Ring-wave repeated drawing high deformation mold for plate and machining method

A mold and plate technology, which is applied in the field of plate ring-wave repeated drawing and strong deformation mold and processing, can solve the problems of uneven plate deformation, uneven strain, and the inability to accumulate strain at the ring-wave connection, so as to achieve a controllable deformation process, The effect of uniform strain distribution and improvement of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

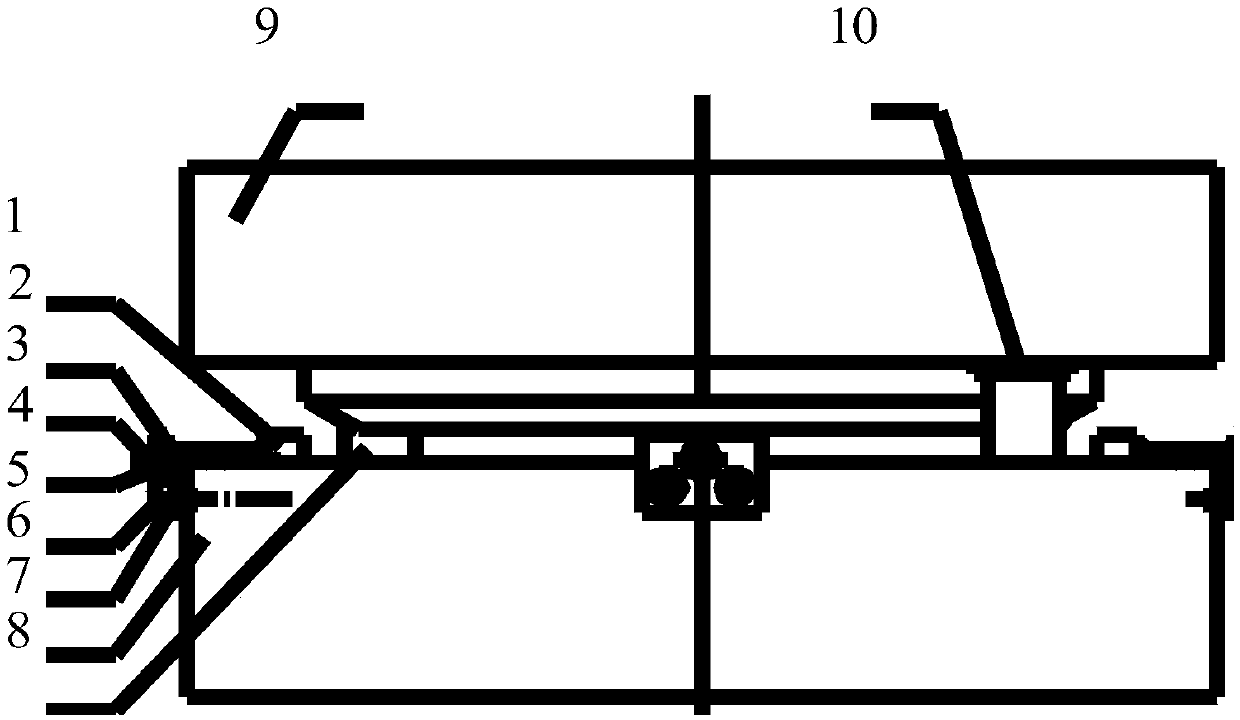

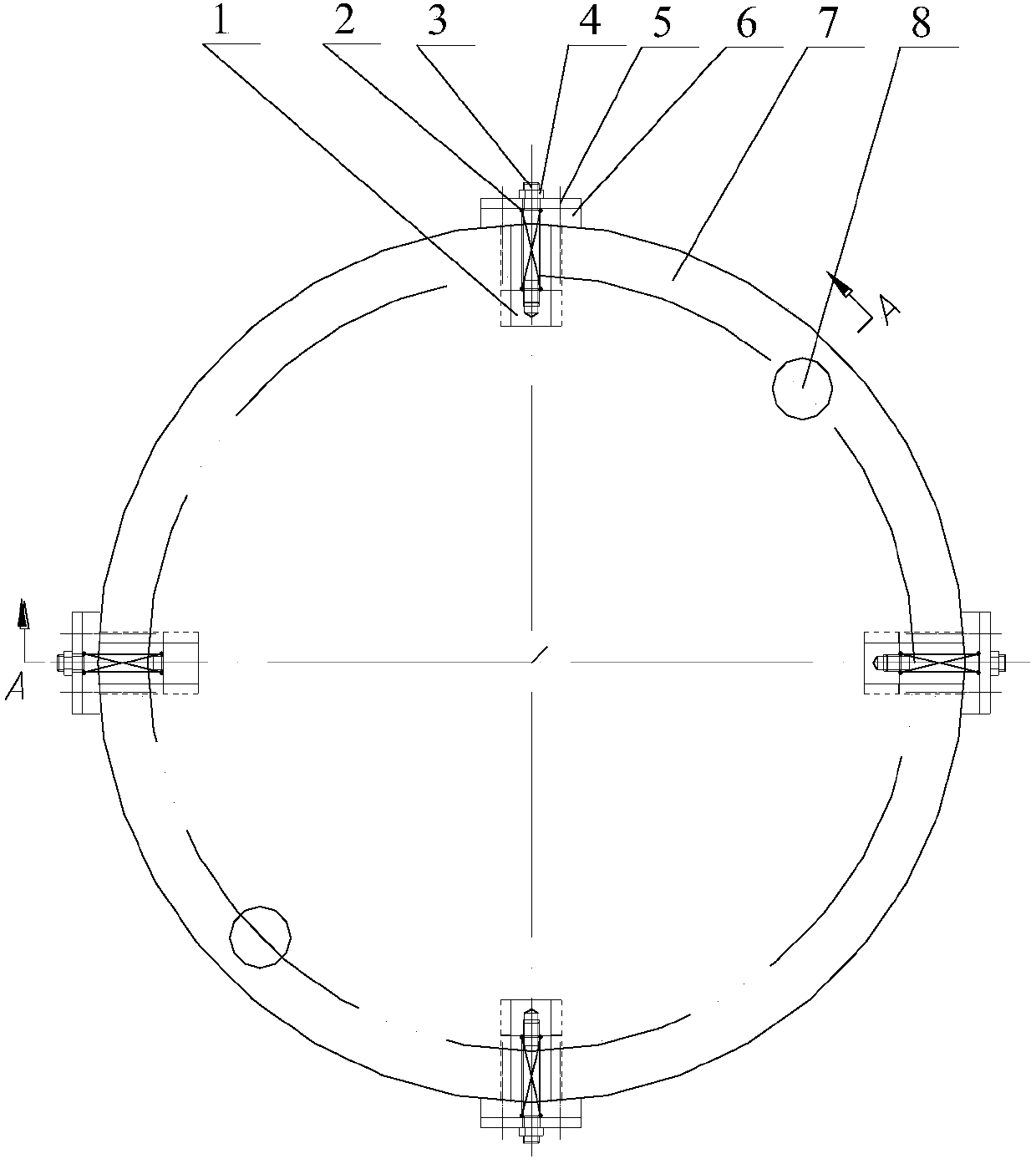

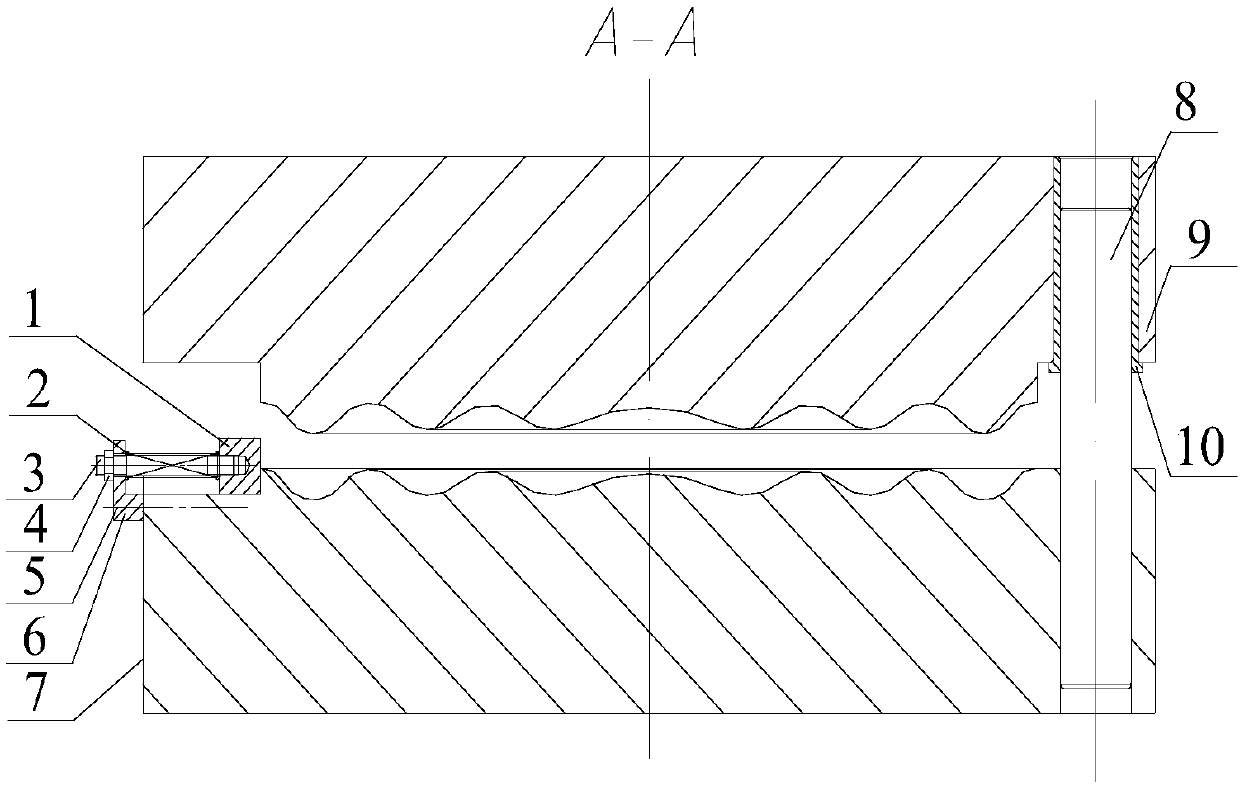

[0049] For a 5083Al alloy circular sheet with a diameter of 88mm and a thickness of 0.63mm (the original sheet, hereinafter referred to as the sheet), the ring-wave repeated drawing and strong deformation is carried out, including the following passes:

[0050] Pass 1: Place the plate in the center of ring wave lower die A7 as Figure 14 As shown in (a), adjust the positioning screw A3, and the calibration plate is accurately aligned with the center of the ring wave lower mold A7.

[0051] Pass 2: Start the hydraulic press, first make the upper die A9 of the ring wave start to move down quickly to a distance of about 0.5mm from the plate, then reduce the speed of the upper die A9 of the ring wave to 0.05mm / min and move down slowly, and stretch and deform the plate to the distance of about 0.5mm After the ring wave upper mold A9 and the ring wave lower mold A7 are bonded together, keep the pressure for 1min.

[0052] The cross-section of the deformed plate after drawing in pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com