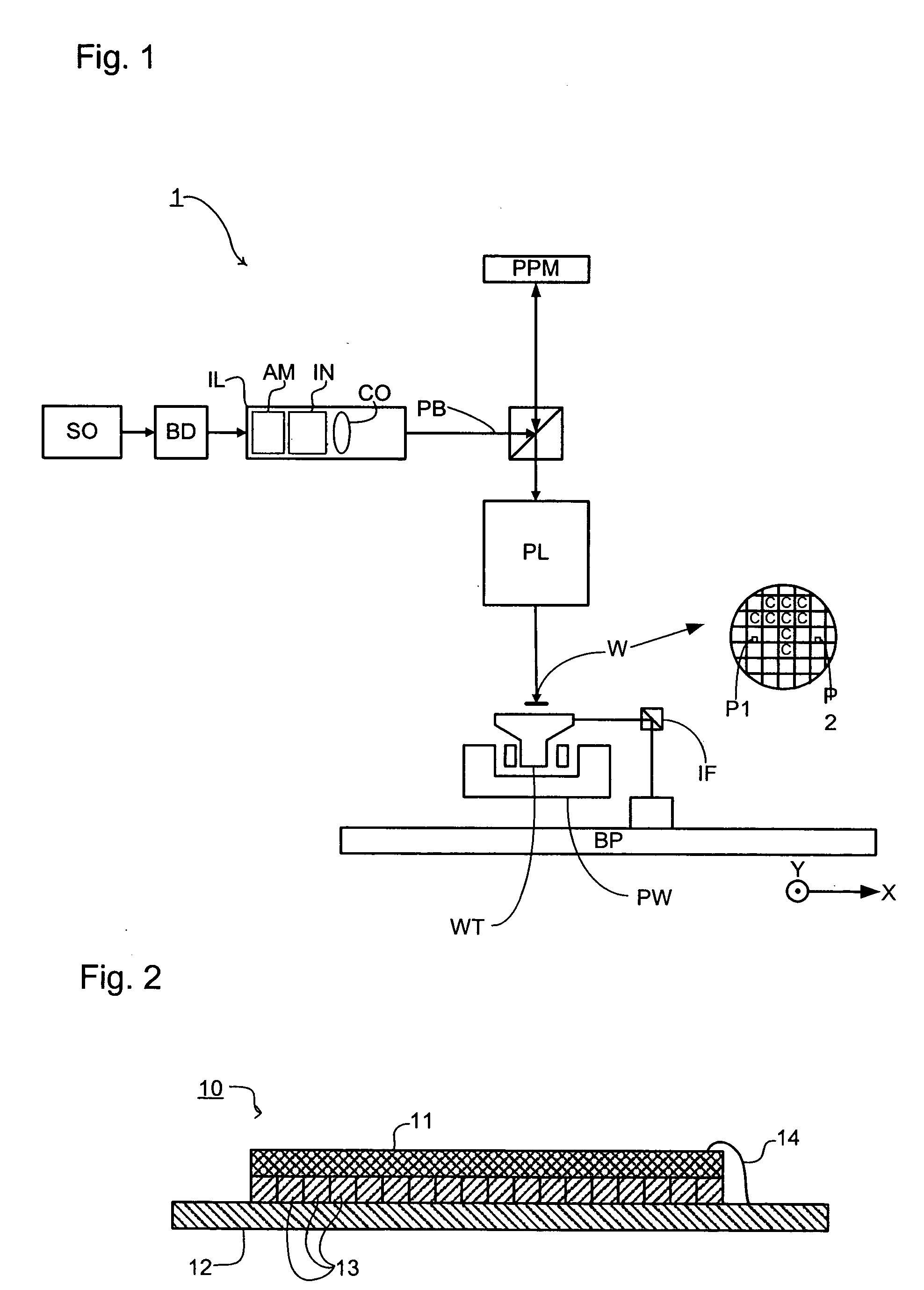

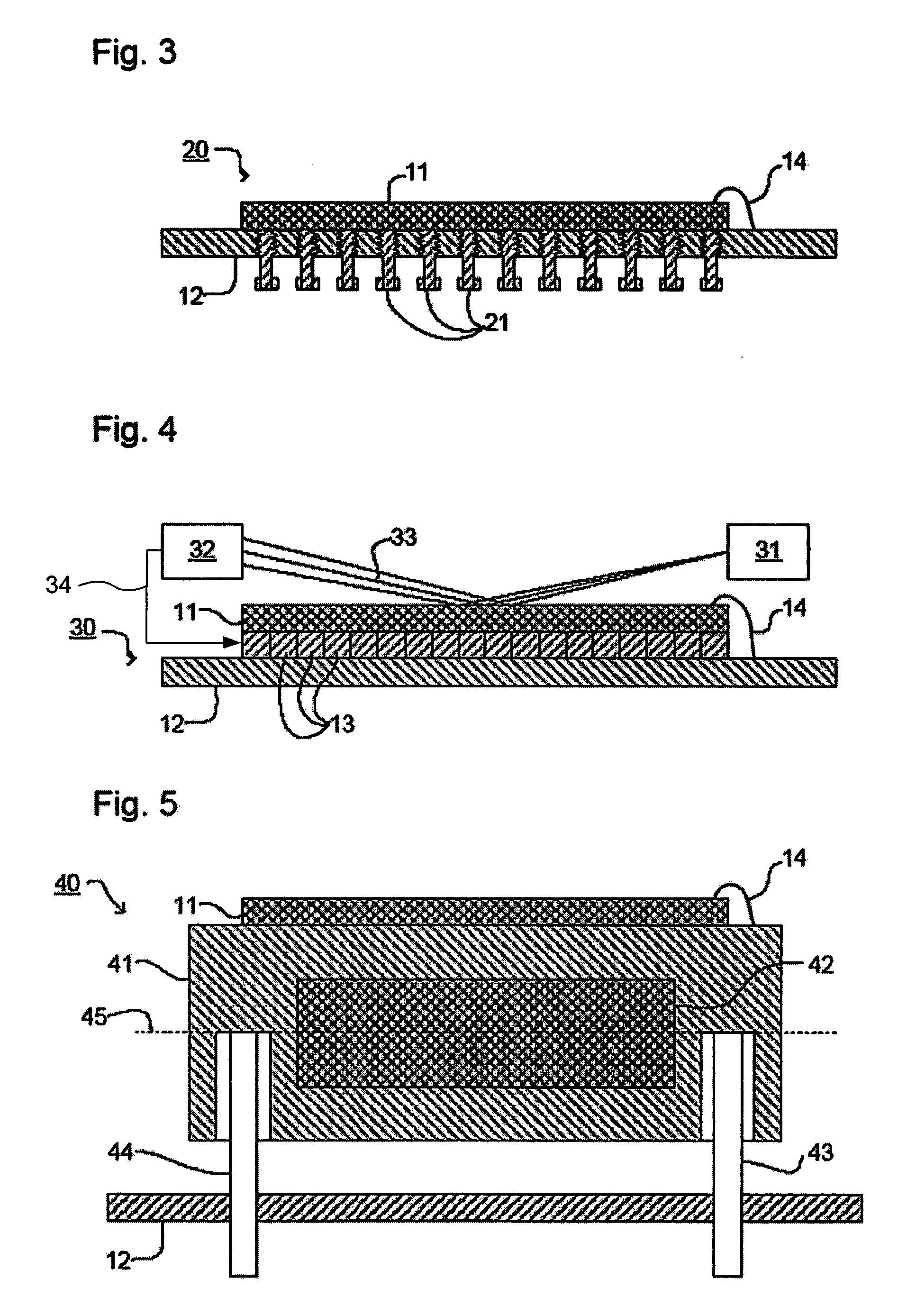

Lithographic apparatus and device manufacturing method

InactiveUS20050068510A1Less stringent specificationFocus deviation can be reducedMirrorsSemiconductor/solid-state device testing/measurementPiezoelectric actuatorsEngineering

One or more patterning arrays are mounted to a mounting plate via height adjustment structures that enable the flatness of the active surfaces of the patterning arrays to be controlled. The height adjustment structures may comprise an array of piezoelectric actuators or screws. Alternatively, the backside of the patterning means may be polished to optical flatness and bonded by crystal bonding to an optically flat surface of a rigid mounting body.

Owner:ASML NETHERLANDS BV +1

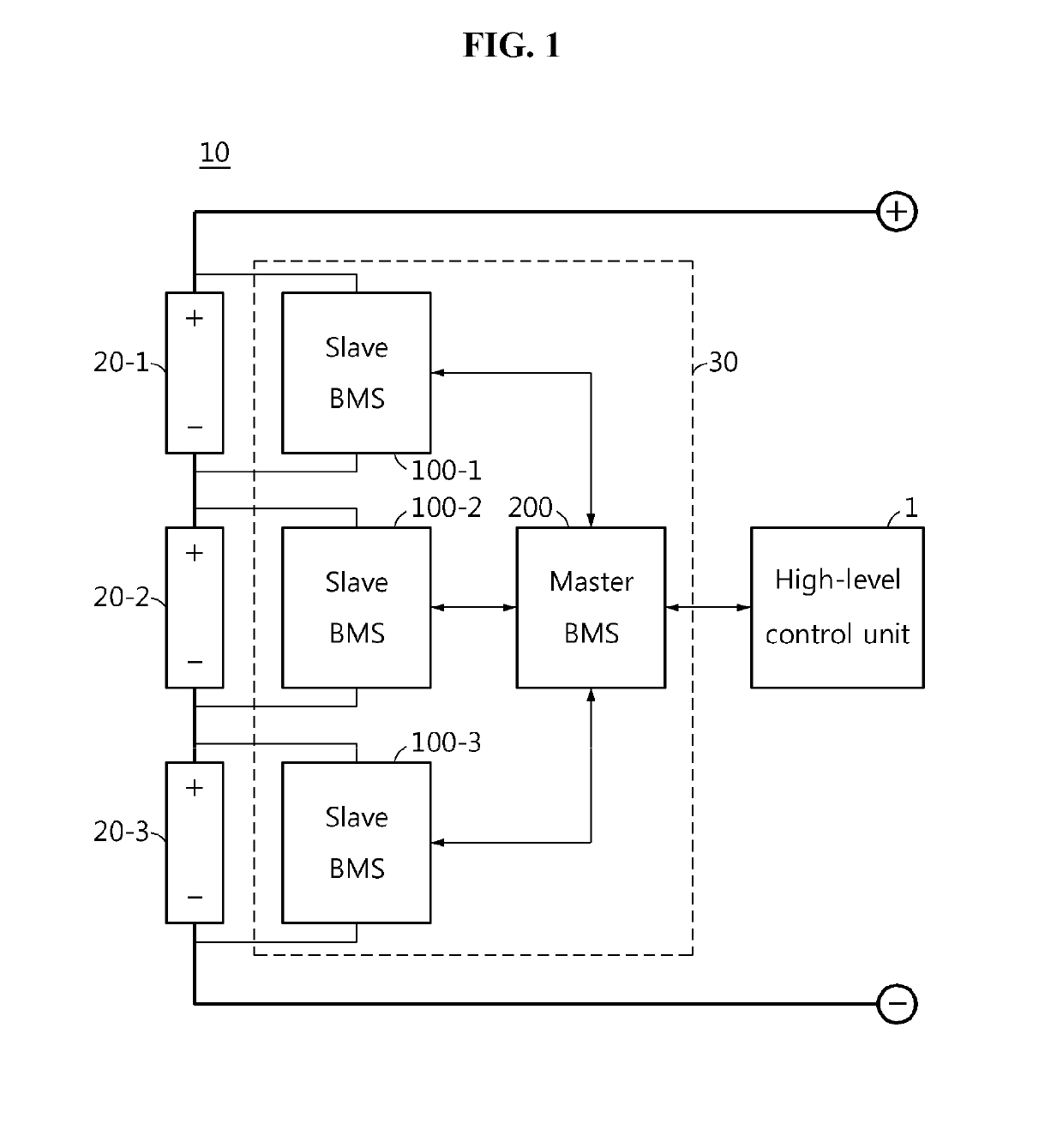

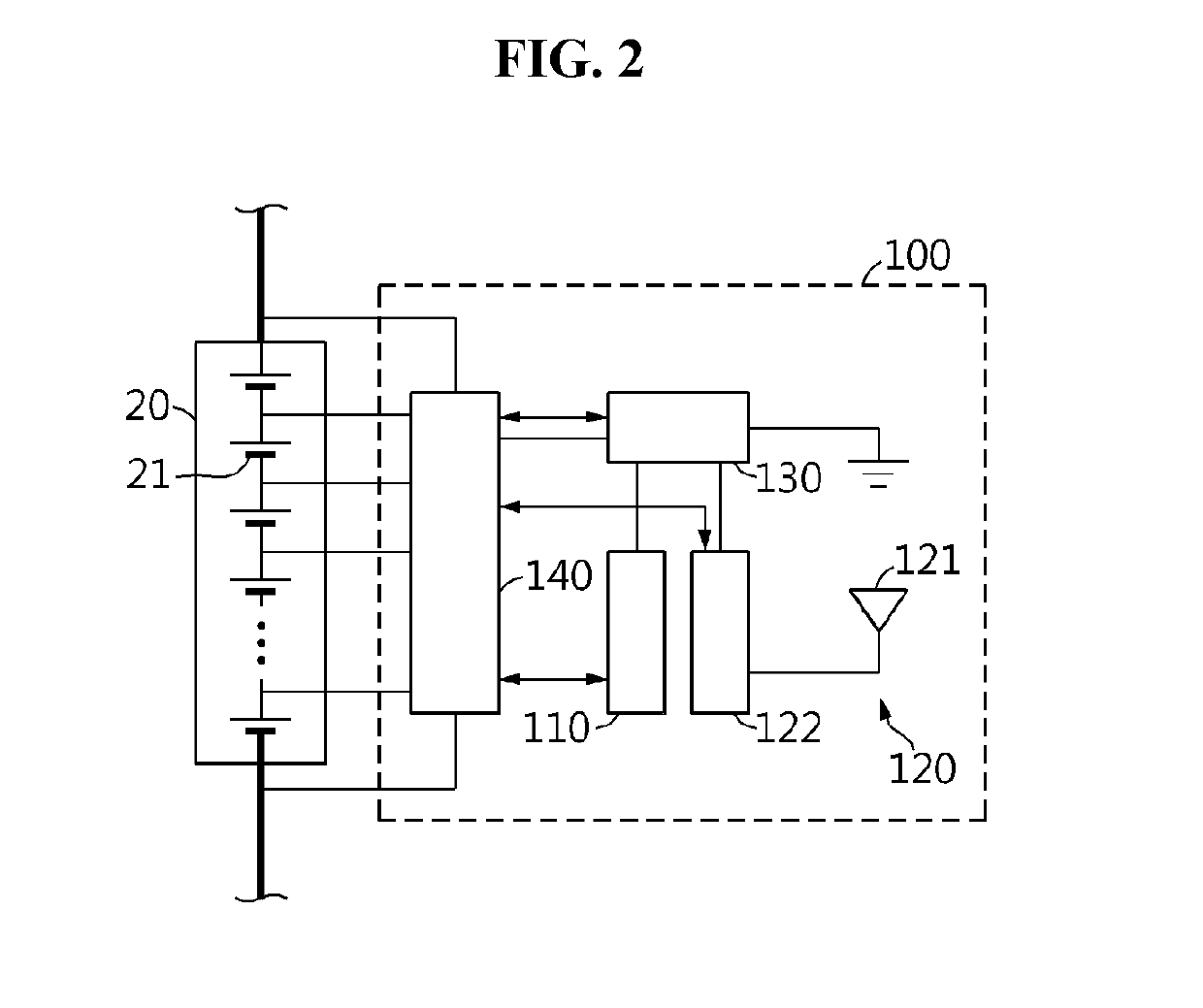

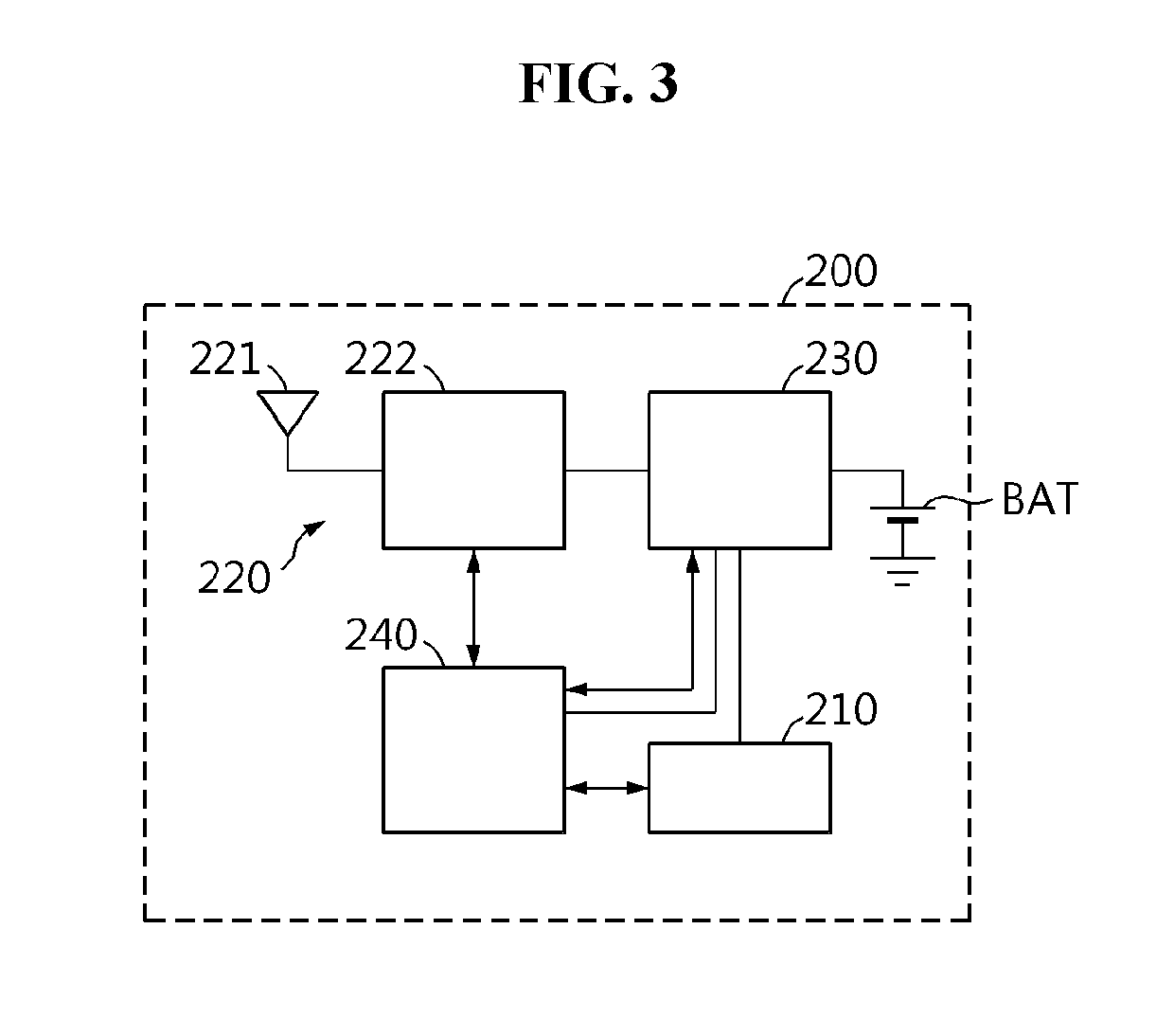

Wireless battery management system and battery pack including same

ActiveUS20190237816A1Reducing residual capacity deviationQuick balanceBatteries data exchangeCharge equalisation circuitWireless transmissionControl signal

A wireless battery management system includes a plurality of slave BMSs coupled to a plurality of battery modules in one-to-one correspondence. Each slave BMS is configured to operate in active mode and sleep mode. Each slave BMS is configured to wirelessly transmit a detection signal indicating a state of the battery module. The wireless battery management system further includes a master BMS configured to wirelessly receive the detection signal from each of the plurality of slave BMSs. The master BMS is configured to set a scan cycle and a scan duration for each of the plurality of slave BMSs based on the detection signal, and wirelessly transmit a control signal to the plurality of slave BMSs. The control signal includes a wireless balancing command indicating the scan cycle and the scan duration set for each of the plurality of slave BMSs.

