Patents

Literature

38results about How to "Reduce broken belt rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preventing strip breakage on startup

ActiveCN103785694AThe number of times to prevent the start of the car from breaking the beltReduce tensile stressRoll force/gap control deviceTension/compression control deviceEngineeringBending force

The invention discloses a method for preventing strip breakage on startup. The method includes, before strip winding, processing sheets with broken strips at first after stopping of a cold rolling mill due to strip breakage, compressing roll gaps of various frames and regulating the minimum rolling force of the roll gaps of the different frames after finishing the strip winding, generating exit tension of the different frames prior to regulating roll bending force of working rolls and intermediate rolls after finishing compressing of the roll gaps, and then, starting the cold rolling mill. The method for preventing strip breakage on startup includes control of the roll gaps of the cold rolling mill, selection of rolling force and tension and generation of tension, regulation of actual inclination and tension deviation of different frames, control of bending conditions of the working rolls and the intermediate rolls after startup, thereby effectively controlling times of startup strip breakage of sheets with the thickness lower than 0.6mm and improving production efficiency.

Owner:SHOUGANG CORPORATION

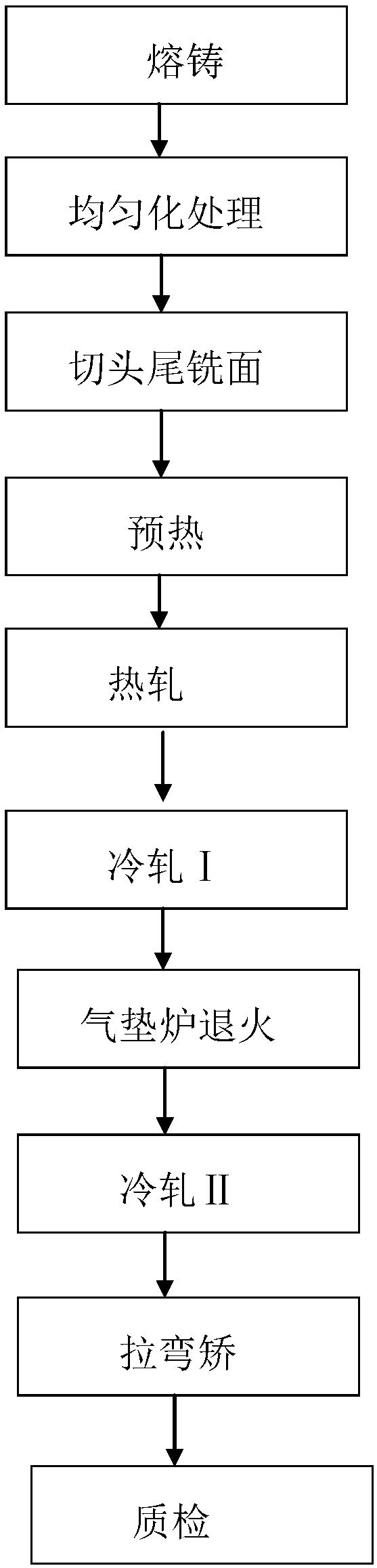

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

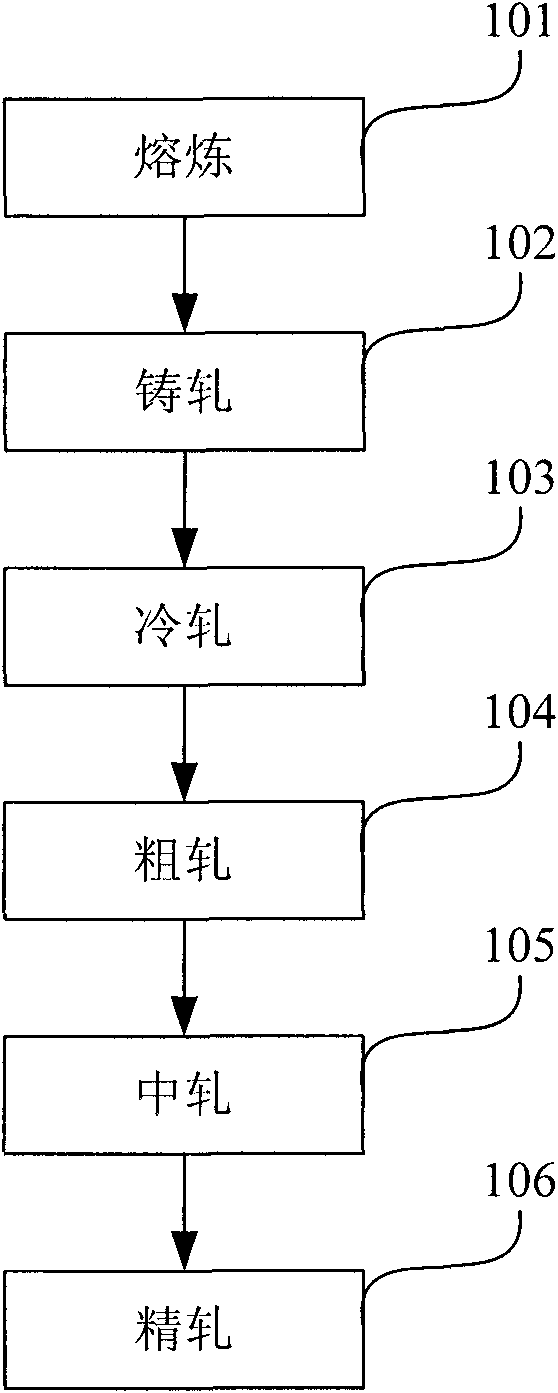

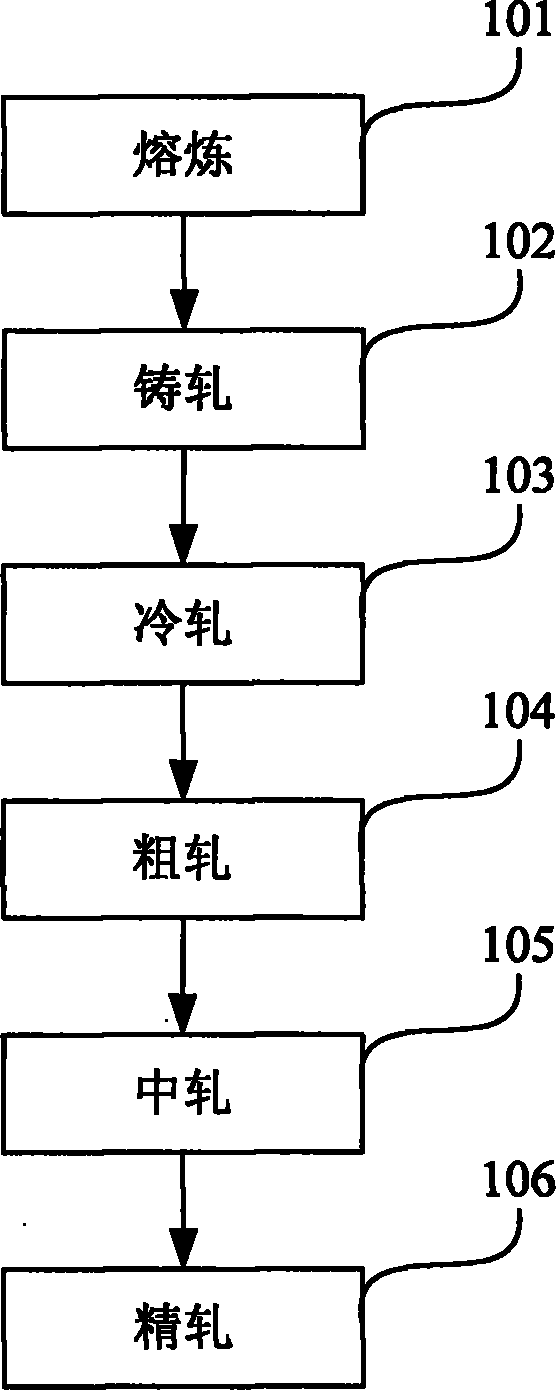

Production process of ultrathin double-face optical aluminum foil

ActiveCN101844152AStable productionProduction batchMetal rolling arrangementsProfile control deviceFiltrationRoom temperature

The invention discloses a production process of ultrathin double-face optical aluminum foil, comprising the following steps of: smelting: fusing raw materials into aluminum liquid by using a heat-storage type smelting furnace and entering into a casting-rolling machine after filtration; casting and rolling: introducing fused aluminum liquid in the casting-rolling machine to be aluminium foil blanks; cold rolling: rolling aluminium foil blanks to 0.78 millimeter by using a cold rolling machine after cooling the aluminium foil blanks to room temperature, then sending the aluminium foil blanks into an annealing furnace for uniformly annealing, and then rolling the aluminium foil blanks to 0.36 millimeter to obtain aluminium foil stocks; rough rolling: roughly rolling the aluminium foil stocks, wherein the reduced passes of rough rolling are 0.36 millimeter to 0.19 millimeter to 0.09 millimeter to 0.043 millimeter; medium rolling: carrying out medium rolling on the roughly rolled aluminium foil stocks, wherein the educed passes of medium rolling are 0.043 millimeter to 0.021 millimeter; and finish rolling: carrying out finishing rolling on the medium-rolled aluminium foil stocks, wherein the reduced passes of finish rolling are 0.021 millimeter to 0.011 millimeter, thereby obtaining aluminum foil finished products. The invention can reduce tape breakage rate in the production process of the aluminum foil by adopting the production process of the ultrathin double-face optical aluminum foil, thereby stably producing the ultrathin double-face optical aluminum foil in batch.

Owner:华北铝业新材料科技有限公司

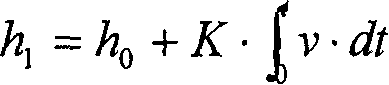

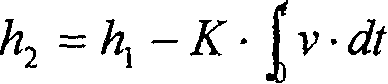

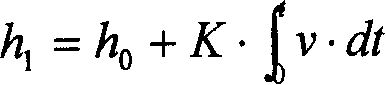

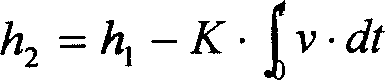

Dynamic thickening rolling process of controlling break of cold rolled thin strip steel

InactiveCN1857809AReduced number of broken beltsReduce broken belt rateRoll mill control devicesMeasuring devicesControl breakMultiple frame

The dynamic thickening rolling process of controlling break of cold rolled thin strip steel has weld seam tracking system used in measuring the weld seam position accurately, and features that in the range of 50 m around the weld seam, the strip steel thickness is increased to 1.0-1.5 times the original target thickness. Two wedge rolling processes are used to increase the rolled thickness dynamically, so as to lower the break rate of the thin rolled material. The present invention has the advantages of reduced strip steel breaking rate, high production efficiency, etc. and is suitable for multi-frame continuous cold rolling machine with 4, 5 or 6 frames.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION +1

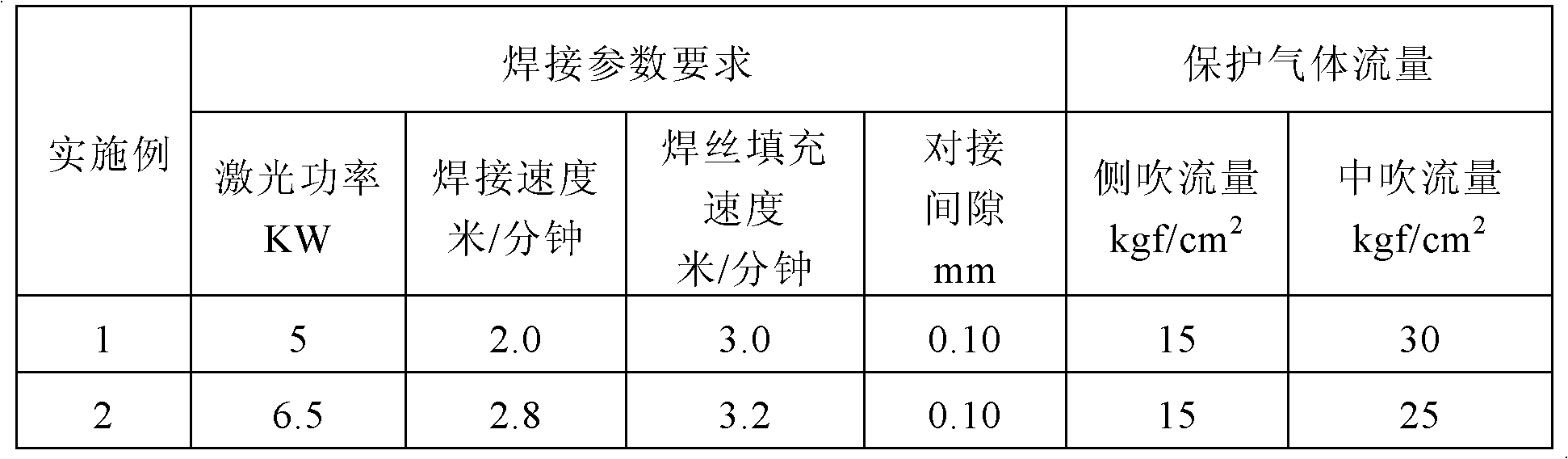

Welding wire filling laser welding method utilizing non-oriented silicon steel

ActiveCN102806423AReduce broken belt rateImprove millabilityWelding/cutting media/materialsWelding/soldering/cutting articlesContinuous productionLow graded

A welding wire filling laser welding method utilizing non-oriented silicon steel includes steps of (1), taking plain carton steel with the silicon content smaller than 1.0% or low-grade non-oriented silicon steel as a leading tape for laser splice welding, taking non-oriented silicon steel with the silicon content ranging from 1.0%-3.5% as a base material for laser splice welding, cutting the tail of the leading tape and the head of the base material and the splicing the two together; (2), performing laser welding by a laser welder with the laser power of 5.0-9.0KW, the welding speed of 2.0-5.8meter / minute and the welding wire filling speed of 3.0-5.8meter / minute; and (3), selecting the plain carton steel with the silicon content smaller than 1.0% or low-grade non-oriented silicon steel as a leading tape after finishing welding, and then repeating the above steps to realize continuous productions. The welding wire comprises, by weight, C< / =0.10%, Si< / =0.85%, Mn< / =0.98%, P< / =0.015%, S< / =0.015%, Cr< / =0.013%, Al< / =0.010% and the balance being Fe; and helium gas is selected as a protective gas for protecting and cooling welded joints during laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

