Method of reducing pickling continuous rolling strip breakage rate of chromium-containing high carbon steel

A high-carbon steel, pickling technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of reduced weld strength, easy-to-break strips, and low weld elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

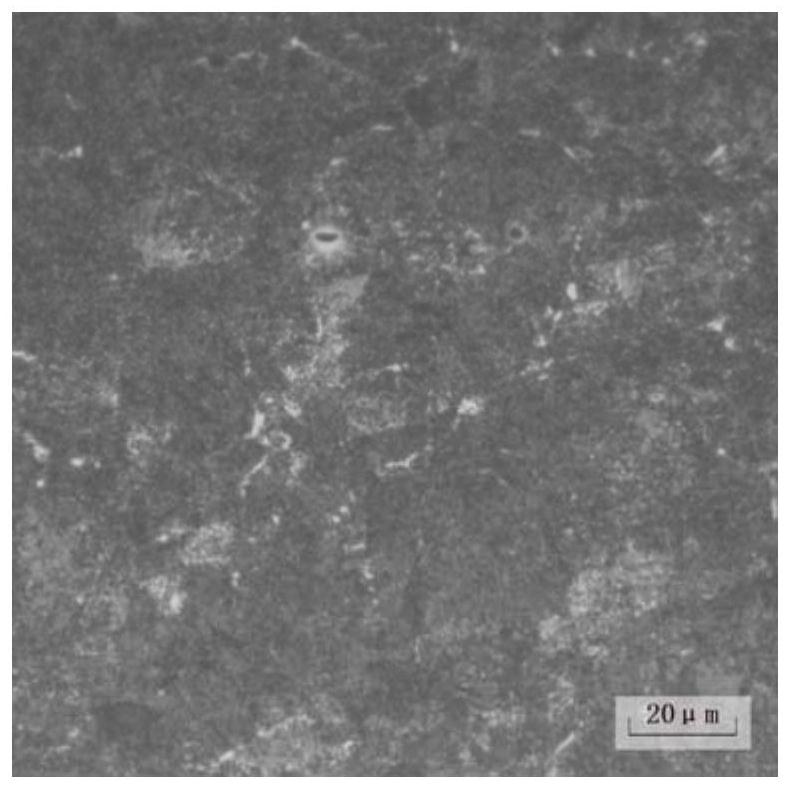

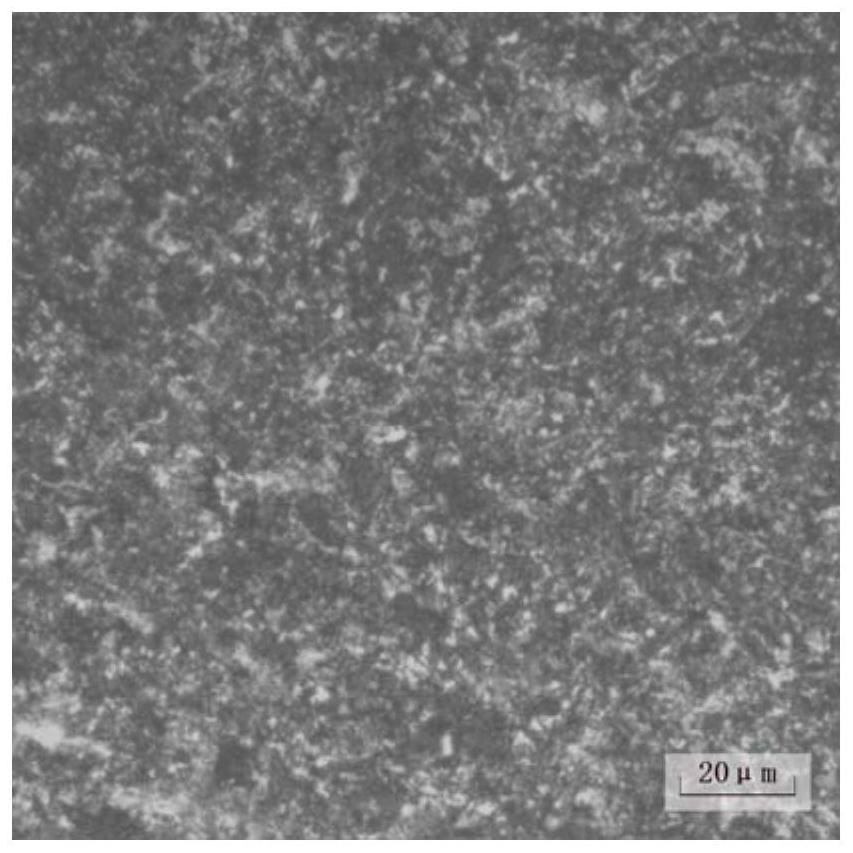

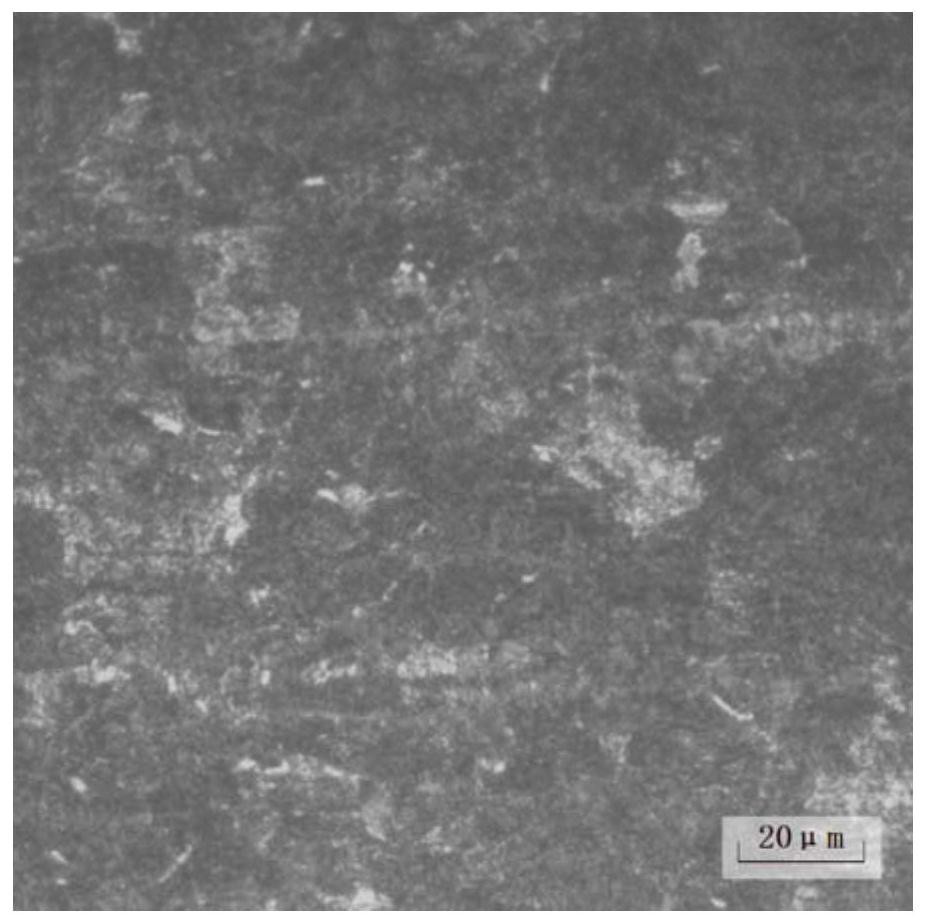

Image

Examples

Embodiment

[0022] A method for reducing the strip breakage rate of chromium-containing high-carbon steel pickling continuous rolling, the method includes the following steps: the strip tail of the previous hot-rolled strip with a thickness of 2.5mm and a width of 1200mm and the current strip The lead is welded by a laser welding machine, and the first tempering is achieved by the post-heating of the laser welding machine while welding, and then the second tempering and the third tempering are sequentially carried out within the weld seam and its left and right 10mm range, After tempering for the third time, it is air-cooled to below 200°C, and then enters the pickling and continuous rolling unit for cold continuous rolling.

[0023] The steel types and welding process parameters of each embodiment and comparative examples are as shown in Table 1 and Table 2, and the process parameters of continuous cold rolling are as shown in Table 3:

[0024] Table 1

[0025] C mn S P ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com