Owner:LG ENERGY SOLUTION LTD

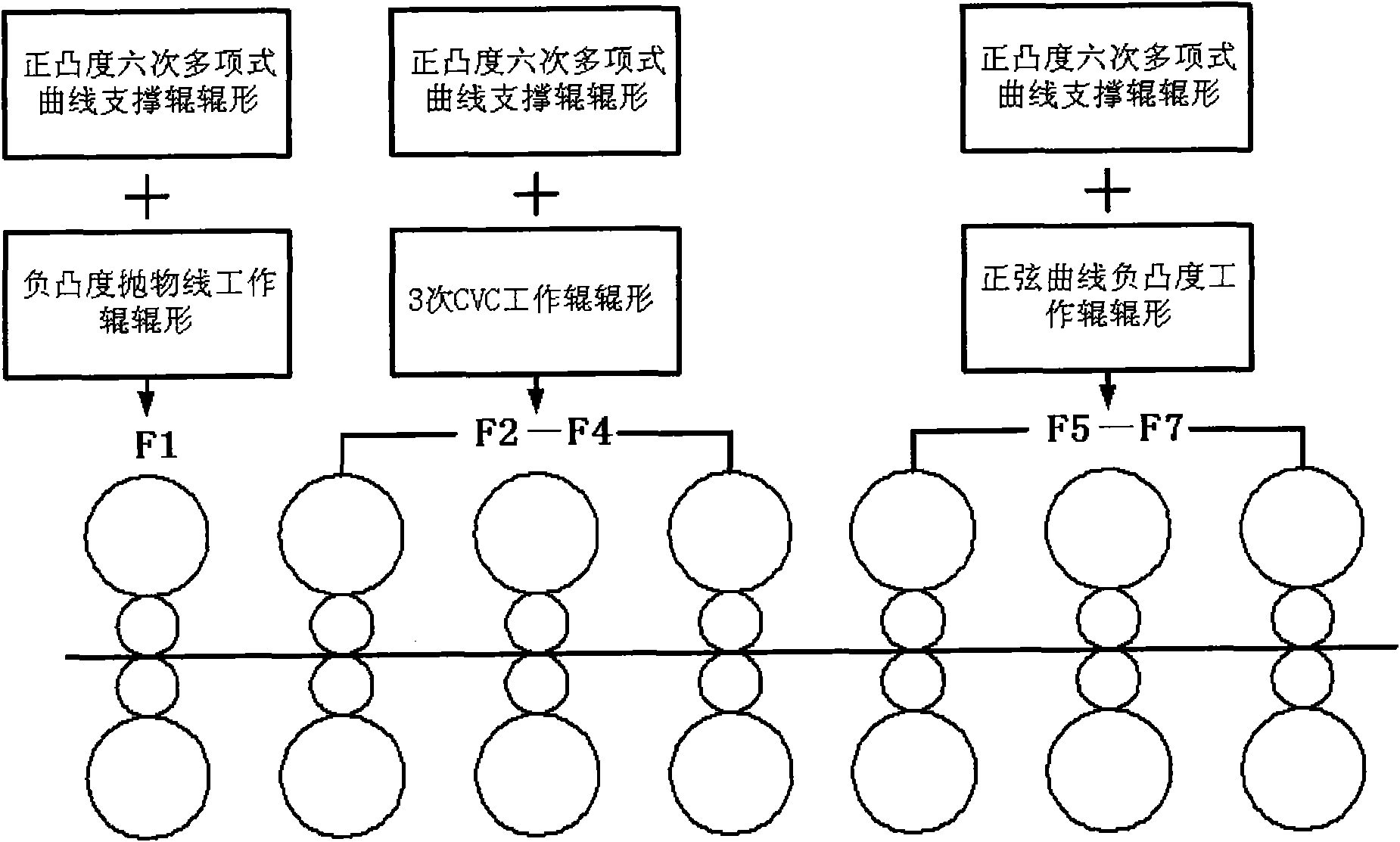

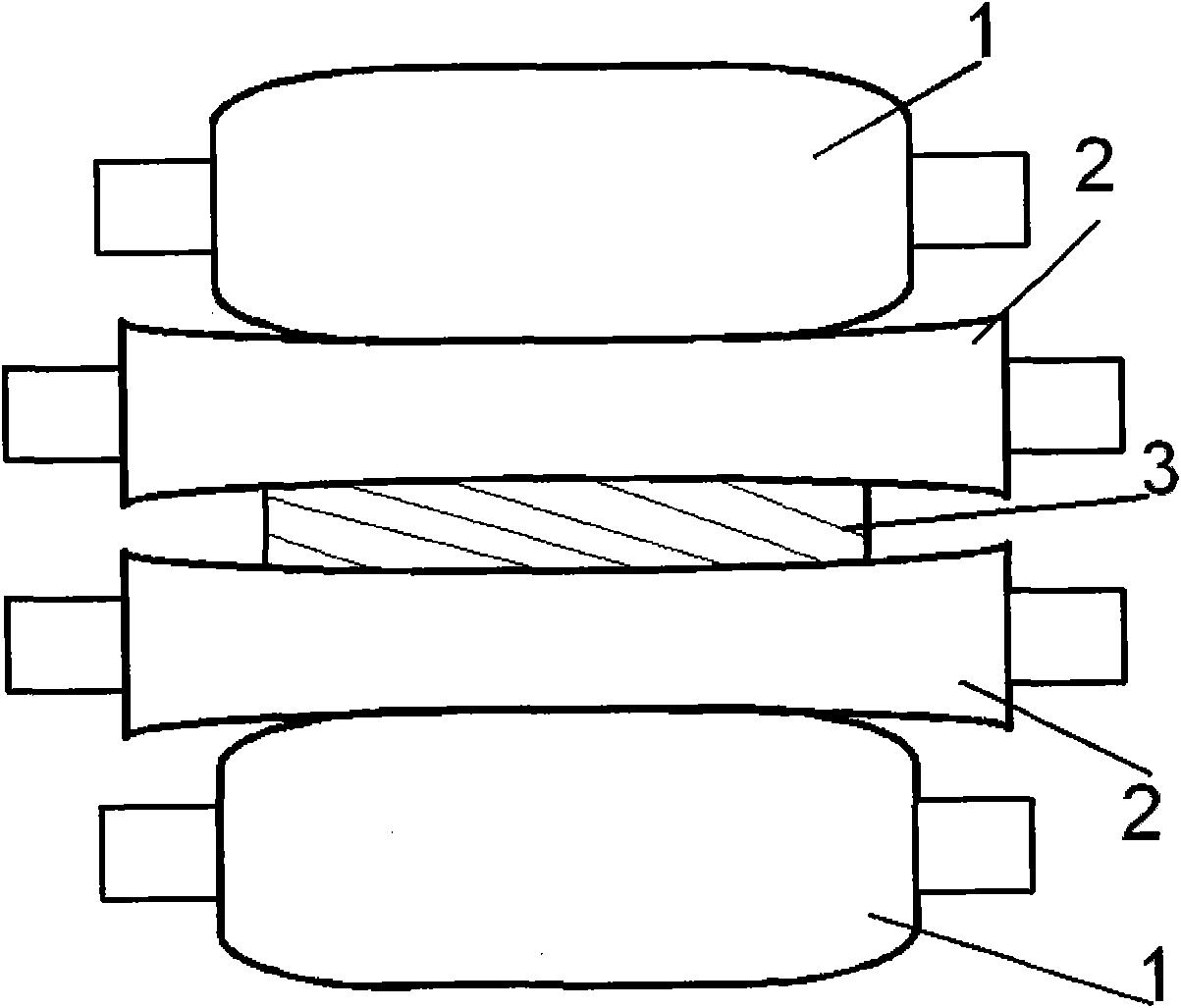

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

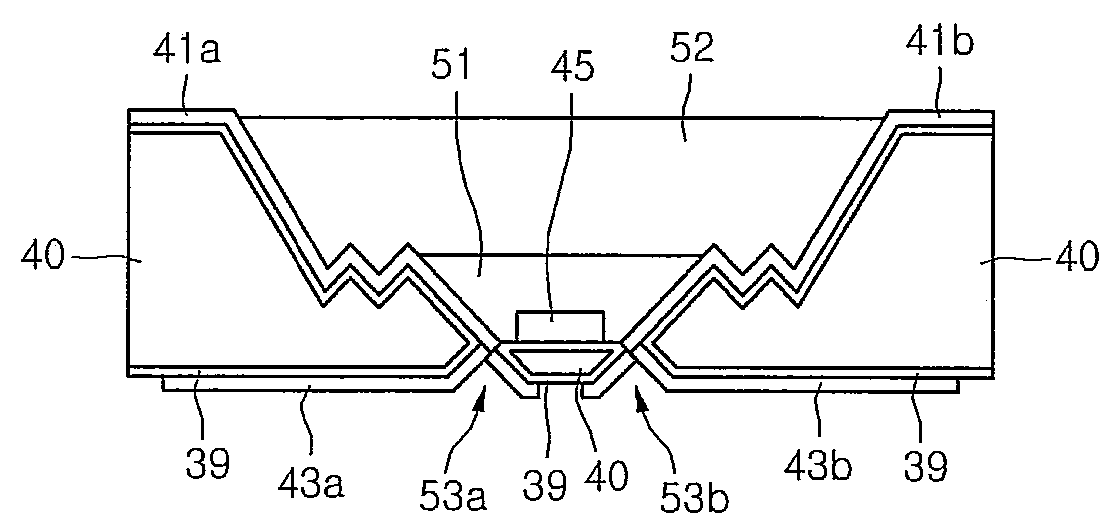

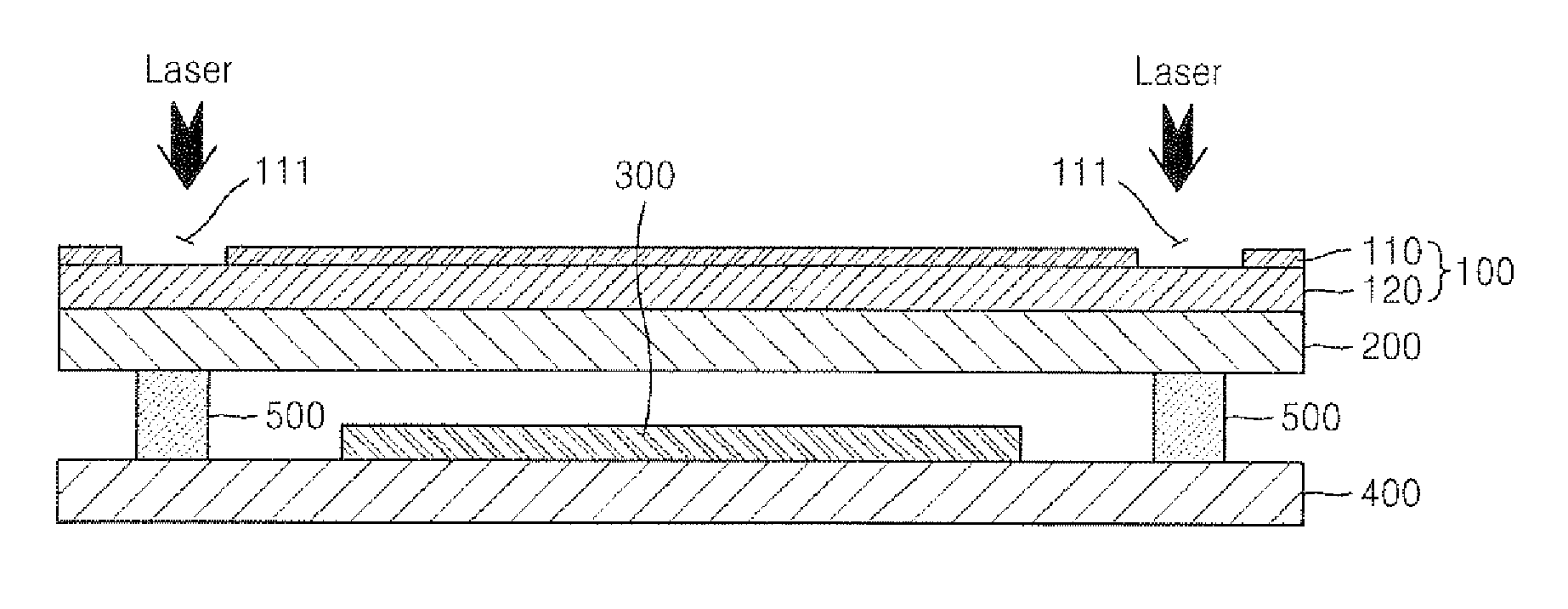

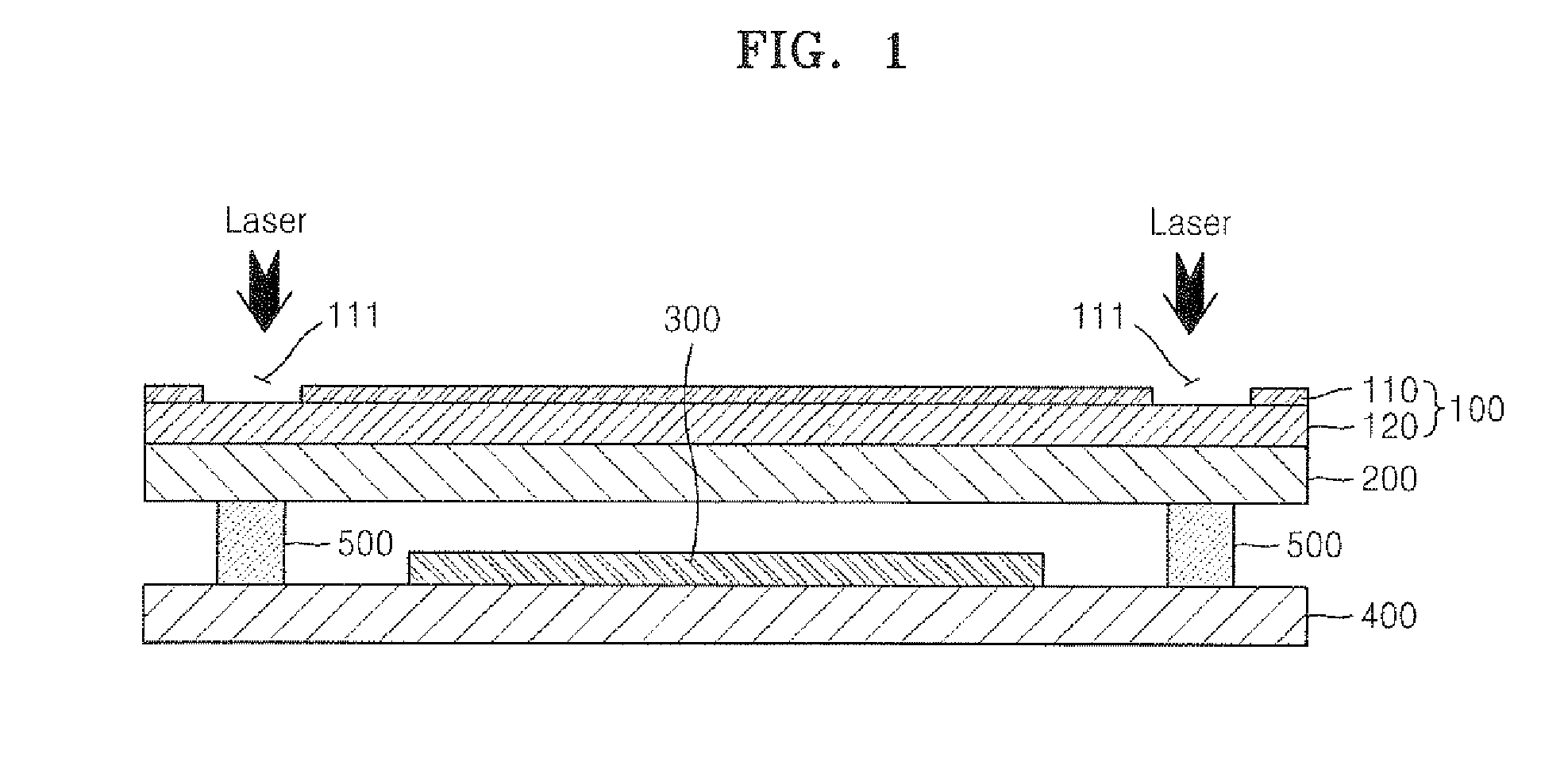

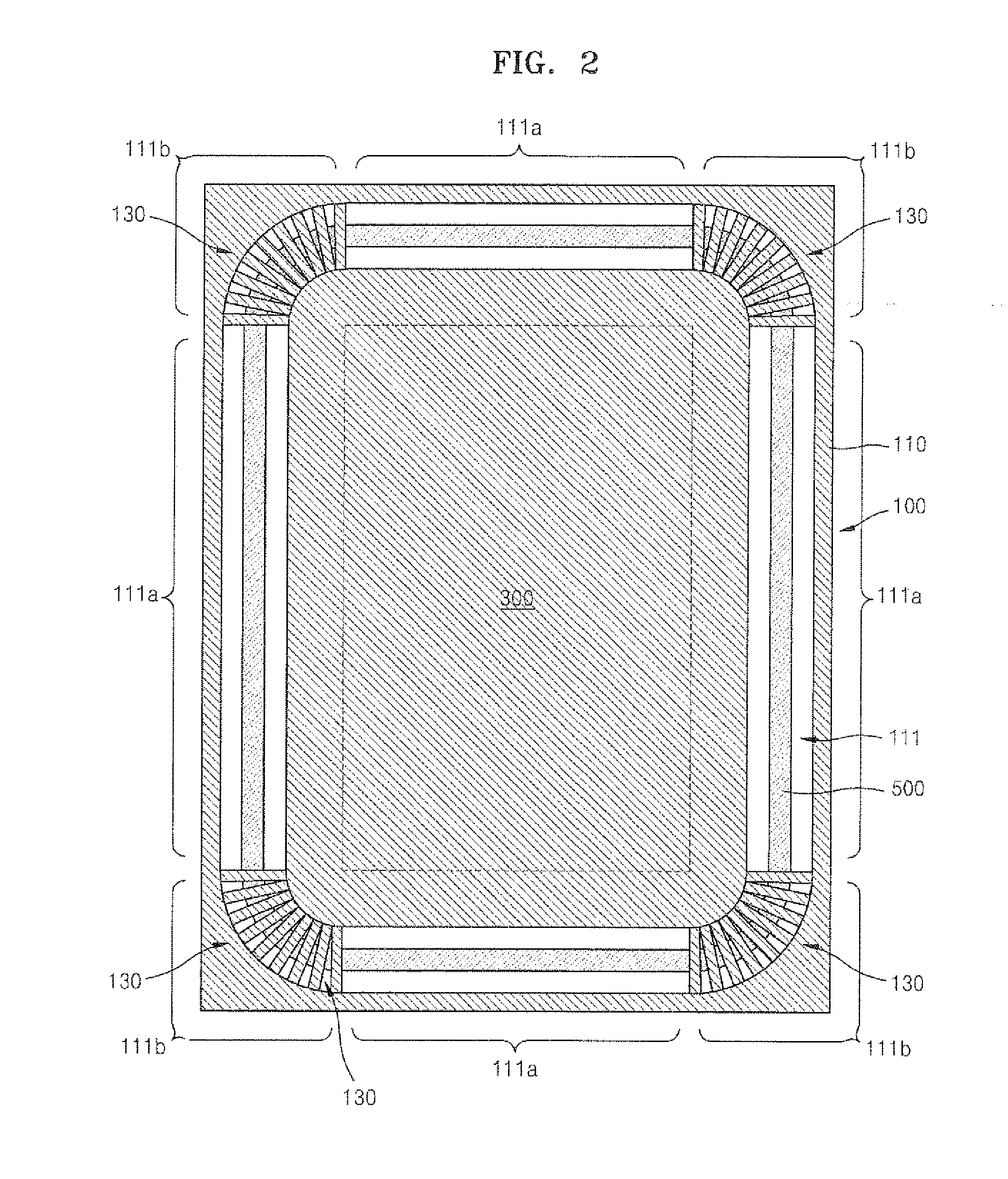

Mask for Hardening Sealant and Method of Manufacturing Flat Display Device Using the Mask

InactiveUS20120048462A1Suppress sealing failureStable structureLamination ancillary operationsLayered product treatmentFlat panelDisplay device

In a mask for hardening a sealant and a method of manufacturing a flat display device using the mask, the mask includes a main body in which a transmission slit is formed, and a partial shielding portion partially shielding the transmission slit. The transmission slit corresponds to the shape of the sealant enclosing a light-emitting portion formed on a substrate. By using such a mask, the partial shielding portion covers a portion where the amount of laser irradiation is relatively large, thus hardening the sealant uniformly across the entire regions of the sealant, and thus guaranteeing a stable encapsulating structure.

