High-strength ultra-low thermal contraction nylon 66 fiber and production method thereof

A production method and ultra-low heat technology, applied in fiber processing, filament generation, melt spinning, etc., can solve the problems of unevenness between production batches, low production efficiency, low dry heat shrinkage rate, etc., and achieve production efficiency. High, improved production efficiency, advanced fiber properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

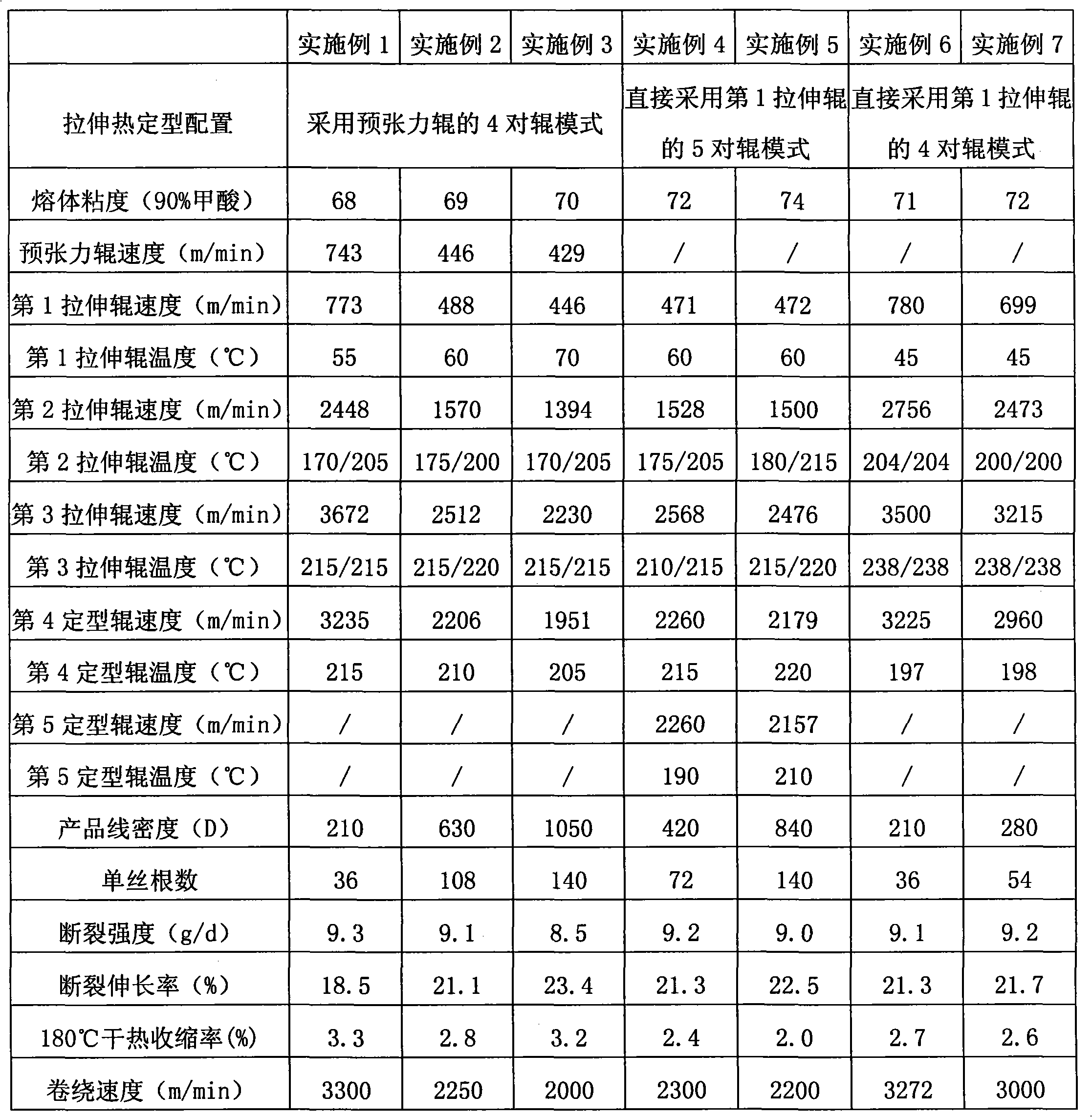

Embodiment 1

[0023] Through continuous polymerization of polyhexamethylene adipamide, a 95% (wt%) polyamide 66 formic acid relative viscosity 68 high-viscosity polymer melt is obtained, which is metered into the module and filtered by a high-precision metering pump, and the upper part of the filter layer is 16- 60 mesh sea sand, the lower part is composed of 4 layers of 50, 100, 300, 500 mesh filter screens. The filtered melt is extruded and spun by the metering pump to form a tow. The tow is cooled by the side air blower. After being oiled by the oil tanker, it enters 4 pairs of hot rollers for stretching and shaping, and the uniform network degree is formed by the network device. Finally, the four-head winder is wound into a silk tube to obtain a high specification of 210D / 36f. Ultra-low heat shrinkage nylon 66 fiber product. See Table 1 for drawing and shaping process, winding speed and product performance.

Embodiment 2

[0025] The raw materials are the same as in Example 1, using 4 pairs of hot rollers to stretch and shape, and double-ended winding machine to wind and form, to obtain a 630D / 108f specification high-strength ultra-low thermal shrinkage nylon 66 fiber product. See Table 1 for drawing and shaping process, winding speed and product performance.

Embodiment 3

[0027] The raw materials are the same as in Example 1, using 4 pairs of hot rollers to stretch and shape, and double-end winding machine to wind and form, to obtain 1050D / 140f specifications of high-strength ultra-low heat shrinkage nylon 66 fiber product. See Table 1 for drawing and shaping process, winding speed and product performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com