Patents

Literature

296results about How to "Uniform and stable performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative electrode and non-aqueous electrolyte secondary battery using the same

InactiveUS20080096110A1Good charge and discharge cycle performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsPorous substrateConductive materials

The negative electrode for a non-aqueous electrolyte secondary battery of the present invention includes a conductive porous substrate, and a conductive material and an active material filled in pores of the porous substrate. The active material contains at least one of a metal element and a semi-metal element capable of reversibly absorbing and desorbing lithium.

Owner:PANASONIC CORP

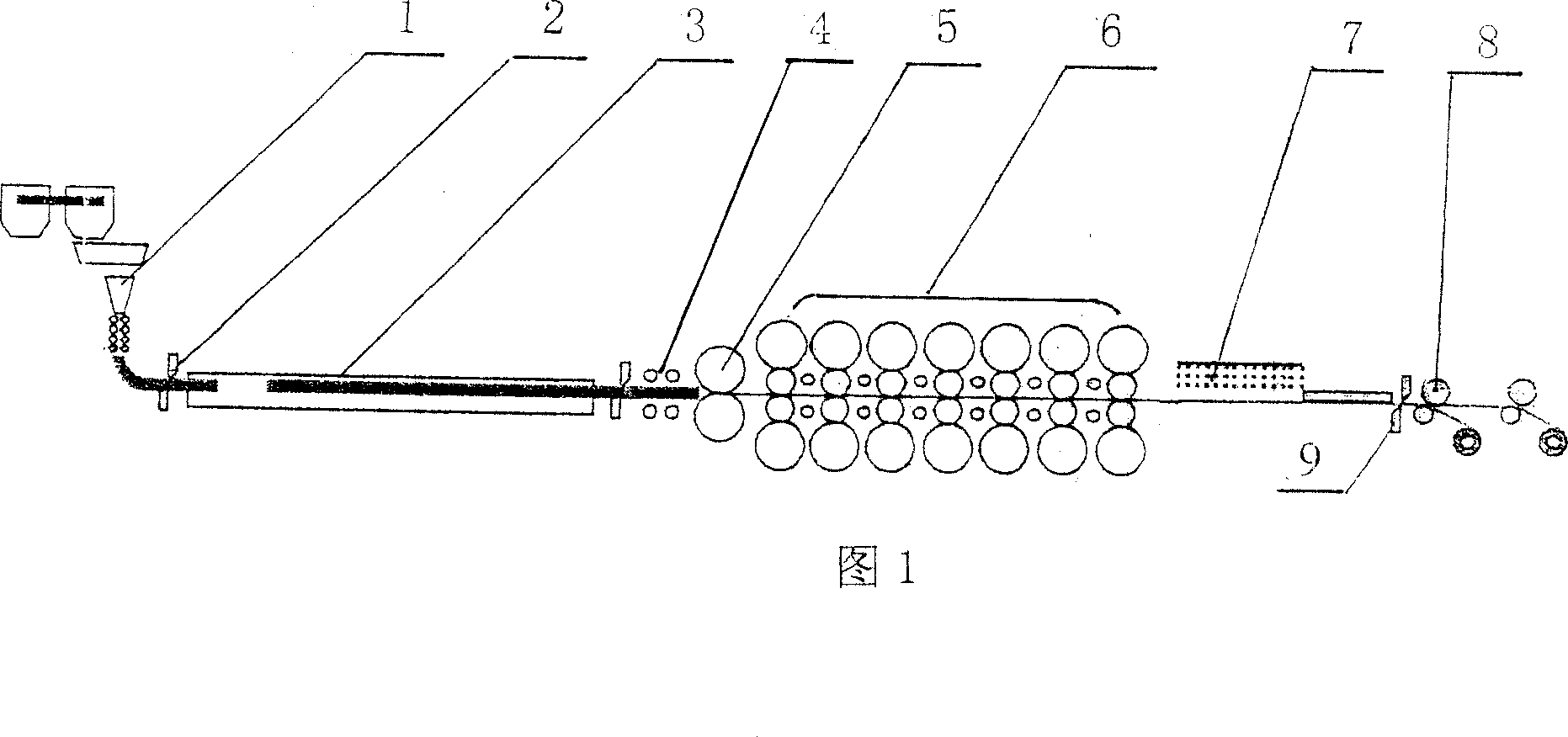

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

Self-dispersion type nanometer gamma A100H and its preparation method and use

A gamma-AlOOH nanocrystal powder able to be automatically dispersed in aqueous and some organic solvents for preparing self-dispersing superfine non-toxic aluminum hydroxide flame-retarding agent, or the high-molecular polymer / inorganic nano-material composition, or the microcrystalline alumina ceramics or high-performance alumina ceramics as grinding medium is prepared through reaction of sodium aluminate or Al salt solution in alkaline medium, extracting the generated deposit, adding peptizing agent and disperser, peptizing and dispersing to obtain aluminum hydroxide colloid, reacting on additive and surfactant for surface modifying, and spray drying.

