Strip breakage prevention cold rolling mill line and strip breakage prevention rolling method

A rolling mill and anti-broken technology, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of easy strip breakage, affecting cold rolling efficiency and yield, etc., so as to reduce the strip breakage rate and improve Rolling efficiency, yield, and effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

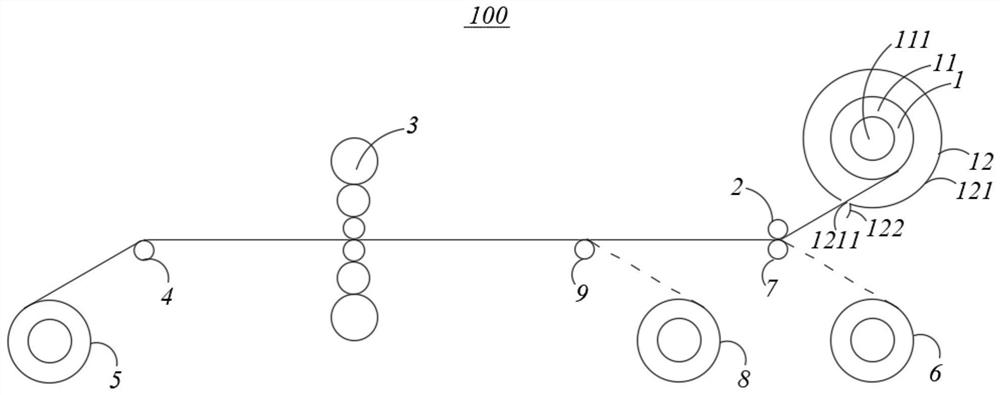

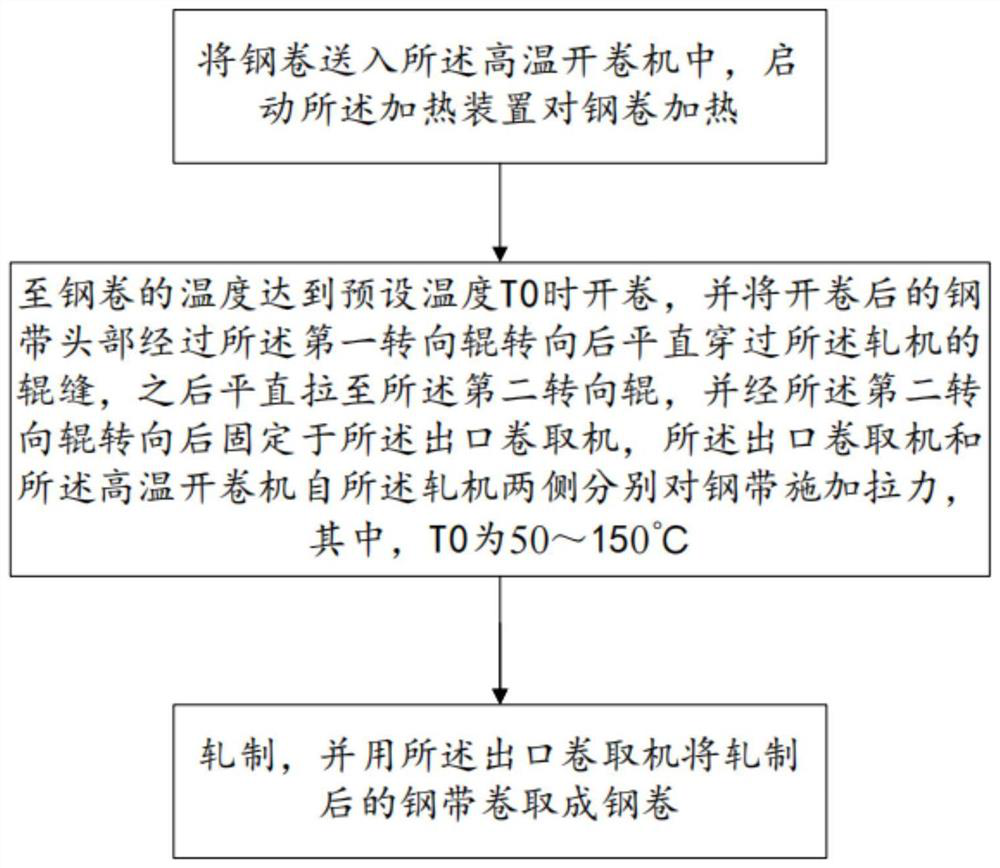

[0068] (1) Adopt anti-breakage strip cold rolling mill train 100 of the present invention, the steel coil of the above-mentioned high-grade non-oriented silicon steel that will pass through normalized pickling is sent into high-temperature uncoiler 1 by coiling dolly;

[0069] (2) Close the first insulation cover, start the heating device to seal and heat the steel coil, the heating temperature is 120°C, and heat for 45min;

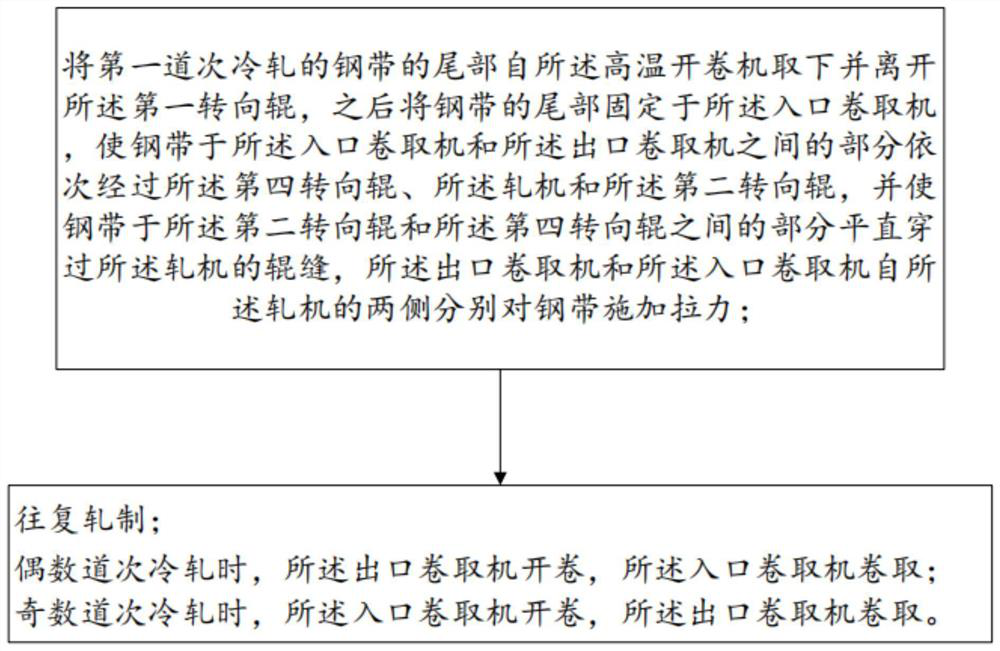

[0070] (3) Uncoiling, and the steel strip head after uncoiling passes through the roll gap of the six-high rolling mill 3 after being turned by the first turning roller 2, and then is pulled straight to the second turning roller 4, and passed through the second turning roller 4 After turning, it is fixed on the exit coiler 5, and the exit coiler 5 and the high-temperature uncoiler 1 respectively apply tension to the steel strip from both sides of the rolling mill 3;

[0071] (4) rolling, and the rolled steel strip is coiled into steel coils with the outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com