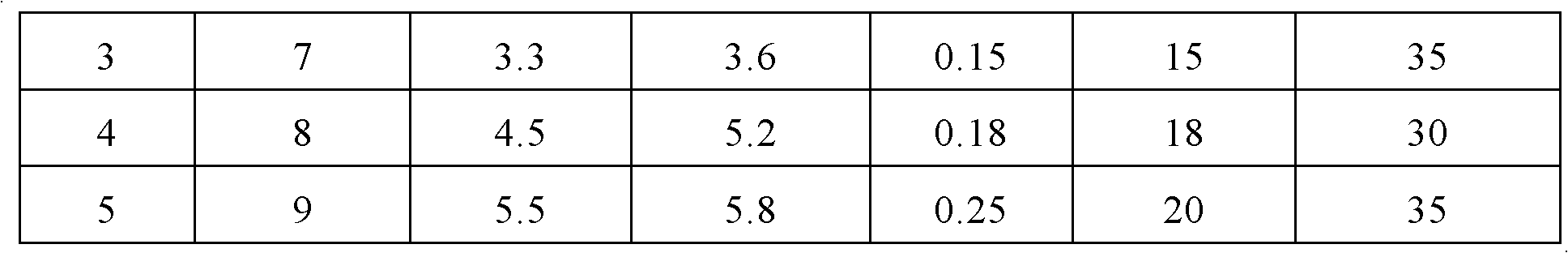

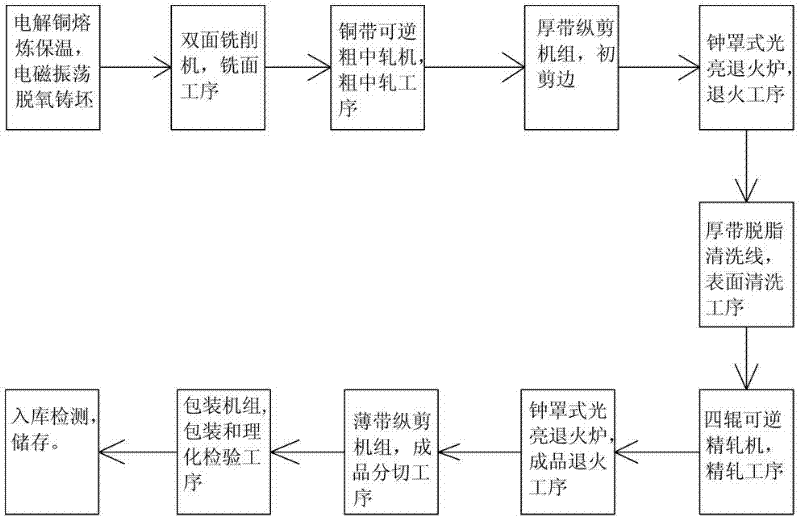

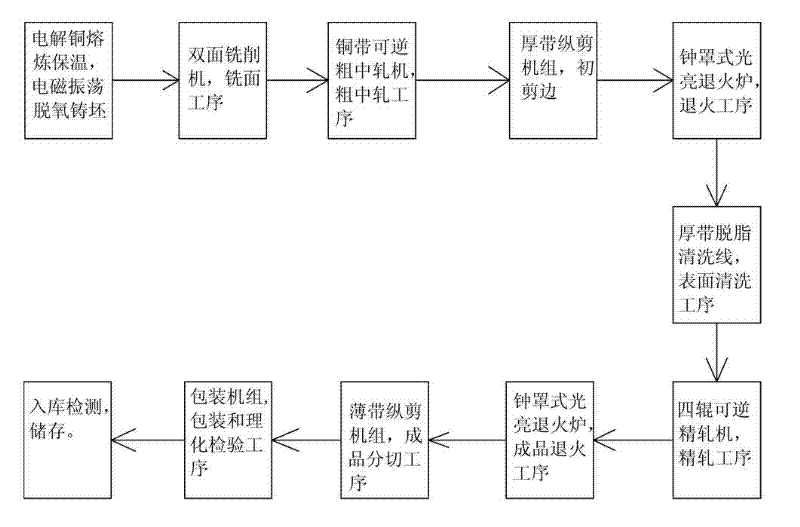

Production method of high-precision ultralong oxygen-free copper strip

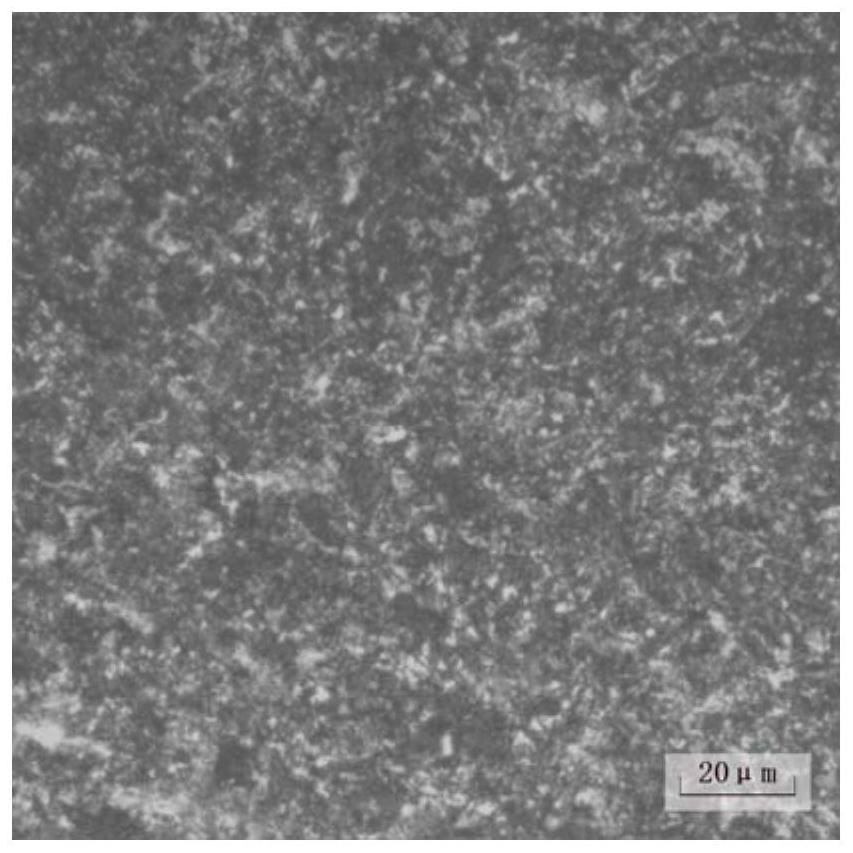

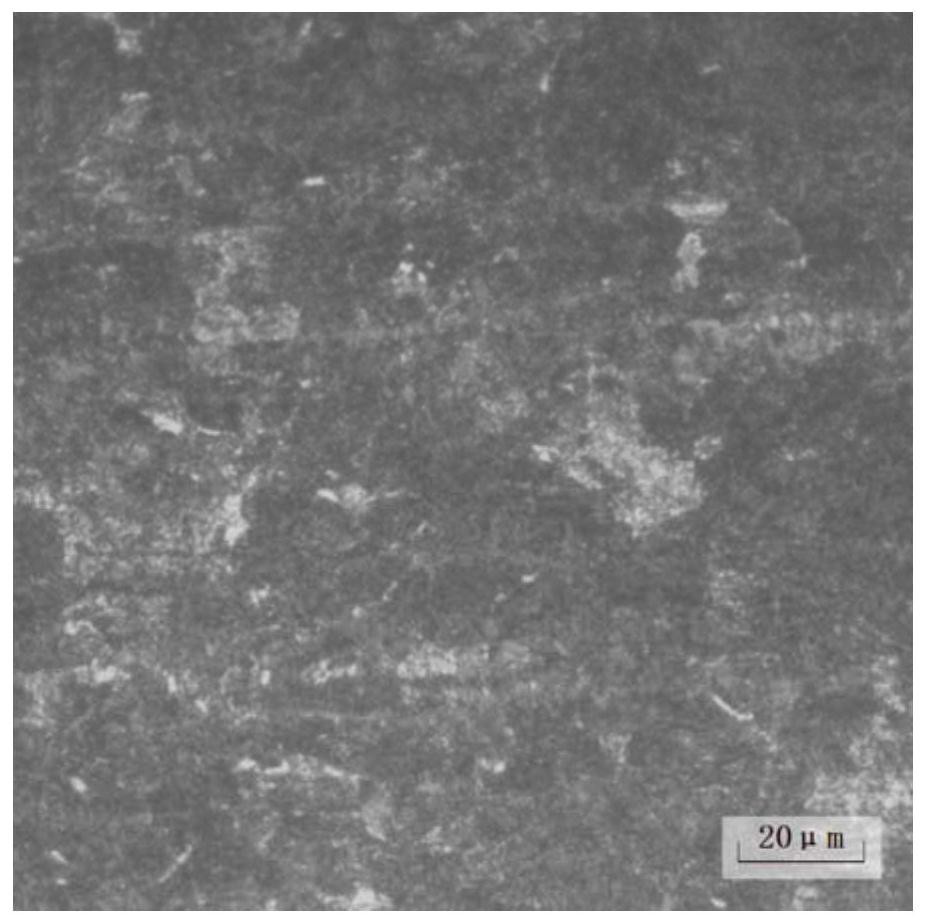

ActiveCN102199711ACompact structureGuaranteed oxygen contentRoll mill control devicesBell type furnacesElectrolysisIngot

The invention relates to a production method of a high-precision ultralong oxygen-free copper strip and belongs to the technical field of oxygen-free copper strip production, processing and manufacturing. The production method of the high-precision ultralong oxygen-free copper strip comprises: (1) selecting electrolytic copper as a raw material, adding the electrolytic copper into a melting furnace, smelting the melting furnace, allowing molten copper to flow into a crystallizer added with an electromagnetic oscillation coil, performing electromagnetic deoxidization of the molten copper and horizontally casting a blank by electromagnetic continuous casting in the electromagnetic continuous casting crystallizer added with the electromagnetic oscillation coil, cooling in the electromagnetic continuous casting crystallizer, crystallizing to form strip copper blanks, and stretching by an ingot leading machine; (2) milling a strip blank by a double-sided miller; (3) performing reversible coarse medium rolling of the copper strip; (4) performing primary trimming by a thick strip longitudinal shearing machine; (5) annealing in a bell type bright annealing furnace; (6) cleaning surface on a thick strip degreasing cleaning line; (7) finely rolling in a four-roller reversible fine rolling machine; (8) annealing a finished product in the bell type bright annealing furnace; (9) cutting the finished product by a thin-strip longitudinal shearing machine; (10) packing in a packaging machine and performing physical and chemical examination; and (11) performing incoming inspection and storing.

Owner:ZHONGTIAN ALLOY TECH

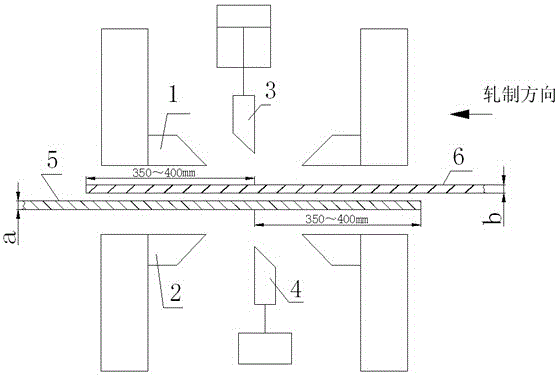

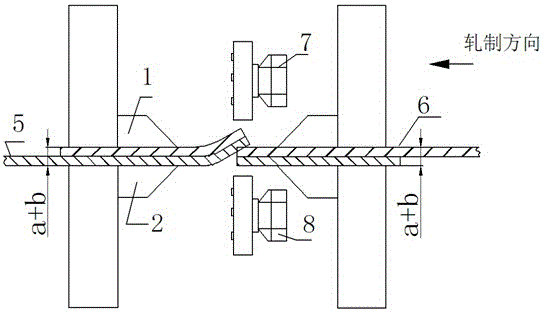

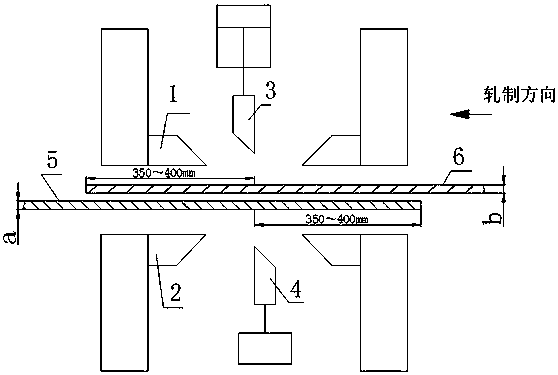

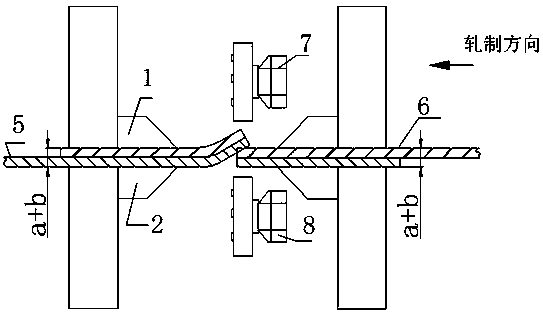

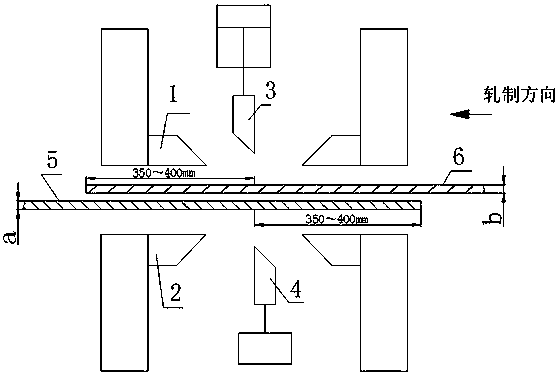

Method for achieving stitch welding of thin strip by means of lap welder of cold rolling rewinding unit

ActiveCN105945579AInnovative weldabilityStable welding productionOther manufacturing equipments/toolsWelding apparatusSheet steelStrip steel

The invention discloses a method for achieving stitch welding of a thin strip by means of a lap welder of a cold rolling rewinding unit. The method comprises the steps that during tail flicking of an online steel coil with the thickness being a, a strip tail is conveyed to the place 350 mm-400 mm away from the edge of a lower clamp at an inlet of the welder and does not enter a shear blade; during coil feeding of a next steel coil with the thickness being b, a strip head passes through the strip tail of the online steel coil, and the strip head is conveyed through a lower shear blade of the welder and enters a lower clamp at an outlet of the welder by about 350 mm-400 mm; and after the strip head and the strip tail are aligned, built-in scissors of the welder are used for shearing the strip head and the strip tail for shear operation, the thickness of a front steel plate and a rear steel plate is changed into a+b after shearing is finished, and lap welding is carried out according to the parameter that the thickness of the steel strip is a+b after overlapping. The method has the beneficial effects that stable welding production of the ultra-thin strip is achieved; the need of cold rolling rewinding production is met; the rewelding time is shortened; production efficiency is improved; the rewelding rate is reduced to 2% from original 83%; and the strip breakage rate is also reduced to 0.

Owner:LIUZHOU IRON & STEEL

Aluminum foil for high performance 1100 alloy lithium ion battery and preparation method thereof

InactiveCN110863162AHigh tensile strengthImprove efficiencyFurnace typesHeat treatment furnacesLithium-ion batteryAluminum foil

The invention discloses an aluminum foil for a high performance 1100 alloy lithium ion battery and a preparation method thereof. The aluminum foil is prepared from the following raw materials in percent by mass: 0.4-0.6% of Fe, 0.1-0.2% of Si, 0.11-0.17% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.05% of Mg, less than or equal to 0.02% of Zn, 0.01-0.03% of Ti, greater than orequal to 99.00% of Al and the balance inevitable impurities. The components and a thermal treatment process of the alloy are adjusted, so that the mechanical property (over 260 MPa) of a product is improved greatly. The tensile strength and the ductility reach the top level. The rate of strip breakage in a downstream step (coating and roll extruding) of the alloy is reduced greatly, so that purposes of improving the efficiency and stabilizing the quality are achieved. By adopting the novel thermal treatment process, the inner structure of an aluminum alloy material is improved, and the mechanical property is optimized, so that the machinability of the aluminum foil in a follow-up production process is better. Pass distribution is optimized, so that the mechanical property of the materialis improved effectively. The shape of the panel is optimized, so that the production efficiency of the product is improved.

Owner:山东德利铝业科技有限公司

Dynamic thickening rolling process of controlling break of cold rolled thin strip steel

InactiveCN100411760CReduced number of broken beltsReduce broken belt rateRoll mill control devicesMeasuring devicesControl breakMultiple frame

The dynamic thickening rolling process of controlling break of cold rolled thin strip steel has weld seam tracking system used in measuring the weld seam position accurately, and features that in the range of 50 m around the weld seam, the strip steel thickness is increased to 1.0-1.5 times the original target thickness. Two wedge rolling processes are used to increase the rolled thickness dynamically, so as to lower the break rate of the thin rolled material. The present invention has the advantages of reduced strip steel breaking rate, high production efficiency, etc. and is suitable for multi-frame continuous cold rolling machine with 4, 5 or 6 frames.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION +1

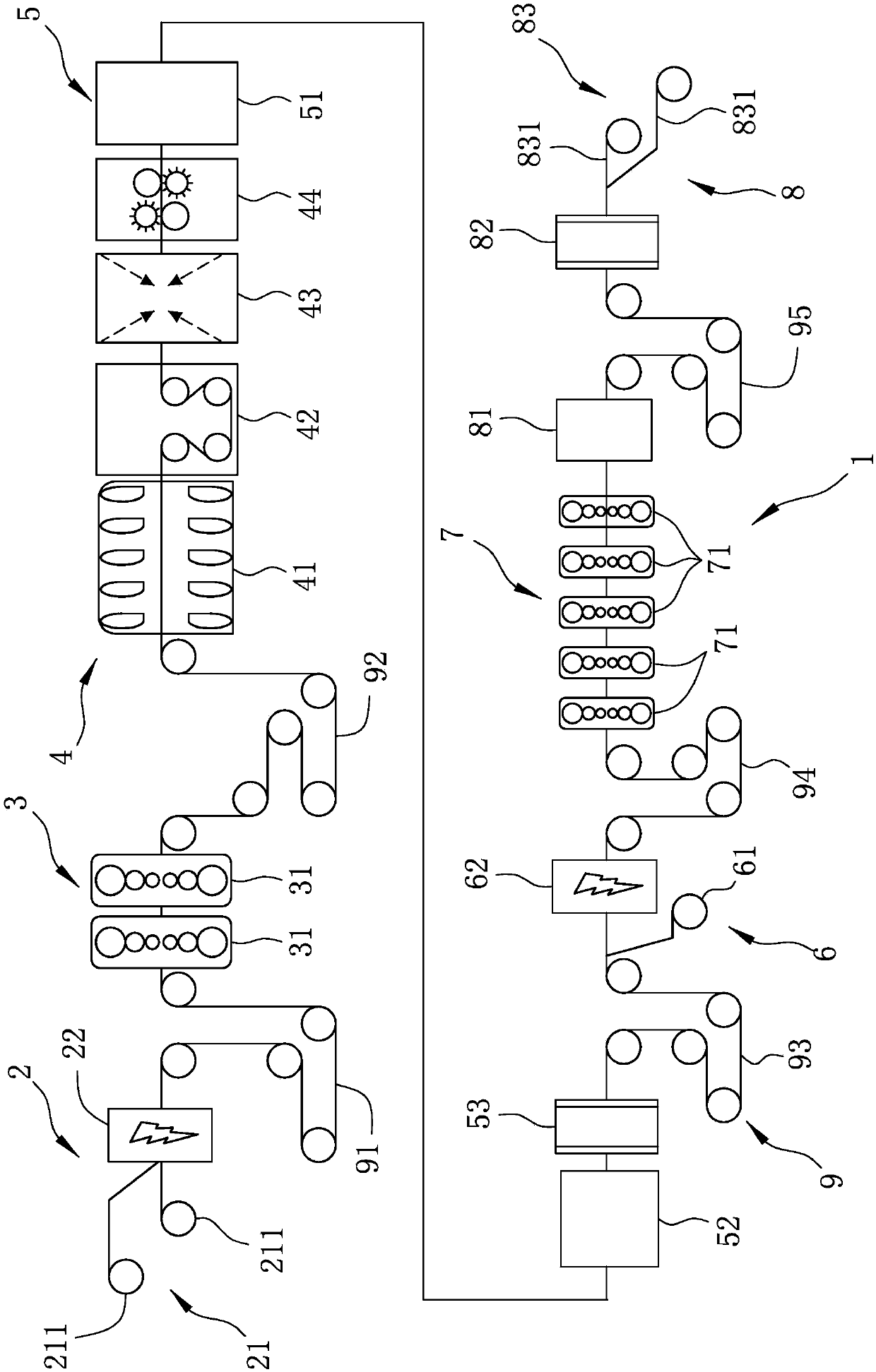

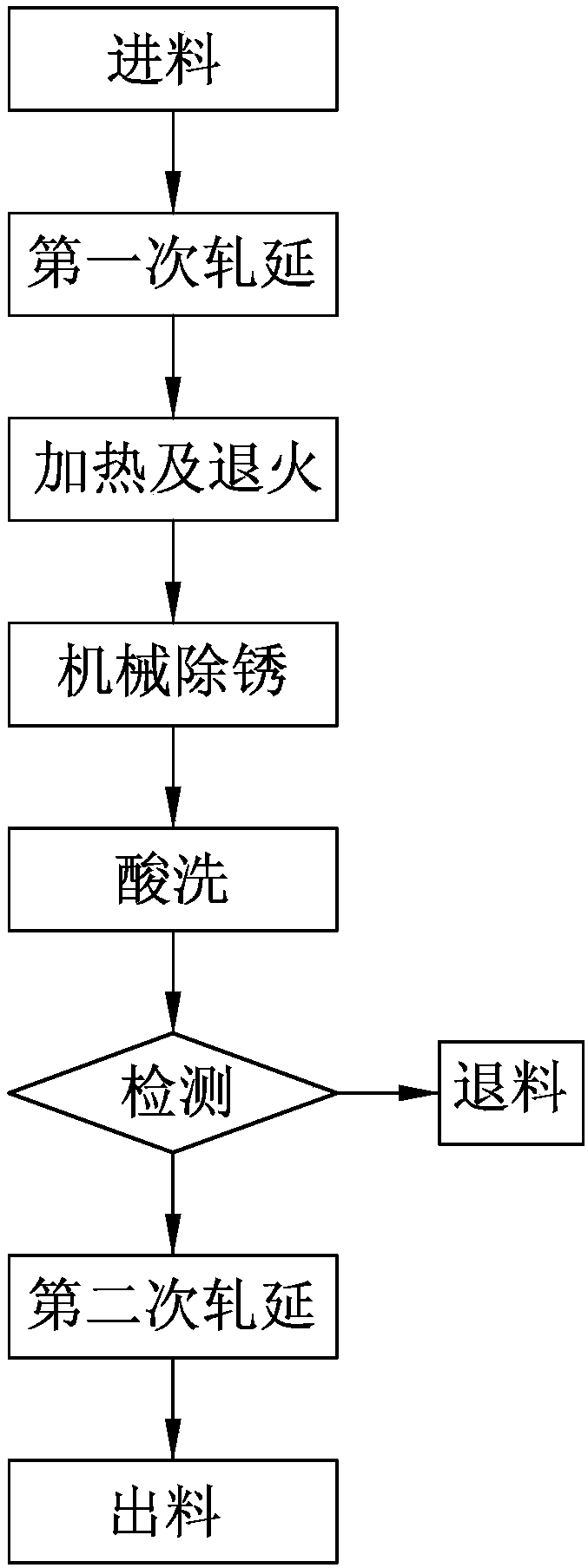

Duplex Cold Rolling Line

InactiveCN107838193AIncrease productivityReduce in quantityMeasuring devicesFurnace typesMaterials scienceHigh productivity

