SBS (styrene butadiene styrene) modified asphalt and preparation method thereof

A technology for modifying asphalt and asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of long curing time, unfavorable production simplification, equipment wear, etc., to reduce segregation phenomenon, improve softening point, reduce needle In-degree effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

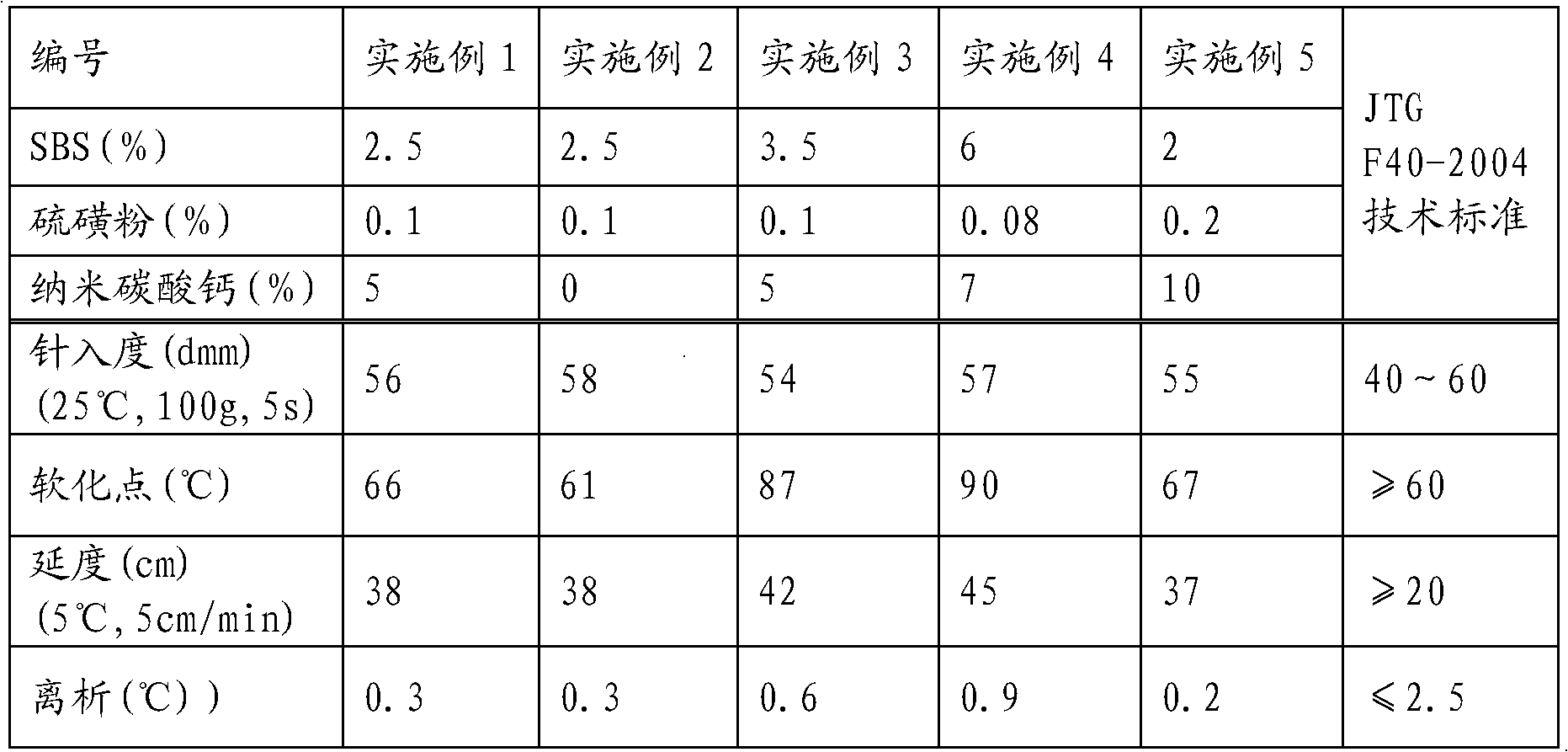

Embodiment 1

[0034] Ingredients: parts by weight of each component are: 92.4 parts of asphalt; 2.5 parts of SBS; 0.1 part of sulfur powder; 5 parts of nano-calcium carbonate.

[0035] Production process: first raise the temperature of the asphalt to 190°C, start stirring, put SBS into the mixing tank, and stir for 180 minutes, then pass the material in the mixing tank through the colloid mill (the speed of the colloid mill is 1 to 3 minutes / ton), and grind all the materials until they swell After the tank, add sulfur powder and nano-calcium carbonate, and stir for 60 minutes to obtain modified asphalt.

Embodiment 2

[0037] Ingredients: parts by weight of each component are: 97.4 parts of asphalt; 2.5 parts of SBS; 0.1 part of sulfur powder; 0 part of nano calcium carbonate.

[0038] Production process: first raise the temperature of the asphalt to 200°C, start stirring, put SBS into the mixing tank, stir for 120 minutes, then pass the material in the mixing tank through a high-speed shear machine, grind all the materials into the swelling tank, add sulfur powder, and stir for 90 minutes , to obtain modified asphalt.

Embodiment 3

[0040] Ingredients: parts by weight of each component are: 91.4 parts of asphalt; 3.5 parts of SBS; 0.1 part of sulfur powder; 5 parts of nano-calcium carbonate.

[0041] Production process: first raise the temperature of the asphalt to 175°C, start stirring, put SBS into the mixing tank, and stir for 240 minutes, then pass the material in the mixing tank through the colloid mill (the speed of the colloid mill is 1 to 3 minutes / ton), and grind all the materials until they swell After the tank, add sulfur powder and nano-calcium carbonate, and stir for 10 minutes to obtain modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com