Owner:SAMSUNG DISPLAY CO LTD

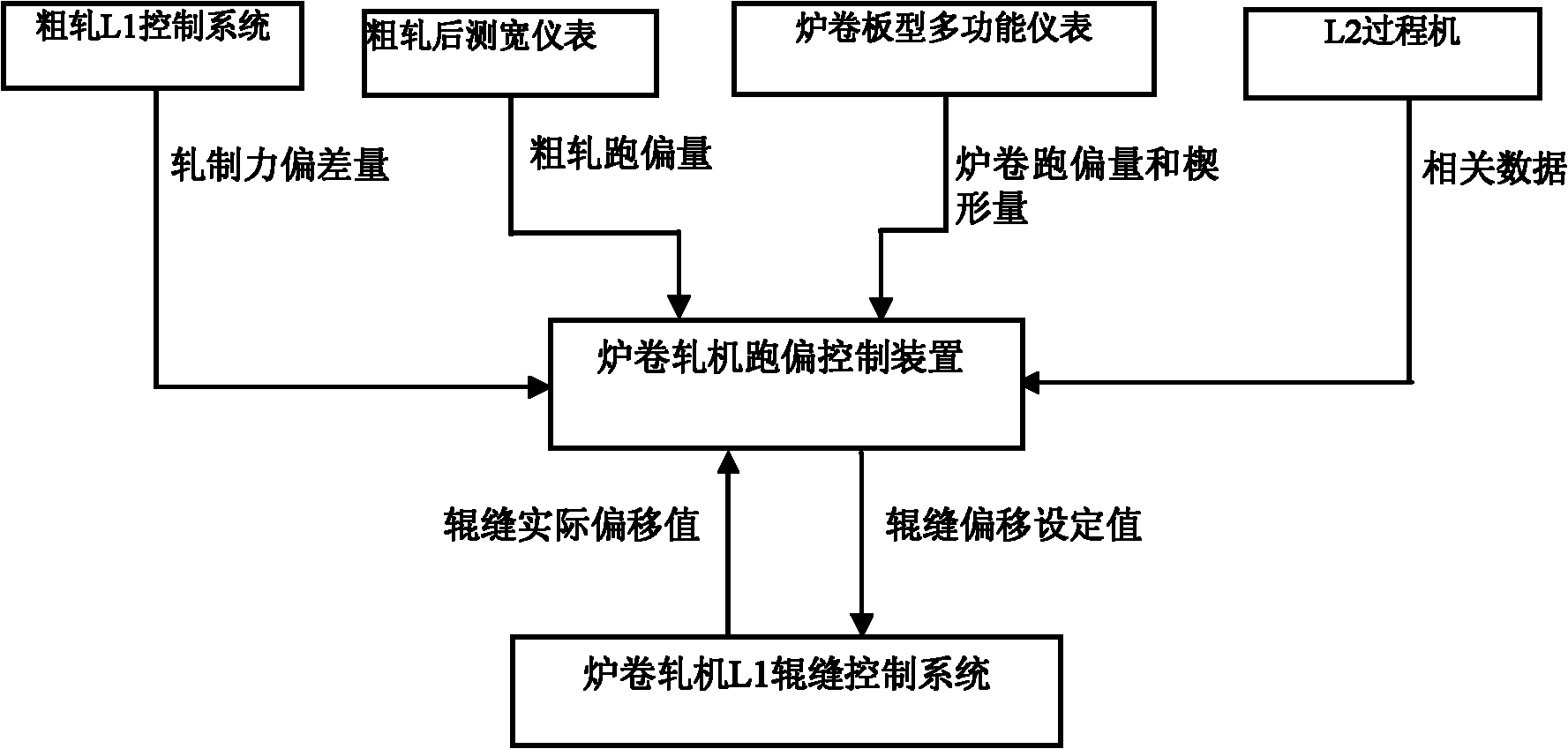

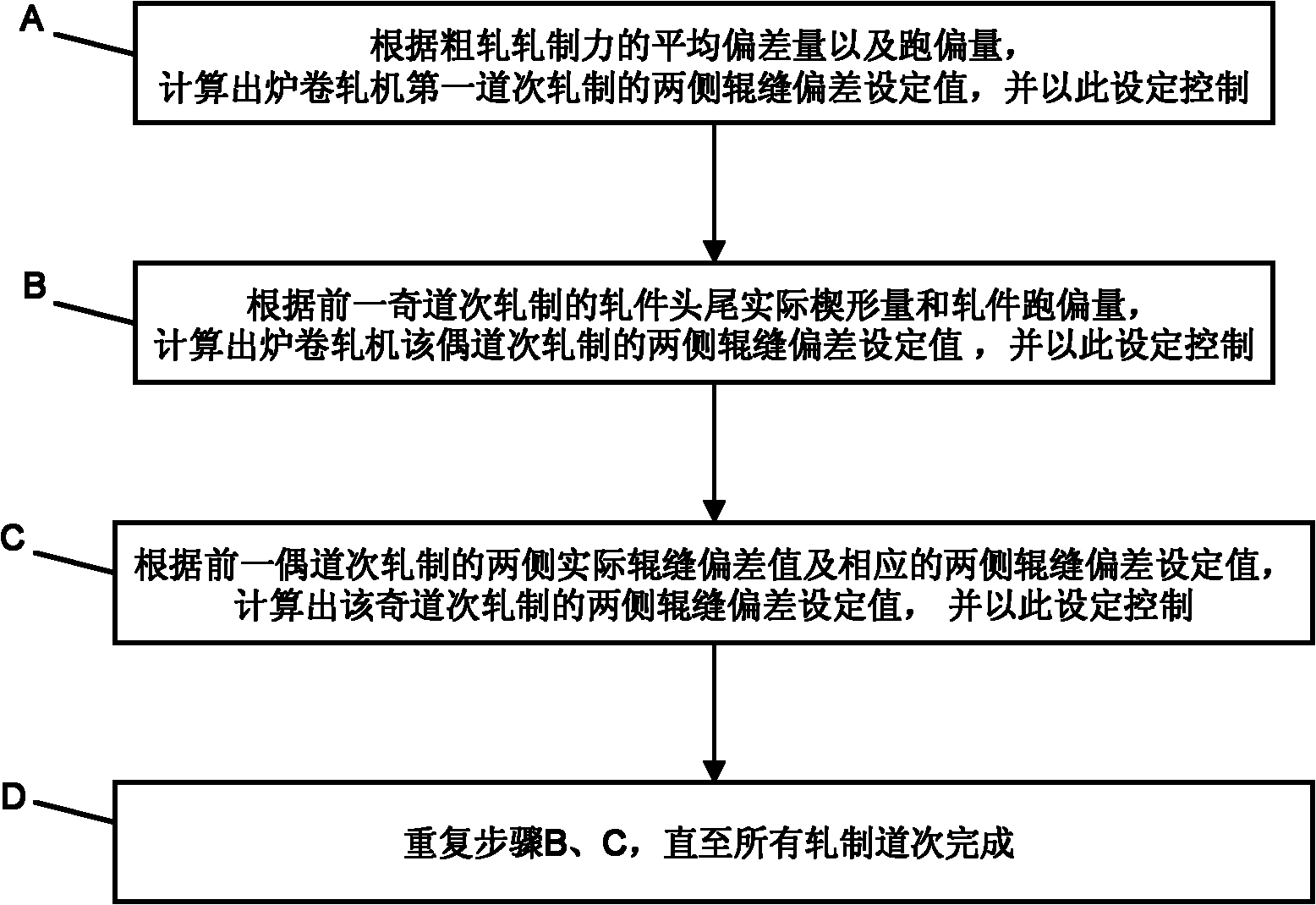

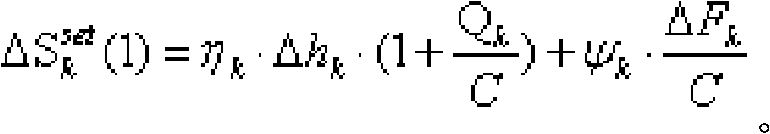

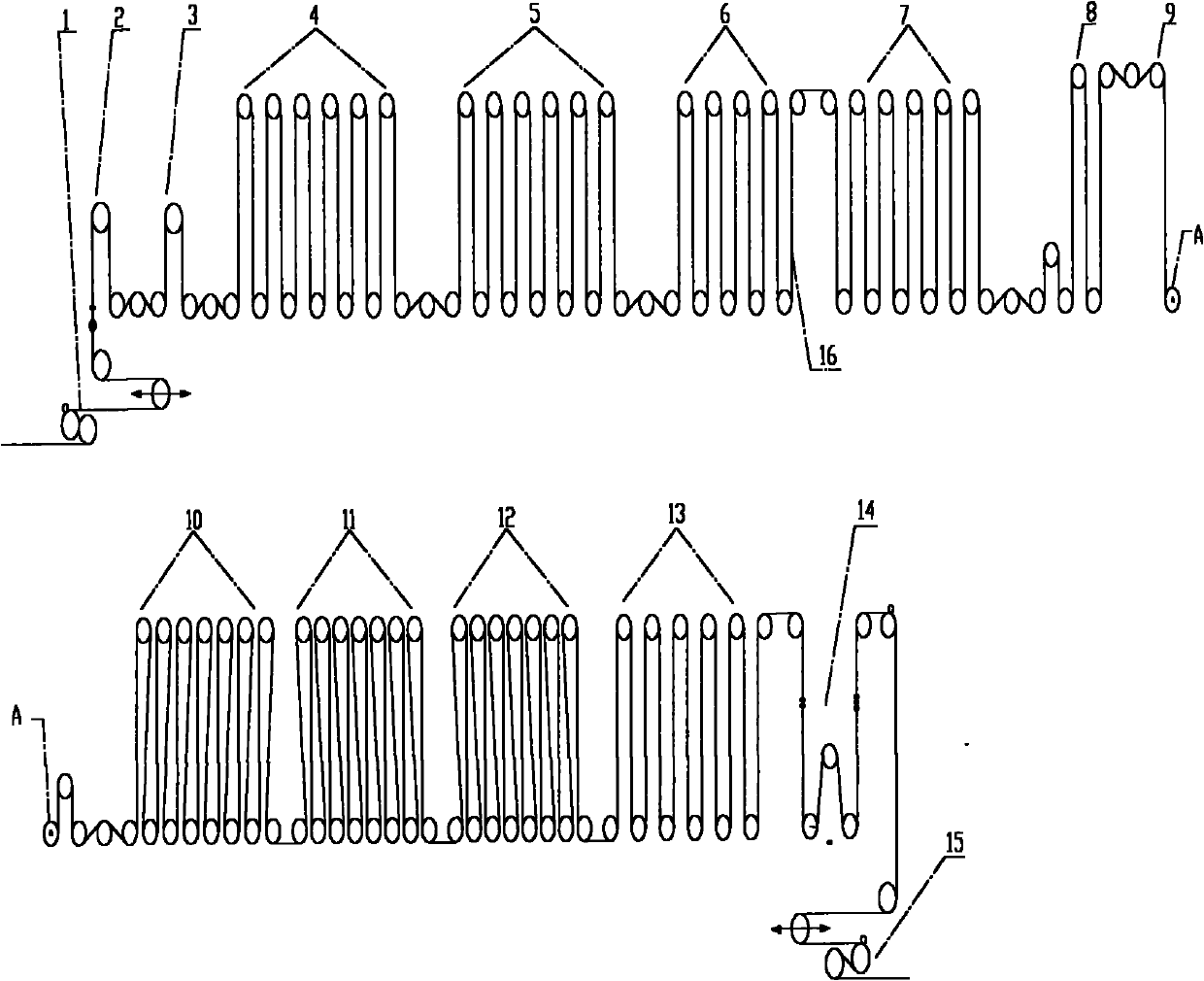

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

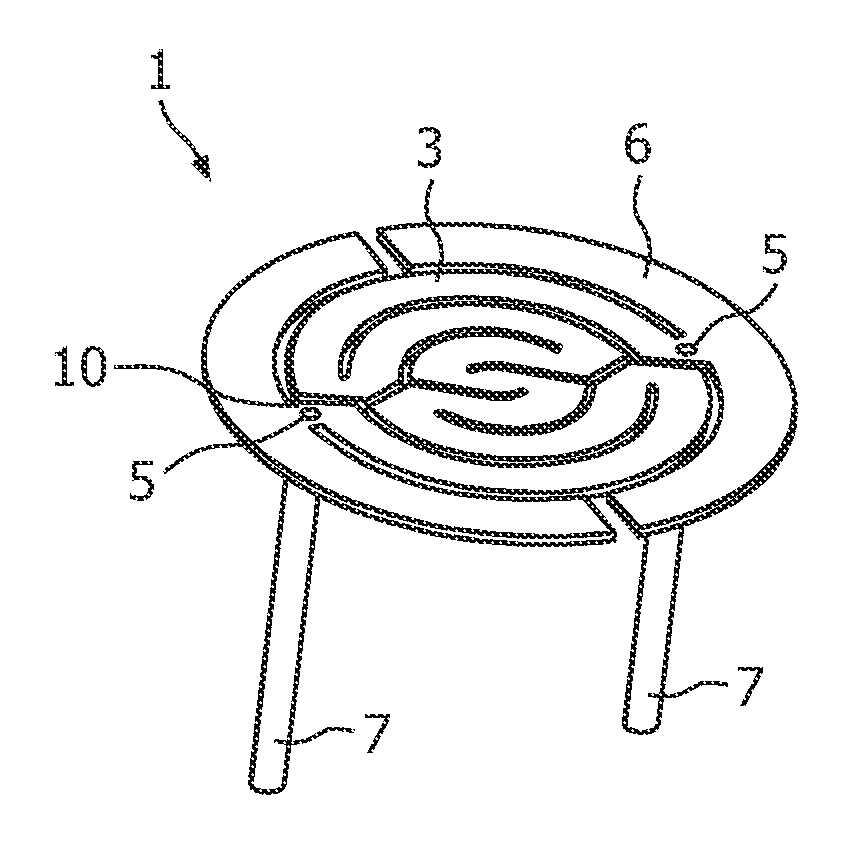

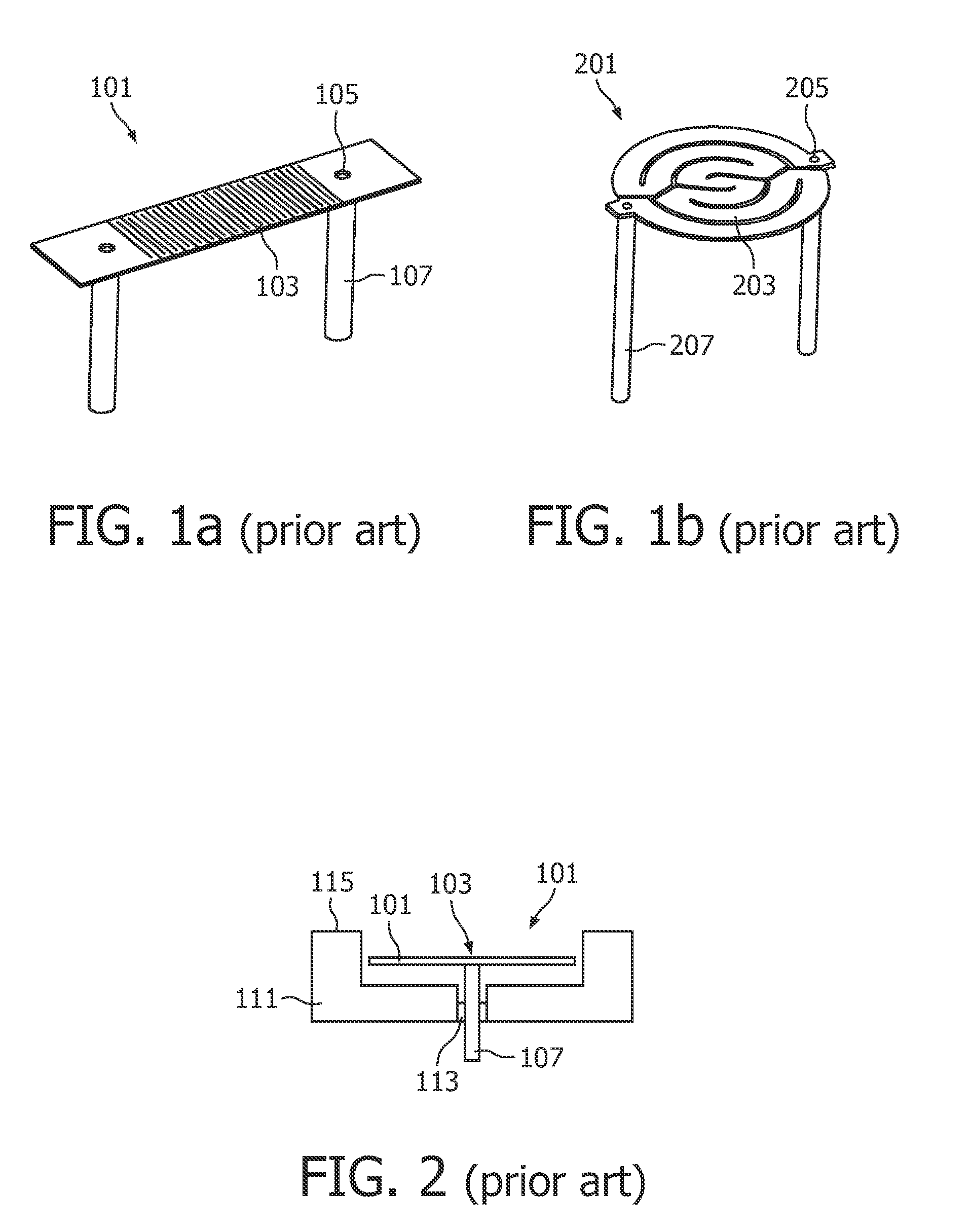

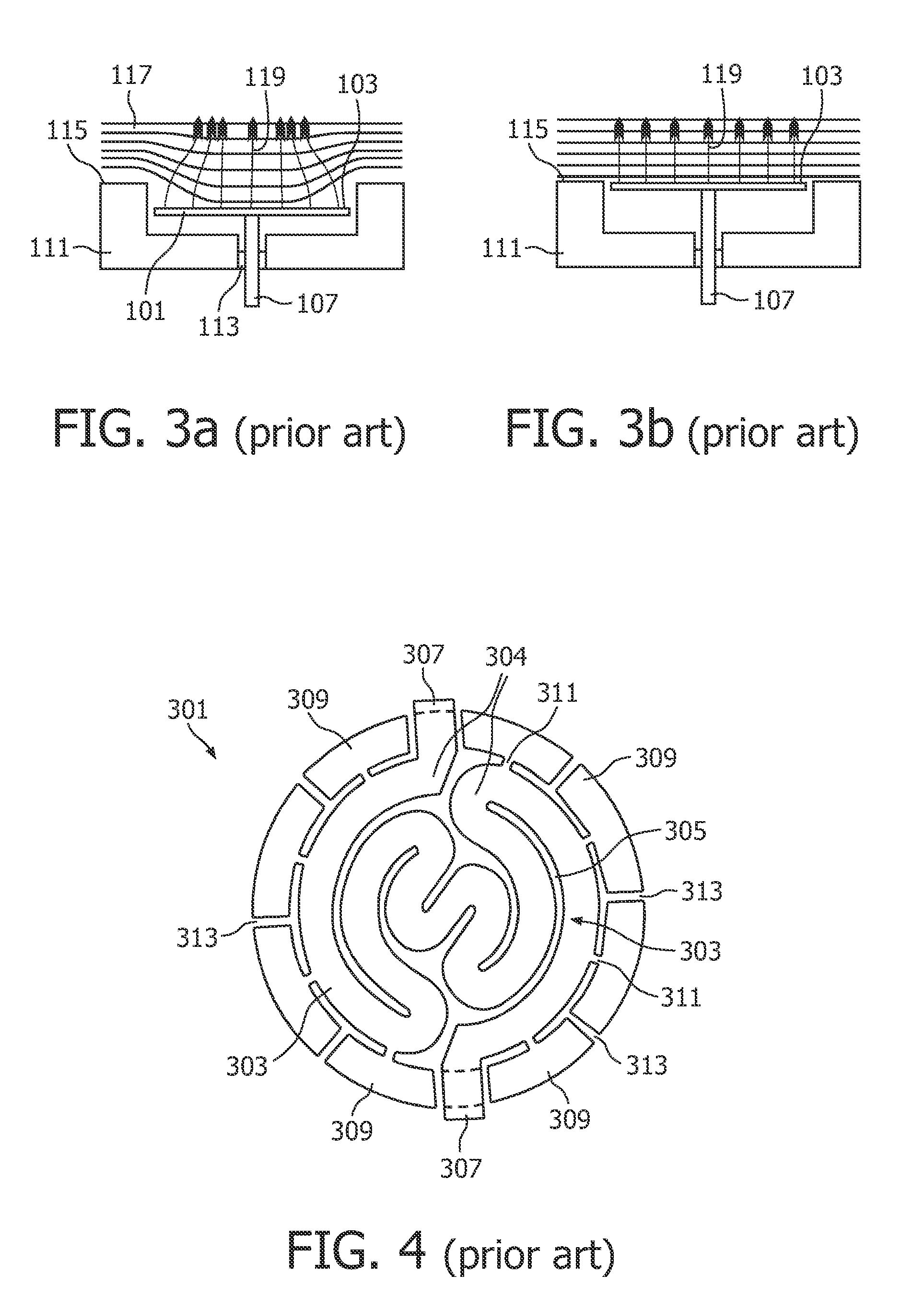

Thermionic electron emitter and x-ray souce including same

InactiveUS20100195797A1Excellent propertyMinimal focal spot sizeX-ray tube electrodesLamp incadescent bodiesX-rayAtomic physics

A thermionic electron emitter (1) is proposed comprising an inner part (2) including a heatable flat emission surface (3) and an outer part (4) including a surrounding surface (6) substantially enclosing the emission surface and a heating arrangement for heating the emission surface to a temperature for thermionic electron emission. The outer part is mechanically connected to the inner part in a connection region (10) apart from the emission surface. Furthermore, the surrounding surface is thermally isolated, e.g. by a gap (14), from the emission surface in an isolation region apart from the connection region. By providing a surrounding surface enclosing the emission surface which may be on a similar electrical potential as the emission surface but which can have a substantially lower temperature than the emission surface without influencing the temperature distribution within the emission surface, an improved electron emission distribution and homogeneity can be obtained.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