A composite cold rolling line includes a feed unit, a first rolling unit at downstream of the feeding unit, an annealing and descaling unit at downstream of the first rolling unit, and a pickling unitat downstream of the annealing and descaling unit, a second rolling unit at downstream of the pickling unit, and a back-feed unit at downstream of the second rolling unit. The first cold rolling millcan perform preliminary rolling before the annealing and pickling process. The product can reduce the thickness of the rolling required for the second rolling, produce a large amount of Cold-rolled thin hard-coated steel coils with continuous high productivity. Due to the initial rolling, the black-skin coils can reduce 30 to 70% of the amount of rust, reduce the number and length of rust removalequipment. In addition to equipment cost reduction, sand blast, usage of acid liquid and discharge of acid are reduced, and the environmental protection effects of energy saving and waste reduction are realized.

Owner:YIEH UNITED STEEL

Method of improving surface quality of light gauge aluminum foil preform body

InactiveCN102921729AImprove firm performanceImprove surface qualityMetal rolling arrangementsAluminum foilScratching

The invention relates to the manufacturing technique of aluminum and aluminum alloy foil, particularly to a method of improving the surface quality of light gauge aluminum foil preform body. The method is that in a process of manufacturing light gauge aluminum foil by means of cast-rolling and cold rolling, when the cast-rolling or the cold rolling is finished and the rolling-up of the preform body is finished, edges of two sides of a roll end of an aluminum roll are fixed on two sides of roll under layer material in a welded mode. The welding range of two side faces of the aluminum roll is 3 - 5 mm deep relative to the surface, and therefore the aluminum roll of the preform body is fixed. Due to the fact that the aluminum roll of the preform body is fixed in a welded mode, the firmness of the fixation of the preform body in subsequent handling (especially after the heat treatment) is effectively improved, scratching is avoided, the surface quality of the preform body is improved, and further the rate of finished products of the light gauge aluminum foil is increased, the rate of strip breakage is decreased, the occurrence of defects like pinholes on a board face is reduced, and then the thickness of the light gauge aluminum foil can be rolled to 0.0055 mm while traditional preform body can only be rolled to 0.006 mm thick in general.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

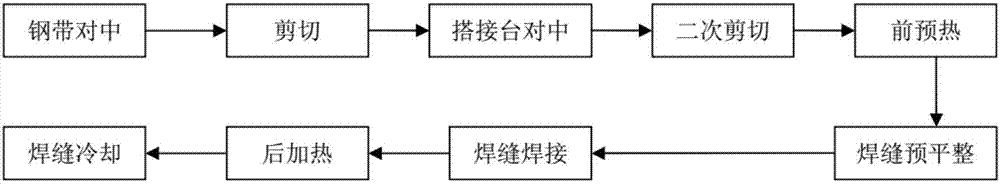

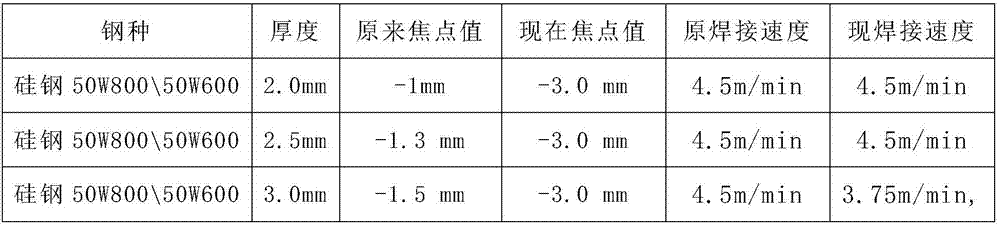

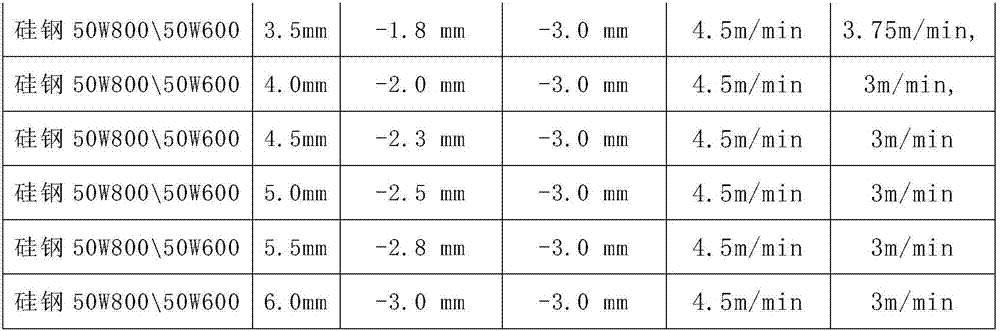

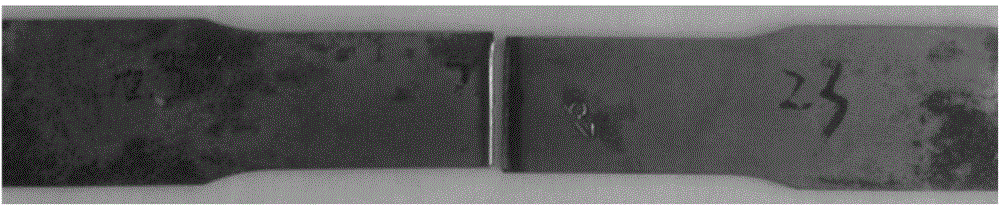

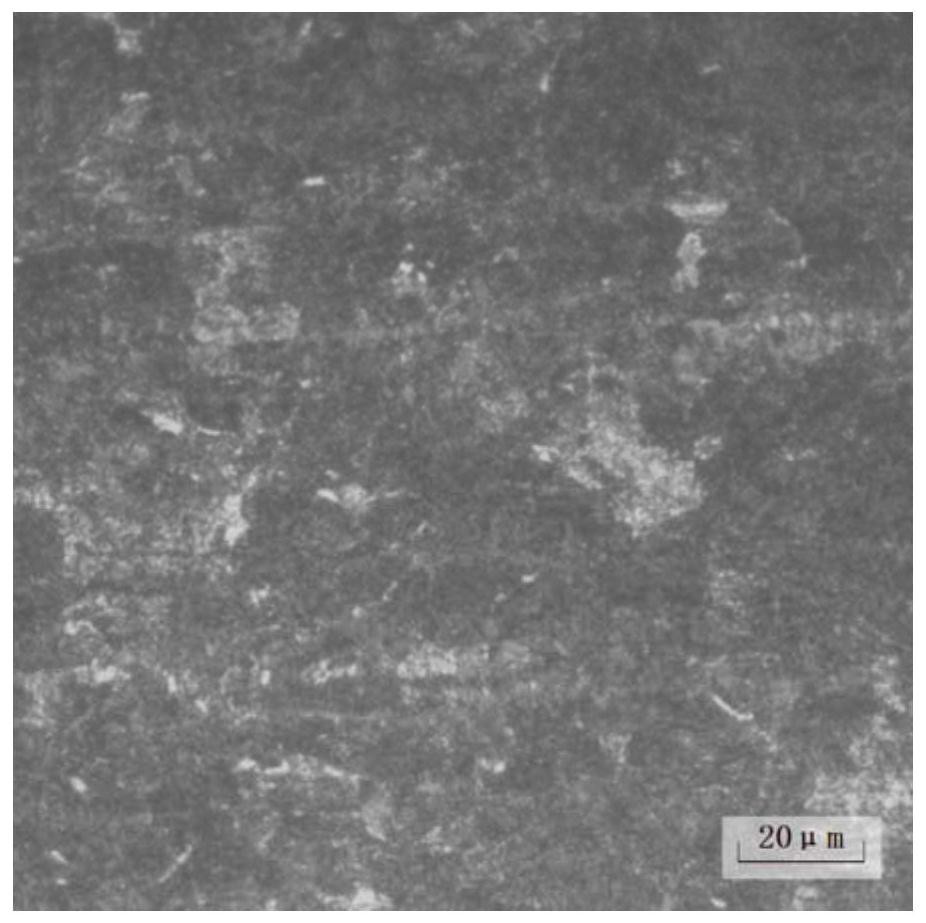

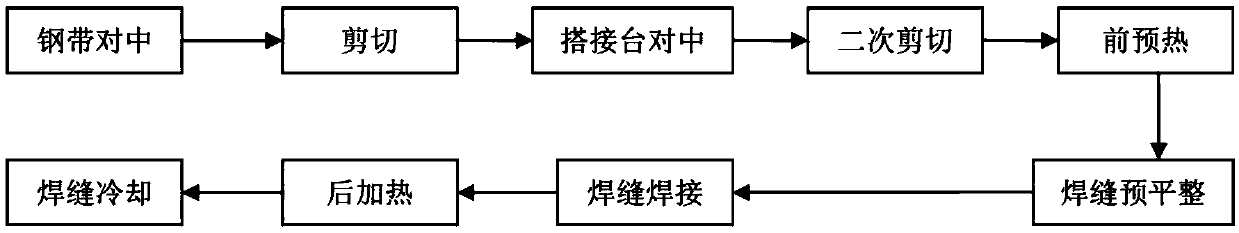

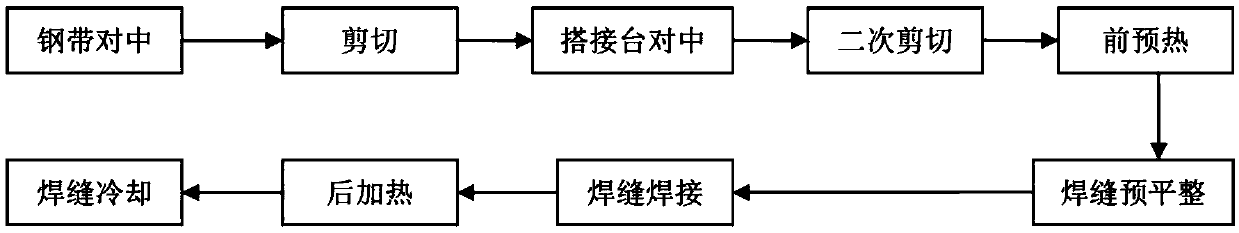

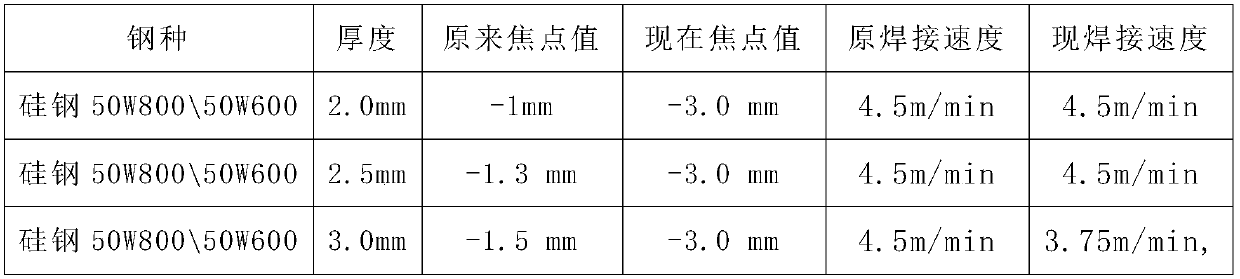

Method for welding low-grade non-oriented silicon steel through laser welding machine

ActiveCN107378239AReduce broken belt rateSmall sizeLaser beam welding apparatusHeat-affected zoneLower grade

The invention discloses a method for welding low-grade non-oriented silicon steel through a laser welding machine. The method sequentially comprises the following steps that a steel band is centered; shearing is conducted; a lapping table is centered; secondary shearing is conducted; preheating is conducted; weld joint pre-levelling is conducted; weld joint welding is conducted; postheating is conducted; and weld joints are cooled. In the weld joint welding process, the laser focal distance of the laser welding machine is set to be -3 mm, and the welding speed is lowered when silicon steel with the thickness being greater than 3 mm is welded. According to the method, the laser focal distance value is fixed, the range of a weld joint heat affected zone is adjusted through speed, and the weld joint band breakage rate is effectively lowered; and meanwhile, secondary shearing is additionally conducted before welding for improving the weld toe section size, and thus the welding quality is improved.

Owner:BAOTOU IRON & STEEL GRP

Method for lowering welding joint tapebreak rate of chill state phosphate-containing IF (interstitial free) steel

InactiveCN104096972AHigh strengthHigh hardnessFurnace typesIncreasing energy efficiencyPhosphateBase metal

The invention discloses a method for lowering the laser welding joint tapebreak rate of a chill state phosphate-containing IF (interstitial free) steel plate with the thickness of 0.8-1.8 mm. The method comprises the following steps of 1) laser welding: connecting the head and tail of the steel plate by laser welding, wherein the power of a laser welding apparatus for laser welding is 2000-5000 W, and the welding speed is 3-20 m / min; high frequency induction heating equipment is not arranged at a welding head of the laser welding apparatus; 2) thermal treatment after welding: a high frequency induction coil is arranged at an outlet of the laser welding apparatus, and the length of the high frequency induction coil is greater than a welding joint by 0-100 mm; after welding, performing thermal treatment on the welding joint and the scope of at least 100mm on each side of the length direction of the welding joint. According to the method, thermal treatment is performed after laser welding, the strength and hardness of the welding joint and base metal are reduced simultaneously, the decrease amplitude of the strength and hardness of the welding joint is greater that that of the base metal, the strength and hardness of the base metal at the welding joint area is lower than the welding joint, and thus the welding joint tapebreak rate is lowered greatly.

