Patents

Literature

163 results about "Steckel mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

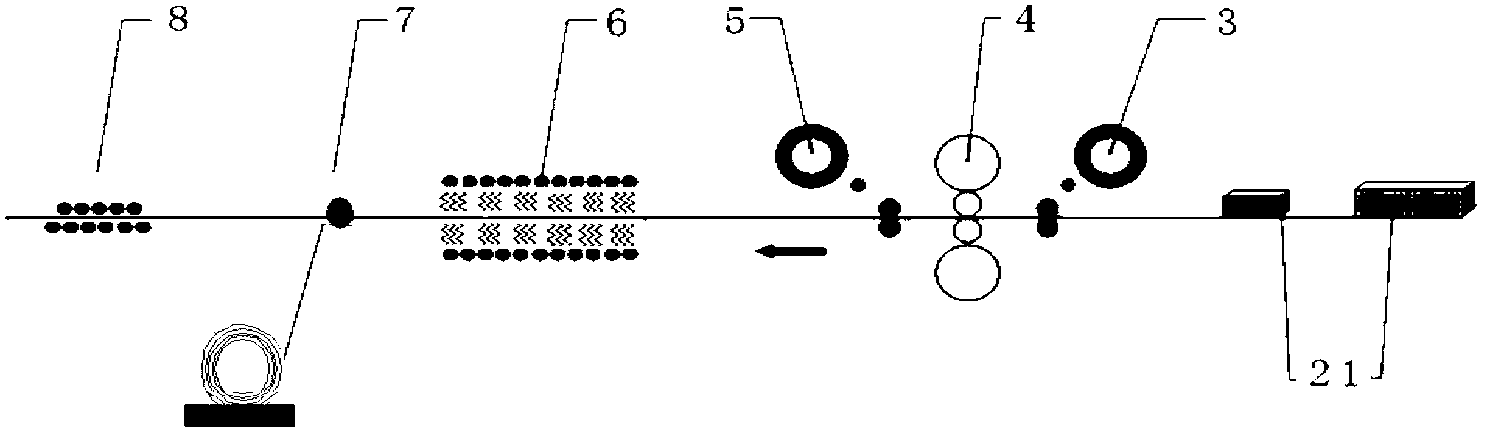

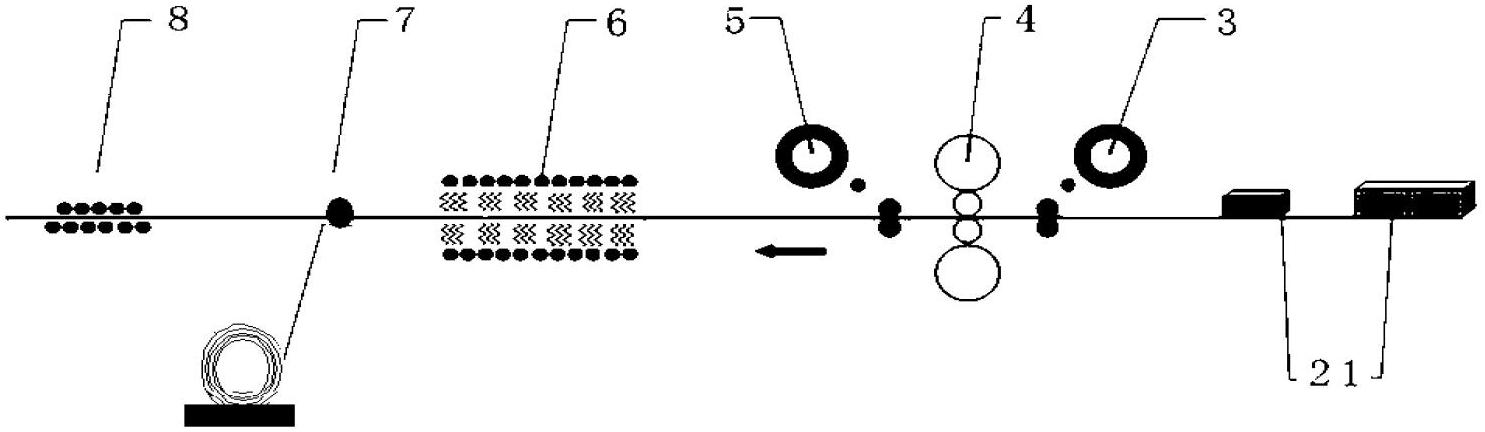

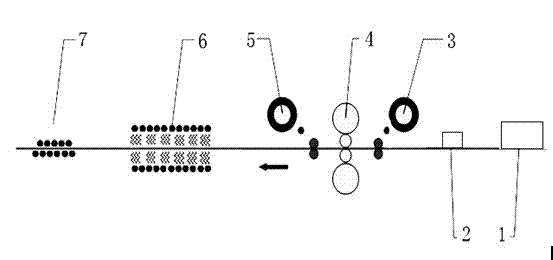

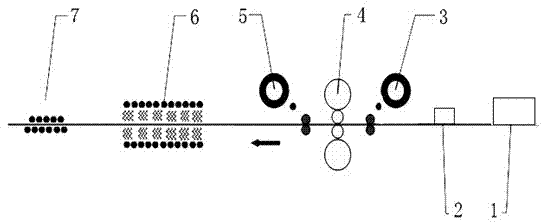

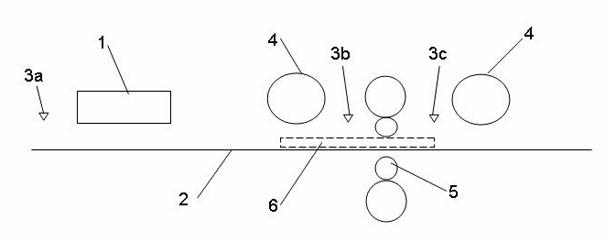

A Steckel mill, also known as a reversible finishing mill, is similar to a reversing rolling mill except two coilers are used to feed the material through the mill. One coiler is on the entrance side and the other on the exit side. The coilers pull the material through the mill, therefore the process is more similar to drawing than rolling. The material is fed back and forth through the mill until the desired thickness is reached, much like a reversing rolling mill.

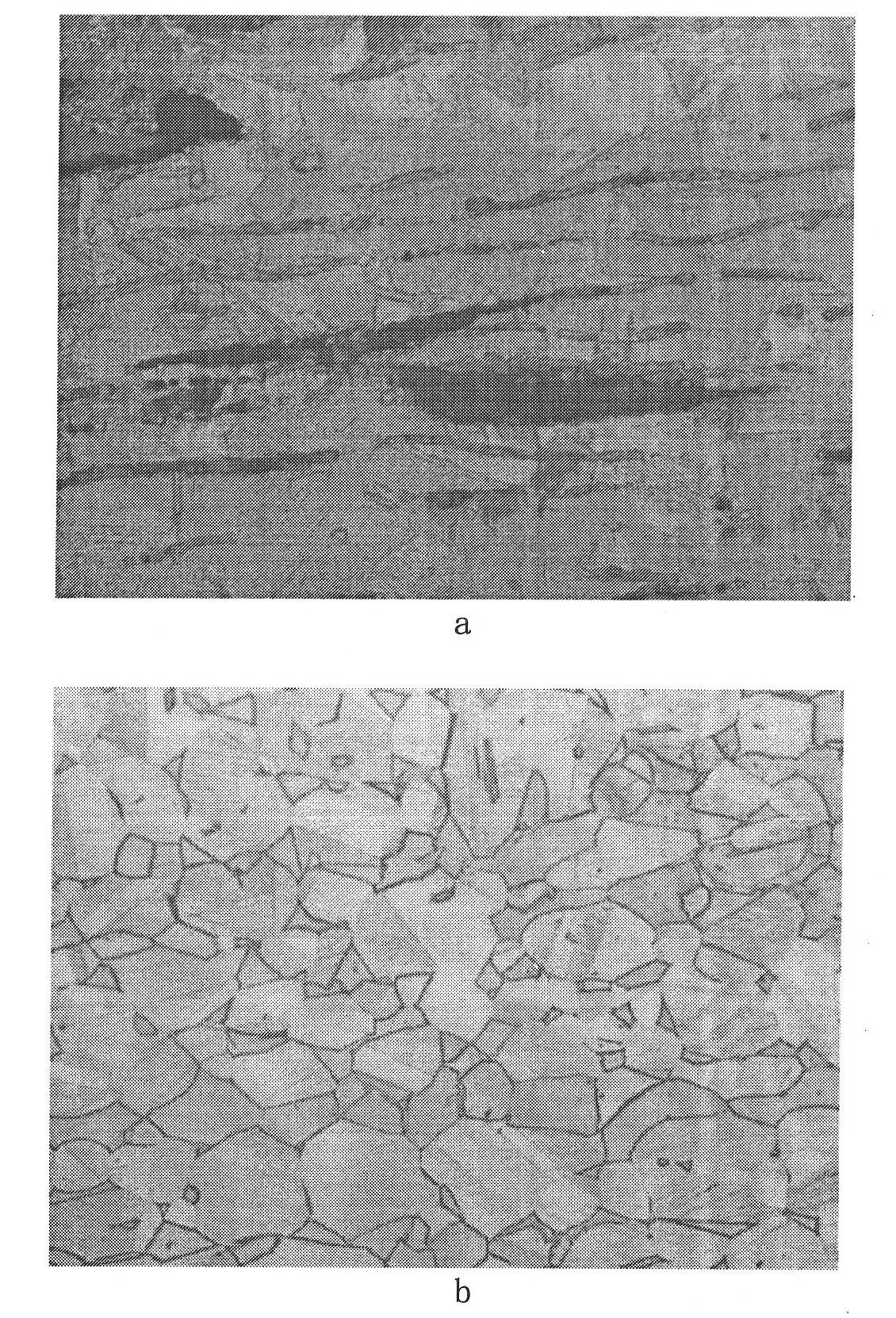

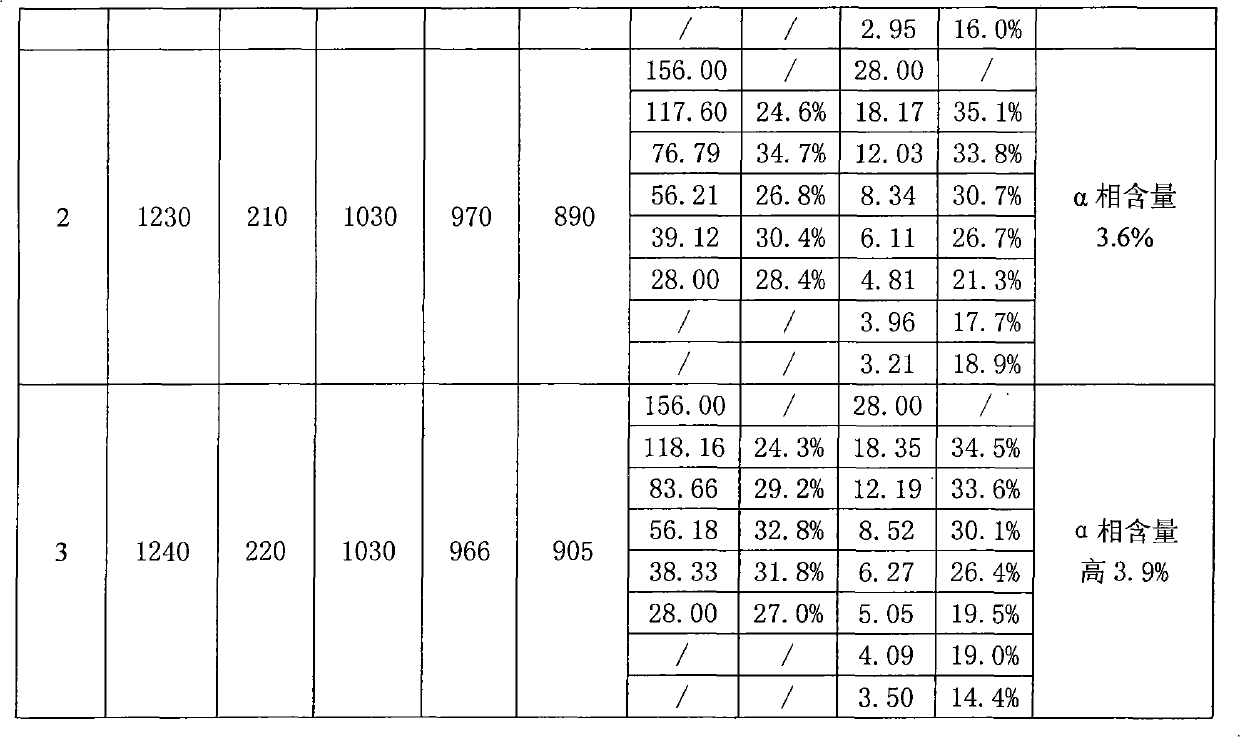

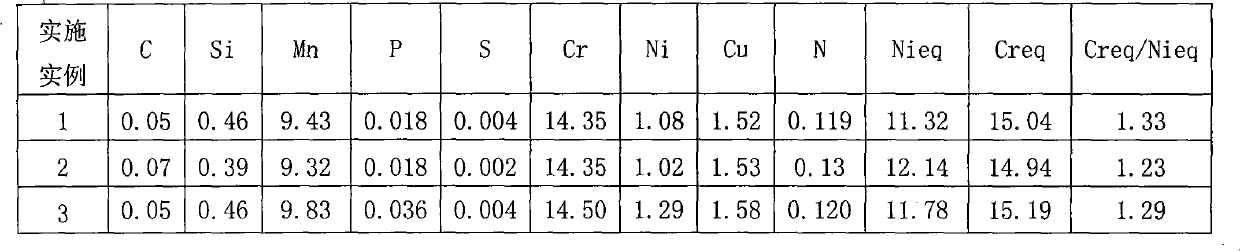

Production technology for inhibiting nickel-saving austenitic stainless steel hot-rolled plate edge crack

InactiveCN101947549AImprove plasticityEliminate edge cracksTemperature control deviceHeat treatment process controlSS - Stainless steelHeating temperature

The invention relates to production technology for inhibiting nickel-saving austenitic stainless steel hot-rolled plate edge crack, which comprises the following steps of: smelting and continuous casting, grinding plate blanks, heating blanks, rolling and the like. By controlling N content in steel below 0.13 percent, controlling Creq / Nieq within 1.35, controlling alpha-phase content in a casting blank texture within 4 percent, setting the reasonable heating temperature of plate blanks by combining on-site reality, and adopting the plate blank one-pass descaling box and frame final-pass descaling descaling technology, in particular the rolling technology of tightly combining hot-rolled rolling pass deformation and blank temperature, the production technology has the advantages of avoiding the edge crack of the produced stainless steel hot-rolled plates, obviously improving the yield, solving the problem of edge crack quality for steel coils in the rolling process through a steckel mill, guaranteeing the edge quality of the hot-rolled steel coils and improving the width yield of finished rolled plates.

