Graphene modified silk fiber preparing method

A technology of graphene modification and silk fiber, which is applied in the field of textile materials, can solve the problems of large damage to the original properties of silk fiber and ignore the performance of regenerated silk fiber itself, and achieve excellent physical and chemical biological shape and excellent biocompatibility and comfort, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

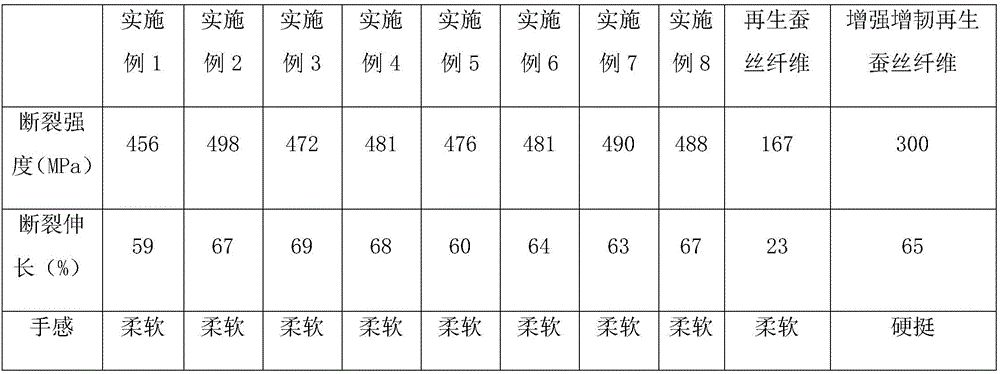

Examples

Embodiment 1

[0028] (1) Add graphene oxide to a deionized aqueous solution, and ultrasonically treat it for 10 minutes until it is uniformly mixed to form a graphene suspension with a concentration of 2 mg / ml.

[0029] (2) Pure silk fibroin solution is obtained by degumming, dissolving, dialysis, purification and filtration of silk fibers. The pure silk fibroin solution is placed in a container and dried naturally at room temperature to form a regenerated silk fibroin membrane, and then the regenerated silk fibroin membrane is dissolved in 90% A silk spinning solution with a mass fraction of 15% is made from formic acid.

[0030] (3) Add graphene suspension and low-molecular-weight chitosan to the silk spinning solution, and stir thoroughly to form a uniform and stable spinning solution. Among the components in the spinning solution, by weight, the silk protein is 20 parts, graphene oxide is 1 part, chitosan is 2 parts, and the regenerated silk fiber is obtained from the spinning solution throu...

Embodiment 2

[0033] (1) Add graphene oxide to a deionized aqueous solution, and ultrasonically treat it for 30 minutes until it is uniformly mixed to form a graphene suspension with a concentration of 20 mg / ml.

[0034] (2) Pure silk fibroin solution is obtained by degumming, dissolving, dialysis, purification and filtration of silk fibers. The pure silk fibroin solution is placed in a container and dried naturally at room temperature to form a regenerated silk fibroin membrane, and then the regenerated silk fibroin membrane is dissolved in 90% A silk spinning solution with a mass fraction of 25% is made from formic acid.

[0035] (3) Add graphene suspension and low-molecular-weight chitosan to the silk spinning solution, and stir thoroughly to form a uniform and stable spinning solution. Among the components in the spinning solution, by weight, the silk protein is 50 parts, 10 parts of graphene oxide, 30 parts of chitosan, and finally the spinning solution is subjected to electrospinning techn...

Embodiment 3

[0038] (1) Add graphene oxide to a deionized aqueous solution, and ultrasonically treat it for 20 minutes until it is uniformly mixed to form a graphene suspension with a concentration of 10 mg / ml.

[0039] (2) Degumming, dissolving, dialysis, purification and filtration of the silk fiber to obtain a pure silk fibroin solution. The pure silk fibroin solution is placed in a container and dried naturally at room temperature to form a regenerated silk fibroin membrane, and then the regenerated silk fibroin membrane is dissolved in chloroform A silk spinning solution with a mass fraction of 20% is prepared.

[0040] (3) Add graphene suspension and low-molecular-weight chitosan to the silk spinning solution, and stir thoroughly to form a uniform and stable spinning solution. Among the components in the spinning solution, by weight, the silk protein is 30 parts, graphene oxide is 5 parts, chitosan is 10 parts, and the regenerated silk fiber is obtained from the spinning solution through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com