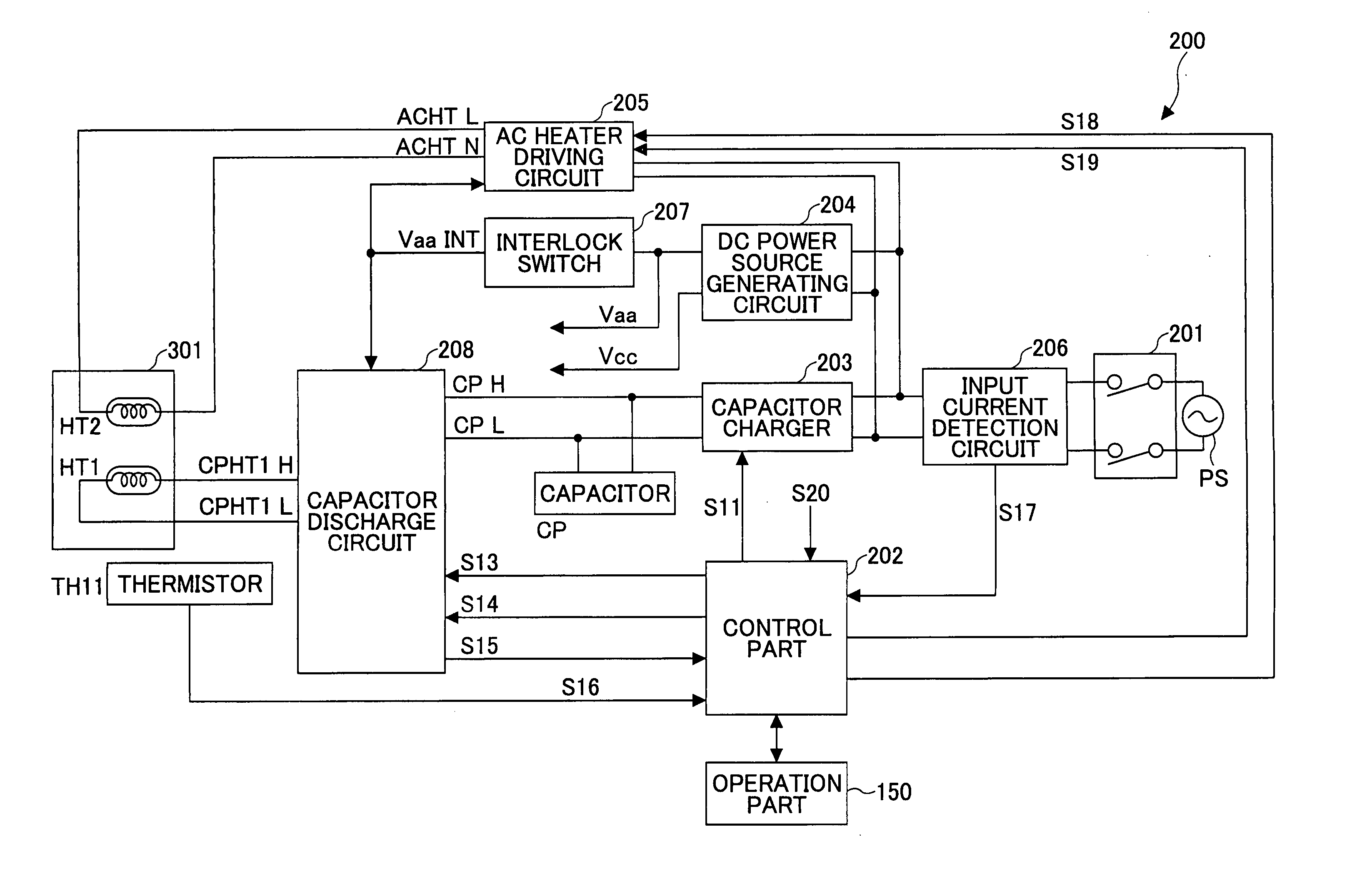

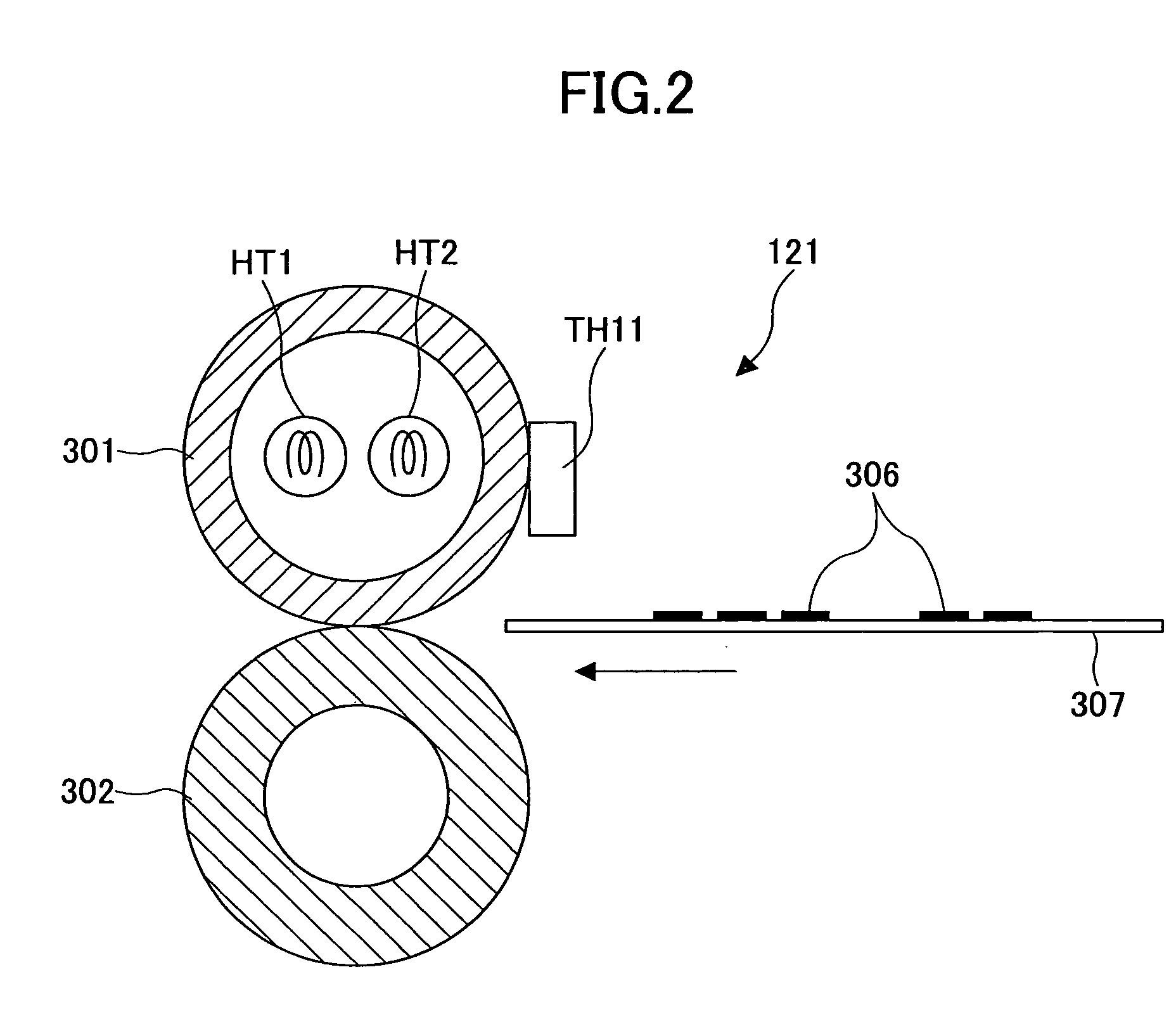

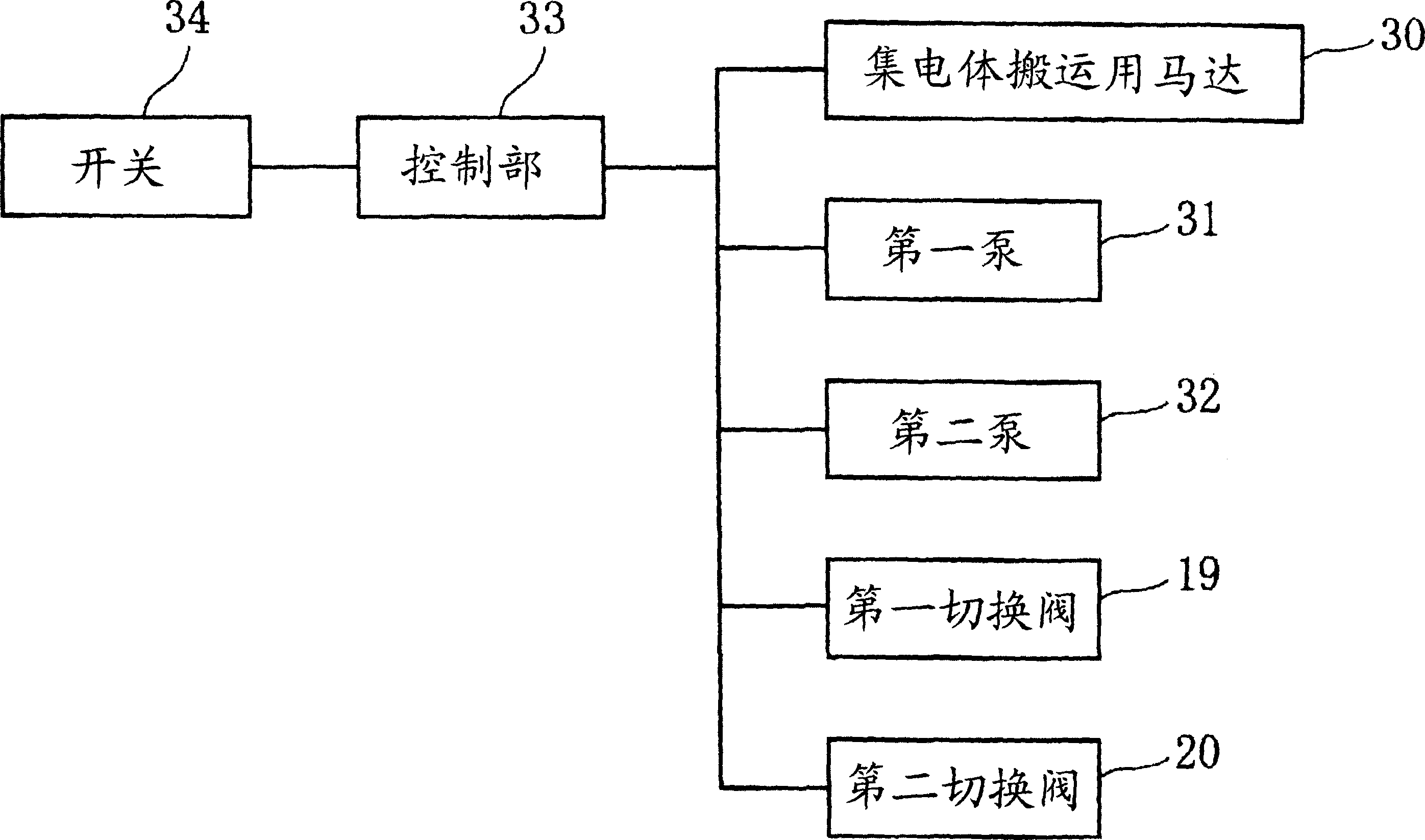

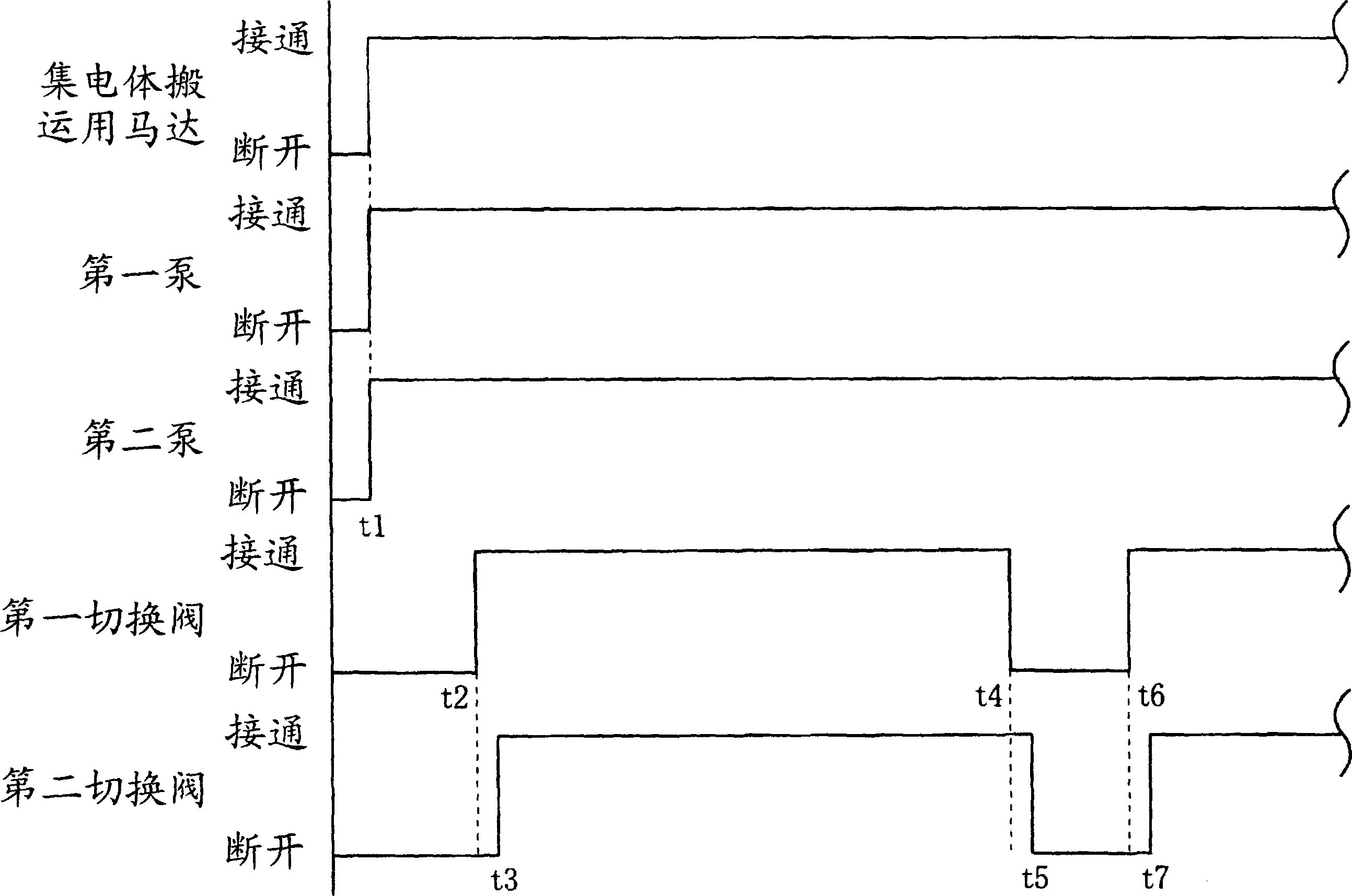

Auxiliary power source device, fixing device, image forming apparatus and charge operation control method

InactiveUS20050189923A1Large amount of chargeReduce chargeBatteries circuit arrangementsElectric powerEngineeringVoltage control

An auxiliary power source device includes: a first battery; a first charger receiving power supply from a commercial power source and charging the first battery; a second battery connected with the first battery in series; a second charger receiving power supply from the commercial power source and charging the second battery; a detecting circuit detecting voltages of the first battery and the second battery; and a control part switching charging operation between the first and second chargers for a final target voltage based on a detection result of the detecting circuit.

Owner:RICOH KK

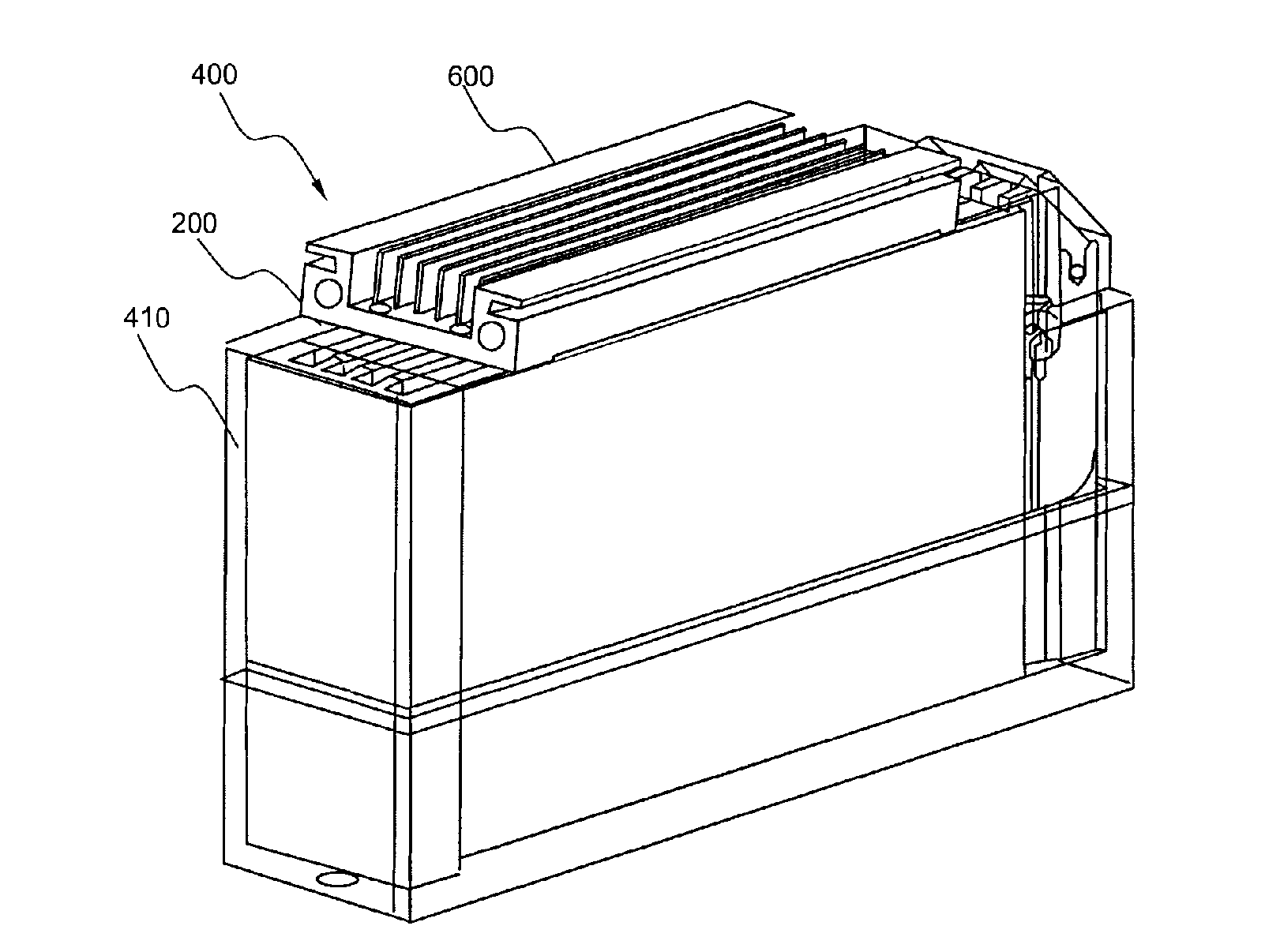

Battery module having heat dissipation member of novel structure and battery pack employed with the same

ActiveUS20120094166A1Uniform temperatureRestricting increase in sizeLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

Disclosed is a battery module including a plurality of plate-shaped battery cells mounted in a module case in a stacked state, wherein each of the plate-shaped battery cells is configured in a structure in which an electrode assembly is mounted in a battery case formed of a laminate sheet, the battery module is configured in a structure in which a plurality of heat dissipation members disposed at two or more interfaces between the battery cells and a heat exchange member to integrally interconnect the heat dissipation members are mounted at one side of a battery cell stack, and heat generated from the battery cells during charge and discharge of the battery cells is removed by the heat exchange member via the heat dissipation members.

Owner:LG ENERGY SOLUTION LTD

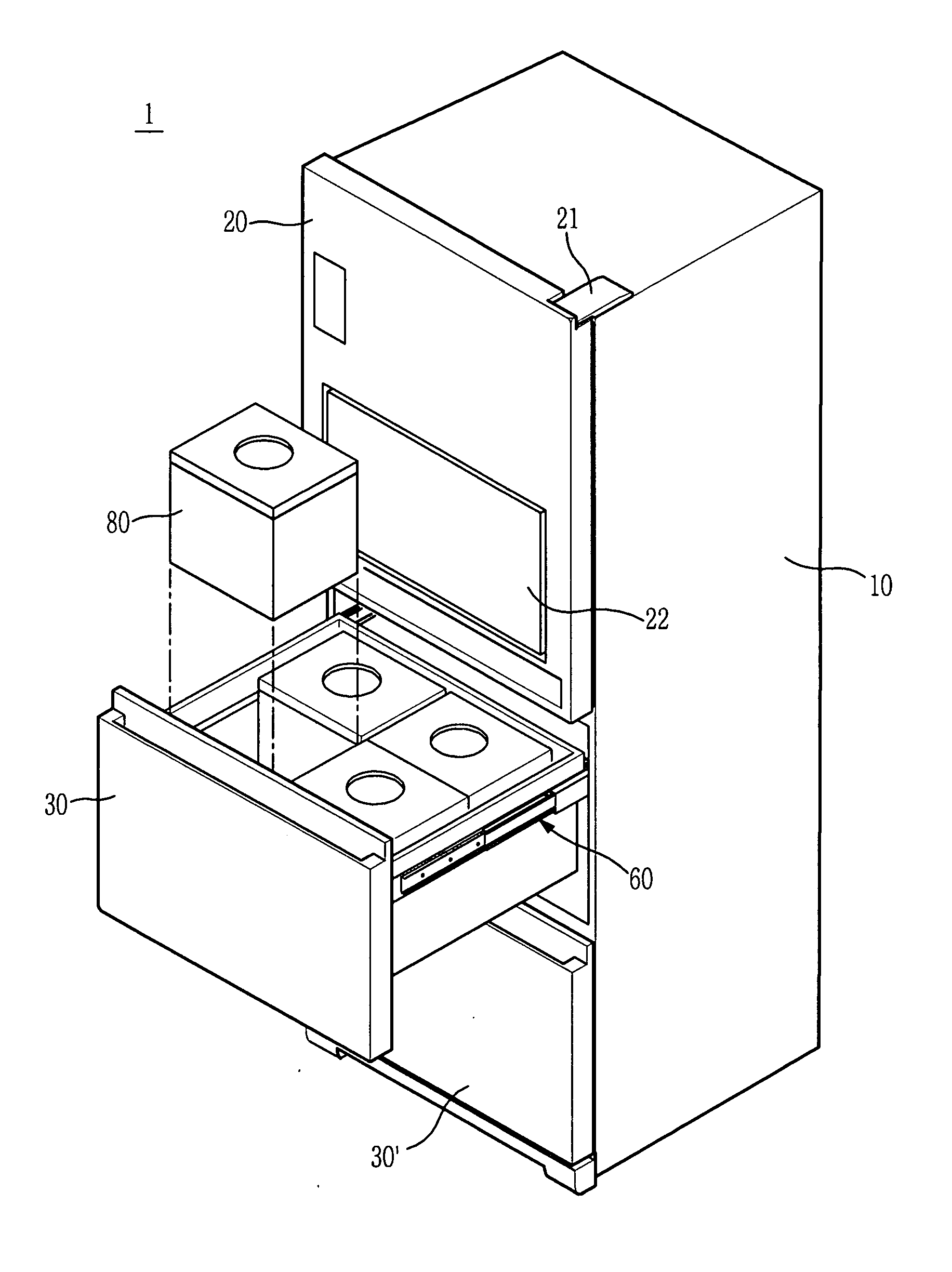

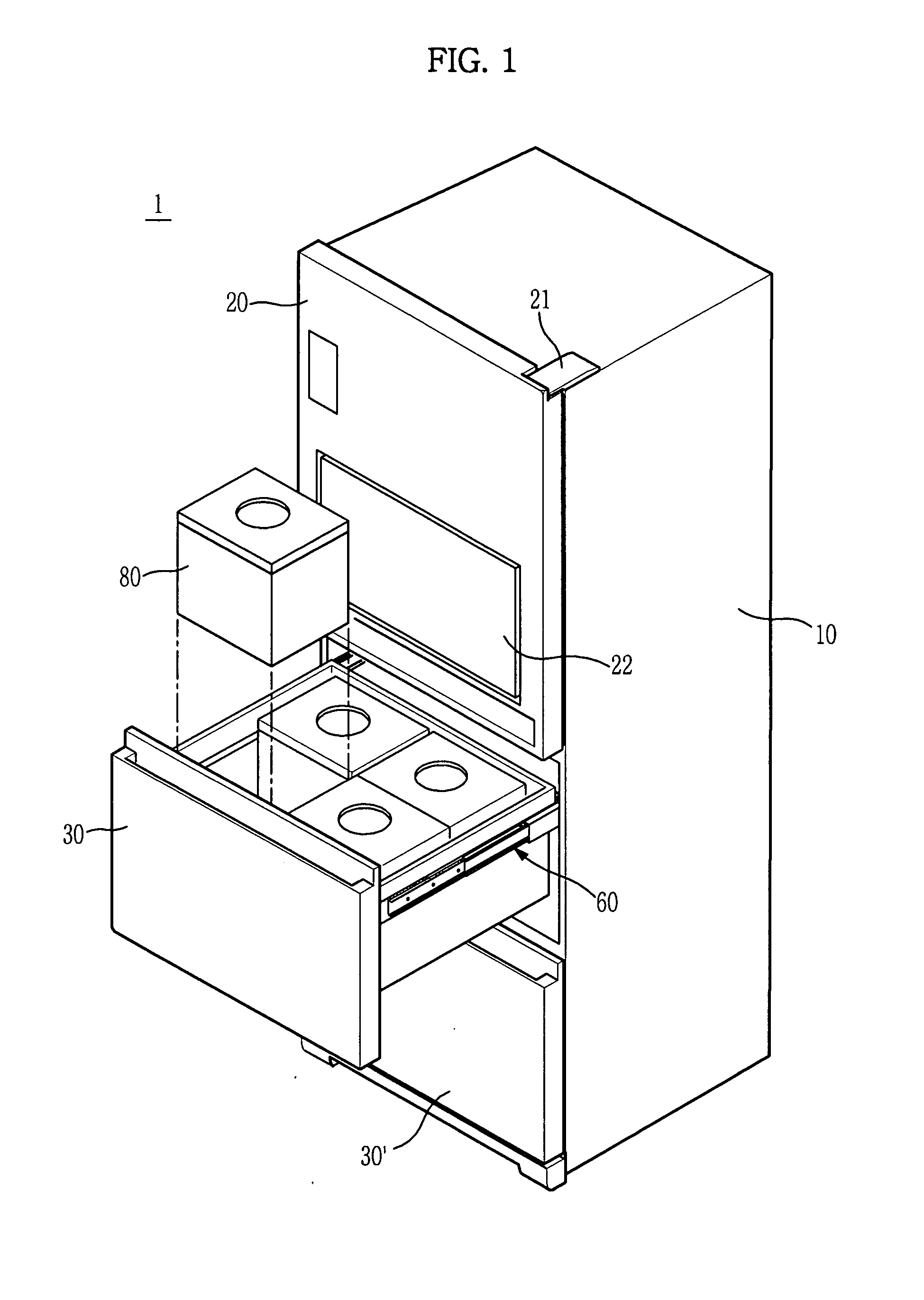

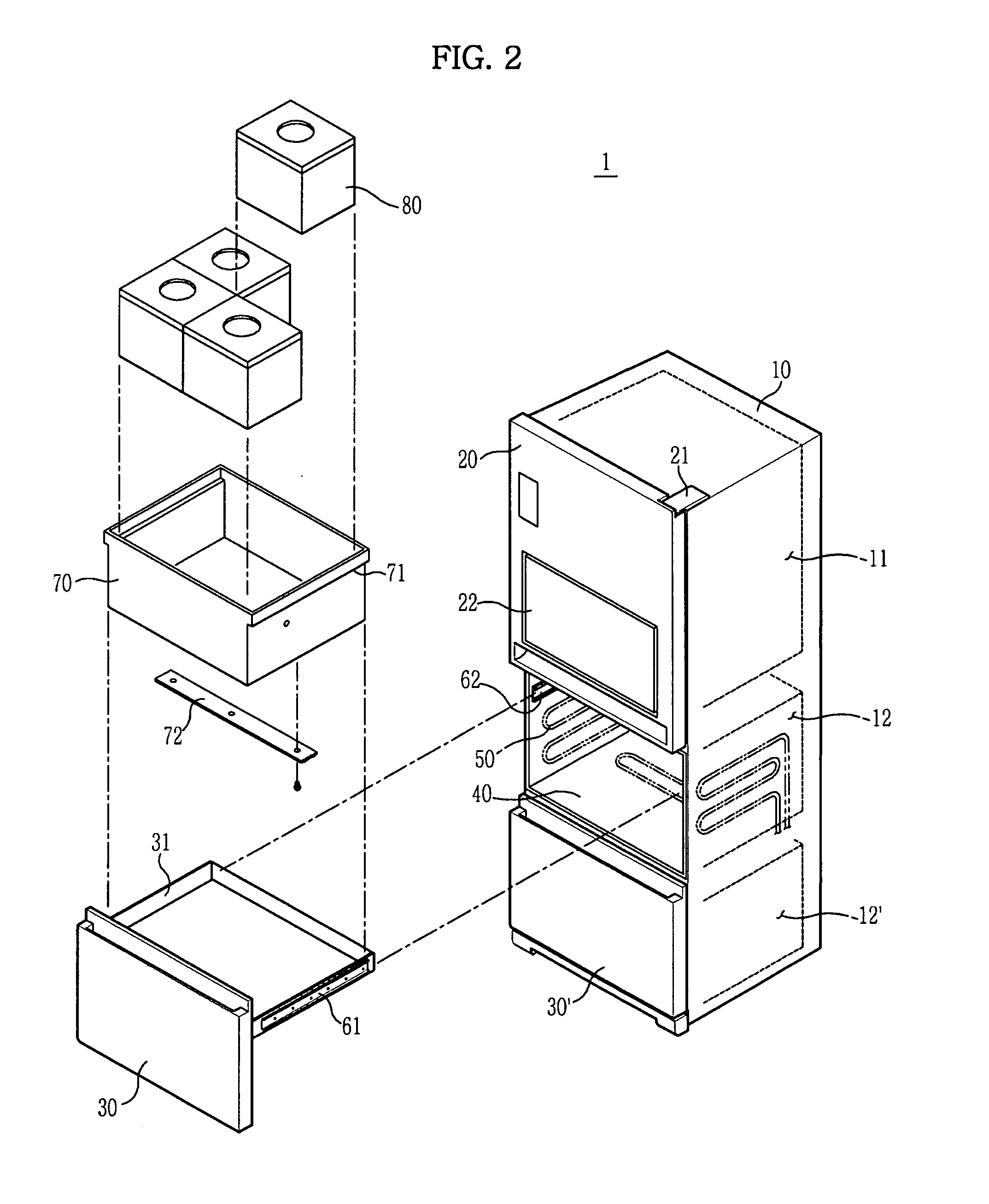

Direct cooling refrigerator and control method thereof

InactiveUS20120047922A1Reduce deviationRefrigeration componentsCooling fluid circulationRefrigerated temperatureEmbedded system

A direct cooling refrigerator having a circulation duct. The direct cooling refrigerator includes a cabinet, an inner case arranged in the cabinet and having an inlet and an outlet, a circulation duct coupled to the inner case at the outside of the inner case and having a suction port communicating with the outlet and a discharge port communicating with the inlet, and a fan to move air from the suction port to the discharge port within the circulation duct. The inlet is located at an upper wall of the inner case so as to be located closer to a front surface of the inner case than a rear wall of the inner case, and the outlet is located at the rear wall of the inner case so as to be located close to a lower wall of the inner case.