Owner:SHANDONG TAISHAN STEEL GROUP

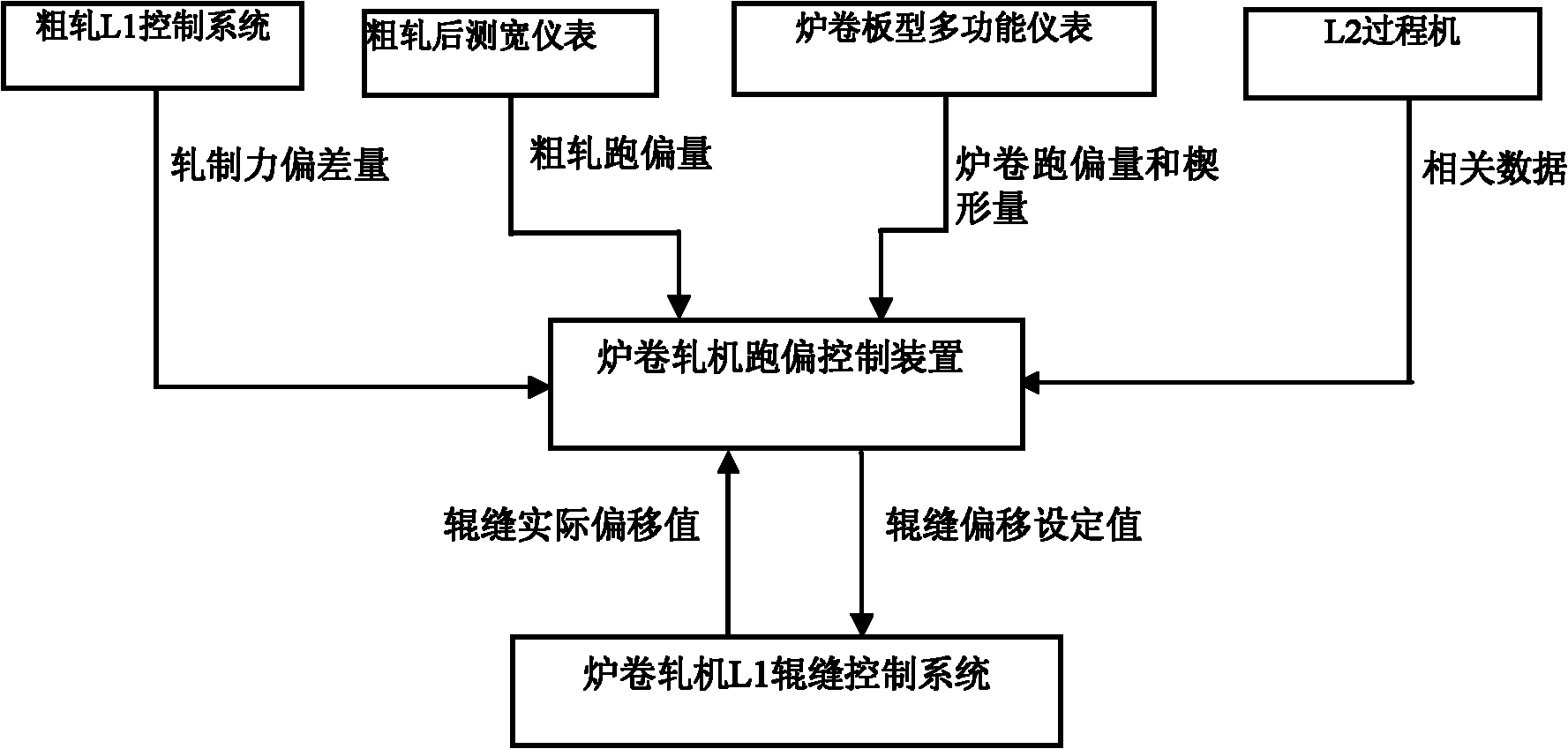

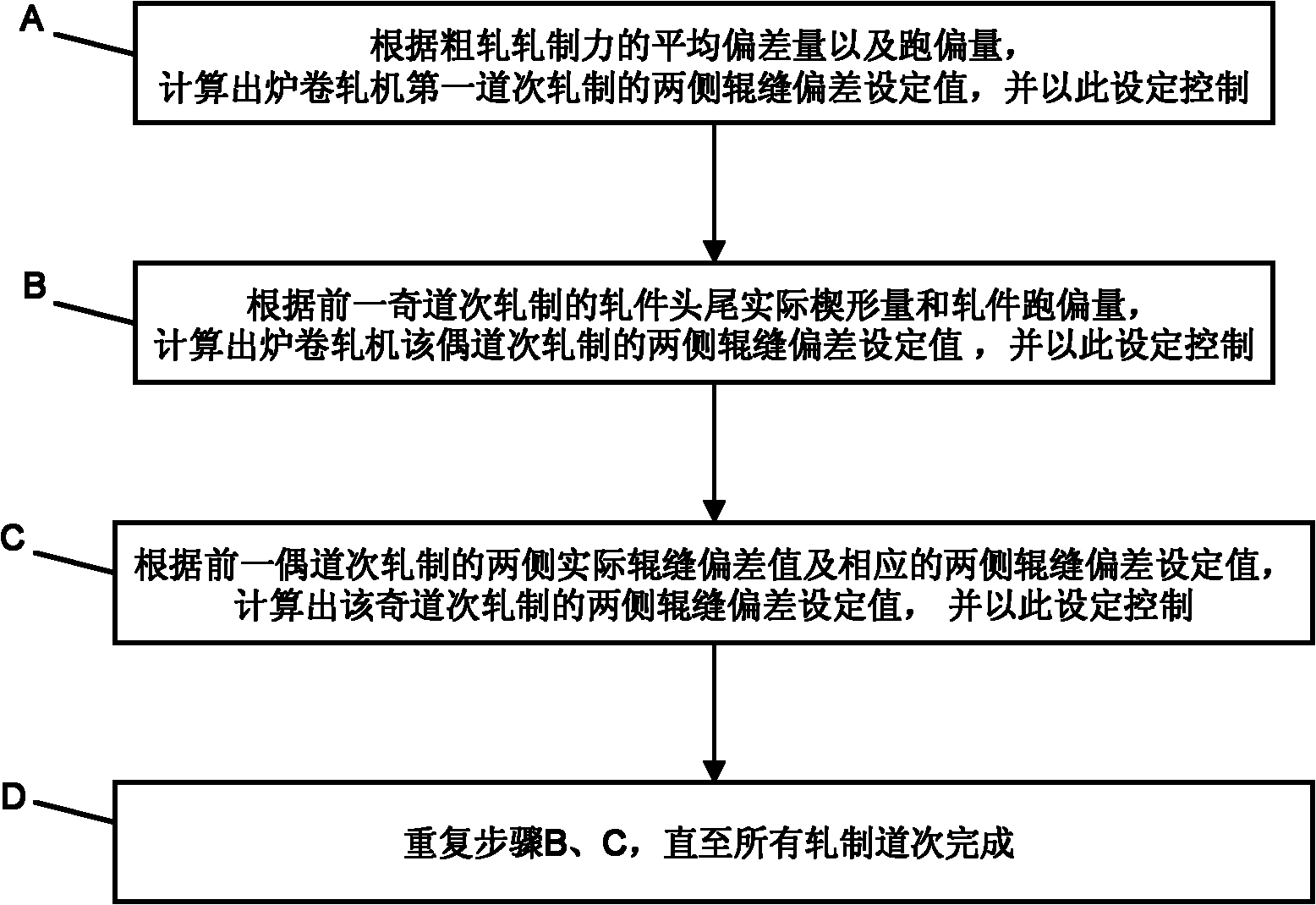

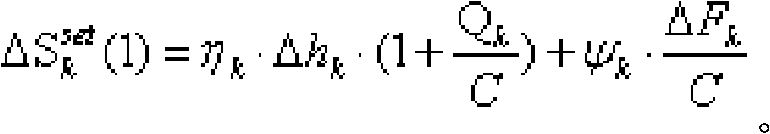

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

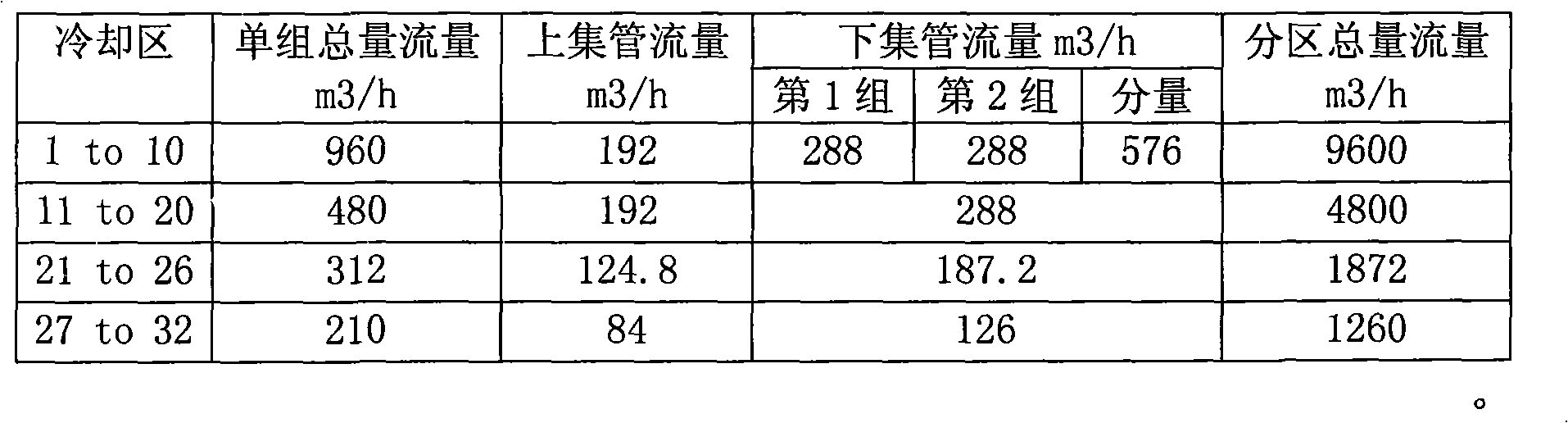

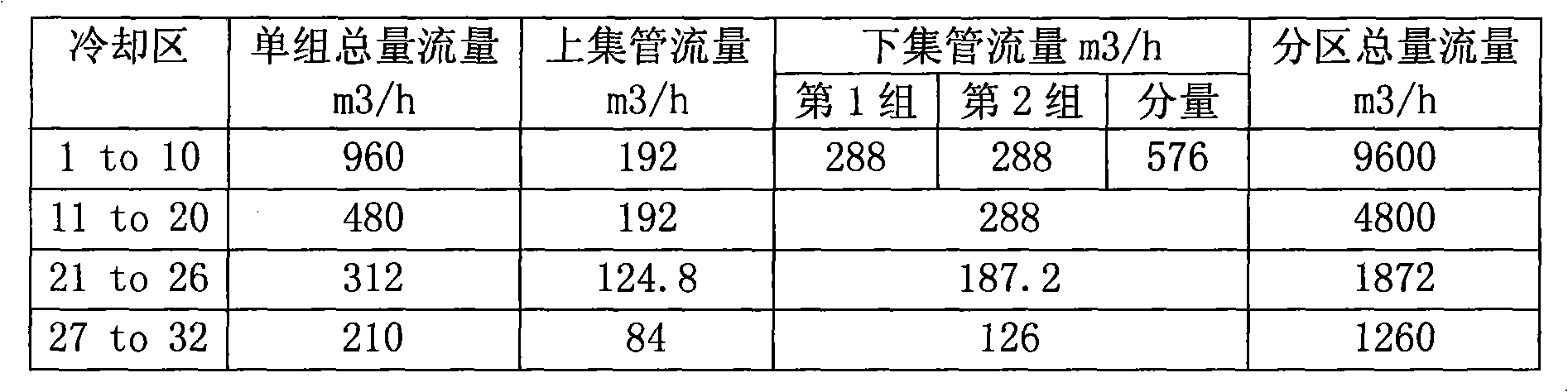

Process for producing high strength hardened and tempered steel by steekle mill on-line quenching

ActiveCN101353717AReduce consumptionLess investmentTemperature control deviceMetal rolling arrangementsWater resourcesHigh intensity