Owner:武汉钢铁有限公司

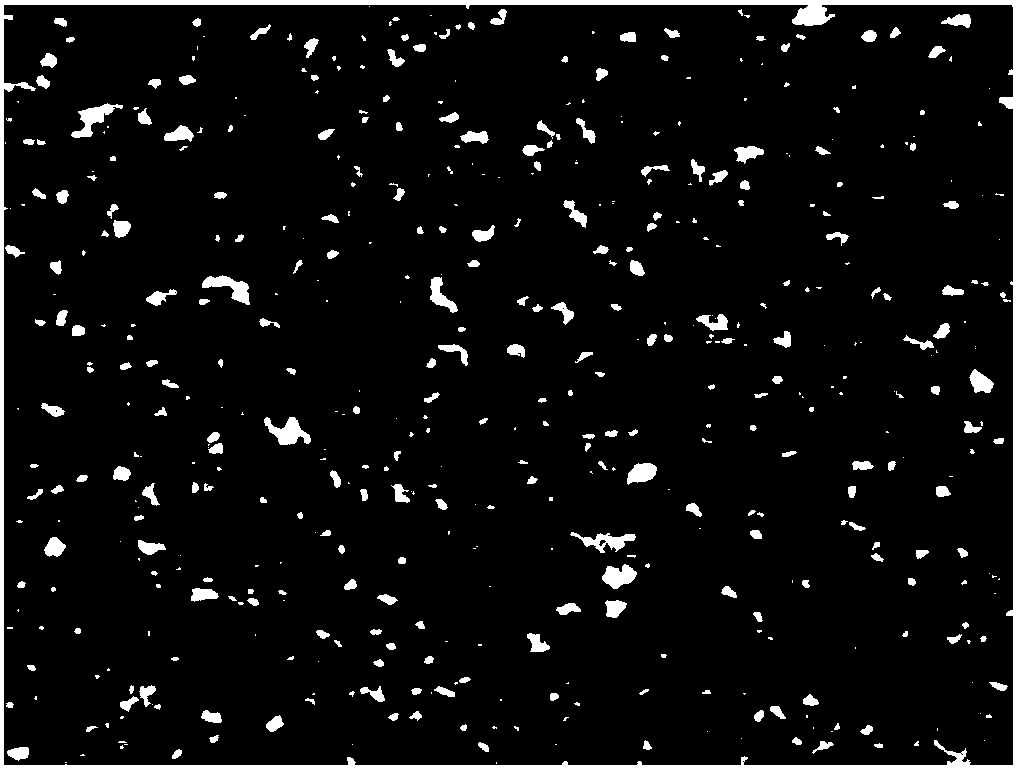

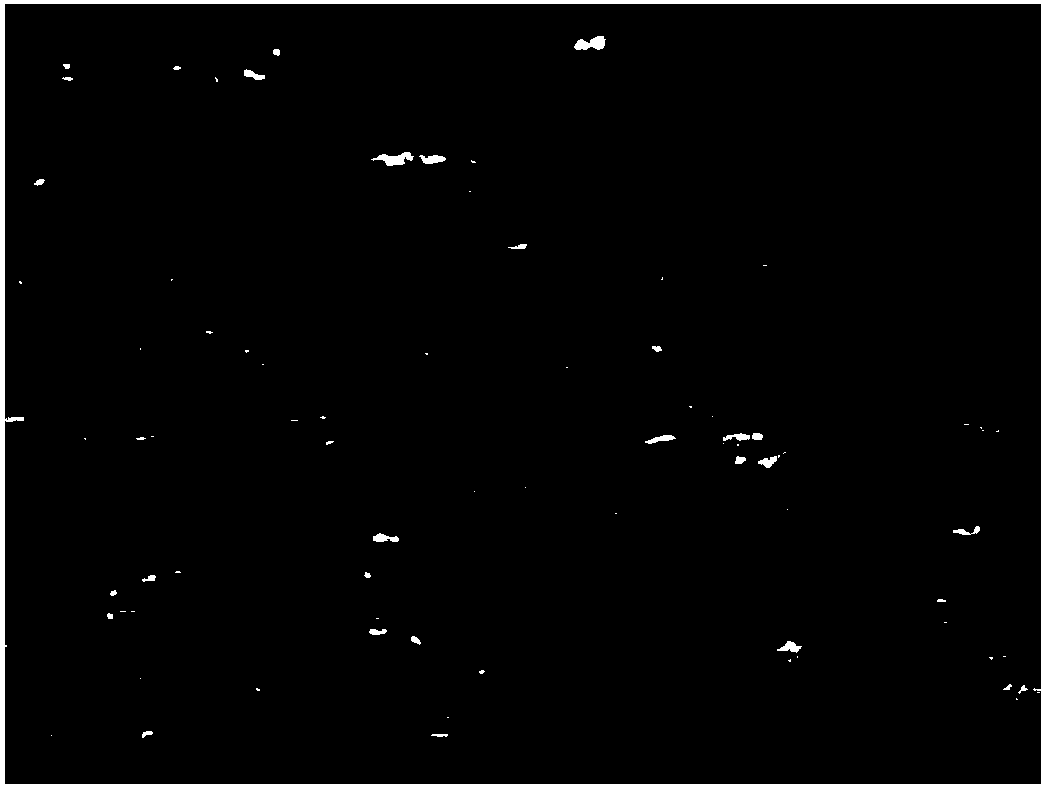

Foil blank for new energy battery and preparation method of foil blank

The invention provides a foil blank for a new energy battery and a preparation method of the foil blank. The foil blank comprises the following components, by mass, less than or equal to 0.1% of Si, 0.1-0.25% of Fe, 0.03-0.05% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.05% of Zn, less than or equal to 0.05% of Ti and the balance Al. The preparation method comprises the steps of (1) smelting, (2) turning down, (3) degassing, (4) deslagging, (5) cast rolling, (6) plate shape control and (7) quality inspection. According to the prepared foil blank for the new energy battery, the tensile strength is larger than or equal to 260 MPa, the ductility is larger than 3%, and the number of pinholes is smaller than or equal to 100 / m < 2 >; while the mechanical performance of the blank is guaranteed, the number of pinholes is small, the strip breakage rate is low, the machining performance is excellent, and the quality of a finished product can be remarkably improved; and compared with a traditional hot-rolled material, the production process is short, and the cost is low, so that resources and energy are saved, and the machining efficiency of products is improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

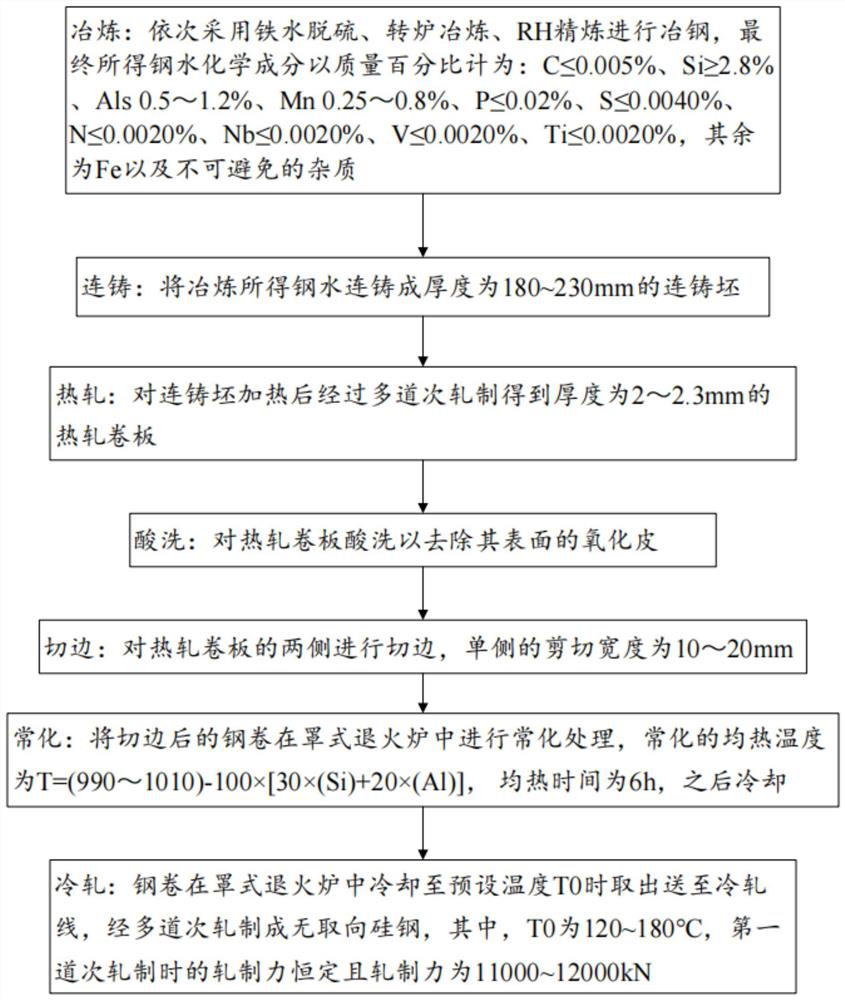

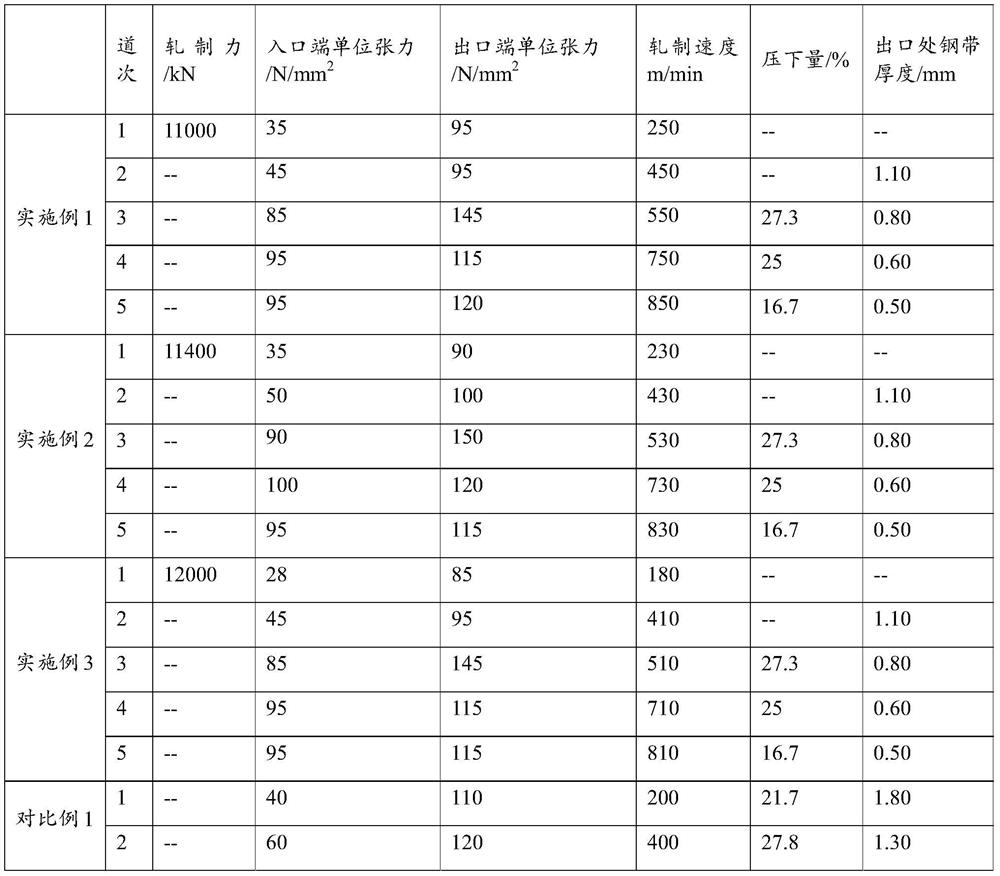

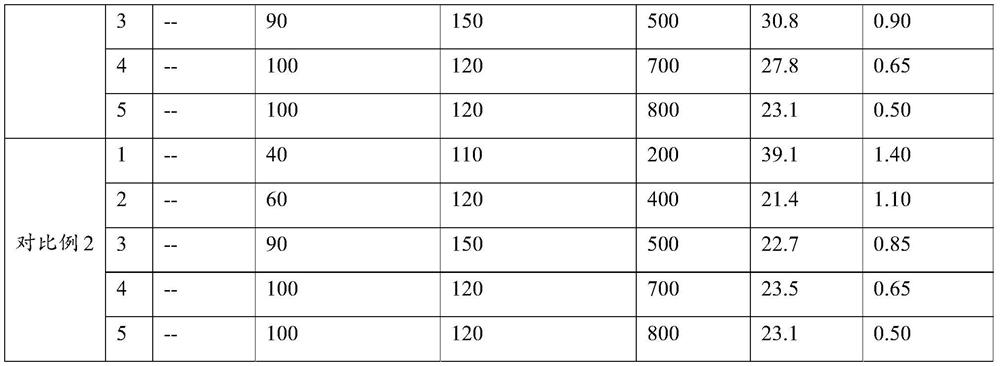

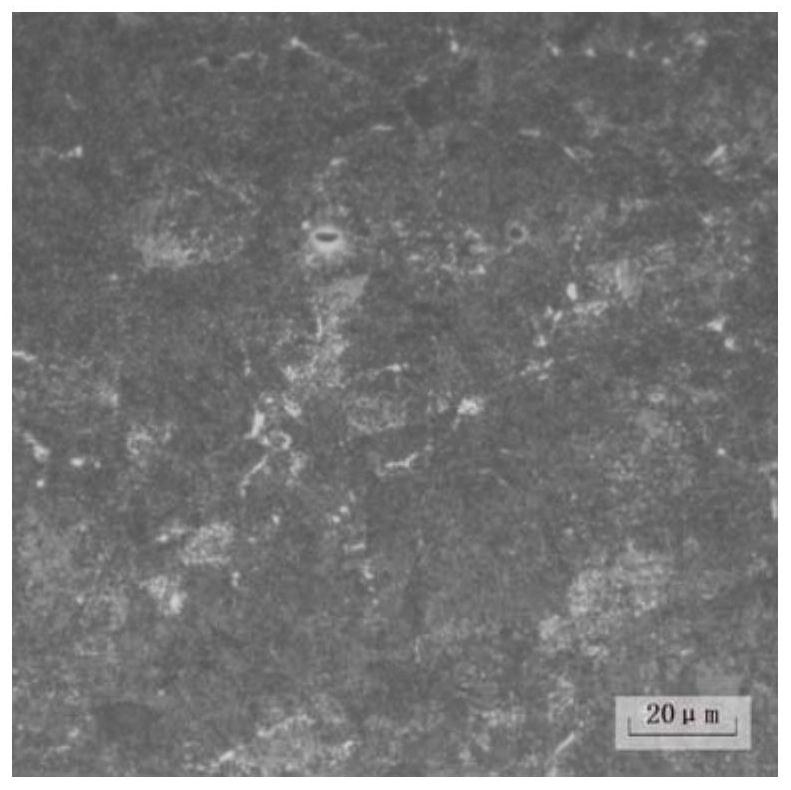

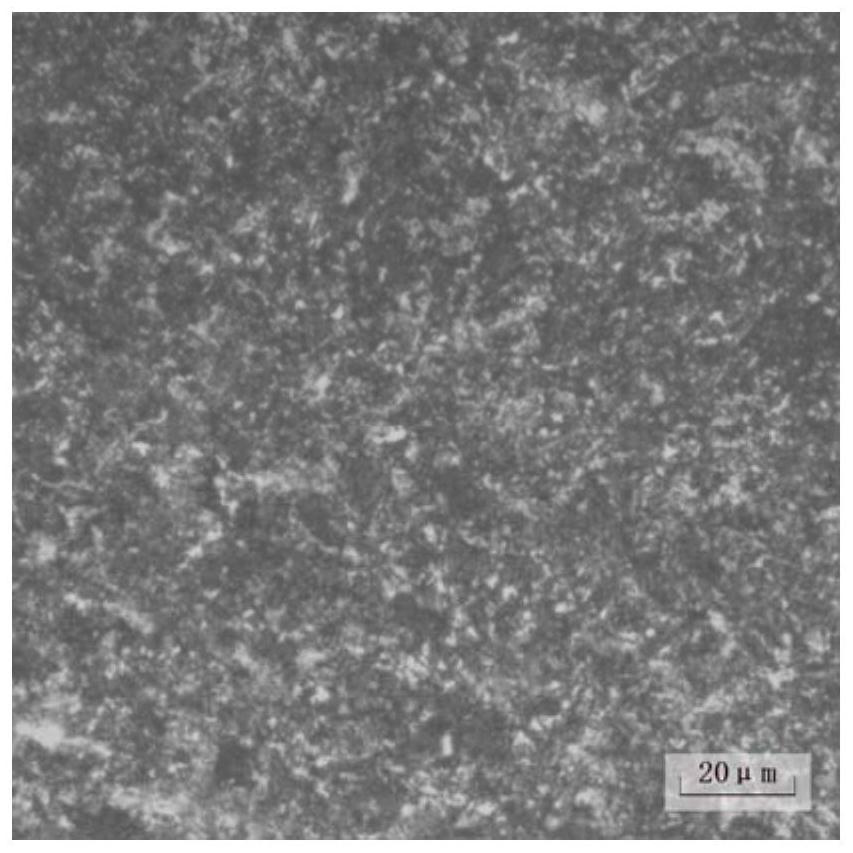

High-grade non-oriented silicon steel and production method thereof

ActiveCN114045434AReduce iron lossExcellent magnetic induction performanceFurnace typesHeat treatment furnacesMolten steelSilicon

The invention discloses high-grade non-oriented silicon steel and a production method thereof. The production method comprises the steps of smelting, continuous casting, hot rolling, acid pickling, trimming, normalizing and cold rolling. The molten steel finally obtained through smelting comprises the following chemical components in percentage by mass: less than or equal to 0.005% of C, more than or equal to 2.8% of Si, 0.5-1.2% of Als, 0.25-0.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.0040% of S, less than or equal to 0.0020% of N, less than or equal to 0.0020% of Nb, less than or equal to 0.0020% of V, less than or equal to 0.0020% of Ti and the balance of Fe and inevitable impurities. In the edge cutting procedure, the two sides of the hot-rolled coil plate are subjected to edge cutting, and the shearing width of the single side is 10-20 mm; normalizing is conducted in a cover type annealing furnace, the soaking temperature T is equal to (990-1010)-100 * [30 * (Si) + 20 * (Al)], the soaking time is 6 h, and then cooling is conducted; when the steel coil is cooled to a preset temperature T0 in the cover type annealing furnace, the steel coil is taken out and sent to a cold rolling line for cold rolling, the T0 is 120-180 DEG C, and the rolling force during first-pass rolling is constant and is 11000-12000 kN. According to the method, frequent strip breakage caused by high brittleness in the cold rolling process of the high-grade non-oriented silicon steel can be avoided.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

Welding wire for silicon steel laser filler wire welding, preparation method of welding wire, and welding method

ActiveCN108971797AImprove toughnessImprove impact toughnessWelding/cutting media/materialsSoldering mediaPorosityArc stability

The invention discloses welding wire for silicon steel laser filler wire welding, a preparation method of the welding wire, and a welding method. The welding wire comprises the following components of, by weight, 0.03-0.10% of C, less than 0.50% of Si, 1.50-2.50% of Mn, less than 0.015% of P, less than 0.010% of S, 0.05-0.15% of Ti, 0.005-0.015% of B, 1.0-3.0% of Ni, and the balance Fe. The welding wire for silicon steel laser filler wire welding has good electric arc stability and meanwhile has the excellent impact toughness, the impact toughness of weld metal at 0 DEG C is greater than 100 J, the weld metal toughness is good in matching, the weld metal has the outstanding characteristics of high intensity and high toughness and has the excellent anti-porosity property, weld joint is formed attractively, the connecting intensity is high, and the strip breaking rate of the silicon steel weld joint can be effectively decreased.