Owner:SAMSUNG ELECTRONICS CO LTD

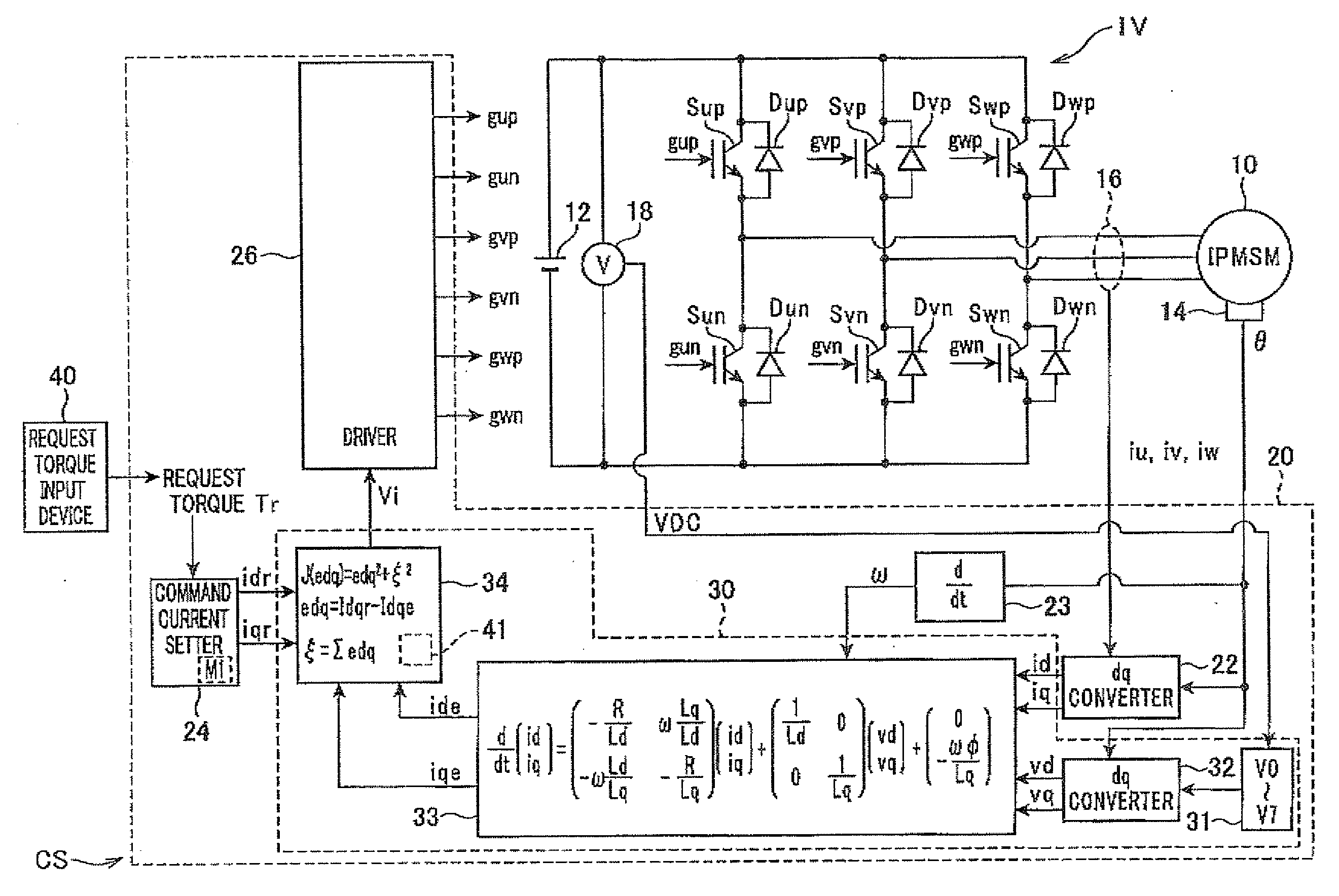

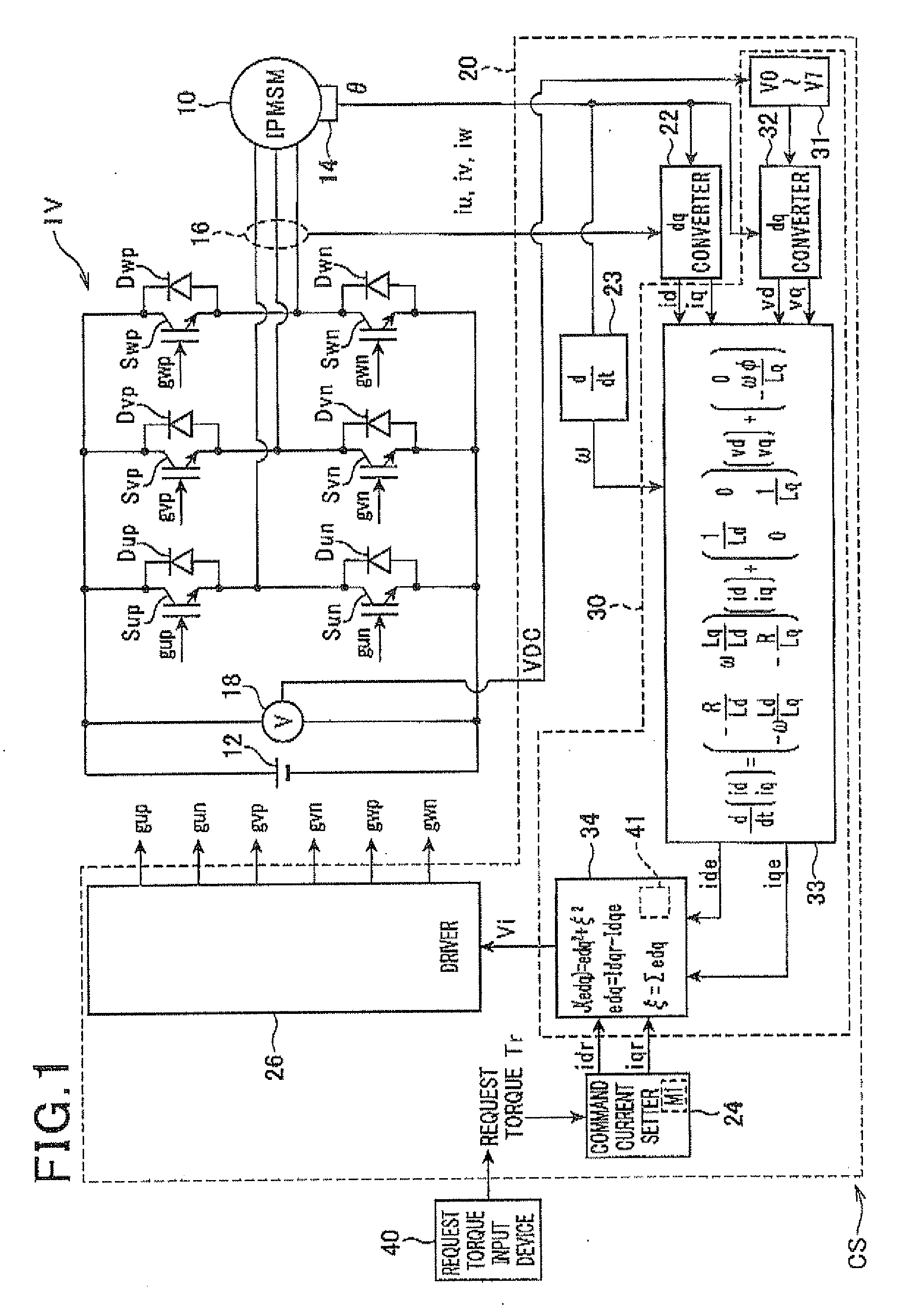

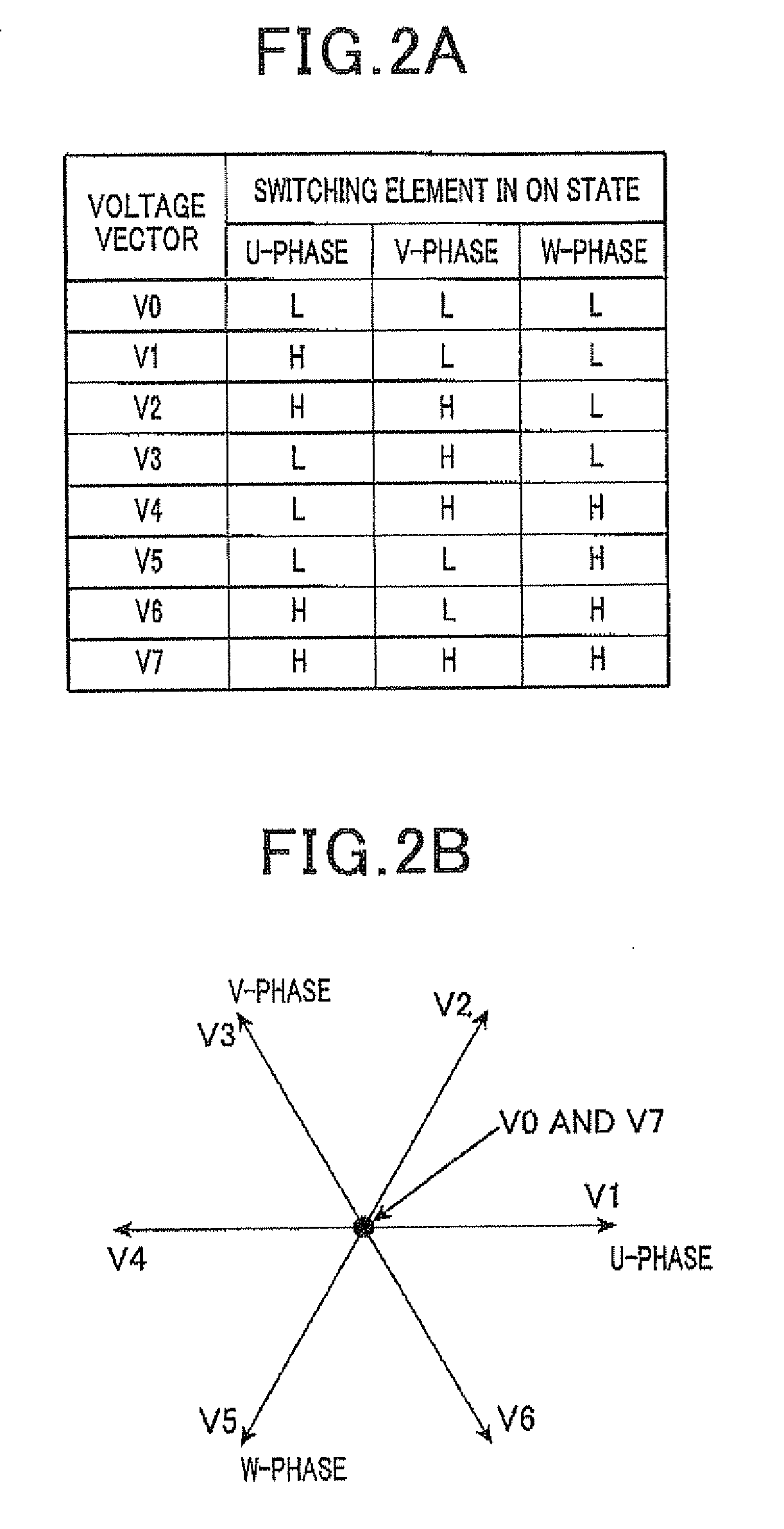

Apparatus for carrying out improved control of rotary machine

ActiveUS20110006711A1Reduce steady state deviationReduce deviationMotor/generator/converter stoppersDC motor speed/torque controlControl variableRotary machine

In an apparatus, a predicting unit uses, as an initial value of a controlled variable, at least one of a first measured value of the controlled variable and a second measured value of a physical variable expressed as a function of the controlled variable. The predicting unit predicts, based on the initial value of the controlled variable, a value of the controlled variable when a driving mode of a switching element of a power converter is set. A driving unit has an integral element and determines, based on an output of the integral element to which a deviation between the predicted value of the controlled variable and a command value of the controlled variable is inputted, an actual driving mode of the switching element to thereby drive the switching element in the determined driving mode.

Owner:DENSO CORP +1

Sputtering target for phase-change memory, film for phase change memory formed by using the target, and method for producing the target

InactiveUS20050115829A1Improving rewriting propertyImprove crystallization speedCellsElectrical apparatusPhase-change memoryTe element

The present invention provides a sputtering target for a phase change memory and a phase change memory film formed with such a target, and the manufacturing method thereof, characterized in that the sputtering target is composed from elements of not less than a three component system and has as its principal component one or more components selected from stibium, tellurium and selenium, and the compositional deviation in relation to the intended composition is ±1.0 at % or less. This sputtering target for a phase change memory is capable of reducing, as much as possible, impurities that cause the reduction in the number of times rewriting can be conducted as a result of such impurities segregating and condensing in the vicinity of the boundary face of the memory point and non-memory point; in particular, impurity elements that affect the crystallization speed, reducing the compositional deviation of the target in relation to the intended composition, and improving the rewriting properties and crystallization speed of the phase change memory by suppressing the compositional segregation of the target.