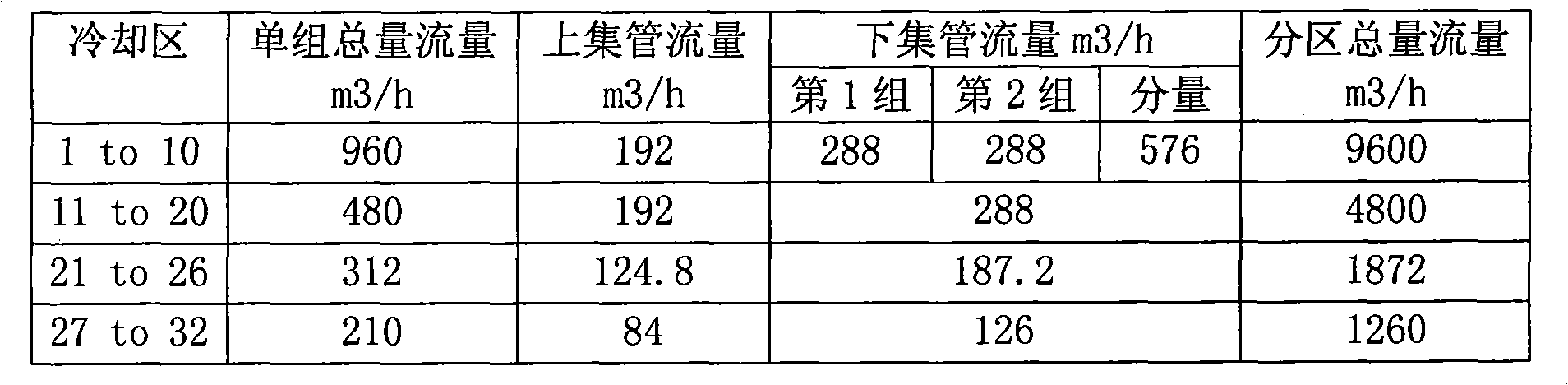

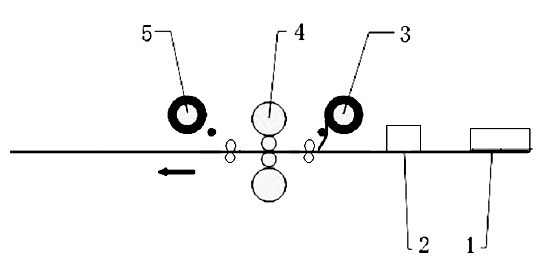

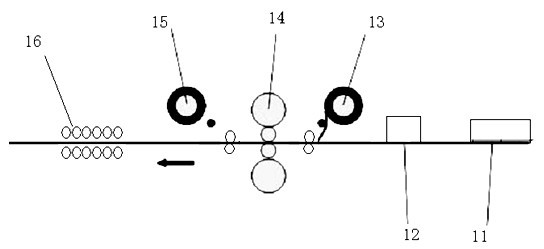

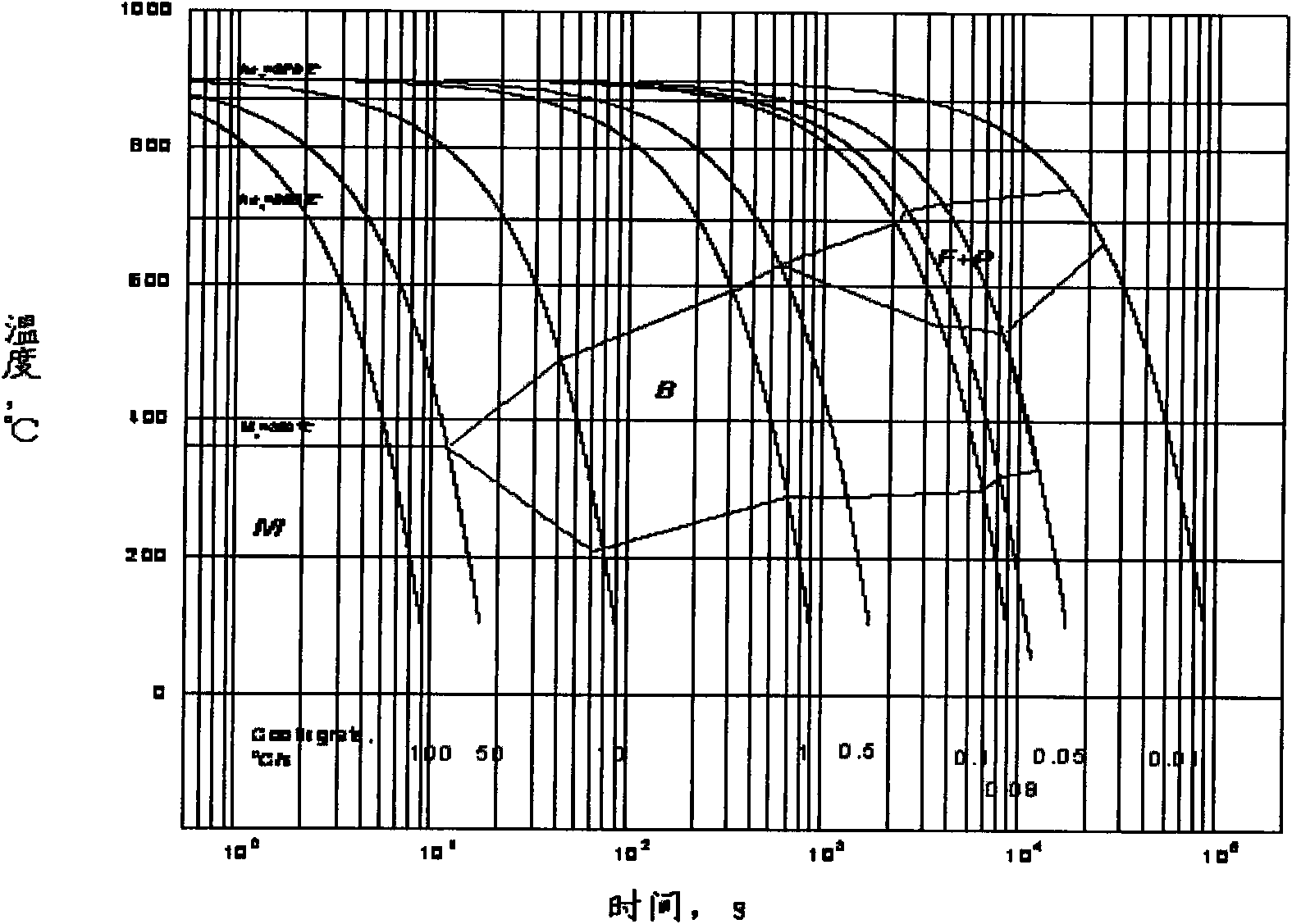

The invention relates to a production technology of high-strength quenched and tempered steel, in particular to a technology for the online quenching production of the high-strength quenched and tempered steel by using a steckel mill, comprising the following procedures of: (1) billet heating: temperature in a preheating section is less than or equal to 600 DEG C, and the temperature in a heating section is between 1220 DEG C and 1180 DEG C; (2) primary scale removal of high pressure water: the water pressure is more than or equal to 18Mpa; (3) controlled rolling: during the controlled rolling of a first stage, single path draft is more than or equal to 10 percent to 15 percent, and the total draft is more than or equal to 50 percent; during the controlled rolling of a second stage, steel rolling is carried out below recrystallization temperature, and the draft is controlled to be between 40 to 70 percent; (4) online quenching by using HACC; (5) offline tempering: the tempering temperature is between 550 to 670 DEG C, and the heat preservation time is 2 to 6min / mm. The technology for the online quenching and self-tempering production of the high-strength quenched and tempered steel by using the steckel mill can improve the production efficiency by dozens of times, lower the cost, not only reduce the reheating energy consumption, but also reduce the water resource consumption of offline quenching, and reduce investment on a quenching machine set.

Owner:NANJING IRON & STEEL CO LTD

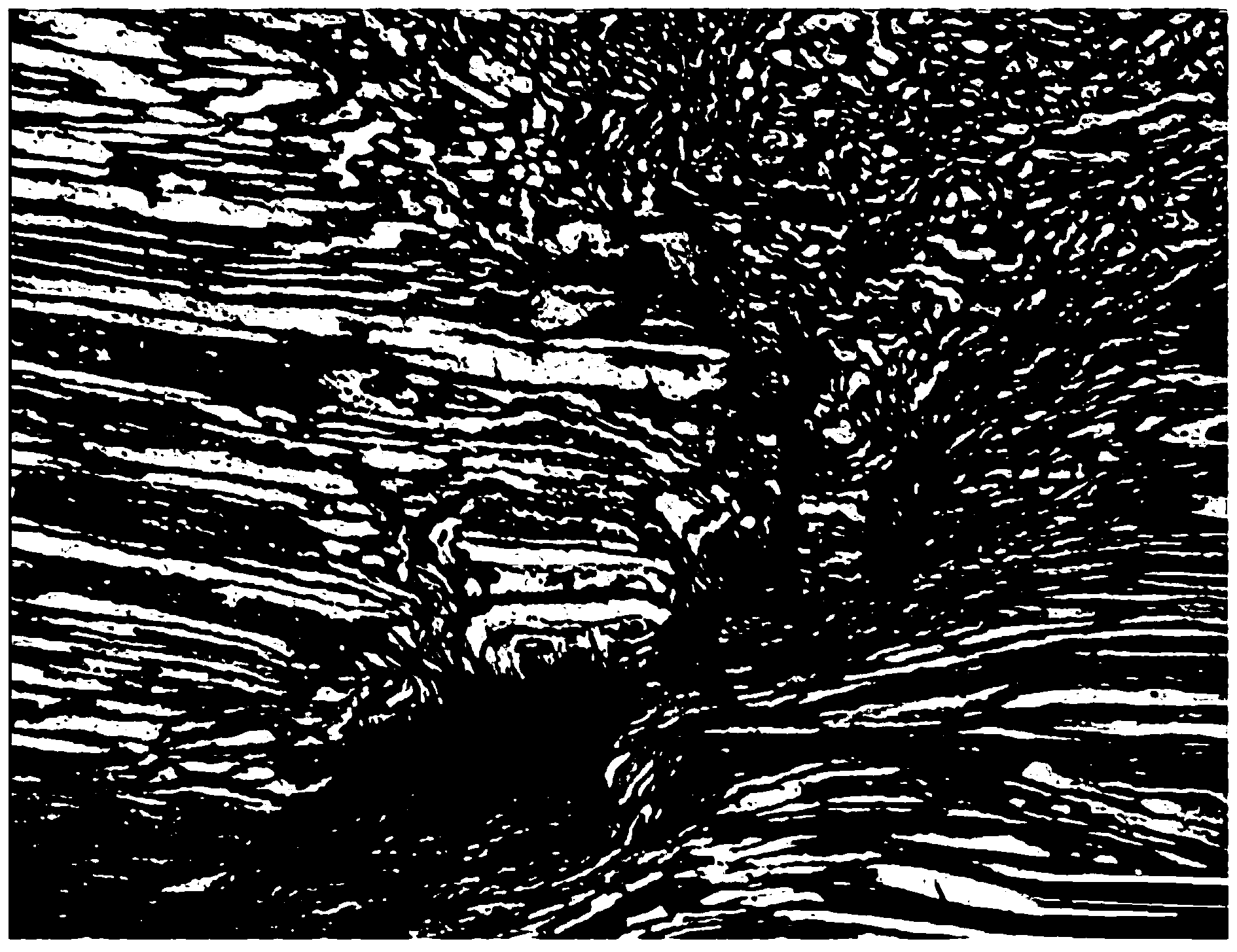

Repair method of backup roll surface of steckel mill and special repair powder used thereon

InactiveCN101358344AThe bonding strength is not lowLow costMetallic material coating processesBackup rollMachining

The invention relates to a machinery part surface repairing method in the metallurgical industry, in particular to a repairing method of steekle mill supporting roller surface and specially used repairing powder; the repairing powder contains the components with the following weight percent: 0.2 percent to 0.5 percent of C, 14 percent to 20 percent of Cr, 6 percent to 12 percent of Ni, 0 percent to 1.5 percent of Mn, 1 percent to 2.5 percent of Mo, 0.5 percent to 2.5 percent of W, 1.5 percent to 2.5 percent of Si, 2.0 percent to 3.0 percent of B, and the rest is Fe. When a supporting roller cannot be used any more because the roller surface is worn or locally falls off, areas to be repaired are molten through a laser process with the repairing powder, so that the missing and damaged parts are repaired and the performance of the repaired parts can meet the use requirements; and then, the shape of the roller surface is recovered through mechanical processing, and a reusable supporting roller can be obtained without heat treatment.

Owner:NANJING IRON & STEEL CO LTD +1

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406ASolve the problem of excessive rolling forceSolve quick stopRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

High strength X100 pipeline steel produced by steekle mill and production technique thereof

InactiveCN101407894AReduce waiting timeImprove purityTemperature control deviceThick plateLine tubing

The invention relates to high-strength steel and a production process thereof, which are high-strength multiplied by 100 pipeline steel produced by a steckel mill and the production process thereof. The main control ranges of parameters of the hot rolling process are as follows: the heating temperature of flat blanks is 1100 to 1250 DEG C; the final temperature of rolling controlling of a recrystallization zone is 1000 to 1080 DEG C; the beginning temperature of rolling controlling of a non-recrystallization zone is 900 to 980 DEG C; the final rolling temperature is 720 to 880 DEG C; and the final cooling temperature is 200 to 500 DEG C and the cooling temperature is 3 to 40 DEG C per second. The production process is suitable for the production line of the steckel mill and also for the production line of medium heavy plates with weaker rolling power, solves the technical problem that the existing production line of the steckel mill or the production line of thick heavy plates with insufficient production capacity can not produce the high-strength pipeline steel smoothly.