Owner:SHOUGANG CORPORATION

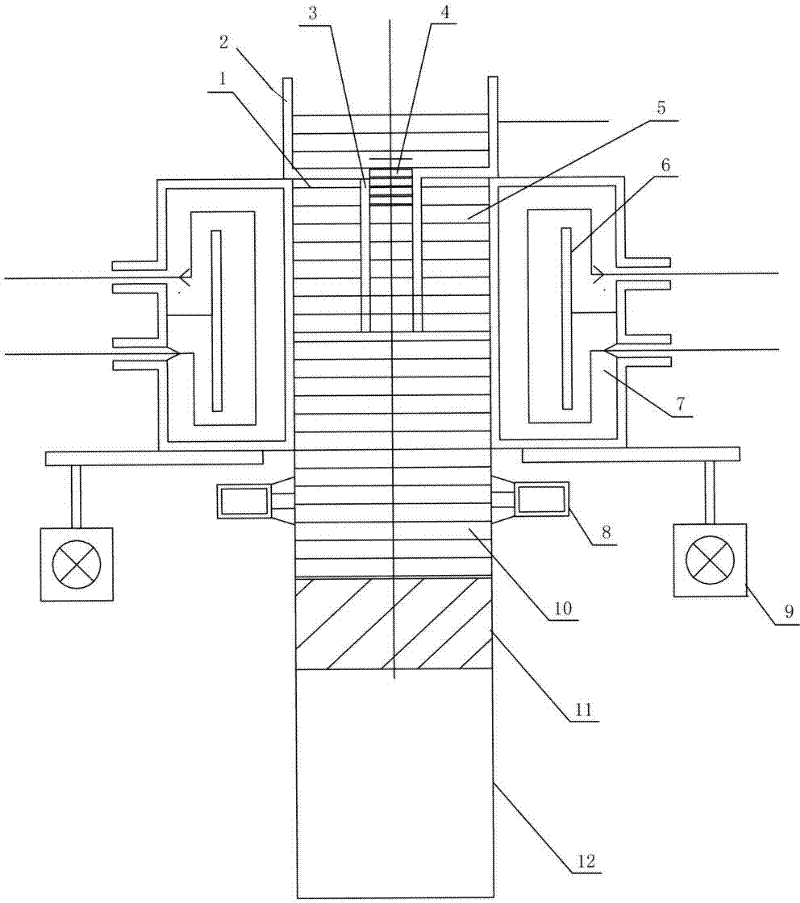

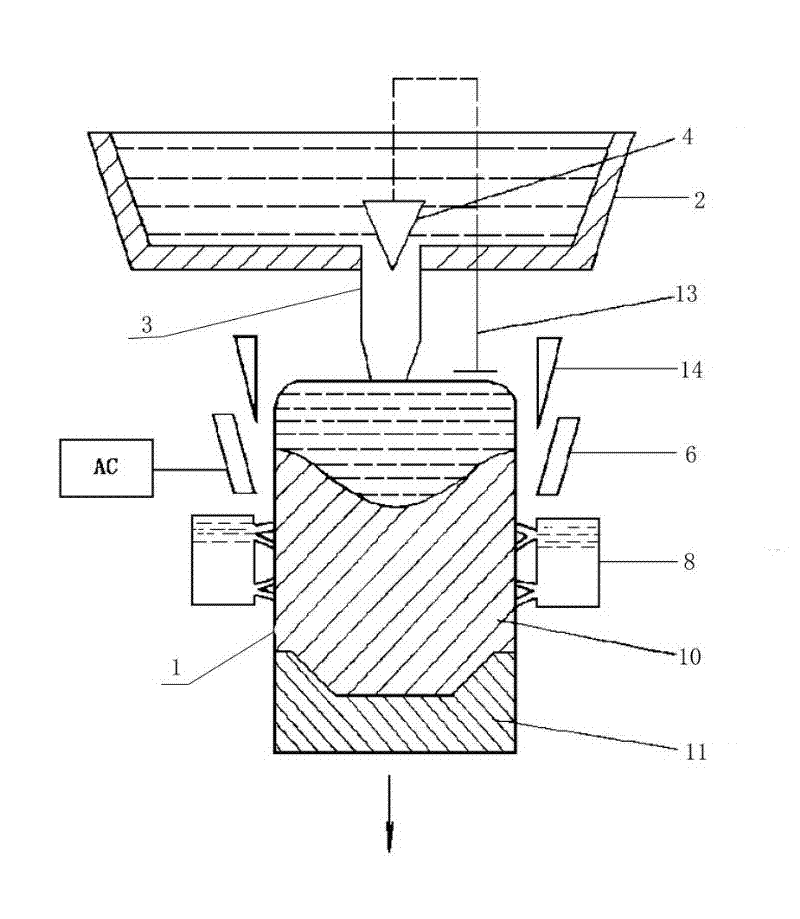

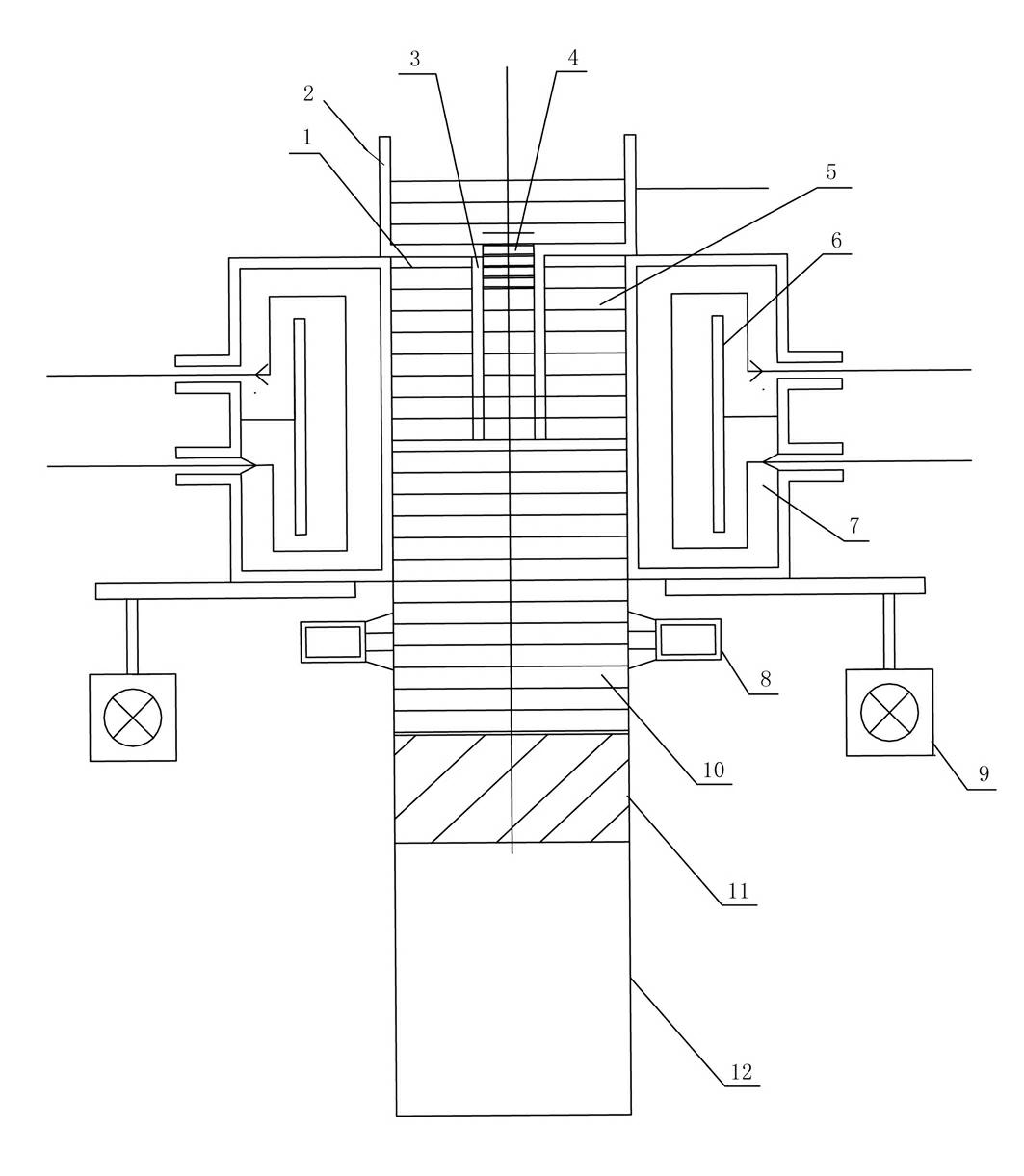

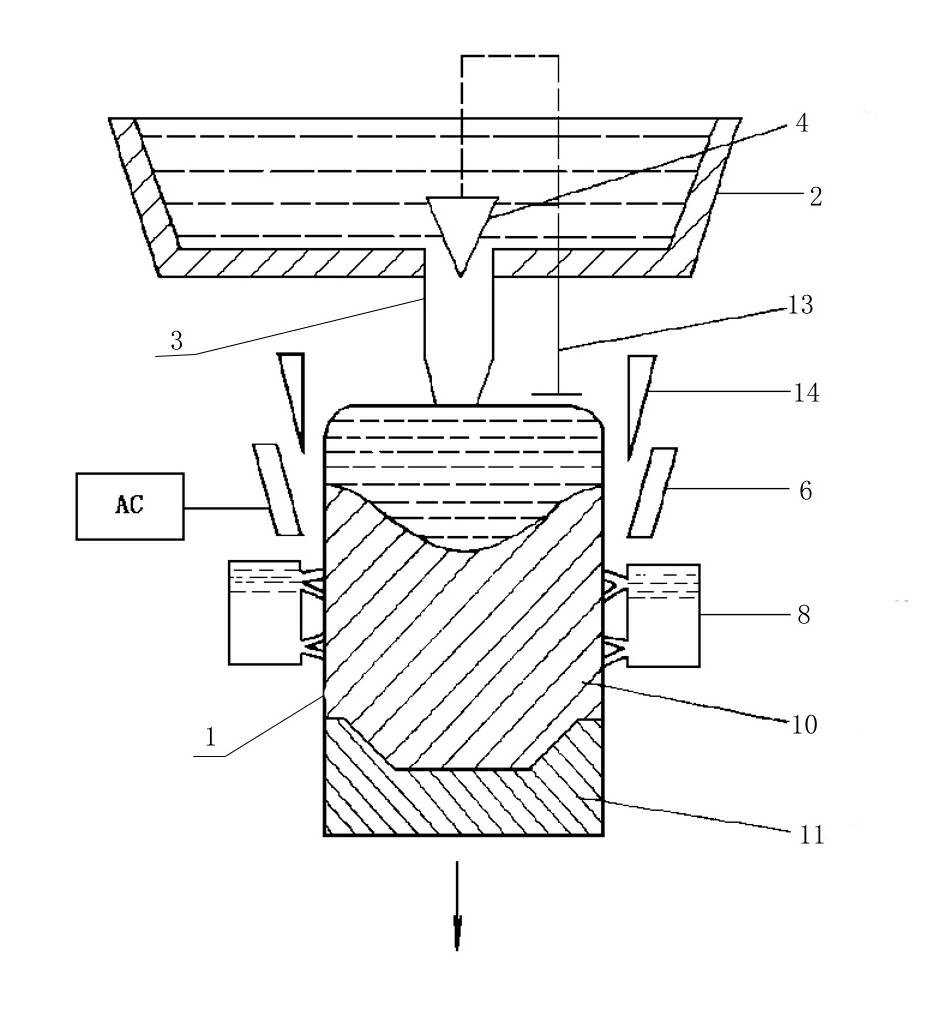

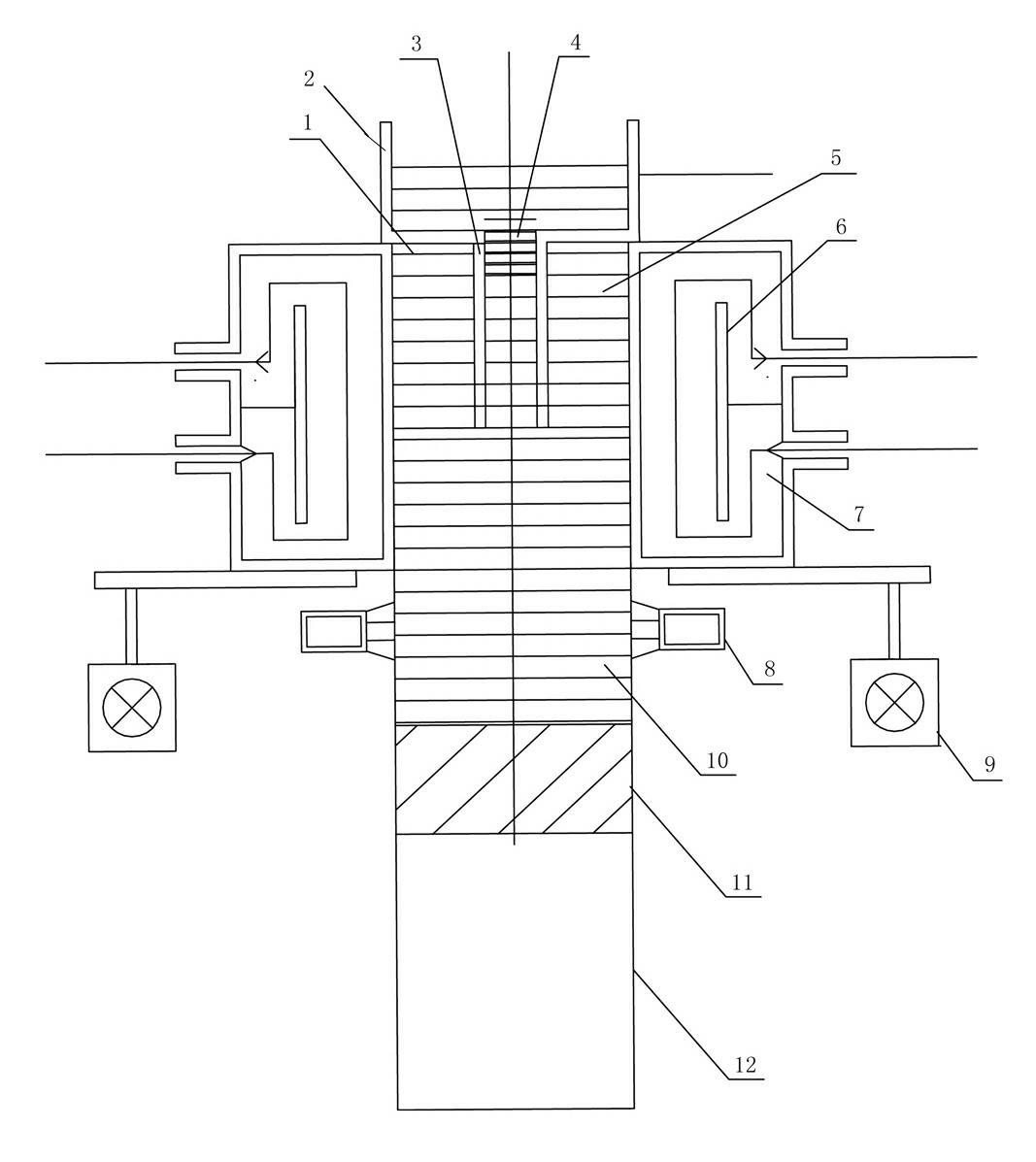

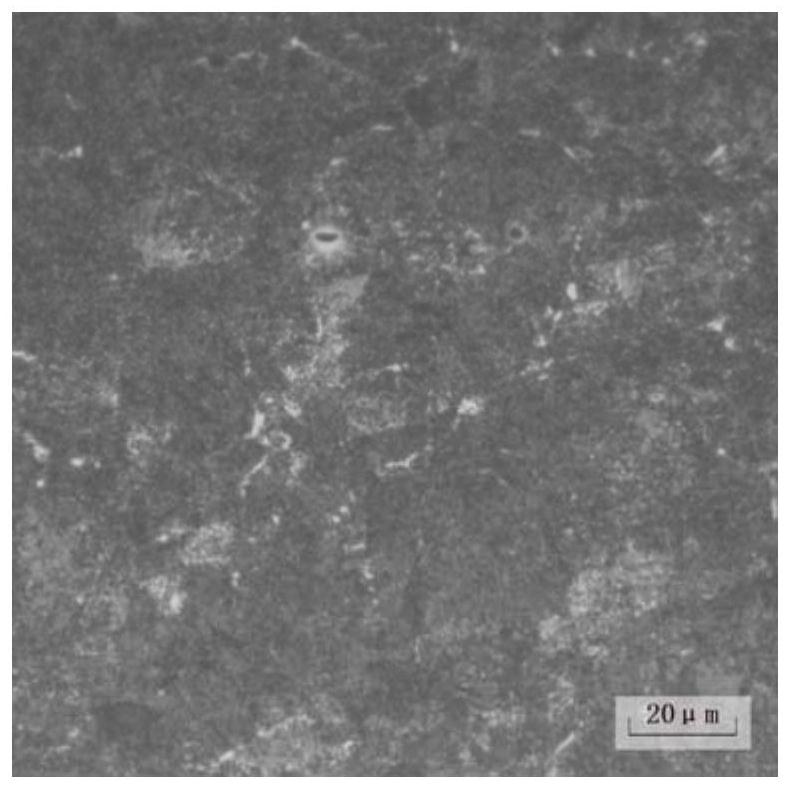

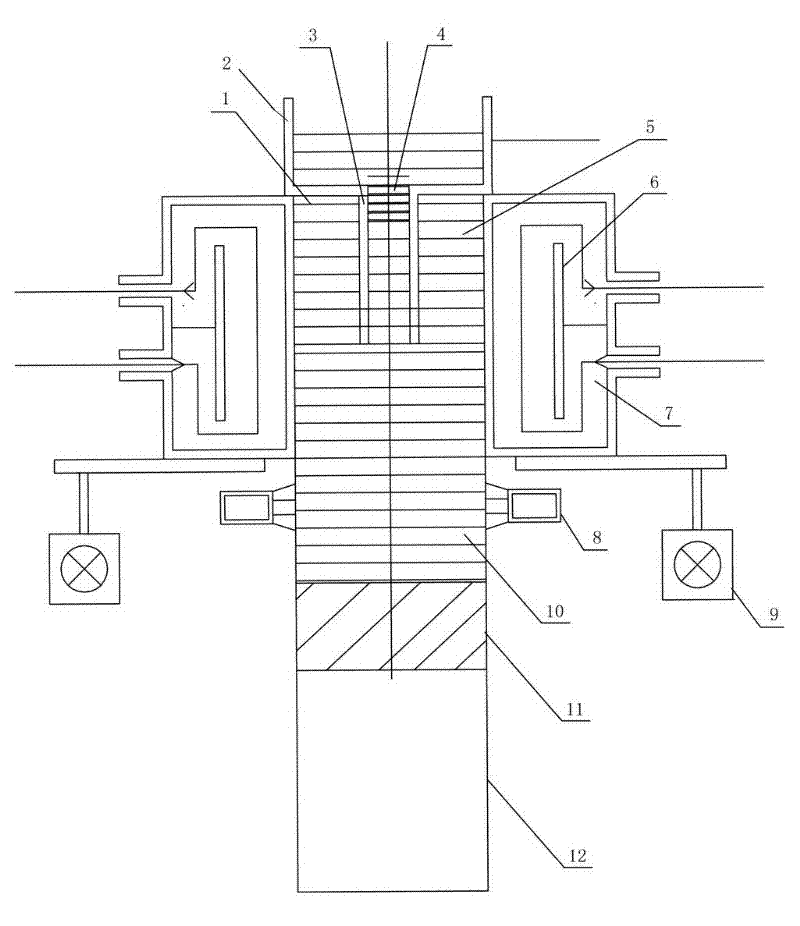

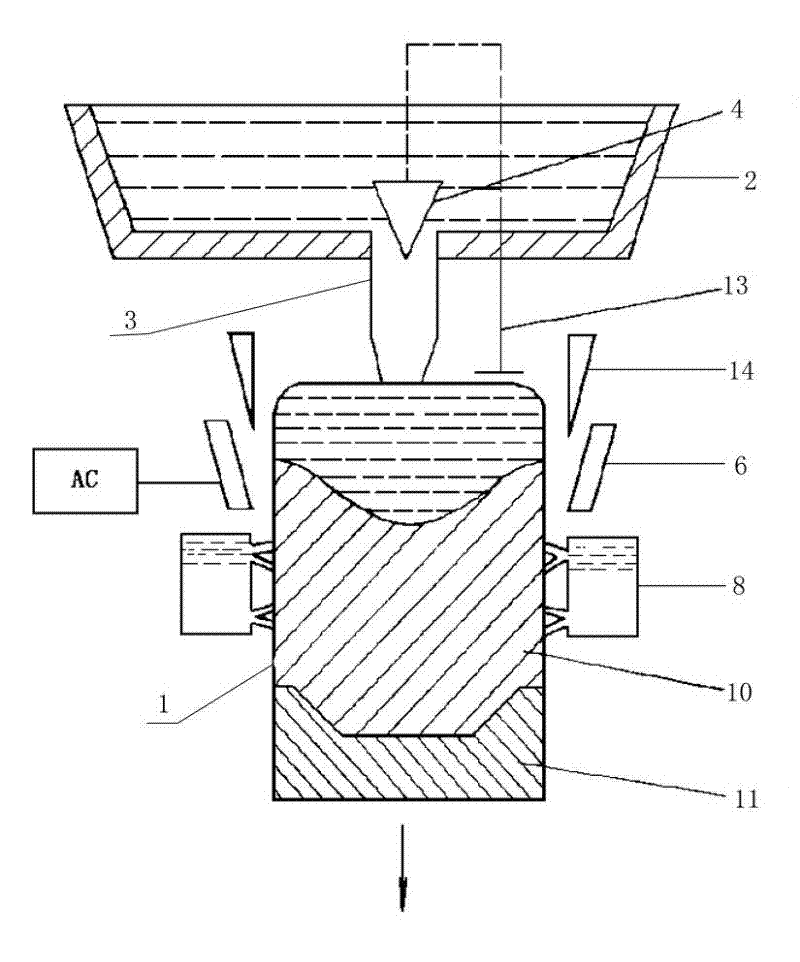

Oxygen-free copper strip horizontal electromagnetic casting device

InactiveCN102179490AImprove material performanceReduce broken belt rateElectromagnetic castingMedium frequency

The invention relates to an oxygen-free copper strip horizontal electromagnetic casting device and belongs to oxygen-free copper strip production and processing matched equipment. The oxygen-free copper strip horizontal electromagnetic casting device comprises a crystallizer shell, a medium-frequency power supply, an induction coil, an electromagnetic oscillator, a shielding cover, a cooling water tank, a bottom die and a pouring mechanism; the pouring mechanism consists of a tundish and a pouring gate plug; the tundish is arranged on the upper part of the crystallizer shell; the bottom of the crystallizer shell is provided with a pouring gate; the pouring gate plug is arranged in the pouring gate; the tundish is communicated with the upper part of the crystallizer shell through the pouring gate; the upper part of the crystallizer shell is provided with the induction coil; the electromagnetic oscillator is connected with the induction coil; the induction coil is connected with the medium-frequency power supply; the induction coil is formed by winding pure copper of which the section is rectangular; the circulating cooling water is filled in the hollow part of the induction coil for the primary cooling; a cooling water box and a shower pipe are arranged on the lower part of the crystallizer shell, and spray water to cool the crystallized stripped copper blank for the secondary cooling; and the bottom of the crystallizer shell is provided with the bottom die.

Owner:ZHONGTIAN ALLOY TECH

Special welding wire for martensitic stainless steel welding in continuous rolling unit

ActiveCN107127476AGuaranteed stabilityWell matched ingredientsWelding/cutting media/materialsSoldering mediaMartensitic stainless steelSS - Stainless steel

The invention discloses a special welding wire for martensitic stainless steel welding in a continuous rolling unit. The welding wire comprises the following components by weight percent: 60 wt.% to 90 wt.% of Ni, 8 wt.% to 30 wt.% of Cr, 1 wt.% to 5 wt.% of Mn, 0 wt.% to 5 wt.% of Fe, 0 wt.% to 0.5 wt.% of Si and 0 wt.% to 0.1 wt.% of C. According to the special welding wire, through reasonable design of the components of the welding wire, distribution of Ni, Cr and Mn elements in a welding molten pool is controlled, formation of austenite in a welding metal is promoted, growing of martensite is inhibited, martensite large-angle orientation difference ratio is increased, toughness of weld joints is finally improved, and the rolling requirement is met; and continuous rolling of martensitic stainless steel can be achieved, production cost of martensitic stainless steel is reduced, and the special welding wire has important meaning for development promotion of the continuous rolling industry of martensitic stainless steel.

Owner:HUAZHONG UNIV OF SCI & TECH

Welding-wire-free welding method for medium and high-grade non-oriented silicon steel

ActiveCN113182678AIncrease productivityGood compatibilityFurnace typesLaser beam welding apparatusTemperingContinuous rolling