Owner:GUANGXI UNIV FOR NATITIES

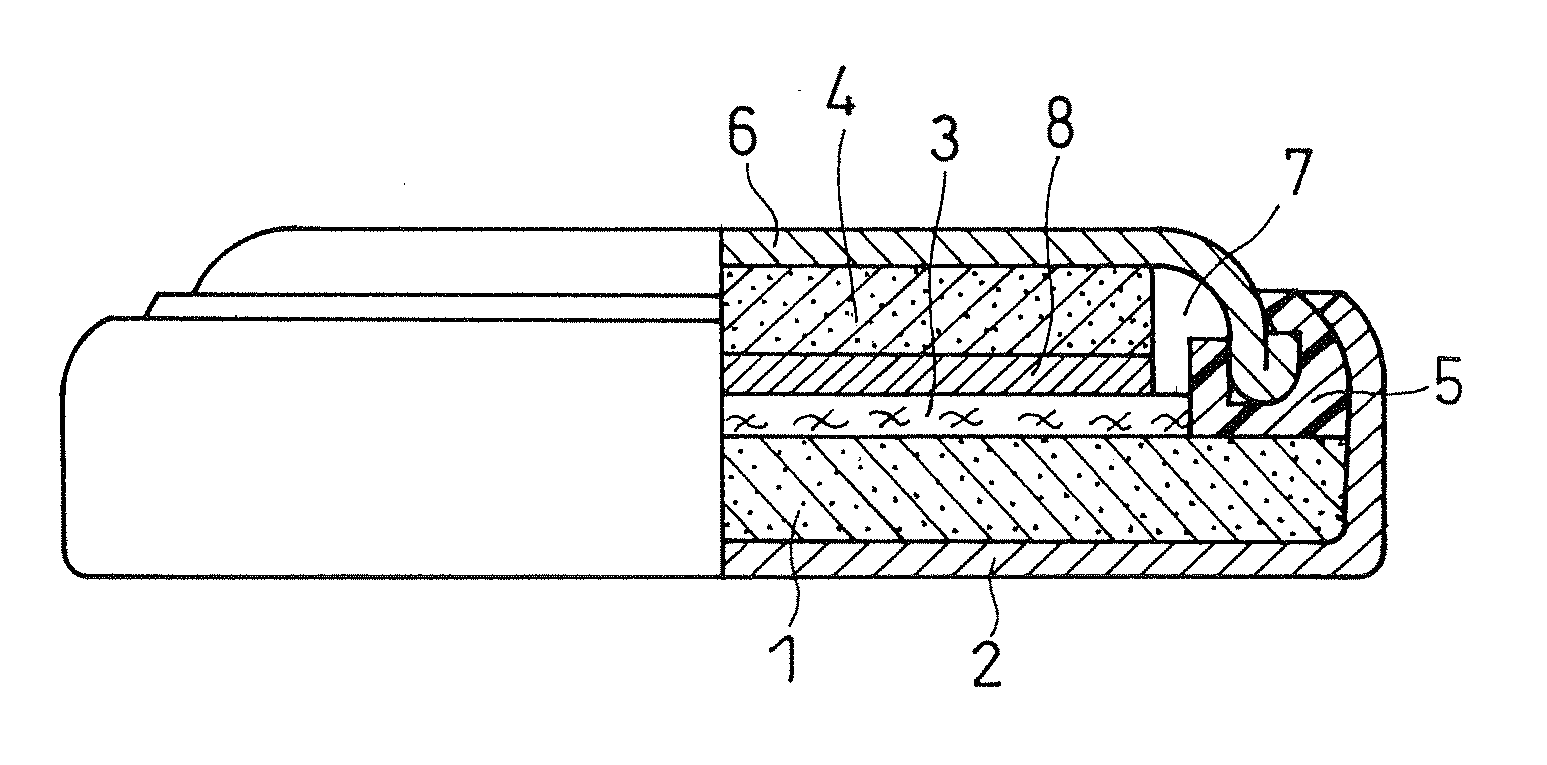

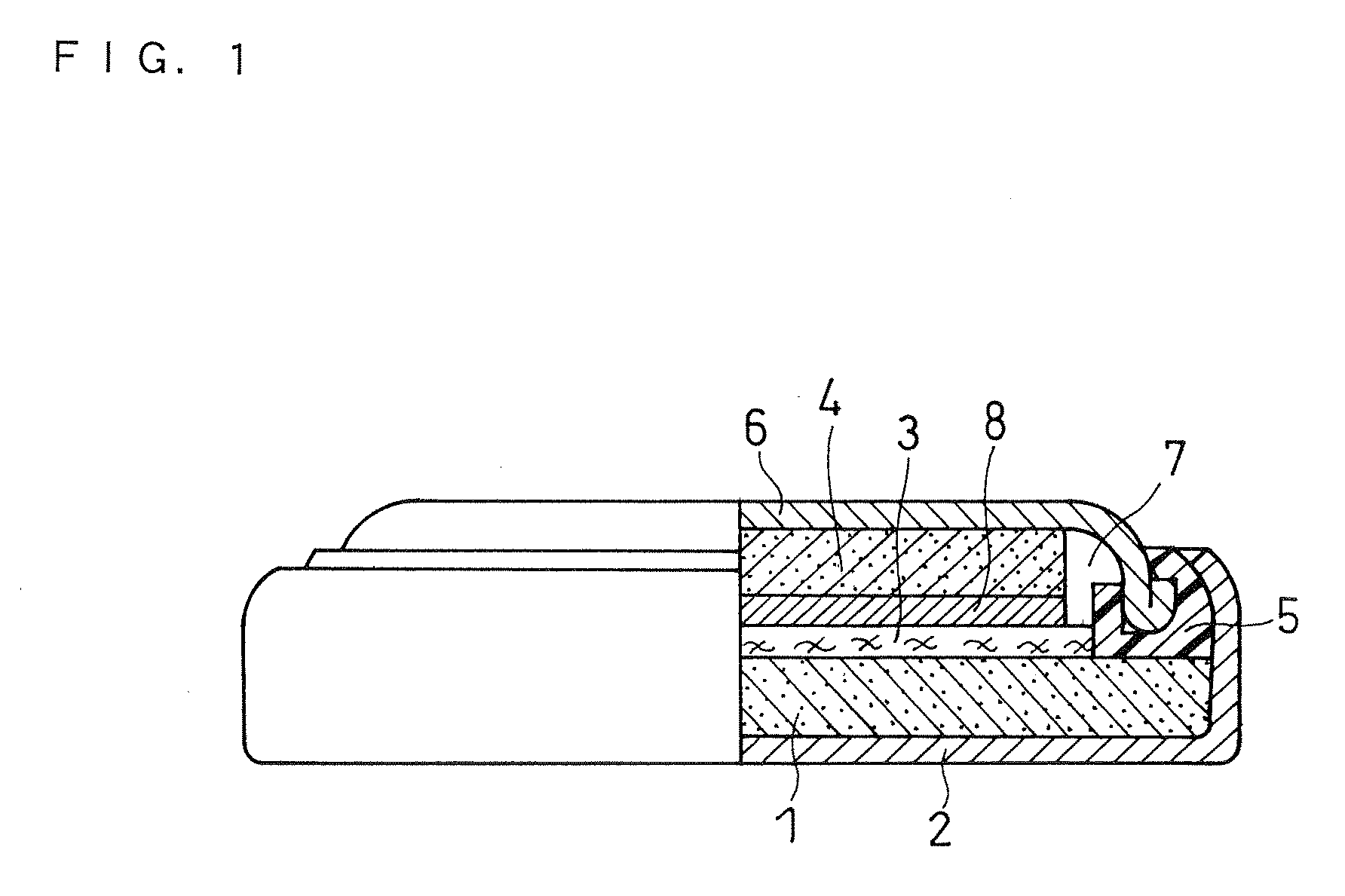

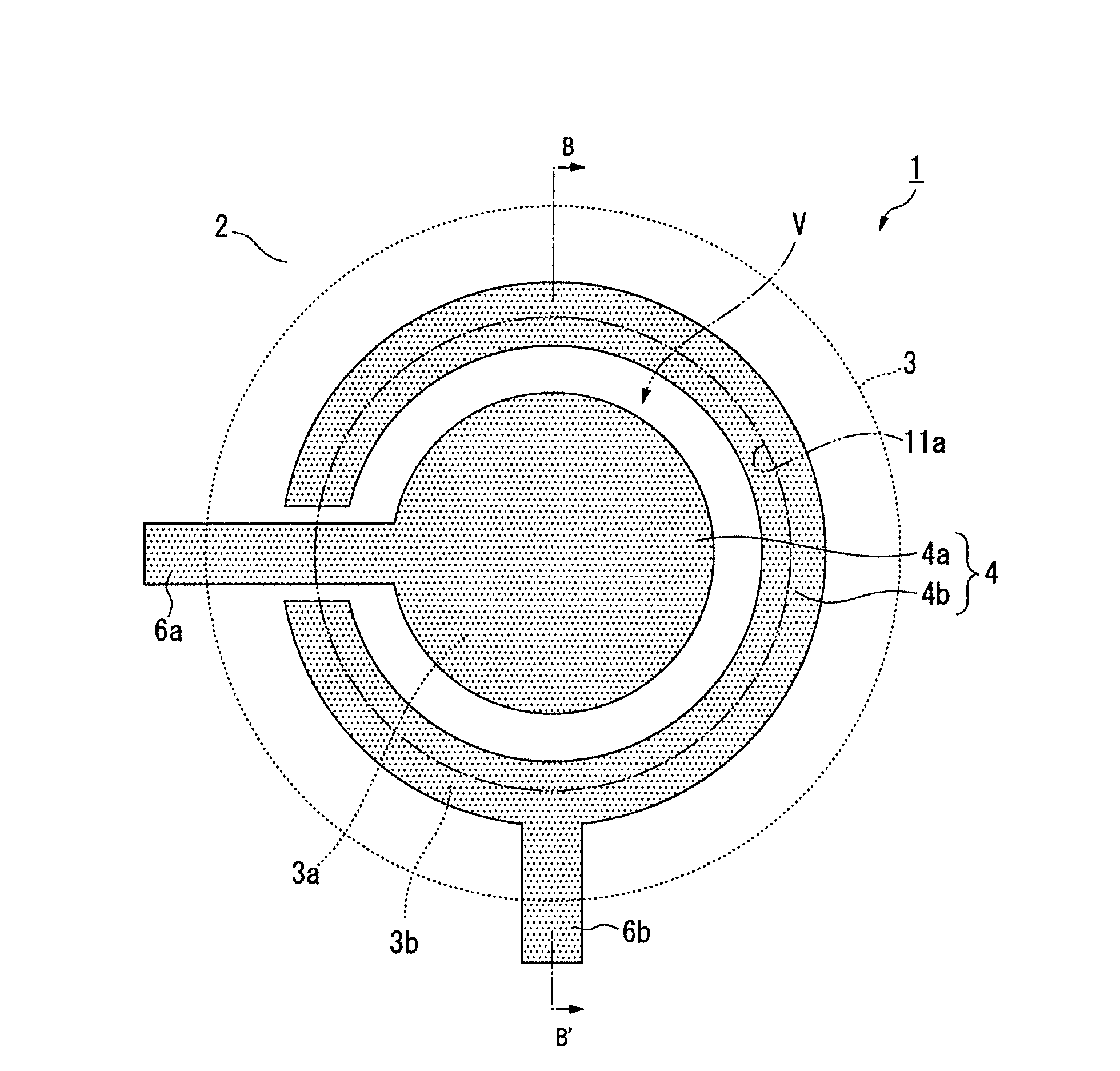

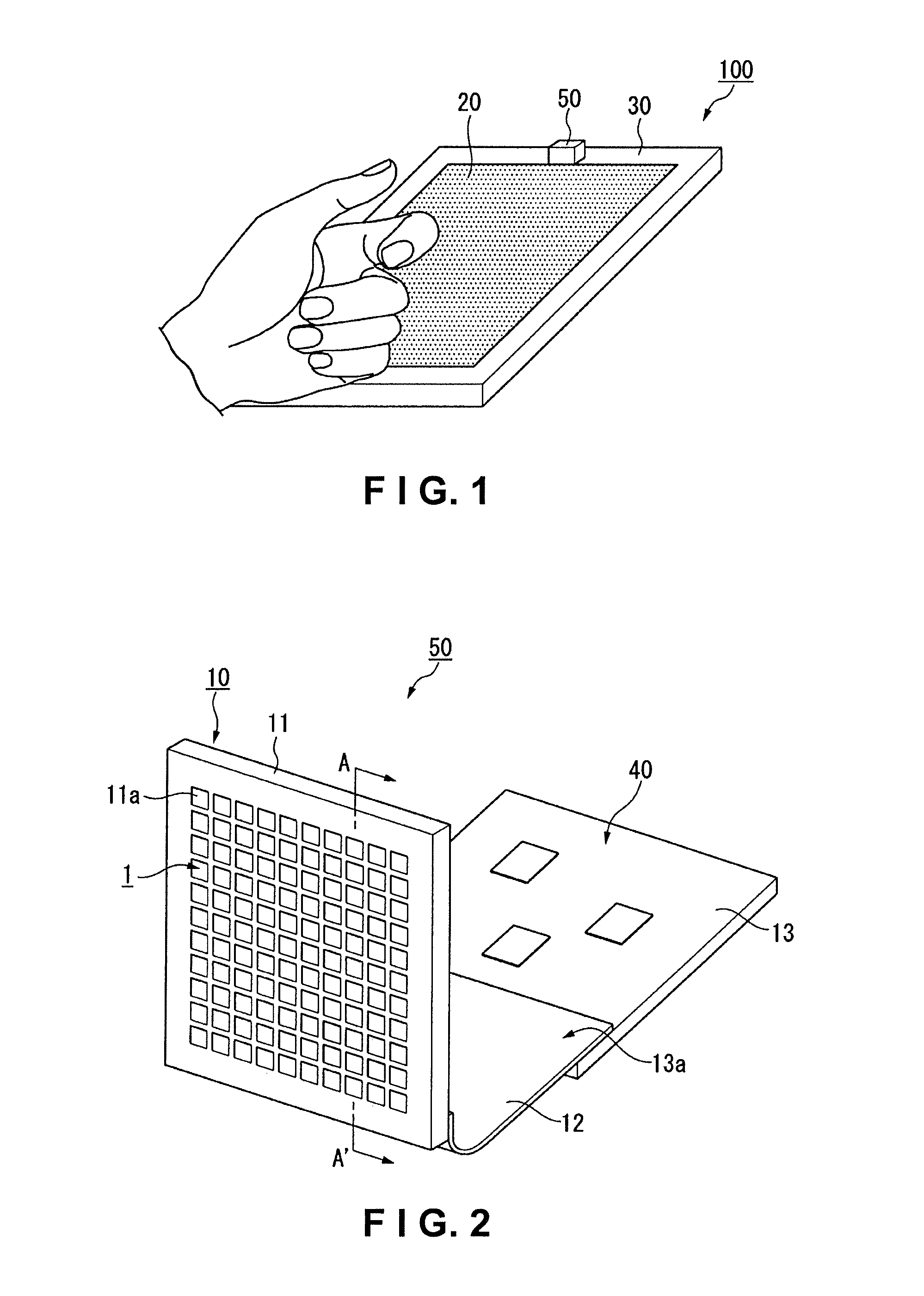

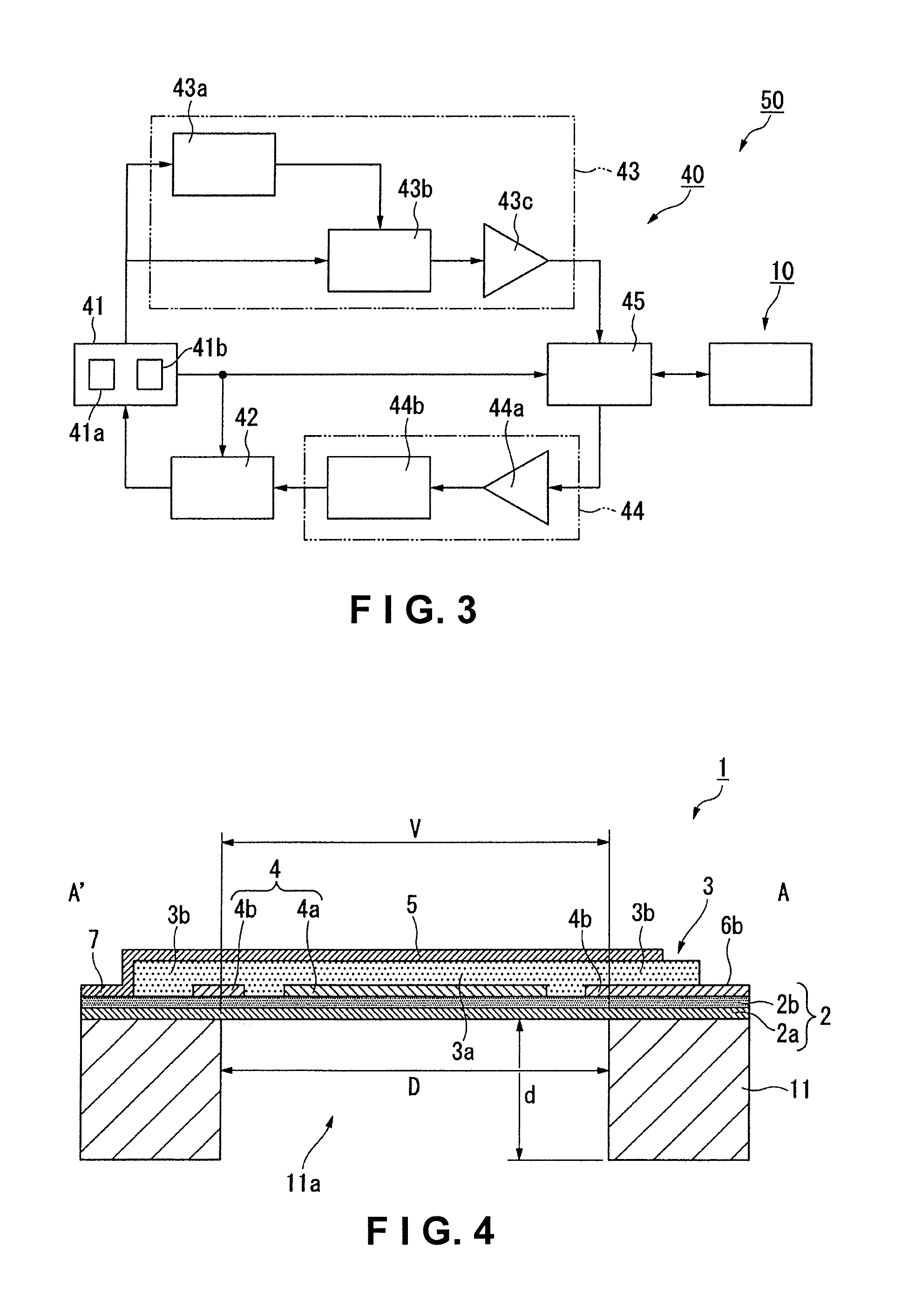

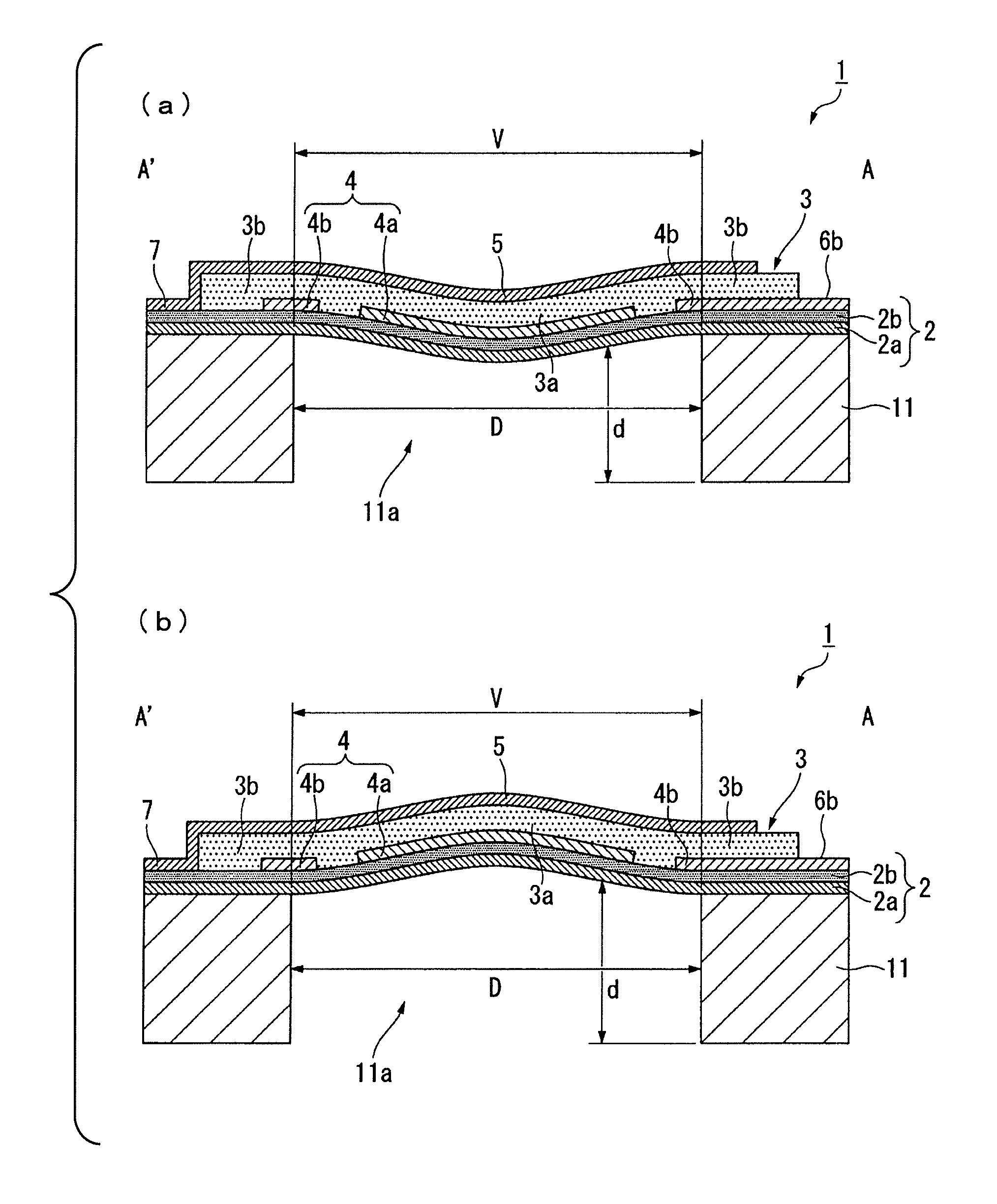

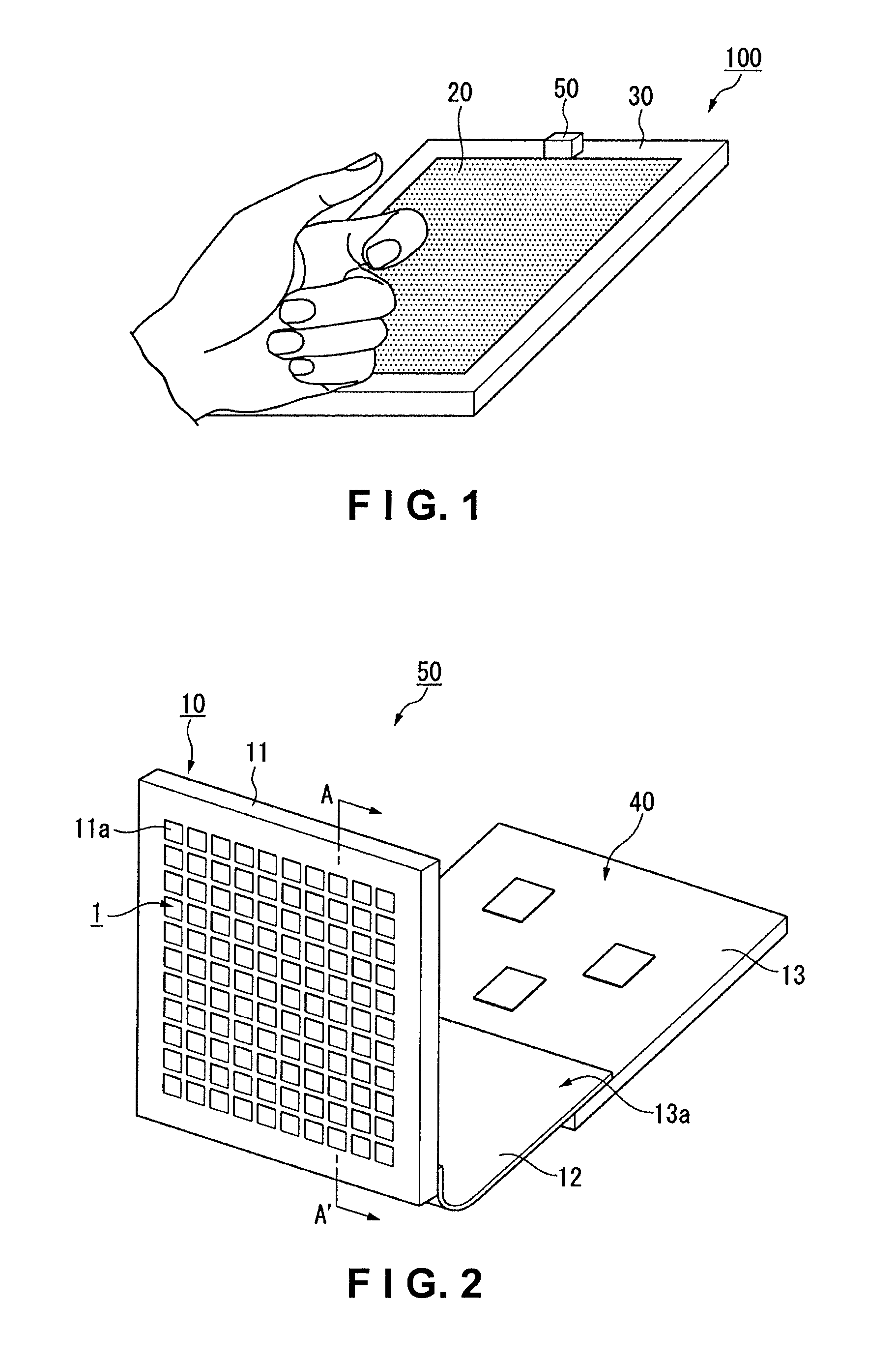

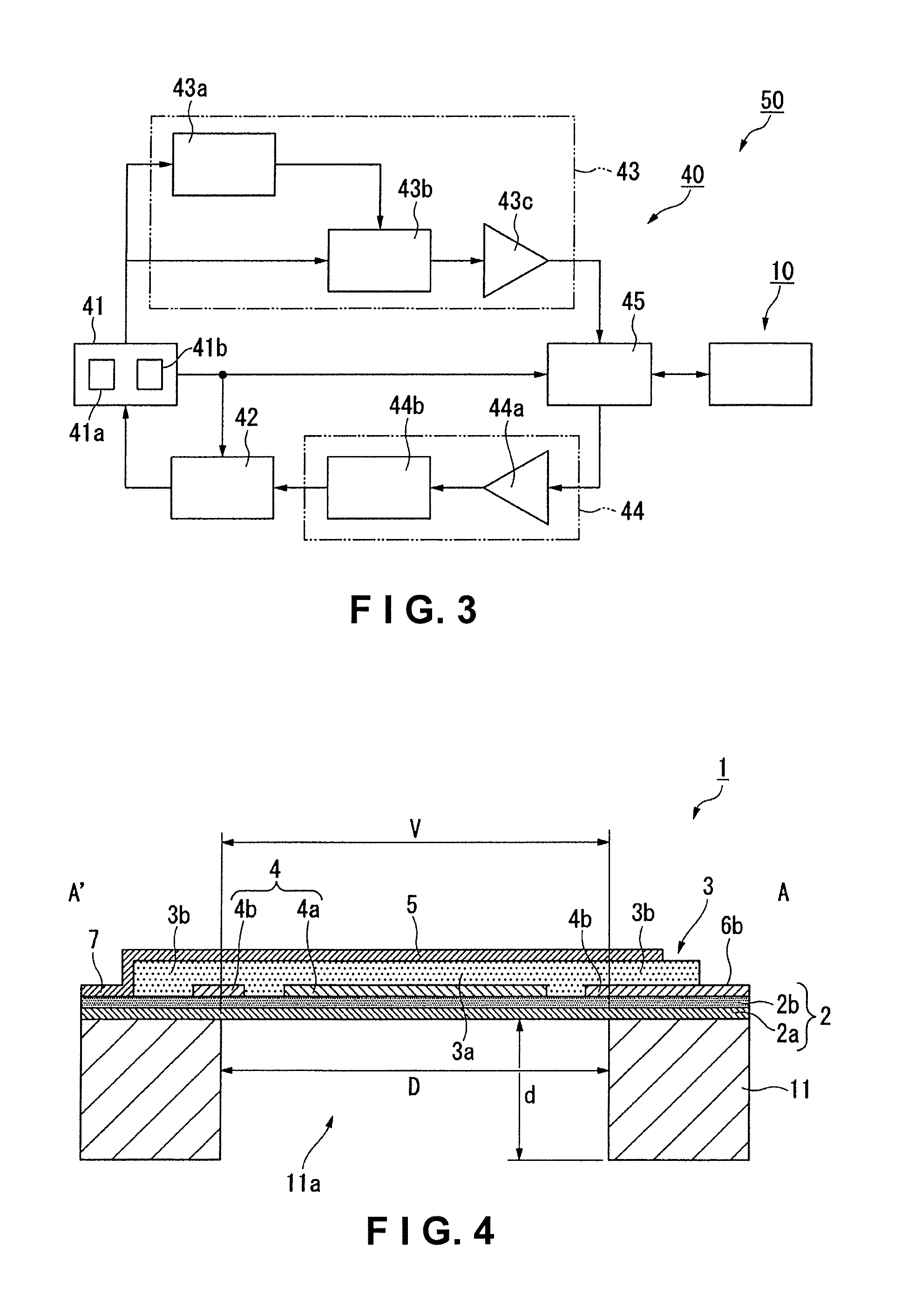

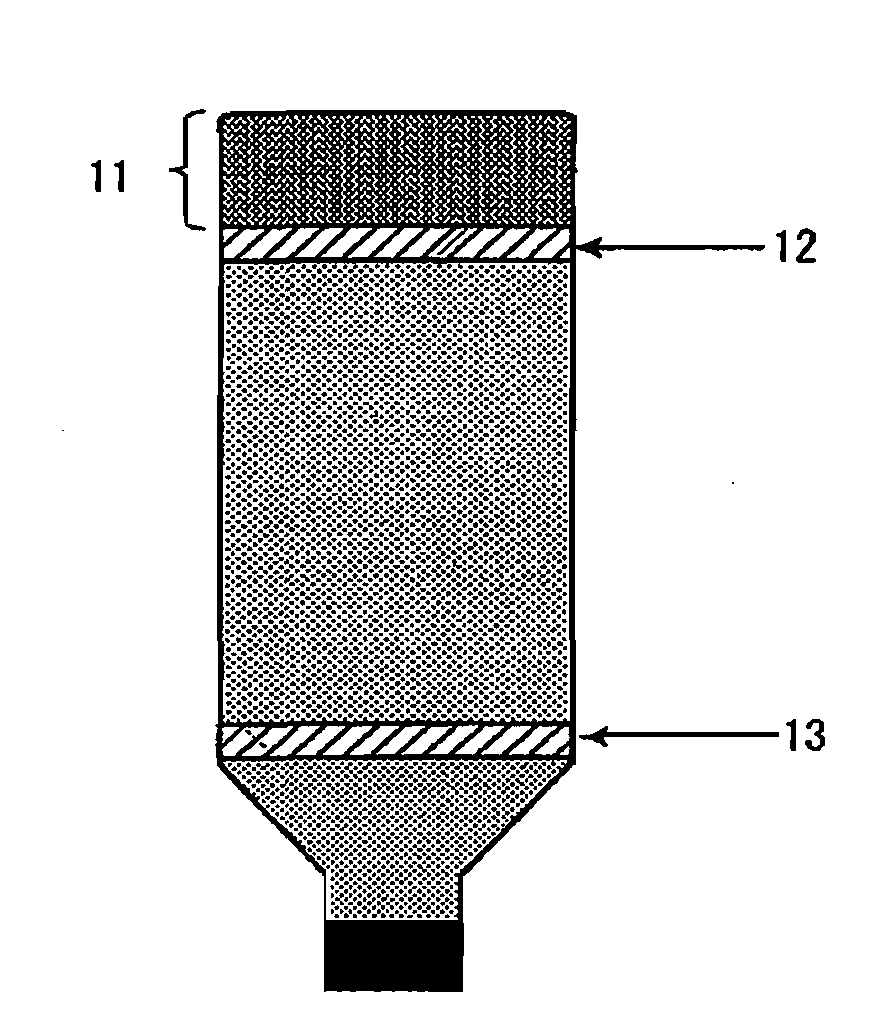

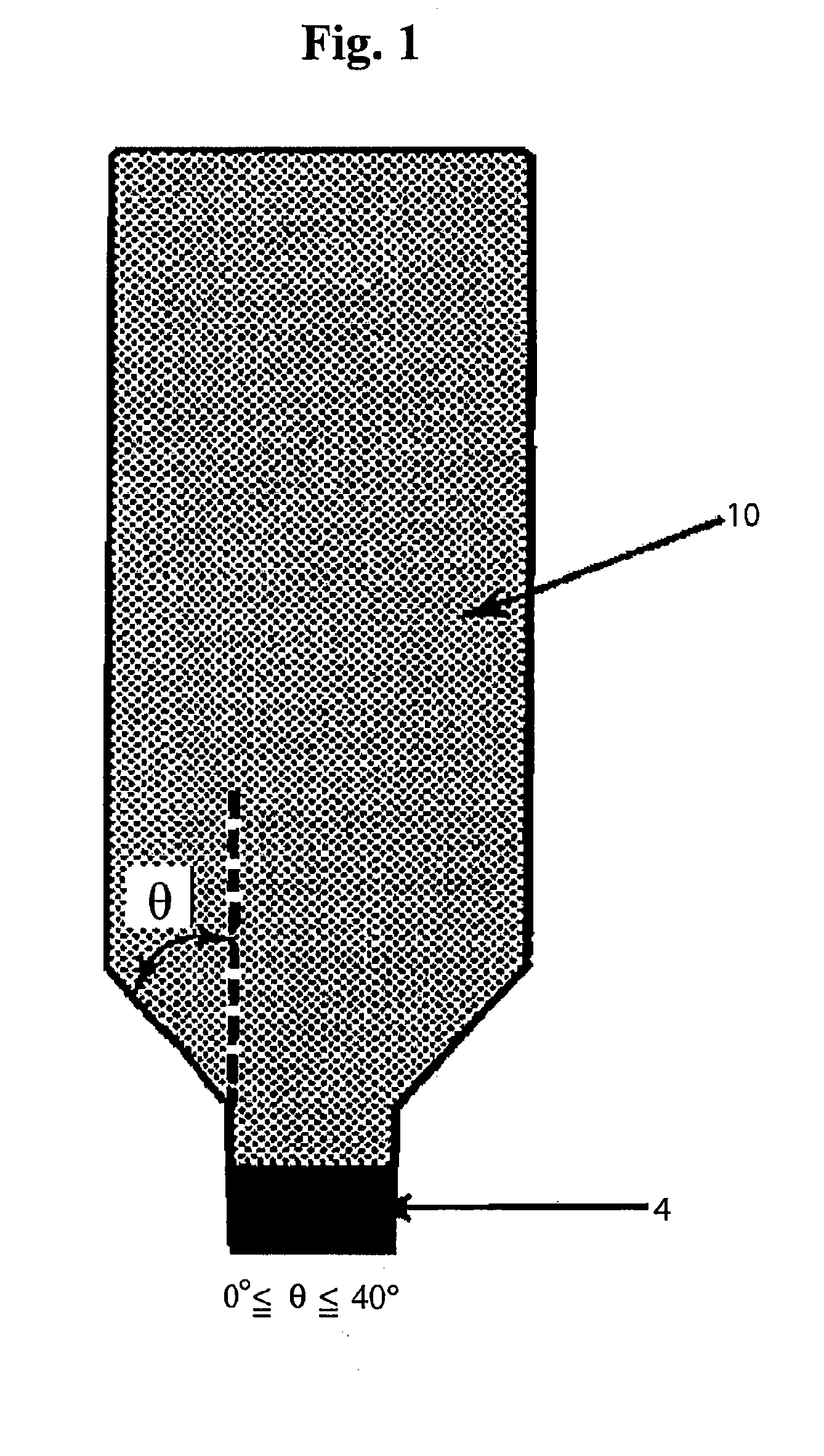

Ultrasonic transducer, ultrasonic transducer array, and ultrasonic device

ActiveUS20100148627A1Easy to optimizeUniform and stable propertiesSubsonic/sonic/ultrasonic wave measurementPiezoelectric/electrostriction/magnetostriction machinesPotential differenceUltrasound

An ultrasonic transducer is configured to transmit or receive ultrasonic waves. The ultrasonic transducer includes a vibrating member and a piezoelectric member coupled to the vibrating member. The piezoelectric member includes a first piezoelectric part configured and arranged to be deformed by applied voltage to vibrate the vibrating member or configured and arranged to be deformed by vibration of the vibrating member to produce a potential difference, and a second piezoelectric part configured and arranged to be deformed by applied voltage to statically deflect the vibrating member.