Owner:NANJING IRON & STEEL CO LTD +1

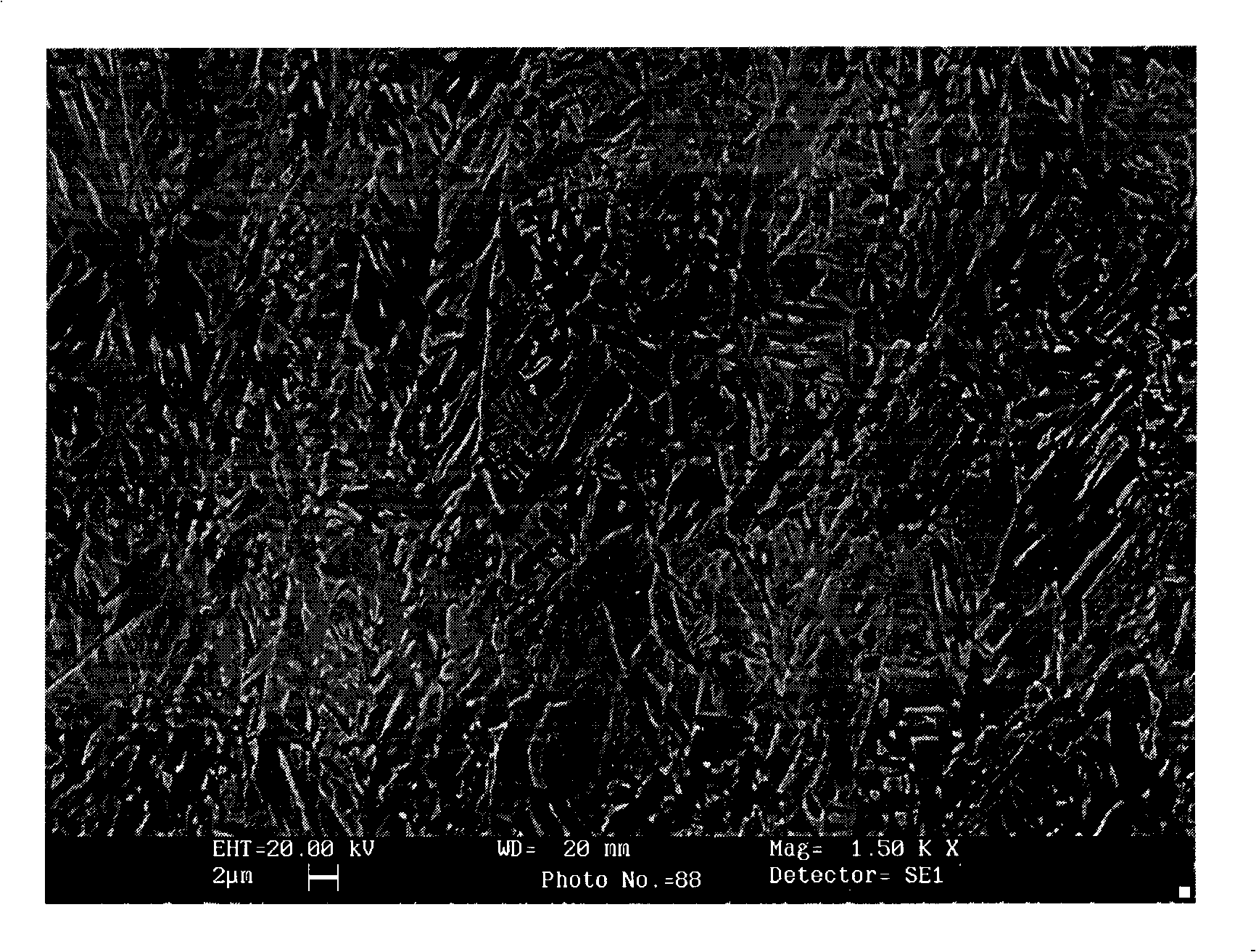

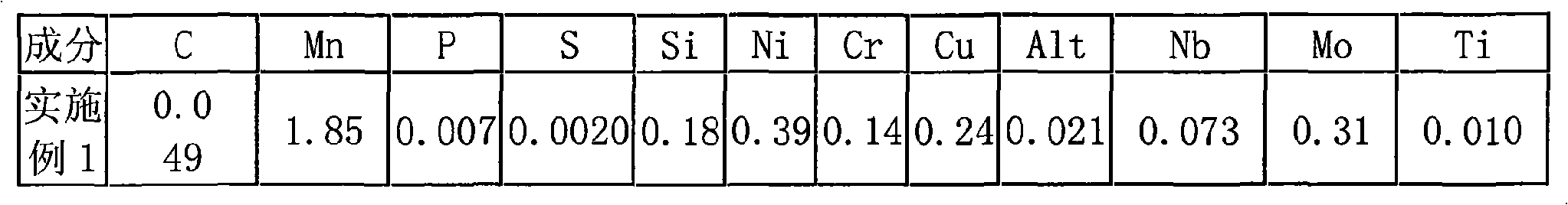

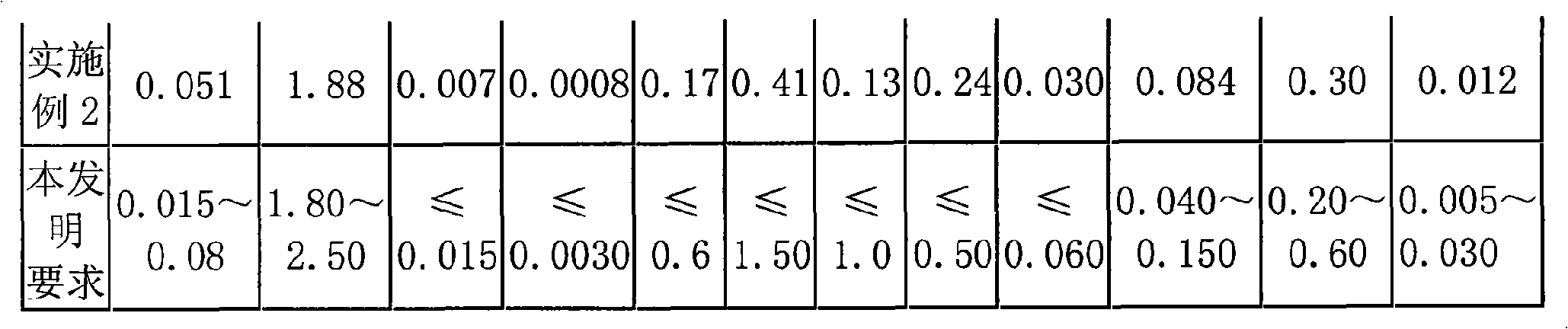

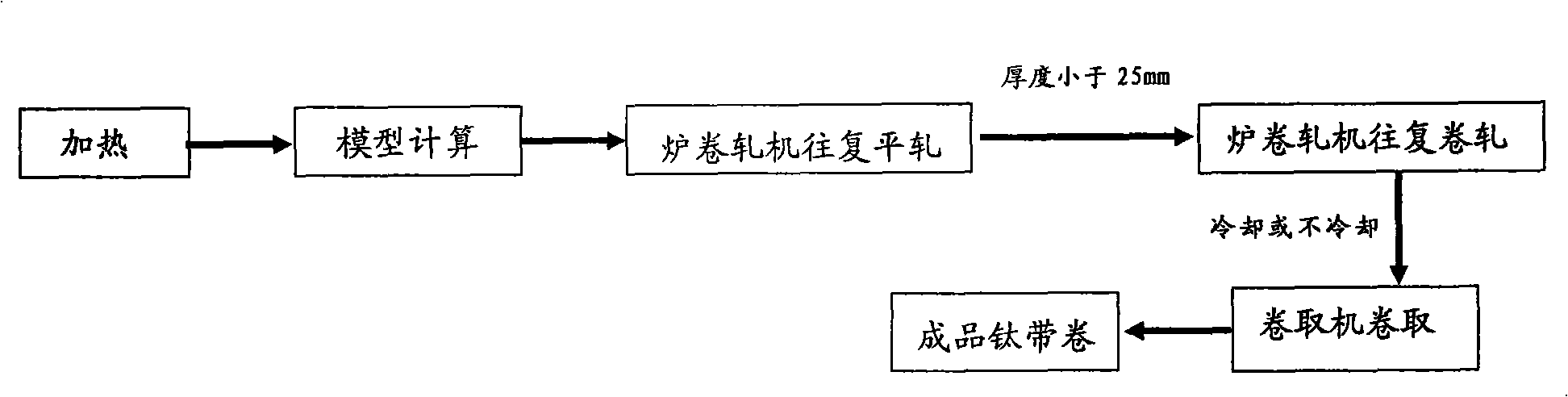

Reversible hot-rolling process of titanium plate coil

InactiveCN101628297ATake advantage ofFulfil requirementsMetal rolling arrangementsTitanium plateSteckel mill

The invention provides a hot-rolling process for manufacturing a titanium plate coil, which comprises the following steps: heating titanium plate blank to tapping temperature; automatically generating process parameters for rolling the titanium plate blank by using a model computation module according to known parameters and predetermined target parameters; repeatedly rolling the titanium plate blank by a steckel mill according to the process parameters, wherein the titanium plate blank has the opening rolling temperature of 800 DEG C to 950 DEG C and the finishing rolling temperature of 500 DEG C to 695 DEG C; and coiling rolled titanium plate strips by using a coiler so as to produce the titanium plate coil.

Owner:WUKUN STEEL

X52 pipeline steel and production method thereof

ActiveCN101928884AIncrease varietySimple structureTemperature control deviceChemical compositionAdditional values

The invention provides an X52 pipeline steel and a production method thereof. The X52 pipeline steel comprises the following chemical components: 0.070-0.090wt% of C, 0.15-0.30wt% of Si, 1.10-1.30wt% of Mn, 0.006wt% or more of S, 0.020wt% or more of P, 0.020-0.040wt% of Nb, 0.010-0.020wt% of Ti, 0.008wt% or more of N, 0.010-0.040wt% of Als, the rest of Fe and unavoidable impurities. After heating and descaling, rough rolling and finish rolling are performed on the same dual-frame compact Steckel mill continuously; through delayed rolling control in rolling process, the enhancement function of microalloy elements such as Nb and V added to the steel are given a full play, thereby obtaining superfine and uniform tissue, effectively preventing the occurrence of mixed crystal, and greatly improving the strength and toughness of the X52 pipeline steel. The X52 pipeline steel produced with the method belongs to high-technology product with high additional value, thus the economical benefit is significant.

Owner:WUKUN STEEL

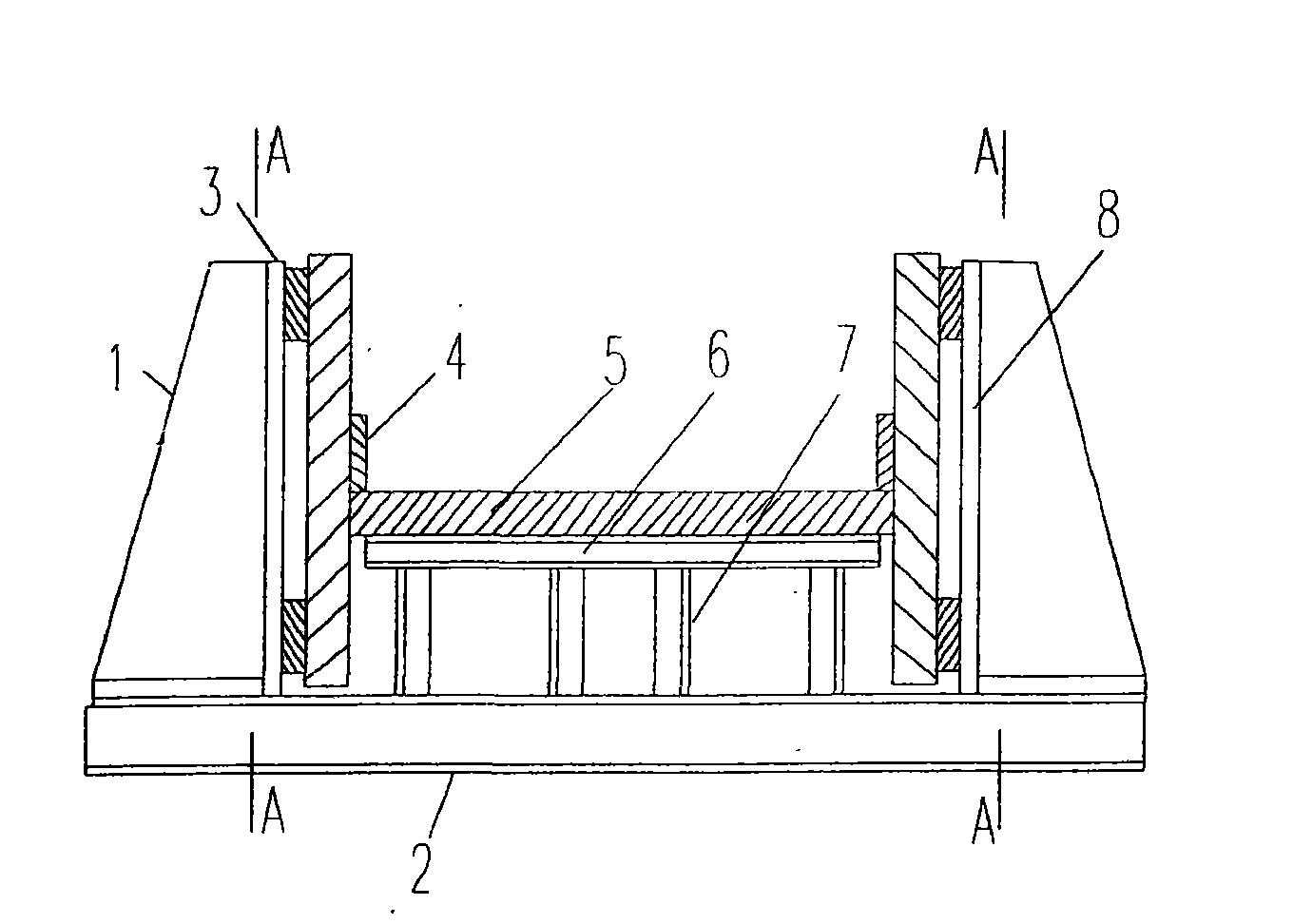

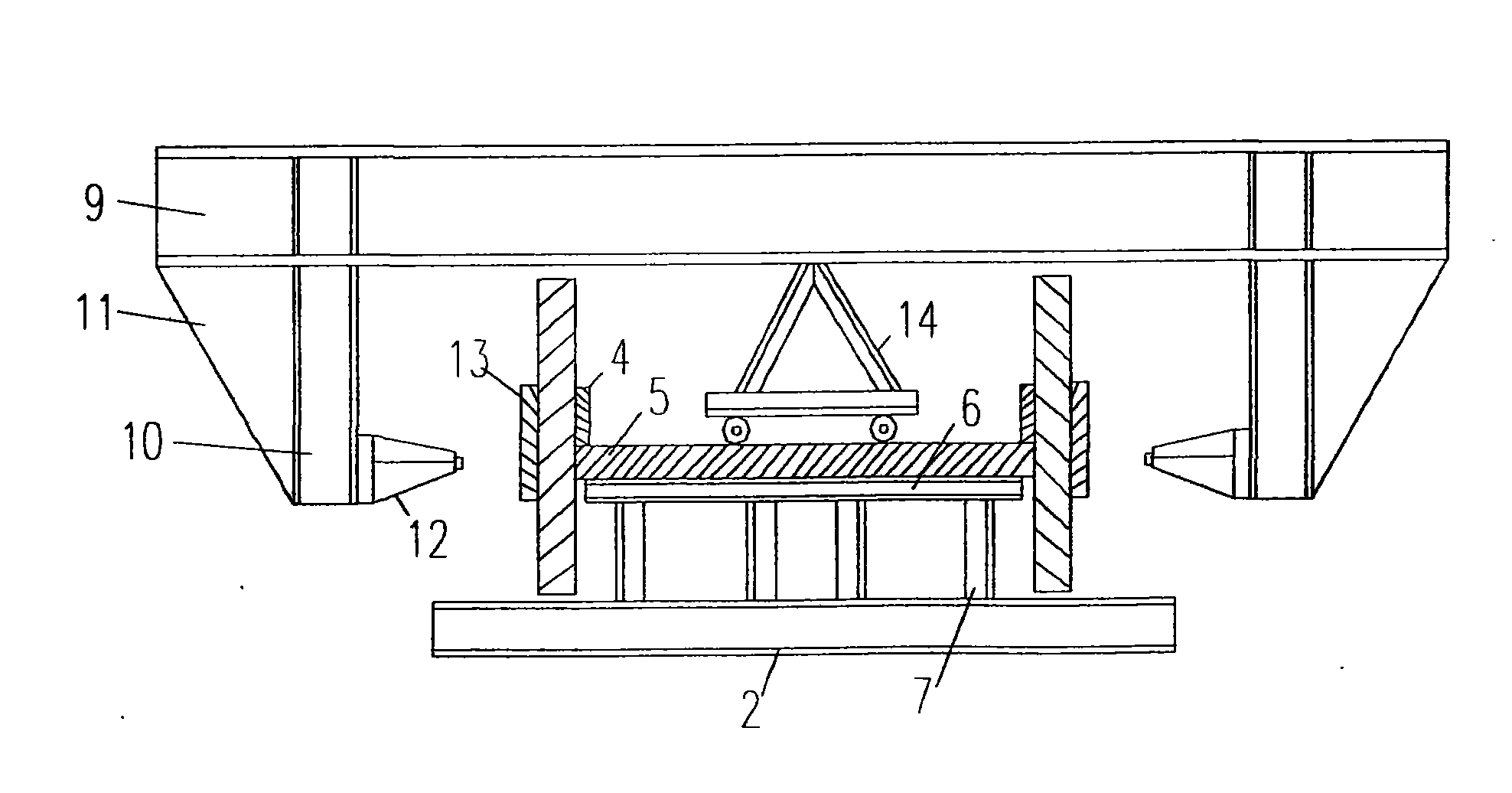

Pairing method of H-section steel for super-large crane beams

The invention relates to a method for pairing and correcting an H-section steel for super-large crane beams. The method comprises the following specific steps: setting up an assembly platform, longitudinally welding to temporarily fix H-section steel outside a central line of a base plate of a platform beam, and welding a reinforced plate; designing and manufacturing a special correcting unit; arranging a mobile roller support member in the middle of the correcting unit; respectively pairing the H-section steel of the crane beams in three sections; hoisting an upper flange slab and a lower flange slab by a traveling crane to two sides of a web plate of the crane beam on the assembly platform; tightly wedging and fixing the H-section steel by a temporary fixing device; hoisting the correcting unit to the assembly platform, and holding a joint face between the upper flange plate, the lower flange plate and the web plate; checking a joint gap, and sectionally welding between middle T-type weld seams; repeating the above correcting steps until finishing all correcting and fixing work; and releasing the temporarily fixed steel bar and starting submerged arc welding of the weld seams. The applicant manufactures and erects 12 super-large crane beams in 120t Converter-Steckel Mill Project of Angang and 4300mm Wide-thick Plate Project of Egang successively by the method and obtains remarkable effect.

