Cold-rolled fine-punched steel strip for automobile child seat locking device and preparation method thereof

A technology of child seat and locking device, which is applied in the field of steel strip preparation, can solve problems such as parts cracking, achieve stable and uniform performance, and improve the quality of the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

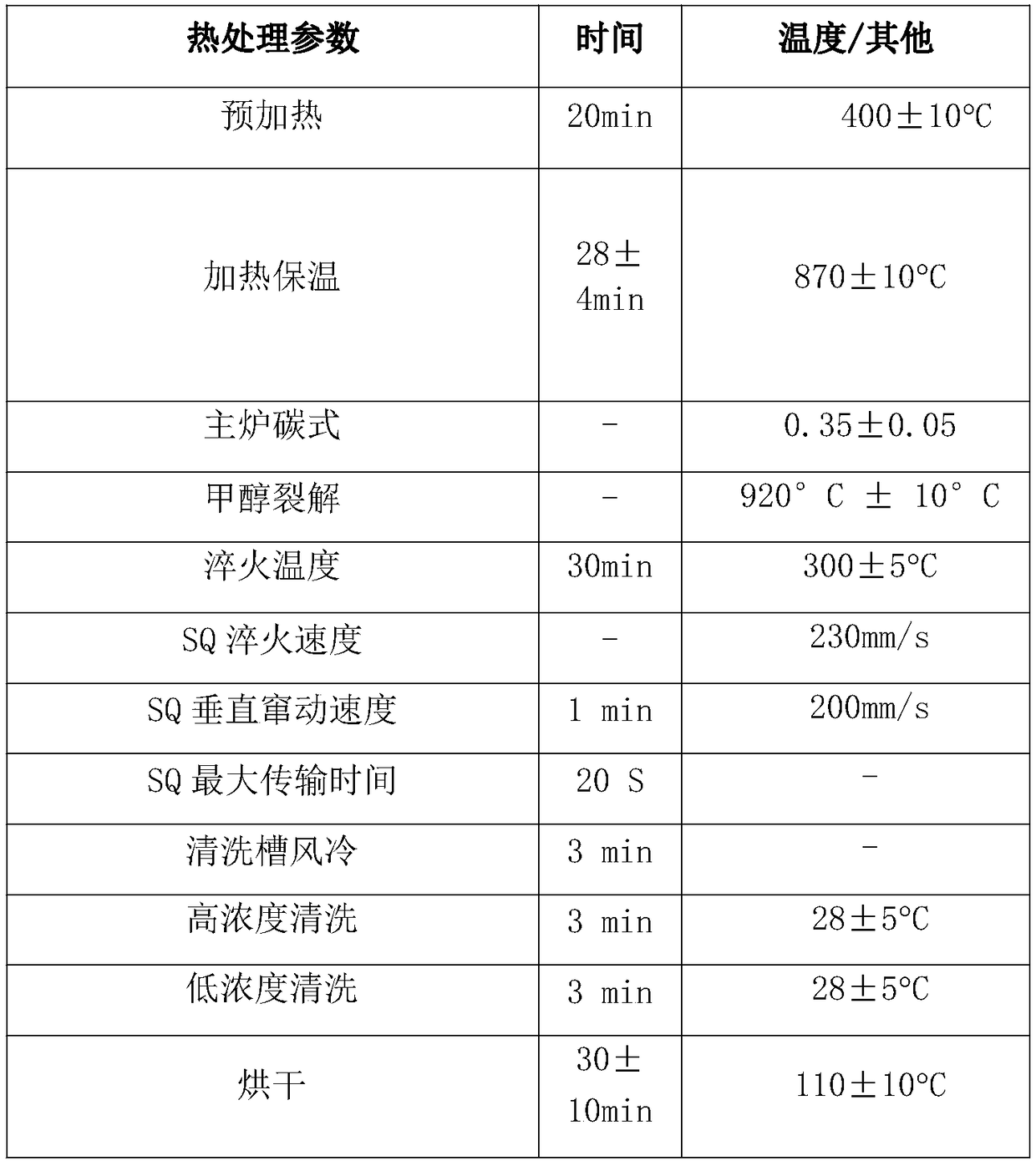

Image

Examples

Embodiment

[0042] An embodiment of the cold-rolled fine-blanking steel strip for the locking device of the automobile child seat of the present invention, the material of the cold-rolled fine-blanking steel strip is 51CrV4, and the composition of the cold-rolled fine-blanking steel strip includes:

[0043] C(%): 0.50-0.55, Si(%): 0.15-0.35, Mn(%): 0.80-1.10, P(%)≤0.015, S(%)≤0.01, Cr(%): 0.90-1.20, V(%): 0.10-0.20, Al(%)≤0.035.

[0044] In this embodiment, the method for preparing the cold-rolled fine-blanking steel strip for the locking device of the car child seat comprises the following steps:

[0045] 1. Take the hot-rolled steel coil 4.5*1250mm*C: pickling to remove the surface oxide layer, and then slitting.

[0046] 2. Slitting to 4.5*234mm*C, annealing the small roll blank.

[0047] The specific annealing process is as follows:

[0048] 1) Heat to 250°C for 2 hours to remove moisture and oil on the surface of the steel strip. Ensure the inner vacuum, and then rush into the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com