Owner:SEIKO EPSON CORP

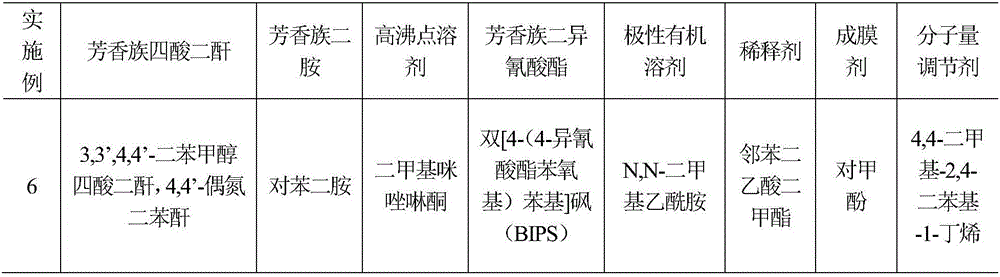

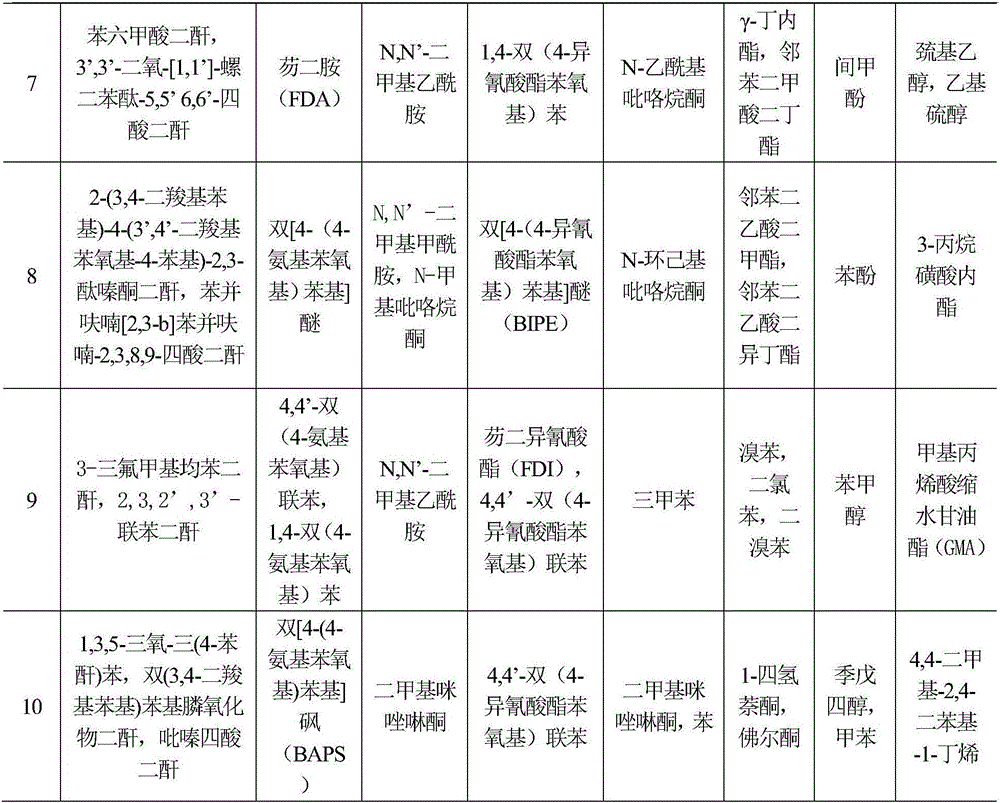

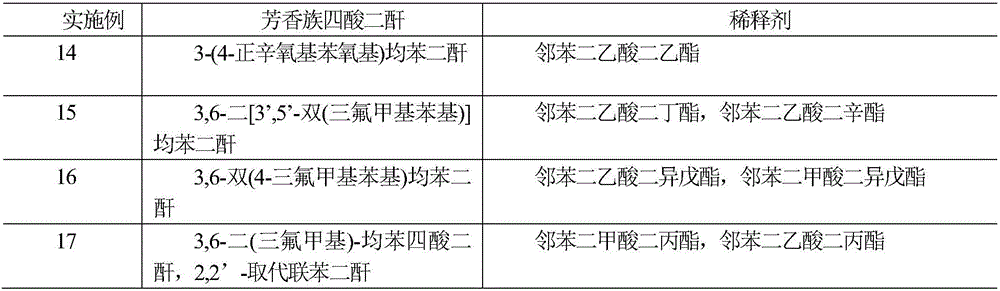

Method for preparing polyimide nano-film

The invention provides a method for preparing a polyimide nano-film. The method comprises the steps: firstly, synthesizing polyimide resin from aromatic tetracid dihydride, aromatic diamine and aromatic diisocyanate; and then, mixing the polyimide resin, a polar organic solvent, a diluent, a film forming agent and a molecular weight regulator so as to obtain a polyimide solution system, then, carrying out nano-scale uniform spreading on a clean substrate by dint of the action of a mechanical external force of 0.5N to 30N, and then, carrying out an imidization method, thereby preparing the polyimide nano-film. According to the film, the high-temperature resistance is 10 seconds at the high temperature of 400 DEG C to 750 DEG C, and the electrical insulation property is that the dielectric constant is 1.5 to 4.5 at the frequency of 103Hz. Compared with the prior art, the polyimide nano-film prepared by the method has the advantages of excellent surface physical properties and stable chemical properties, high-temperature resistance, electrical insulation properties and chemical corrosion resistance.