Owner:MCC SHIJIU CONSTR

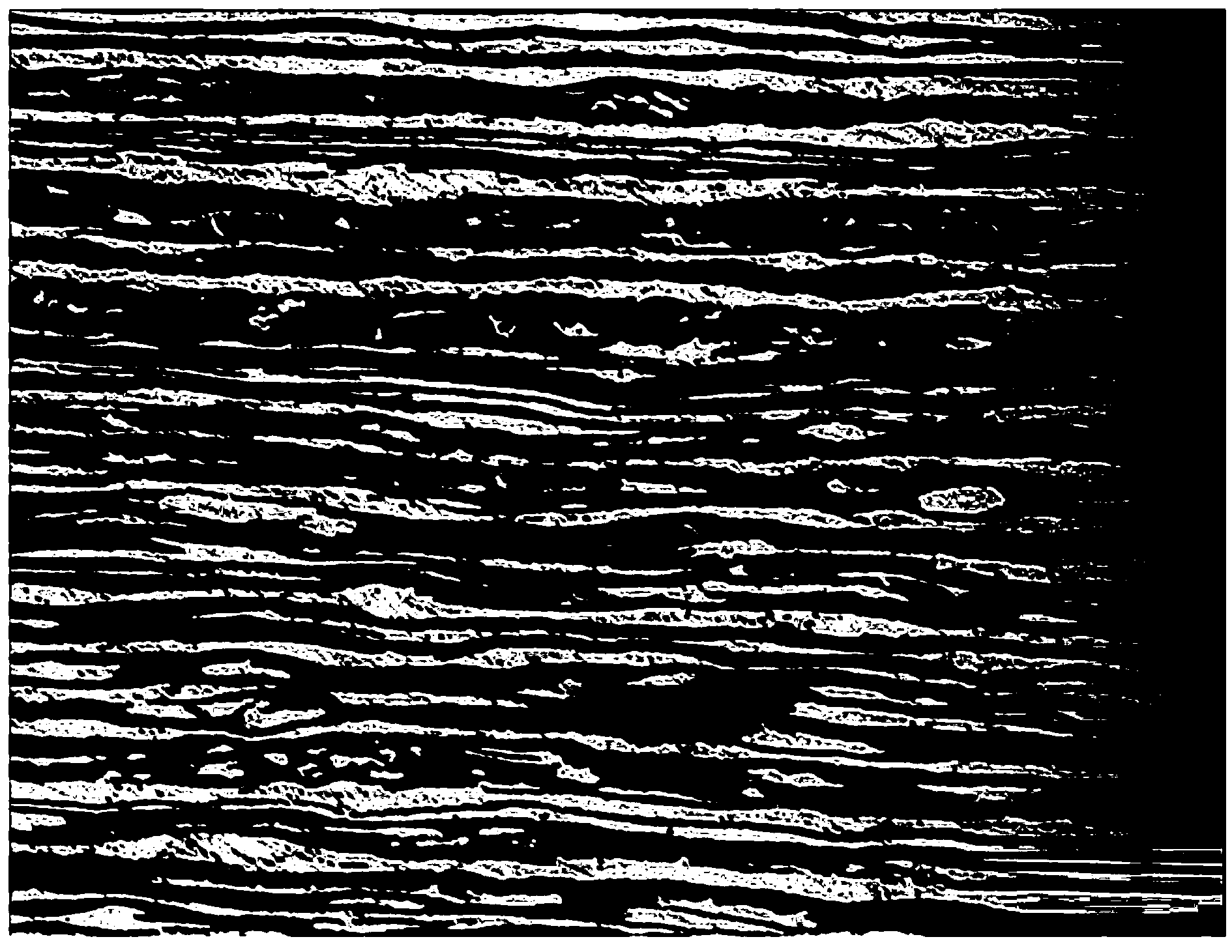

Method for controlling red oxide scale on surface of steckel mill steel plate

ActiveCN103769424AEliminate red rustQuality improvementTemperature control deviceWork treatment devicesSheet steelHigh pressure water

The invention relates to the method for controlling a red oxide scale on the surface of a steckel mill steel plate. The method comprises the following steps that a casting blank enters a heating furnace for heating, oxide scale removal of the casting blank is conducted through high pressure water after the casting blank is discharged out of the furnace, rough rolling is conducted on the casting blank after oxide scale removal is conducted, a billet is obtained, and at least three times of oxide scale removal are conducted on the casting blank in the rough rolling step; after rough rolling, finish rolling is conducted on the billet and at least three times of oxide scale removal are conducted on the casting blank in the finish rolling step. The quality of the oxide scale on the surface of the steel plate is improved through control over a oxide scale removal system in the billet rolling technology and the rolling process, the red, loose, multi-hole and smashed oxide scale is prevented from being generated on the surface of the steel plate, a green and compact oxide scale is generated, the quality of the surface of the steel plate is improved, and the corrosion-resistant performance of the surface of the steel plate is further improved.

Owner:NANJING IRON & STEEL CO LTD

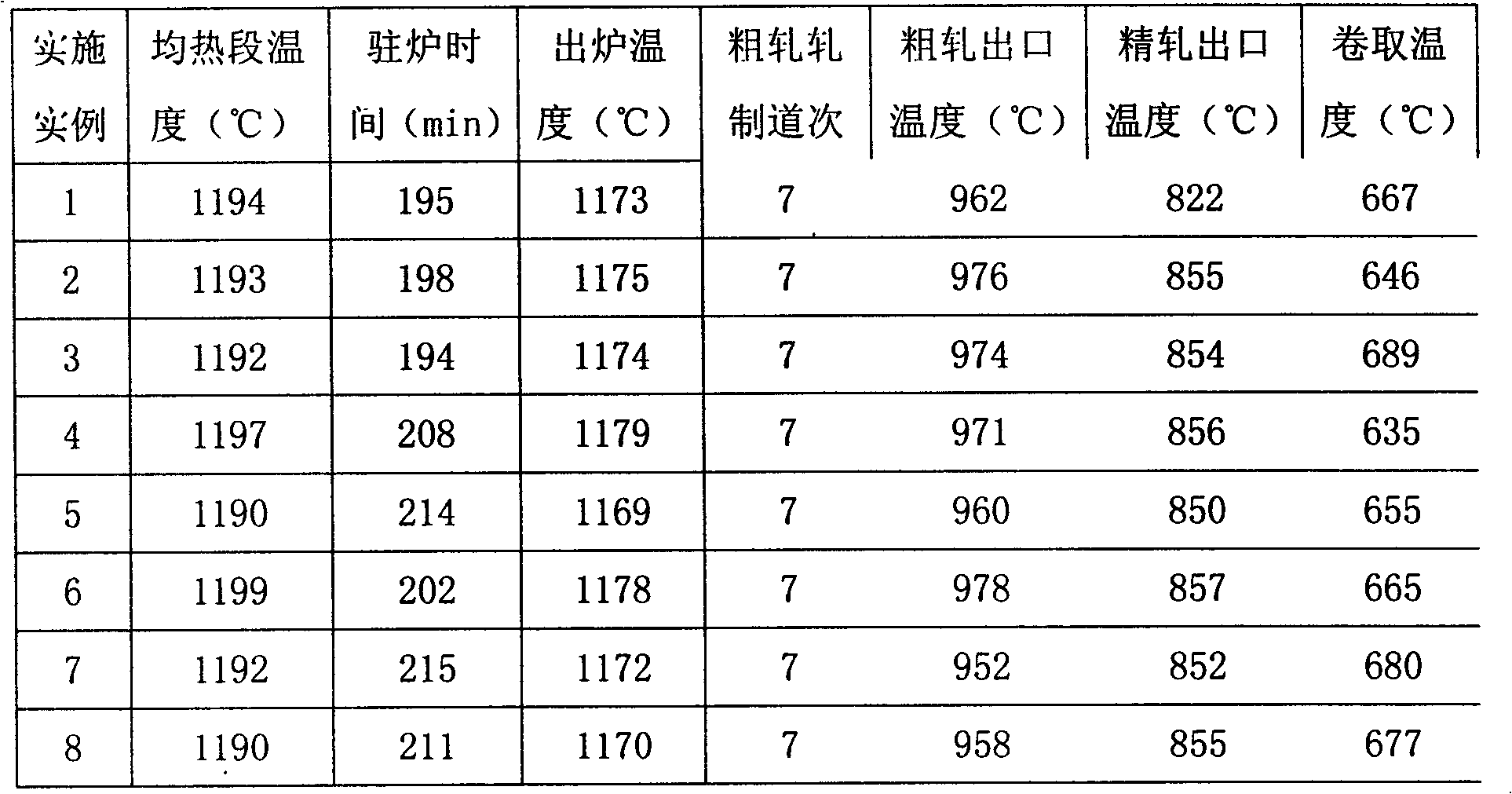

Method suitable for steckel mill to manufacture hot rolling steel strips of ferritic stainless steel

InactiveCN101607266ASuppression of edge cracksImprove the hard problemMetal rolling arrangementsPositive pressureLoad distribution

The invention discloses a method suitable for a steckel mill to manufacture hot rolling steel strips of ferritic stainless steel, comprising the following steps: (1) smelting and continuous casting sheet billet according to conventional process; (2) hot rolling heating: a stepping heating furnace is adopted for heating the sheet billet, the heating area is divided to four sections which sequentially are a heat recovery section, a preheating section, a heating section and a uniform heating section, the pressure in a furnace cavity is micro positive pressure, and the atmosphere in the furnace is weak oxidizing atmosphere; (3) hot rolling: rolling pass of the rough rolling is 7, start rolling temperature is 1130 + / -10 DEG C, the draft of the first pass is no more than 15 percent, and the second pass is no more than 20 percent; and precision rolling adopts the steckel mill for rolling, the rolling pass of the precision rolling is 7, and load distribution rate of each pass of the precision rolling is adjusted so as to ensure that the draft of the sixth pass is no more than 20 percent and the draft of the last pass is larger than 10 percent and is less than 12 percent. The method can effectively solve the quality problem of edge crack of the hot rolling steel strips, and has strong operability and low manufacture cost.

Owner:SHANDONG TAISHAN STEEL GROUP

Method for producing wear-resisting hot-rolling steel plate by using furnace rolling machine and steel plate prepared by the same method

InactiveCN101186960AHigh strengthUniform tissueRoll mill control devicesHeat treatment process controlWear resistantAlloy

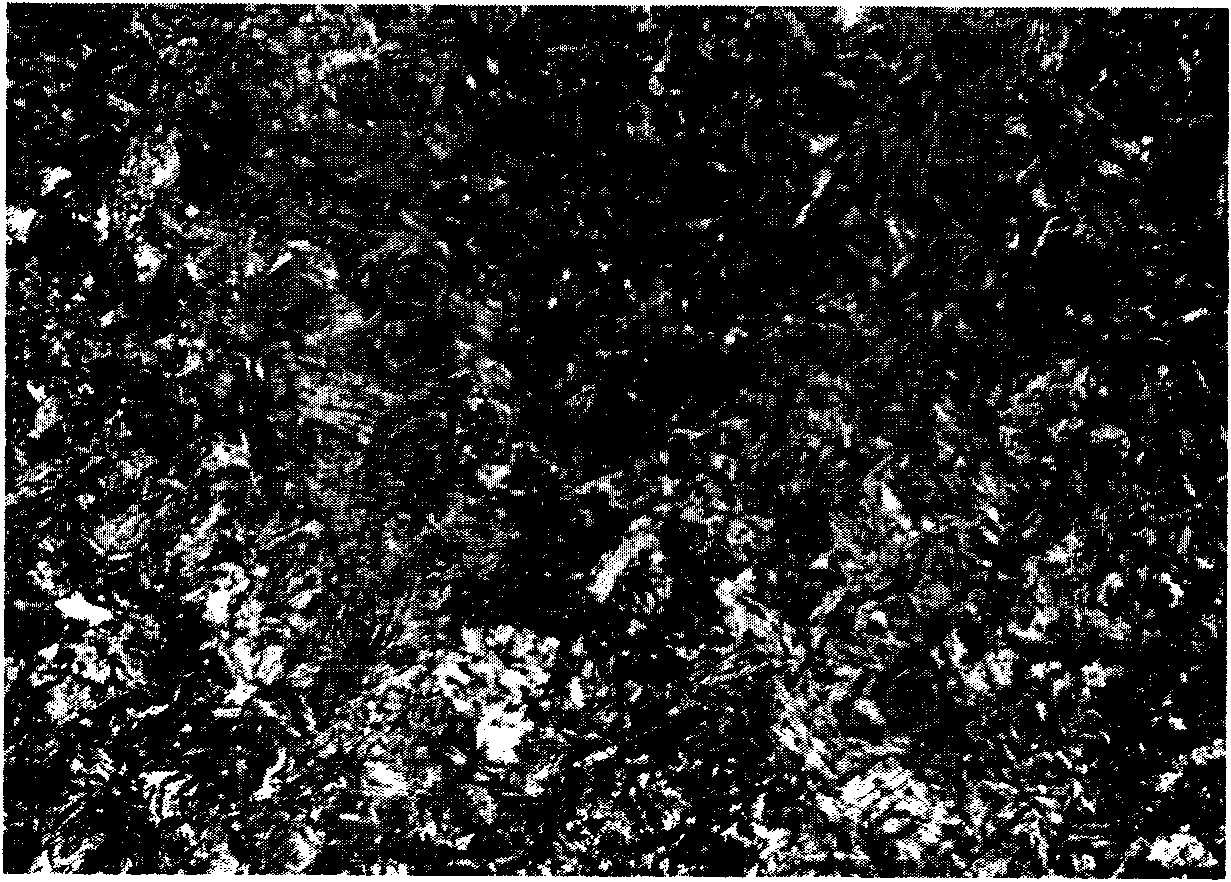

The invention discloses a production process of using a steckel mill to produce wear-resistant steels and produced steel plates thereof. Selected components of the invention are that C<=0.30%, Mn<= 2.5%, P <= 0.015%, S <= 0.005% and Si <= 2.2%. Continuous casting slab of alloys which includes Cr, Mo, Nb, V and the like (Cr <= 1.3%, Mo <= 0.9%, Nb <= 0.05%, V <= 1.0%) is moderately added. The invention employs warm loading and delivery. Steel plates of medium thickness are flatly rolled on the steckel mill with the employment of TMCP + off-line tempering processes, thin steel plates utilize coil rolling + cooling control + off-line tempering processes, and the uniformity, thinning and intensification of tissue are realized by controlling dynamic recrystallization and meta-dynamic recrystallization in the rough rolling stage, strain accumulation and relaxation process in the finely rolling stage, cooling rate within the range of producing lower bainite, and final cooling temperature between the formation temperature of lower bainite and the formation temperature of martensite by employing the off-line low tempering temperature which is equal to or less than 350 DEG C(<= 350 DEG C), thereby ensuring high-intensity, high ductility and abrasion resistant combination property of the steel plates.

Owner:NANJING IRON & STEEL CO LTD +1

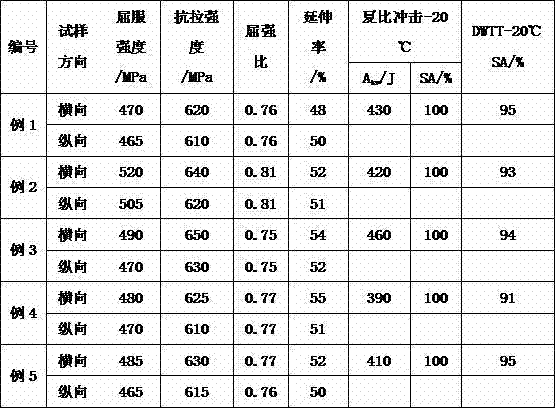

Control method for limit specification steel roll hot rolling by single-stand steekle mill

ActiveCN102699022AGuarantee the qualified stability of rolling yield strength ≥ 360MPa limit specification steel coil performanceGuaranteed performance and stabilityRoll force/gap control deviceTemperature control deviceChemical compositionUltimate tensile strength

The invention belongs to the field of steel rolling and relates to a control method for limit specification steel roll hot rolling by a single-stand steekle mill. Through the measures of optimizing the chemical ingredient design, developing he layer flow cooling system head and tail avoiding function, optimizing the rolling control processes matched with the chemical ingredients and the like, the performance qualification stability of limit specification steel rolls at the level with the yield strength being higher than or equal to 360 MPa rolled by the single-stand steekle mill is integrally ensured. The control method provided by the invention has the advantages that the performance qualification stability of limit specification steel rolls at the level with the yield strength being higher than or equal to 360 MPa rolled by the single-stand steekle mill can be integrally ensured, the steekle mill rolled steel rolls with the limit thinnest and widest specification being 5mm*2500mm can be produced, and the steekle mill flat rolled steel rolls with the limit thickest and widest specification being 25mm*2500mm can also be produced.