Owner:JX NIPPON MINING& METALS CORP

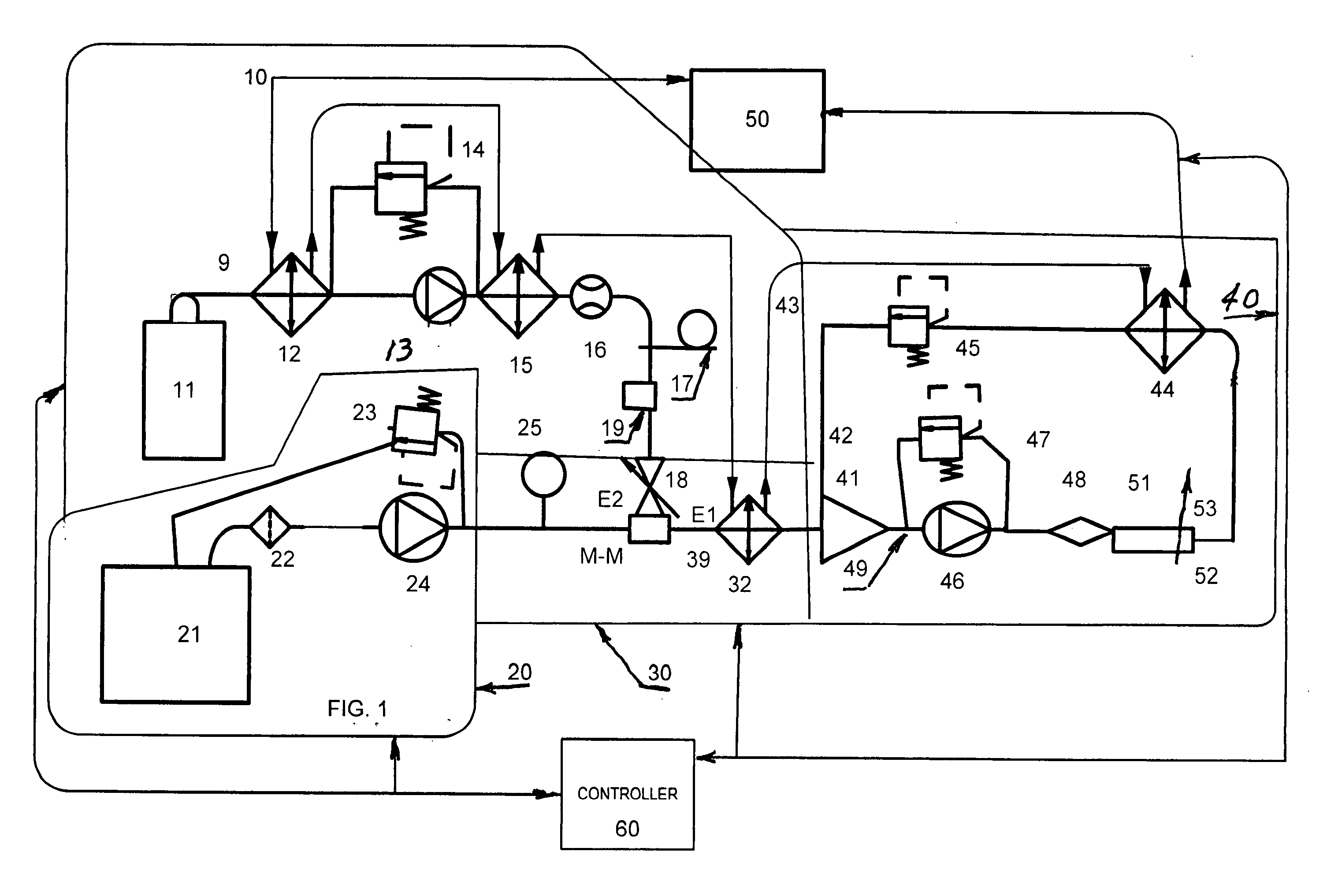

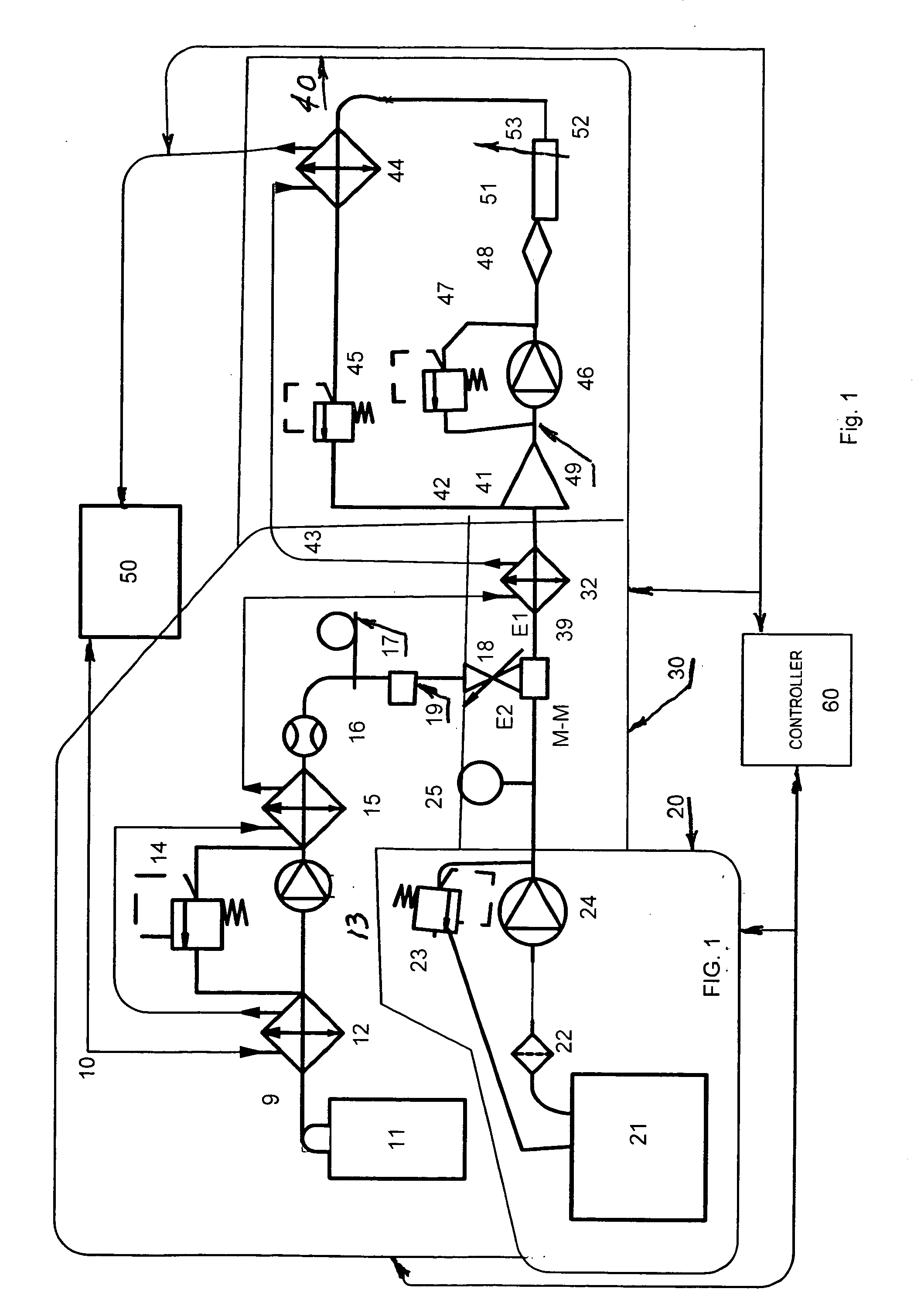

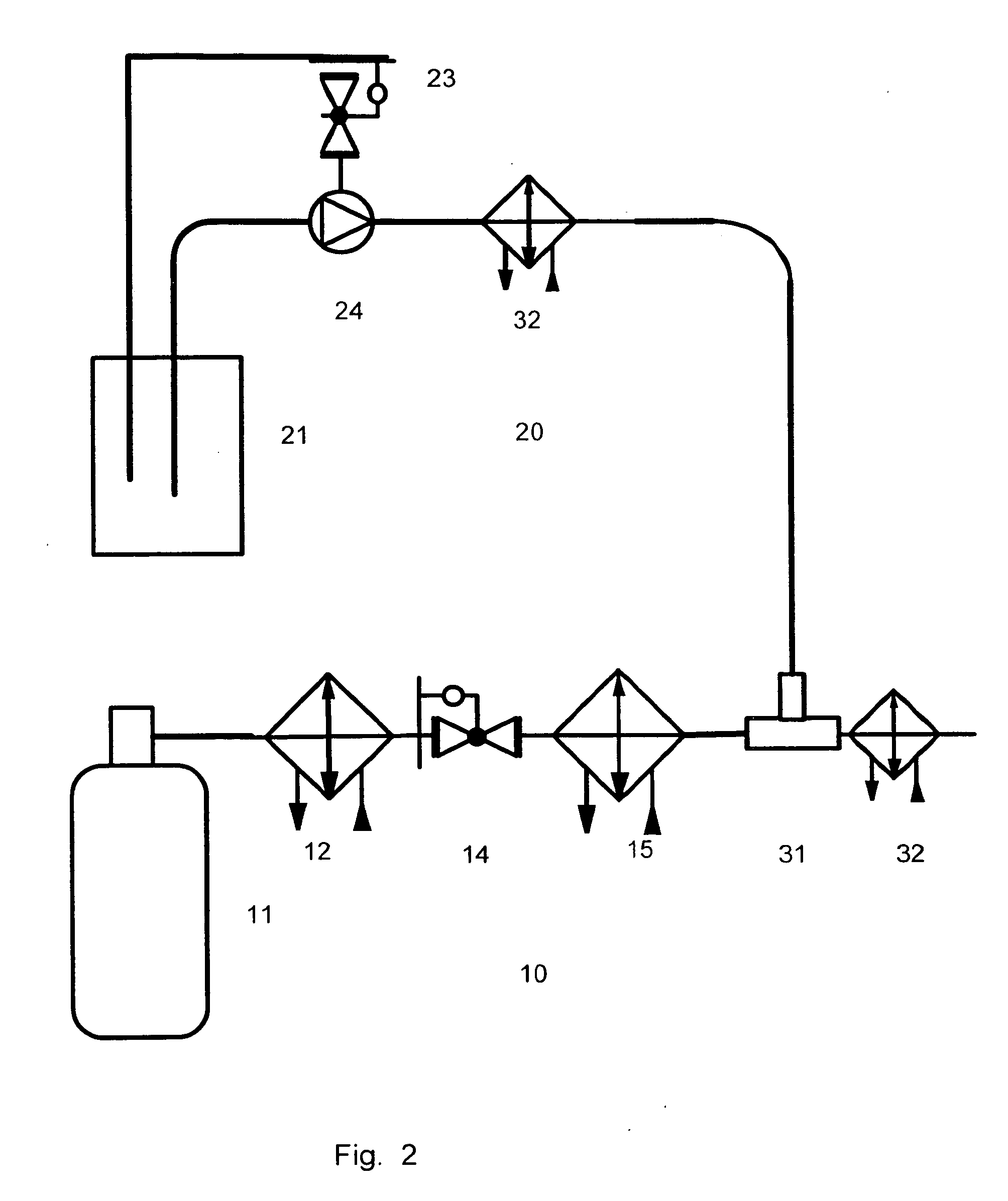

Fuel system and method for burning liquid ammonia in engines and boilers

ActiveUS20100288211A1Easy to igniteImprove combustion characteristicsElectrical controlControlling ratio of multiple fluid flowsCombustion chamberEngineering

A process and apparatus is provided for burning liquid ammonia in an energy device such as a diesel engine, boiler or gas turbine. In particular, the process and apparatus include mixing a renewable fuel with a low flame speed and high ignition temperature, e.g., ammonia, with a combustible liquid fossil or bio-fuel and supplying the mixture into a closed fuel loop where part is efficiently burned in an engine combustion chamber, and part is used to cool the engine and returned by the loop for mixture with fresh incoming fuel mixture. The invention provides for the mixing and emulsifying in such a way that vapour lock is avoided. In the loop, the mixture is emulsified into a disperse distribution of fuel droplets such that upon injection of a portion into the combustion chamber, the renewable fuel in an emulsified droplet evaporates, mixes with the air and forms a small combustion cell surrounding the liquid fuel droplet. The fuel droplet burns and then serves as an ignition kernel for the gas mixture in the small combustion cell producing efficient and rapid combustion of the renewable fuel. The fuel loop allows the fuel system to automatically scale for engines varying in power output from 1 to 35,000 horsepower.

Owner:CAHN RICHARD C +1

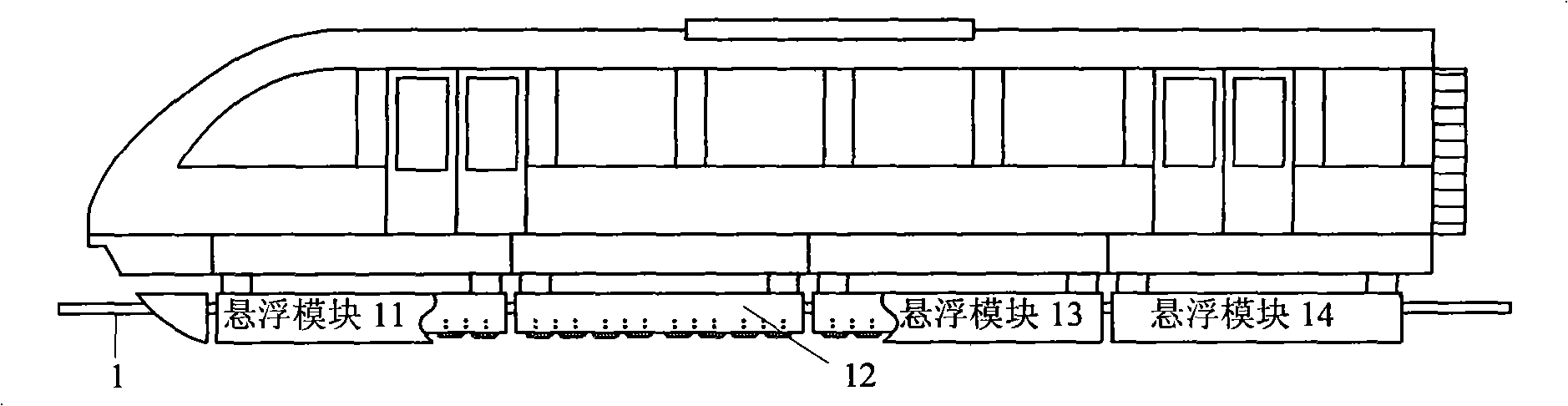

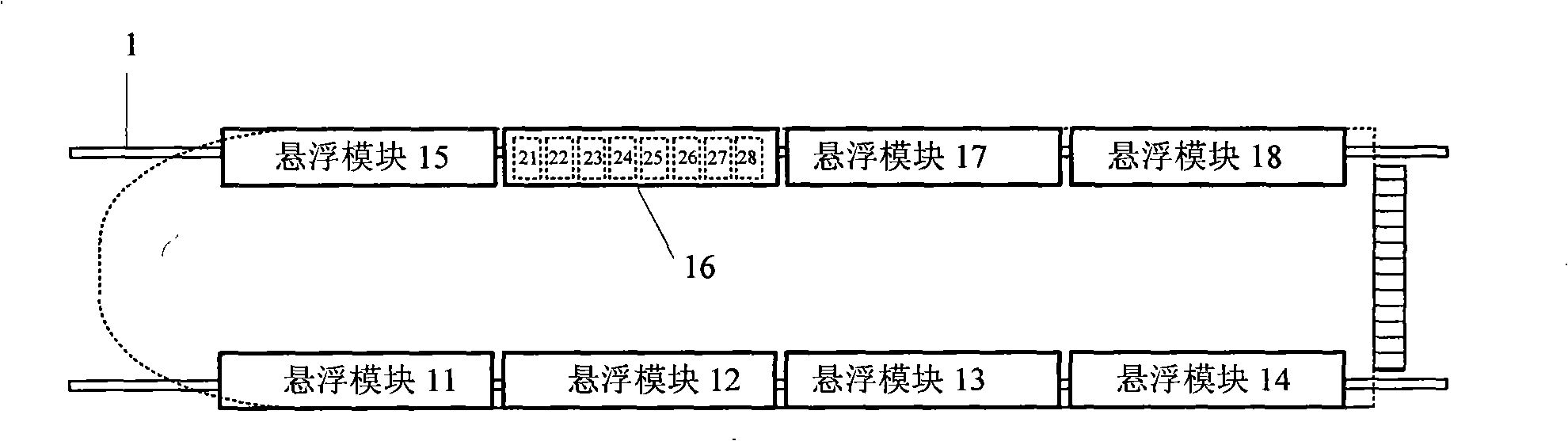

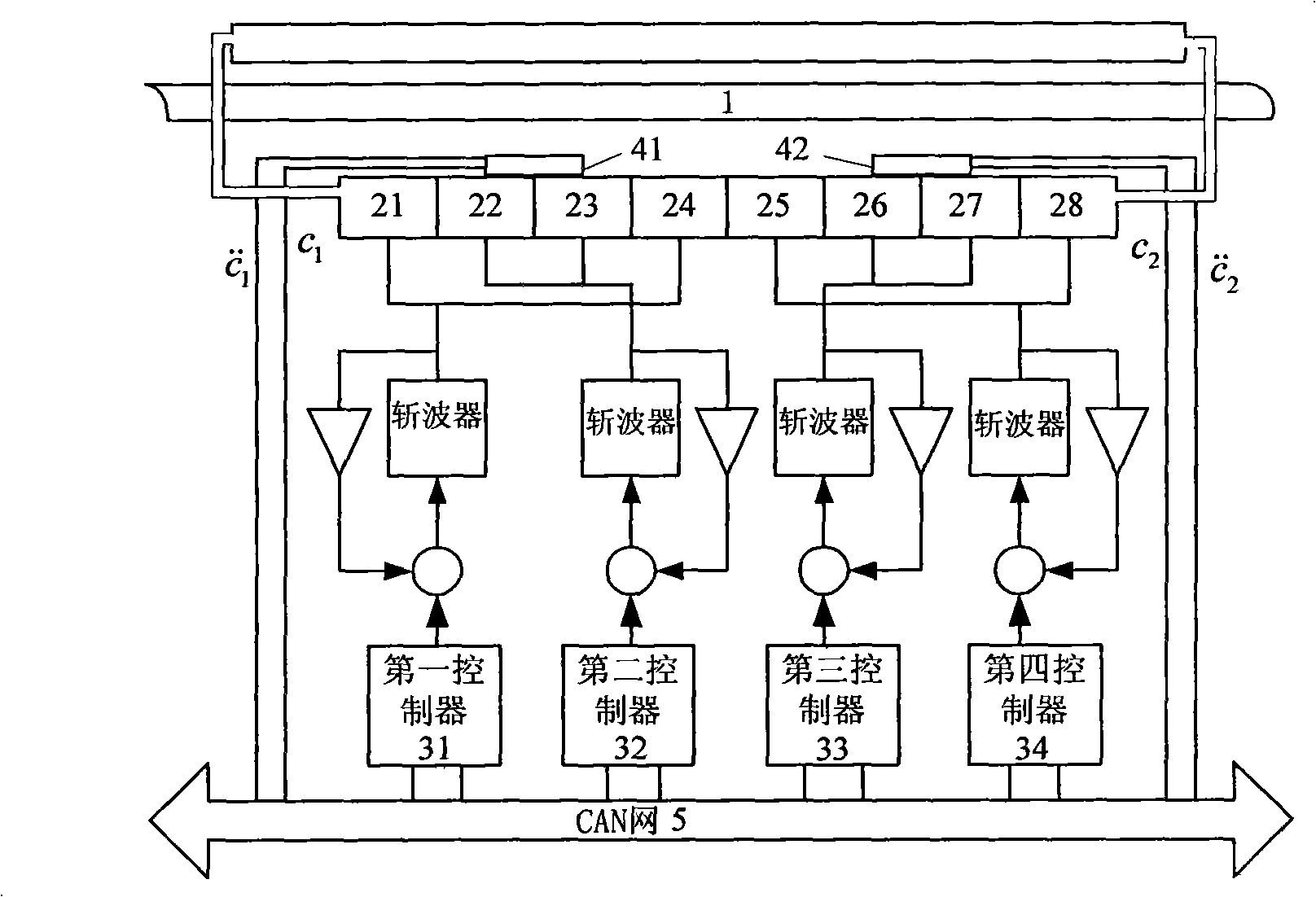

Distributed active fault tolerant control system of electromagnetic type magnetic floating train suspending module

ActiveCN101327747ASuspension stabilityReduce deviationElectric propulsionActive faultMonitoring system

The present invention relates to a distributed active fault-tolerant control system of suspension module of electromagnetic maglev train. The control system comprises 8 electromagnets which are arranged on the suspension module, 4 independent suspension controllers, a first sensor group and a second sensor group; the 8 electromagnets are divided into 4 electromagnet groups; each electromagnet group comprises two electromagnets which are connected in series; each suspension controller is connected with an electromagnet group through a chopper; the first sensor group and the second sensor group are respectively arranged at two ends of the suspension module; the suspension controller, the first sensor group and the second sensor group are connected through a CAN bus; the suspension controller is connected with the vehicle monitoring system of the maglev train. The distributed active fault-tolerant control system of the suspension module of the electromagnetic maglev train can tolerate failures of the controller, the sensor and the actuator in the suspension system, and thus greatly improve the reliability, stability and security.