Owner:SHAANXI UNIV OF SCI & TECH

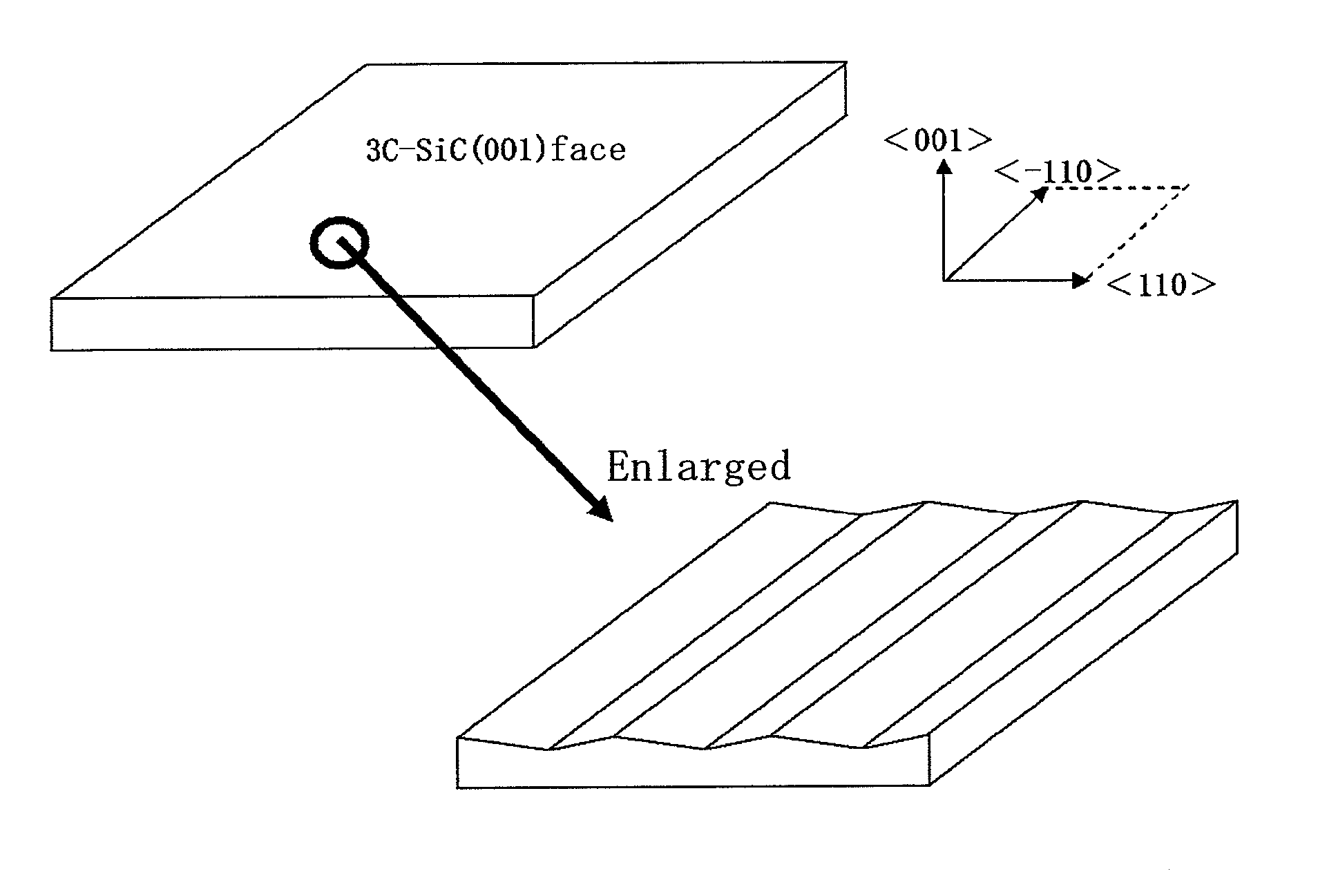

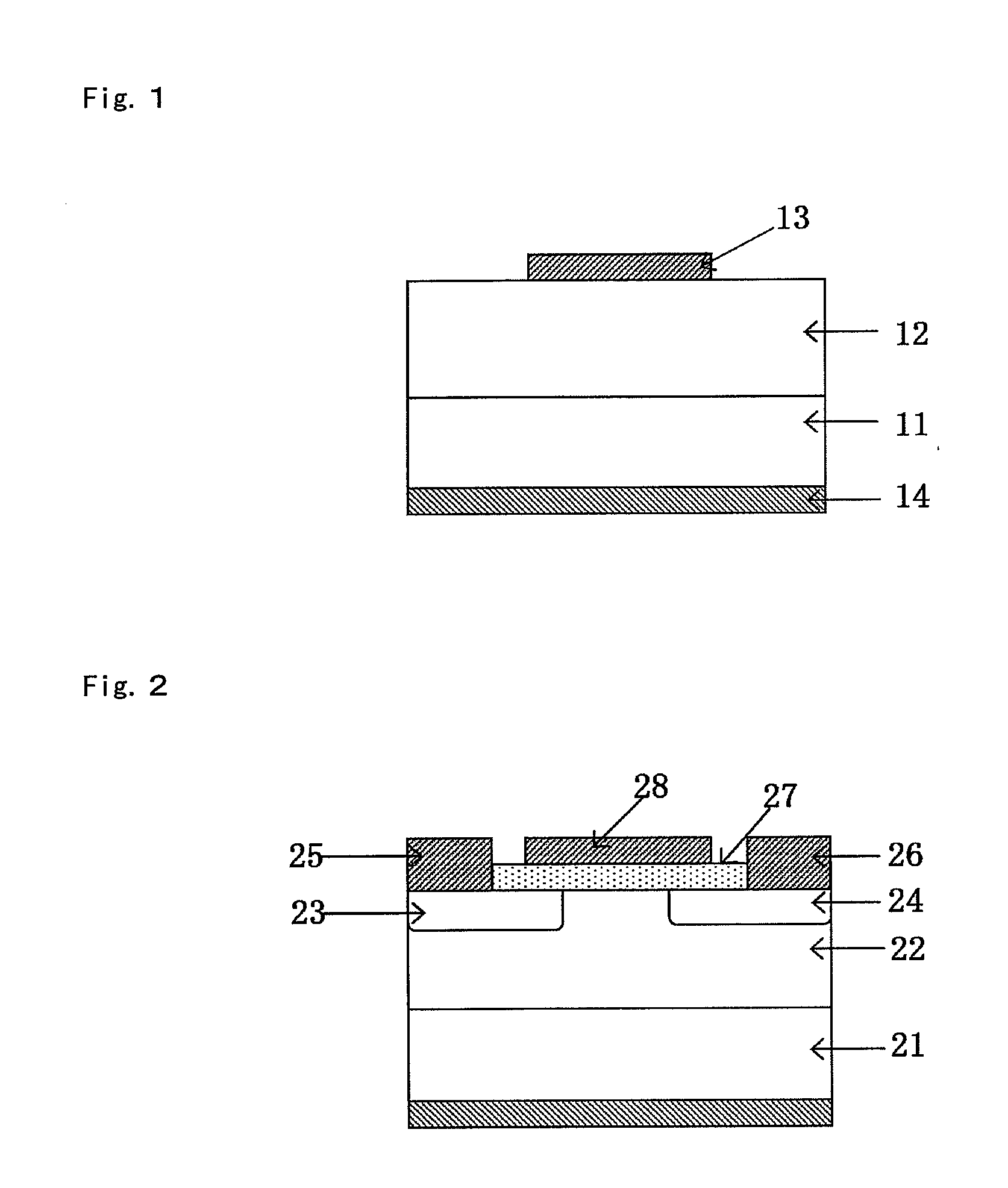

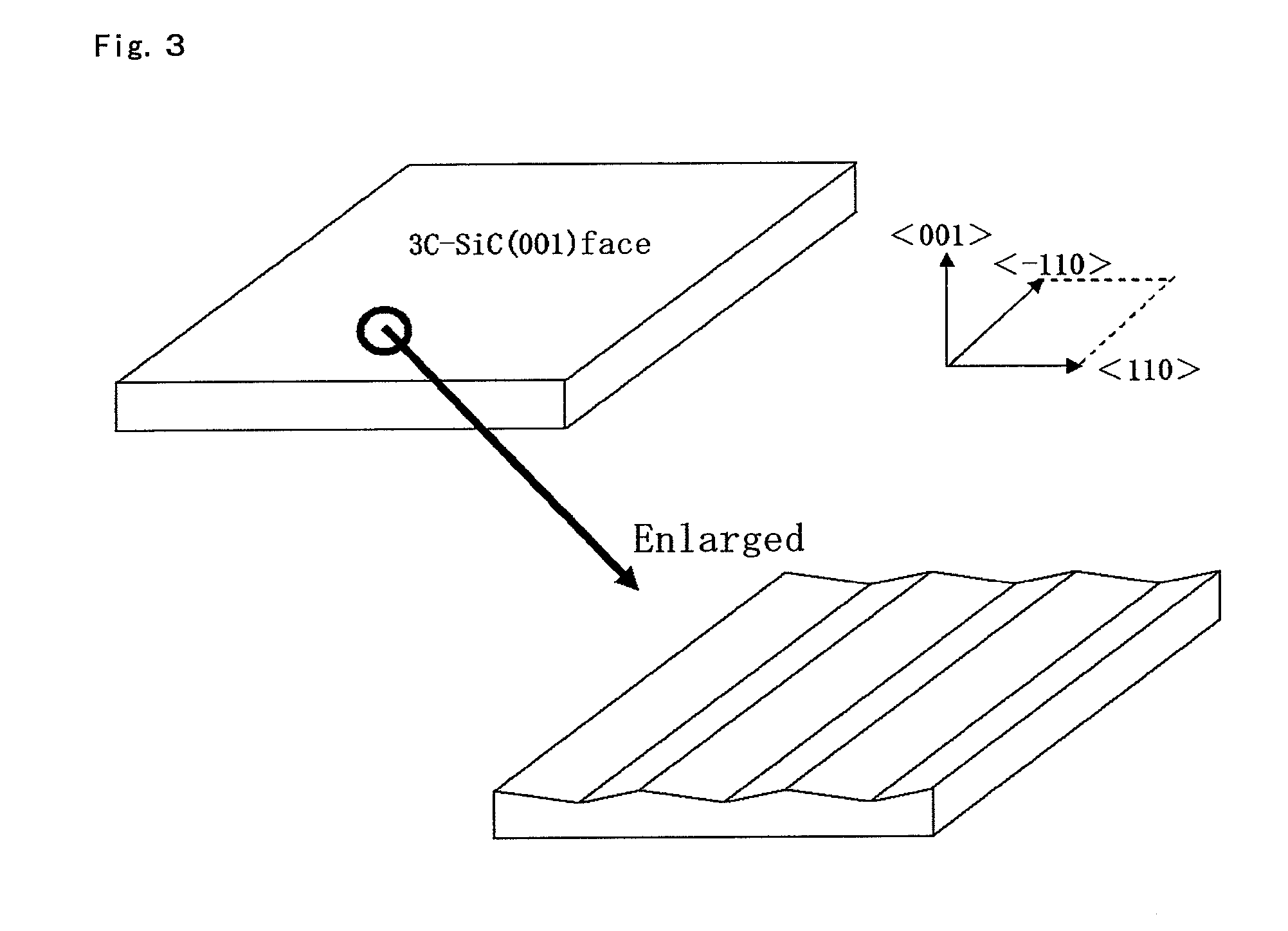

Semiconductor device and semiconductor device manufacturing method

InactiveUS20110006310A1No deterioration smoothnessUniform and stable rectifying propertySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialCarbide

A semiconductor device comprises a semiconductor substrate made of silicon carbide, a gate insulating film formed on the semiconductor substrate, and a gate electrode formed on the gate insulating film. The junction surface of the semiconductor surface joined with the gate insulating film is macroscopically parallel to a nonpolar face and microscopically comprised of the nonpolar face and a polar face. In the polar face, either a Si face or a C face is dominant. A semiconductor device comprises a semiconductor substrate comprised of silicon carbide and a gate electrode formed on the semiconductor substrate. The junction surface of the semiconductor surface joined with the electrode is macroscopically parallel to a nonpolar face and microscopically comprised of the nonpolar face and a polar face. In the polar face, either a Si face or a C face is dominant. The present invention is a semiconductor device having a silicon carbide substrate, and the electrical characteristics and the stability of the interface between the electrode and the silicon carbide or between the oxide film (insulating film) and the silicon carbide in the nonpolar face of a silicon carbide epitaxial layer can be improved.

Owner:HOYA CORP +1

Lignose and process for modifying phenolic resin with derivates thereof

The invention discloses a lignin and a method for modifying a phenolic resin which is a ramification thereof. The method that the polymerization is performed for a plurality of times and the extent of polymerization is deepened gradually is adopted to improve the uniform stability, the inoxidability, the toughness and the intensity of the product, effectively recycle the wasted resources, lower the cost and make the industrialization easier. The invention is realized by the technical proposal which is as follows: the phenolic resin low polymer is prepared firstly; the lignin or a ramification thereof is added to polymerize in order to obtain a preformed polymer secondly; finally, phenol and formaldehyde are added to polymerize in order to obtain the high polymer. A molding material prepared by the phenolic resin can be widely applied to the manufacture of a low-voltage apparatus, an insulating structure and a product for daily life.

Owner:JILIN UNIV

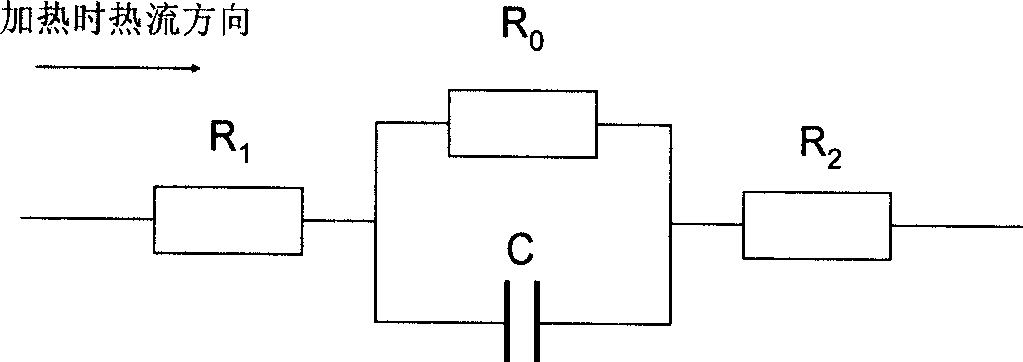

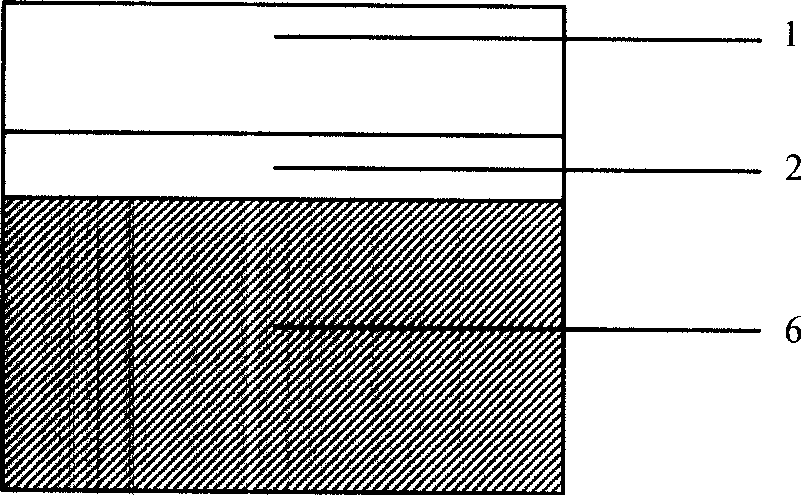

Novel phase change-heat preservation composite wall structure

InactiveCN101413299AImprove peak clipping delay effectImprove thermal inertiaWallsHeat proofingInsulation layerThermal insulation

The invention relates to a novel phase change and heat insulation composite wall structure, which is applied to the heat insulation of a wall and mainly comprises a heat insulation layer, a figurate phase change layer and a wall base body to form an integrative composite structure. The heat transmission resistance of the composite wall structure can be evaluated according to the material and the thickness of the wall base body so as to figure out the material thickness of the heat insulation layer and ensure that the heat transmission resistance of the wall base body is equal to that of the heat insulation layer, so that the despicking delay effect of the phase change layer to the temperature variation is improved to the utmost extent. The composite wall structure gives full play to the heat insulation effect of the heat insulation layer and the heat storage and temperature regulation effect of the phase change layer to improve the thermal inertia of the wall body greatly. The composite wall structure has stable performance and is convenient in construction and energy-saving reconstruction of old buildings to achieve the effects of high efficiency and environmental protection.

Owner:武汉科华高新材料发展有限公司

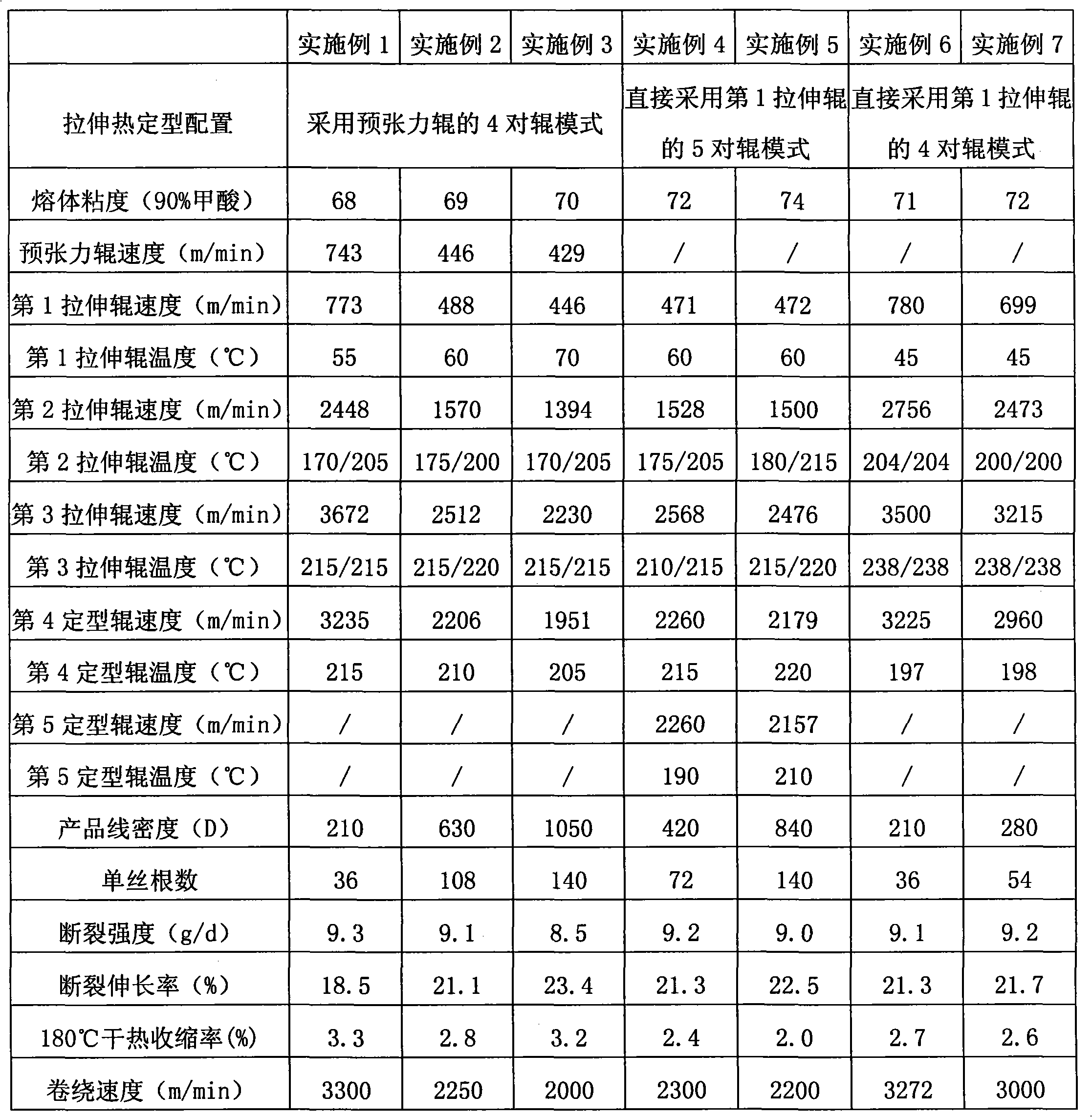

High-strength ultra-low thermal contraction nylon 66 fiber and production method thereof

InactiveCN101619503AIncrease productivityImprove performanceFilament manufactureArtificial filament heat treatmentShrinkage rateEconomic benefits

The invention belongs to the technical field of synthetic fiber production, in particular relates to a high-strength ultra-low thermal contraction nylon 66 fiber and a production method thereof. The nylon 66 fiber is characterized in that the strength is 8.0-9.5g / d, the elongation at break is 18-24%, the free hot air shrinkage rate at 180 DEG is 2.0-4.0%, the linear density is 150-1050D, and the monofilament linear density is 4.0-8.0D. The high-strength ultra-low thermal contraction nylon 66 fiber has advanced performance and can meet higher industrial use requirements; the production adopts a one-step method, thereby achieving high-speed, continuous and stable production with high production efficiency and high yield and uniform and stable performance of products in different batches; and the production method has short technological processes and obvious economic benefit.