Owner:NANJING IRON & STEEL CO LTD

Method for manufacturing wear-resistant steel pipe by using hot-rolling coiled plate

ActiveCN101602079AImprove mechanical propertiesRefined mechanical propertiesFurnace typesIncreasing energy efficiencyWear resistantMartensite

The invention relates to a method for manufacturing a wear-resistant steel pipe by using a hot-rolling coiled plate, comprising a smelting method process, refining outside a furnace and steel blank manufacture. The method is characterized in that a steel blank is rolled and manufactured into a hot-rolling coiled plate blank material by using a hot continuous-rolling machine set or a furnace coiled rolling machine, the hot-rolling coiled plate blank material is rolled and welded into a pipe blank of an ERW steel pipe by using an ERW steel pipe machine set, and heat treatment is carried out after internal and external burrs are removed. The heat treatment method comprises the following steps that: (1) the pipe blank welded into the ERW steel pipe is heated in induction heating equipment to 910 to 960DEG C and austenized, the heating time is 60 to 140s, then the steel pipe with the austenitizing temperature is quenched in a water-cooling or steam-cooling quenching machine set, the quenching and cooling speed is greater than or equal to 10DEG C / S, the steel pipe with a quenched martensite organization is obtained, then induction tempering is carried out, the tempering temperature of the steel pipe is 210DEG C to 320DEG C, the tempering time is 60 to 180s, the quenched martensite is converted into a tempered martensite, and then straightening, flaw detection, surface inspection and sampling inspection are carried out to finally obtain the wear-resistant steel pipe with favorable wear resistance.

Owner:武汉钢实机电设备有限公司

Resource-saving Q345 low-alloy series steel plate and production method thereof

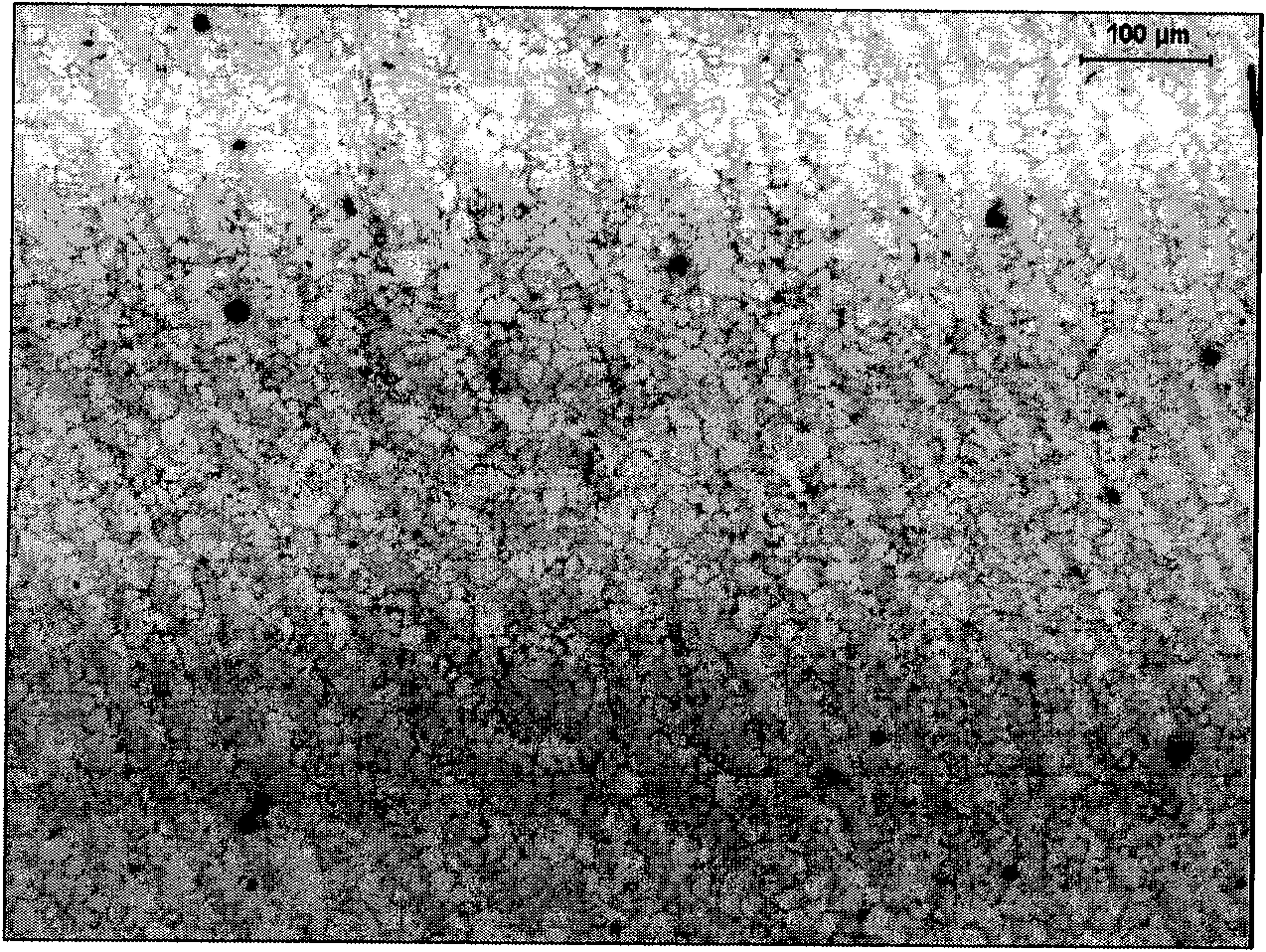

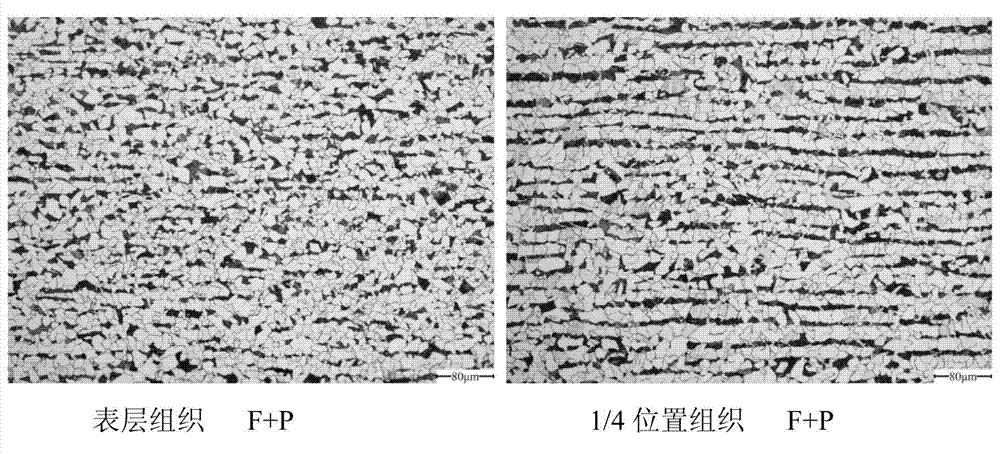

InactiveCN103045939AImprove performanceGuaranteed final performanceHeat treatment process controlAlloyPearlite

The invention discloses a resource-saving Q345 low-alloy series steel plate and a production method thereof. The steel plate comprises the following chemical components in percent by weight: 0.15 to 0.18 percent of C, 0.15 to 0.50 percent of Si, 1.10 to 1.25 percent of Mn, not more than 0.030 percent of P, not more than 0.035 percent of S, 0 to 0.045 percent of Alt, not more than 0.44 percent of carbon equivalent, and the balance of Fe and inevitable impurities. The production process of the steel plate comprises 150 t converter, LF external refining, slab continuous casting, slab heating, steckel mill controlled rolling, controlled cooling, thermal straightening, cooling, shearing and mark warehousing. The resource-saving Q345 low-alloy series steel plate, produced by the production method, has the yield strength of 360 to 420 MPa, the tensile strength of 500 to 550 MPa, and the elongation of 24 to 32%, and acicular ferrite with the thickness of 3 to 6 mm, polygonal ferrite, degenerate perlite and a small amount of granular bainite are arranged on the surface layer of the steel plate.

Owner:ANYANG IRON & STEEL

X65 pipe line steel and production method thereof

ActiveCN101928883AIncrease varietySimple structureTemperature control deviceChemical compositionEconomic benefits

The invention provides X65 pipe line steel and a production method thereof. The X65 pipe line steel comprises the following chemical components in percentage by weight: 0.055 to 0.090 percent of C, 0.15 to 0.35 percent of Si, 1.50 to 1.65 percent of Mn, less than or equal to 0.005 percent of S, less than or equal to 0.020 percent of P, 0.040 to 0.055 percent of Nb, 0.040 to 0.070 percent of V, 0.010 to 0.025 percent of Ti, less than or equal to 0.008 percent of N, 0.005 to 0.060 percent of Als, and the balance Fe and inevitable impurities. After heating and descaling, rough rolling and finish rolling are continuously completed on the same double-rack compact steckel mill, the reinforcing effect of Nb, V and other microalloyed elements added in the steel can be sufficiently played by delay controlled rolling in the rolling process, a micro-uniform tissue can be obtained, the occurrence of mixed crystals can be effectively prevented, and the strength and toughness of the X65 pipe line steel can be greatly improved. The produced X65 pipe line steel belongs to the product with high technology content and high additional value, and has remarkable economic benefit.

Owner:WUKUN STEEL

Process for rolling thin low-temperature tank box steel plate by using rolling machine with single machine frame furnace

ActiveCN102974612ALarge amount of depressionSmall amount of depressionTemperature control deviceWork treatment devicesLaminar coolingHeating furnace

The invention discloses a process for rolling a thin low-temperature tank box steel plate by using a rolling machine with a single machine frame furnace. The low-temperature tank box steel plate of which the thickness is less than or equal to 11mm is formed by rolling a plate blank of which the thickness is 150mm. The process comprises the following steps of coldly or hotly loading the plate blank in a storehouse, heating the plate blank in a heating furnace, crudely removing scales, finely removing the scales, rolling the plate blank by using a furnace rolling machine, cutting the head or sectioning by using a pair of flying shears, cooling with laminar flow, straightening by using a hot straightening machine, performing air cooling by using a cooling bed, checking the lower surface of a steel plate, cutting two sides, sectioning or sampling by cutting to length, spraying steel seal, stacking the products, and storing the finished products in the warehouse, wherein the temperature for delivering the steel plate from the heating furnace is 1,150 to 1,230 DEG C, the temperature of a rolling furnace in front of the machine and the temperature of a rolling furnace behind the machine are set to be 850 to 950 DEG C, the rolling times is 11, two rolling steps are performed, flat rolling is performed in the first step for 7 times, and rolling is performed in the second step for 4 times. The requirement of refining and organizing crystalline grains can be met according to the plate produced by the invention, and meanwhile, the shape and the performance of the plate are ensured.

Owner:NANJING IRON & STEEL CO LTD

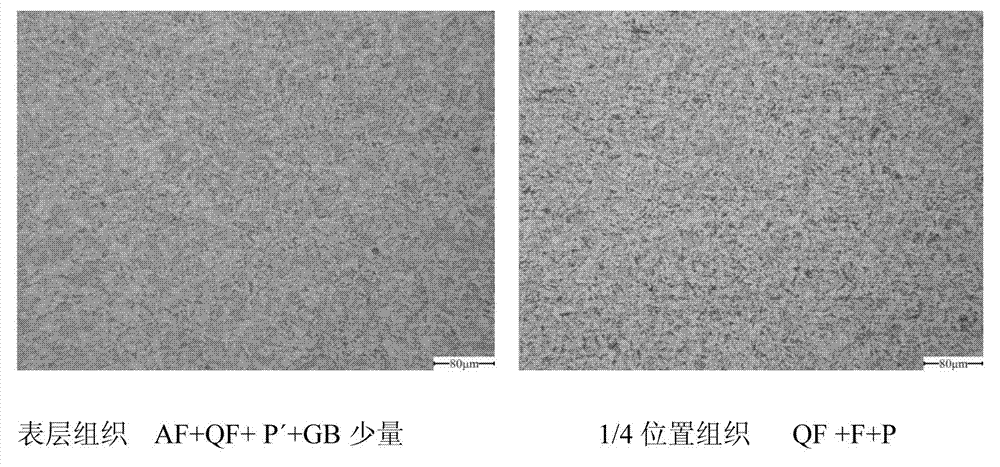

Deep sea pipeline steel produced based on steckel mill and preparation method thereof

ActiveCN102367540AIncrease productivityUniform and stable performanceTemperature control deviceHeat treatment process controlToughnessCooling temperature

The invention relates to deep sea pipeline steel and a preparation method thereof, and in particular relates to deep sea pipeline steel produced based on a steckel mill and a preparation method thereof. The deep sea pipeline steel comprises the following components by weight percent: 0.02-0.06% of C, 0.10-0.30% of Si, 1.3-1.65% of Mn, less than 0.010% of P, less than 0.002% of S, less than 0.006%of N, 0.03-0.06% of Nb, 0.1-0.3% of Ni, less than or equal to 0.3% of Cr, less than or equal to 0.3% of Cu, less than or equal to 0.25% of Mo and the balance of Fe and trace impurities. According to the preparation method, billet steel is heated for 2.5-4 hours at the temperature of 1120 DEG C-1210 DEG C; in the first-stage rolling process, rolling-starting temperature is 1030-1130 DEG C, the final-rolling temperature is ensured between 950 DEG C and1100 DEG C, and deformation is more than 60%; in the second-stage rolling process, rolling-starting temperature is 800-940 DEG C, the final rolling temperature is ensured between 780 DEG and 880 DEG C, and deformation is more than 60%; and the cooling speed is 15-25 DEG C / s, and the final cooling temperature is in a range of 200-500 DEG C. Thepreparation method has low cost and simple process, can be used for producing the deep sea pipeline steel having low yield ratio and high toughness, and is suitable for the steckel mill for large-scale production.

