Production method of high-precision ultralong oxygen-free copper strip

A production method and oxygen-free copper technology, applied in lighting and heating equipment, rolling mill control devices, metal rolling, etc., can solve problems such as difficult to meet the needs of supporting industries, complex equipment structure, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

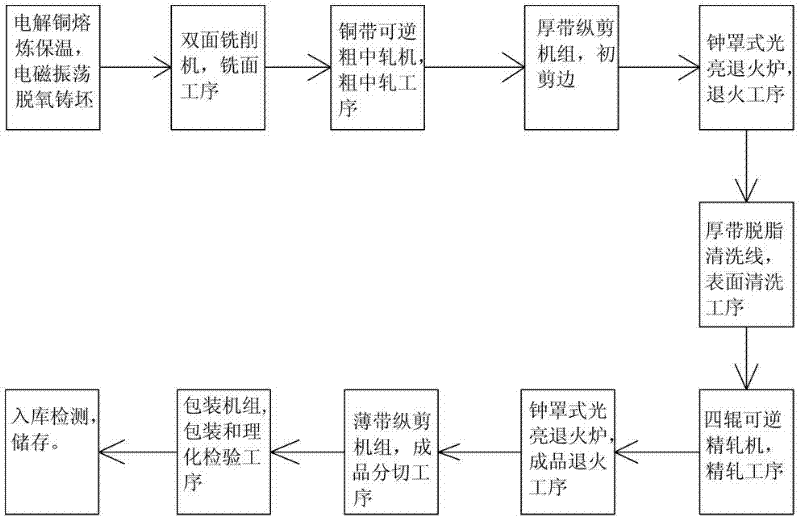

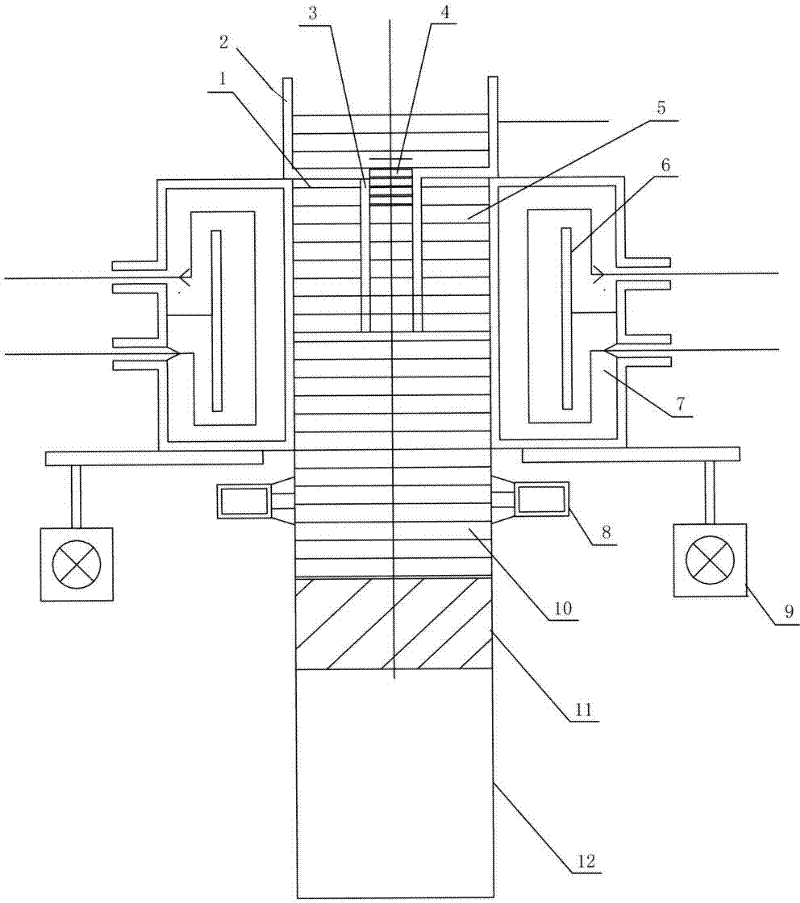

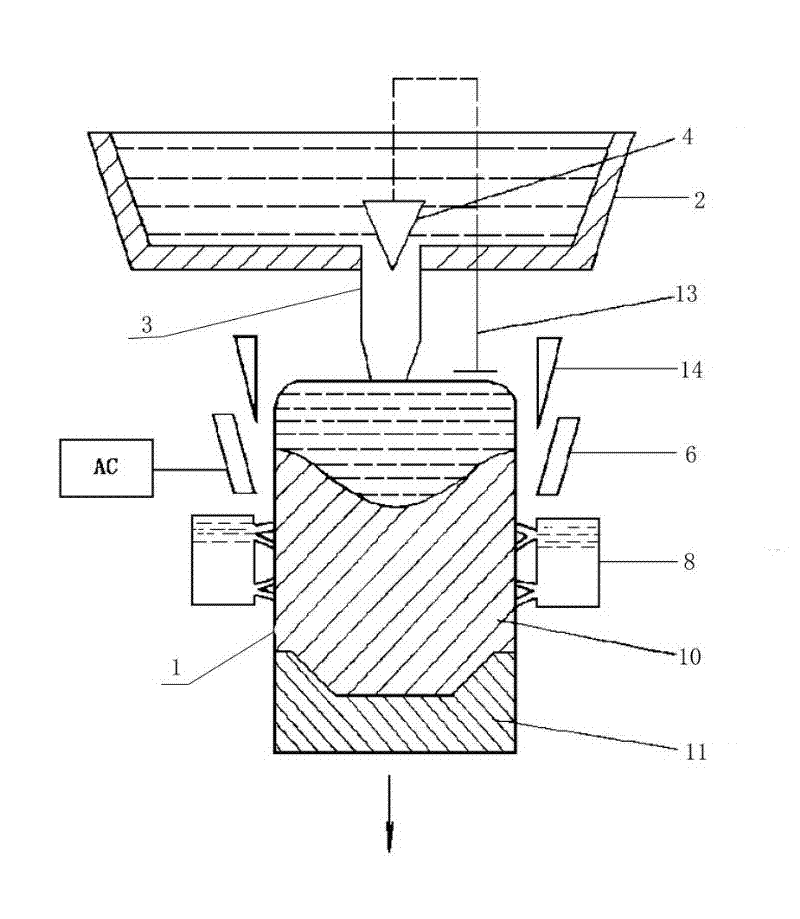

[0086] Refer to attached Figure 1~3 , the production method of high-precision ultra-long oxygen-free copper strip is as follows:

[0087] ! 1. Select the raw material electrolytic copper plate according to the regulations of the process document, and add the electrolytic copper to the melting furnace for melting; when smelting, add a calcined charcoal covering agent with a thickness of 50 to 100 mm into the melting furnace, and add the raw material electrolytic copper regularly and quantitatively, and the melting voltage The AC is 380-400V, and the melting temperature is maintained at 1180-1250°C. The melted copper in the melting furnace cavity submerges into the holding furnace cavity from the launder at the bottom of the furnace, and the temperature of the copper liquid in the holding furnace is adjusted and adjusted by the PID intelligent instrument. The gear position of the device is used to realize automatic temperature control. The copper liquid maintains the casting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com