Owner:SHEN MA INDUSTRY CO LTD

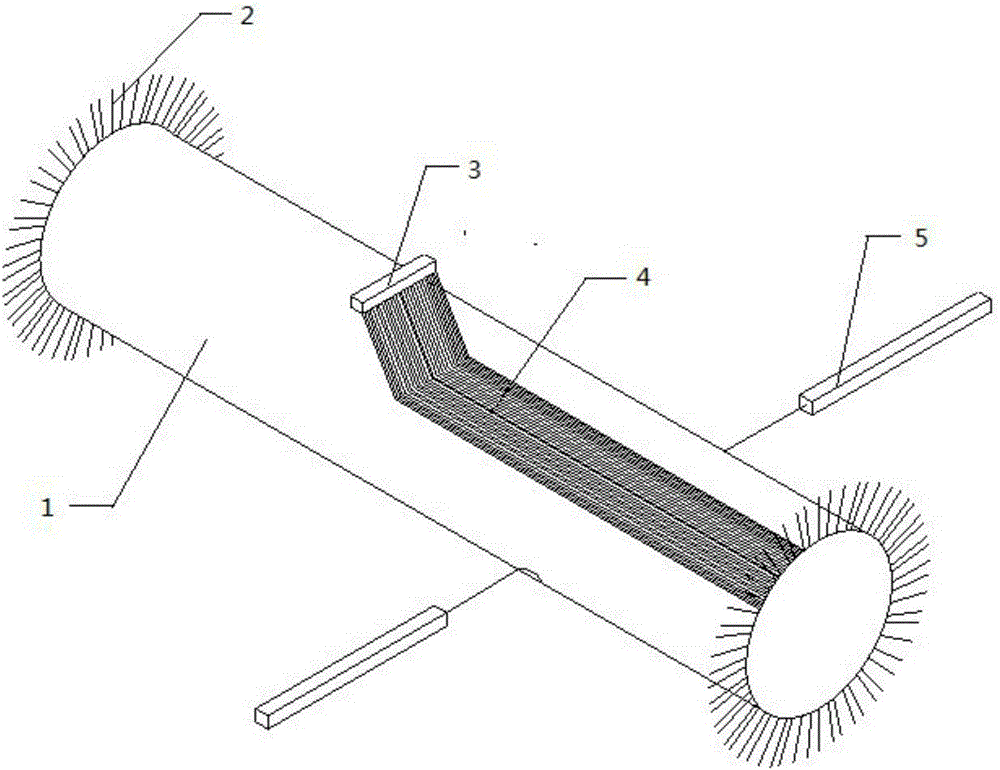

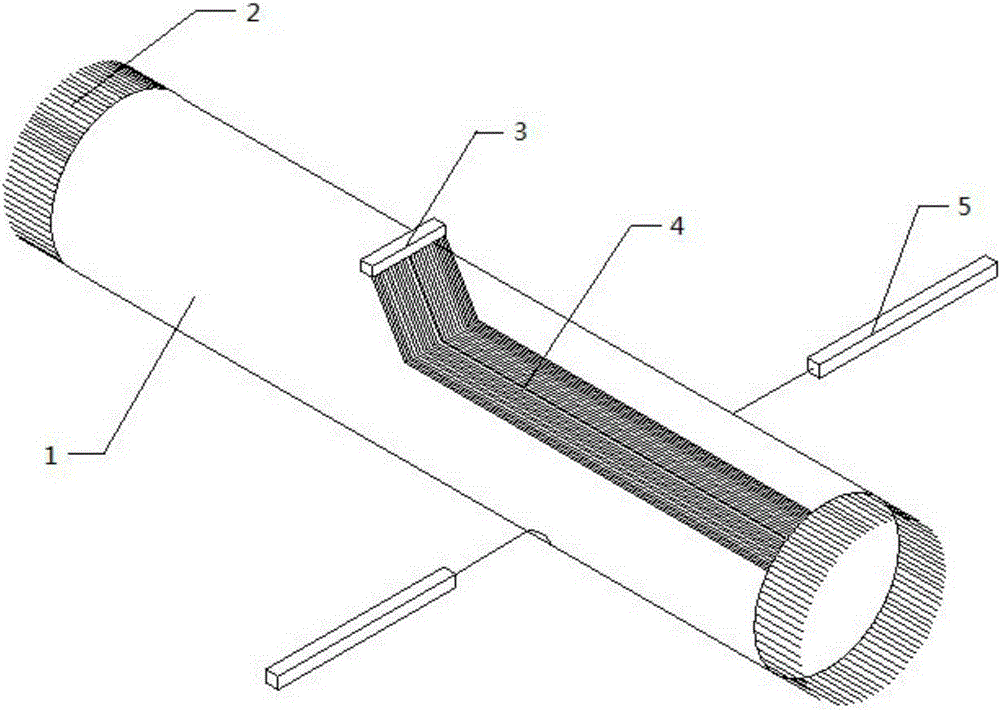

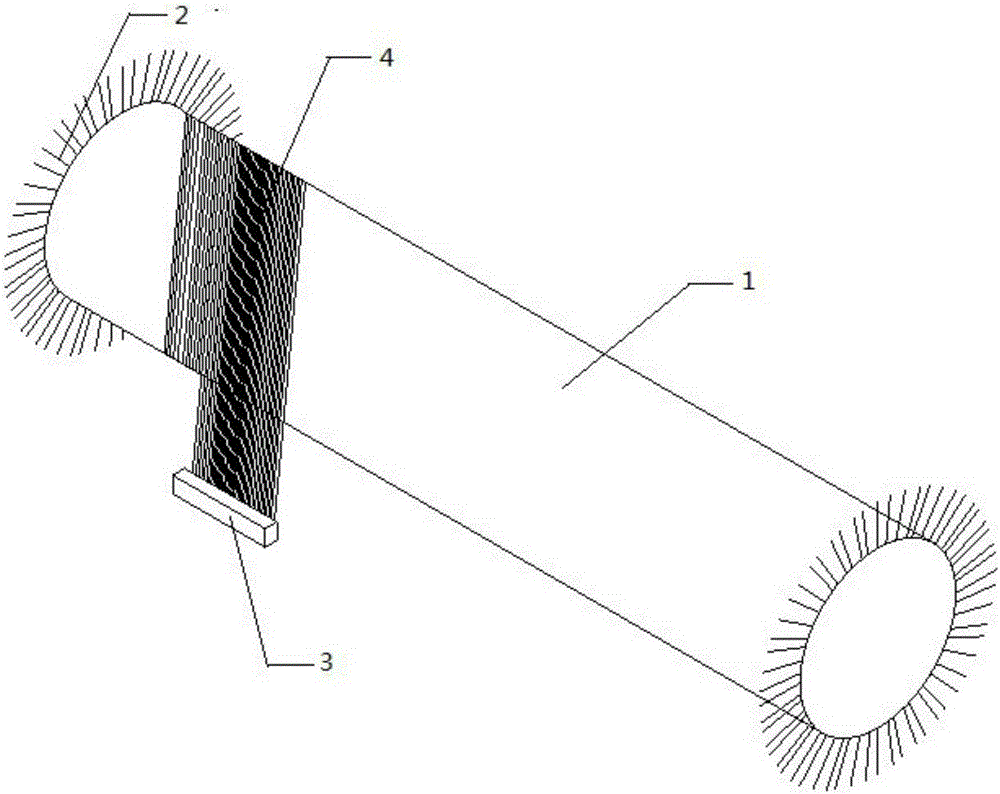

Manufacturing method for glass steel pipeline in zero-degree winding manner

The invention discloses a manufacturing method for a glass steel pipeline in a zero-degree winding manner. The method sequentially comprises the steps that winding yarn immersed in resin is used for hoop winding, then, a wire guiding head drives the winding yarn to pass multi-tooth comb rings buckled at the two ends of a core die to be axially wound, finally, winding yarn immersed in resin is in hoop winding again to stabilize an axial winding layer, hoop and axial winding is repeated, and pipeline winding with different strength requirements is achieved. Continuous winding of the axial zero degree of the winding yarn and pipelines is achieved, the axial mechanical performance of the pipelines is optimal, and then the high requirement of industrial fields for the axial performance can be met. The required axial strength is achieved, the production cost is reduced to the maximum degree, meanwhile, the pipeline thickness is reduced, and the pipelines are convenient to transport and use.

Owner:HEBEI HAOZHENG NON METALLIC MATERIALS TESTING SERVICES CO LTD

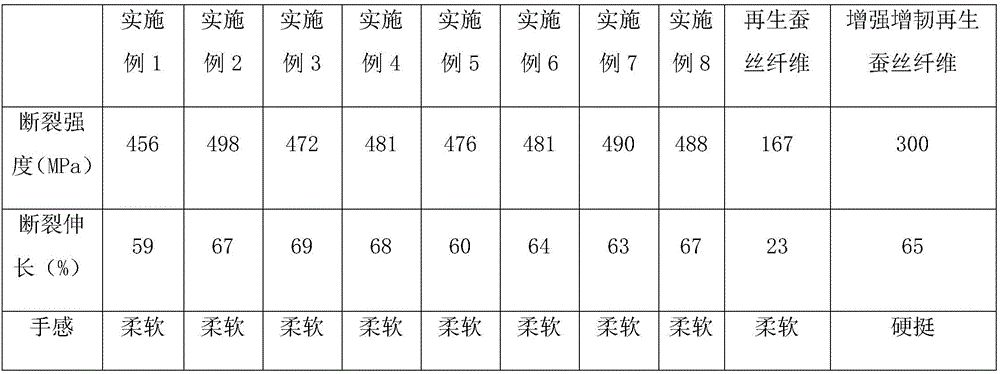

Graphene modified silk fiber preparing method

ActiveCN105926075AExcellent physical and chemical propertiesGood biocompatibilityElectroconductive/antistatic filament manufactureMonocomponent fibroin artificial filamentHigh intensityThermal stability

The invention provides a graphene modified silk fiber preparing method. Regenerated silk aqueous solution is prepared by dissolving a fibroin membrane and then mixed with graphene oxide aqueous solution and chitosan with low molecular weight to prepare regenerated silk fiber, and a graphene film is formed on the surface of the regenerated silk fiber through atomization; in this way, graphene exists inside the regenerated silk fiber and on the surface of the regenerated silk fiber, the functions of the silk fiber are modified fundamentally, high strength, high conductivity and high thermal stability of the silk fiber are realized, and the original properties of the silk fiber are optimized to the maximum degree by optimizing the regenerated silk aqueous solution preparing process.

Owner:ZHAOQING LAIXIN BODY BEAUTY UNDERWEAR

Preparation method of multiphase ceramic powder

The invention relates to a preparation method of a multiphase ceramic powder, comprising the following steps of: (1) mixing carbide, boride, silicide and a metal oxide as raw material powders, adding a dispersant and a binder and grinding in an aqueous system to obtain a wet material; (2) carrying out spray-drying and granulation on the wet material obtained from the step (1) to obtain the multiphase ceramic powder. With the introduction of the dispersant, the binder and an antifoaming agent and with the combination of the stirring, grinding, mixing, spray-drying and granulation technologies,multi-phases are uniformly dispersed, thus greatly raising material reliability and performance uniformity. By the adoption of the advanced spray-drying and granulation technology, the powder is moresuitable for dry-pressing or continuous dry-pressing molding after spray-drying and granulation. The preparation method can be used to realize batch production and produce a heating-surface heating element with stable and uniform performance and adjustable resistivity, and has advantages of high production efficiency and low cost.

Owner:宁波沃甘电子科技有限公司

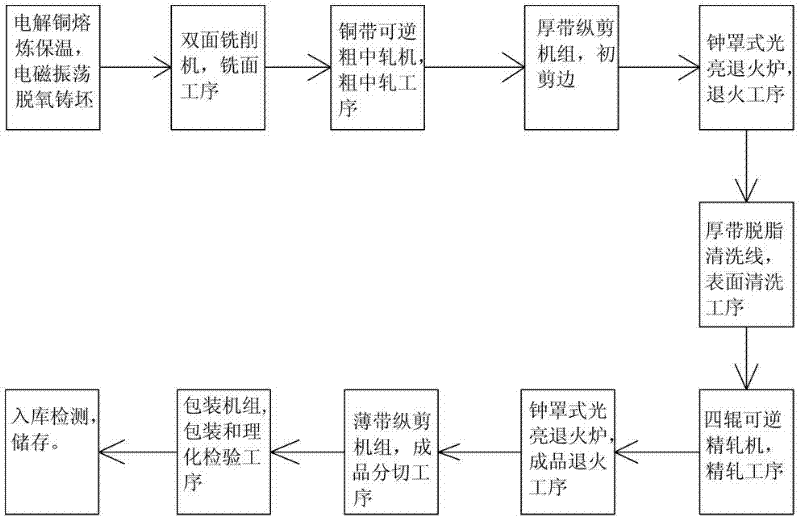

Production method of high-precision ultralong oxygen-free copper strip

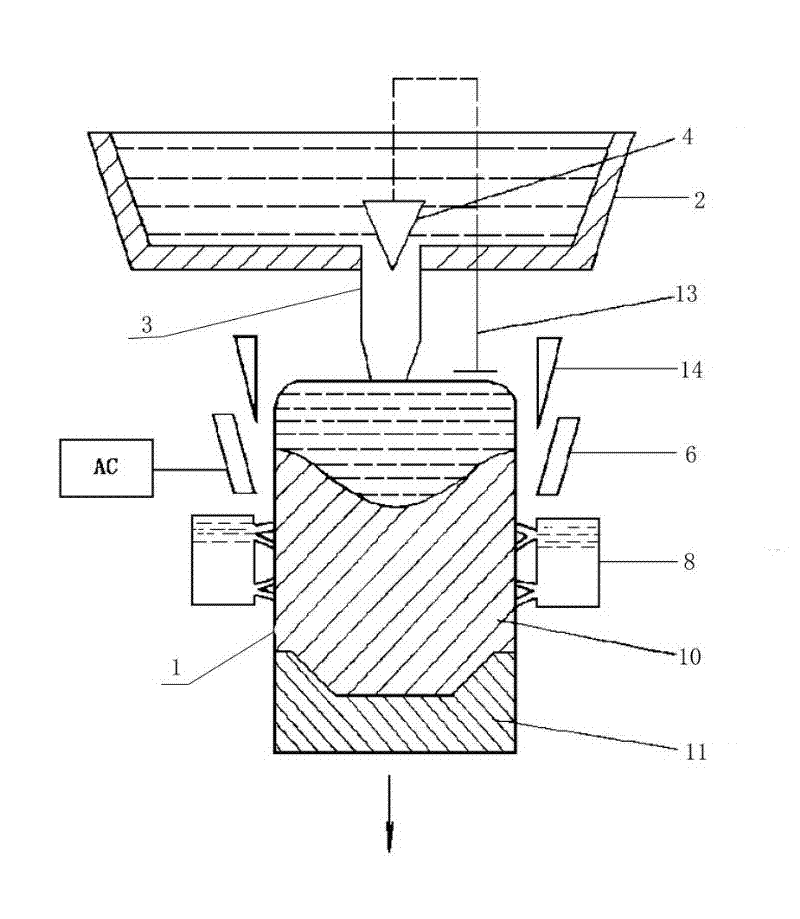

ActiveCN102199711ACompact structureGuaranteed oxygen contentRoll mill control devicesBell type furnacesElectrolysisIngot

The invention relates to a production method of a high-precision ultralong oxygen-free copper strip and belongs to the technical field of oxygen-free copper strip production, processing and manufacturing. The production method of the high-precision ultralong oxygen-free copper strip comprises: (1) selecting electrolytic copper as a raw material, adding the electrolytic copper into a melting furnace, smelting the melting furnace, allowing molten copper to flow into a crystallizer added with an electromagnetic oscillation coil, performing electromagnetic deoxidization of the molten copper and horizontally casting a blank by electromagnetic continuous casting in the electromagnetic continuous casting crystallizer added with the electromagnetic oscillation coil, cooling in the electromagnetic continuous casting crystallizer, crystallizing to form strip copper blanks, and stretching by an ingot leading machine; (2) milling a strip blank by a double-sided miller; (3) performing reversible coarse medium rolling of the copper strip; (4) performing primary trimming by a thick strip longitudinal shearing machine; (5) annealing in a bell type bright annealing furnace; (6) cleaning surface on a thick strip degreasing cleaning line; (7) finely rolling in a four-roller reversible fine rolling machine; (8) annealing a finished product in the bell type bright annealing furnace; (9) cutting the finished product by a thin-strip longitudinal shearing machine; (10) packing in a packaging machine and performing physical and chemical examination; and (11) performing incoming inspection and storing.

Owner:ZHONGTIAN ALLOY TECH

High-strength ship hull structural steel and production method of plate roll

ActiveCN101082102AReduce smelting costSmelting operation is simpleRoll mill control devicesFurnace typesProduction lineHull structure

The present invention relates to low alloy steel and is especially steel for hull structure and its production process. The steel for hull structure consists of C 0.03-0.075 wt%, Si 0.01-0.35 wt%, Mn 1.40-1.60 wt%, Als 0.015-0.100 wt%, V 0.020-0.080 wt% and Fe and impurity elements for the rest. It is produced in a CSP production line with special temperature system, reduction schedule and cooling system, and through casting blank, hydraulically shearing, heating and descaling, rolling into strip steel, stream cooling and finally winding. It has the advantages of less alloy elements, simple production process, high production efficiency, low power consumption, high product performance, etc.

Owner:MAANSHAN IRON & STEEL CO LTD

Yeast composition and its use as cow feed additive

Yeast composition for cow feed additive including at least ruminant yeast and a carrier. The carrier is selected from DDGS (corn lees), chaff, zein powder, brewery mash, bean pulp, soybeanhull, rice bran, or wheat bran. The yeast composition can alleviate the negative effects of heat stress experienced by cows during summer months and improve milk yield.

Owner:YU XUEFENG +5

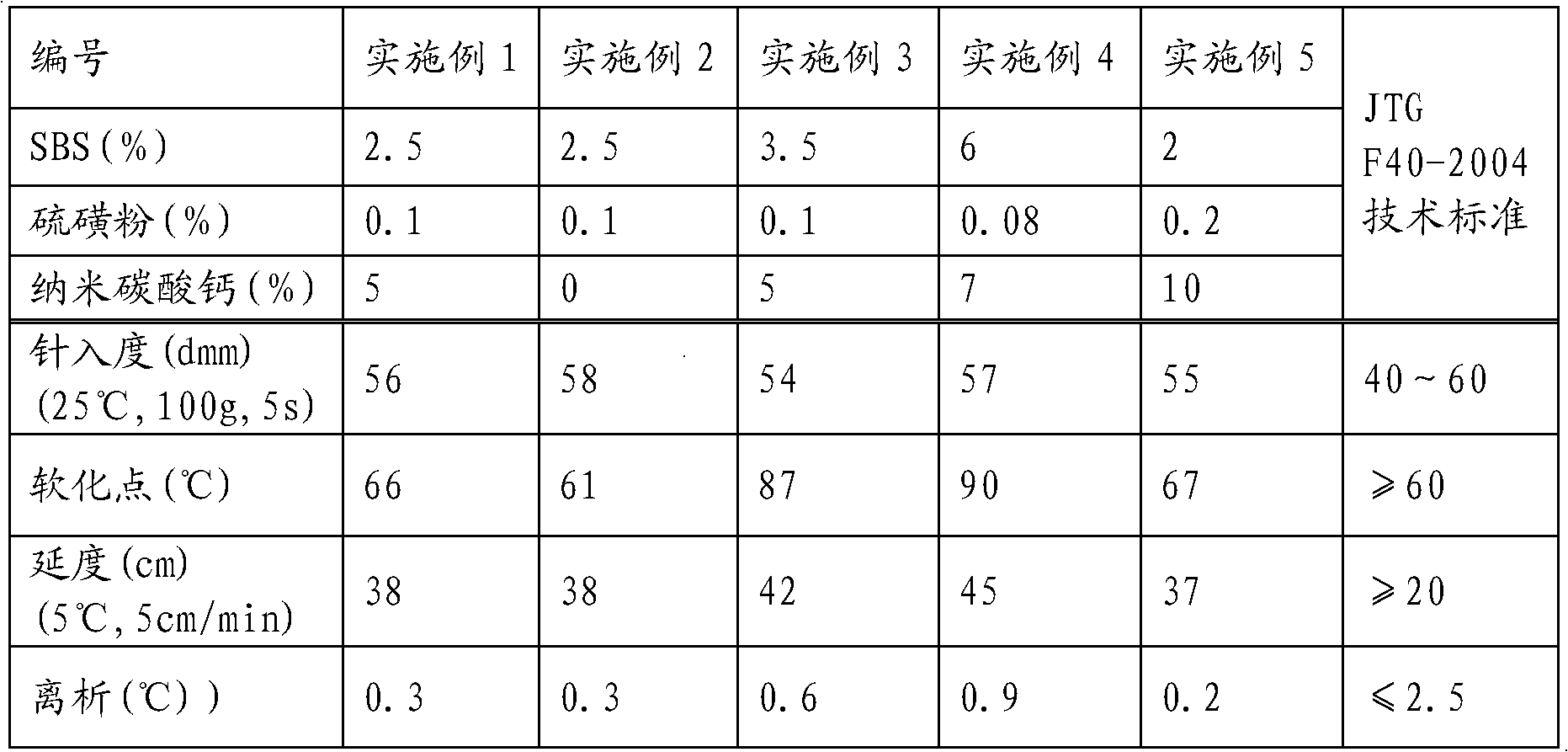

SBS (styrene butadiene styrene) modified asphalt and preparation method thereof

InactiveCN102010610AImprove performanceEvenly dispersedBuilding insulationsSulfurButadiene-styrene rubber

The invention discloses SBS (styrene butadiene styrene) modified asphalt which comprises the following components in percentage by weight: 2.0 to 6.0 percent of star SBS, 0.08 to 0.2 percent of sulphur, and 2 to 10 percent of nano calcium carbonate. The invention also discloses a method for preparing the SBS modified asphalt. The SBS modified asphalt and the preparation method thereof are characterized in that the star SBS is taken as a modifier of the asphalt so as to improve the performance of the asphalt; meanwhile, the nano calcium carbonate and powdered sulfur are taken as stabilizers of the star SBS modifier so as to ensure the uniform dispersion of the modifier after being added in the asphalt, reduce the occurrence of segregation phenomenon, and improve the performance of the modified asphalt; and the nano calcium carbonate is used for diluting the powdered sulfur, and has the functions of improving the softening point of the modified asphalt and reducing the penetration degree of the modified asphalt.