Owner:NANJING IRON & STEEL CO LTD

Process for controlling shape of hot-rolled flat-rolled high-grade pipeline steel plate by using single-rack steckel mill

ActiveCN102189119ASolve the shape problem of flat rolled high steel grade pipeline steel plateSolve the curved plate shapeRoll force/gap control deviceProfile control deviceSheet steelLine tubing

The invention discloses a process for controlling the shape of a hot-rolled flat-rolled high-grade pipeline steel plate by using a single-rack steckel mill. The process realizes the shape control of a hot-rolled flat-rolled high-grade pipeline steel plate by using a single-rack steckel mill by the following steps of: optimizing the two-stage rolling temperature and the thickness of a blank to be heated, reasonably optimizing and using reduction per pass, particularly the reduction of the last three passes in a finish rolling stage, adjusting the roll bending force, controlling convexity of a working roll, accelerating a final rolling on line, performing an edge shielding process additionally according to plate width, and optimizing the laminar cooling water ratio and the inlet / outlet rollgap setting, straightening speed and the like of a straightener. Through the invention, the maximum length of the blank that can be flat-rolled is 13m. When a long blank with thickness of 150 mm is rolled into a high-strength steel plate with thickness of less than or equal to 32 mm, the shape of the steel plate is comprehensively controlled while the performance uniformity of the final product is improved.

Owner:NANJING IRON & STEEL CO LTD

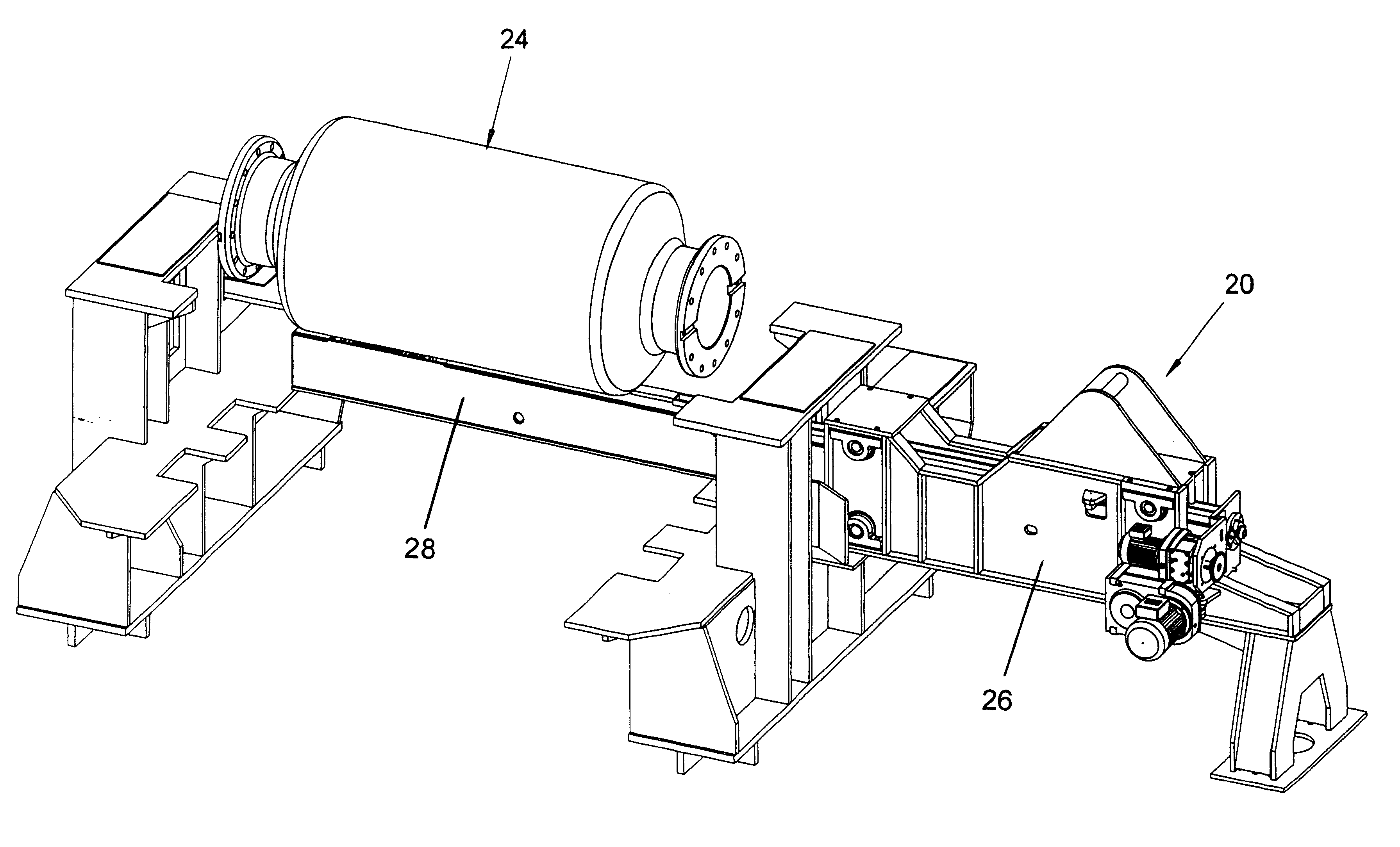

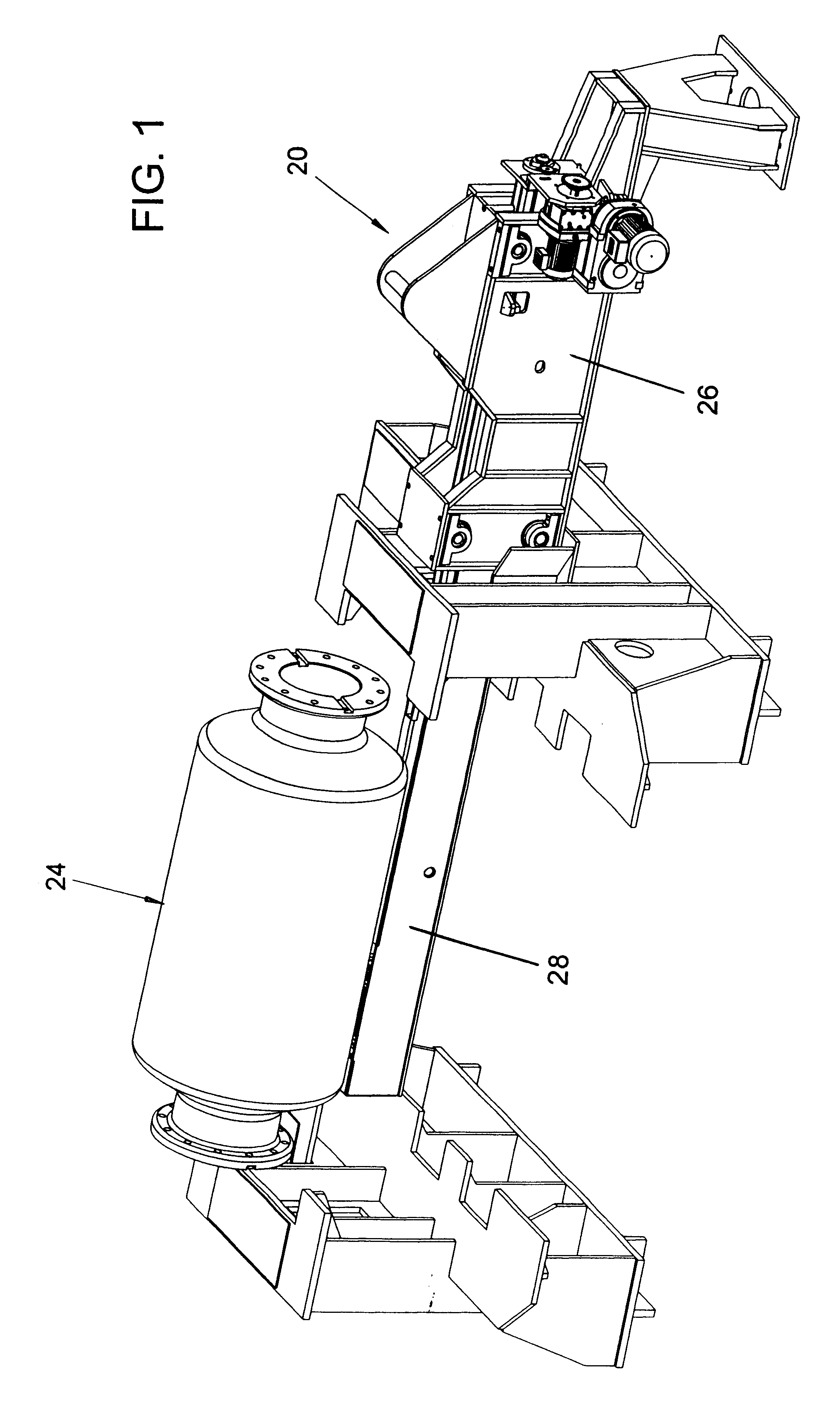

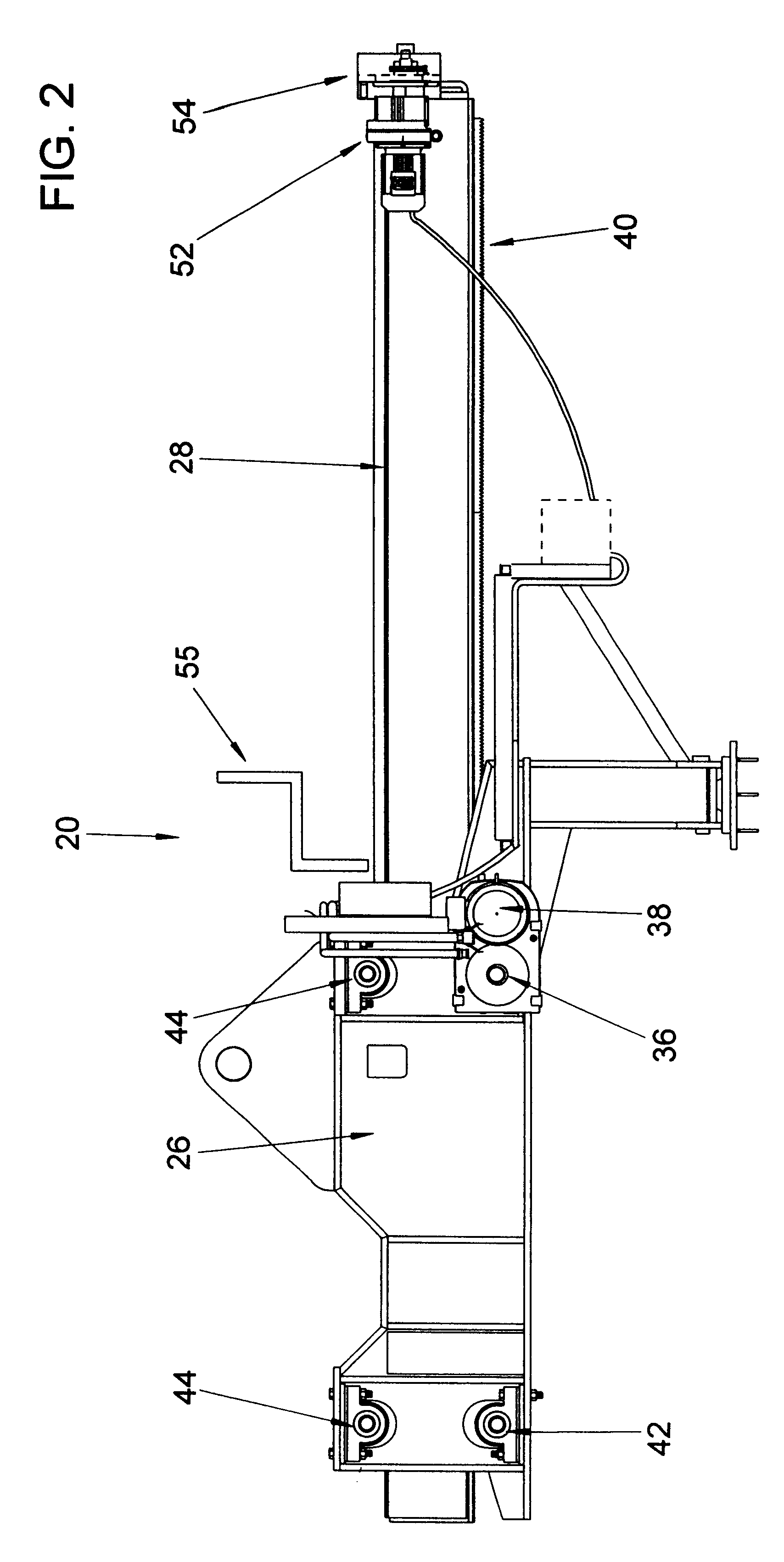

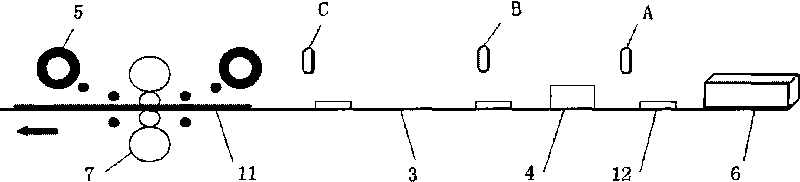

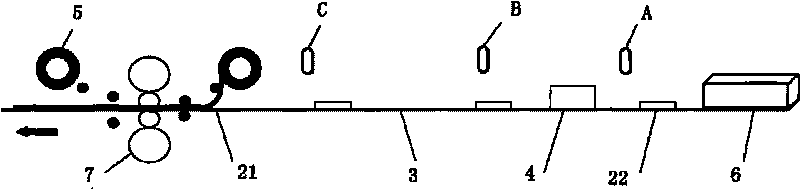

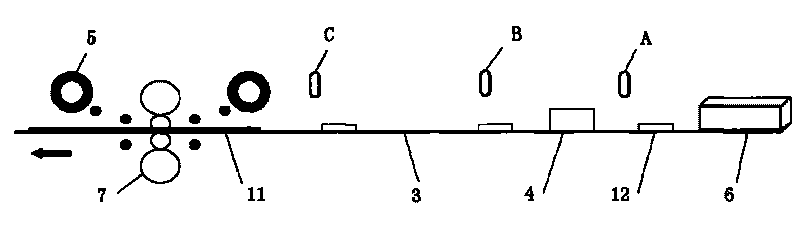

Apparatus for cleaning a coiler furnace drum

A coiler drum cleaner for cleaning the drum of a coiler furnace (typically associated with a reversing rolling mill or Steckel mill) is disclosed. The coiler drum cleaner includes a cleaning element rotatably mounted at one end of a longitudinally extending tubular member, the tubular member being movably installed in association with a coiler furnace such that the cleaning element may be inserted into the coiler furnace and moved across the surface of the coiler drum, by moving the tubular member substantially parallel to the axis of rotation of the coiler furnace drum. The tubular member also includes means for moving the cleaning element roughly perpendicular to the longitudinal axis of the tubular member so as to bring the cleaning element into contact with the drum. In use, the cleaning element is inserted into the coiler furnace, brought into contact with the coiler drum and rotated so as to clean the coiler drum. Preferably, the cleaning element is a cylindrical brush having a plurality of resiliently-flexible carbide-tipped steel tines arrayed about its circumference. The tubular member may also include cooling means.