Owner:NAT UNIV OF DEFENSE TECH

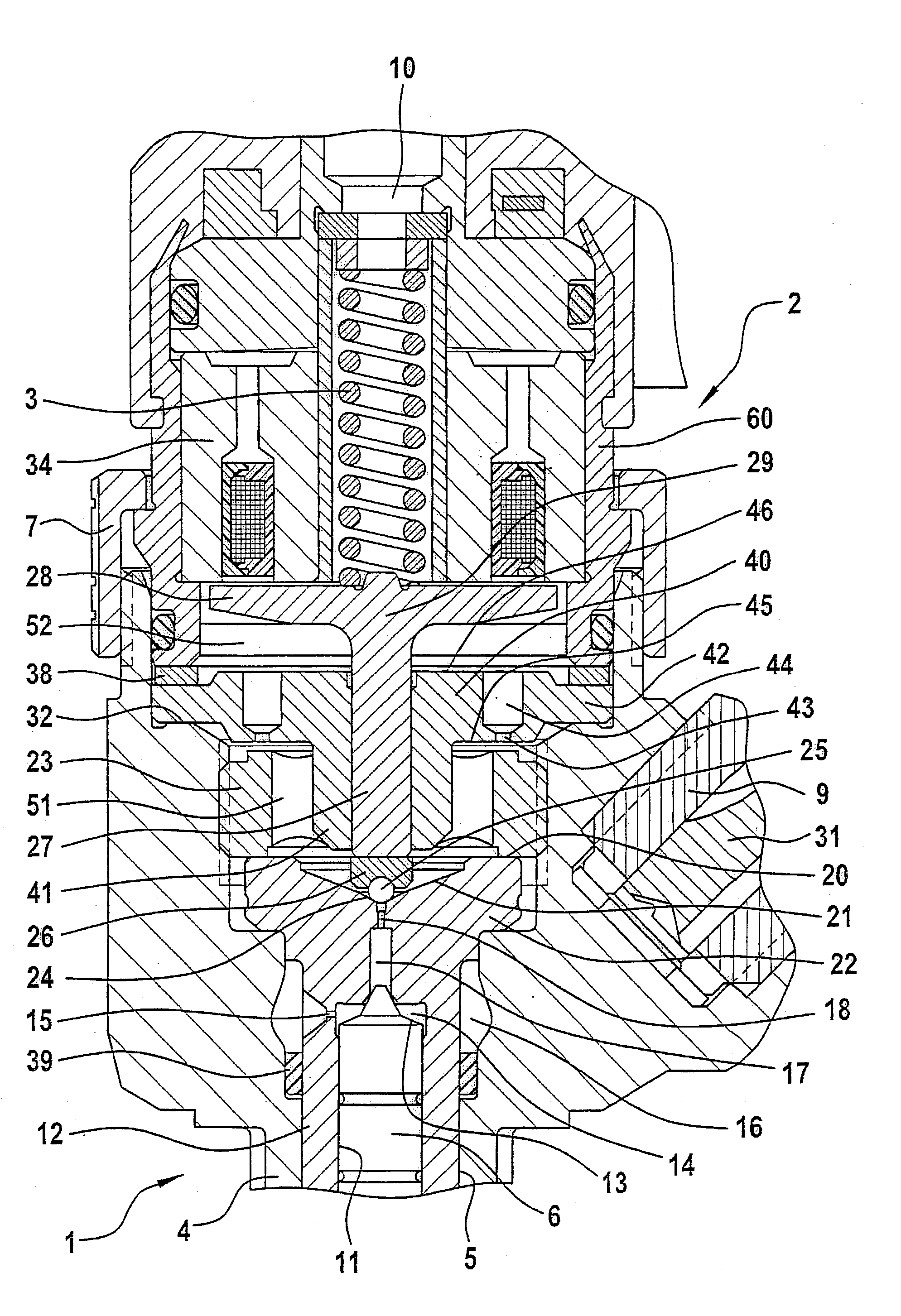

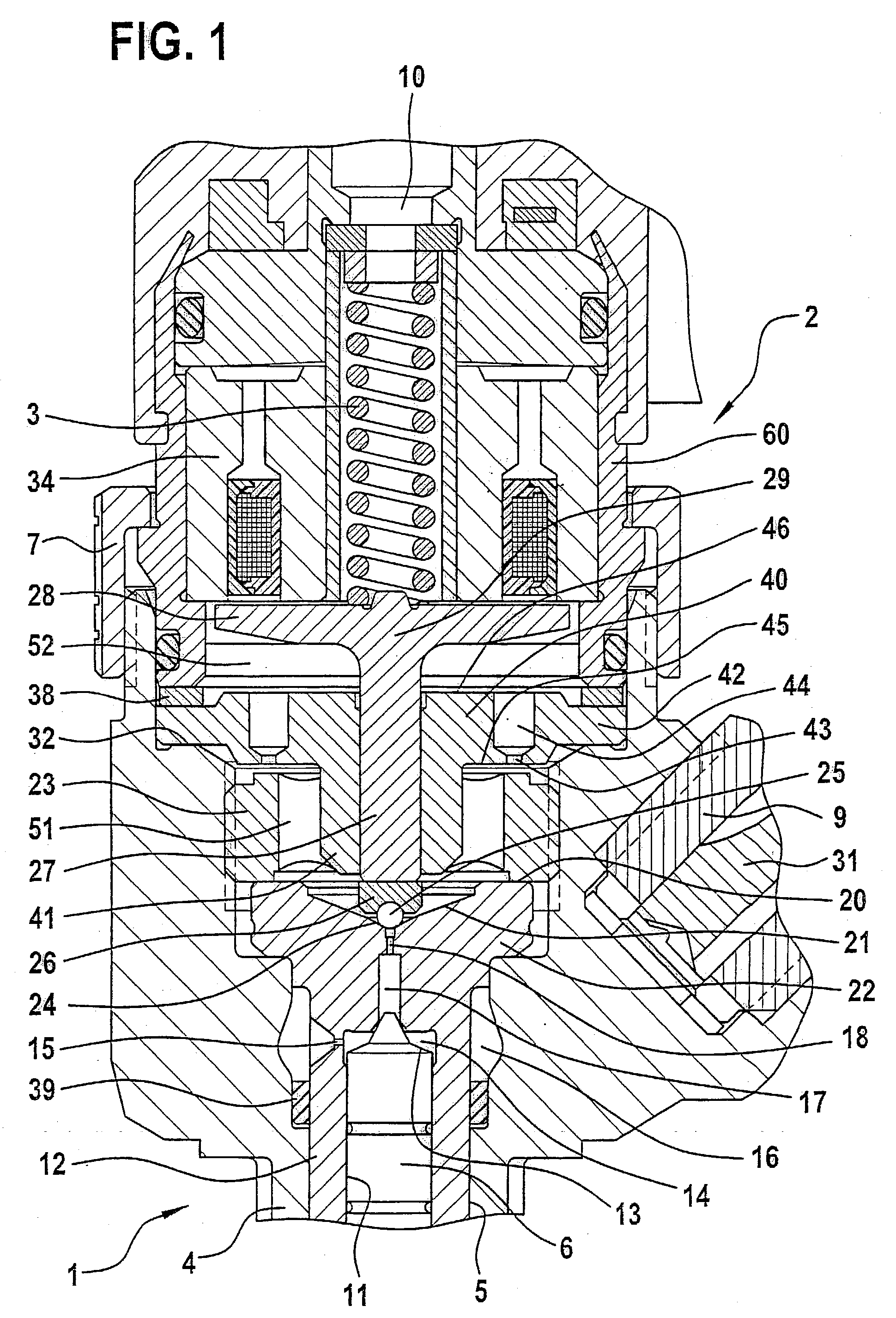

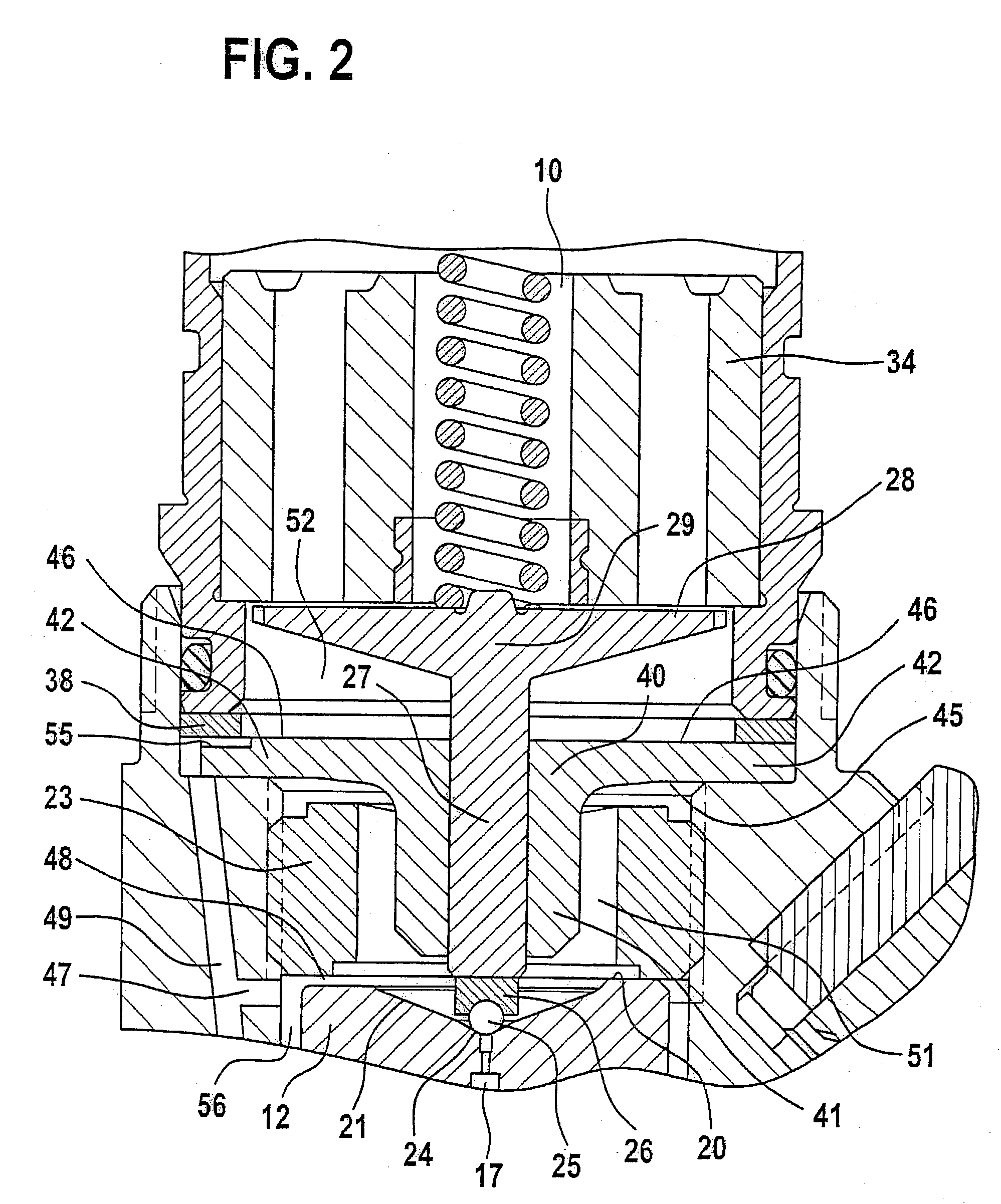

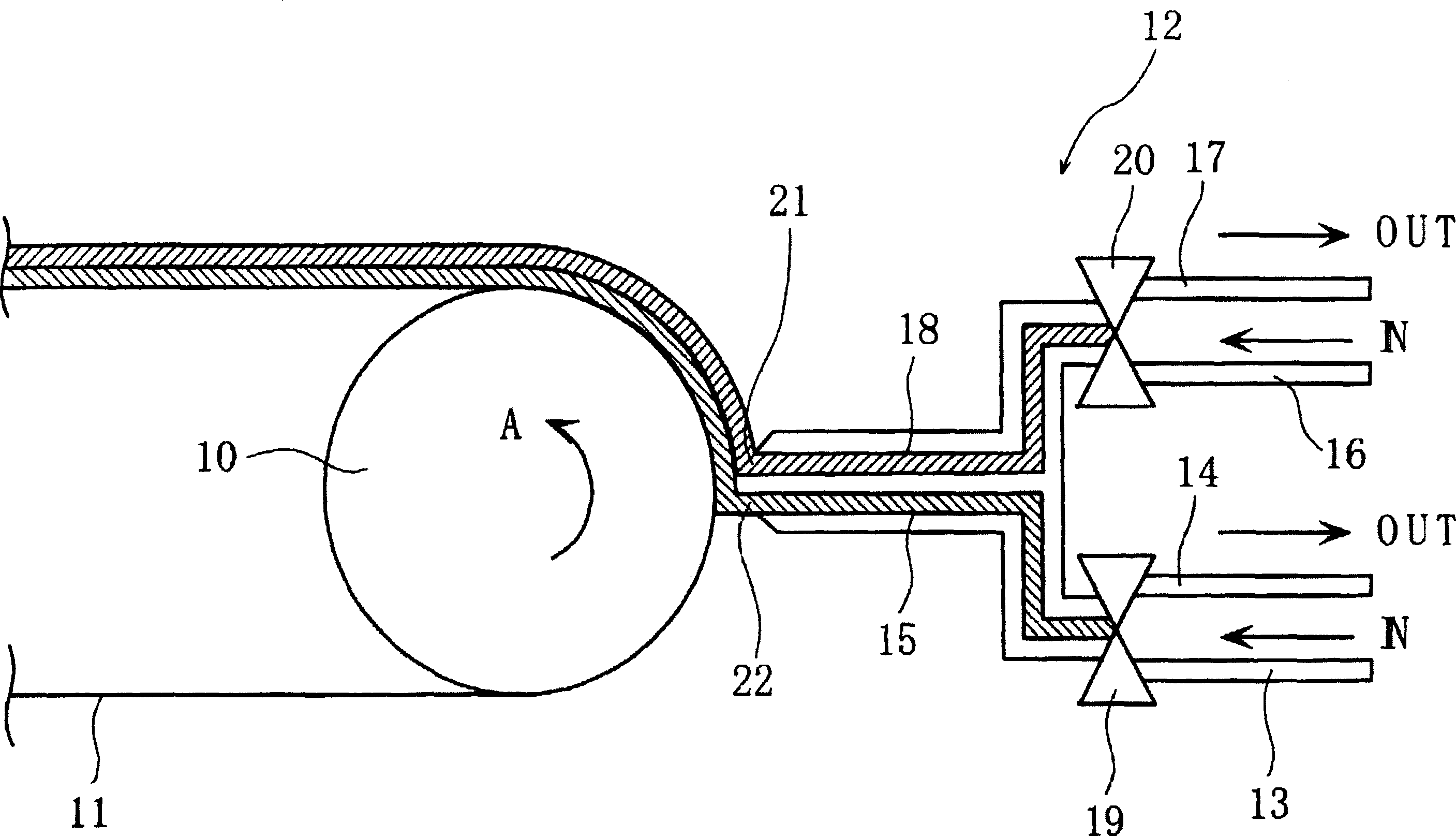

Electromagnetic valve for controlling an injection valve of an internal combustion engine

InactiveUS20030127614A1Quantitative deviationReduce biasOperating means/releasing devices for valvesFluid pressure injection controlExternal combustion engineSolenoid valve

The present invention relates to a solenoid valve (2) for controlling an injection valve (1) of an internal combustion engine, including an electromagnet (34), a movable armature (29), a control valve member (25,26) moved with the armature (29) and cooperating with a valve seat (24) for opening and closing a fuel discharge channel (17) of a control pressure chamber (14) of the injection valve, and a sliding piece (40) guiding the armature (29), which is positioned together with the armature (29) and the control valve member (25,26) in an armature chamber (51,52). For reducing the bounce of the armature, it is proposed that the sliding piece (40) subdivides the armature chamber into a pressure relief chamber (52) connected to a fuel low-pressure connection (10) and an hydraulic damping chamber (51), into which fuel discharge channel (17) opens out, which damping chamber may be pressure-relieved to a pressure relief chamber (52) via at least one connecting channel (44,47) provided with a throttle (43,48), the speed of the control valve member (25,26) being lowered during the closing of solenoid valve (2), before the impact on valve seat (24), by a fuel pressure cushion acting upon the control valve member (25,26) in the damping chamber (51).

Owner:ROBERT BOSCH GMBH

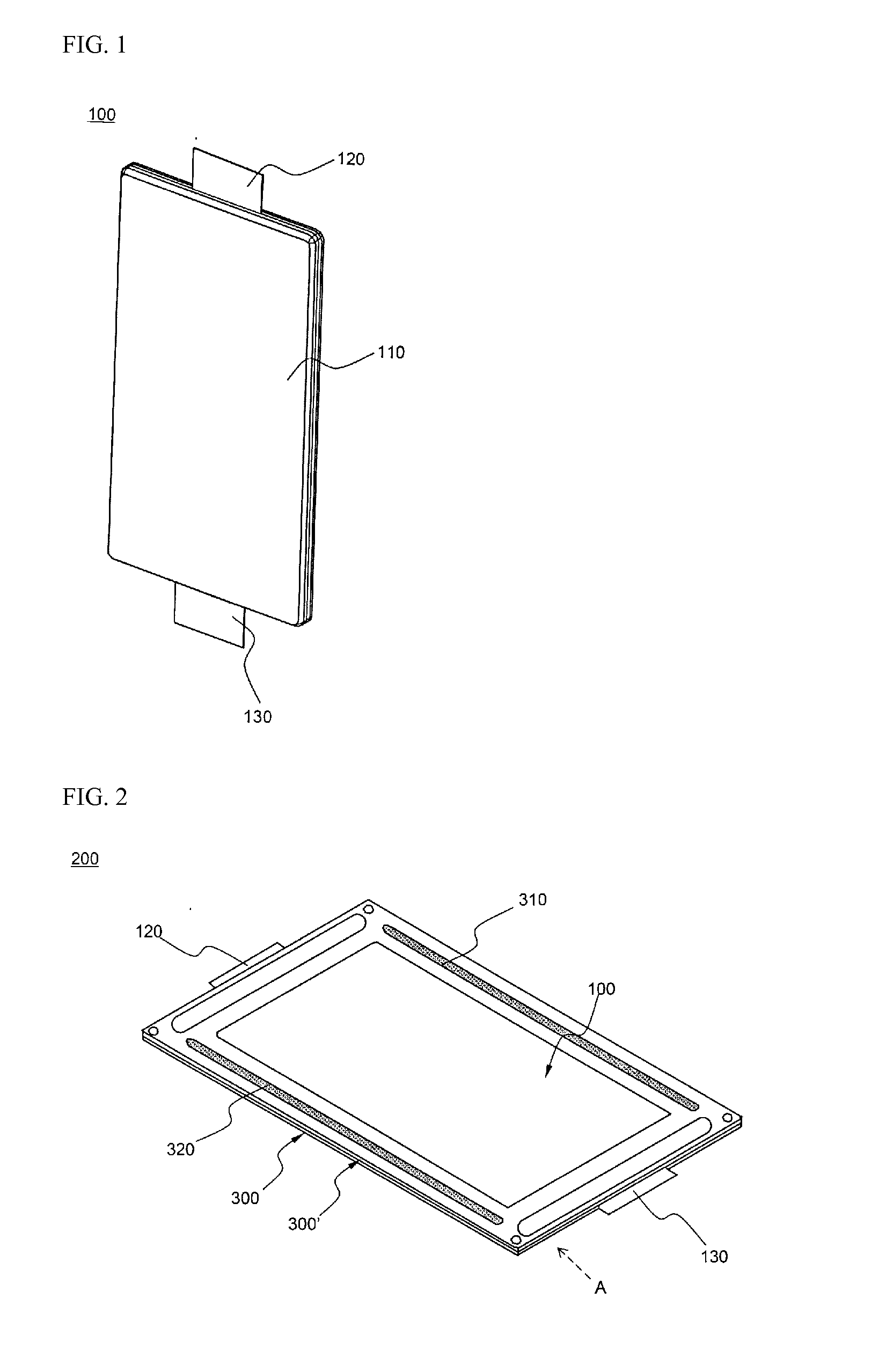

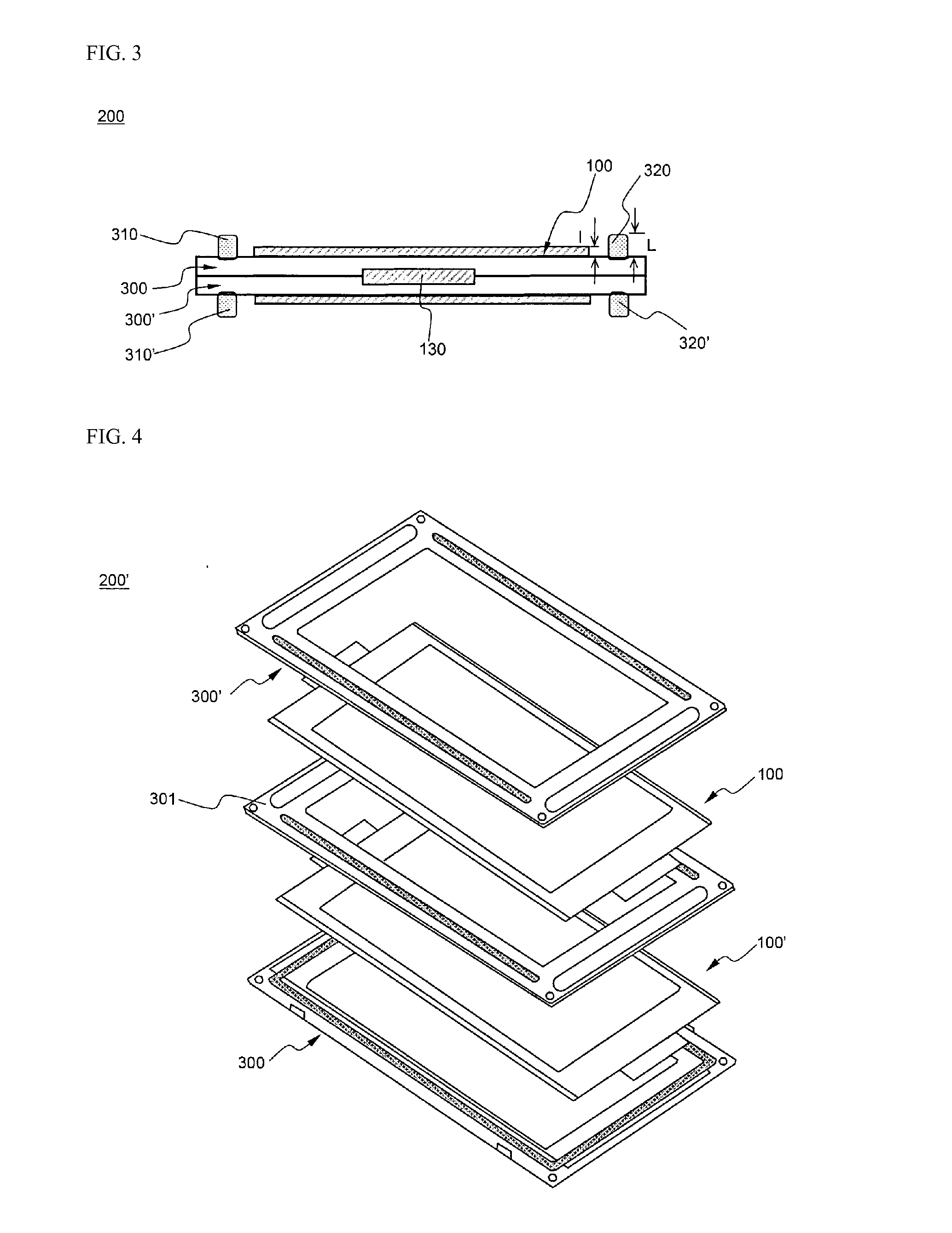

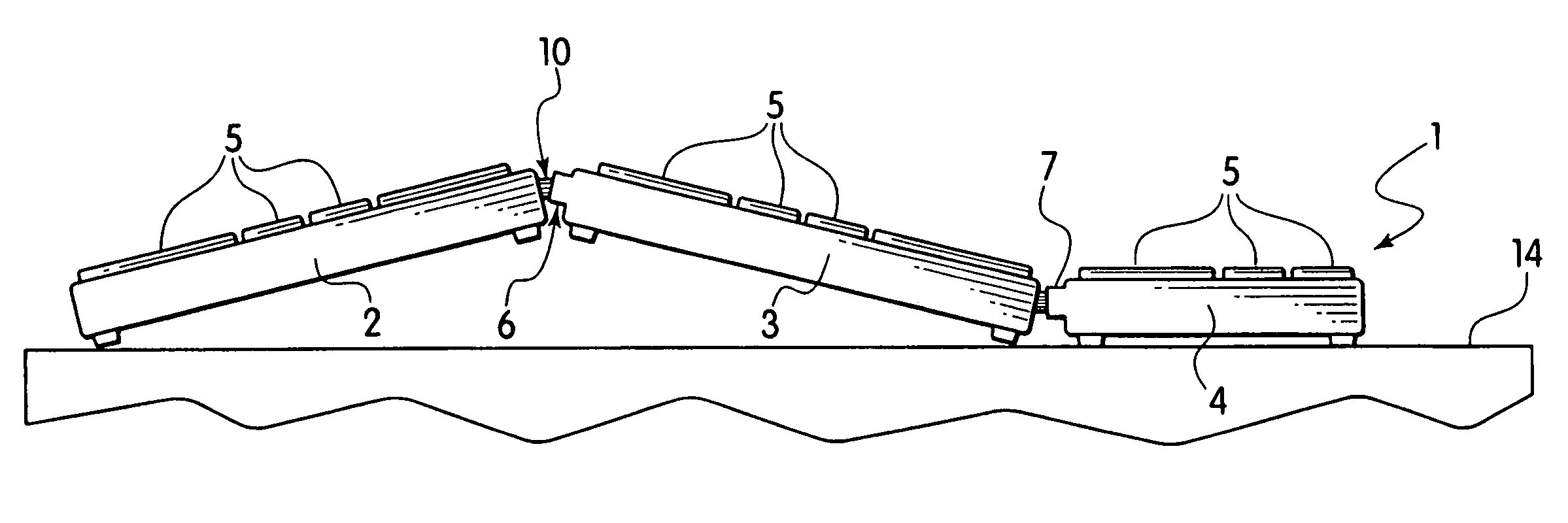

Apparatus and method of manufacturing electrodes, and battery

InactiveCN1905247APrevent deviationReduce performanceLiquid surface applicatorsActive material electrodesEngineeringSlurry

The object of the present invention is to provide an electrode manufacturing method, a manufacturing device, and a battery. It is possible to suppress the reduction in battery performance during normal charging and discharging due to the increase in the internal resistance of the electrode, and at the same time to improve the overcharge characteristics, and to suppress the occurrence of deviation between the active material layers and the adhesion between the active materials. reduce, or increase manufacturing costs. Two active material layers ( 2, 3) In the electrode manufacturing method, the above-mentioned plurality of active material slurries are sequentially laminated and coated on the surface of the current collector in a wet state, and then all the active material slurries are dried.

Owner:SANYO ELECTRIC CO LTD

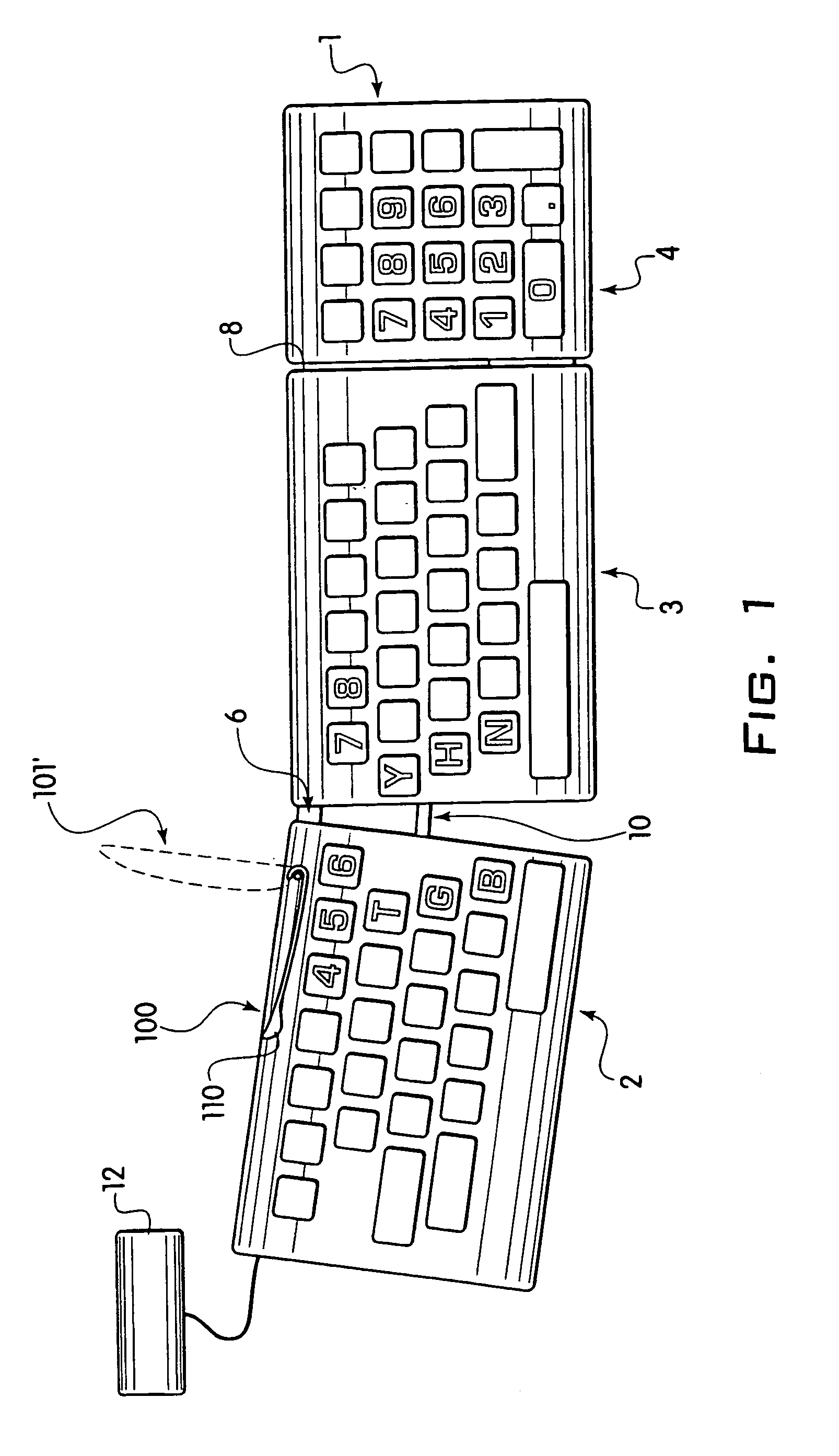

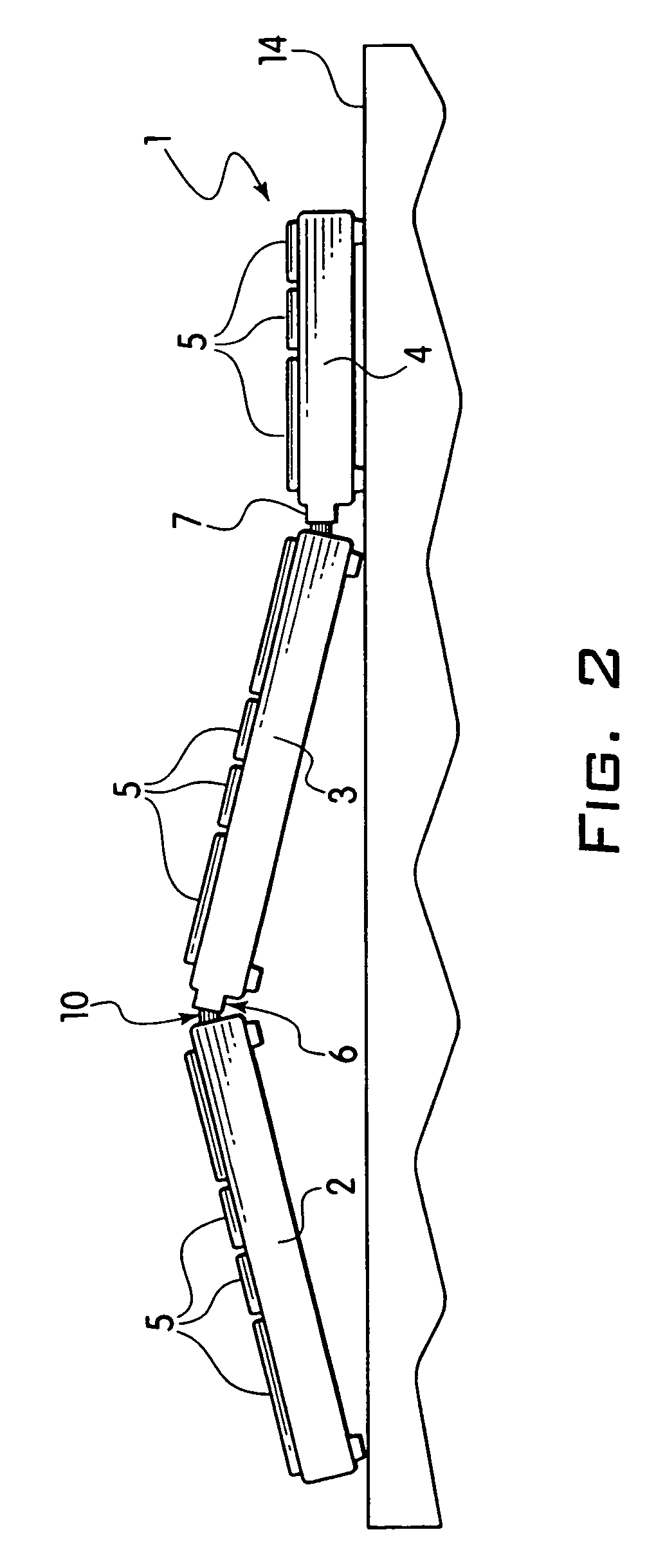

Adjustable keyboard with adjusting and locking mechanism, and method of its use

InactiveUS6984081B1Simple and inexpensive to manufactureEasy to assembleInput/output for user-computer interactionOther printing apparatusLocking mechanismPronations

The invention relates to an adjustable keyboard to be used, for example, at a computer terminal (12). The preferred embodiment is in the form of a keyboard having a number of keys (5), the keyboard being formed in at least two segments (2, 3) which are mutually movable relative- to one another using a hinge or joint (6). Each of the segments (2, 3) of the keyboard has mounted thereon some of the keys (5). The relatively movable nature of the keyboard aims at reducing stress and discomfort to the user by eliminating contortion to the user's wrists. More particularly, discomfort to the user caused by pronation of the wrists and / or ulnar deviation of the wrists is reduced. The hinge or joint (6) may be in the form of a ball and socket-type joint with a locking mechanism, which preferably includes a pivoted handle (100), in the form of a lever, used for locking and unlocking the hinge or joint (6).