Owner:QINGDAO ANBANG LUFA ASPHALT

Ultrasonic transducer, ultrasonic transducer array, and ultrasonic device

ActiveUS8110963B2Easy to optimizeUniform and stable performanceSubsonic/sonic/ultrasonic wave measurementPiezoelectric/electrostriction/magnetostriction machinesPotential differenceUltrasonic transducer array

An ultrasonic transducer is configured to transmit or receive ultrasonic waves. The ultrasonic transducer includes a vibrating member and a piezoelectric member coupled to the vibrating member. The piezoelectric member includes a first piezoelectric part configured and arranged to be deformed by applied voltage to vibrate the vibrating member or configured and arranged to be deformed by vibration of the vibrating member to produce a potential difference, and a second piezoelectric part configured and arranged to be deformed by applied voltage to statically deflect the vibrating member.

Owner:SEIKO EPSON CORP

Niobium-titanium-boron microalloy high-strength gas protecting welding wire

InactiveCN1654160AHigh strengthImprove low temperature impact toughnessArc welding apparatusWelding/cutting media/materialsWeld seamCopper plating

The gas protected Nb-Ti-B micro alloy weld filament contains C 0.04-0.15 wt%, Mn 1.00-2.00 wt%, Si 0.30-1.20 wt%, Ni 0.60-1.80 wt%, Ti 0.08-0.20 wt%, Mo 0.10-0.80 wt%, Nb 0.01-0.05 wt%, B 0.002-0.012 wt%, S not more than 0.10 wt% and P not more than 0.20 wt%, except Fe and inevitable impurity. Under the protection of mixed gas of Ar and CO2 and proper welding technological parameter and interlayer temperature, the weld seam metal can reach tensile strength over 800 MPa and impact power at -30 deg.c higher than 100 J. When used in multilayer welding, the weld seam metal has excellent structure and performance homogeneity, and the weld filament has excellent technological performance. The present invention may be used widely for welding low alloy high strength steel in engineering machinery, railway bridge, marine facility, high pressure container, etc.

Owner:YANSHAN UNIV

Indium phosphide substrate, indium phosphide single crystal and process for producing them

InactiveUS20090072205A1High strengthLarge deformationNon-metal conductorsPolycrystalline material growthDevice materialVolumetric Mass Density

An indium phosphide substrate for semiconductor devices is obtained as follows. In order to have the direction of growth of the crystal in the <100> orientation, a seed crystal having a specified cross-sectional area ratio with the crystal body is placed at the lower end of a growth container. The growth container housing the seed crystal, indium phosphide raw material, dopant, and boron oxide is placed in a crystal growth chamber. The temperature is raised to at or above the melting point of indium phosphide. After melting the boron oxide, indium phosphide raw material, and dopant, the temperature of the growth container is lowered in order to obtain an indium phosphide monocrystal. An average dislocation density is a function of a carrier density and diameter of the substrate, dislocation density, and a dopant concentration on the wafer is substantially uniform in the depth direction.

Owner:SUMITOMO ELECTRIC IND LTD

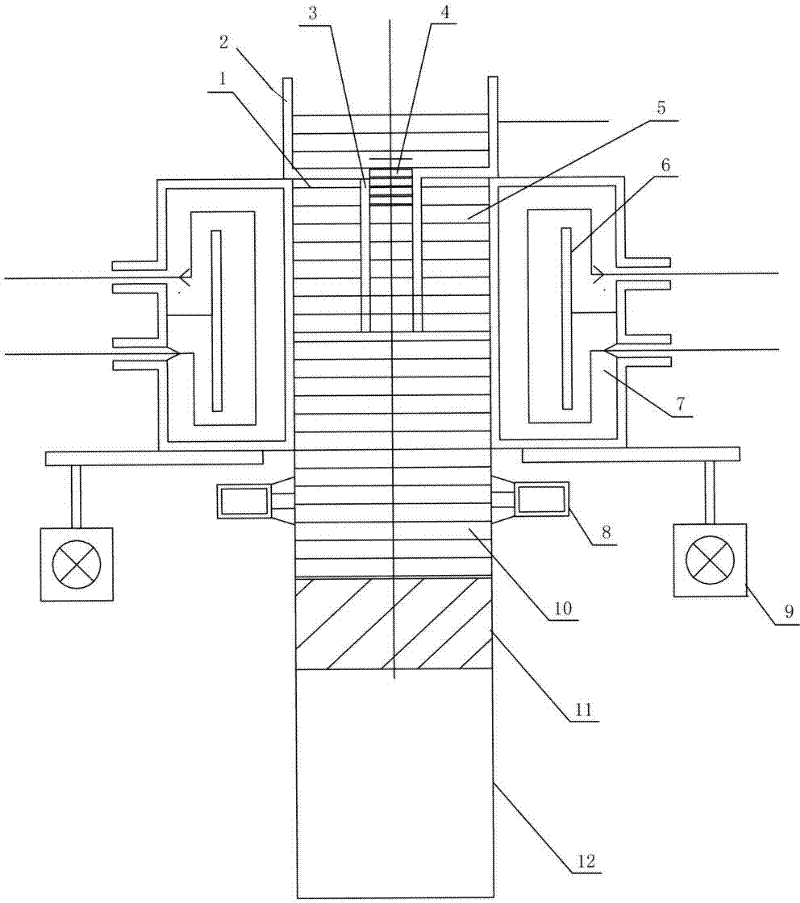

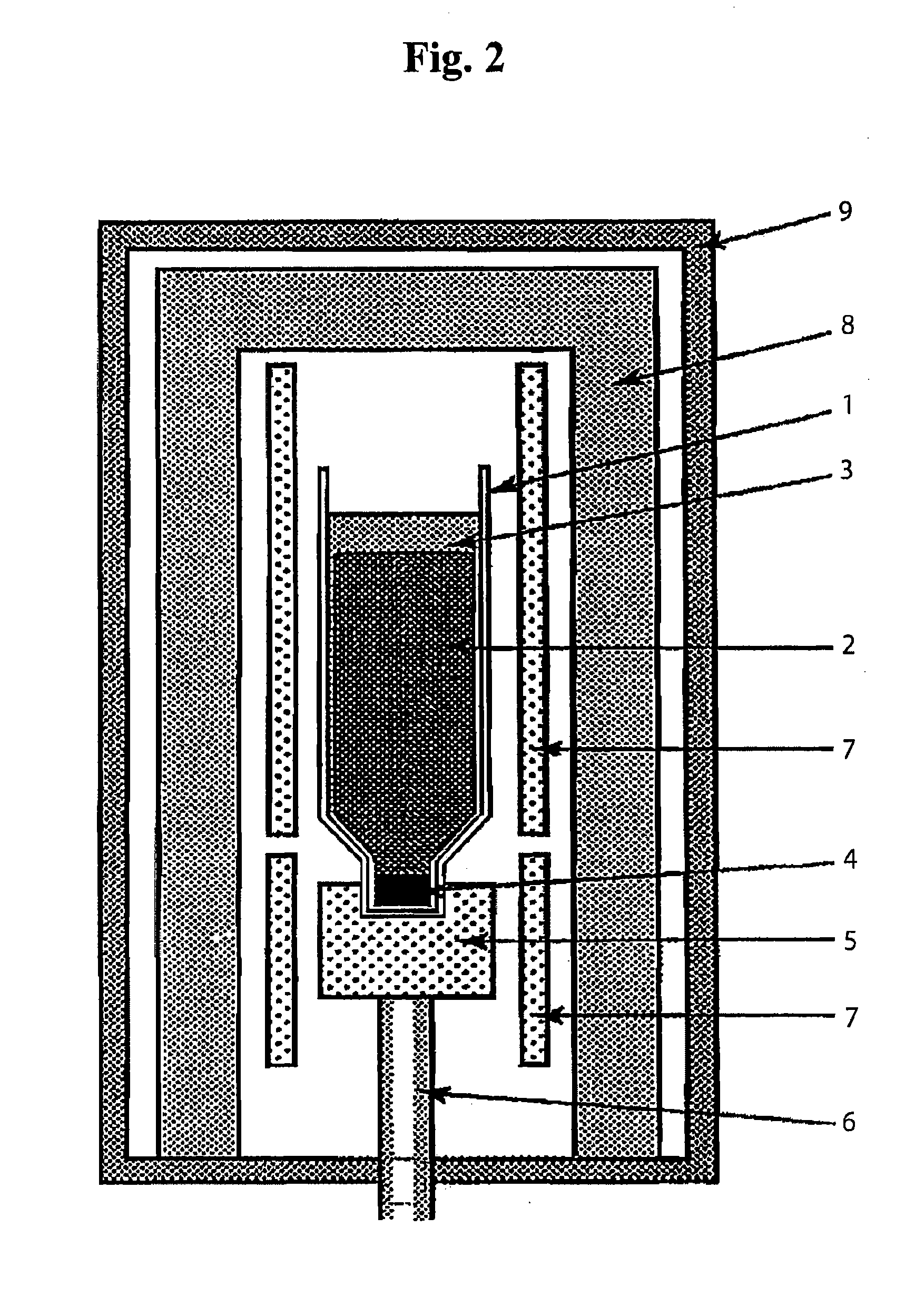

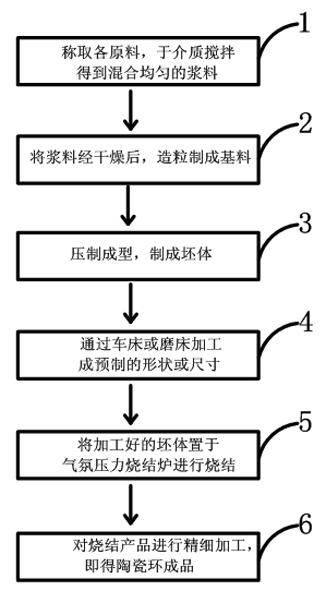

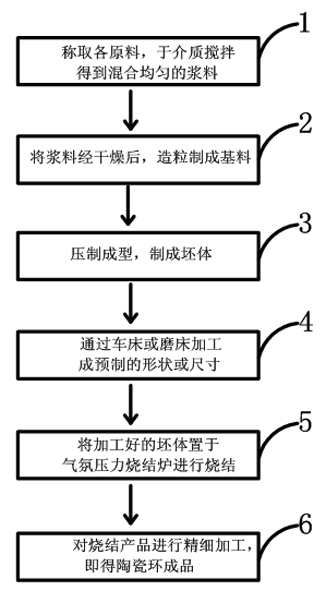

Preparation method of silicon nitride ceramics ring for polysilicon reduction furnace

The invention relates to a preparation method of a silicon nitride ceramics ring for a polysilicon reduction furnace, comprising the following steps: weighing various raw materials, and stirring in media to obtain evenly mixed slurry; after the slurry is dried, prilling to prepare base stock; pressing and shaping to prepare a green body; processing by a lathe or a grinder into preset shape and size; sintering the processed green body into an atmosphere pressure sintering furnace; and carrying out finish machining to a sintered finished product to obtain the ceramics ring finished product. Thepreparation method has the beneficial effect that silicon nitride ceramics ring has good insulativity, high toughness, and good thermostability and antiknock characteristic, the service life can be prolonged, and added agglomerant is favourable for densification. The invention can satisfy environment use requirement of a polysilicon reduction furnace, has long service life and improves work efficiency.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

800 MPa-grade high-toughness weather-resistant thick steel plate and preparation method thereof

The invention discloses an 800 MPa-grade high-toughness weather-resistant thick steel plate. The 800 MPa-grade high-toughness weather-resistant thick steel plate is characterized by being prepared by smelting the following components of, in mass percentage, less than or equal to 0.12% of C, 0.05%-0.55% of Si, 1.20%-1.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.001% of S, 0.45%-1.20% of Cr, 0.30%-1.20% of Cu, 0.30%-1.40% of Ni, greater than or equal to 0.030% of Alt, 0.002%-0.030% of Ti, 0.002%-0.10% of V, 0.10%-0.80% of Mo, 0.0001%-0.0030% of B, 0.001%-0.010% of Ce, 0.80%-1.60% of Cr+Cu, 2.00%-3.00% of Cr+Mn+Mo, greater than 6.5% of I, less than or equal to 0.64% of CEV, less than or equal to 0.27% of Pcm and the balance Fe and inevitable impurities. A heat treatment method of the thick steel plate comprises the following steps of quenching the steel plate twice, and carrying out heat preservation for 2.5-4.5 min / mm under the temperature 400-720 DEG C and then carrying out tempering so as to obtain a fine and uniform lath-shaped microstructure of tempered bainite or tempered sorbite with ferrite. The steel plate has the advantages of being large in thickness, low in yield ratio, high in strength, good in toughness, resistant to atmospheric corrosion and the like, and can be widely applied to construction of steel structures such as large bridges and buildings.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-strength and low-density cement paste using fluid loss agent

The invention discloses a high-strength and low-density cement paste using a fluid loss agent, relating to the technical field of oil field well sealing cement paste. The high-strength and low-density cement paste using the fluid loss agent comprises the following components in part by weight: 100 parts of G-level oil well cement, 23-50 parts of lightening admixture 6.5-8 parts of microsilica, 2 parts of fluid loss agent and 0.05-0.15 parts of setting retarder, wherein the using amounts of the fluid loss agent and the setting retarder are the percentage of the total mass of the G-level oil well cement, the lightening admixture and the microsilica; the ratio of water to solid in the cement paste is 0.7-0.75 and is the ratio of water to the total mass of the G-level oil well cement, the lightening admixture and the microsilica. The cement paste has a density of 1.20-1.35g / cm<3>, has high strength, good fluidity, no free water and good systematic stability, and can meet well sealing requirements on long-term sealing or full sealing of a deep well in an easily-leaking stratum.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