The invention discloses a welding-wire-free welding method for medium and high-grade non-oriented silicon steel, and belongs to the technical field of laser welding for non-oriented silicon steel. The welding method comprises the following steps: 1) connecting the strip tail of low-grade non-oriented silicon steel with the strip head of the medium and high-grade non-oriented silicon steel in a centering contact manner; 2) carrying out preheating treatment on a weld joint between a leading strip and base metal before laser welding, then adopting a laser welding machine for welding, and after the welding is completed, carrying out high-temperature tempering treatment on the weld joint; and 3) after the welding is completed, alternately welding the medium and high-grade non-oriented silicon steel and the low-grade non-oriented silicon steel according to the steps. The welding method has the following beneficial effects: the rolling parameters of a continuous rolling unit are properly adjusted through the processes of reasonably selecting the leading strip, preheating before the welding and carrying out the tempering treatment after the welding, so that welding-wire-free welding for the medium and high-grade non-oriented silicon steel is realized, the quality of the weld joint is improved, the strip breakage rate is reduced, continuous rolling for the weld joint is guaranteed, and the rolling efficiency is increased.

Owner:新余钢铁股份有限公司

Method of reducing pickling continuous rolling strip breakage rate of chromium-containing high carbon steel

ActiveCN112251571AHigh tensile strengthHigh elongationFurnace typesTension/compression control deviceTemperingStrip steel

The invention discloses a method of reducing pickling continuous rolling strip breakage rate of chromium-containing high carbon steel. The method comprises the following steps of welding a strip tailof a previous coil of strip steel and a strip head of current strip steel together and achieving first time tempering during welding; and then carrying out second time tempering and third time tempering successively, and carrying out cold continuous rolling after tempering. By controlling process parameters of welding and carrying out tempering processes for three times after welding, the ductility of a weld joint is improved, so that the strip breakage rate of the chromium-containing high carbon steel rolled by a pickling continuous rolling unit is further reduced, and therefore, online highspeed batched production of the chromium-containing high carbon steel on the pickling continuous rolling unit is realized smoothly.

Owner:新余钢铁股份有限公司

Production method of high-precision ultralong oxygen-free copper strip

ActiveCN102199711BCompact structureGuaranteed oxygen contentRoll mill control devicesBell type furnacesElectrolysisIngot

The invention relates to a production method of a high-precision ultralong oxygen-free copper strip and belongs to the technical field of oxygen-free copper strip production, processing and manufacturing. The production method of the high-precision ultralong oxygen-free copper strip comprises: (1) selecting electrolytic copper as a raw material, adding the electrolytic copper into a melting furnace, smelting the melting furnace, allowing molten copper to flow into a crystallizer added with an electromagnetic oscillation coil, performing electromagnetic deoxidization of the molten copper and horizontally casting a blank by electromagnetic continuous casting in the electromagnetic continuous casting crystallizer added with the electromagnetic oscillation coil, cooling in the electromagneticcontinuous casting crystallizer, crystallizing to form strip copper blanks, and stretching by an ingot leading machine; (2) milling a strip blank by a double-sided miller; (3) performing reversible coarse medium rolling of the copper strip; (4) performing primary trimming by a thick strip longitudinal shearing machine; (5) annealing in a bell type bright annealing furnace; (6) cleaning surface ona thick strip degreasing cleaning line; (7) finely rolling in a four-roller reversible fine rolling machine; (8) annealing a finished product in the bell type bright annealing furnace; (9) cutting the finished product by a thin-strip longitudinal shearing machine; (10) packing in a packaging machine and performing physical and chemical examination; and (11) performing incoming inspection and storing.

