Deep sea pipeline steel produced based on steckel mill and preparation method thereof

A furnace coil rolling mill and pipeline steel technology, applied in the field of deep-sea pipeline steel and its preparation, can solve problems such as immature deep-sea pipeline steel technology, and achieve the effects of compact equipment, uniform and stable performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

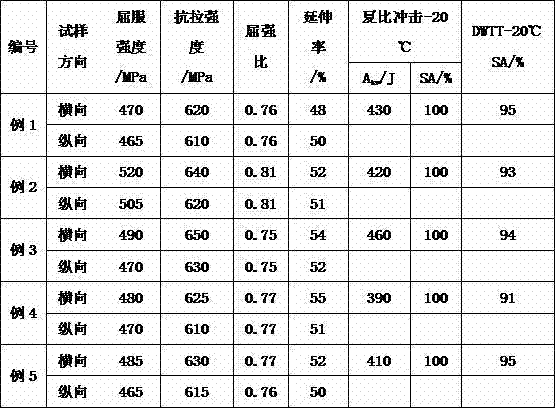

[0031] The chemical composition (wt%) of Examples 1-5 is shown in Table 1.

[0032] The chemical composition (wt%) of table 1 embodiment

[0033] C Si mn P S N Nb Ni Cr Cu Mo Example 1 0.04 0.25 1.52 0.008 0.001 0.0041 0.049 0.16 0.03 0.04 0.10 Example 2 0.04 0.24 1.54 0.007 0.001 0.0042 0.052 0.15 0.02 0.03 0.09 Example 3 0.045 0.15 1.55 0.009 0.001 0.0047 0.052 0.17 0.02 0.03 0.10 Example 4 0.05 0.24 1.51 0.008 0.001 0.0038 0.053 0.17 0.02 0.04 0.09 Example 5 0.05 0.25 1.55 0.009 0.001 0.0043 0.050 0.18 0.03 0.04 0.11

[0034] In the above table 1, the chemical composition balance of each embodiment is Fe and trace impurities.

[0035] Preparation Process:

[0036] Each chemical composition in Table 1 is smelted to obtain molten iron;

[0037] Molten iron pretreatment: The molten iron pretreatment is processed according to the end-point sulfur ≤ 0.002% mode, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com