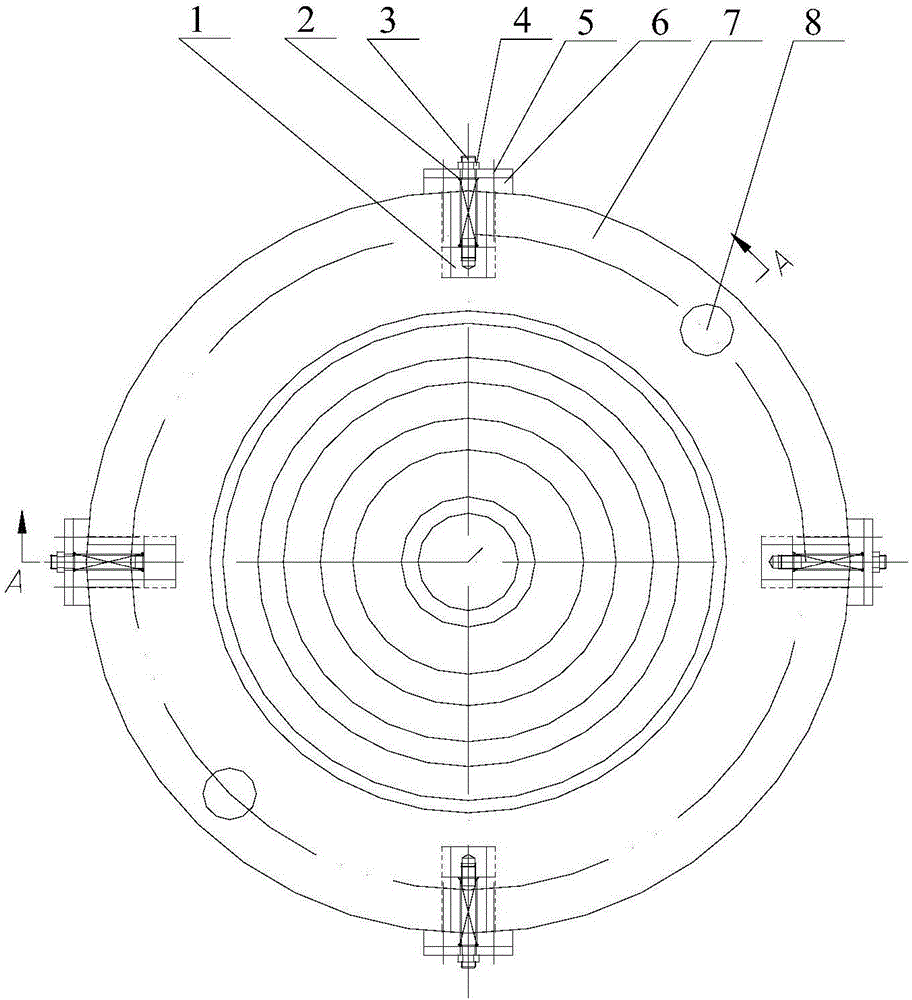

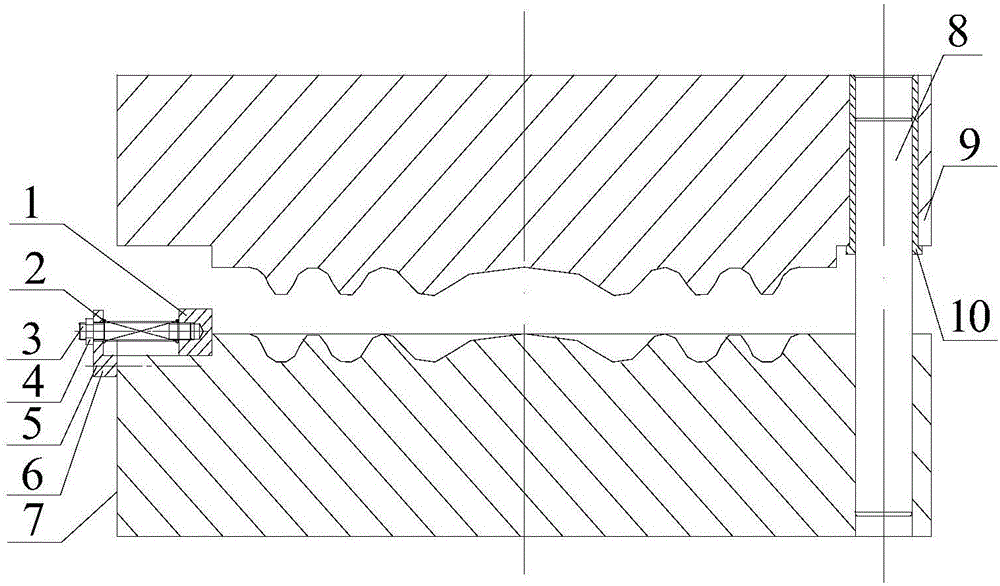

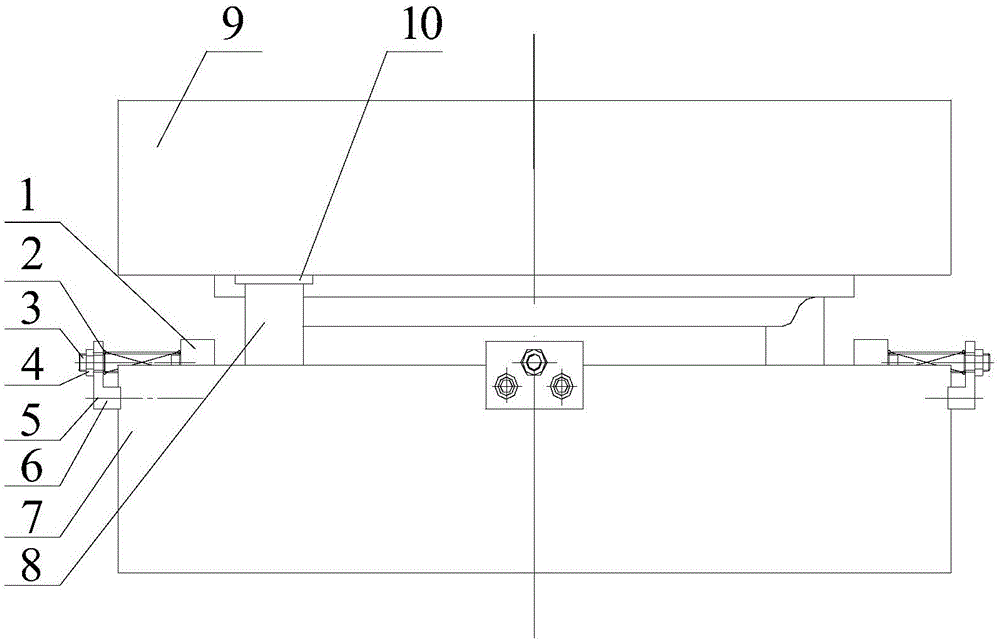

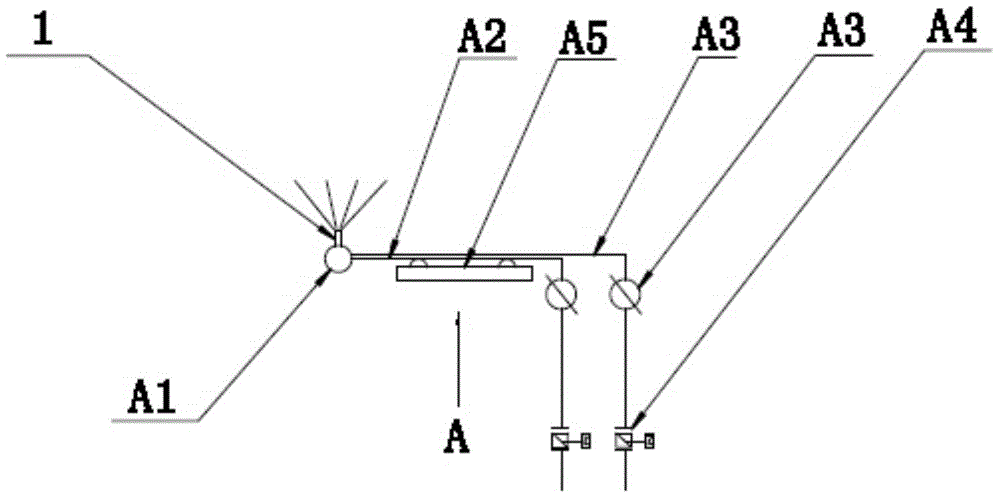

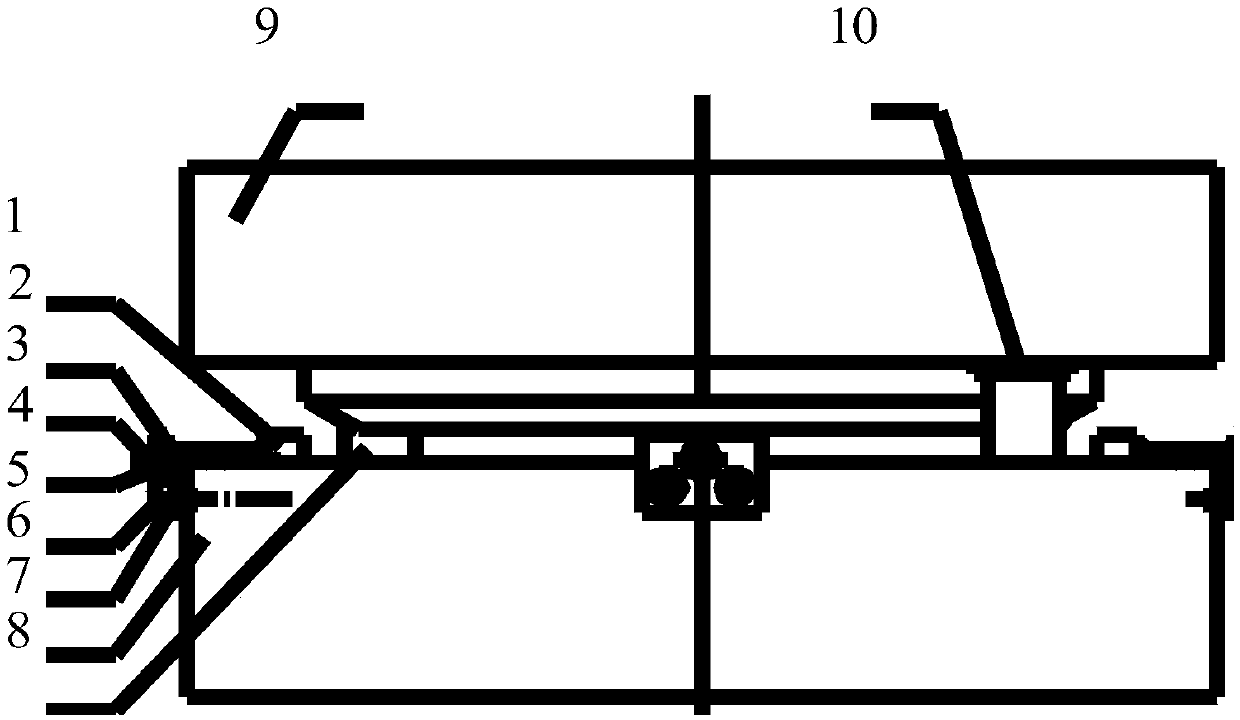

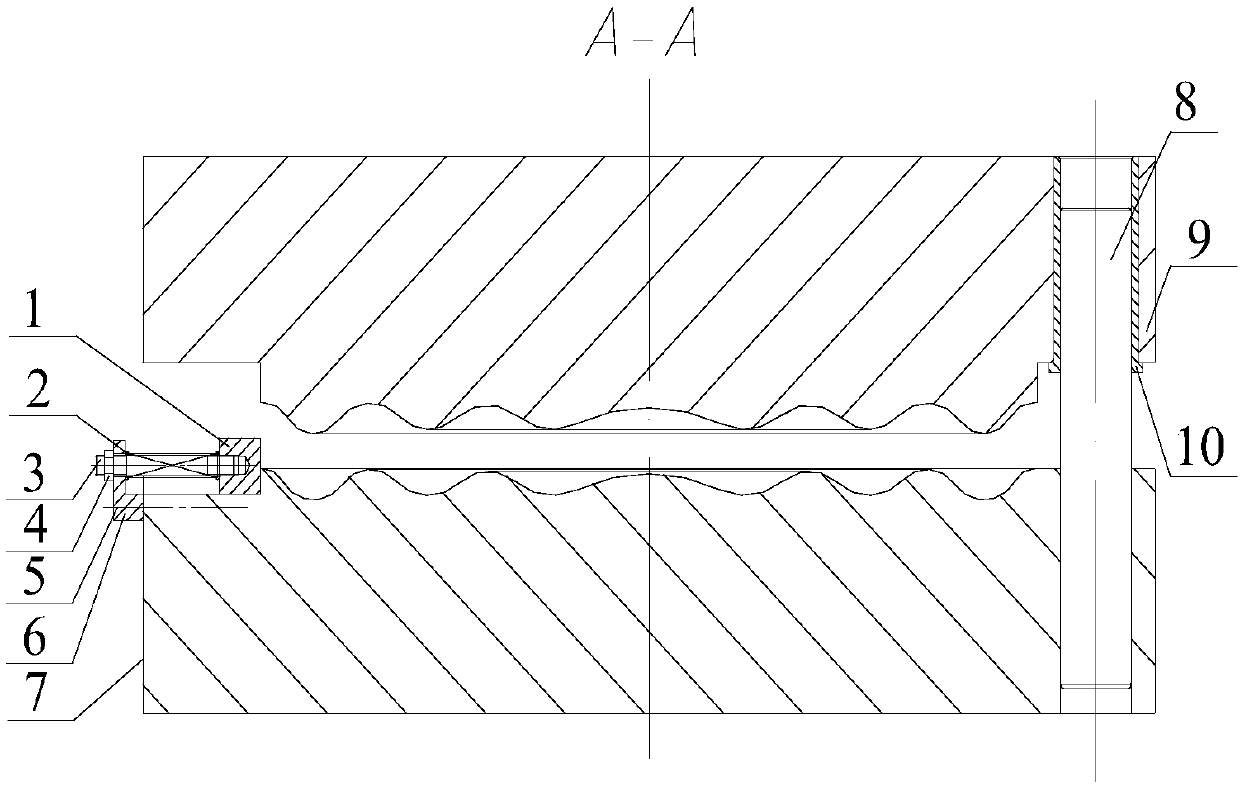

Repeated plate ring wave drawing intense deformation die and technology

InactiveCN106424261AUniform plastic deformationUniform strain distributionShaping toolsMetal-working feeding devicesMicrometerWave shape

The invention discloses a repeated plate ring wave drawing intense deformation die and technology. The die comprises an upper ring wave die body and a lower ring wave die body, wherein the upper surface and the lower surface of the upper ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves, and the upper surface and the lower surface of the lower ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves. The upper ring wave die body is connected with a movable cross beam of a hydraulic machine. The lower ring wave die body is fixed to a working table board. The upper ring wave die body is a movable die, and the lower ring wave die body is a fixed die. Two locating mechanisms arranged symmetrically in the radial direction are arranged at the upper end of the lower ring wave die body and can locate a plate. The upper ring wave die body and the lower ring wave die body are guided through a guide column and a guide sleeve which are arranged symmetrically in the axial direction, and directly participate in formation of the plate. By means of die closing, the plate is drawn to a set ring wave shape. According to the technology, through the die, repeated drawing is carried out for deforming and refining plate grain particles to enable the size of the grain particles to reach the micrometer level or the sub-micrometer level, finally, a flattening die is used for flattening the deformed plate, and a smooth plate is obtained. The die is free of restrictions of the size of the plate, the plate in the large size can be machined, and the comprehensive performance of the aspects such as physics, chemistry and mechanics of the plate are improved greatly.

Owner:河北华杰缝纫机零件有限公司

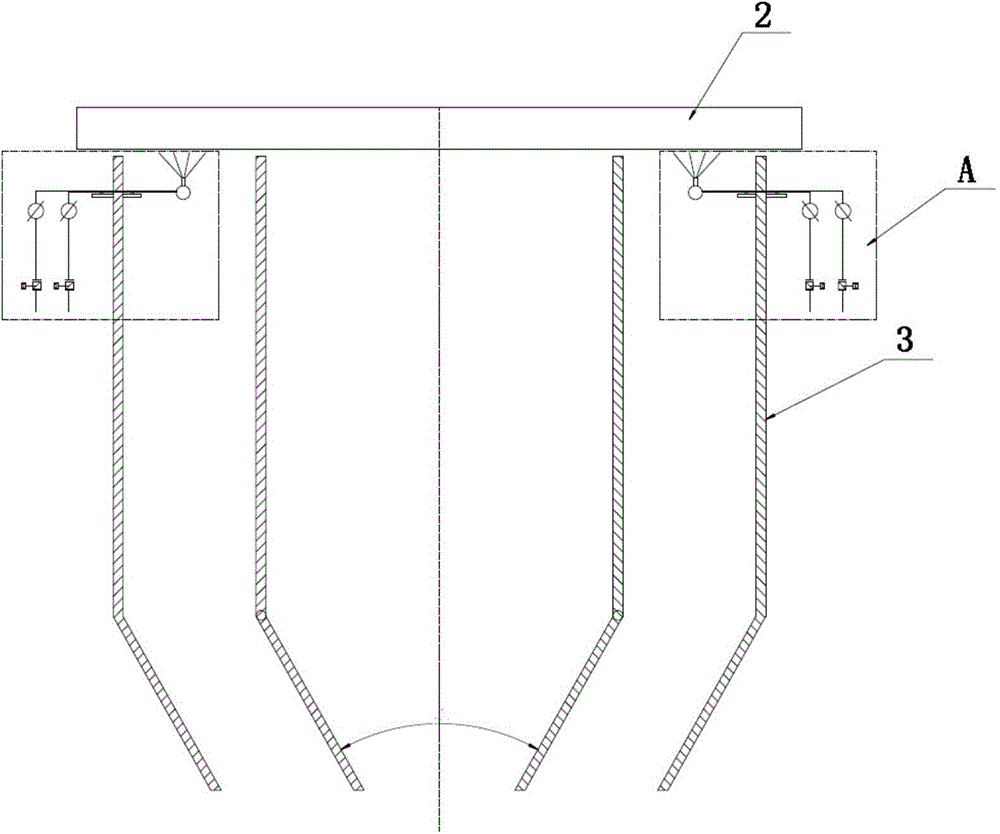

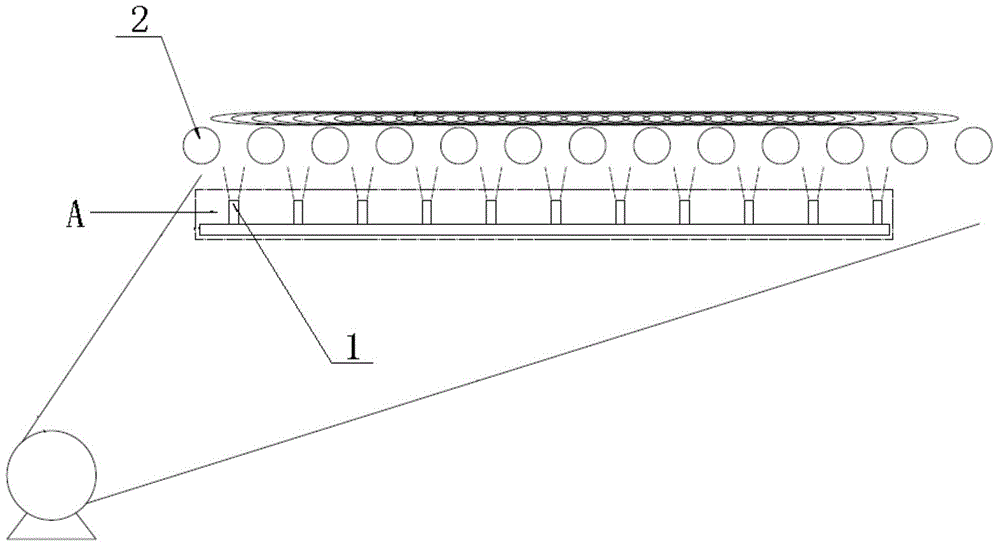

Wire rod edge cooling device and wire rod edge cooling method

ActiveCN105436214AUniform temperatureUniform tissueTemperature control deviceWork treatment devicesWire rodLap joint

The invention provides a wire rod edge cooling device and a wire rod edge cooling method thereof. The device comprises nozzles, each nozzle is connected with a cooling device assembly, and the cooling device assemblies are arranged in air ducts located on the lower portions of the two sides of a roller bed. The cooling device assemblies can move left and right through guiding parts of the cooling device assemblies, and therefore the whole cooling device assemblies can be adjusted in position to be aligned with coil lap-joint points so as to carry out cooling operation. By means of the device and the method, the temperature differences of coils can be adjusted in any position, especially the temperature of a phase change area can be adjusted, so that uniformity of the temperature of the phase change area is guaranteed, structure uniformity is directly guaranteed, and product performance is consistent. According to the device and the method, air mist sprayed from edge cooling equipment can be better blown to wire rods, and water mist which is not gasified is blown to the position above the roller bed and does not drop, so that the air ducts, fans and the like are not influenced. In addition, the device is arranged in the length direction of the Stelmor line and can be lengthened or shortened, the number of switch sets is adjustable, and the sufficient temperature difference adjusting capacity is achieved. In addition, the carbon and oxidation problems in the lap-joint point positions can be solved, and the site operation environment is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for prefabricated building

The invention provides a construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for a prefabricated building. The mortar board comprises an inner PC board layer, an outer PC board layer and a filling material layer arranged between the inner PC board layer and the outer PC board layer. A preparation method of the mortar board comprises the following steps of performing hammering, vibrating, crushing, grinding and other processes on concrete and brick slag in construction wastes to form a regenerated building aggregate; performing high-speed rotation on the regenerated building aggregate to obtain regenerated micro powder, and collecting the regenerated micro powder; mixing the regenerated building aggregate, the regenerated micro powder, a polymer, cement, rice hulls and straws, basalt fibers and glass fibers, ceramsite and other auxiliaries to obtain the PC board layers; mixing polystyrene foam, asbestos foam or nano-sized aerogel with the polymer to obtain the filling material layer; and finally, compounding the PC board layers and the filling material layer to obtain the construction waste-containing high-strength light-weight composite PC mortar board for the prefabricated building. The preparation method is simple; and as regenerated building agricultural wastes are taken as a large part of raw materials, on the basis of guaranteeing high strength and light weight, the cost is reduced, and the mortar board is green and environment friendly.

