Method for achieving stitch welding of thin strip by means of lap welder of cold rolling rewinding unit

A lap welding and unit technology, which is applied in the field of steel rolling production, can solve the problem that the heavy coil welding machine cannot effectively weld thin strips, and achieve the effect of reducing re-welding time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

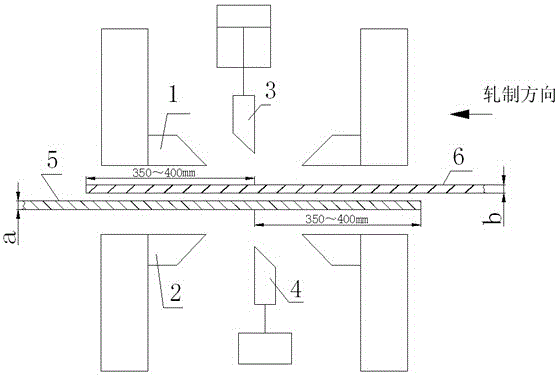

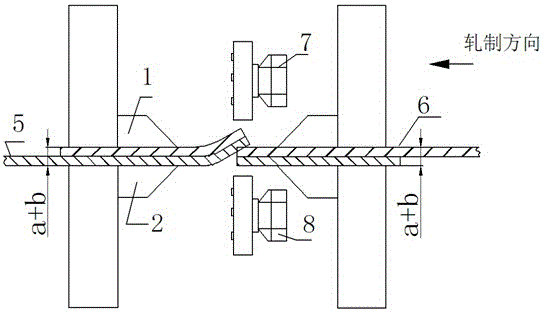

[0015] Attached below figure 1 , 2 The present invention is described in detail:

[0016] The specific operation steps are as follows:

[0017] 1. Use two rolls of strip steel at the front and back as superimposed raw materials: when the thickness a of the online steel coil is flicking, send the strip tail to a place about 350mm to 400mm from the edge of the lower clamp at the entrance of the welding machine, and do not enter the cutting edge; the next Coil thickness b When coiling up, the lead passes through the tail of the steel coil on the line, the lead passes through the lower shear blade of the welding machine, and enters the lower clamp of the welder exit with a length of about 350mm to 400mm (see figure 1 ).

[0018] 2. Use the built-in scissors of the welding machine to cut the head and tail: after the head and tail are aligned manually or automatically, the cutting operation is performed. At this time, there are two plates clamped in the welding machine’s output a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com