Polycarbonate material composition of reinforced LED lamp shade and preparation method and LED lamp shade

A technology of LED lampshade and material composition, which is applied in the direction of lampshade, lighting and heating equipment, parts of lighting devices, etc. Insufficient and other problems, to achieve uniform and stable overall performance, excellent light transmittance and light diffusion, and the effect of improving light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

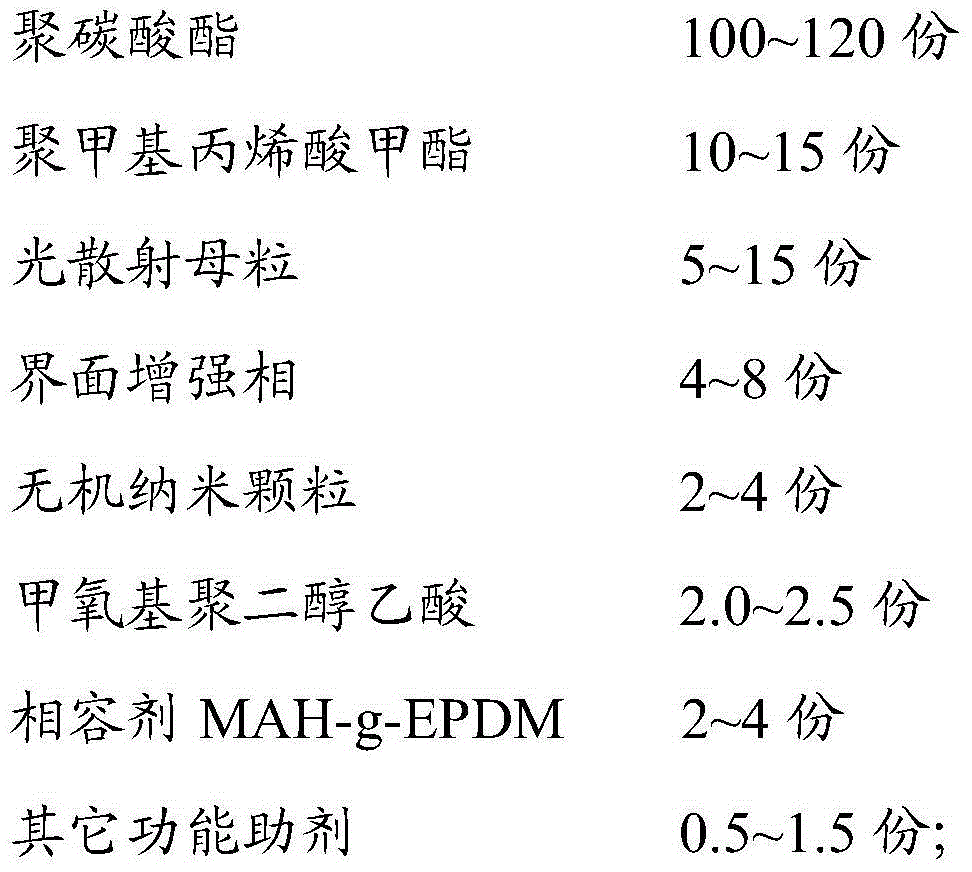

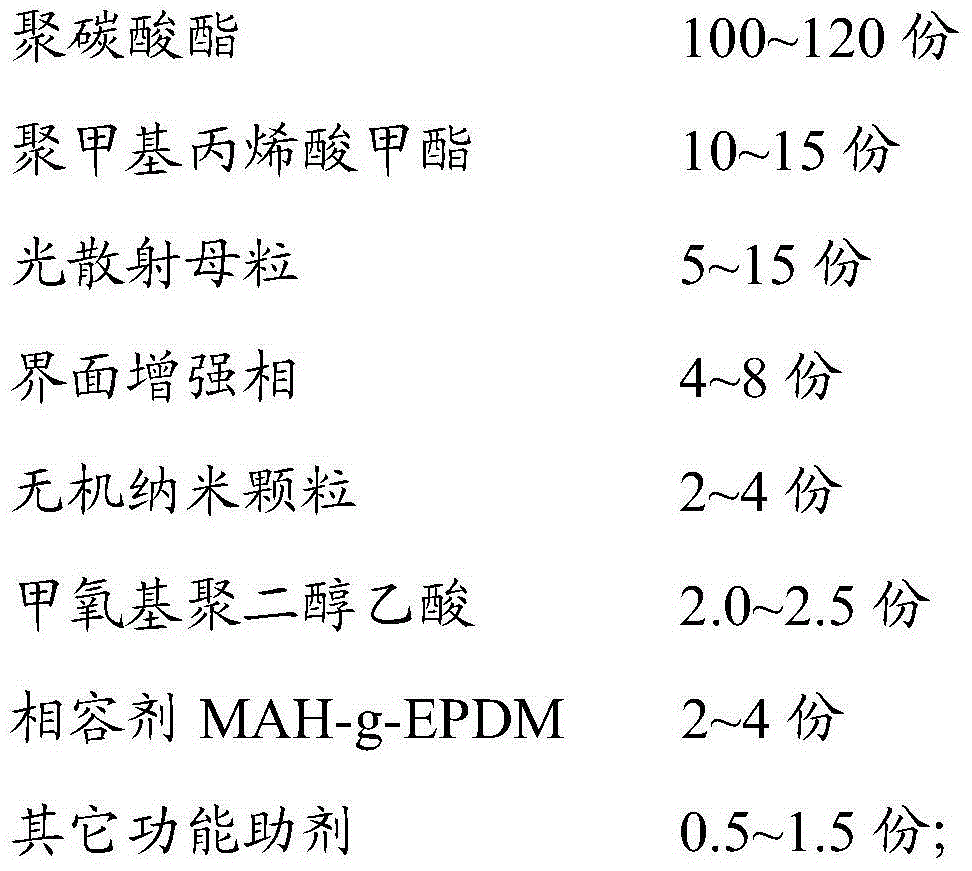

Method used

Image

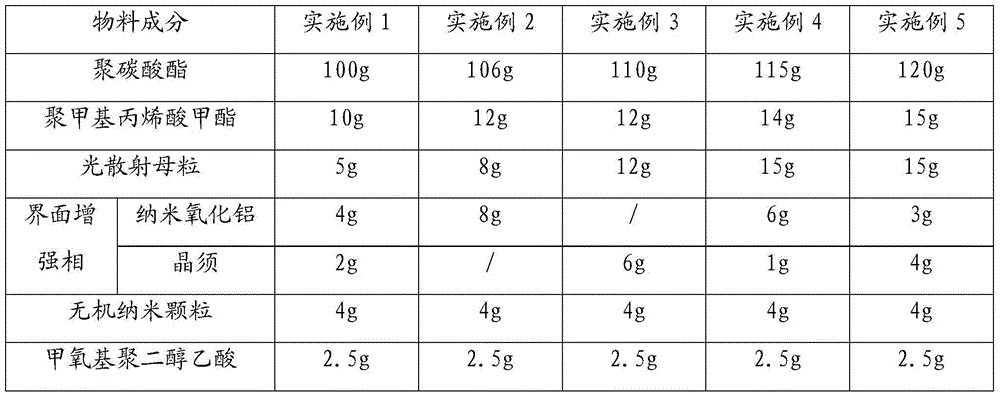

Examples

preparation example Construction

[0029]The present invention further proposes a preparation method of the polycarbonate composite material of the above-mentioned enhanced LED lampshade, comprising the following steps:

[0030] S01. Weigh the formula components: weigh each component according to the formula of the polycarbonate composite material of the above-mentioned enhanced LED lampshade;

[0031] S02. Preparation of mixed material: weighing each component in step S01 for mixing treatment to obtain mixed material;

[0032] S03. Melt-extrusion of the mixed material: melt-extrude the mixed material in step S02 to obtain a polycarbonate composite material for a reinforced LED lampshade.

[0033] Specifically, the formulation of the polycarbonate composite material of the enhanced LED lampshade in the above step S01 and the preferred content and type of each component in the formulation are as described above, and will not be repeated here to save space.

[0034] In the above step S02, the time for mixing eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com