Owner:SHAOXING YISHENG MORTAR

Semicircular plate used for oil drilling platform leg and manufacture process thereof

ActiveCN101576197AReduce manufacturing costUniform and stable performanceArtificial islandsSheets/panelsOil drillingMolten steel

The invention discloses a process for manufacturing an oil drilling platform leg, comprising the following steps of: continuously casting a molten steel with the composition complying with the requirement into a solid tube blank; processing the tube blank as a seamless steel pipe; and finally sawing the seamless steel pipe into the semicircular plate by longitudinal sawing operation. The invention also discloses a semicircular plate used for the oil drilling platform leg. The process directly changes the existing technology of pressing semicircular plate by steel plate, adopts the mode of a formed steel pipe to segment and manufacture the semicircular plate and leads the process forming way to be different from the original type; the processing technology route is firstly created in the field; and the manufacture cost is greatly reduced as large-tonnage presses are not adopted.

Owner:CHINA NAT OFFSHORE OIL CORP +1

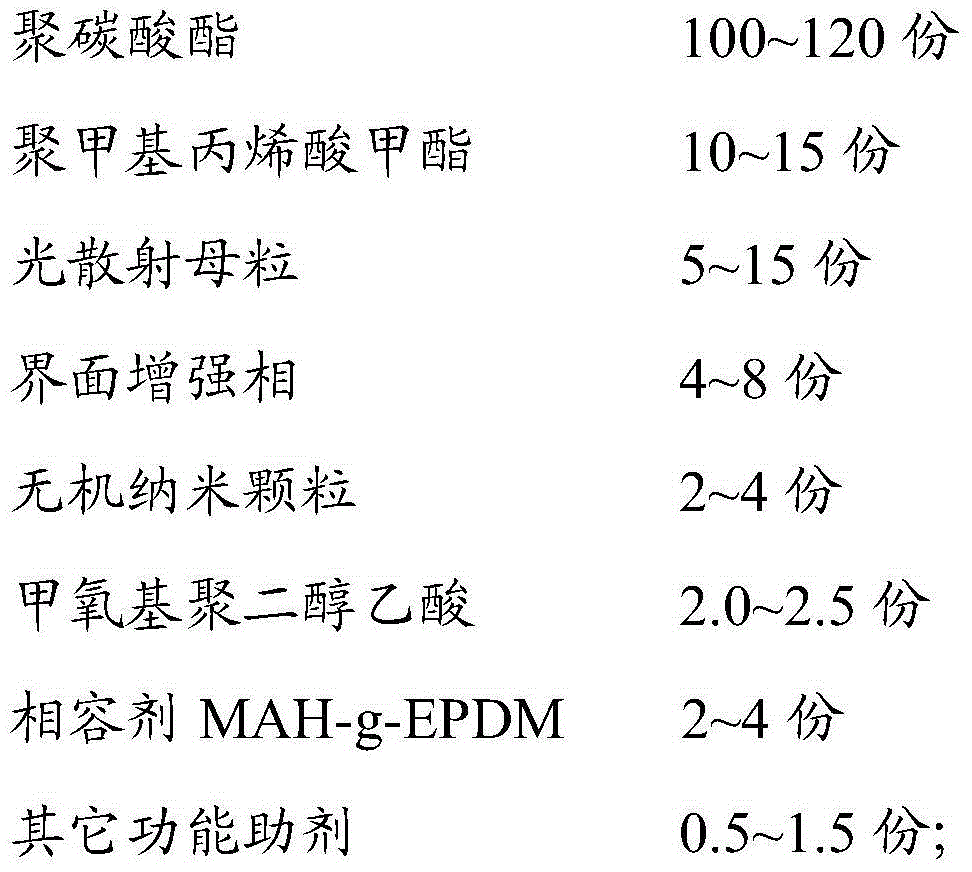

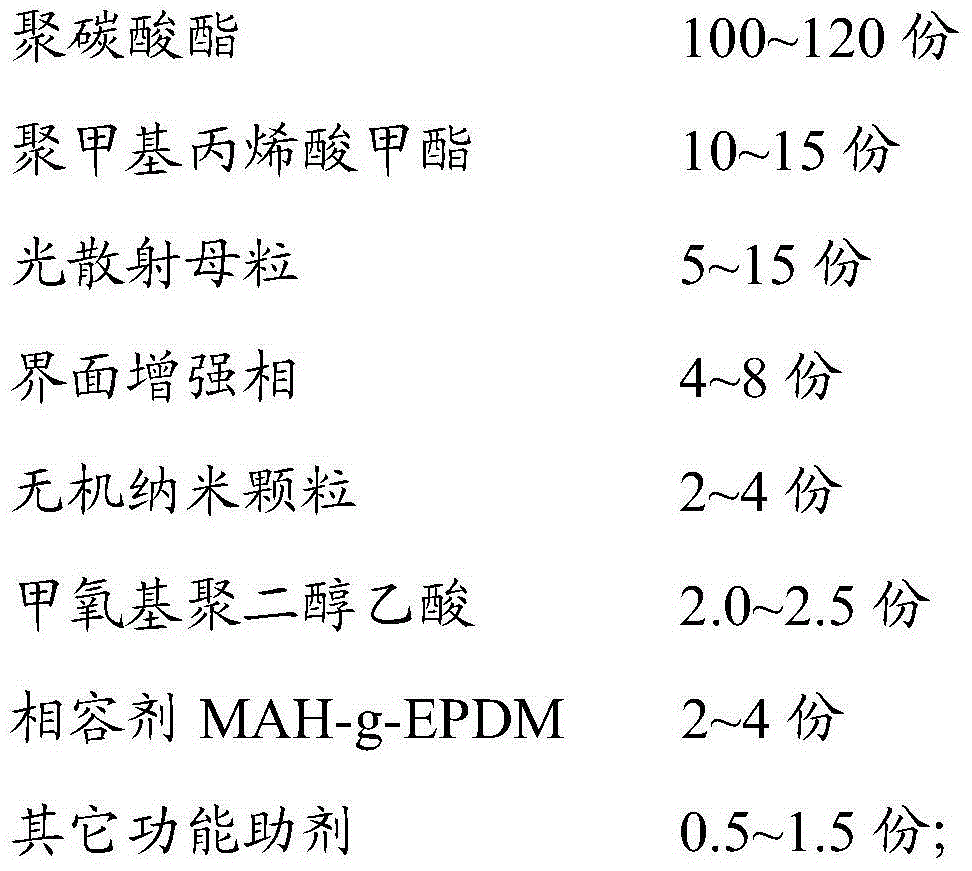

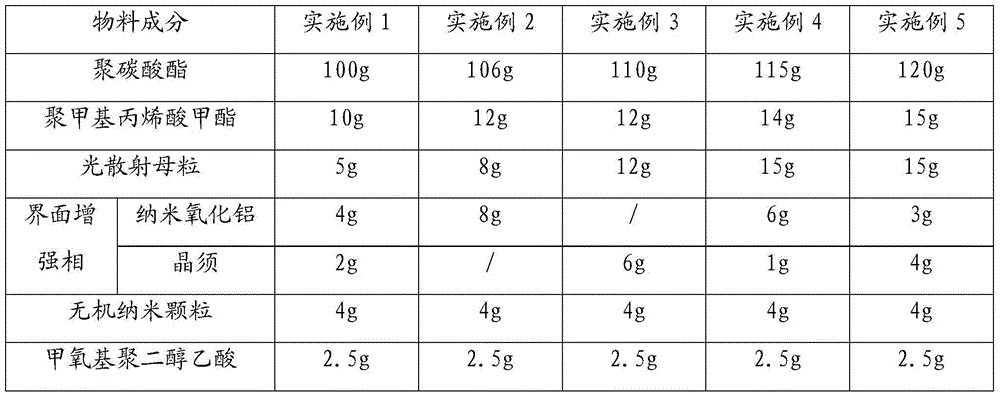

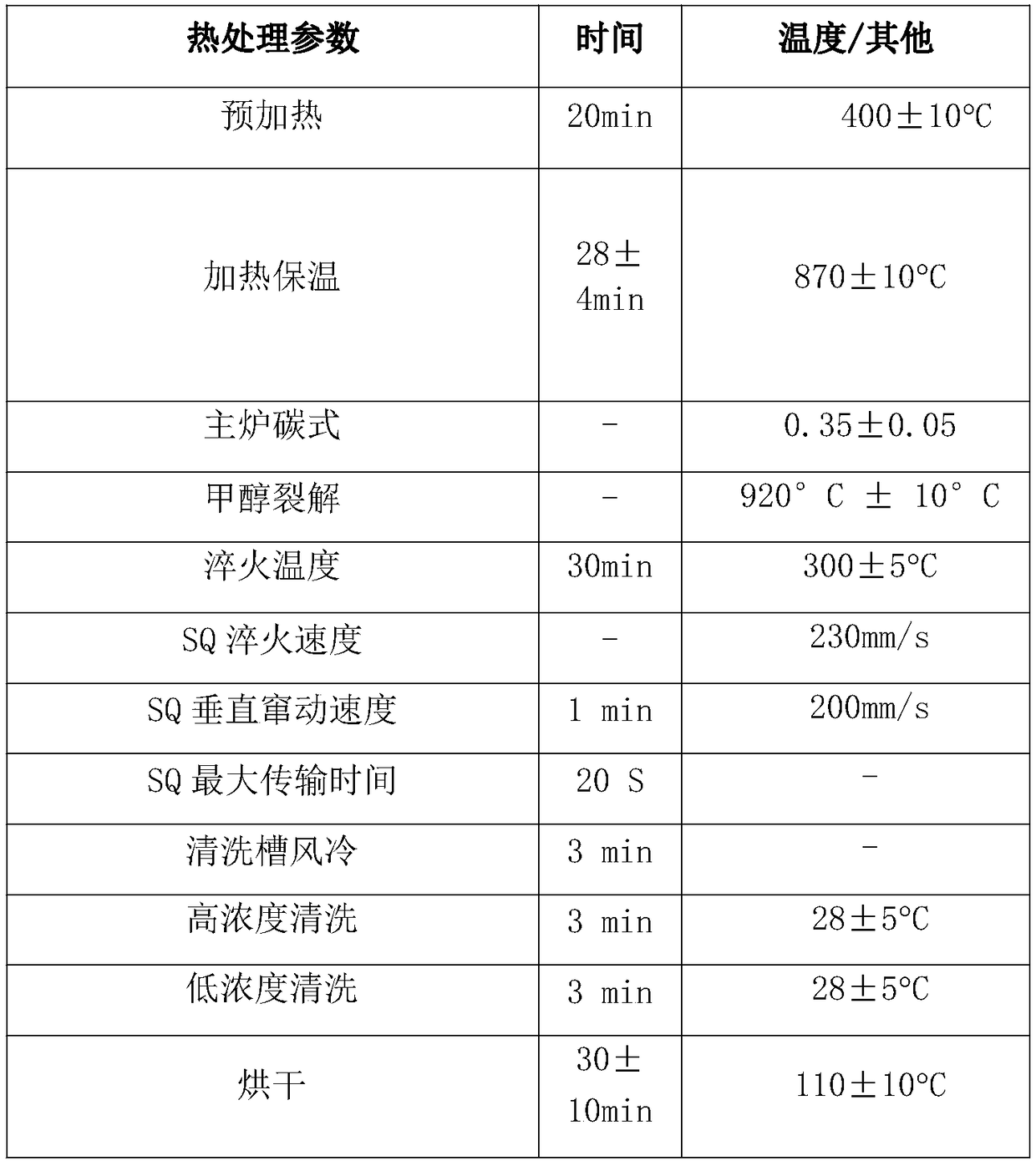

Polycarbonate material composition of reinforced LED lamp shade and preparation method and LED lamp shade

ActiveCN104356626AHigh light transmittanceGood light diffusion effectGlobesNano al2o3Polymethyl methacrylate

The invention provides a polycarbonate material composition of a reinforced LED lamp shade. The polycarbonate material composition comprises 100-120 parts of polycarbonate, 10-15 parts of polymethyl methacrylate, 5-15 parts of light scattering master batch, 4-8 parts of interface reinforcing phase, 2-4 parts of inorganic nanoparticles, 2.0-2.5 parts of methoxyl polyglycol acetic acid, 2-4 parts of a compatilizer MAH-g-EPDM and 0.5-1.5 parts of other functional additives, wherein the interface reinforcing phase is at least one of nanometer aluminum oxide crystal particles or crystal whiskers. The polycarbonate material composition of the reinforced LED lamp shade, which is provided by the invention, is relatively excellent in light permeability and light scattering property, is capable of eliminating the phenomena of halo or dark spot generated from the dispersibility, and is also relatively excellent in mechanical property.

Owner:惠州市沃特新材料有限公司

Cold-rolled fine-punched steel strip for automobile child seat locking device and preparation method thereof

The invention discloses a cold-rolled fine-punched steel strip for an automobile child seat locking device. The cold-rolled fine-punched steel strip is made of 51CrV4, and comprises the following components by mass percentage: 0.50-0.55 of C, 0.15-0.35 of Si, 0.80-1.10 of Mn, less than or equal to 0.015 of P, less than or equal to 0.01 of S, 0.90-1.20 of Cr, 0.10-0.20 of V, and less than or equalto 0.035 of Al. Directed at the special processing technology and application requirements of the child seat locking device, the cold-rolled fine-punched steel strip provided by the invention rationally optimizes the chemical components of 51CrV4, and rationally controls the C, S, P, Si and other elements sensitive to hydrogen embrittlement.

Owner:SUZHOU XIANGLOU METAL PROD

Alloy steel material for anti-corrosion pump valve and preparation method thereof

The invention discloses an alloy steel material for an anti-corrosion pump valve. The alloy steel material for the anti-corrosion pump valve is prepared from the following raw materials in percentage by weight: 0.12 to 0.22 percent of C, 1.2 to 2 percent of Cr, 0.5 to 1.5 percent of Ni, 0.8 to 1.5 percent of Mn, 0.3 to 0.8 percent of Cu, 0.8 to 1.4 percent of Si, 0.05 to 0.2 percent of Nb, 0.2 to 1.2 percent of Be, 0.02 to 0.08 percent of Ta, 0.02 to 0.08 percent of Zr, 0.02 to 0.08 percent of V, 0.02 to 0.08 percent of Ce, 0.1 to 0.2 percent of rear earth, and the balance Fe. The invention provides the alloy steel material for the anti-corrosion pump valve, which has favorable corrosion resistance and abrasive resistance, a good anti-rust property, high hardness and good toughness and brittleness. A preparation method provided by the invention can be beneficial to enabling the performance of the alloy steel material to be more stable and uniform, and is high in casting yield and production efficiency, low in cost, and worth popularizing.

Owner:滁州市大工机电有限公司

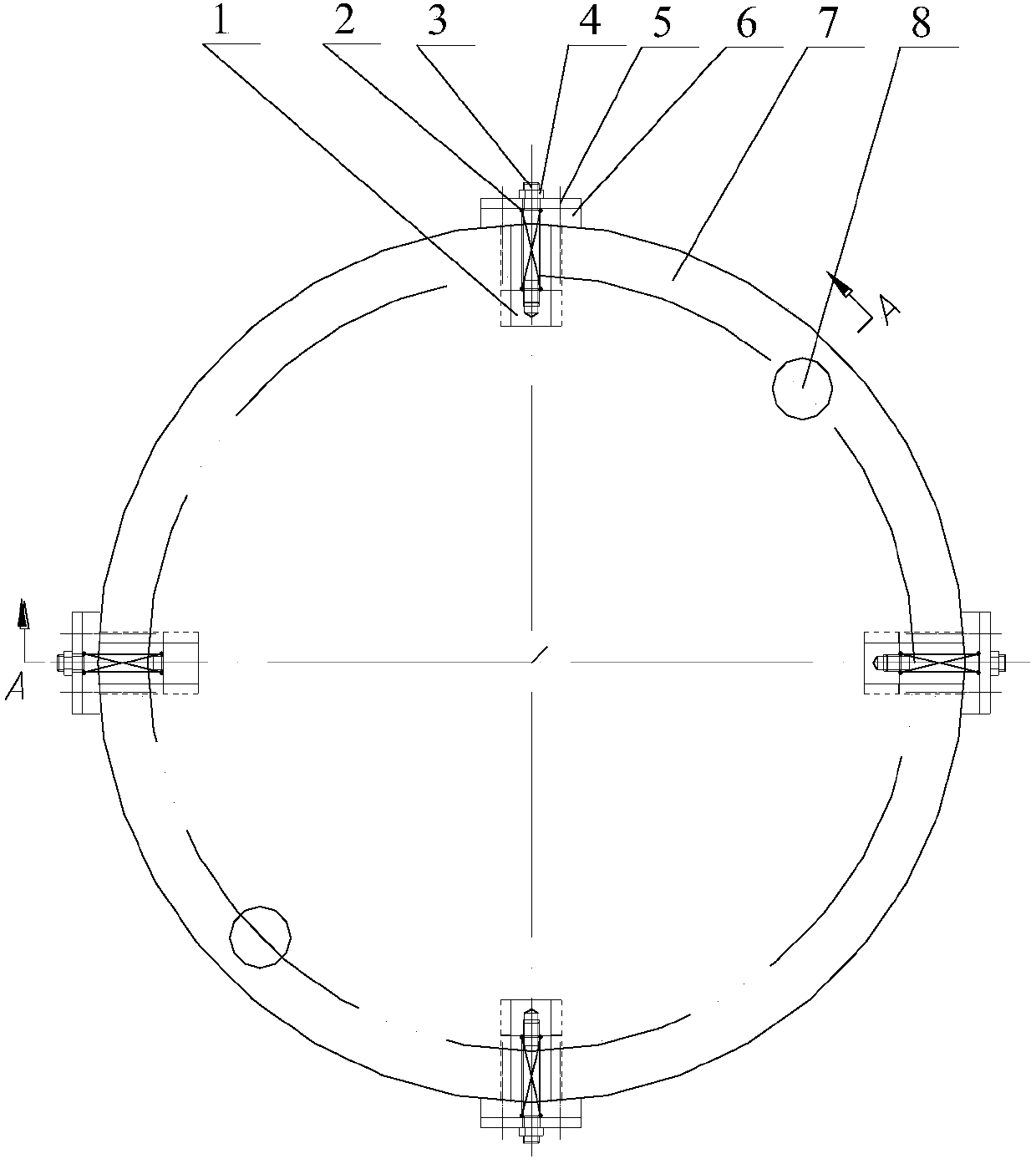

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com