Owner:ZHONGTIAN ALLOY TECH

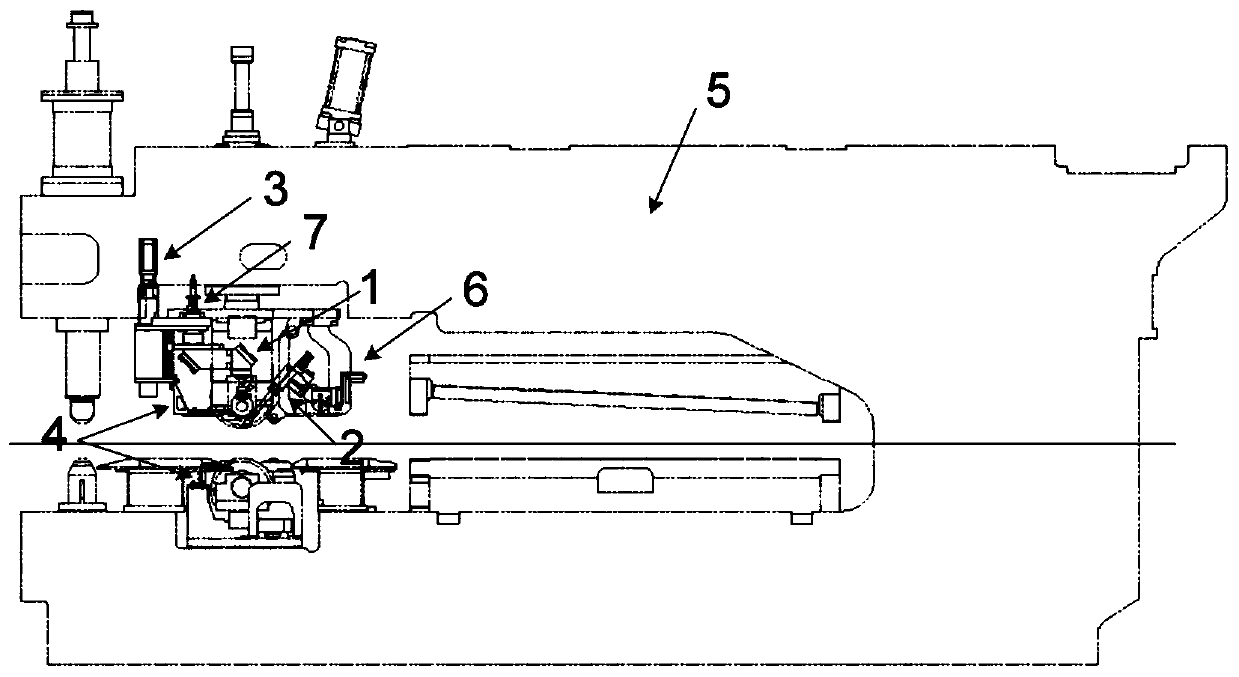

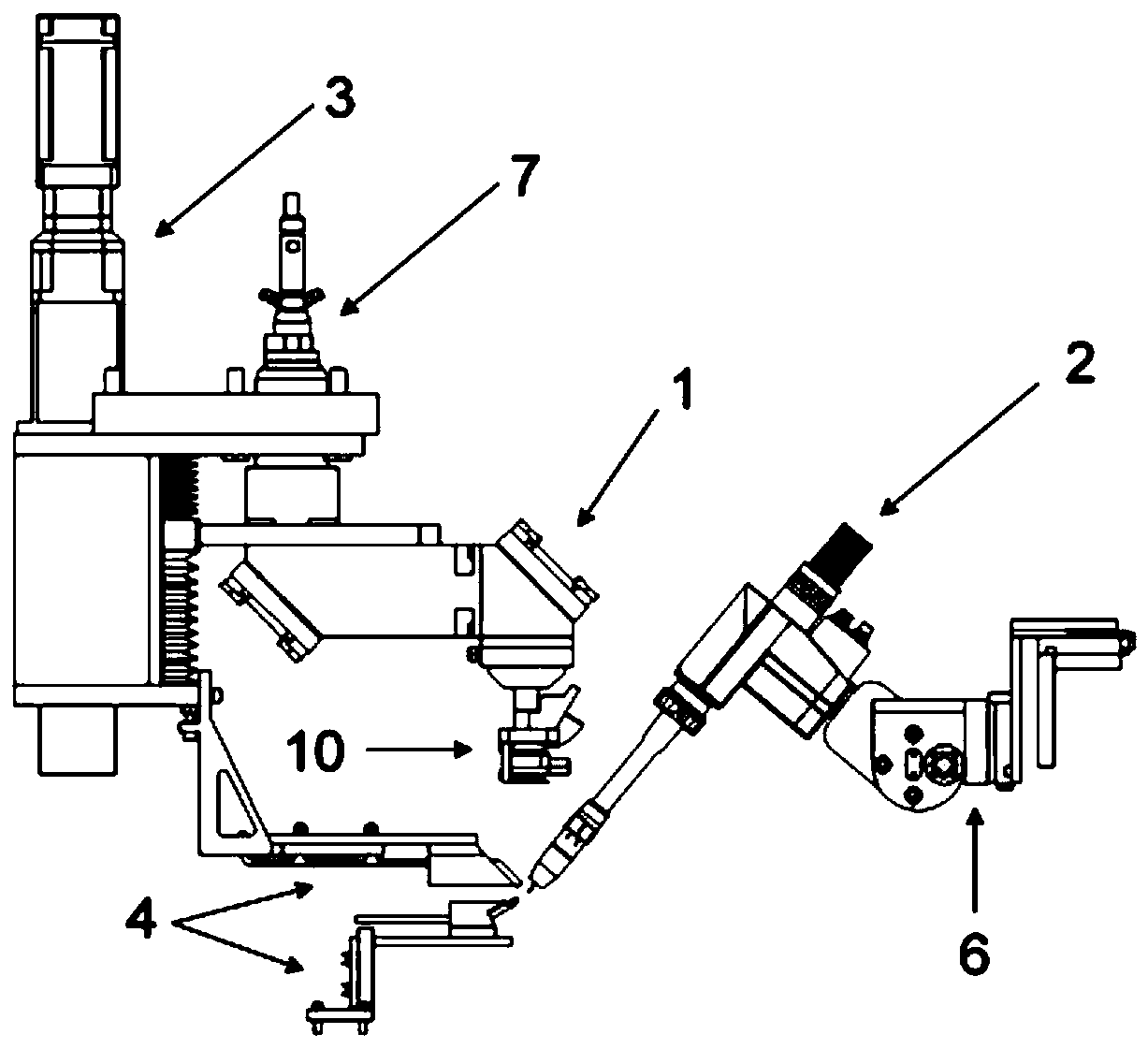

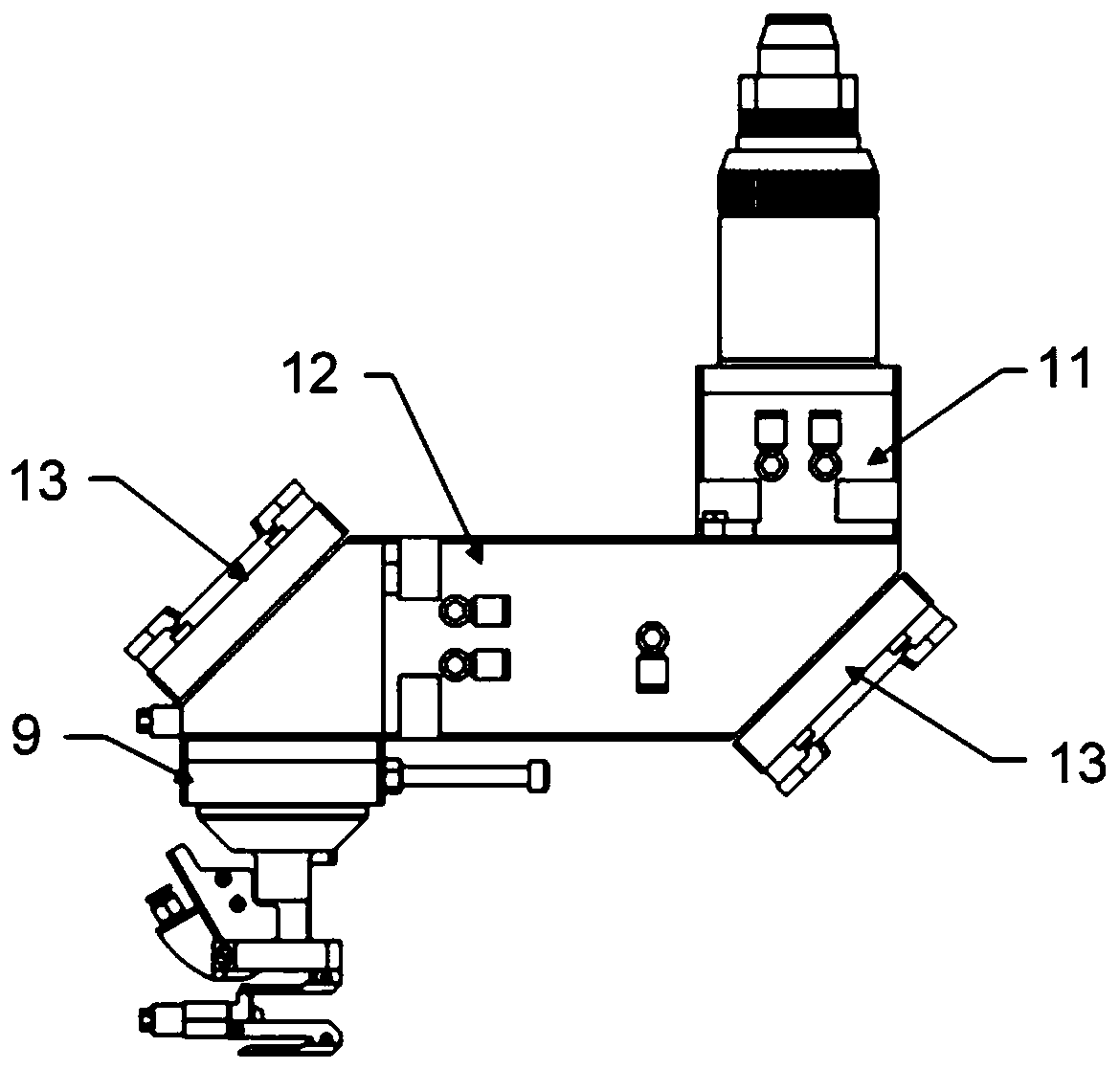

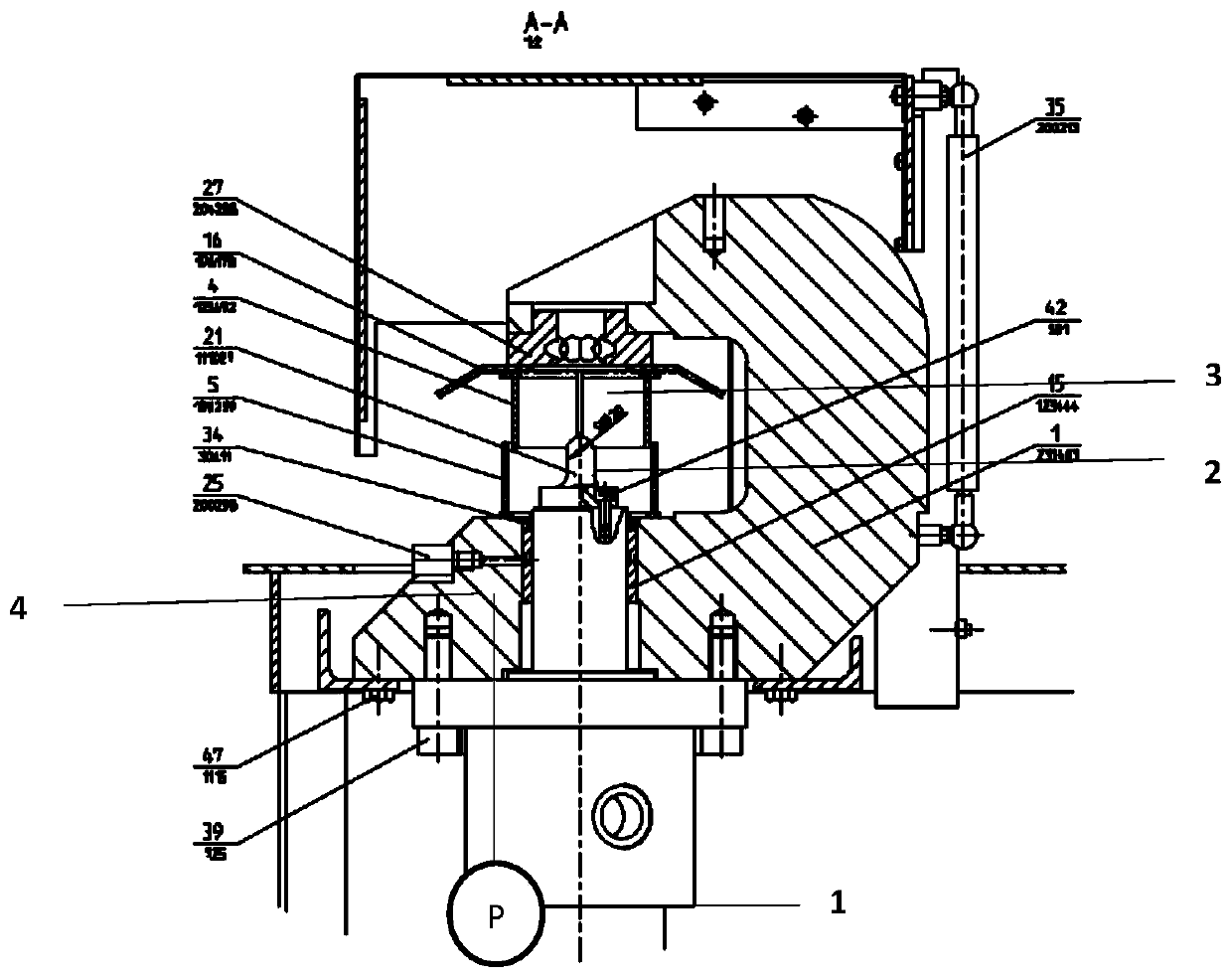

Multifunctional welding equipment and method for continuous rolling

InactiveCN109834389ASolve the narrow installation spaceHigh compactnessLaser beam welding apparatusElectric arcMultiple function

The invention belongs to the field of welding correlation technology, and discloses a multifunctional welding equipment and method for continuous rolling. The multifunctional welding equipment for continuous rolling comprises a vertical transmission mechanism, a laser welding connector, an electric arc welding gun, a connecting seat and a machine frame, the vertical transmission mechanism is arranged on the machine frame, and the laser welding connector is arranged on the vertical transmission mechanism; the connecting seat is arranged on the machine frame, and the electric arc welding gun isconnected to the connecting seat; and the laser welding connector comprises a second cavity body and two reflecting mirror modules, the second cavity body is connected with the vertical transmission mechanism, the two reflecting mirror modules are separately and detachably arranged on the second cavity body, the two reflecting mirror modules are used for changing the light path transmission direction of a laser beam entering the second cavity body, and the laser beam is reflected by the two reflecting mirror modules and incident perpendicularly on the surface of a piece to be welded. The multifunctional welding equipment for continuous rolling improves production rhythm, functions are complete, and the structure is compact.

Owner:HUAZHONG UNIV OF SCI & TECH

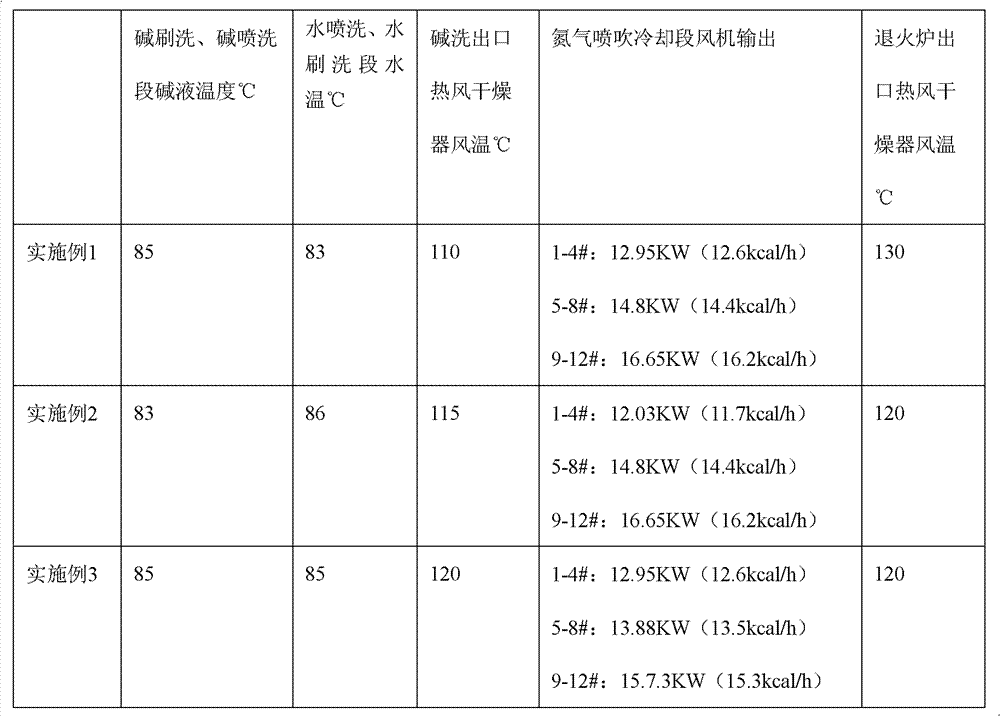

Method for reducing strip breakage of oriented silicon steel intermediate annealing

ActiveCN103361471AImprove work rateReduce broken belt rateFurnace typesHeat treatment furnacesShielding gasBreakage rate

The invention provides a method for reducing strip breakage of oriented silicon steel intermediate annealing. The method comprises the following steps of: in the intermediate annealing process of a continuous annealing furnace, ensuring the temperature of a steel plate to be 55-80 DEG C before furnace entrance by raising the alkali-washing-section cleaning and alkali-spray-washing-section alkali liquor temperature of the annealing furnace and air temperature of a hot-air dryer at the outlet of the alkali washing section; and ensuring the temperature of the steel plate after furnace discharge to be 85-100 DEG C by raising the air temperature of the hot-air dryer at the outlet of the annealing furnace and lowering the output power and cooling capacity of a fan at the protective gas cycle injection cooling section. During oriented silicon steel intermediate annealing according to the technical scheme, the strip breakage rate is greatly reduced, the time of causality is lowered, the unit operability is improved, and the consumption is lowered.

Owner:ANGANG STEEL CO LTD

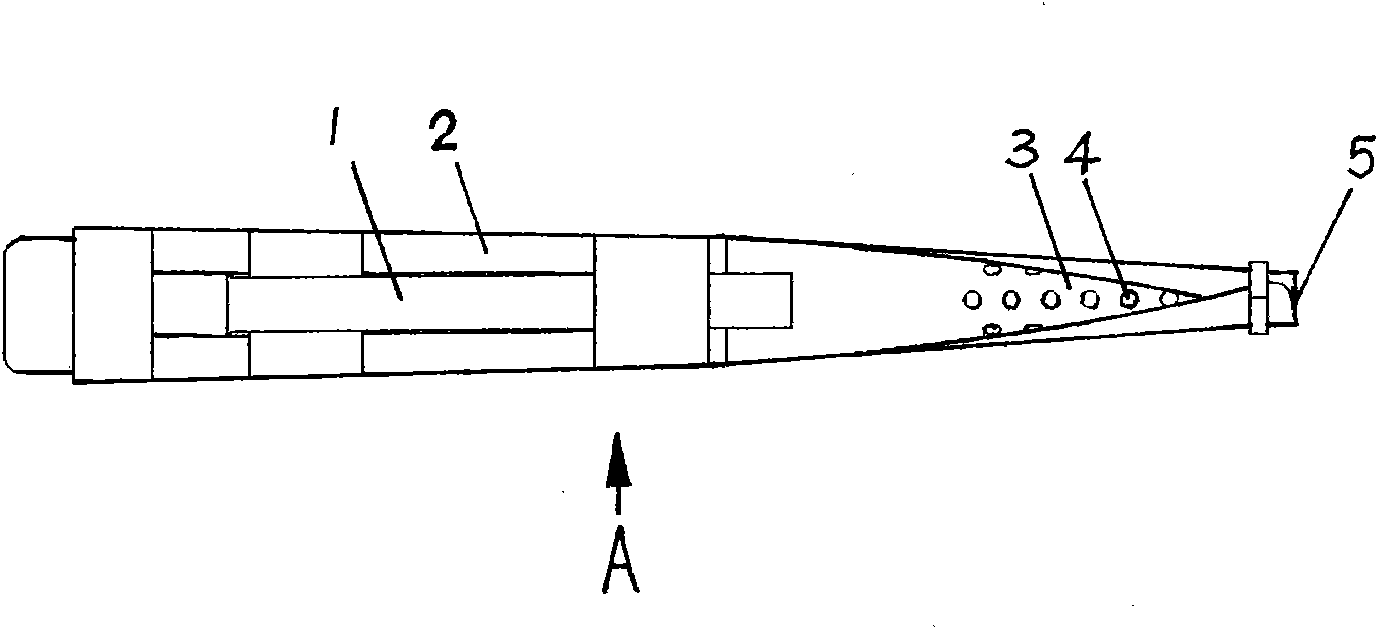

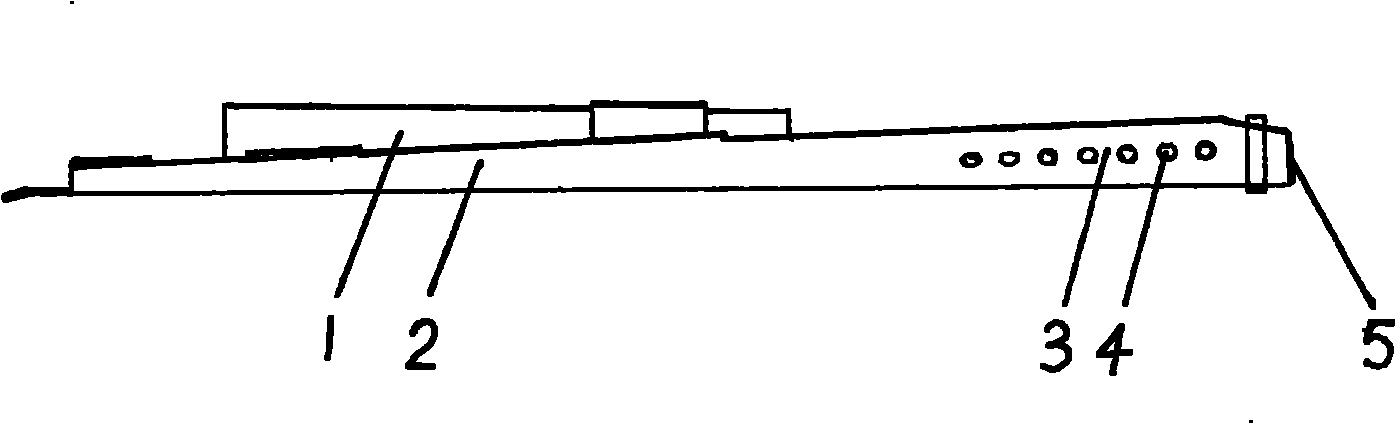

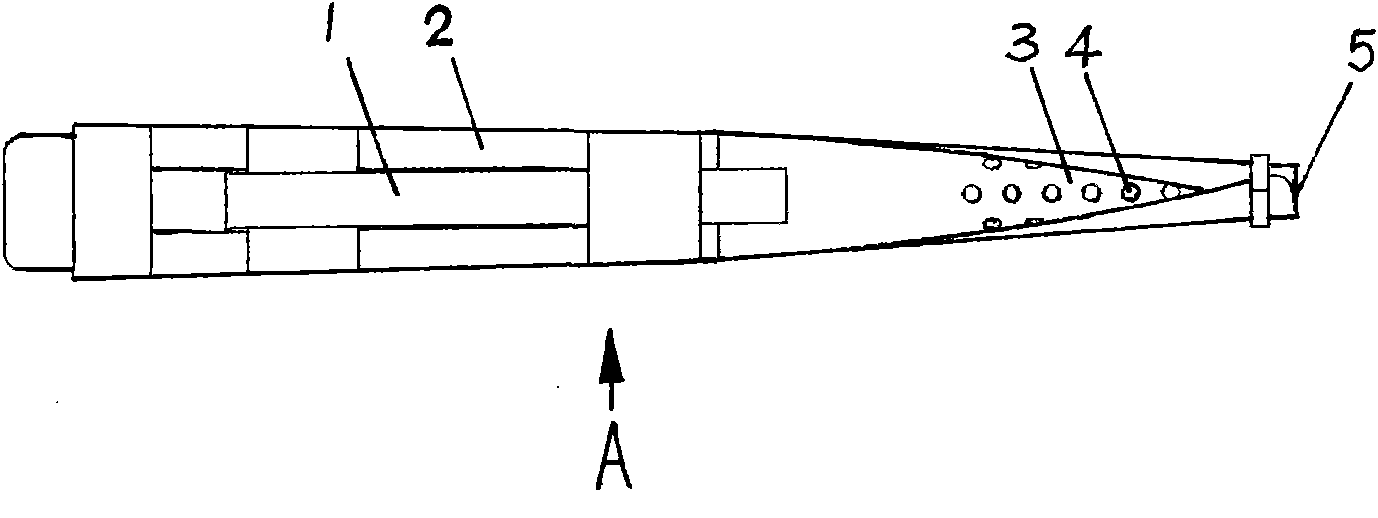

Longitudinal flat overlapping joint die of cable Al-plastic composite tape

InactiveCN101968560AReduce broken belt rateImprove longitudinal package qualityFibre mechanical structuresEngineeringBreakage rate