Owner:IPSCO ENTERPRISES

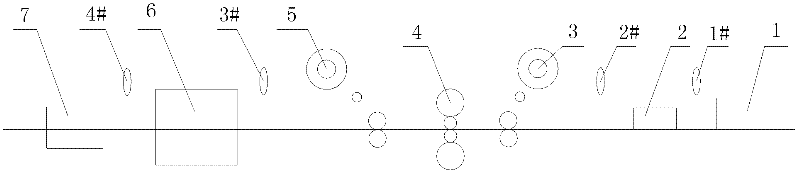

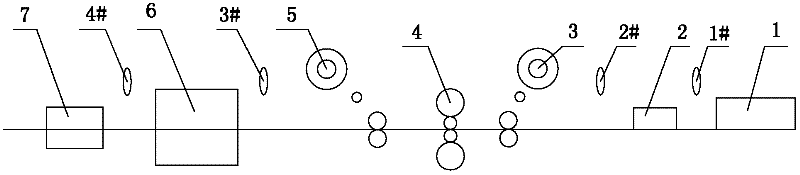

Gapless rolling process for single-strand steckel mill

InactiveCN101722194ARealize gapless rollingIncrease hourly outputRoll mill control devicesMetal rolling arrangementsHeating furnaceRolling mill

The invention discloses a gapless rolling process for a single-strand steckel mill. The rolling process is characterized in that before the steel throwing of the first blank, the second blank can be tapped and descaled, and can follow at safe speed; during the steel throwing of the first blank, the second blank is delivered into the mill to be rolled, and then the gapless rolling of the steckel mill is realized. The blanks can be flat rolling plate blanks or rolled rolling plate blanks. By modifying the two-stage and one-stage control programs of the mill, the rolling gap time of the two blanks is shortened; when the present blank is rolled, the rolling process of the next blank can be proceeded to a heating furnace area of the one-stage interface, and the tapping of the heating furnace in advance is realized; the next blank is descaled before the rolling of the previous blank is finished, and runs along with the previous blank towards the mill direction, and then the gapless rolling of the steckel mill is realized, and the hourly yield of the mill is enhanced.

Owner:NANJING IRON & STEEL CO LTD

Processing method for high-purity titanium sheet for coating titanium anode base material

Provided is a processing method for a high-purity titanium sheet for a coating titanium anode base material. O-stage sponge titanium with the average particle size being 3-25.4 mm is placed in an electron beam cold hearth and melted in a vacuum state so that a high-purity titanium slab can be obtained through purification; a hot coil which is 2.5-5 mm thick is manufactured through rolling of a steckel mill, and annealing is performed; shot blasting and pickling treatment need to be performed after annealing; the hot coil is placed on a reversible cold rolling machine to be subjected to many times of rolling; finally, a cold coil which is 0.5-2 mm thick can be obtained; the deformation rate is controlled to be 40-60% during each time of rolling; then the cold coil is subjected to degreasing treatment; then complete recrystallization annealing is performed in the vacuum state or the argon protection state, wherein the annealing temperature is controlled to be 600-720 DEG C and a titanium coil is obtained. As is detected, the average grain size of the titanium is controlled to be 15-30 microns, and the high-purity titanium sheet for the coating titanium anode base material is obtained after the titanium coil is straightened. The unevenness of the high-purity titanium sheet is smaller than or equal to 3 mm / m, and no strip-shaped flow direction lines exist after the high-purity titanium sheet is used as a coating.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

X56 pipeline steel and production method thereof

The invention provides X56 pipeline steel and a production method thereof. The X56 pipeline steel comprises the following chemical components: 0.060-0.090wt% of C, 0.20-0.30wt% of Si, 1.30-1.50wt% of Mn, not more than 0.008wt% of S, not more than 0.020wt% of P, 0.035-0.055wt% of Nb, 0.020-0.040wt% of V, 0.010-0.022wt% of Ti, not more than 0.008wt% of N, 0.010-0.040wt% of Als and the balance Fe and inevitable impurities. The production method is characterized by continuously finishing rough rolling and finish rolling on the same double-stand compact steckel mill after heating and descaling. The X56 pipeline steel has the following advantages: the strengthening effects of the microalloying elements added to the steel, such as Nb, V and the like are brought into full play through delay rolling control in the rolling process and the superfine and uniform structure is obtained, thus effectively preventing mixed crystals and greatly improving the strength and toughness of the X56 pipeline steel; and the X56 pipeline steel produced by the method has high-tech content, high added value and obvious economic benefits.

Owner:WUKUN STEEL

Production method for duplex stainless steel hot-rolled coils

ActiveCN104032108AEliminate edge cracksImprove thermoplasticitySS - Stainless steelHigh pressure water

The invention relates to a production method for duplex stainless steel hot-rolled coils. The production method comprises such steps as smelting, continuous casting, slab polishing, tandem type slab heating, high-pressure water scale removal, rough rolling, rolling by a steekle mill and coiling; the content of S in steel is controlled below 0.0007%; Creq / Nieq is controlled within 1.92-1.97; the slab isometric crystal rate is controlled above 80%; the reasonable slab length and slab heating temperature are actually determined by combining with the scene; the process of slab high-pressure water scale removal one-gate and rough rolling frame non-scale removal is adopted; in particular, the rolling temperature of the hot rolling steekle mill is controlled; the produced stainless steel hot-rolled coils have no edge cracks, so that the yield is prominently improved; the problem of the edge crack defect generated by rolling the steel coils through the steekle mill in the rolling process is solved; and the edge quality of the hot-rolled steel coils is guaranteed.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Hot rolling process of stainless plate strip coil

ActiveCN101767106AThe overall thickness is thinIncrease the lengthTemperature control deviceMetal rolling arrangementsFurnace temperatureComposite plate

The invention provides a hot rolling process of a stainless composite plate strip coil, which comprises the following steps of: heating and sending a stainless composite plate blank to a steckel mill; flatly rolling: repeatedly carrying out rough rolling for a plurality of times under the conditions that a rolling temperature is 1050-1250 DEG C and the rolling speed is smaller than 12.6 mm / min; then, sending into a coiling furnace; carrying out coil rolling: repeatedly carrying out fine rolling for a plurality of times under the conditions that the coiling furnace temperature is 550-1000 DEG C and the final rolling temperature is 800-1000 DEG C; finally, directly sending the plate blank into a coiling machine or after cooling the plate blank to 450-700 DEG C; and coiling to obtain a thinner and longer stainless composite plate strip coil with better flatness and surface quality and higher strength and plasticity. The invention has high working efficiency, yield rate, low consumption, high automation degree and low production cost, and can roll various types of stainless composite plate strip coils with different thicknesses and sizes in a batch of dozens of tons to several hundred of tons and fully utilize the additional rolling equipment to produce.

Owner:WUKUN STEEL

High-pressure low-flow descaling process of four-roller reversing steckel mill

InactiveCN101862760APrevent pitting/pocket defectsAvoid damageWork treatment devicesMetal rolling arrangementsSheet steelEngineering

The invention relates to a descaling process of a steckel mill, which is a high-pressure low-flow descaling process of a four-roller reversing steckel mill; two sets of independent descaling systems are simultaneously arranged on the steckel mill; one set is high-pressure and high-flow, maintains quite large hitting force, is used when a milled piece is in the starting phase of milling and is quite thick, and removes quite thick primary oxidized iron skin with quite high viscosity; the other set is high-pressure low-flow, reduces the flow while maintaining the descaling pressure unchanged, is used when the milled piece is in the last procedure and is quite thin, removes quite thin and loose secondary oxidized iron skin during the milling process and special oxidized iron skin in a coiling furnace, prevents the over temperature drop of the descaling water to the milled piece, and ensures that the milling temperature meets the process requirements. The high-pressure low-flow descaling process of the four-roller reversing steckel mill can reduce the temperature drop of a steel sheet during a descaling process, can descale in all procedures of the steckel mill, and can prevent the descaling water from entering the coiling furnace.

Owner:NANJING IRON & STEEL CO LTD

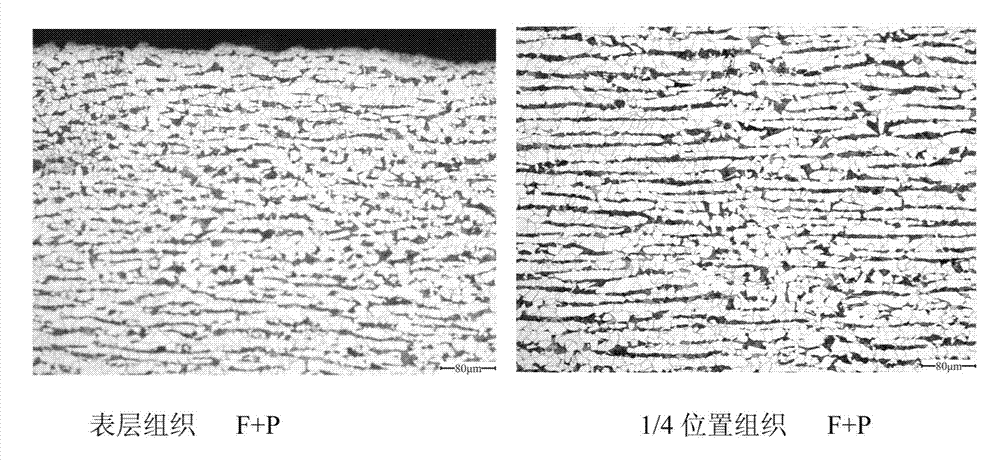

Control process for single-stand Steckel mill to produce special-purpose pipeline steel

InactiveCN102513370AEasy to controlMeet the temperatureTemperature control deviceMetal rolling arrangementsOne passThermal dilatation

The invention relates to a control process for a single-stand Steckel mill to produce special-purpose pipeline steel, which has the following requirements: the tapping temperature of a heating furnace is equal to or higher than 1150 DEG C, the second-stage bloom rolling temperature is lower than or equal to 900 DEG C, the thickness of temperature-holding billets is smaller than or equal to 3.3h, the finish rolling temperature ranges from 780 DEG C to 820 DEG C, nine or eleven rolling passes are required, the reduction rate of the last but one pass is equal to or larger than 9% or equal to or smaller than 13%, the reduction rate of the last pass is 0%, the finish rolling speed at the last but one pass V is equal to or larger than 1.45m / s or is equal to or smaller than 1.75m / s, the secondary rolling coefficient is selected according to conditions of plate shapes, roll body cooling water is turned on according to conditions of rolling cycle, abrasion of working rolls and heat expansion, rolled workpieces are required to swing on a roll bed in front of a straightening machine before entering a cooling system, and a gap between an inlet of the straightening machine and an outlet roll is set according to the requirement that plastic deformation of the rolled workpieces is equal to or larger than 80% at least in the thickness direction before the rolled workpieces enters the straightening machine. The control process not only can meet requirements for finish rolling temperature, entry temperature and re-reddening temperature but is combined with rolling and straightening processes, controls performance and plate forms comprehensively, and particularly realizes comprehensive control in hot rolling and flat rolling of the single-stand Steckel mill to performance and plate forms of special-purpose pipeline steel.

Owner:NANJING IRON & STEEL CO LTD

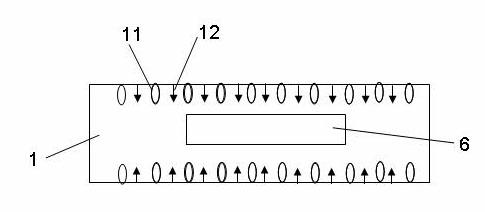

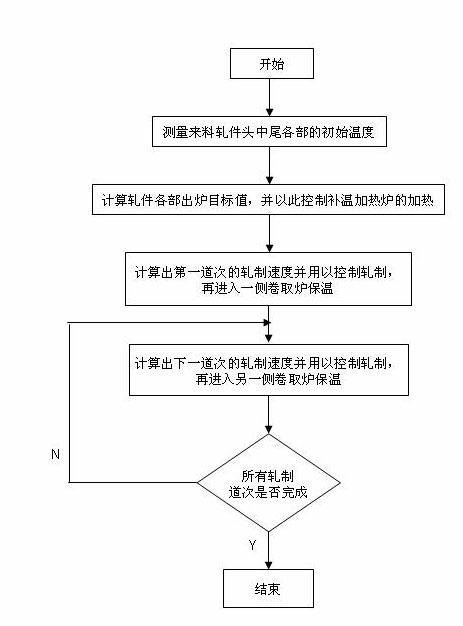

Temperature difference control method for rolling pieces for steckel mill

InactiveCN102601128AReduce temperature differenceImprove calculation accuracyTemperature control deviceProduction lineStrip mill

The invention discloses a temperature difference control method for rolling pieces for a steckel mill. The method includes steps of measuring initial temperature of the rolling pieces; calculating discharging target temperature value of a temperature complement furnace and heating the rolling pieces according to the target temperature value; calculating a set value of rolling speed of each rolling step and performing controlled rolling at each step according to the set value to reduce temperature difference; and measuring actual temperature of an exit and an entrance of a rolling mill and comparing the actual temperature with corresponding values to realize self-learning of the model and enhance calculating precision of the model. By the method, the temperature differences among the head, the middle and the tail of each rolling piece are reduced greatly, and rolling stability and quality of finished products and production ability of a production line are enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Gauge control technique for top and tail of hot rolled strip steel of Steckel mill

ActiveCN103801565AMitigate temperature differencesReduce super thick effectRoll force/gap control deviceTemperature control deviceWork rollHigh-pressure area

The invention discloses a gauge control technique for top and tail of strip steel, and overpressure protection rolls which is located in a high pressure area of top and tail and is protected from being damaged. The gauge control technique comprises steps as follows: during a strip steel rolling process, the end of the strip steel firstly entering the mill is the top, the end later entering the mill is the tail, a high pressure area is set at the top and tail of the strip steel during calendaring, the length of the high pressure area is 0-30 m, and the actual roll gap is S-(S minus 2.5) mm; high rolling reduction of the top is reduced during the last rolling process of the strip steel; during rolling of the tail, when 10-18 m of the tail length remains, the actual roll gap is adjusted gradually to S plus 0.5 mm-S plus 1.5 mm, S represents a target roll gap which refers to a roll gap set between upper and lower work rolls of the mill according to a calculation instruction. The gauge control technique has the advantages that high rolling reduction is performed on the top and tail of the strip steel, so that not only is thickness tolerance of the top and tail of the strip steel reduced and the rolling yield improved, but also roll damage accidents due to strip steel clamp by the rolls are avoided.

Owner:浦项(辽宁)汽车配件制造有限公司

Process for improving ultra-thick head and tail of hot rolling strip steel of Steckel mill

InactiveCN101745540AReduce overthicknessHigh yieldRoll mill control devicesMetal rolling arrangementsStrip steelEngineering

The invention discloses a process for improving ultra-thick head and tail of a hot rolling strip steel of a Steckel mill. The process comprises the steps that: an automatic thickness control mode for eliminating the ultra-thick head and tail is added in an automatic thickness control mode of a finishing mill and is adopted in the front three passes of a finish rolling process; when the part is bitten into the strip steel head by less than or equal to 20 meters in the mode, the roll gap is set as 3 to 5 percent less than the normal value; when the part is bitten into the strip steel tail by less than or equal to 30 meters, the roll gap is set as 2 to 3 percent less than the normal value; and moreover, the temperature of the cooling water for a scroll is raised to 70 to 80 DEG C from the normal temperature in order to achieve better improvement effect. The process has the advantages of greatly reducing the ultra-thick degree of the head and the tail, shortening the ultra-thick length and improving the hot rolling casting yield through the temperature change of the cooling water for the scroll and the addition of the thickness control mode.

Owner:朱浩锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com