A method for reducing strip breakage rate of chromium-containing high carbon steel in pickling and continuous rolling

A high-carbon steel, continuous rolling technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of easily broken belts, poor thermal conductivity, and low internal stress elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

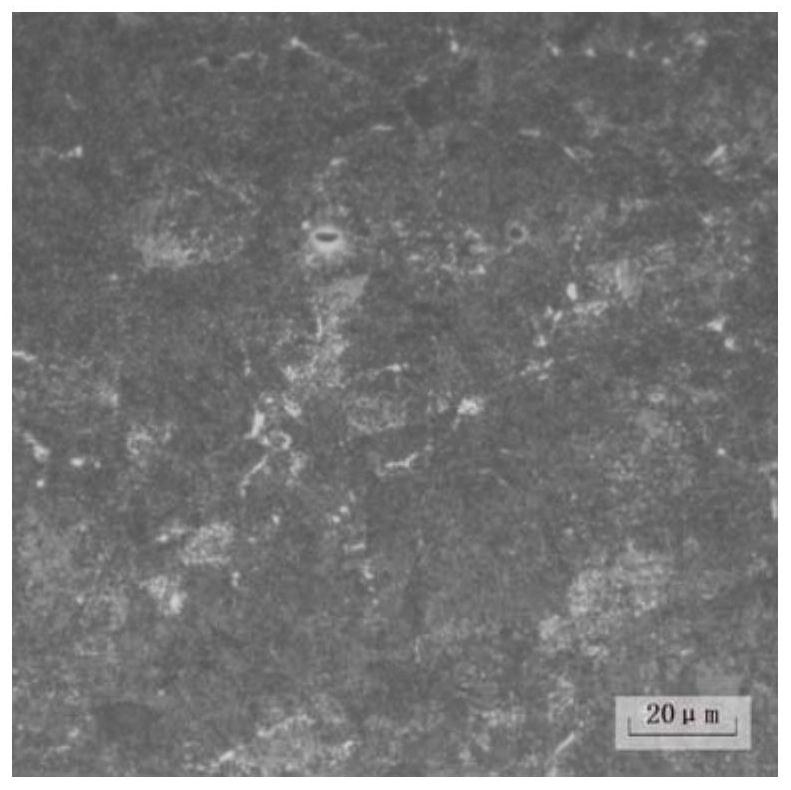

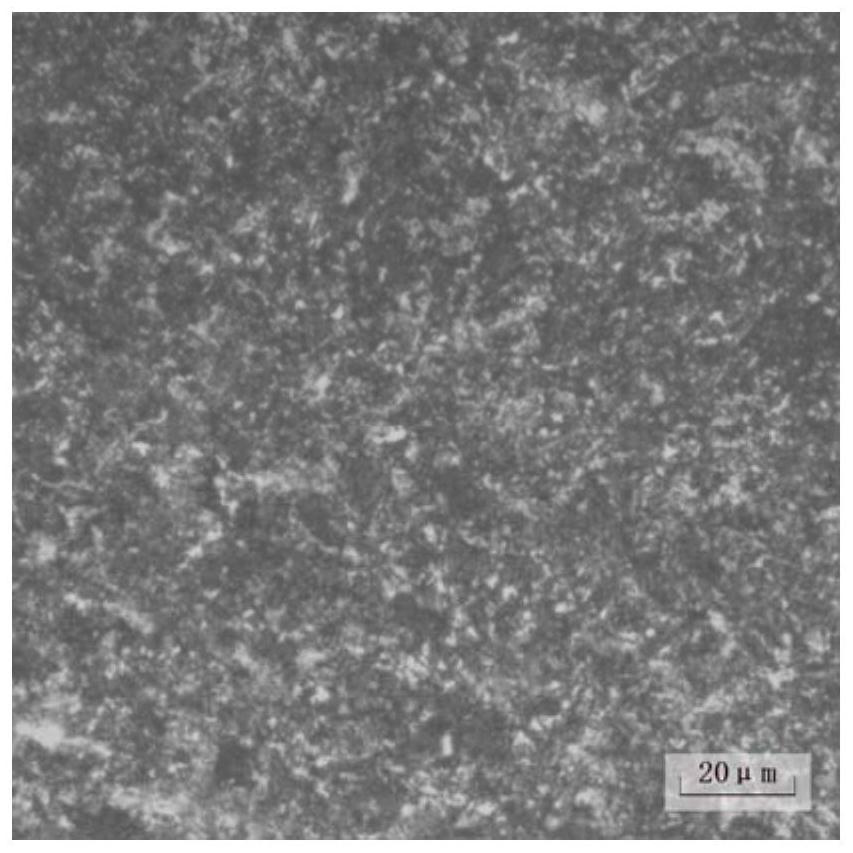

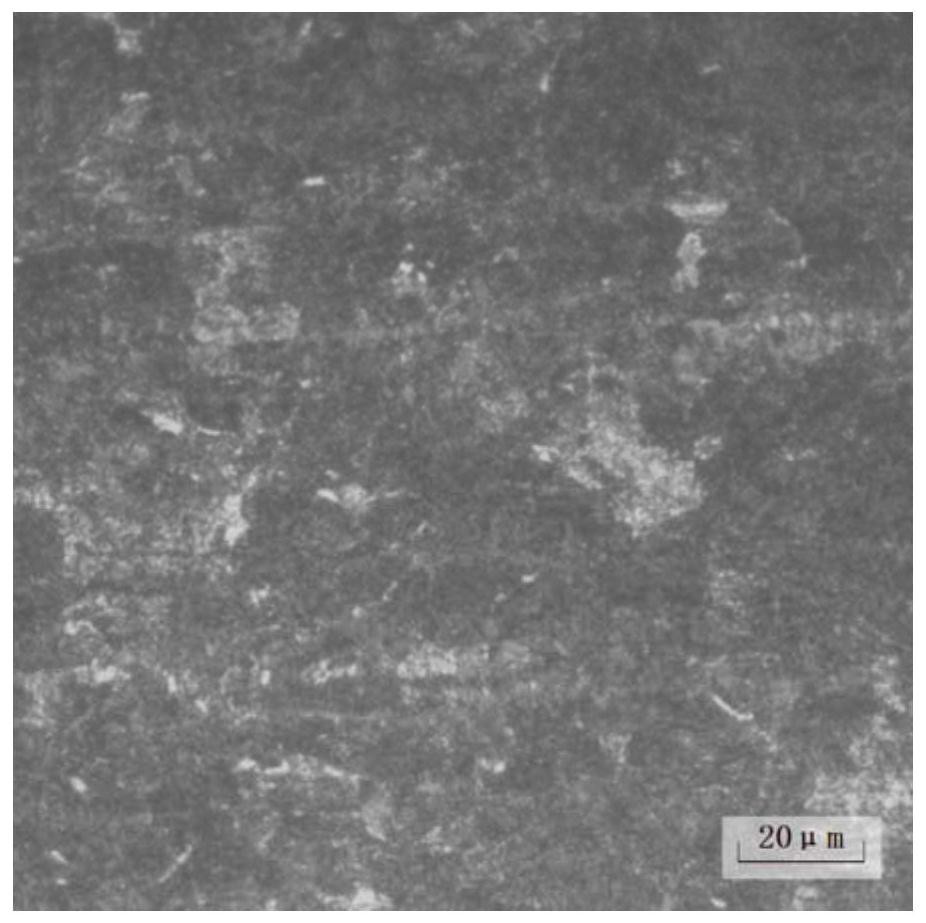

Image

Examples

Embodiment

[0022] A method for reducing the rate of strip breakage in pickling continuous rolling of chromium-containing high carbon steel, the method comprising the steps of: removing the strip tail of a previous hot-rolled strip with a thickness of 2.5 mm and a width of 1200 mm and the current strip The lead of the welding machine is welded by a laser welding machine, and the first tempering is realized by the post-heating of the laser welding machine at the same time of welding, and then the second tempering and the third tempering are performed sequentially within the welding seam and its left and right 10mm range. After the third tempering, air-cooled to below 200 ℃, and then entered the pickling tandem rolling unit for cold tandem rolling.

[0023] The steel grades and welding process parameters of each embodiment and comparative example are shown in Table 1 and Table 2, and the process parameters of cold tandem rolling are shown in Table 3:

[0024] Table 1

[0025] C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com