The invention relates to a longitudinal flat overlapping joint die of a cable Al-plastic composite tape, which is a closed die and provided with an Al-plastic composite tape guide groove and a coned overlapping cavity that are connected together, a cable core guide pipe is arranged in the Al-plastic composite tape guide groove, the coned overlapping cavity is provided with a circular outlet, and the wall of the coned overlapping cavity is provided with a plurality of holes. The invention has the advantages of less quantity of dies and simple structure, can reduce the die cost and the strip breakage rate of the Al-plastic composite tape because the Al-plastic composite tape is not embossed in advance when wrapping, improves the production speed and the longitudinal overlapping quality of the Al-plastic composite tape, and ensures that the cable has excellent waterproof and moisture-preventing properties.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Thin strip lap welding method of lap welding machine of cold rolling recoiling unit

ActiveCN105945579BInnovative weldabilityStable welding productionOther manufacturing equipments/toolsWelding apparatusMaterials scienceSteel plates

Owner:LIUZHOU IRON & STEEL

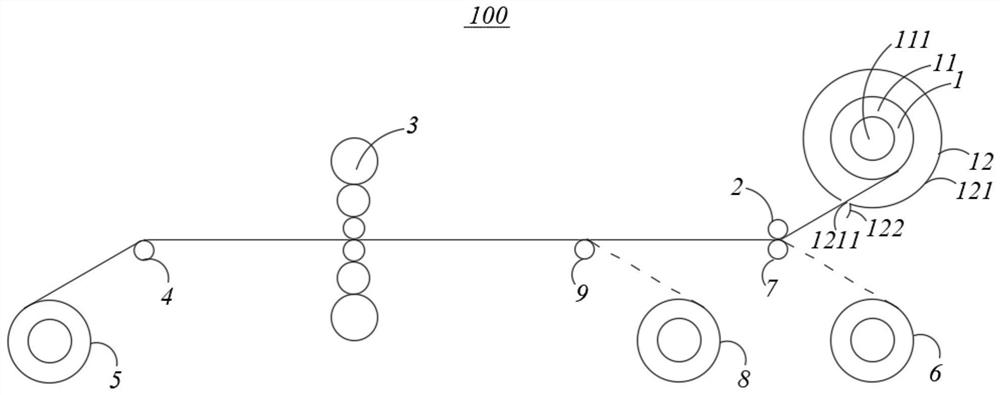

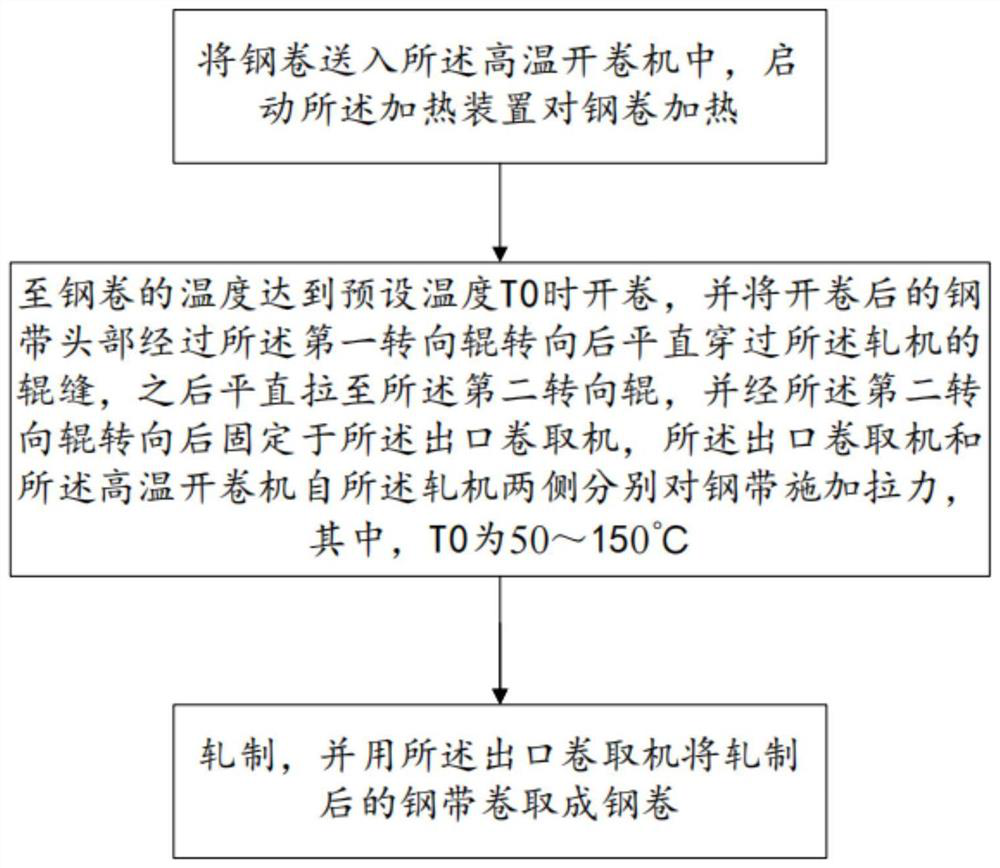

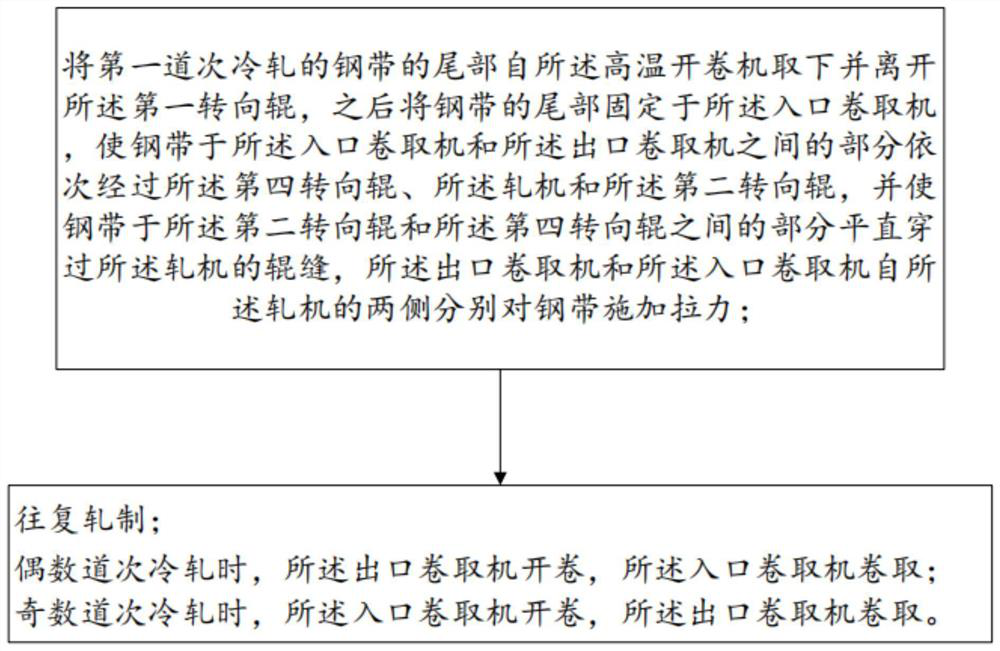

Strip breakage prevention cold rolling mill line and strip breakage prevention rolling method

PendingCN113941601AIncrease length spaceIncreased footprintWork heating devicesMetal rolling arrangementsEngineeringHeat conservation

The invention discloses a strip breakage prevention cold rolling mill line and a strip breakage prevention rolling method. The strip breakage prevention cold rolling mill line comprises a high-temperature uncoiler, a first turning roll, a rolling mill, a second turning roll and an outlet coiler which are arranged in sequence. The first turning roll and the second turning roll are configured in the mode that the part, between the first turning roll and the second turning roll, of a steel belt straightly penetrates through a roll gap of the rolling mill, and the high-temperature uncoiler comprises an uncoiler body, a heating device for heating the uncoiler body and a heat preservation cover arranged on the periphery of the uncoiler body. The high-temperature uncoiler is arranged on the cold rolling mill line, so that the hot rolled steel coil is preheated before cold rolling, the temperature of the steel coil before cold rolling is improved, the strip breakage rate during cold rolling is reduced, the length and occupied space of the cold rolling mill line are prevented from being increased, and the temperature drop of the outer layer of the steel coil when the steel coil is conveyed to the cold rolling mill line from preheating equipment is avoided; and the rolling of a previous steel coil and the preheating of the next steel coil can be achieved at the same time, and the rolling efficiency and the yield are greatly improved.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

A method for reducing strip breakage rate of chromium-containing high carbon steel in pickling and continuous rolling

ActiveCN112251571BHigh tensile strengthHigh elongationFurnace typesTension/compression control deviceTemperingBreakage rate

The invention discloses a method for reducing the strip breaking rate of chromium-containing high-carbon steel by pickling and continuous rolling. The first tempering, then the second tempering and the third tempering are performed in sequence, and the cold rolling is performed after the tempering is completed. Improve the elongation at the weld, thereby reducing the strip breakage rate of chromium-containing high carbon steel after being rolled by the pickling tandem mill, and successfully realize the online high-speed mass production of chromium-containing high carbon steel on the pickling tandem mill. .

Owner:新余钢铁股份有限公司

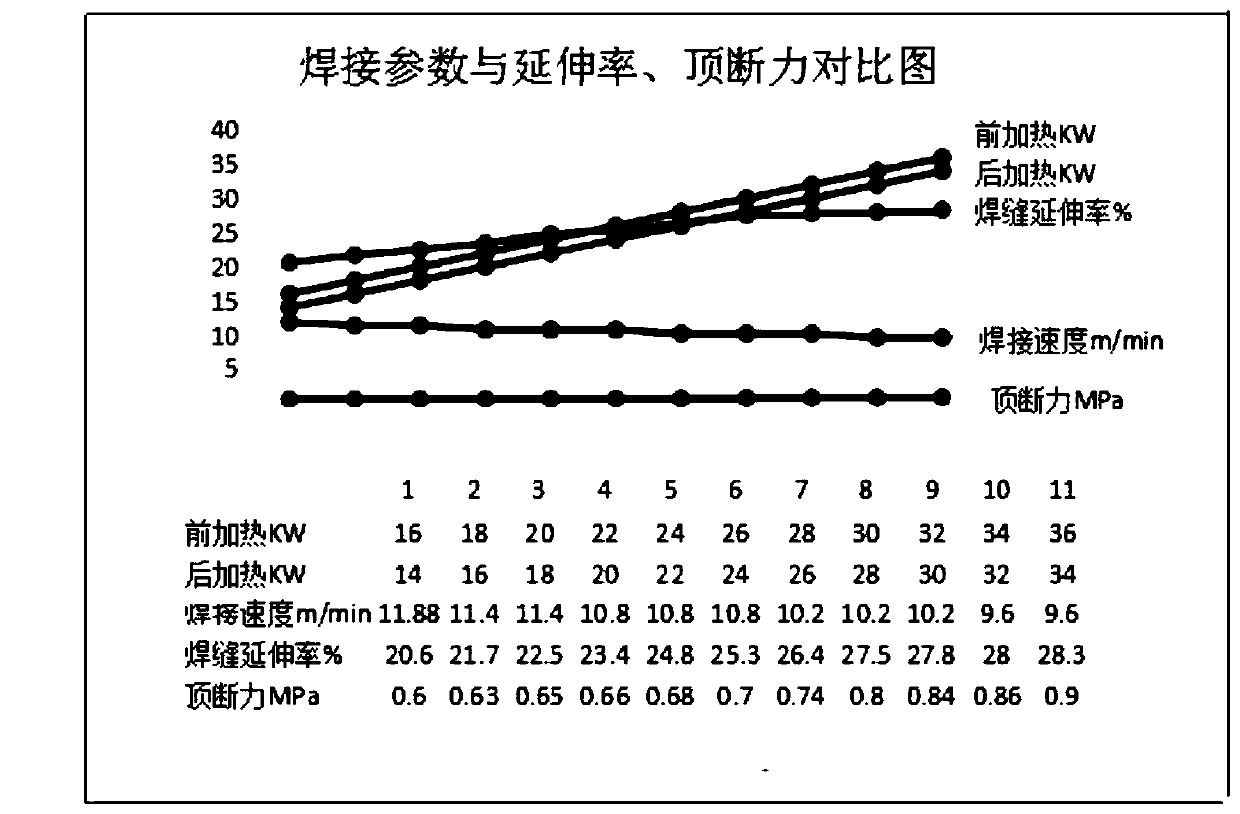

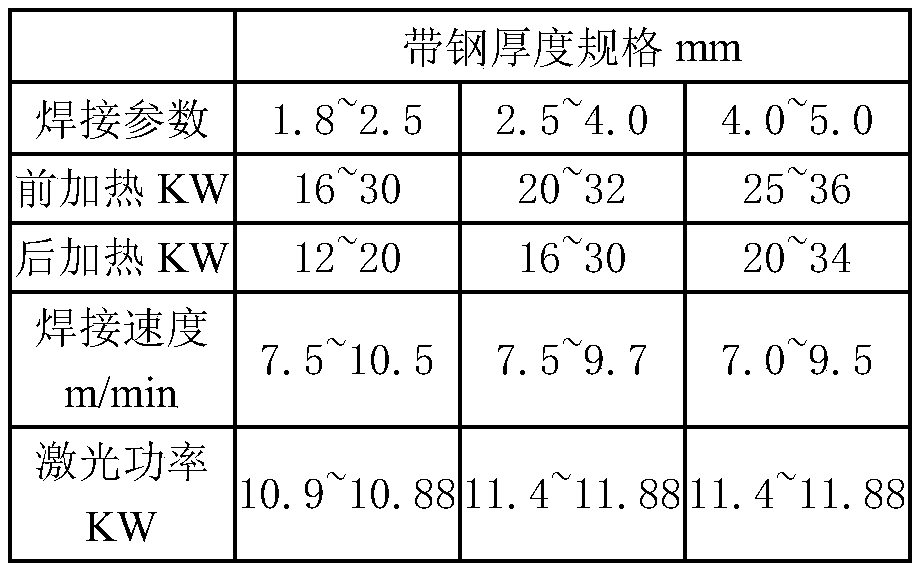

Method for avoiding belt breakage of cold-rolled hot forming steel welding line rolling mill

InactiveCN111331268AAccurate judgmentSimple and fast operationWelding apparatusTemperingBreakage rate

The invention discloses a method for avoiding belt breakage of a cold-rolled hot forming steel welding line rolling mill. The method specifically comprises the following procedures that firstly, to improve extensibility of a welding line, front and back heat parameters and welding speed of a laser welding machine are optimized; secondly, low-temperature tempering treatment is conducted on the welding line, and grains of a welding line heat-affected zone of the laser welding machine are refined; and thirdly, a pressure detection instrument is additionally arranged in a cup drawing test machinehydraulic jacking breakage system for detecting a welding line sample plate and is used for detecting the pressure during welding line jacking breakage, the welding line extension performance is judged according to the pressure during welding line jacking breakage, and the quality of the welding line is judged. By means of the method, the hot forming steel welding line ductility is improved by 10%, the rolling mill belt breakage rate of the cold-rolled hot forming steel welding line is reduced to 1.5% from 100%, and the cold-rolled hot forming steel ton-steel hourly output is increased.

Owner:BENGANG STEEL PLATES

Ways to prevent belt breakage

ActiveCN103785694BThe number of times to prevent the start of the car from breaking the beltReduce tensile stressRoll force/gap control deviceTension/compression control deviceEngineeringBending force

The invention discloses a method for preventing strip breakage on startup. The method includes, before strip winding, processing sheets with broken strips at first after stopping of a cold rolling mill due to strip breakage, compressing roll gaps of various frames and regulating the minimum rolling force of the roll gaps of the different frames after finishing the strip winding, generating exit tension of the different frames prior to regulating roll bending force of working rolls and intermediate rolls after finishing compressing of the roll gaps, and then, starting the cold rolling mill. The method for preventing strip breakage on startup includes control of the roll gaps of the cold rolling mill, selection of rolling force and tension and generation of tension, regulation of actual inclination and tension deviation of different frames, control of bending conditions of the working rolls and the intermediate rolls after startup, thereby effectively controlling times of startup strip breakage of sheets with the thickness lower than 0.6mm and improving production efficiency.

Owner:SHOUGANG CORPORATION

A method for welding low-grade non-oriented silicon steel with laser welding machine

ActiveCN107378239BReduce broken belt rateSmall sizeLaser beam welding apparatusHeat-affected zoneLower grade

The invention discloses a method for welding low-grade non-oriented silicon steel through a laser welding machine. The method sequentially comprises the following steps that a steel band is centered; shearing is conducted; a lapping table is centered; secondary shearing is conducted; preheating is conducted; weld joint pre-levelling is conducted; weld joint welding is conducted; postheating is conducted; and weld joints are cooled. In the weld joint welding process, the laser focal distance of the laser welding machine is set to be -3 mm, and the welding speed is lowered when silicon steel with the thickness being greater than 3 mm is welded. According to the method, the laser focal distance value is fixed, the range of a weld joint heat affected zone is adjusted through speed, and the weld joint band breakage rate is effectively lowered; and meanwhile, secondary shearing is additionally conducted before welding for improving the weld toe section size, and thus the welding quality is improved.

Owner:BAOTOU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com