Owner:KEY OVATION

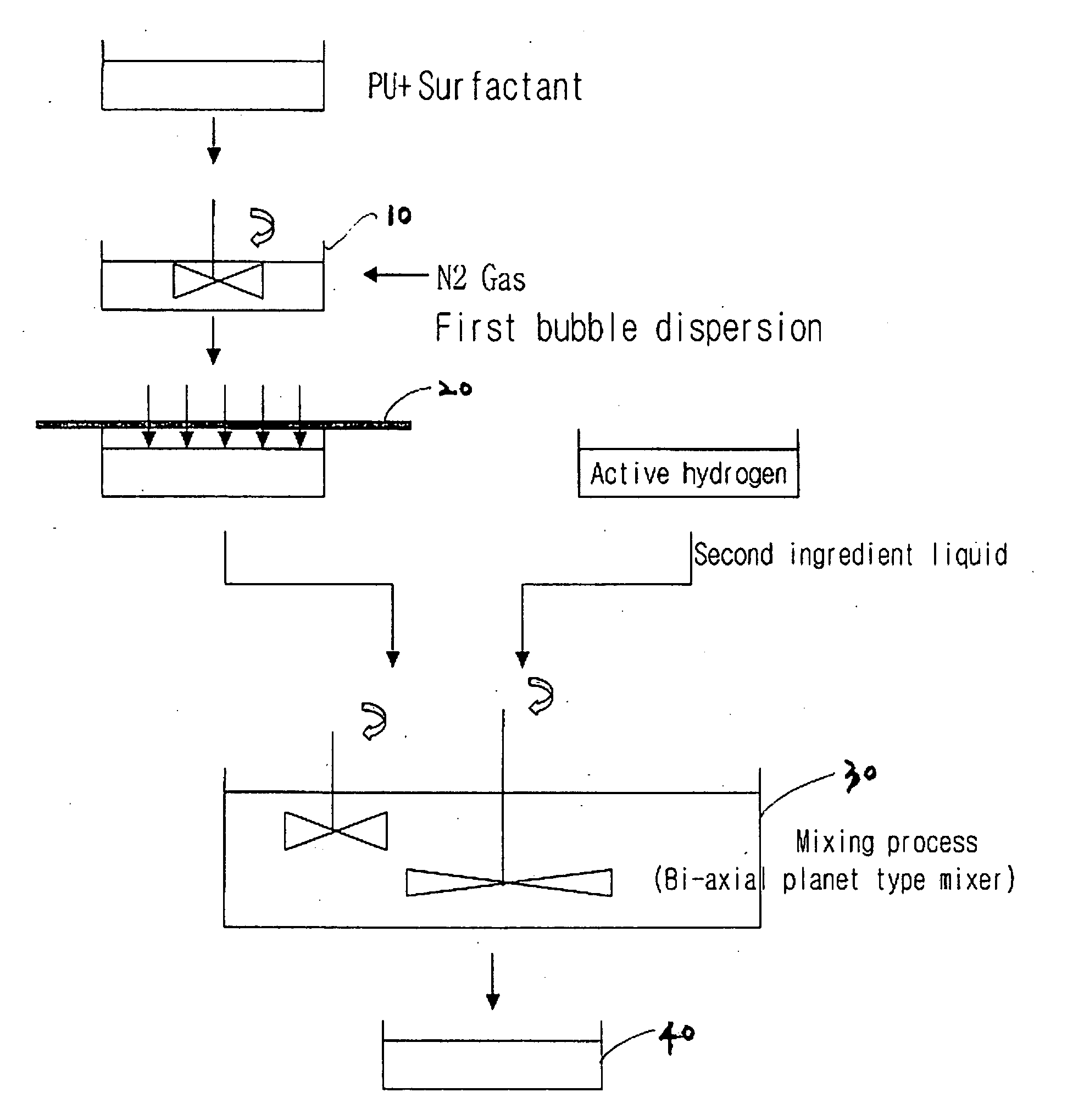

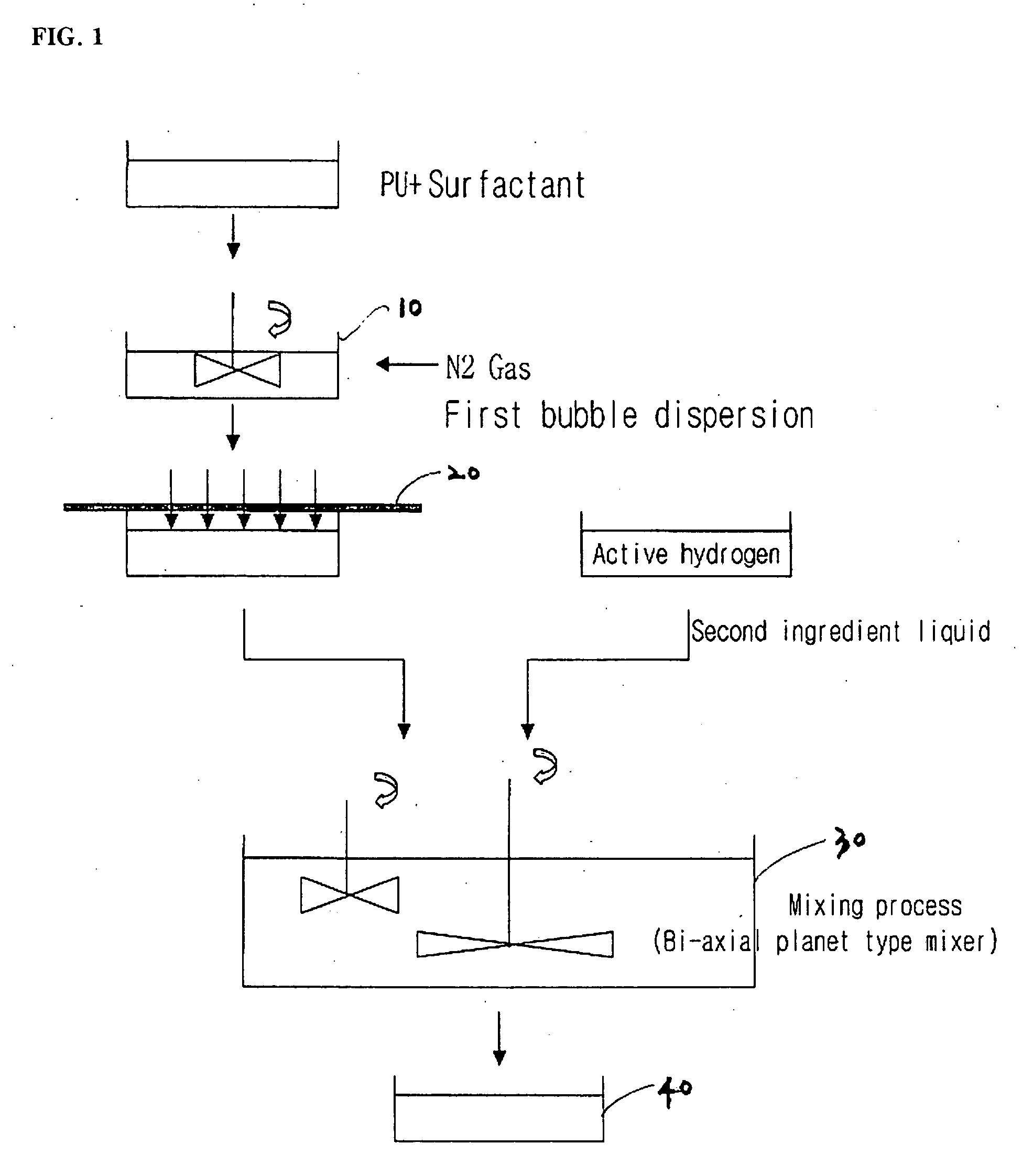

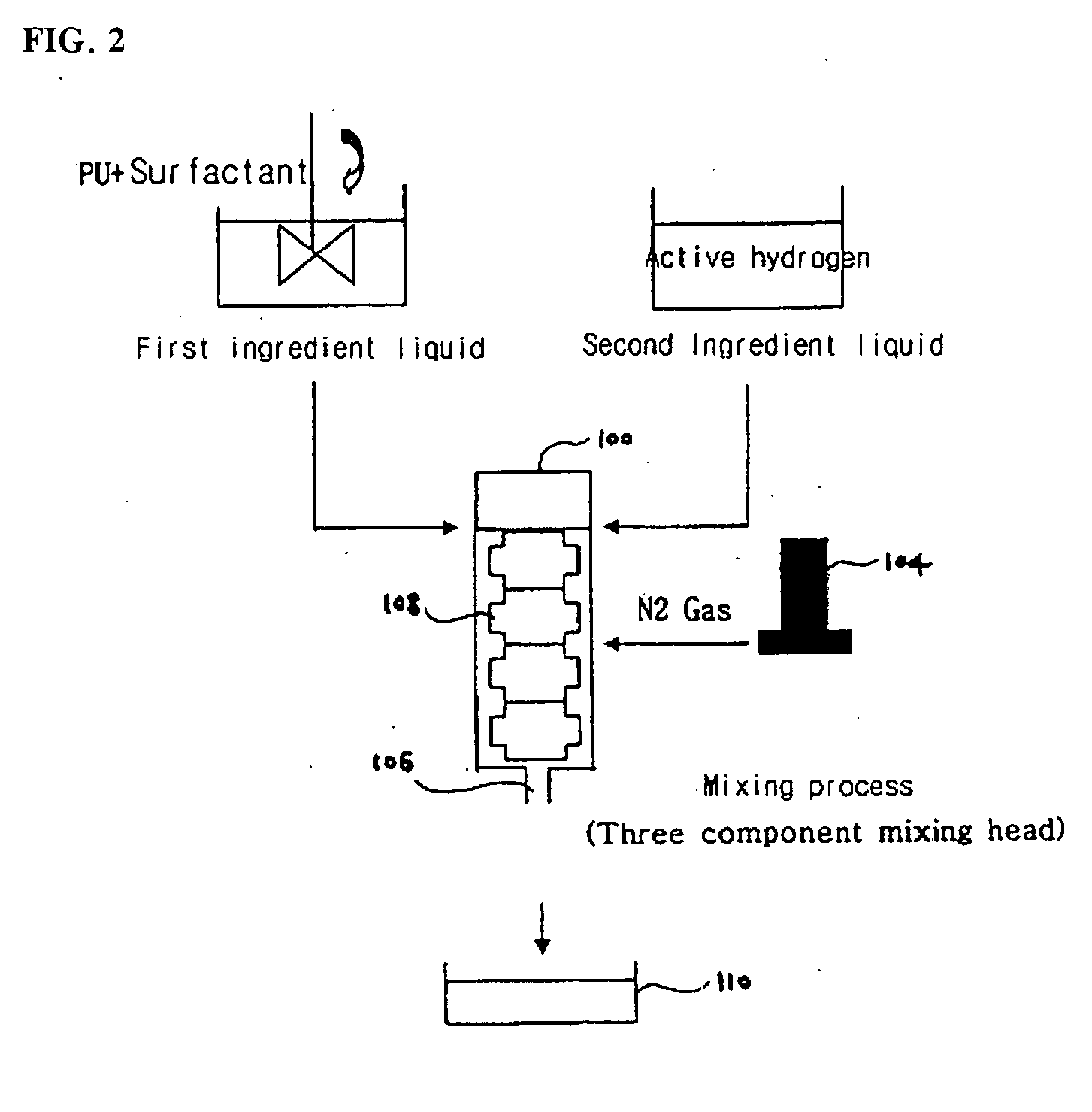

Method of fabricating polyurethane foam with micro pores and polishing pad therefrom

InactiveUS20060022368A1Good flexibilitySimplify the manufacturing processSemiconductor/solid-state device manufacturingFlexible-parts wheelsHydrogenAdditive ingredient

To provide a method of fabricating a polyurethane foam with micro pores, and a polishing pad therefrom, the method including steps of (a) adding a nonionic surfactant into at least one of a first ingredient including an isocyanate group-containing compound and a second ingredient including an active hydrogen group-containing compound, (b) agitating and mixing the mixture of the first ingredient and the second ingredient while adding a non-reactive gas thereto, (c) discharging the mixture out of a container at a predetermined rate, and (d) injecting the discharged mixture into a mold so as to form a mold body into a predetermined shape.

Owner:DONG SUNG A & T

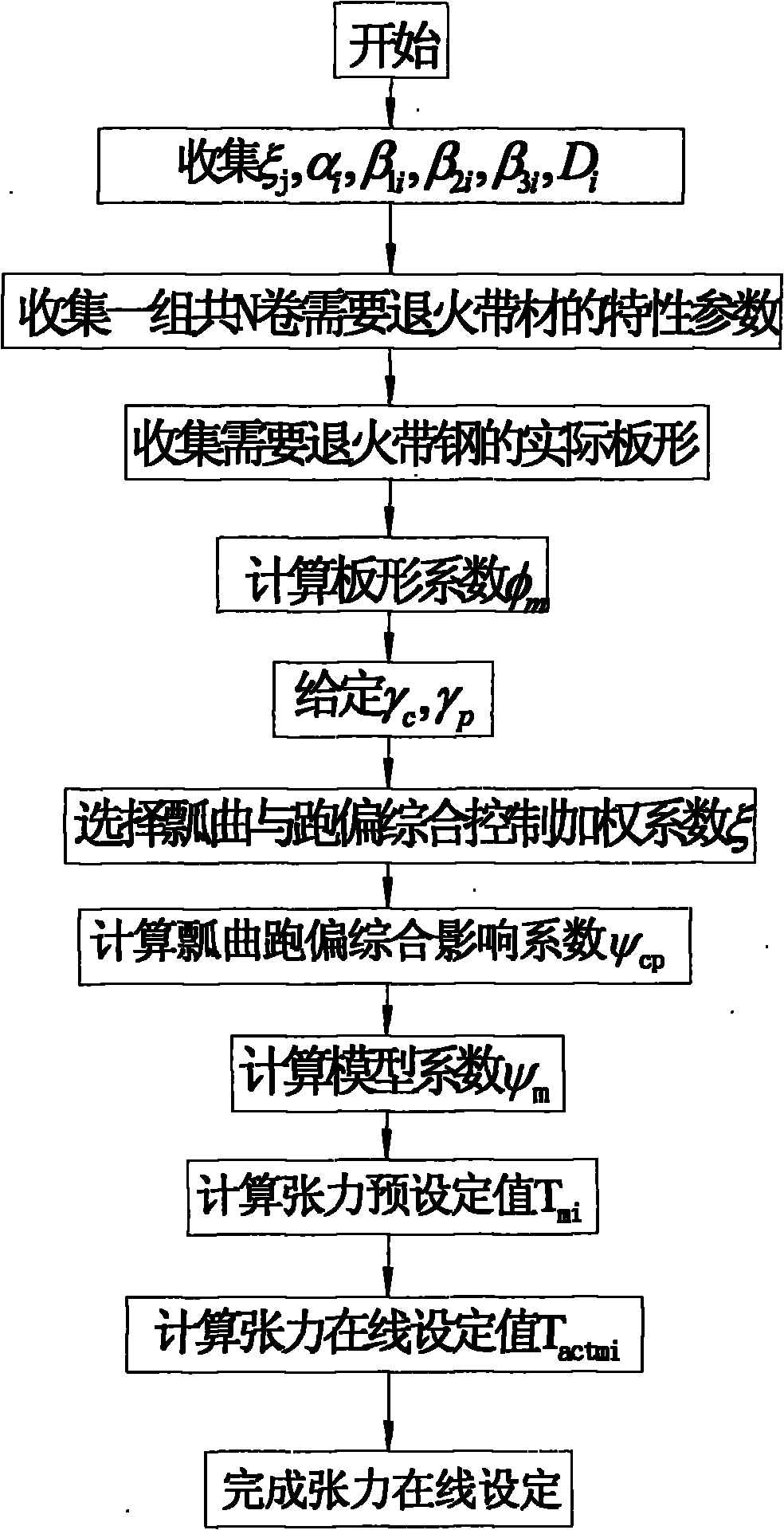

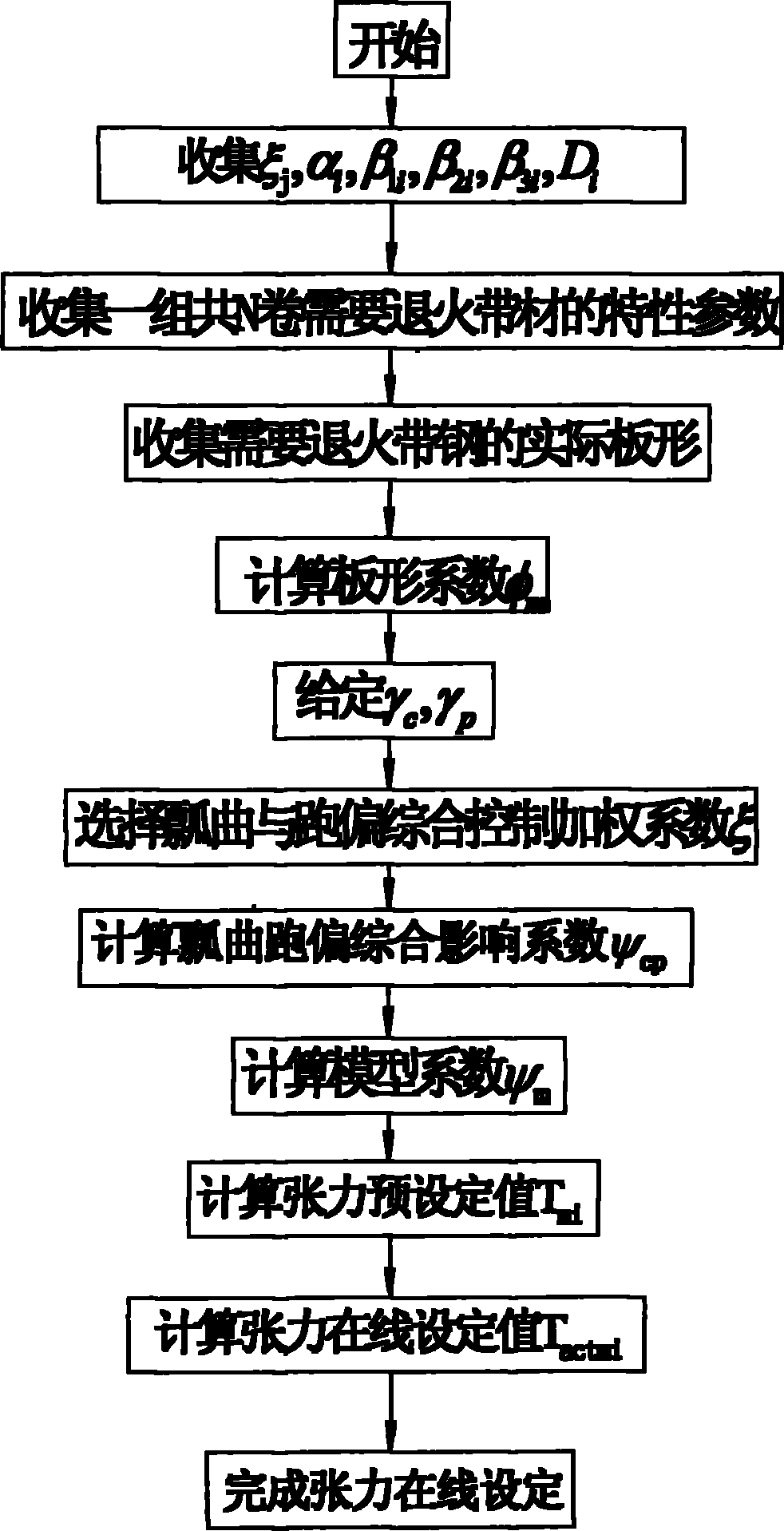

Method for setting in-furnace tension of continuous annealing unit on line

ActiveCN102004812AImprove stabilityReduce deviationFurnace typesSpecial data processing applicationsThermal bucklingContinuous annealing

The invention relates to a method for setting the in-furnace tension of a continuous annealing unit on line. The method comprises the following steps of: collecting the equipment structural characteristic influence coefficient and the sectional influence coefficient of a continuous annealing furnace and the furnace roller diameter of each section of the continuous annealing furnace; calculating a model coefficient in consideration of the influences of deviation, buckling and plate shape; calculating a preset value of the in-furnace tension of the continuous annealing unit; and putting the set value Tactmi of the in-furnace tension of the continuous annealing unit into the operation of the unit so as to finish the steps of setting the tension on line and the like. The method mainly has the advantages that: (1) by adopting a tension optimization model, the type and the specification of steel and the influence of the plate shape of an actually-supplied material are considered, namely one more dimension is considered; (2) actual equipment characteristics and an annealing process regulation can be completely combined by the tension model; and (3) in consideration of the problem of the comprehensive treatment of thermal buckling and deviation, the tension model is more flexible and more practical than a fixed table, and the model is simple and can be applied on line.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com